Search the Community

Showing results for tags 'tape'.

-

I'm about to start planking the hull of the Amati/Victory Models Lady Nelson, and I was hoping to get some feedback on the lines of my proposed planking bands. I basically just divided up the plank widths on my tick strips for each bulkhead by 3 (4 top planks, 5 middle planks, and 4 bottom planks), then tweaked the lines at the bow to be a little more aesthetically pleasing. I'm still considering lowering both lines at the bow to give me a little more space for the upper planks and tighten up the area around the garboard strake. Any and all comments are appreciated! Thanks!

-

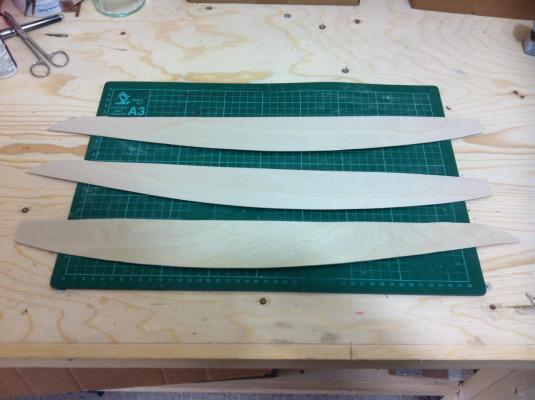

So, I've made the decision to spile all the planks for my upcoming build, as I love the look and fit of spiled planks. I'll basically be cutting each plank from a piece of sheetwood, by hand. While I will be using masking tape to trace the curve of the last plank in order to trace out my spiled plank, I'm still going to need a way to smoothly connect the dots that mark the widths of the proposed plank at each bulkhead on the other side, to complete the outline of the plank. Many people use's a set of ship's curves for this purpose, but I've been looking at the ACU-ARC adjustable curve ruler as an alternative. It looks like this: Basically, it consists of a number of flexible plastic strips bunched together. You can flex the ruler to meet the points you've marked and it will hold its shape due to the friction between the strips. You then simply trace along the flat edge to make your line. I'm wondering if this might be a better choice, since it will provide a nice smooth curve from start to finish, rather than using the traditional method of finding the best fit for a portion of the points with a ship's curve and repeating the process until the line is complete. What do you guys think? Also, one of the things I'm worried about is not currently owning a scroll saw... As it is, my only option seems to be cutting the rough shape of each plank out of the thin sheetwood using an X-Acto blade, then filing/sanding to the final shape. How easy do you think this will be with basswood and walnut sheetwood ranging from 1/32" to 1/16" thick? If I do decide to purchase a scroll saw, what type of blade should I get to smoothly cut sheetwood in this thickness range? I'm assuming I'd be looking for one with a high number of teeth-per-inch. Do you guys have any suggestions for the proper TPI range? My last question refers to the method of laying the tape in order to trace the correct curve of the last plank. I've read some descriptions of this process (and seen a few pictures), but I want to make sure I have this right. The correct method, as I understand it, is to lay the tape so that the portion of the tape that is laying on the existing plank is smooth, with no wrinkles or bends. The other edge of the tape (i.e., the portion that's hanging over the edge of the existing plank) can be a little wrinkled without affecting the accuracy of the curve you're tracing. Is that right? I've tested this method on the rim of a glass that is wider at the mouth than at the base, and I ended up with a nice curved strip that wrapped around the glass and was perfectly parallel to the rim of the glass, so it seems to be a good way of doing it. What do you guys think? As always, thanks for your advice, opinions, and assistance!

-

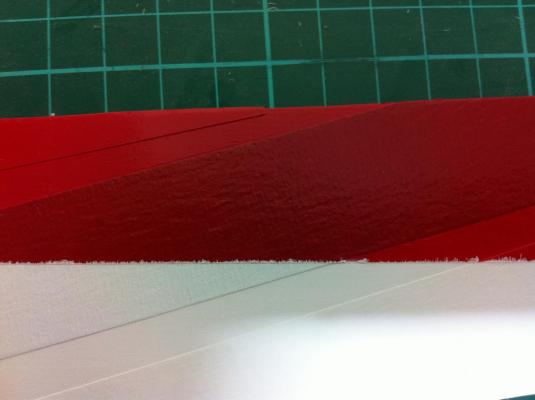

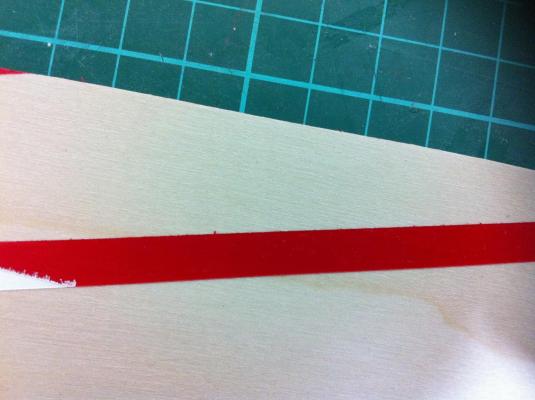

Dear friends following a disastrous attempt at painting the waterline I decided to take a step back and do a bit of testing. My main problem was bleeding of the paint under the masking tape. It seems that the consensus is that Tamiya masking tape works and it was also suggested to me to use masking film which seems a great but expensive option. However I first thought of testing tapes that are cheap and widely available, a general purpose masking tape by 3M, insulating (electician's) tape and frog tape (low tack). I intend to test these tapes on common modelling substrates, that is sealed and sanded wood, primed wood and cured paint. I will also use red auto paint (Halfords) and modelling acrylic white paint (Humbrol), both spray cans. It might be useful to post a few photos with the results. I prepared three pieces of plywood, (sanded to 400 grit, then acrylic sanding sealer, followed by sanding to 400 grit) First test is the sealed wood surface. I applied the three tapes, white is insulating, blue is masking and yellow frog. I painted one half with the red auto paint and the other with the white acrylic (2 coats each). The red paint was applied first and the two halves were separated with the 3M blue masking tape well tucked down. Although unintentional it is evident that a lot of white paint has bled and the line is not sharp. In the next photo the blue masking tape was top and the frog tape bottom. The masking tape bled a lot with both paints but the frog tape was almost flawless. In the next photo the insulating tape is top and the masking tape bottom. The insulating tape was better but still there was some bleed with both paints. Also, the tape left glue residue on the wood. On sealed wood the yellow low tuck frog tape is the clear winner and the only real option, allowing crisp lines for a cost of £6 for 41 m (24mm). The dead cheap insulating tape if extra care is used may have reasonable results but is far from perfect. The ordinary masking tape simply should not be used for masking purposes. Of note, the Humbrol paint left a raised edge when the tapes were removed but not the Halfords one. Next comes the same on primed and painted surfaces.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.thumb.jpg.6fd4c1b78768bb3efd745ab810936005.jpg)