-

Posts

51 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by owend

-

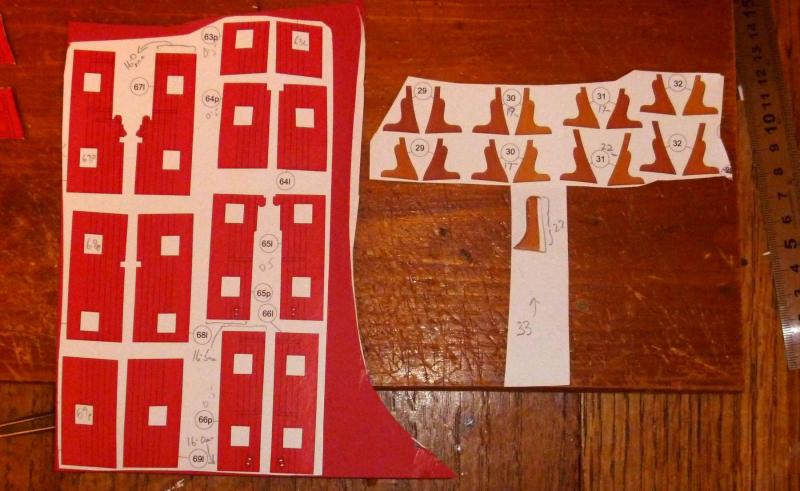

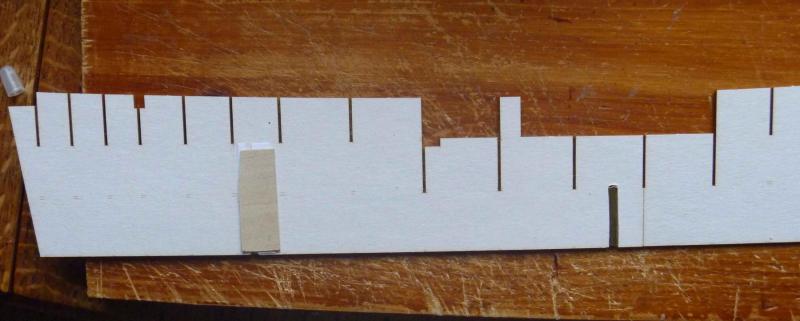

A bit more done, and the first quality problem arises. As Clare (catopower) has noted on his buildlog, the knees (bulkhead extensions? bulwark supporters?) seem to be different sizes for port and starboard. They are also strange sizes - for instance part 31 is either 17mm or 22mm, whereas the height of the inner bulwark parts 65 and 66 which should be supported by knee 31 is 16.5mm. As the knees are all about the same shape and will be partially obscured under the spar deck, and the bulwarks are 16-16.5mm, I'm going to scratch some at 16mm high, but using at least the outboard profile of each pair as they are slightly different. I'll try the shorter of the two options of the printed profiles, they LOOK more accurate. I would guess that in the typesetting, someone copied one set on knees and pasted for the second pair, and somewhere the image was stretched. PeteW, as Captain Slog says, the laser-cut hull skeleton is worth paying extra for, which comes with Mercury. I think for Enterprise the price is lower but without laser-cut parts; the laser-cut extra pack will nearly double the price and it's otherwise the same, as far as I know. Owen

-

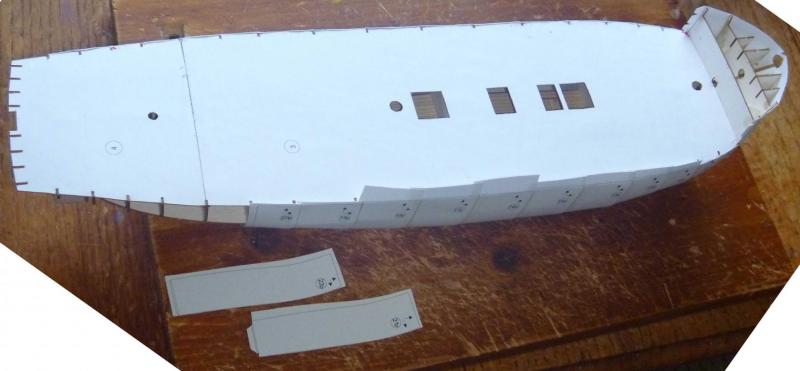

I also went out of sequence to add the "plating" to the upper part of the bows, so that the horns were again protected. Also in the interests of safeguarding delicate bits I haven't attached the transom yet, it'll go on after the plating/planking is on. I have done the plating slightly off-instruction, by leaving a tab on one side of each plate so that they are in effect vertically clinker-built, and not cutting to precisely deck level until after attachment. When the glue has fully set I'll knife and sand the joins smooth and remove the above-deck pieces. A bit labour-intensive but easier for me as my card skills are less than perfect. The instructions suggest using "putty" after the "longitudinal planking" is on - I'm not sure if this is the second, decorative, layer or this white underlayer (more likely), which suggests they expect some unevenness. We'll see!

-

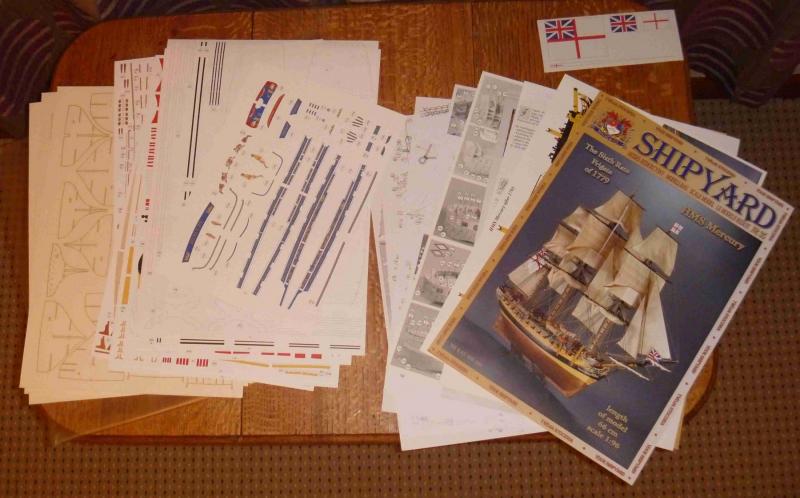

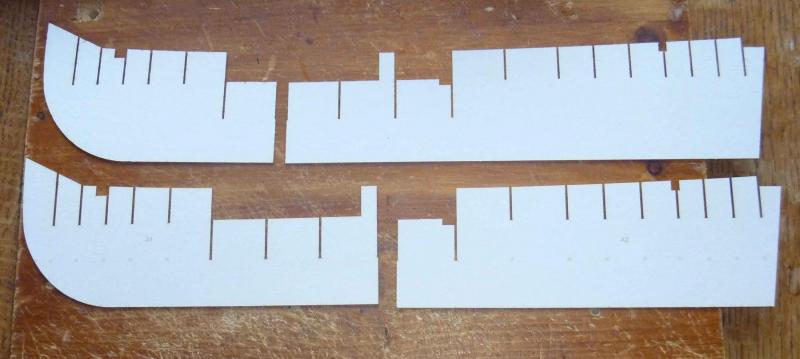

I've started this kit, which was a Christmas present to me from the First Mate (although she's not terribly enthused!). It's similar to the Enterprize kit also by Shiptard, but the Mercury version is slightly more expensive and includes a laser-cut skeleton although otherwise identical as far as I know; laser parts are available as extra for the Enterprize and there are extra kits of masts and of pre-made sails for both kits. I'm intending this as a hull-only model, loosely based on Admiralty models. I've previously done mainly wood kits, but also HMS Saumarez and Consul Pust in paper/card. This kit is considerably more complex and definitely not for beginners. It's 1/96 scale, and the skeleton is about 390mm with the kit claiming 660mm for the completed model It's an impressive kit: 15 pages of printed parts (1 x A4, 14 x A3) well-printed on good quality paper, 3 A3 sheets of laser-cut skeleton, 11 A3 sheets of instructions and photos and a sheet of flags. It includes printed parts for the 1779 original (decorative) and post-1795 (Nelsonic black-and-ochre), although the choice doesn't have to made for a while. The printing looks good and sharp, and the laser-cut parts (on 1mm card) are beautifully precise; my only minor gripe is that the card on the coarse side and needs a bit of care to avoid delaminating. I didn't have to make any adjustments to the skeleton to get things to fit, which is commendable. The instructions are non-verbal, with a series of photos of the kit being bullt and the instruction to add parts in the sequence shown, which is fairly clear with care, although the parts are clearly numbered but aren't in number order on the sheets so a lot of time is spent searching! Some also have to be doubled onto card of 0.5. 1.0 or 2.0mm. I started after Christmas and I am expecting it to take me well past Summer. Some photos: firstly the kit as unpacked (and I think keeping track of all the bits will be a major exercise in itself). Secondly the spine, which is two thicknesses of the 1mm card, with a substantial overlap. Thirdly, I've cut in two brass tube for a mount later - I may not use them but they need to go in now just in case; not very neat as they will be hidden inside. Lastly for now the skeleton ready for plating. Note how small the horns are on frames I and II, and the fiddly small pieces for the stern framework. The instructions say to build this off the ship and attach when done, which I haven't got to, but again they look fragile. PS I started this as a simple kit review last week, in the Card and paper models section, but it's going to be a buildlog, so I've re-started it here.

-

Both sound good, although your sailing season is nearly finished I'd imagine, with winter nearly on us in the Northern hemisphere? It'll be an interesting winter project, designing a scale model of the Star - what scale? And static or sailing? Owen

-

I'd seen your log, Simon, and very impressive, I hope I can get that good a result. I'll be double-planking and leaving the hull in natural wood, possible painted below the waterline, but otherwise you've given me some useful tips! I assume your 1:1 racing used something smaller than Bluenose, Rick? Owen

-

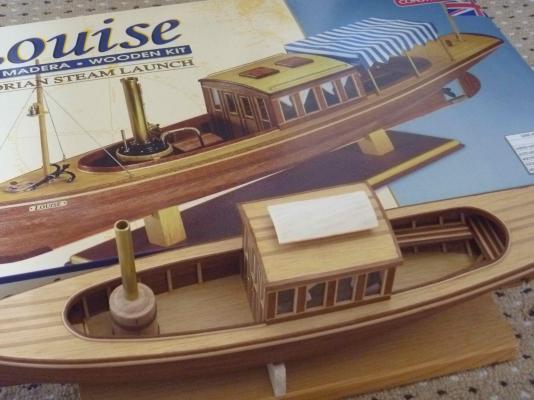

It's arrived, and I've had a quick look. Instructions quite comprehensive but need some translating; timber looks very good quality and well packed, and the second planking is a bit dark but I think it'll be good for leaving natural; other fittings seem to be well detailed. I haven't undone anything yet, I'm not starting for a couple of weeks and then I'll start a buildlog. I can see what you meant Rick: everything looks small, it's going to be new-glasses time!

-

Thanks for the tips hamilton - it'll be a while before I'm there, so there's plenty of time for reading-up! I made a Marie-Jeanne from the Billings kit, my first kit, which included sails; I was quite pleased overall, but it was instructive to find how often the plans didn't fit reality, so I know what you're saying about possible errors on plans. The different-coloured sails was a deliberate move, there's a photo of a similar boat on the Net (Google Earth, from memory): Owen

-

Thanks for the photos, hamilton, I've been browsing buildlogs of various brands and scales on MSW, but not many Amatis out there. Did you do a buildlog for your Bluenose - I haven't found it? Yours looks really good - great folds on the sails. Are the sails from the kit? The kit's on order, should be here tomorrow or Tuesday, then I'll see how good the second planking timber is. It's been a slight gamble, as I intend to leave it unpainted, at least above the waterline. Owen

-

Thanks, all, especially Rick. I've just ordered the Amati kit; I'm not such a young lad as your customer, but I'm not a beginner, so I hope that compensates! I'll try to run a buildlog, not planning to start for a few weeks yet though. Owen

-

Thanks, all, that's really helpful. Frank: I want a natural timber finish, at least above the waterline, so the Model Shipways one sounds difficult if I have to replace the planking. drmac and thibaultron: I'll write off Constructo and Billings, and keep AL under consideration at 50%! Rick: thanks for the endorsement of Amati. I'll look deeper: have you built it? Or do you know what the second planking timber is - it's double-planked according to its kit details? Owen

-

Apologies if this isn't the right forum, but I'd like to appeal to builders of Bluenose/Bluenose II kits: I'm thinking of this as my next, winter (!), project, and I'm confused by the number of kits, from 1/135 to 1/64 scale. I can see kits from Amati, Artesania Latina, Billings, Constructo and Model Shipways, and perhaps others if I look deeper. Can anyone advise on the comparative merits? I want something with reasonable quality components, ideally precut sails as I'm not too good with cloth, and I'm intending to leave the above-waterline hull in wood so reasonable-quality planking. Any advise welcome, and Moderators, please move this post if you think fit! Owen

-

I'm starting a scratch-build of a Thames barge. These have near-vertical sides and for about 3/4 length and a near-flat bottom (for estuary work), with a sharp angle ("hard chine"). It's going to be planked, with a bare wood finish (no paint!). I can't find any clear information on planking patterns, most hard chine designs seem to be for ply or ply strip construction. I'm thinking of a strip along the bottom of the vertical side chamfered at the bottom, and planking up and down, with stealers towards the bottom, then turning over and doing the same to the bottom, with a plank at the chine chamfered to the bottom strip of the side, a garboard strake, then planking in and out with stealers. Does this sound right? Can anyone advise a more correct method? ANY help gratefully received! Owen

-

Thanks for the comments, Brian and hamilton, although it doesn't answer the clerestory/no clerestory dilemma! I'll leave it off for now, and see if it grows on me - it'll be easier to glue it on later than to peel it off later. Mario: yes, the original hull planking (described as Sapelly and 2mm thick) was too thick to get a good finish on both sides but its finish is very attractive. I second-planked with the 0.5mm veneer they included; they don't say what it is but it's very similar to the Sapelly and takes a light sanding and varnish well, and the end result is pleasing. Owen

- 28 replies

-

- louise

- constructo

-

(and 1 more)

Tagged with:

-

I'd seen your log, Mario, and it gave me a good bit of help - lovely marquetry! Thanks, Bob, you're quite right of course, I deliberately set the whistle at the front so I can warn anyone ahead of my approach Anyway, a last burst of building and she's almost there. The brass wire in the kit is supplied rolled up; it's nearly impossible to get it straight, so I used some hollow brass tube for the uprights, and the supplied wire fitted in for the crossbeams, held in with a spot of CA: And finished! I haven't put the collar (?) on the top of the chimney, I think it looked out of scale and possibly not very secure as it just sits on top. I may try an inverse-cone shape in the future. These photos are of her with and without the clerestory; I'm still not decided. It's only sitting there; if it's permanent I'll glue it on. Opinions welcome! Conclusion: I've enjoyed the build, the kit is basically good although some timber was missing and all the timber was hard to identify, especially as the instructions tell you to use,say, a 13mm piece of 2 x 3, but there are several other items from 2 x 3 and no clue as to cutting the 480mm length supplied (if that makes sense). Also, single-planking with 2mm strips was not the best design decision, although the extra veneer pieces were a good solution. The timber was all excellent quality as were the fittings, and the instructions, with step-by-step colour photos, were the clearest I've seen. And now for my scratch-build barge!

- 28 replies

-

- louise

- constructo

-

(and 1 more)

Tagged with:

-

OK, no definite feelings apparent! I'm going to hedge bets, I'll leave the cabin roof plain, but I'll make a clerestory and keep it in the spares box, and attach it later if it looks better. Latest work has been the boiler and engine. It's not fully finished and varnished yet: The eagle-eyed will notice the whistle on the front of the chimney: this is because I carefully drilled and fitted the two eyelets to hold the steampipe and carefully lined it up and carefully stuck it into the boiler with the eyelets carefully lined up fore and aft. And then realised the chimney was 180 degrees out . The thing with instant glue is it's glue-ey and instant. Patrick, sorry I didn't reply to your post on Hermes; you've obviously found this log as my next task! To get ahead and save me failing to answer your next query, my next project is the Thames spritsail barge Will Everard at 1/80th. I'm drawing up the plans based in outline on the Billings kit; it'll be part-POB and part-POF, and "Admiralty model"-ish, left in bare wood and with only an inch or so of masts and bowsprit but no rigging. I'll install mast steps so if I want to I can finish rigging later. It's a challenge as I've never drawn up proper plans before. Not likely to start until October/November!

- 28 replies

-

- louise

- constructo

-

(and 1 more)

Tagged with:

-

Thanks for your kind words, all! Yes, 2mm planking wasn't good as a single layer, but Constructo obviously realise that, and the second layer, of 0.5mm veneer, went on much easier, so just think of it as a double-planked kit. I must say it's an elegant design, Rowan D and Patrick, and a fun kit to build (mostly!). I've got the cabin on now, and my mistake, there are two "stops" included which I hadn't spotted to close up the gap beside the front end of the cabin - remember to fix them before the cabin goes in, unlike me ! Another piece of wood missing: 0.5 x 2mm Manzonia, which looks to be a dark brown, isn't anywhere in the kit; used for edging the cabin roof and rooflights. I replaced it with time-consumingly carved offcuts: Which brings me to the next point: the kit has two small roof hatches. I've planked the roof with the same pattern as the deck, which I think looks quite good as-is. I don't think I want the two-hatch design, I think it looks a bit fussy. So, either leave the roof plain (no hatch at all), or possibly a single clerestory as the mock-up which would be planked and edged with dark timber: What does anyone think? The clerestory could be larger or smaller, it's only mocked-up.

- 28 replies

-

- louise

- constructo

-

(and 1 more)

Tagged with:

-

Thanks, Bob, I'm on a roll (it was raining most of the day) so the next instalment already! The coamings came up OK, although one of the 1x1mm light strips wouldn't bend smoothly, causing some swearing and taking a long time: The cabin so far: basically as plan except I didn't use a light panel for the lower part of the doors, as I thought the dark wood looked better. Also, with three benches outside I felt there was no need for two more in the cabin, so I gave them a table on which to carve the cold roast swan, serve the champagne, etc. The spurs at the foot of the front panel are because when the cabin is in place there's a gap between the vertical cabin wall and the curved hull; I'm hoping to put in a filling piece when the cabin is permanently fixed, so the spur is to glue that to. The cabin fits into the hull with a gentle twisting action! There are also reinforcing struts inside the corners of the cabin walls; I felt the cabin needed the extra strngth because it still had some handling to come (sanding, glazing, curtains, roof) and I wasn't confident of its strngth. In the event I don't think it was needed, but they don't show from outside. And finally a dry fit: Next, a bit of varnishing and sanding, curtains, windows and roof, then glue in the cabin.

- 28 replies

-

- louise

- constructo

-

(and 1 more)

Tagged with:

-

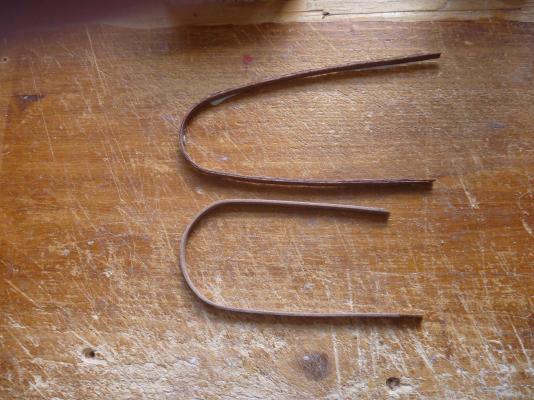

The rear benches are in: I couldn't see why the rear cross bench sat on top of the side benches, so I trimmed back the "spur" on the keel: (note the benches, it was easier to glue all the laminates in one, then cut the three benches from the strip) and fitted a new cross bench, with a couple of pieces of scrap glued underneath to take the side benches: and the finished benches, with a strip of veneer to hide the cut-off edge of the keel spur: Next up (slightly out of order, as I wanted to be able to check for size after building the cabin) was the coamings round the two wells, Problems: firstly Mike Dowling in his buildlog found difficulty bending to such a tight radius, and secondly the instruction calls for 1.5mm x 4mm, and I don't have it! It's the first missing item I've come across. I had already decided to laminate the coamings anyway, so I glued three strips of the 0.5mm veneer, using the cutout from the deck sheet as a template: The laminates are sitting on paper, so that they get attached to easily-removed paper rather than the cutting block. After removing, and first sanding for the bottom one, the end result looks good, I'm happy with it: I've done some work on the cabin, mostly to the plan, but more detail later.

- 28 replies

-

- louise

- constructo

-

(and 1 more)

Tagged with:

-

The veneer is easier to plank with: it's only 0.5mm thick and like all the wood in this kit it's good quality, so it bends, trims etc with no splitting, a pleasure to use. I found the single-piece transom slightly shallow, and I used the hull planking (2mm!) strips to build it up: You can see that the second planking has gone quite well, I'm pleased with it. The small mark in the centre is actually the drilled hole for the rudder shaft - I'm using a piece of rigid brass rod rather than the soft brass supplied (which is quite thick and being rolled up will be difficult to get looking perfectly straight - a strange way to supply metal intended for straight use!). I've now got the rudder attached, but not the propeller yet. Its hole is drilled ready but it's a white metal casting, quite rough finish, so I'll smooth it with some filing and paint it gold, and fit it quite late on to avoid knocks in the meantime. The outer hull is otherwise finished - a light coat of satin varnish to keep marks away while I work on the inside. The two-coloured wales attached very easily and echo the deck planking and outer keel nicely. Note the inset, slightly darker, deck planks; not sure if it works yet, I'll reserve judgement until the striped benches are in and it's varnished! Conclusions so far: the kit has good instructions and good quality wood and hardware apart from the brass rod which is supplied rolled up. The hull planking is too thick to use as instructed. if I was to repeat the build I would aim for a neat finish inside where the inner skin shows, and complete the rest with less worry about the finish, and use the supplied veneer for second planking. It's so thin it doesn't affect the thickness of the hull and it's good quality and fairly easy to apply.

- 28 replies

-

- louise

- constructo

-

(and 1 more)

Tagged with:

-

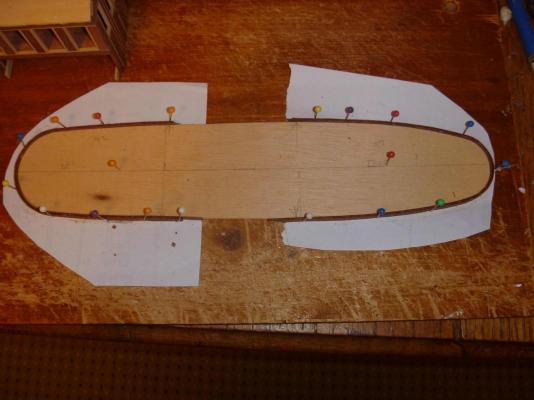

I've been planking, as usual a slow process. I found it difficult to plank with the 2mm thick planks supplied, as I found them very difficult to bend tightly enough, and the curve of the hull meant having to chamfer the edges to achieve a smoth fit both inside and outside, and with this open hull the inside is visible. My best efforts were, as expected, wanting! I did some filing with some effect: and then filled, filed and stem and keel attached: The result doesn't look too good, but feels smooth enough to the touch to act as the base for second planking.

- 28 replies

-

- louise

- constructo

-

(and 1 more)

Tagged with:

-

Tug Hermes 1/150 - Finished

owend replied to owend's topic in - Build logs for subjects built 1901 - Present Day

He's a quickie from balsa, 11.5mm which is 5' 8" at 1/150 scale. Owen -

Planking the hull: progress is very slow - the hull planking supplied is 2mm x 5mm sapele, which is difficult to bend accurately, and I'm making a poor job of it. It's doubly difficult because the inner side of the planks will be on show inside the boat, so both sides should be perfect. Also, at 2mm thick and some fairly tight curves to the hull the planks need to be filed down at one side to eliminate any gaps which is a pig to do. I'm almost too ashamed of my work at this stage to include photos, but I'll take some tomorrow! I've had to admit defeat on the single-planking approach, but I think Constructo have had a lot of feedback on that point, as they include enough thin veneer (0.5mm) for a second planking, with a slightly condescending comment on a printed slip that it's included at the request of a number of customers who are new to modelmaking. I'll be filling and sanding down the first planking and apply the veneer, which seems very malleable and it's so thin it shouldn't affect the lines of the hull. On the plus side, all the wood seems to be of high quality - very straight and tight bends and assorted cuts and drillings haven't led to any splitting at all yet.

- 28 replies

-

- louise

- constructo

-

(and 1 more)

Tagged with:

-

Tug Hermes 1/150 - Finished

owend replied to owend's topic in - Build logs for subjects built 1901 - Present Day

Thanks for those kind words, Patrick, I enjoyed the opportunity to invent/adapt/interpret (not sure which is the best word!). I now have a crew of one, who will be kept busy:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.