-

Posts

30 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by PETERPETER

-

I am envious of the work you have done on this little SPERWER. The display case will surely protect your work for many generations to come. I like the use of LED's which allow viewers to see all of the tiny details. Kudos to you and thanks for sharing the build with us.

-

Bravo! Ever the perfectionist. Were you able to make any progress on your next build while away?

-

Excellent work as expected each time you add to your log. Nearing the end of your Kathryn build! Recall that I have a large sheet of Perspex/Plexiglass you should look at when you get around to building the display case... or might you be thinking to use glass? I'll bring you my jib sail so you can see how I fashioned the shackles and stitched them to the sail. Use of grommets at this scale would be difficult to say the least. Best regards, Peter

-

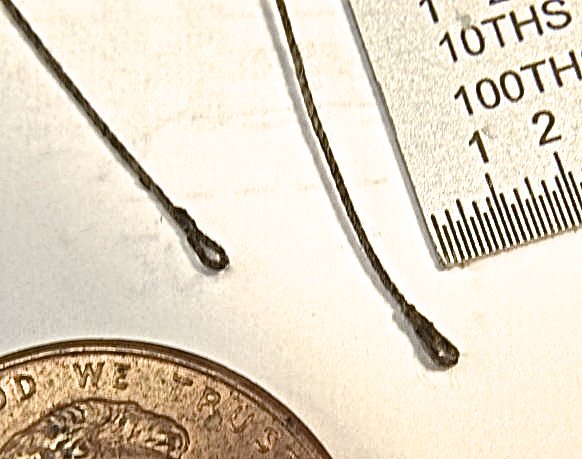

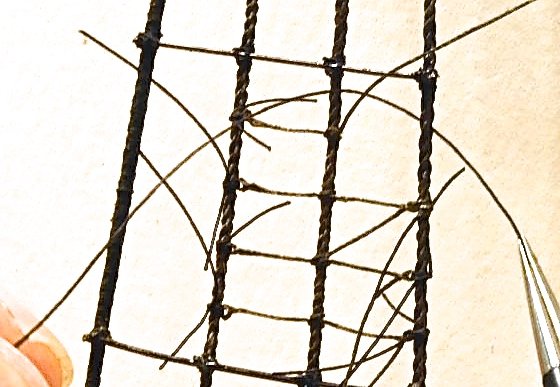

Very pleased to see that you have passed through the most difficult part of your recent event and good to see you back to work on Kathryn. I note that you have not pencil lined the sail to represent seamed cloth panels. Possibly the sail was not made up from seamed panels??? You have also shortened the height of the sail, (with fewer hoops) so that the furled and tied appearance will be visually to scale. Your wire shrouds and stays, using Surfstrand fishing leaders add realistic detail to your Kathryn. All around superb work.

-

Looking forward to better things for your family and ours during 2019. Peace be with you in the New Year Peter and Joanne

-

Five star ***** rating on all of your metal work and looking forward to the upcoming items you listed. So far you haven't mentioned the great conundrum represented by the two dredge baskets. I know that it will be another challenge which you will master. Meanwhile, this watch-bird will be watching you. Peter

-

- 3,596 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Frank, Your completed hull is tres elegant! I have been fortunate to see your work close up, while learning many new things about modeling. Looking forward to seeing Kathryn finished and hoping you may consider making a set of sails for her. It would not be that much extra work and would really bring her to life. Peter

-

Sterling detail on your wheel construction. Curious (as usual) to know how long it took you to build it? Peter

-

Your entire builders log is a treasure trove of information for each and every model shipwright. Always looking forward to seeing your continuing progress on this magnificent model. PeterPeter

- 3,596 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Excellent work on the yawl boat. Resistance soldering is the absolute best way to go when assembling tiny parts. Solder goes where you want it and accuracy is maintained by fixing parts position before applying the heat. Have a great trip. Peter

-

G'day Frank. Stellar work as always. You appear to have all of the skills, equipment, materials and knowledge required to build museum quality models. Hoping to see your forthcoming rigging and sail work after all carpentry is completed. Peter

-

Your centerboard pivot nut and bolt look very realistic, Have to bring to our next meeting a set of very tiny taps and dies, with which you can make real miniature bolts. Knowing the treasures you have stored in your shop, you probably already have these tools. Peter

-

It's always a pleasure to see your work and the speed with which you move ahead with logical, well planned steps. Peter

-

No sailing here in Arizona. Lived five years in Puerto Rico and sailed in the first annual "Round PuertoRico" race n a mall sloop. At 82 I'm too old for sailing and don't own a boat. Have to settle for modeling.

My Dad used to Kite Skate on the Finger Lakes many years ago and sometimes encountered ice sailors. Sorry if I bored you with making hoops dialog the other day. My friend, neighbor and club member Mahuna, is scratch building the Skipjack Kathryn. He is a five star model shipwright.

Peter

-

You said you would finish the frames this weekend and by golly you did. I am still wanting to understand how the frames were fastened to the keel after being slotted into the mortises. Your encouragement finally has me back to work on Willie Bennett. The plans have a tremendous amount of detailed I not did recall, having last worked on her years ago. The work I did then passes my scrutiny. I finished the woodwork and iron fittings on the bowsprit today and I will be able to show some progress at our next meeting. Thanks for your help. Peter

-

G'day Frank, Excellent photos of the method you used for replicating the lodging knees for the mast step. This is what we discussed during my visit Sunday. You must be using a tripod setup to take your photos, no? Peter

- 649 replies

-

- finished

- cross section

-

(and 3 more)

Tagged with:

-

You have come a long way since we first met and are now miles beyond my abilities as a model shipwright. I enjoy watching your progress on this "Mayflower", especially since our family ancestry includes, one John Howland, who was at that time an indentured servant on this famous ship. Your friend and neighbor, Peter Howland Florance

-

G'day Gaitan, Please tell us the source of supply for your linen thread. Also kindly tell us the different sizes of thread you purchased. Possibly you have already answered my questions elsewhere in your log, however, I cannot find it. I continue to admire your work and expertise as a master model shipwright. I learn something new and valuable each time I visit your Le Fleuron Log. Thanks for your time and effort to help us improve. Peter

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

HMS Druid by Krug - 1:48 Hahn finished

PETERPETER replied to kruginmi's topic in - Build logs for subjects built 1751 - 1800

Hi Mark, Zoom in on the figurehead photo dated 7/28, and concentrate on the drape of the robe over the left arm and shoulder. It looks as though you could round the corner of the sleeve, from the cuff all the way up and around the top of the shoulder. You might also do some rounding on the robe hanging under the arm, down towards the foot. Then zoom in on the 7/28 photo showing the right arm. A bit of rounding similar to the other side might then have your Druid looking more realistic... rounder and less square. Also. look at the hood on the bottom two photos dated 7/29. You might also shave the back of the hood a bit to make the fabric drape more vertically down to where his shoulders would be. The hood fabric would then be shaped more like the outside of the Druid's skull. A friend, a magnificent carver of birds, and now starting to work on ship models, might have some more useful observations on your Druid figurehead. I'll email him and have him take a look. Take a look at the website he recently put together, showing some of his magnificent bird carvings. http://www.wingedexpressions.com/home.html Peter -

HMS Druid by Krug - 1:48 Hahn finished

PETERPETER replied to kruginmi's topic in - Build logs for subjects built 1751 - 1800

Hi Mark, Your DRUID is spectacular in every way :im Not Worthy:. I especially like your figurehead... a Druid... of course... why not. Mine has languished these past months since our move to a new home,some 7 months back. She's stuck in the doldrums... ZZZzzz! . Waiting for a breeze, anything... to inspire me to get back to work. Your display case is also top-of-the-line. Time to sit back and admire your work Peter -

HMS Druid by Krug - 1:48 Hahn finished

PETERPETER replied to kruginmi's topic in - Build logs for subjects built 1751 - 1800

G'day Mark, Though I have not had anything to say for a long time, I have been lurking in the shadows watching your log, admiring your progress and the excellence of your work. We recently moved to a newer and smaller home where I have taken over the guest bedroom and arranged my workspace in order to finish my DRUID. I will now have your photos and comments to help me along the way. Great work! Peter

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.