-

Posts

152 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Nijmegen - The Netherlands

Recent Profile Visitors

-

Andre reacted to a post in a topic:

Papegojan 1627 by mati - FINISHED - 1/48

Andre reacted to a post in a topic:

Papegojan 1627 by mati - FINISHED - 1/48

-

Andre reacted to a post in a topic:

Papegojan 1627 by mati - FINISHED - 1/48

Andre reacted to a post in a topic:

Papegojan 1627 by mati - FINISHED - 1/48

-

Andre reacted to a post in a topic:

Sovereign of the Seas 1637 by md1400cs - Sergal - 1:78 - to be hopefully bashed

Andre reacted to a post in a topic:

Sovereign of the Seas 1637 by md1400cs - Sergal - 1:78 - to be hopefully bashed

-

JanV reacted to a post in a topic:

Wasa 1628 by JanV - Corel - scale 1:75 - Vasa

JanV reacted to a post in a topic:

Wasa 1628 by JanV - Corel - scale 1:75 - Vasa

-

Andre reacted to a post in a topic:

Sovereign of the Seas 1637 by md1400cs - Sergal - 1:78 - to be hopefully bashed

Andre reacted to a post in a topic:

Sovereign of the Seas 1637 by md1400cs - Sergal - 1:78 - to be hopefully bashed

-

Andre reacted to a post in a topic:

Wasa 1628 by JanV - Corel - scale 1:75 - Vasa

Andre reacted to a post in a topic:

Wasa 1628 by JanV - Corel - scale 1:75 - Vasa

-

Andre started following Dutch Whaler by Jean-Pierre - Sergal - modified 17th century flute

-

Andre reacted to a post in a topic:

Wasa 1628 by JanV - Corel - scale 1:75 - Vasa

Andre reacted to a post in a topic:

Wasa 1628 by JanV - Corel - scale 1:75 - Vasa

-

Andre reacted to a post in a topic:

Sovereign of the Seas 1637 by md1400cs - Sergal - 1:78 - to be hopefully bashed

Andre reacted to a post in a topic:

Sovereign of the Seas 1637 by md1400cs - Sergal - 1:78 - to be hopefully bashed

-

Andre reacted to a post in a topic:

Wasa by Andre - FINISHED - Corel - 1:75

Andre reacted to a post in a topic:

Wasa by Andre - FINISHED - Corel - 1:75

-

DARIVS ARCHITECTVS reacted to a post in a topic:

Wasa by Andre - FINISHED - Corel - 1:75

DARIVS ARCHITECTVS reacted to a post in a topic:

Wasa by Andre - FINISHED - Corel - 1:75

-

DARIVS ARCHITECTVS reacted to a post in a topic:

Wasa by Andre - FINISHED - Corel - 1:75

DARIVS ARCHITECTVS reacted to a post in a topic:

Wasa by Andre - FINISHED - Corel - 1:75

-

DARIVS ARCHITECTVS reacted to a post in a topic:

Wasa by Andre - FINISHED - Corel - 1:75

DARIVS ARCHITECTVS reacted to a post in a topic:

Wasa by Andre - FINISHED - Corel - 1:75

-

DARIVS ARCHITECTVS reacted to a post in a topic:

Wasa by Andre - FINISHED - Corel - 1:75

DARIVS ARCHITECTVS reacted to a post in a topic:

Wasa by Andre - FINISHED - Corel - 1:75

-

DARIVS ARCHITECTVS reacted to a post in a topic:

Wasa by Andre - FINISHED - Corel - 1:75

DARIVS ARCHITECTVS reacted to a post in a topic:

Wasa by Andre - FINISHED - Corel - 1:75

-

Snug Harbor Johnny reacted to a post in a topic:

Wasa by Andre - FINISHED - Corel - 1:75

Snug Harbor Johnny reacted to a post in a topic:

Wasa by Andre - FINISHED - Corel - 1:75

-

Andre reacted to a post in a topic:

Wasa by Andre - FINISHED - Corel - 1:75

Andre reacted to a post in a topic:

Wasa by Andre - FINISHED - Corel - 1:75

-

Coyote_6 reacted to a post in a topic:

Wasa by Andre - FINISHED - Corel - 1:75

Coyote_6 reacted to a post in a topic:

Wasa by Andre - FINISHED - Corel - 1:75

-

Seventynet reacted to a post in a topic:

Wasa by Andre - FINISHED - Corel - 1:75

Seventynet reacted to a post in a topic:

Wasa by Andre - FINISHED - Corel - 1:75

-

Stevinne reacted to a post in a topic:

Wasa by Andre - FINISHED - Corel - 1:75

Stevinne reacted to a post in a topic:

Wasa by Andre - FINISHED - Corel - 1:75

-

Welcome back Jan! Good to see that your Vasa built is continueing! I see that you have white color for the horizontal parts of the ratlines. Most others (including myself) use dark color. Why the ligher color?

-

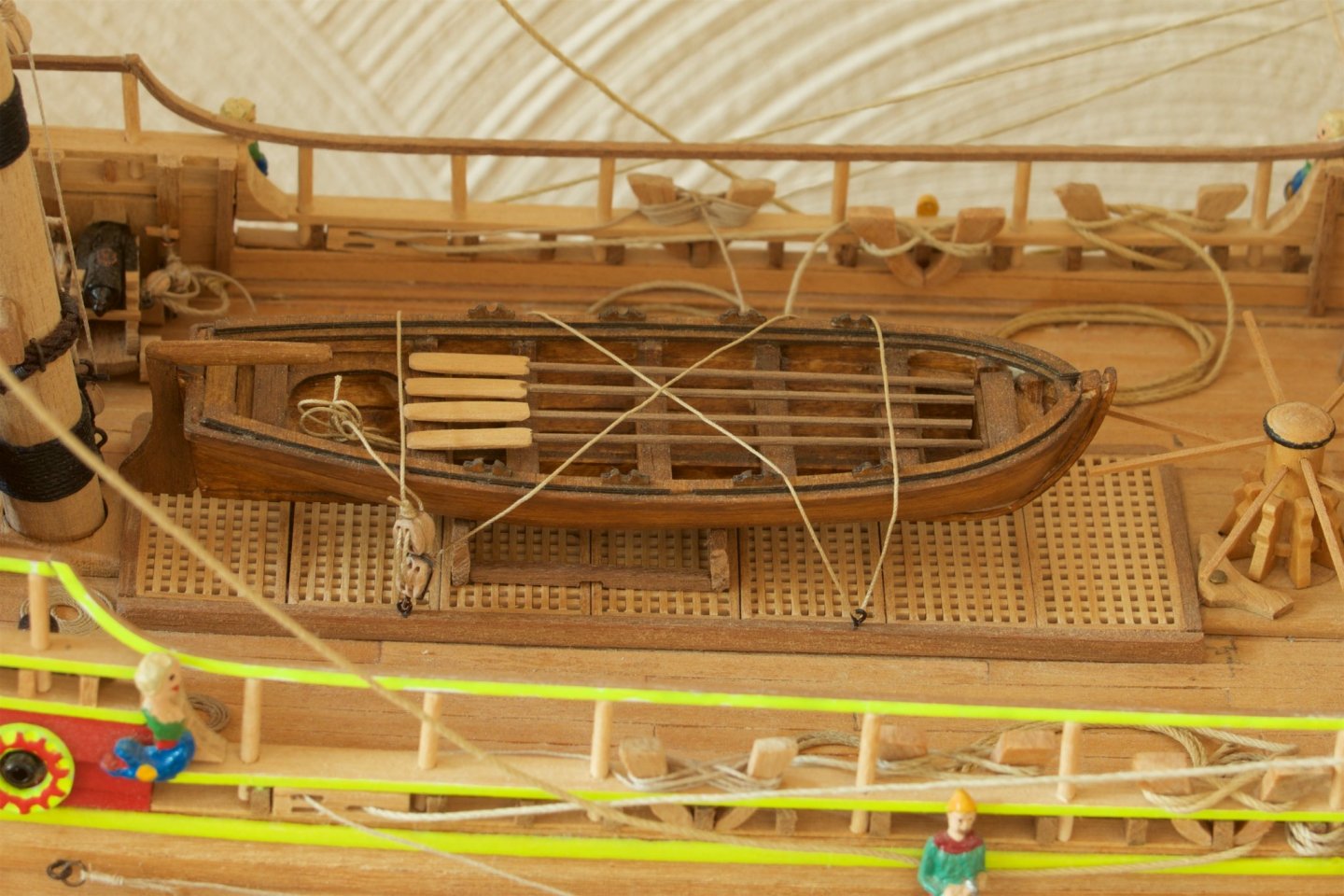

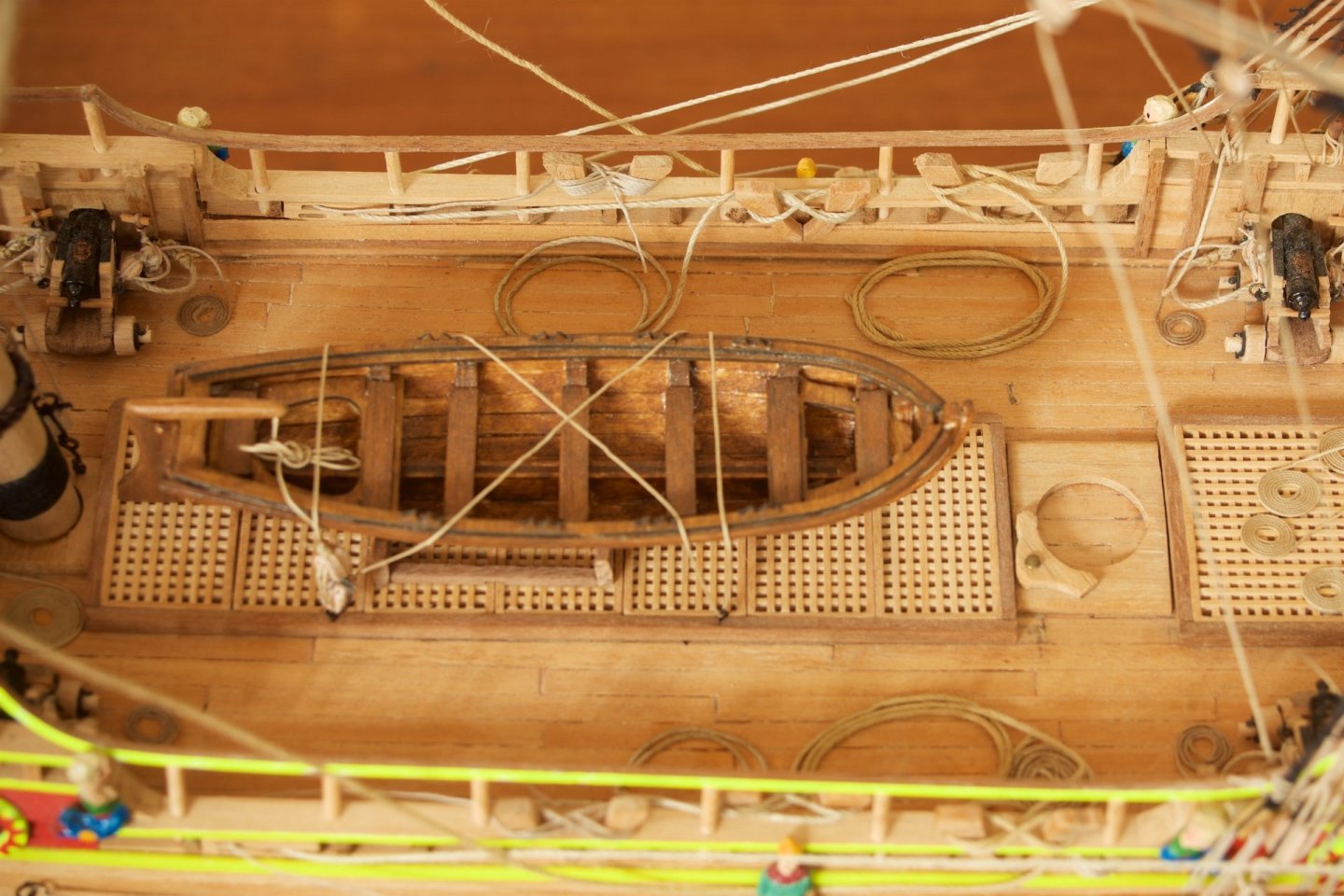

Before placing the model in the display case: one last detail: I made four oars for the life boat. The diameter of the length of the oars are 1 mm round nutwood. I had first made the wooden parts of the display case and then measured the sizes of the glass that I needed. The thickness of the glass of the lid is 4 mm, the thickness of the vertical glass windows is 5 mm. Without glass, the display case was kind of wobbly, but inserting the glass in the groves gave enormous stability to the complete set-up, even when the lid was not yet present. The lid of the case was made to house LED strips, for which the cable is housed in one of the vertical beams of the display case. The cable is hidden in a groove of the vertical beam, and a matching thin strip of wood, also with a groove, was then 'clicked' over the cable. So, this part is without glue. Most parts of the display case are without glue. Glued are the only the big base, the lid, the small pins on the top horizontal strips. To add stability, I also glued the horizontal top strips to the top of the vertical beams. To fix the stand of the model at the desired location on the base, I had made a small combined strip of wood that fits exactly under the stand, and glued this strip on the base. This allowed me to insert the ship into the display case from the small side. The Vasa in the display case is now COMPLETED. I am very happy with the results.

-

In the last weeks working on the display case. I had bought oak wooden planks, and I used mainly my table saw to make the planks and also to make the grooves in the various parts. I used my small milling machine to make the slots for the poles. My colleague helped me with the milling of the rounded curved planks, because I do not have such 'large scale' equipment. The display case is made such that it can stand on its own, without glueing, because of the (simple) mortise and tenon joints. The cover is prepared to house led strips. I used tung oil to treat the wood. Now it is ready, except for the glass that needs to go in it. I calculated that the weight of the 5 mm glass for such large areas (width of case is 110 cm and height is 80 cm and depth is 40 cm) of glass is really large. I guess about 40 kgs of glass...

-

Thank you for the nice comments! Jan, Indeed, I had noticed that your model (updates) had stopped for a long time. I will be looking forward to see your resumed updates.

-

The last item of the model that I wanted to do was to make the name badge. I used the kit supplied shield and printed (at work) a sticker with the (translated from Dutch) text "Vasa Swedish ship of war, built and sunk in Stockholm 1628. Model in scale 1:75, built 2012-2021, by <me>". The sticker was cut to fit into the shield. I have added some photos of my now completed VASA: The next big thing for me is building a display case. I have seen a very nice one here on MSW and will use it as guideline: The display case made by Shipshaper for his Emma C Berry

-

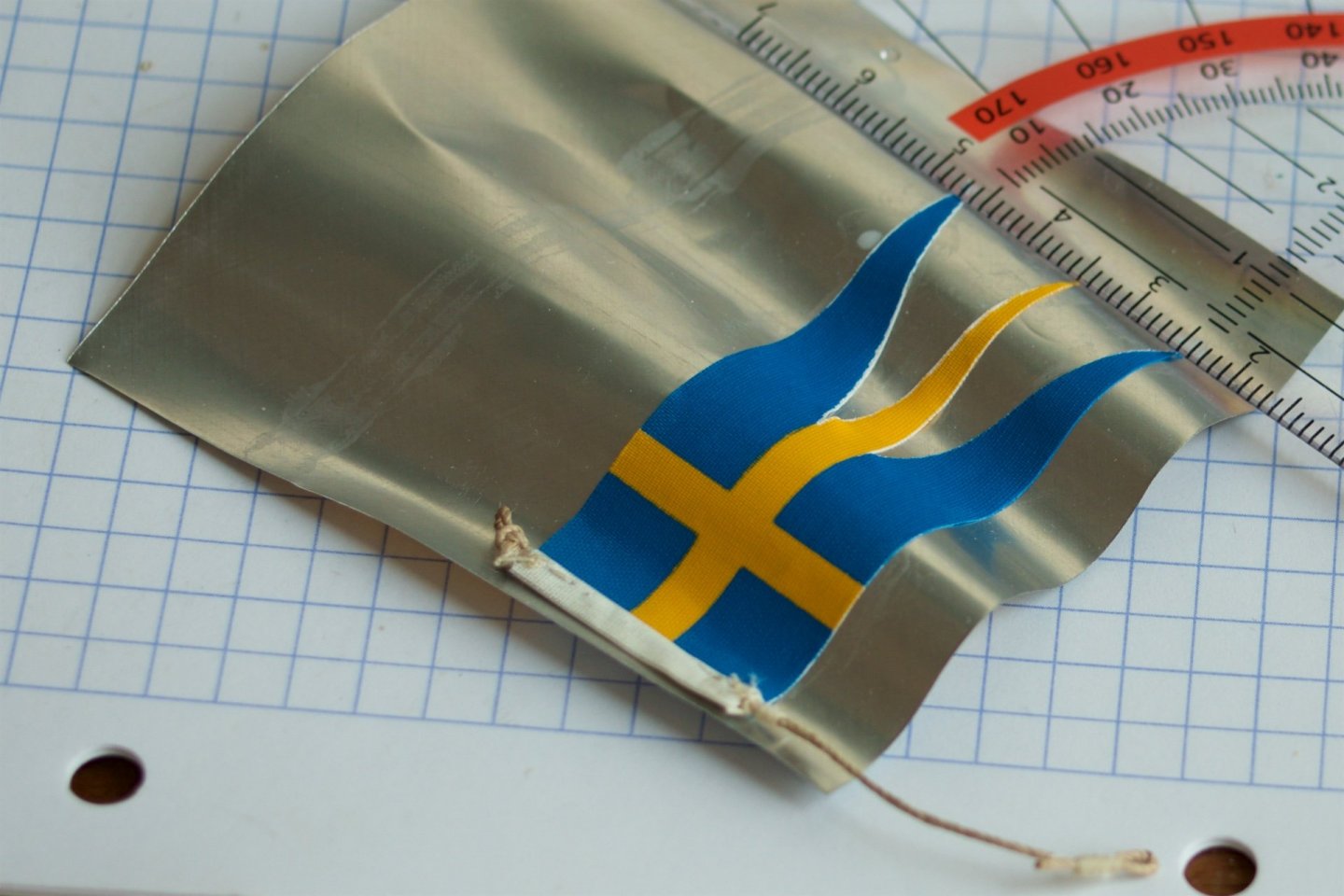

Hi Frank, Thanks. I had read that in your log. Luckily, my flags were the same color on both sides.

-

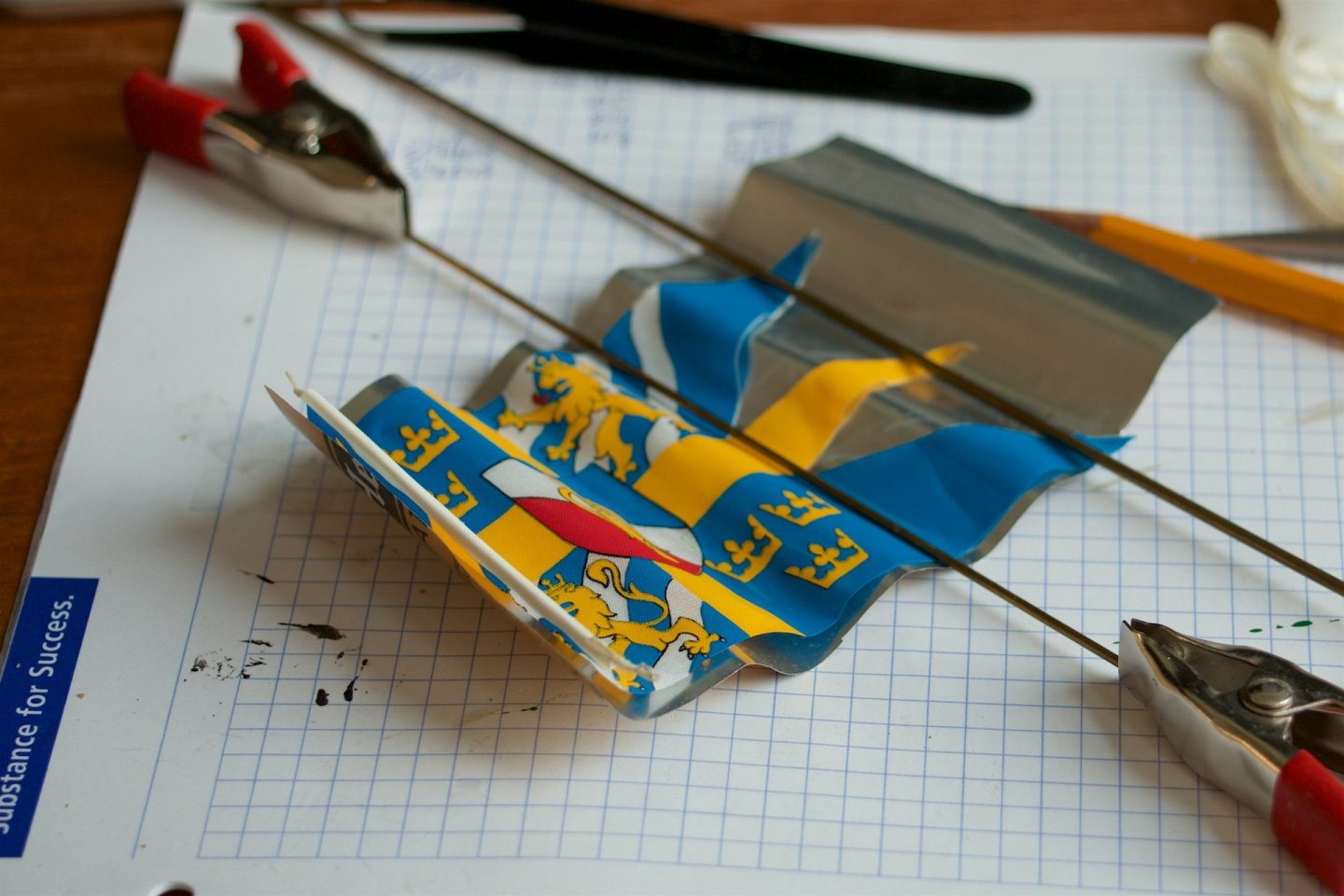

I made and installed the flags, which were supplied in the kit. I have shaped them with via the ' tin can' method, using diluted wood glue to fixate the shape of the flags. This worked quite well. The flags were made with small rope loops, and I connected one long line/rope that ran circular: from the top of the flag, through the block and then to the bottom of the flag, using the same 'knot' as for the sheet lines. This left thus a double rope to tye to the belaying pin. To make it easier to attach these double lines to the belaying pin, I had glued the two lines together. The big flag at the stern flagpole was not done using a seperate block at the top of the flagpole, but I had made the top of the flagpole to function as a block, by drilling two small holes in the top. The line runs through this. I did so, because the (much smaller) flagpole of my fathers ship (see one of my completed builts) also had the block inside the top and not separately.

-

The galleries were already some years ago made by me, but they were not yet fully complete. I had earlier replaced the supplied metal parts by simple wooden strips, that I had painted yellow. And between them, I had left empty space. Now, I have added some small wooden pillars, which I had painted white. The size was 2 by 1.5 mm. I have placed them in line with some of the decorative figures on the roofs. Picture before and after (at almost the same camera angle..)

-

Micheal, Thank you for your comments. Of course, I had looked carefully at your example and solutions. I did not know that no lantern was found of the real Vasa. As it is thus unknown how a lantern would have looked (if added after its maiden voyage), all interpretations may be valid.

-

I have made and installed the lantern at the stern. As many Vasa builders on this forum, I have chosen not to use the kit-supplied circular lantern (first picture), even though the Zu Mondfeld book does have it included as Swedish example. It turned out that I had another lantern in stock, but I do not remember how I obtained this, probably in a combined purchase. This lantern was more traditional shaped. I did insert a candle-like shape, but this is not good visible anymore once the plastic windows were placed.. I found the color of the lantern too shiny, so I painted it with black paint, and then padding some of it away. This because I do not have a 'wash'. The lantern was attached to wooden piece that I made to fit the top of the existing stern ornaments. The orginal Vasa in the museum has here some snakes sculpted in the wood, but I am not able to do this. Therefore, I made some groves in it, to give this wooden piece 'less weight' appearance.

-

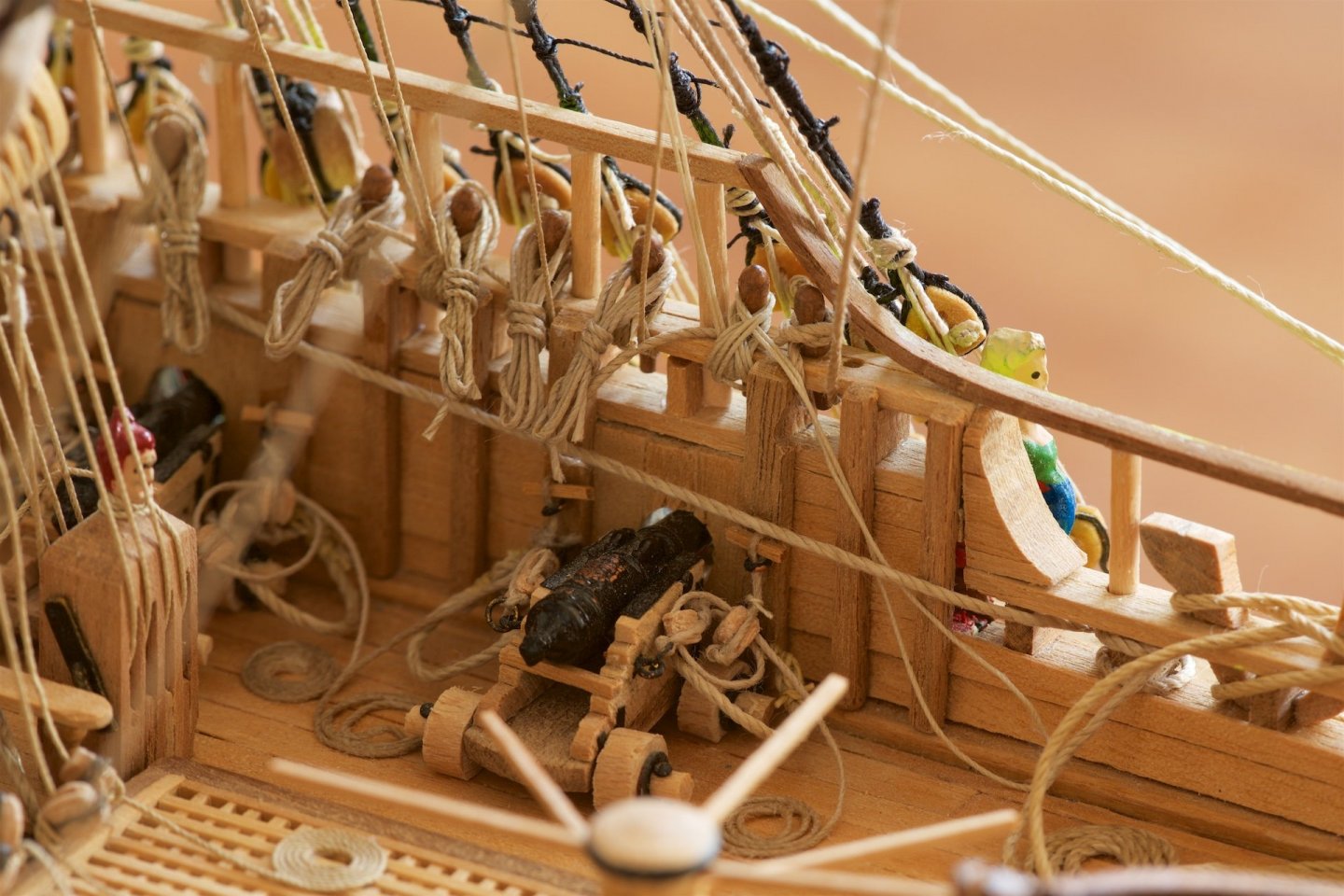

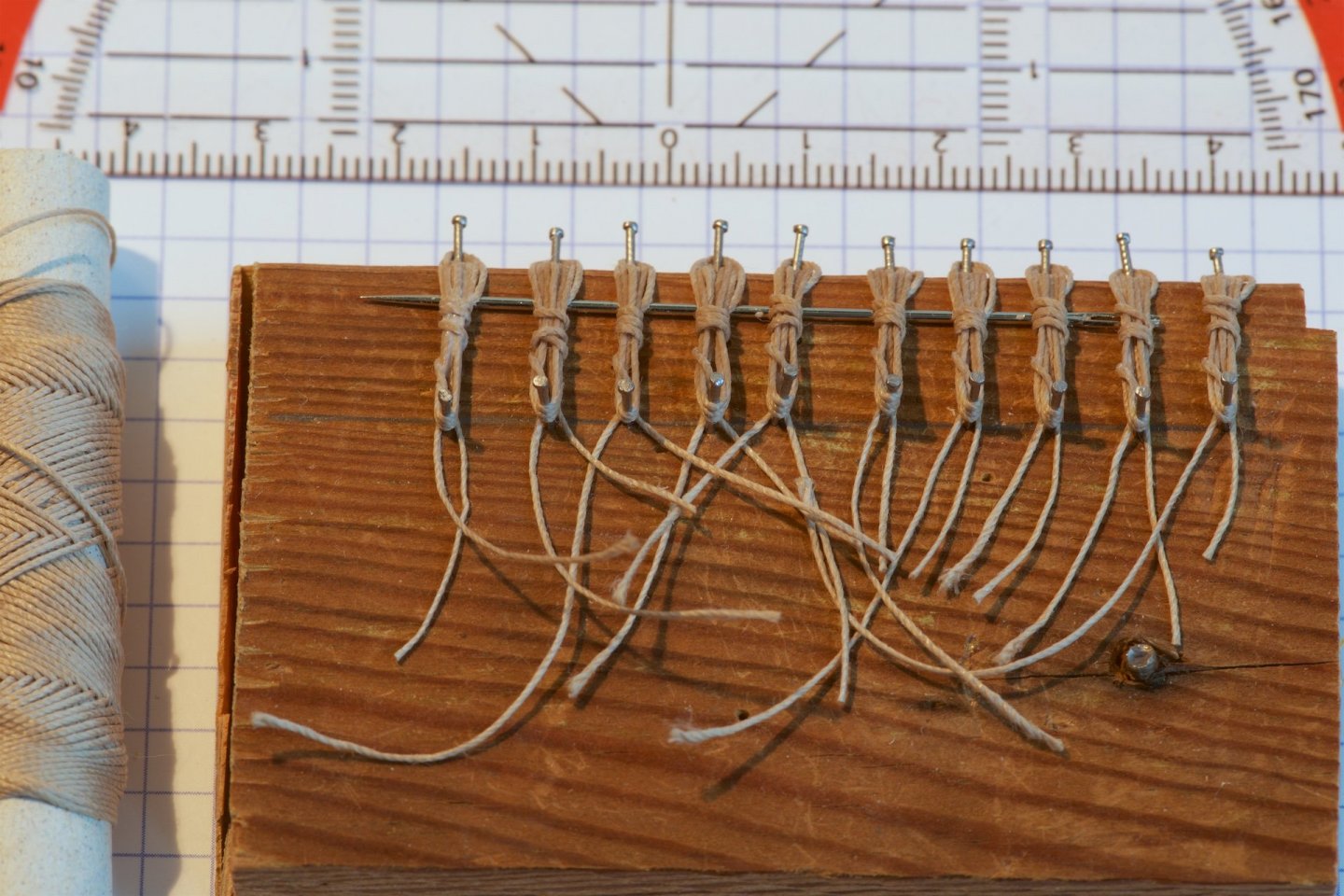

I added lines/coils/ropes to the belaying pins, using the pin method. First the rope a few turns around the pins, under 90 degrees angle, and then made some turn-arounds to tye the rope together. I used a needle underneath to have some space under the ropes to pull the ropes underneath. It makes the appearance of the belaying pins much better, but it is also a pity that this hides the 'real' belaying knots.. Also a picture of the deck, with the coiled ropes, from the sheet lines of the lower sails, on deck.

-

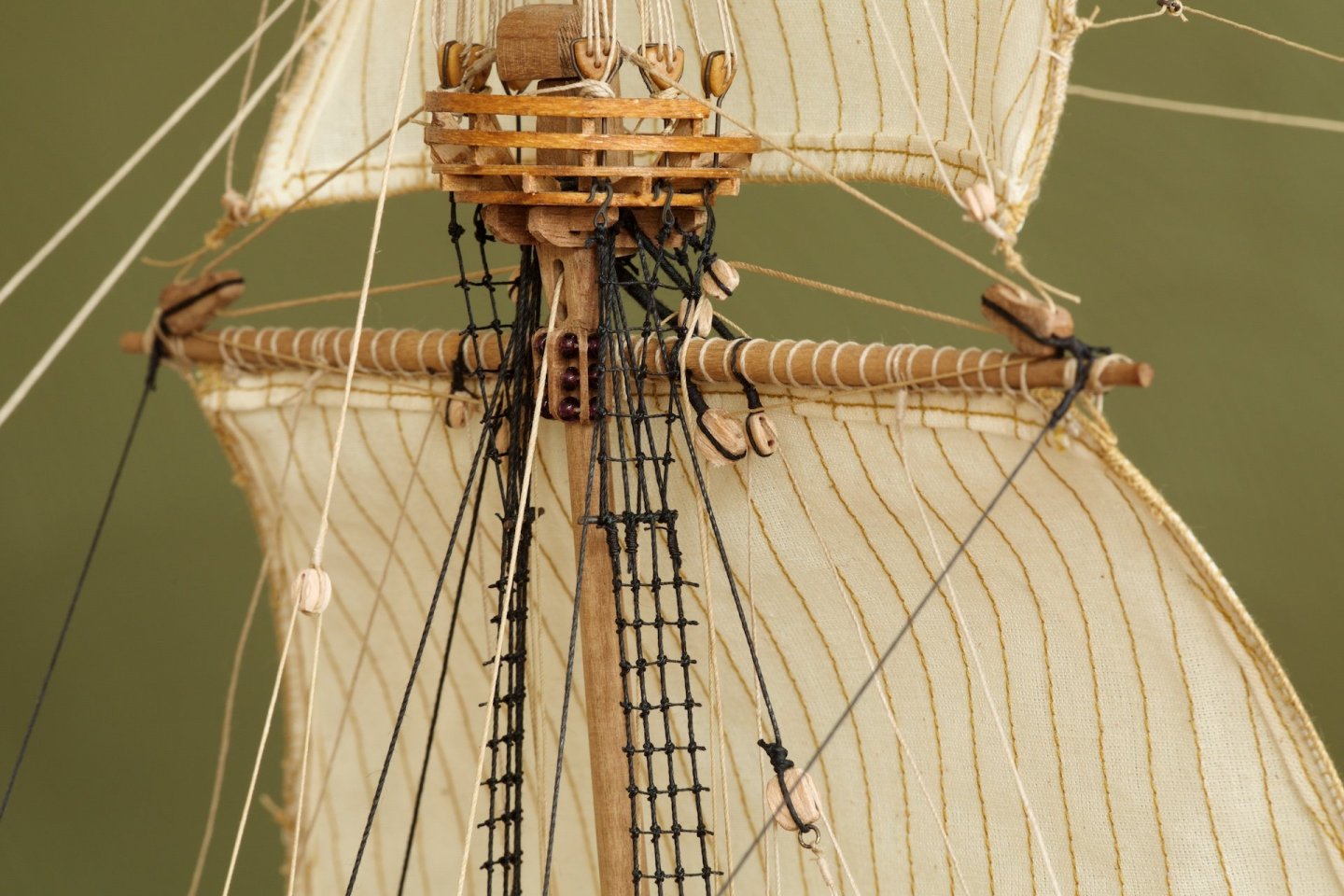

The main topsail was the last sail to mount. As most of the sails, I had inserted copper wires to give the sail curves, to simulate wind. Without the sheet lines to the yard below, the curvature is actually too much. Attaching to the yards results in a nice wind-like appearance. The sheet lines, from the topsail through the violin block to below had to have a lot of tension to bent the sails close to the yard. With the topsail installed, I could also fixate the lower yard and then hoist the bunt lines and clue lines to have the main sail semi-folded. My attempt was to simulate the Vasa Museum 1:10 model, but my sails are of too thick and stiff fabric to have the sail hang like that. But I am happy with the result anyway. Meanwhile also installed the bowlines of the main mast sails and also the sheet lines of the lower sails.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.thumb.jpg.51663d40cf48bd5949e06628da9d07ad.jpg)