-

Posts

28 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Rick020763

-

Hello again: The restoration of the Wm. H. Batson is now complete; progress impeded by a health problem. The name is that of the gentleman who built the hull, almost 50 years ago. Because of my limited building space (and metal fabricating skills), I used Model Shipways parts for the metal deck fittings and also for the blocks. The sails, masts, running and standing rigging, and cabin hatches, are all scratch built. I still have to make fishing dories, which will replace the two plastic dinghies on the after cabin top. The longer boat on the forward cabin top came with the hull and will stay there, since I like the effect. It's been great fun, even more so because of what I've learned from MSW. Rick

- 17 replies

-

- schooner

- restoration

-

(and 1 more)

Tagged with:

-

Beautiful vessel, Bob. Congratulations and well done. Rick

- 420 replies

-

- lettie g. howard

- schooner

-

(and 1 more)

Tagged with:

-

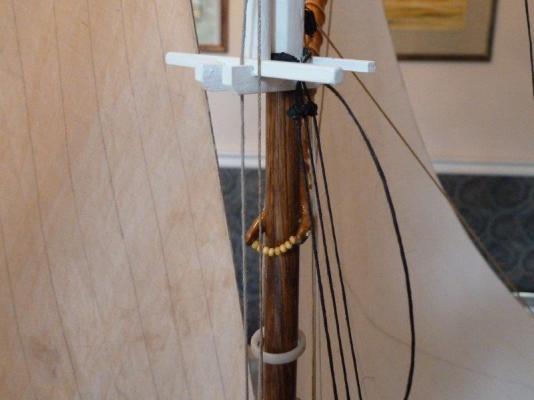

Hello again, Here is an update on my painful ratline education. After numerous attempts, I just couldn't achieve anything remotely acceptable in terms of neatness or scale by tying knots, so I reverted to another method I had read about on MSW: sewing the thread directly through the shrouds. I've been using a course waxed black thread for the standing rigging, so it was relatively easy to pierce the shrouds with a small needle and fine beige thread that I'd run through beeswax. I then put a tab of clear flat lacquer on each of the joints and, after it dried, clipped off the excess thread. Finally, I dabbed some flat black paint on the ends of the beige thread. This worked reasonably well, if not quite up to the normal standard of this section of MSW, and the mainmast ratlines are now done. Please see the attached pictures. Now it's on to various deck fittings, foremast ratlines, final adjustments of the sails and rigging and, finally, the name. Rick

- 17 replies

-

- schooner

- restoration

-

(and 1 more)

Tagged with:

-

Pete: Your workmanship, combined with the great Herreshoff design, has brought about an absolutely beautiful little vessel. Well done indeed. Rick

- 296 replies

-

- yacht

- herreshoff

-

(and 2 more)

Tagged with:

-

Michael: I also vote for the dark hull, mostly on the basis of the traditional look for that working boat. Whatever colour you ultimately choose, she'll be gorgeous. Rick

- 2,196 replies

-

Splendid work, Michael. The pilot cutter is a beautiful vessel anyway and the scale of this one makes it all the more impressive. And that's a wonderful picture of you and the lad working on the dory. Rick

- 2,196 replies

-

Hello again: I'm in the process of working on the standing rigging and doing a lot of little things that needed fixing or completion. Parrel balls were added to the gaffs and booms, which I think look all right. I've also completed running backstays on the mainmast. In trying to create a boat underway with the sails drawing wind, it's important to have the mainsheets stiffened, which I do with cc (although I'm extremely allergic to it and can only use it very rarely and with strict safety precautions). While the cc works well to stiffen the sheets, it leaves them shiny. I tried eliminating the shine with flat clear acrylic but as can be seen in the picture, it didn't work very well. If anyone knows a better way of doing this, I'd love to hear it. I've started doing ratlines for the first time, a tedious and humbling experience. This first set is really both an experiment and learning experience. I hate the way they look at this point but till reserve judgment until this set is finished; I'll probably end up doing it over again, avoiding the first-time mistakes. I've attached some pictures of the above. Comments and suggestion as always welcome. Rick

- 17 replies

-

- schooner

- restoration

-

(and 1 more)

Tagged with:

-

Thank you, Michael, Bob, Elia, and Pete. Mark, I too have noticed that the further back I stand, the better it looks (reminds me of a great line from "Tootsie"). Elia: Let me add a couple of things to what I said about sails on in the new-members' page. But first, what is the schooner pictured on your profile? She's a real beauty. In order to counter the effects of gravity, in addition to reinforcing the edges of the sails with wire (see, for example, the fisherman's staysail, where all but the luff are stiffened), I also use very fine stainless steel wire to help the sails "stand up" the way they would when drawing wind. So on this model, both the jib and the jib topsail have such wires. They're obvious close up but beyond six or eight feet they almost invisible and, at a couple of thousand miles, completely invisible! See the attached picture. To get the gaff topsails to stand out from the gaff, the sheets are supported by heavier wire painted the same colour as the sheet. The attached picture of the main gaff topsail shows this -- it also shows that the sheet got beaten up in the process and is now on my rapidly growing list of things to correct or do again. As I work on and shift the boat around, the shape of various sails often needs adjusting. If they can be taken off, the ironing method of course works well; if they can't be removed, then a portable hair dryer on low speed can be effective. I'm currently working on shrouds and ratlines -- a humbling if educational experience -- and so have the fisherman's staysail off. I've attached a picture to show it like this. Many thanks again. Rick

- 17 replies

-

- schooner

- restoration

-

(and 1 more)

Tagged with:

-

It's really beautiful, Pete, and those stern and quarter shots are breathtaking. How are you going to finish the rear deck? Rick

- 296 replies

-

- yacht

- herreshoff

-

(and 2 more)

Tagged with:

-

Here are some close-up shots of the various sails as well as the current state of the whole rig taken in indirect early-morning light. Given the fine work so evident on MSW, I put these up with some trepidation and with the reminder that I'm aiming for the overall effect of the rig, viewed from a distance of eight feet or more. Comments, observations and suggestions all welcome. Rick

- 17 replies

-

- schooner

- restoration

-

(and 1 more)

Tagged with:

-

The white deck and cherry coamings are perfect. Excellent call, too, on the flat white: that's a working area so a non-skid finish makes practical sense, in addition to looking good. Rick

- 296 replies

-

- yacht

- herreshoff

-

(and 2 more)

Tagged with:

-

Gorgeous planking, bringing out the beautiful lines. Rick

- 142 replies

-

- herreshoff

- buzzards bay

-

(and 2 more)

Tagged with:

-

Thanks, Pete; you're very kind. The deck and hull are rough, reflecting my dining-room-table boatyard and modest joinery skills, but I think the rig is coming together reasonably well. Warm regards, Rick

- 17 replies

-

- schooner

- restoration

-

(and 1 more)

Tagged with:

-

Hello Again: Having only joined MSW a couple of weeks ago, I don't have many pictures of the build up to that point. However, here are a few which show the partially-painted hull, the masts with topmasts added, gaff temporarily in place in order to begin the process of deciding the size and shape of the main, the mainsail temporarily in place, and the main and foresail, which was progress to early January. Late January through to the present was a process of designing, making and temporarily rigging, adjusting and fixing, the rest of the sails, the current state of which can be seen in the last two pictures. Not knowing if the builder had intended it to be a scale model of an actual vessel (but believing he had not) and not having any plans was, in a sense, liberating: I could simply try to design the most attractive rig possible. So what you see in the pictures of its current state reflects my own sense of the Grand Banks fishing schooner rig, a bit of Bluenose (which we Canadians grow up with because it's on our ten-cent piece), Gertrude Thebaud, Columbia, and other attractive schooners of which I could find pictures. Thanks to our PVR, I also stumbled upon a great source of actual film footage of the Gloucester fishing fleet in the 1935 production of Kipling's Captains Courageous: it's filled with absolutely wonderful shots of these beautiful schooners on all points of sail, with many different sail combinations, and in different weather conditions (it's also a great story and film!). While my sense of the boat evolved as I made progress, right from the outset I've been trying to achieve the look of a working boat with beaten-up sails; this also harmonized with the look of the hull after almost 50 years in a garage, even after repair and painting. Hence, six of the sails were made from an old piece of sailcloth, and I'm working on the main and foresail (made from cloth in a kit) to give them more of a weathered look. The last two pictures above, both of which are partially backlit, show the overall effect with the varied colours and imperfections. I've now started shrouds and ratlines -- a daunting prospect, on which I'll be seeking help -- and there are still many, many other small things to adjust, fix and add. Suggestions and comments welcome. Rick

- 17 replies

-

- schooner

- restoration

-

(and 1 more)

Tagged with:

-

Gorgeous finish. "Kate" on the cherry transom in gold leaf will be a beautiful blend of colour with the natural-wood finish of the hull. How are you going to finish the mast and boom? Rick

- 296 replies

-

- yacht

- herreshoff

-

(and 2 more)

Tagged with:

-

Bob: I thought it was simply left as set - that's what I did, but I was making relatively short tacks and usually single-handing. The topsail looks much better and certainly works more efficiently when it's set to leeward of the halyard since its shape isn't being distorted by the halyard, so it makes sense to try to shift it to leeward on certain tacks. I just don't know how it would be rigged or carried out. Rick

-

Thanks, Pete. Your wife has excellent taste. I agree re Epiphanes and used nothing else on my 14. Rick

- 296 replies

-

- yacht

- herreshoff

-

(and 2 more)

Tagged with:

-

The Epiphanes finish, together with the cherry transom and a white waterline, will be gorgeous. Good decision, great job. What kind of rig are you going to have? Rick

- 296 replies

-

- yacht

- herreshoff

-

(and 2 more)

Tagged with:

-

Pete: Please forgive a dumb question, but what's the purpose of the rubbing alcohol? Many thanks, Rick

- 296 replies

-

- yacht

- herreshoff

-

(and 2 more)

Tagged with:

-

Pete: Again, beautiful lines and splendid craftsmanship. Fascinating to watch the 12.5 and 14 come to life almost simultaneously. Rick

- 142 replies

-

- herreshoff

- buzzards bay

-

(and 2 more)

Tagged with:

-

Hello Again: One of the first challenges I faced, after eliminating many years' accumulation of dust, dirt, grease, etc. , was the break in the top plank on both sides, visible in the first picture above. I tried injecting cc and clamping, reinforcing with a top rail (which I was going to do anyway since the top of the planks were exposed and quite rough), and adding a rub rail. None of this worked and the breaks continued to widen as the planks pulled away from the deck at the point of fracture. I finally resorted to gluing pieces of 0.25" stock to the deck and bulwarks for most of the length of the deck: this did the trick and had the additional benefit of almost hiding the very sloppy white paint job someone had attempted along the edges of the deck. Unfortunately, any semblance of realism and scale was lost as a result. I've attached a picture showing the 0.25" stock and the white paint it almost covers. It also shows the small afterdeck I ultimately built to screen the white paint on the deck at the stern, an inch fore to aft and particularly horrible. I'm sure there were probably other less-unsightly ways I might have dealt with the fractured-plank problem and certainly would be interested in hearing any. The next big question was what to do about the iron or lead fin keel. It's an interesting look in some ways and some people actually like it, but it's highly unrealistic and I hated it. I was tempted to try to remove it but, given its age, the fact that I had no idea how it was attached, and my own skill level, I decided to leave well enough alone and live with it. Part way through the build, however, I made two pieces to modify the display stand to screen the fin. Debate continues within the family as to which way it looks better. All for now. Suggestions and comments welcome. Rick

- 17 replies

-

- schooner

- restoration

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.