-

Posts

656 -

Joined

Content Type

Profiles

Forums

Gallery

Events

Everything posted by David Lester

-

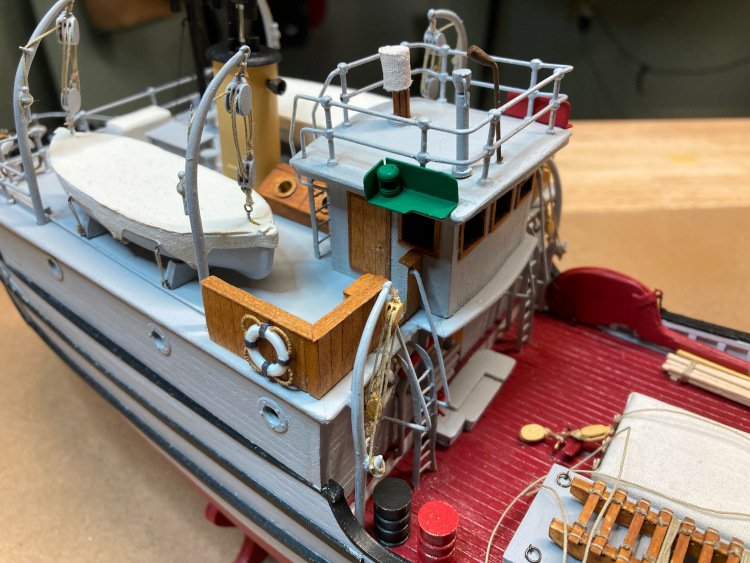

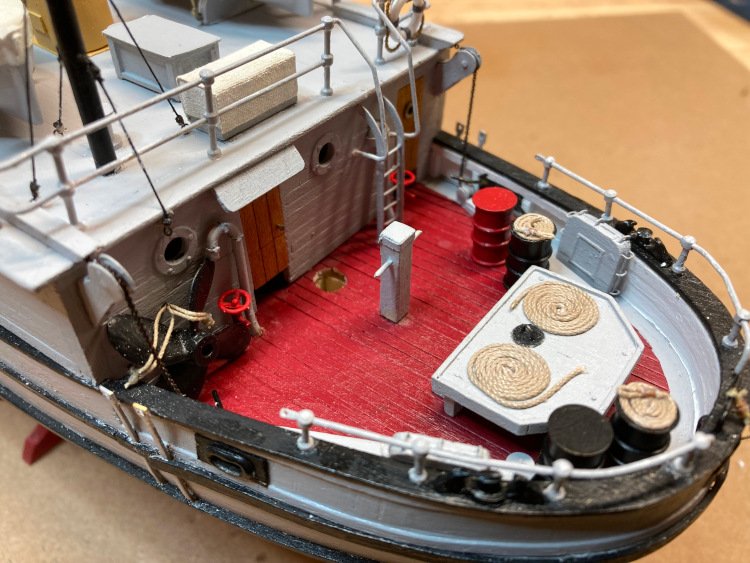

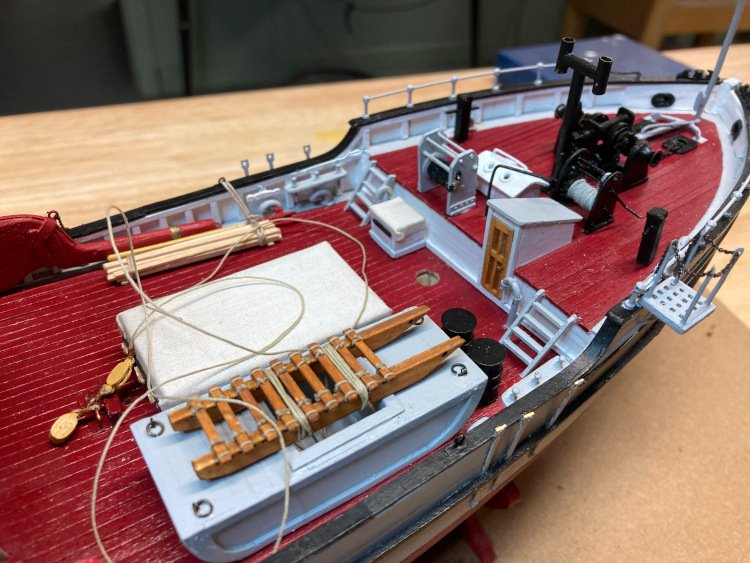

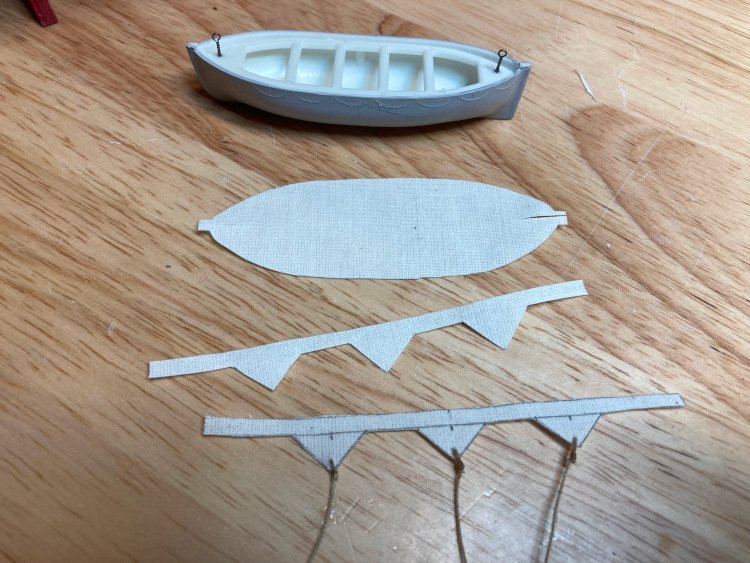

Good Morning, Well, I think it's about time to quite adding things to this boat - those decks and roofs are pretty much full! I've added many details that are not included in the kit, and I need to stop because I'm just about out of room. It's been fun improving what is really a very basic kit. While the kit omits many of the details, at least it was reasonably accurate so far as it went and I couldn't detect any really glaring errors in what was included. I did have a bit of trouble fitting some things in, due to scale, but I think it's ok overall. Here's how I made the fire hose. I started with a piece of sail fabric from another kit and painted it with watered down white glue to prevent fraying. I cut a strip 3/16" wide and then folded it in half lengthwise and glued it. This resulted in a 3/32" wide strip with one rounded over edge. I simply rolled it up and secured it with some glue. That was the easy part. I had a bit of trouble with the wooden frame that holds the hose. I tried to make the frame separately and then just slip the coiled hose into place. This wouldn't work for me as I couldn't get the tiny pieces of wood to stay together, especially with the odd angles at which they meet. Then I had another one of my 3 am epiphanies and realized I was going about it the wrong way. The answer was to glue the individual pieces of the frame directly to the coil, one by one. This was very easy to do and the result is much better than my failed earlier attempts. So that's the hull and all of its details done. Now it's on to the masts and rigging. With many models this is often only about the half way point, but this one has so little rigging, that it won't be long before I'm looking for a new project. I've started the shrouds. The shrouds on the real boat have serving in a contrasting colour, so that was a fun detail to add. That's all for now. Many thanks for checking in. David

-

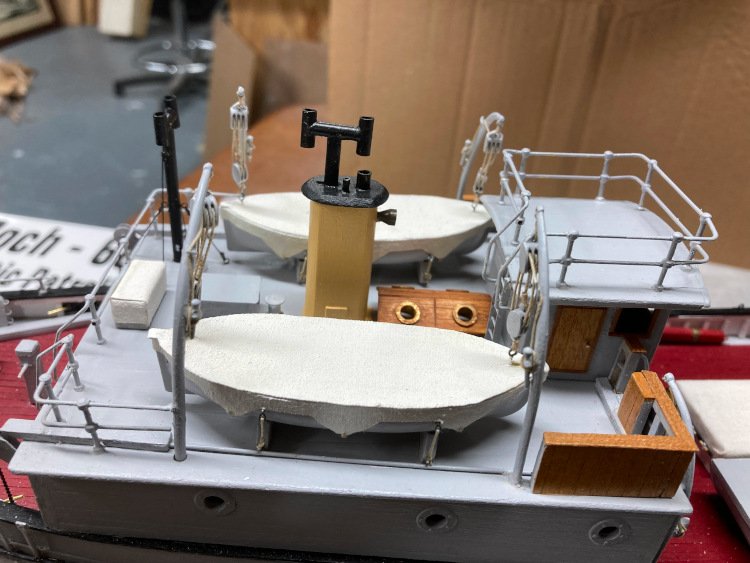

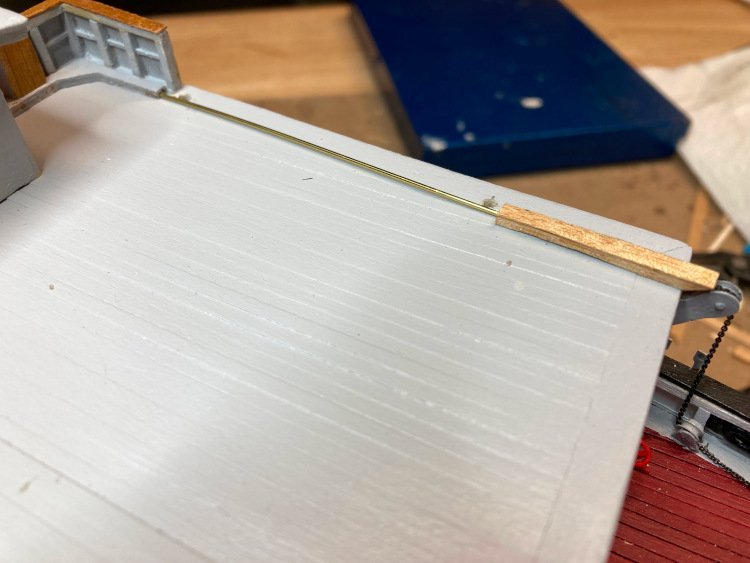

Good Morning, A short update, but what appears to be a lot of progress. Really just a few minutes of gluing the components on the decks and it almost looks like the model is done. What I found the most challenging so far has been the railings. The ones running along the rail are easy, but the ones on the roofs of the deck house and wheel house were much more difficult. In my naivete I thought I could use one piece of brass rod for each run of the railing, bending it in the appropriate places and feeding it through the stanchions. After about an hour I was about as bent out of shape as the brass rod! In the end, and after restraining myself from throwing the whole thing across the room, I used individual pieces, gluing them between the stanchions. There's a small platform on the starboard side of the hull. On the real boat, the stanchions are very thin and end in an "eye" through which the chain passes. I experimented with a small piece of dowel, drilling a small hole in the end for an eyebolt. This worked ok, but looked far too heavy. The stanchions need to be no bigger than the 1/32" brass rod to look right and there was no way I could drill into the end of that, so I flattened a small bit of the rod at the end with a hammer and drilled through that. Not 100% accurate, but I think it works ok. Just a couple more small details to attend to -the axe and fire hose and some paint touch-up, and then it's time to start working on the shrouds. Many thanks for checking in. David

-

I see your problem. I believe that the bulkhead extensions needed to either be pared down to the same size as the false stanchions or else removed completely and a false stanchion put in its place. It's still not too late to do that, but, of course, the issue is this would leave gaps in your deck planking. I guess you could add a new plank on top of the existing planking and it would be like a waterway; slightly elevated from the rest of the decking, but that would entail cutting it around the false stanchions which would be very onerous. Another idea is to replace all of the railing with wider material and another would be to taper the bulkhead extensions so that they are full width where they meet the deck and narrower where they meet the railing. If it were me, at this point in the process, I think I would opt for this last approach. I think it would give the best overall result and shouldn't be too noticeable to the casual observer. Your workmanship is really great and the model is looking really nice. David

-

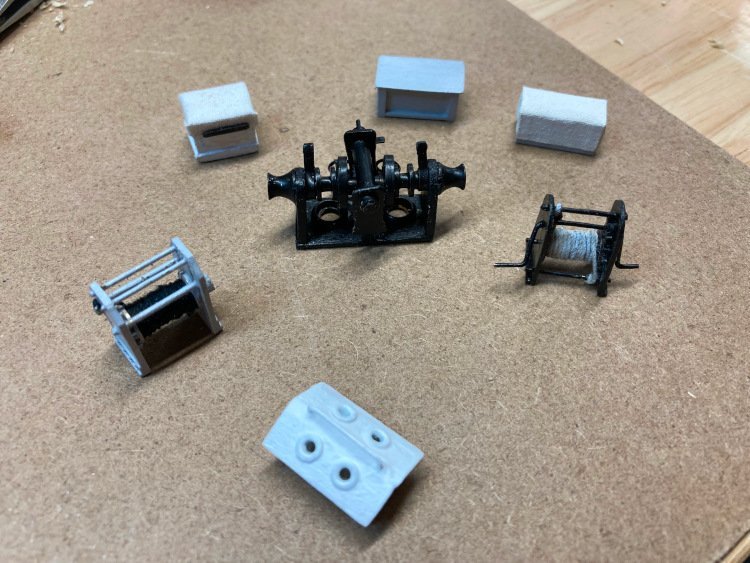

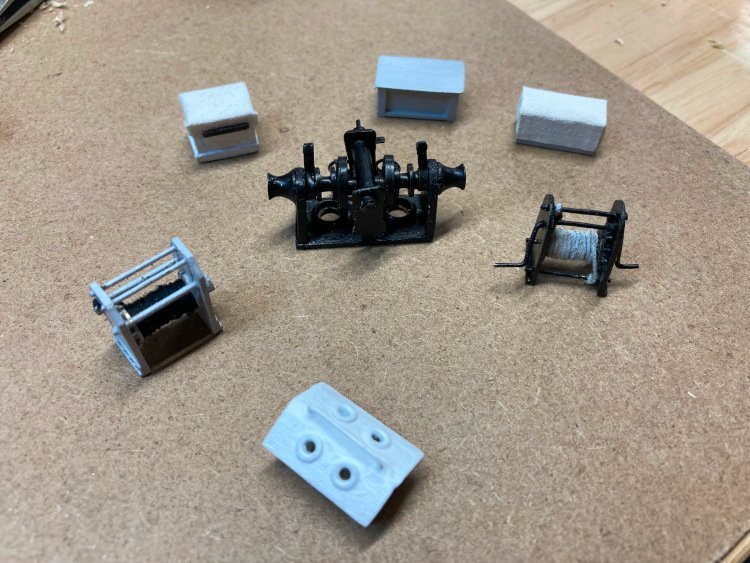

Good Morning, I have most of the bits and pieces ready to be added to the deck. Getting the size correct on these has been a bit of a challenge. The plans cannot be trusted. The drawings differ between the plan view and elevation view by as much as 10mm on some things! There is a measuring tool on the 360 tour on-line that works very well, but it's difficult to get every measurement needed and not always easy to get the same measurement twice. So it's been a matter of trial and error and discovering what fits and looks about right to the eye. I enhanced the kit provided windlass a little bit, relying on the on-line pictures and working only with the limited supplies and tools that I have. I'm not sure that it's completely correct, but it looks complicated enough to be believable 😁 Thanks for looking it and I hope everyone has a great Easter weekend. David

-

This solves a mystery for me. A few years ago I bought some "boxwood" strips from Model Expo and received this same rough yellow stuff. I was at a loss to understand why everyone raved about boxwood so much. I could see no improvement over the basswood strips I was intending to replace. Now that I understand I want to try some of the real thing. David

-

Brief update for this morning - Bill, if you use the 360 tour and go to the extreme forward starboard side of the roof of the deck house, you can just get a glimpse of the rod arrangement running along the roof. It appears to be a complicated set-up and pretty hard, if not impossible to model accurately at this scale, at least without a better reference. So I'm just representing it with a simple single rod. I'm not going to add sails. I tend to prefer my models without them, but this model would be an ideal one to show furled ones on. Have you seen Tom Lauria's youtube video on making furled sails from silkspan? It's quite good. I've been working on the lifeboats. I don't like the fact that they're plastic, yet at the same time, I don't really like the idea of building new ones either and I can't seem to locate cast ones that are quite right. So my solution is to use the plastic ones and show them with their canvas covers. I use some sail material from another kit. I was hoping to leave them unpainted, but did paint them in the end, because they looks just a bit too dirty by the time I finished. I first thought I could make each one from one piece of cloth, but soon realized that wouldn't work. The real ones, of course, are constructed out of several pieces, taking the shape into consideration. So, my solution was to use three pieces for each boat like this: I simple glued the side pieces on first. I used white glue which holds quite well. I didn't want to use CA in case I had to remove the piece and start over. I don't think the plastic boat would stand up to the acetone. (It may not have stood up to alcohol any better, had I needed to start over, but I thought the odds were better.) As it turned out, I didn't need to start over. This seems to work fairly well and with so little of the boat showing, it's hard to tell what it's made of. Next, I'm going to attack the windlass. Thanks for checking in. David

-

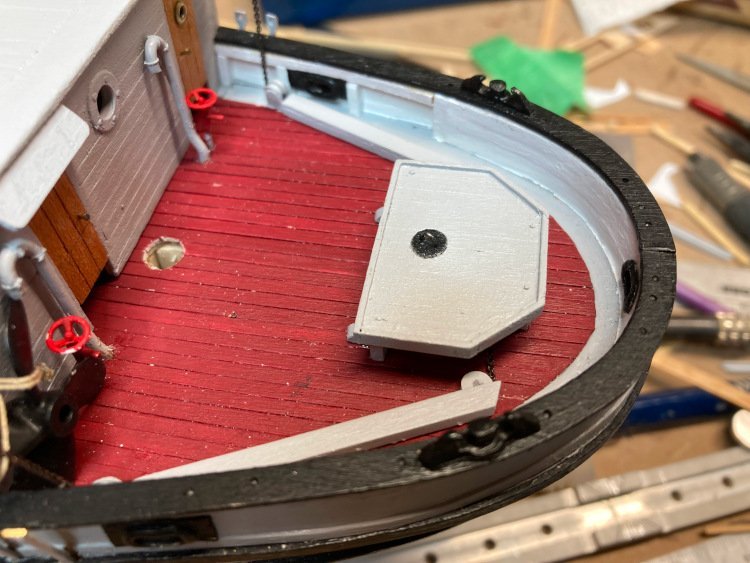

I've been trying to figure out the complicated steering arrangements on this boat. The kit provides some, but not all of the parts that are required and absolutely no mention of any of it in the plans or instructions. However, I've managed to decipher enough of it from the on-line 360 tour to make an acceptable representation of it. It seems really odd to me that considering that this boat spent most of its life in the Arctic, exposed to snow and ice that so much of this gear would be external, rather than internal. It appears to me that either cable or chain (which is encased and not visible) connects the wheel to rods that in turn connect to chain that runs down the aft side of the deck house, then runs aft along the deck to the rudder which is located beneath a deck fitting; a table or bench (not sure what it should be called.) Now I'm mulling over how to handle the two winches and windlass. The ones provided in the kit are over-simplified and mostly plastic. The winches shouldn't be too hard to re-imagine, but the windlass is a complex piece and will be more difficult. At least, too difficult for my evening brain; more suited to my morning brain. All I'm good for by this time of night is a detective series on BritBox! (my favourite is Vera) David

-

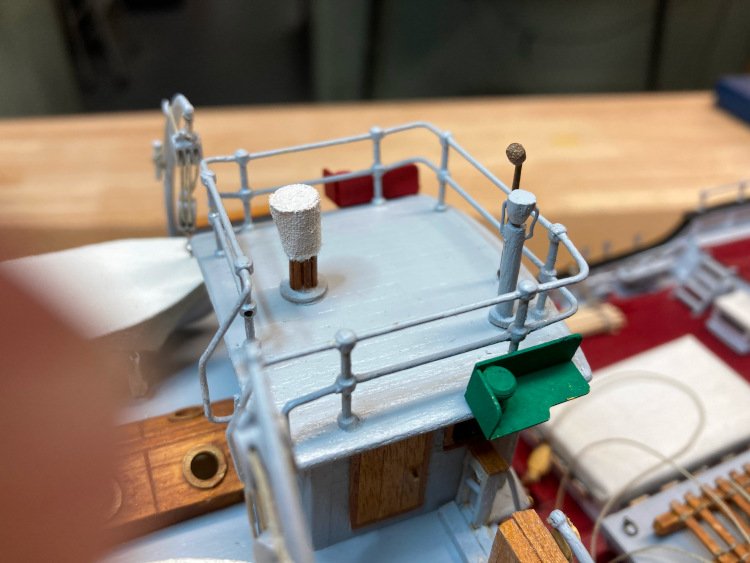

Good Morning, Bill, those models look great. Just saw your post now; we've been away for a couple of days. A Saturday morning update - Lately I seem to have the attention span of a gerbil and have been working on all kinds of different things. First, the four vent pipes: They're made out of 1.5mm brass rod, bent into shape. I wanted to indicate the joints. First I tried some Evergreen styrene strips, .01" x .02" but it was much too large to be in scale. Then I tried some rigging thread. By trial and error I discovered that both .5 mm and .25 mm lines were too heavy. I settled on ordinary sewing thread and it seems about right. Next, I was concerned that the supplied piece of dowel was not going to be quite right for the funnel. Taking measurements from the on-line 360 tour, I discovered that at 16mm diameter it was spot one. It was just a matter of flattening the sides to about 12mm. Finishing the funnel is probably next in my peripatetic approach to the details. The biggest challenge for me has been the four metal ladders. The ones provided are brass and are not bad quality, but don't look anything like the actual ones on the boat. It took me several attempts, but I have come up with something that I think is acceptable and are a pretty close approximation of the real ones. The three that mount on the deck house have curved tops, flat sides and round rungs. So I used some 1/64" x 1/16" brass strips for the sides. I made a small saw kerf at about the place where I wanted it to bend, and then just bent it using two pairs of pliers. It buckled a little, so using my best blacksmithing skills, I just hammered it flat. It's not very elegant, but once painted gray, it's going to work just fine. The rungs are .5mm wire. I'm really bad at soldering, but I discovered that one of the secrets is to hold the parts very firmly. I made two parallel grooves in a piece of wood. Once I had the holes drilled and the wire rungs inserted, I just placed the sides in the two grooves and gave the whole thing a tap with a hammer to seat it. This worked really well, and it wasn't too difficult to solder each rung in place. The ends of the rungs are snipped off and they've had some cleanup ready for paint. I think these will work, and besides, it's the best I can do, and once I know I've reached that point, I can live with it. The fourth ladder that mounts to the wheelhouse doesn't have a curved top and I'll cut it to length when I get to that point. The final item for today is the railing that extends out from the wheelhouse on both sides. These pieces were easy to make and I added the detail to the back side to match that of the real boat. So that's it for now. Again, many thanks for checking in, likes etc. David

-

Hi Dave, I hope you don't mind my chiming in. I honestly just don't get including plastic parts in a wooden kit. It they're going to do that, then why not just make the whole thing out of plastic and be done with it. My build log probably won't be of too much help, because I built the Model Shipways version, not the Billing version and they seem to differ a fair bit. There seems to be a problem with the way your grating is sitting on the stem piece. The grating appears to be sitting up against the hull quite well, but by the time you get to the end of the stem piece, the grating is sitting well to the port side. I'm not sure what needs to be adjusted to get the grating centred on top of the stem piece for its entire length, but if you can do that then that should go a long way to getting the side pieces to fit. If you don't like the plastic side pieces, I don't think it's too big a job to make new ones out of wood. Is there some billet material of the same thickness that's big enough? If so, I would use that; if not, I would just glue up some strip material of the right thickness. Sometimes glued up stripwood will tend to split or come apart, especially if you have to cut close to a seam or against the grain. I sometimes glue the strips to a piece of paper which gives the whole thing a surprising amount of strength. If the piece is to be used in such a way that the paper side won't show, I leave it on. If it's going to show, (as it would in this case) I just sand the paper off after the piece is cut out.You can use the plastic pieces as templates, trace them and cut the new pieces out. Another big advantage to replacing the parts, besides appearance, is that there is always a lot of flexibility with wood to make minor adjustments to make them fit. (I don't believe I have ever been able to build a truly symmetrical model; fortunately you can only ever see one side at a time, so I don't worry about it.) Plastic doesn't give this kind of flexibility. Not sure if that's of any help or not, but hopefully it is. David

-

Bill - I didn't use the plastic for the windows. I have never used it on any of my models. I always just leave the opening. For some reason, I find it distracting to look at and difficult to install without getting glue all over it (at least in my case) so I always just opt to leave it off. I did paint the interior of the wheel house. I used a dark brown. I haven't had a good look at the stack yet, but I do know that the supplied piece is pretty far off from being the right shape. I'm not sure how I'll approach it just yet. The small vents on the bottom of the stack will be pretty hard to do as the scale makes them only about 4mm long. I don't think I would try building them, I think I would be inclined to used a small piece of wood, the correct size, and suggest the vent slots by scoring the wood horizontally. These type of things I tend to experiment with and if the result looks ok, I use it and if not, then I omit it. The box on the back of the wheel house is an easy detail to replicate, so I will probably add it. The ladders! I have spent the better part of the afternoon trying to make ladders that look better than the provided ones, but I'm having a lot of trouble. I've tried some small brass strip for the sides. I drilled a series of holes and then soldered in brass wire representing the steps. Unfortunately I am the world's worst solderer and the result was quite a mess. I then tried using brass wire for the sides, soldering smaller brass wire across for the steps. Again, quite a mess. There are always two possible outcomes for me - a joint that fails or a glob of solder the size of a golf ball. So, I am still contemplating my options and waiting for another one of my 3 am revelations. 😄 David

-

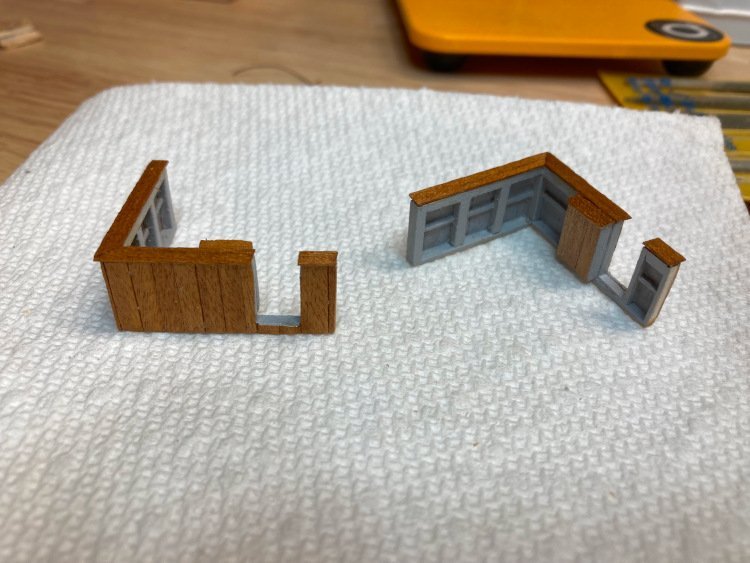

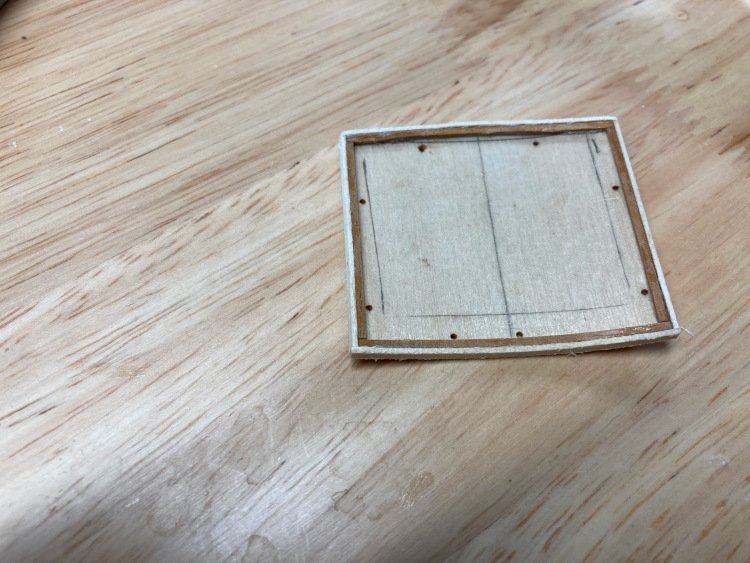

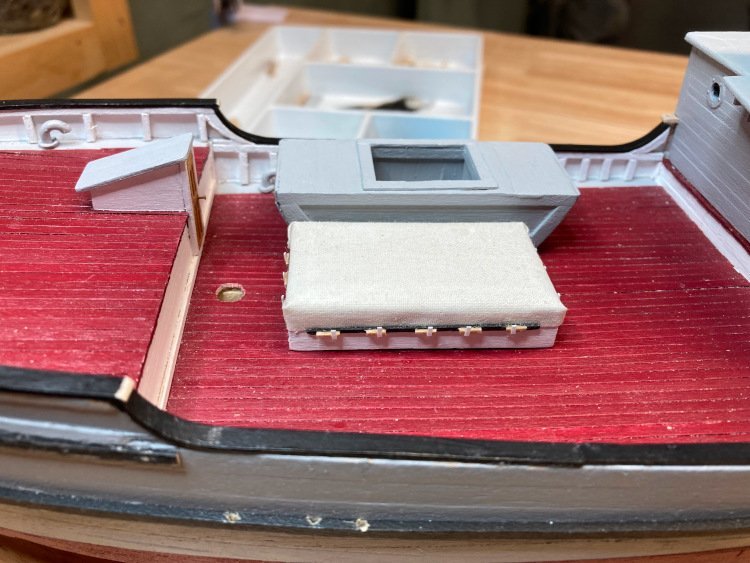

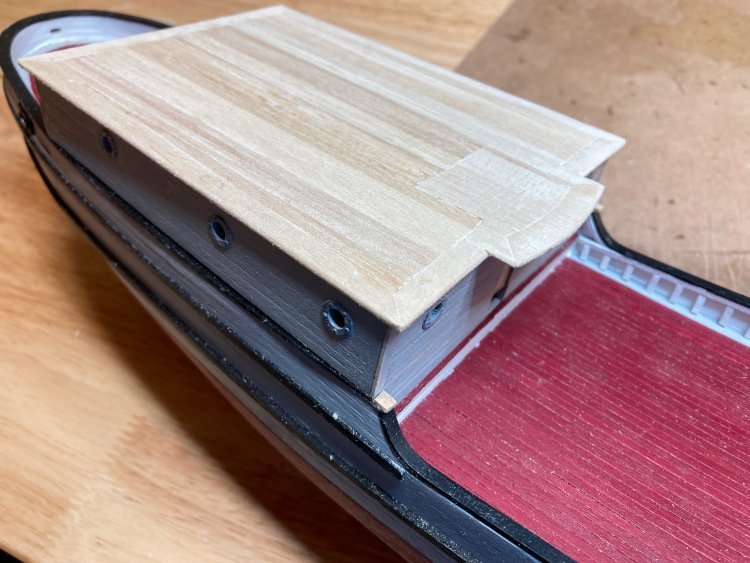

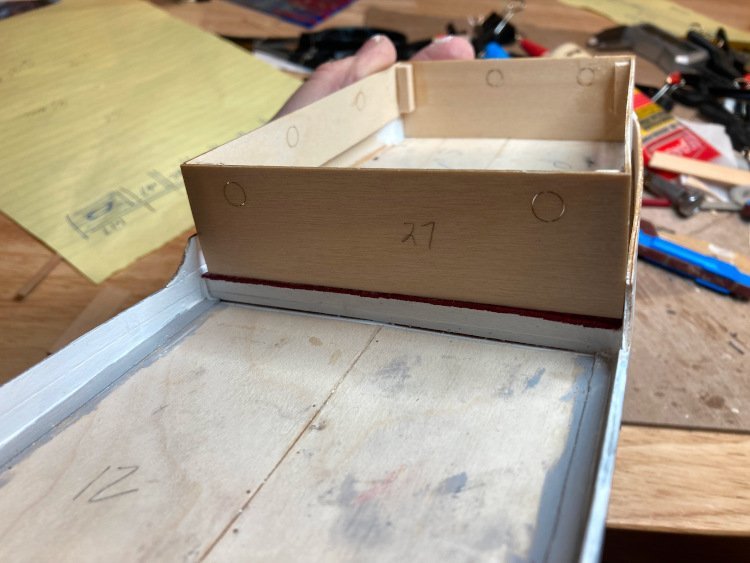

Small update this morning - I've been working on the wheel house. The first thing was building up the depth of the roof - Then the assembly was quite simple. The walls are made out of very thin plywood and I didn't like the idea of the exposed edges, so I applied a narrow strip of Tamiya tape over the joints, which both hid the raw edges and more or less replicated the look of the real thing. I noticed that the real wheel house has one operable window, while the rest are all stationary, so I tried to replicate that with the cross bar in the one window. You can't see it in this picture, but I also added an actual steering wheel, which you can see when looking straight one. I also built what is referred to as a cargo scow. I assume it's designed to be towed across snow/ice. It has curved ends and sits on runners. For some reason the kit shows this component as a simple box. It's shown below along with the hatch, both of which are not installed yet, but just sitting in their approximate locations. You can also see two of the six gooseneck vents which are not included in the kit. I bought some from Cornwall Model Boats and cut them down to size - I also made the three water outlets, which are not included in the kit, using the valves which are not needed for the vents. To make these I used some 1mm brass rod and some brass tubing just big enough to fit the brass rod and the stem of the valve. That's it for this morning. I'm currently working on a number of the other small deck details. Thanks again for checking in! David

-

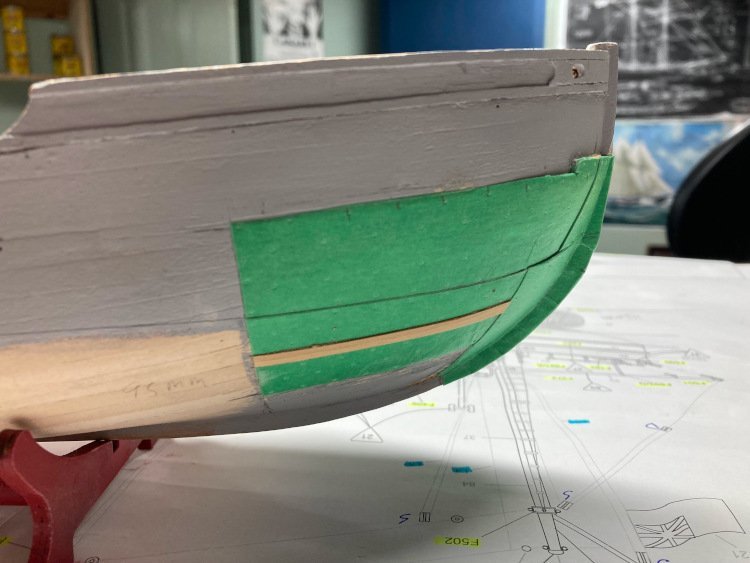

So, here are some pictures of my progress. I wanted to replicate the steel cladding on the hull and wasn't sure how to do it. I ordered some thin foil, but unfortunately when it arrived, it was much too heavy to manipulate, so a thought occurred to me, and here is the result: I used masking tape. The beauty of it is, it will stretch in more than one direction. I don't know what the longevity of it will be, but to be honest I don't care. I'm old and realistically, how long does anyone need this thing to last? I represented the nails, or rivets, or whatever they should be called, with a mechanical pencil with no lead in it. It was the ideal tool to make the round indentations. They don't show up too much from a normal viewing distance, but just enough. First, I built up the raised area Then tapered it. Then I applied the masking tape, trying to duplicate the actual pattern, and used multiple layers to get the effect needed. Next up was the deck house. This was actually a bit trickier to position correctly than I anticipated. I planked each of the four walls first and after a quite a bit of swearing, got everything more or less square and secure. The plastic port holes are going to look just fine. They need another coat of paint, of course, and I still have a bit of "corner work" to do. The roof had me concerned for a moment, It's a one-piece sheet of thin plywood, which is intended to be planked. My concern was how to treat the edges. On the real boat, there is a nice overhang on all sides, which is finished with a bullnose. There was no real overhang with the provided roof and I wasn't sure how to treat the edges, so I decided to discard the plywood roof and thin planking, in favour of using heavier 1/16" x 3/32" planks for the centre area and 1/'16" x 1/4" planks for a frame. It was easy to give the 1/16" stock a nice looking bullnose. First I added some framework. The I rounded over the outside edge of the edge pieces. I handled the centre section, where the pilot house sits, separately. Then I filled in the rest and it's ready to be painted and have the crazy complicated collection of things added on top. Many thanks for checking in! David

-

Hi Bill, Sorry, I just noticed your post now. Yes, I have planked the deck house and will be posting pictures later today. I too have been thinking about how best to add the fire hose. One thought I had (they come to me at 3 in the morning) is to use some sail material from another kit. I'll coat one side of it with watered down glue, so it doesn't fray like crazy. Then I thought I would cut a narrow strip, let's say about 1/4"wide, then fold it over along its length, making it about 1/8" wide. This will leave a rounded edge and a raw edge. Then roll the strip up, placing the folded, rounded edge out. I don't know yet if it will work, but that is what my first attempt will look like. The real fun of this kit is the many missing details that can be added. Thank goodness for that 360 tour on the museum website. David

-

I'm not sure if I mentioned it in my build log or not, but I left the bottom piece off and using a fine hand saw, I cut the whole thing in two, running the saw stem to stern through the centre. It made it much easier to sand the interior and it glued back together perfectly. I can't take credit for the method however; I read it on another build log, but I can't really recall which one. David

-

Steve - I had a very unpleasant day to day, but your comment completely turned things around for me.Thanks for that! As much as I loved building this model, (in fact of all the ones I've done, this was my very favourite) I really hated doing the boats. There just doesn't seem to be any way around them. And there are so many of them! I'm sure yours will look great. David

-

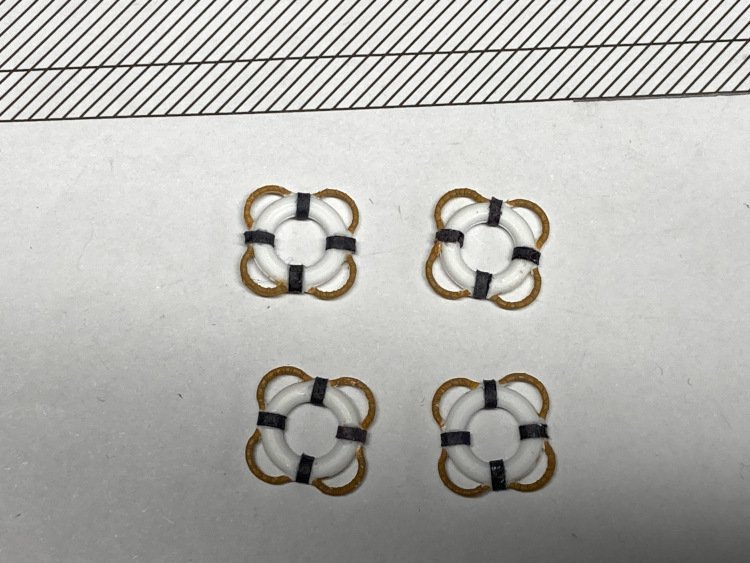

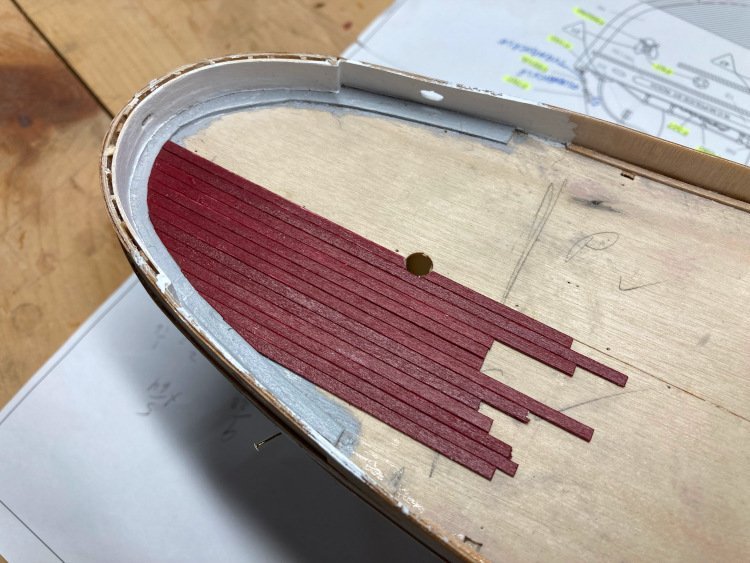

A quick update today - I've been working away at a variety of things. I've added the stanchions (which are not part of the kit's plans) including the curved transition piece where the deck levels change. This recreates the actual boat quite closely. The stanchions are much closer together in the centre part of the boat and further apart at the bow. I've also been working on the decking. I didn't use the provided decking material, which is that .5 x3mm stuff of indeterminate origin which I don't like very much. Instead I used some 1/32" x 3/32" basswood. The decks on the St. Roch appear to be painted, so that's how I finished these decks too. I have never painted a deck before and I was afraid that it would completely obscure the planking, so I tried something I've never done before and that was to paint the planking before installing it. It's not likely that I would ever do it this way for a deck that was finished in one of the more usual ways, but for this painted deck, I think it worked quite well. I also added waterways, which the kit doesn't provide for, but I did make a compromise. On the actual boat the waterways sit higher than the decking, but I have opted to make them all level. With the slightly thicker planking that I used, It was getting a bit too tight along the bulwarks if I made the waterways any higher than I did. This is a small compromise that I can readily live with. A couple of other little things - I made the chimneys from scratch using 3mm brass tubing. I am really bad at soldering and don't really like doing it very much. However after several stabs at it, I managed to get an acceptable result. I've finished the rudder, which is now ready for paint, as well as made a spare one to sit on the deck, as per the actual boat. The kit doesn't reference this spare rudder, but it does provide two rudders. The spare had to be modified to be made longer as the one to be installed on the stern only just reaches the bottom of the hull. The kit provides four life rings which are plastic and I decided that once they were painted up they looked as good as any cast metal upgraded version would. So I chose to use these ones rather than replacements like I'm doing for so many of the other fittings. That's it for tonight. My next challenge is to try to figure out a simple, but effective way to replicate the steel sheathing on the bow of the hull. Many thanks for checking in. David

-

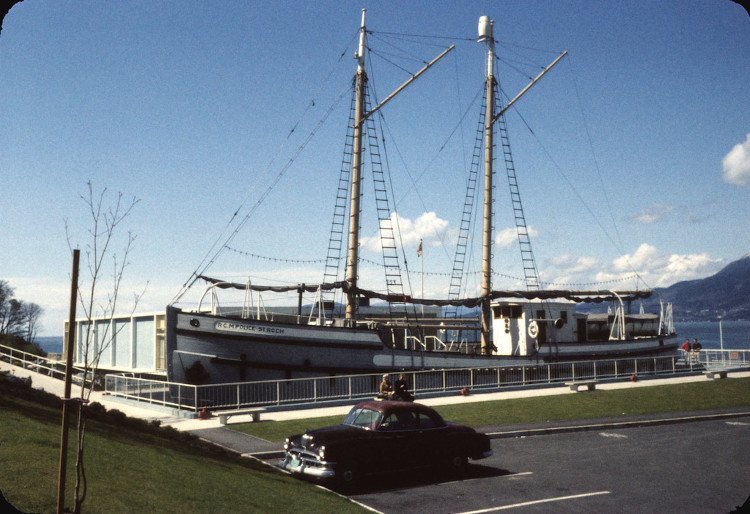

Good Monning, Look what I am the "lucky" recipient of - I have a friend who is interested in all aspects of history, but especially naval and military history. When I mentioned to him that I was building St. Roch, he was the first person I had spoken to who knew the vessel I was talking about, knew its history and even knew its captain's name. Furthermore, he said he had a picture of it that I needed to have (or he needed to be rid of, I can't quite remember.) For some reason my wife does not want to see it hanging over our fireplace, so I guess it will be my basement shop for the time being. David

-

I found these pictures, which answer the question about the location of the steering wheel - But there seem to be unending questions: In the pictures above, which would seem to be about the same era, the first one shows three port holes and the second one shows two. Also the planking around the lettering is different. The boat has clearly had several rebuilds, in which it has been changed considerably. This picture is supposedly from 1928, the year it was launched: It had a totally different masting and rigging, three port holes, no cabin, I guess that's a pilothouse, big cowl vents, different paint scheme etc. But by the time of its Northwest Passage days, which were in the 1940's it seems it was altered to looked pretty much the way it does now, but then here's a picture from probably the 50's and it's been rebuilt again, closer to when it was launched, but still differing in several ways - the pilot house is different, the port holes have gone from three to two etc. I'm guessing they restored it to look like its Northwest Passage years when it went on display at the museum, but that still leaves the question of why the steering wheel isn't there. They obviously made choices at the museum, but I'm not sure what were the deciding factors for those choices. I haven't found any narratives on-line yet that outline these changes, but I'll keep digging. David

-

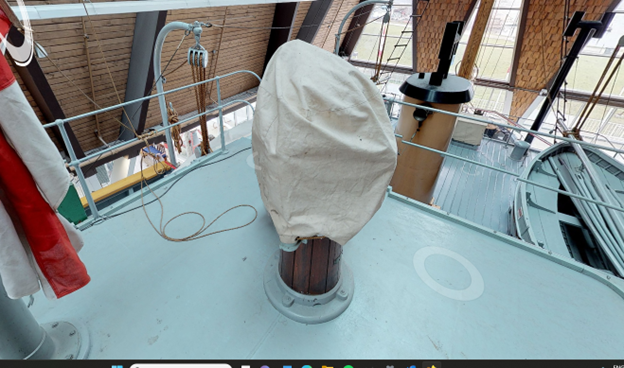

Hi Bill, I have noticed both early on and to be honest, haven't really given it any thought since. It's a bit confusing, isn't it? I think this is what you are referring to on the top of the pilot house, but it doesn't look to me as though the canvas-covered structure is large enough to contain a steering wheel; certainly not one as large as the one shown in the historical picture. Also the historical picture shows a wide base rather than a column. (It also shows a cowl vent which the boat doesn't currently have.) Clearly changes have occurred over the life of the boat. Another question - if this is a steering wheel, there appears to be no mechanism to connect it to the rudder. There's nothing visible on the ceiling of the pilot house. This leads me to suspect that the canvas-covered structure is not a steering wheel, but if that's the case, I don't know what it might be. I may be showing my ignorance here, but there's another thing on the roof that I can't identify - Any ideas of what this might be? David

-

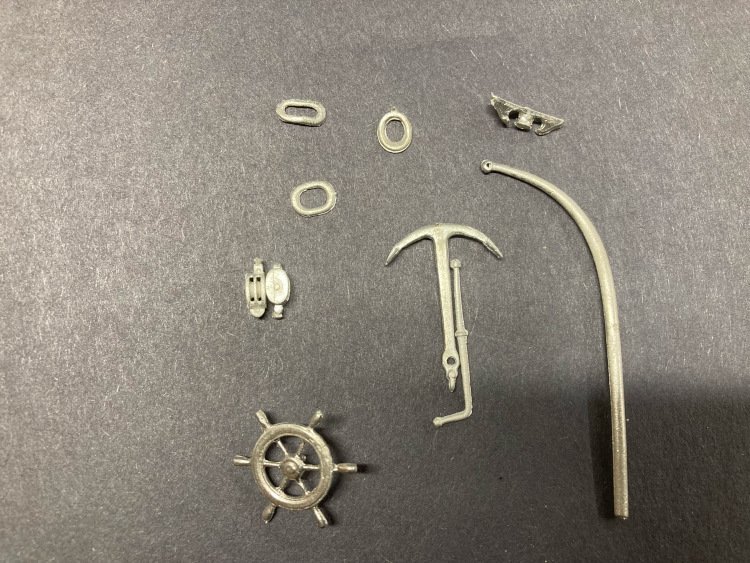

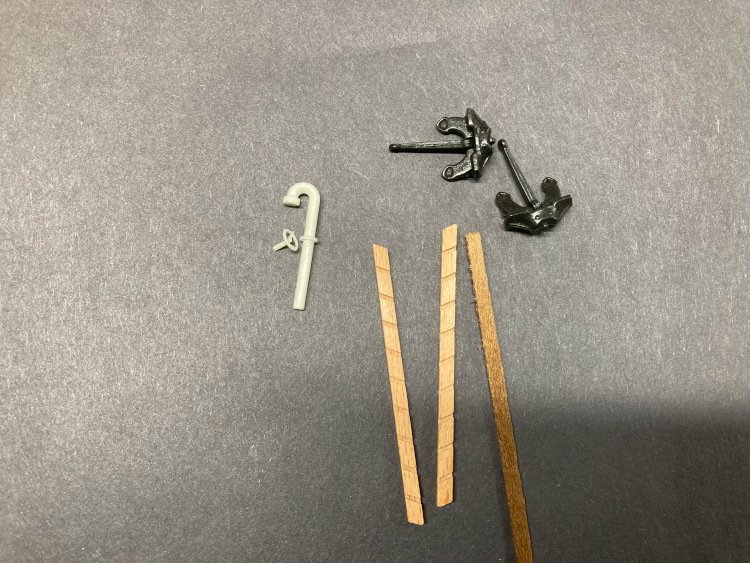

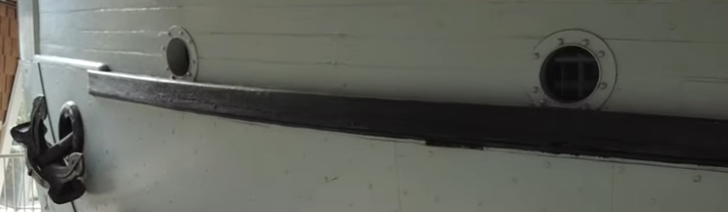

Thanks everyone for your input on the placement of the portholes vis-a-vis the rubbing strake. I believe most of you favour placing the portholes so that they just clear the rubbing strake and I think that's the way I will go. I think if I place the rubbing strake over the portholes, it will look like I messed up somewhere along the way, (and since that never happens 😁, why suggest that it did!) Bill, your St. Roch is coming along very nicely. You asked where I found the trim for the hawse holes. They are a BlueJacket fitting. Here's a picture of the fittings I bought from BlueJacket. BlueJacket calls them hawse lips(F0743.) They're in the upper left of the picture. The lower one is how they come and the upper one is after a little squeeze to more closely resemble the real thing. The others are Hawse lips for the anchors (F0451.) Also there is an anchor for the deck (F0506,) the davits(F0071,) these are not quite the right arc, but can be easily bent into the right shape. They are a bit too long, but I can either cut them off or sink them deeper. Chocks for the rail (F0089,) and blocks. The blocks on the real boat are all internally stropped. These ones (7/32" - F0378 and F0403) will work well. I'll paint them. Also, I decided to add a ships wheel (F0291)which I think will be visible through the window. I also added a few things from Cornwall Model Boats. On the real boat there are six gooseneck vents along the waterways, which are not included in the kit. I thought I'd try these ones. I'm not sure that they're quite right. As small as they are, I think they are still a bit overscale. My plan B is to make them from scratch using pieces of 3mm solder that I have kicking around. (It's about 40 years old and dates from the days when I was still suffering from the delusion that I could successfully accomplish my own plumbing repairs.) Even if I don't use those gooseneck vents, there's another reason why I bought them and that was to get the valves that come with them. They aren't needed for the vents, but another detail that can be added is the two or three water spigots. These won't be hard to make from scratch, but the valves would be. These ones should work for that quite well. I also bought a ladder kit as well as a couple of anchors for the side of the hull. I mentioned in an earlier post that although I generally don't like the plastic parts included in the kit, I actually prefer the provided plastic portholes to the provided brass ones. The plastic ones match the real ones quite accurately and since they will be painted they should look just fine. Cornwall offers these, so I bought a few more to replace the brass ones, which I think have too big a rim. I want to show the ends of the deck planking under the cabin, so I cut the sub deck back a bit and put in a support to carry the ends of the planking stubs. I then filled in the mini planks. This way it won't throw the measurements of the cabin out of whack, as the provided pieces don't account for the extra 1/32" or so that would result if I placed them directly over the sub deck. So that's it for now. This simple kit is proving to be even more fun that I expected. Many thanks for checking in. I really appreciate it. David

-

I am torn! Looking ahead, I discovered this about the portholes in the hull. The rubbing strake runs right over the flanges. What should I do? If I include that detail then I run the risk of looking like I've made an error, but it appears it would be the most accurate. Or do I locate the portholes slightly higher to look a little tidier, but sacrifice some accuracy. Such problems I have! David

-

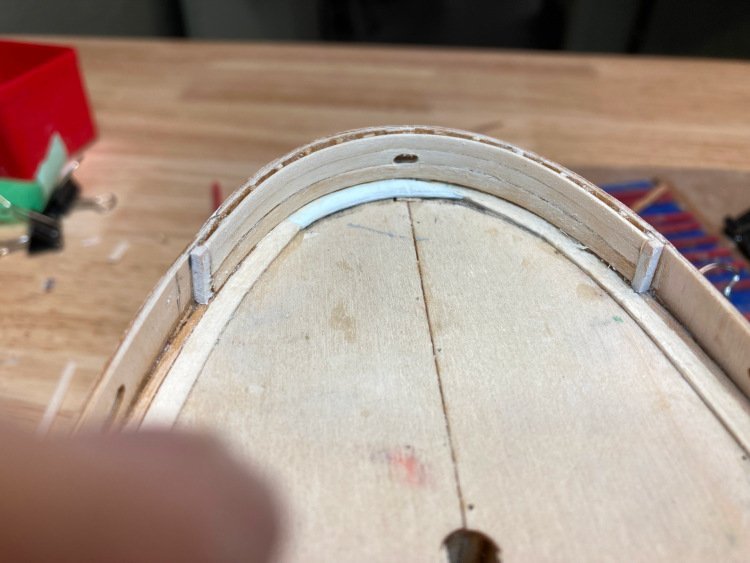

A little progress to report - I finished up the planking and painted the gray on the hull. I intend to add all the stanchions to the bulwarks as well as the waterways, both of which are missing from the kit. In order to do that, I broke off (some by accident) all of the bulkhead extensions. I added the first strip of the waterways (1/32" x 1/16") to the subdeck following its contour. Without the bulkhead extensions, I needed something to place the upper hull pieces against. The waterway created a small lip. I glued the upper hull pieces in place. I added the second strip of the the waterways. The bulwarks are planked on the inside, just at the stern and bow of the boat. This detail is omitted from the kit, but I wanted to add it. I have the stern done. There is a hawse opening at the stern of the boat which I wanted to add as well, so I've cut it in, using the hawse trim (from BlueJacket) as a guide. There are none included in the kit, but I'll add them for all five of the hawse openings. The smallest ones from BlueJacket are about the right length, but just a tad too high. A gentle squeeze with a pair of pliers fixed it easily. I added the planking to the upper hull at the bow and the stern. That's everything so far. Please forgive how rough everything looks. I know I still have plenty of sanding and painting ahead of me. Many thanks for the comments and 'likes.' David

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.