-

Posts

63 -

Joined

-

Last visited

-

GrandpaPhil reacted to a post in a topic:

HMS Victory by Davesellindge - Constructo - Scale 1:94 - first build

GrandpaPhil reacted to a post in a topic:

HMS Victory by Davesellindge - Constructo - Scale 1:94 - first build

-

GrandpaPhil reacted to a post in a topic:

HMS Victory by Davesellindge - Constructo - Scale 1:94 - first build

GrandpaPhil reacted to a post in a topic:

HMS Victory by Davesellindge - Constructo - Scale 1:94 - first build

-

GrandpaPhil reacted to a post in a topic:

HMS Victory by Davesellindge - Constructo - Scale 1:94 - first build

GrandpaPhil reacted to a post in a topic:

HMS Victory by Davesellindge - Constructo - Scale 1:94 - first build

-

Bobstrake reacted to a post in a topic:

HMS Victory by Davesellindge - Constructo - Scale 1:94 - first build

Bobstrake reacted to a post in a topic:

HMS Victory by Davesellindge - Constructo - Scale 1:94 - first build

-

Sad bit of news have just discharged myself from hospital after 4 weeks needed to get home with the wife, they found lung cancer.being refered for treatment will keep in touch Dave

- 78 replies

-

- victory

- constructo

-

(and 1 more)

Tagged with:

-

Blue Pilot reacted to a post in a topic:

HMS Victory by Davesellindge - Constructo - Scale 1:94 - first build

Blue Pilot reacted to a post in a topic:

HMS Victory by Davesellindge - Constructo - Scale 1:94 - first build

-

Blue Pilot reacted to a post in a topic:

HMS Victory by Davesellindge - Constructo - Scale 1:94 - first build

Blue Pilot reacted to a post in a topic:

HMS Victory by Davesellindge - Constructo - Scale 1:94 - first build

-

AndyW reacted to a post in a topic:

HMS Victory by Davesellindge - Constructo - Scale 1:94 - first build

AndyW reacted to a post in a topic:

HMS Victory by Davesellindge - Constructo - Scale 1:94 - first build

-

Davesellindge reacted to a post in a topic:

HMS Victory by Paul0367 - Constructo - Scale 1:94 - First wooden ship build

Davesellindge reacted to a post in a topic:

HMS Victory by Paul0367 - Constructo - Scale 1:94 - First wooden ship build

-

dgbot reacted to a post in a topic:

HMS Victory by Davesellindge - Constructo - Scale 1:94 - first build

dgbot reacted to a post in a topic:

HMS Victory by Davesellindge - Constructo - Scale 1:94 - first build

-

Managed to recycle old steps by cutting them smaller not so sure if its looks okay yet, will think about before I make new ones, will compare the other side when done with correct size.

- 78 replies

-

- victory

- constructo

-

(and 1 more)

Tagged with:

-

Davesellindge reacted to a post in a topic:

HMS Victory by Paul0367 - Constructo - Scale 1:94 - First wooden ship build

Davesellindge reacted to a post in a topic:

HMS Victory by Paul0367 - Constructo - Scale 1:94 - First wooden ship build

-

AndyW reacted to a post in a topic:

HMS Victory by Davesellindge - Constructo - Scale 1:94 - first build

AndyW reacted to a post in a topic:

HMS Victory by Davesellindge - Constructo - Scale 1:94 - first build

-

Thank you David its down to all the helpful comments from everyone that spurs me on, every one is so helpful

- 78 replies

-

- victory

- constructo

-

(and 1 more)

Tagged with:

-

How to waste time, money and precious wood cut out the steps using 4mm instead of 3mm I wouldn't mind but from the front view they looked quite good for me. Start again.

- 78 replies

-

- victory

- constructo

-

(and 1 more)

Tagged with:

-

Thanks Paul about the davits it was like the advice doing the rudder earlier that made a difference. Did you make the barrels

- 699 replies

-

- victory

- constructo

-

(and 1 more)

Tagged with:

-

CaptainSteve reacted to a post in a topic:

HMS Victory by Paul0367 - Constructo - Scale 1:94 - First wooden ship build

CaptainSteve reacted to a post in a topic:

HMS Victory by Paul0367 - Constructo - Scale 1:94 - First wooden ship build

-

Its going to a show piece when done, I just cant believe how much you are doing

- 699 replies

-

- victory

- constructo

-

(and 1 more)

Tagged with:

-

Davesellindge reacted to a post in a topic:

HMS Victory by Paul0367 - Constructo - Scale 1:94 - First wooden ship build

Davesellindge reacted to a post in a topic:

HMS Victory by Paul0367 - Constructo - Scale 1:94 - First wooden ship build

-

I am still working away every time I built the bell a bit came unstuck, but got there in the end. Will add more photos soon but as I have said before I cannot master the bending so when it came to the reinforcements I stuck two planks together and decided to sit and whittle away till I got the shape. I don't think it looks to bad only five more to make

- 78 replies

-

- victory

- constructo

-

(and 1 more)

Tagged with:

-

Davesellindge reacted to a post in a topic:

HMS Victory by Paul0367 - Constructo - Scale 1:94 - First wooden ship build

Davesellindge reacted to a post in a topic:

HMS Victory by Paul0367 - Constructo - Scale 1:94 - First wooden ship build

-

Davesellindge reacted to a post in a topic:

HMS Victory by Paul0367 - Constructo - Scale 1:94 - First wooden ship build

Davesellindge reacted to a post in a topic:

HMS Victory by Paul0367 - Constructo - Scale 1:94 - First wooden ship build

-

Davesellindge reacted to a post in a topic:

HMS Victory by Paul0367 - Constructo - Scale 1:94 - First wooden ship build

Davesellindge reacted to a post in a topic:

HMS Victory by Paul0367 - Constructo - Scale 1:94 - First wooden ship build

-

Have done one side and I think it works. The engine in the background is an American Case half size there's six of us get together at my mates place for the annual steam test and inspection.

- 78 replies

-

- victory

- constructo

-

(and 1 more)

Tagged with:

-

I found an wooden cigar box and have been drawing the curves on it for the bow, cutting them out and then sanding them down 2mm, its a type of ply but very fine and does not splinter. Also when its sanded down its very bendable so when glued just bend it to shape when gluing. Will post photo when completed one side.

- 78 replies

-

- victory

- constructo

-

(and 1 more)

Tagged with:

-

When looking at the angle of the davitts they were not correct so removed them and replaced them. I just thought you might like to look at my other hobby, I restored this traction engine, I had to strip it down to the last nut and bolt and put in a new boiler. You can see why I am struggling with tiny pieces of wood

- 78 replies

-

- victory

- constructo

-

(and 1 more)

Tagged with:

-

Have had a good day today and managed to get some more done, as I am painting I am going to have to do it as I go along other wise it will be impossible holding it to get to certain part's and not break other bits off like the rails. Gave up on bending 1mm so carved the pieces out of scrap wood.

- 78 replies

-

- victory

- constructo

-

(and 1 more)

Tagged with:

-

Davesellindge reacted to a post in a topic:

HMS Victory by Paul0367 - Constructo - Scale 1:94 - First wooden ship build

Davesellindge reacted to a post in a topic:

HMS Victory by Paul0367 - Constructo - Scale 1:94 - First wooden ship build

-

Davesellindge reacted to a post in a topic:

HMS Victory by Paul0367 - Constructo - Scale 1:94 - First wooden ship build

Davesellindge reacted to a post in a topic:

HMS Victory by Paul0367 - Constructo - Scale 1:94 - First wooden ship build

-

It seem's I have cracked it, made both the longer rails the joints were so tight I could not put any glue into them, but they seem tight enough no movement.

- 78 replies

-

- victory

- constructo

-

(and 1 more)

Tagged with:

-

Davesellindge reacted to a post in a topic:

HMS Victory by Paul0367 - Constructo - Scale 1:94 - First wooden ship build

Davesellindge reacted to a post in a topic:

HMS Victory by Paul0367 - Constructo - Scale 1:94 - First wooden ship build

-

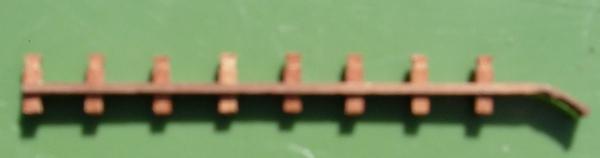

Thanks everyone for your support, I have started on the railings, I found cutting the posts into to two pieces was a pain trying to get them to look straight. When I started on the front ones I thought I would recess the complete post on the ends, this worked. So on the side railings I am going to try and cut out the the holes so that I can put complete post's in.Photo shows first attempt on the small part, know to try the long piece.

- 78 replies

-

- victory

- constructo

-

(and 1 more)

Tagged with:

-

Davesellindge reacted to a post in a topic:

HMS Victory by Davesellindge - Constructo - Scale 1:94 - first build

Davesellindge reacted to a post in a topic:

HMS Victory by Davesellindge - Constructo - Scale 1:94 - first build

-

Thank you all for your comments it has been one of the best things I did when I joined Modelshipworld, I will continue to do my best and with all your help I shell get threre. The trouble is I write down the suggestions and then get carried away following the plans and then make a mess and remember the help offered.

- 78 replies

-

- victory

- constructo

-

(and 1 more)

Tagged with:

-

Hi Andy I might have another go and change them. The paint is a dull yellow and so is the blue the photos make it look much lighter. I use the Caldercraft Admiralty Paints. Have a look at Cornwallmodelboats.co.uk they have the kits or you can also buy them separate.They are a very good shop to deal with and have a good range of products If you look at the above photo and the yellow at the stern is nearer to the colour

- 78 replies

-

- victory

- constructo

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.