-

Posts

7 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by MrPete

-

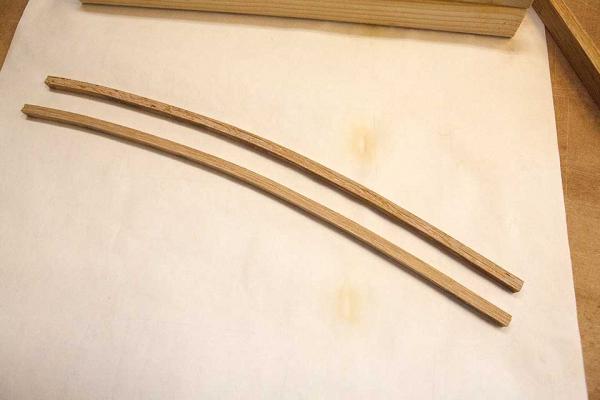

I wanted to confirm exactly how I was going to build the deck system, so I tried mocking up one idea, to see 1) how it looked, and 2) how was I going to build it (clamping, glues, sand, finish - techniques) It turned out clamping is going to be a really big consideration. I wanted to simulate the caulking between planks. I've tried a number of different techniques, but for this project wanted to try something new. I milled some Alaskan Yellow Cedar into 1/8" thick, 1/4" wide planks and then used some stripped fiber mat material, that my guitar builder friends use for perfling on guitars as the caulk material. The stuff comes in specific widths and thicknesses. I found some that are 0.020" thick by 5 feet long by 3/16" wide. Close enough. I first cut the edge strip (please forgive my lack of boat terms) from mahogany and glued it to two beams I built for the mockup. After the glue set, I laid a piece of the black fiber strip, then a plank of yellow cedar, then a black strip, then cedar, so I had two of each laid down. I throughly applied epoxy to both edges of the strips and planks before assembling them, and then clamped them tightly to the curve of the edge piece and to each other, and to the beams. Clamping this mess during assembly is going to be the hard part. It needs to pull the planks tight against each other, but also keep the planks pressed tight against the beams. I may use an over-head go-bar system. (like luthiers use) I let the epoxy set for the first group of 4 pieces (two planks, two caulking strips) then did it again. After sanding, here is the result - It looks fantastic, better than I imagined.

-

Twister - I completely agree - soaking for 10 minutes does nothing but raise the grain. I tried a number of steaming techniques, but they ended up being more work than they were worth. Cutting them out is not a bad idea - I may try that. I'm still un-decided about the plywood sub-deck. I did some mockups of how I was going to lay up the deck, and they turned out great. (see next post) I thin I can make a water-proof deck just with planks. We'll see. Thanks for your comments and interest. MrPete

-

capnharv2 - No, I don't have plans for Malabar I. I have some plans for a "37' Aux Cruising Schooner" designed by John in 1930. It is similar, but the deck houses are different. I have some old photos of the Malabar I and some pics of other models of the M1, but no plans. I kind of like the single deck house of the Malabar 2 instead of the two house design of the M1. Still haven't decided which to go with. Where did you see the plans for the M2 ?

-

I need to figure out how thick the deck is going to be, so I can establish the under-deck framing plan. Questions: Should I put in a plywood sub-deck first ? What kind of wood should I use for the deck planks ? How thick should the deck planks be ? How do I make the deck water-proof ? The hull is 48" stem to stern, 14" wide at the waist. The deck has a two way curve - the deck beams are crowned, and the hull curves front to back. (one piece of ply-wood won't fit easily) It MUST be water-proof. ( the ship will be radio controlled - insides can't get wet ) I was going to use Teak for the deck - 'cause I thought it was traditional, but it's usually left un-finished for skid control. I guess I'll have to varnish the entire deck for water-proof-ness, or come up with some way to guarantee all joints are sealed. I have access to oak, spruce, teak, port-orford cedar, mahogany and pine. I guess I could find other stuff if I need. thanks in advance for any suggestions and advice. Pete

-

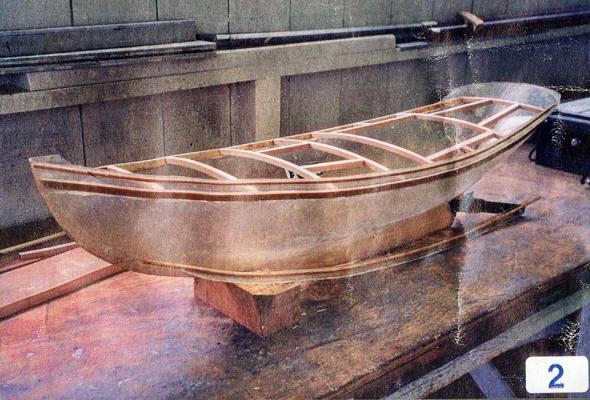

I feel like I should decide exactly what I'm going to do in a number of areas before I begin anything. How the deck gets constructed is not nailed down, nor am I comfortable about wood selections yet. I decided to try building the deck beams out of a couple different woods to see what happenens. I wanted to try bent laminations to see if it would keep the crown shape better than steam bending. I scaled info about the deck crown from the real boat drawings ( 6" in 10'-6" ) to my boat ( 5/8" in 14" ) and made a form out of a 2x4 and 3/4" MDF: I ripped 3/4" white oak into strips 3/4" x 3/32" Glued 4 of them together with epoxy and pressed them together in the form: After the epoxy set, I ripped the 3/4" lamination down the center with a band saw and ended up with two crowned oak beams 16" long: Here they are - just checking how they look across the hull: The beams seem to be holding their shape, they only spring out 1/16" when they come out of the press. I might try steam bending the oak strips first, then glueing them, to relieve some stress and get beams that want to keep their shape.

-

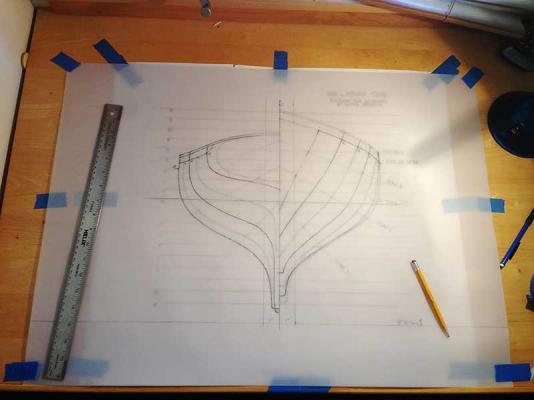

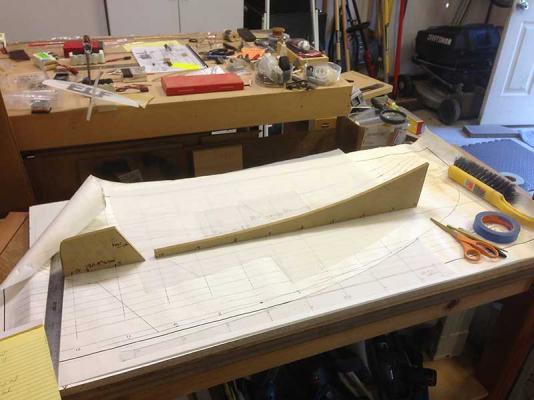

I know I need a reference frame to hold the fiberglass hull while I build the deck. I had a big piece of melamine coated particle board sitting around - if well supported it likes to stay nice and flat, so I used it and laid out the centerline and the 12 station marks: I traced the hulls lines from the drawing I had to a piece of velum so I could cutout the hull supports: I transferred the information from the drawings to a piece of pboard for the keel support: And cut out the hull supports using the velum copies in 1/2" birch plywood: Now I need to figure out how thick the deck will be so I can mark where the sheer strip goes.

-

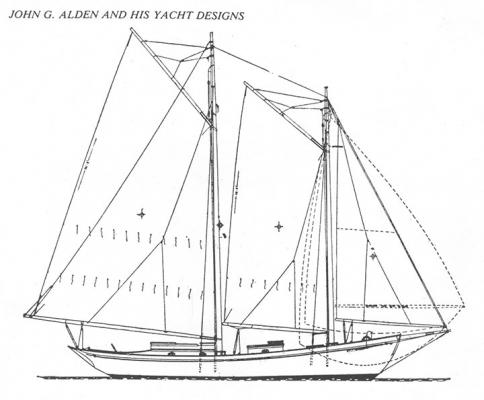

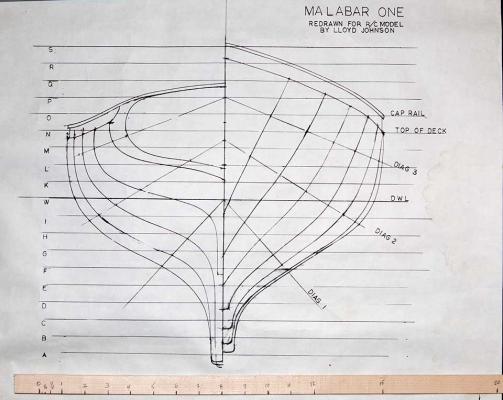

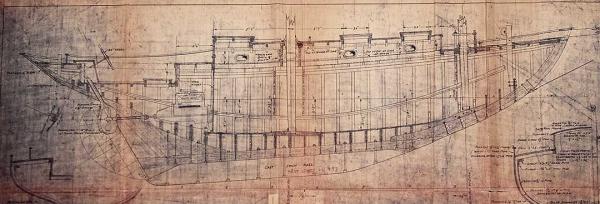

I'm about to try and build an RC racing schooner, the Malabar One, designed in 1922 by John Alden. It was the first of a series of ten schooners he designed all named Malabar. I've never bult a boat from scratch, so it will be interesting how it comes out. A friend gave me an empty fiberglass hull, a lead keel and a stack of old drawings, and that's it. The hull is 48" stem to stern. The keel weights 18 lbs. Here's what I have as reference materials to go by: This is from a different, but similar boat also designed by John Alden: I was also given an old print of another build using the same hull: So I have lot's of questions about woods and techniques. The original boat used White Oak for framing, and hard pine for deck planks. (Why pine? - seems soft and not water friendly) I've been told that aircraft spruce works great for model framing members. I also have easy access to lots of white oak, and the tools to machine it. I originally planed to do the deck in teak, and the deck houses and details in mahogany. The deck MUST be water-proof - this will be a working, sailing model, so I guess I have to seal and varnish the deck or ?? Don't know what to make the masts and spars out of. (spruce?)

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.