simon porter

Members-

Posts

34 -

Joined

-

Last visited

-

Obormotov reacted to a post in a topic:

Medway Longboat - Keel, Frames and build board discussion

Obormotov reacted to a post in a topic:

Medway Longboat - Keel, Frames and build board discussion

-

Trussben reacted to a post in a topic:

Medway Longboat 1742 by simon porter - 1:24 Scale

Trussben reacted to a post in a topic:

Medway Longboat 1742 by simon porter - 1:24 Scale

-

doxidad reacted to a post in a topic:

Medway Longboat 1742 by simon porter - 1:24 Scale

doxidad reacted to a post in a topic:

Medway Longboat 1742 by simon porter - 1:24 Scale

-

dvm27 reacted to a post in a topic:

Medway Longboat 1742 by simon porter - 1:24 Scale

dvm27 reacted to a post in a topic:

Medway Longboat 1742 by simon porter - 1:24 Scale

-

Ryland Craze reacted to a post in a topic:

Medway Longboat 1742 by simon porter - 1:24 Scale

Ryland Craze reacted to a post in a topic:

Medway Longboat 1742 by simon porter - 1:24 Scale

-

Ryland Craze reacted to a post in a topic:

Medway Longboat 1742 by simon porter - 1:24 Scale

Ryland Craze reacted to a post in a topic:

Medway Longboat 1742 by simon porter - 1:24 Scale

-

Ryland Craze reacted to a post in a topic:

Medway Longboat 1742 by simon porter - 1:24 Scale

Ryland Craze reacted to a post in a topic:

Medway Longboat 1742 by simon porter - 1:24 Scale

-

Ryland Craze reacted to a post in a topic:

Medway Longboat 1742 by simon porter - 1:24 Scale

Ryland Craze reacted to a post in a topic:

Medway Longboat 1742 by simon porter - 1:24 Scale

-

GuntherMT reacted to a post in a topic:

Medway Longboat 1742 by simon porter - 1:24 Scale

GuntherMT reacted to a post in a topic:

Medway Longboat 1742 by simon porter - 1:24 Scale

-

GuntherMT reacted to a post in a topic:

Medway Longboat 1742 by simon porter - 1:24 Scale

GuntherMT reacted to a post in a topic:

Medway Longboat 1742 by simon porter - 1:24 Scale

-

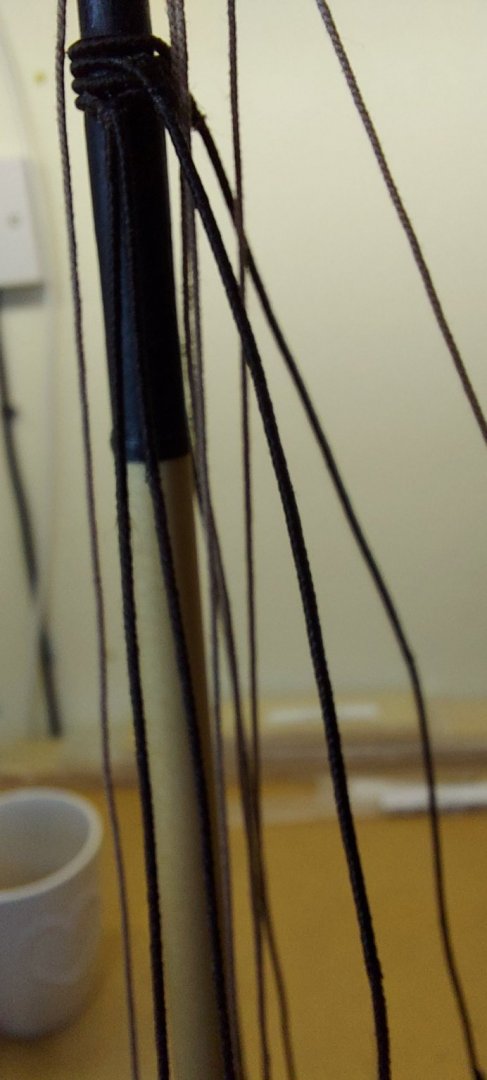

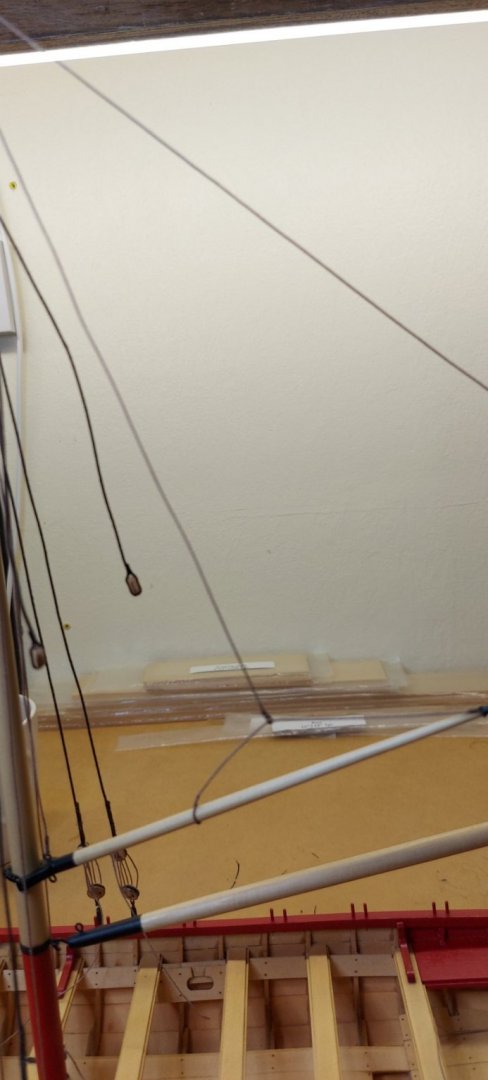

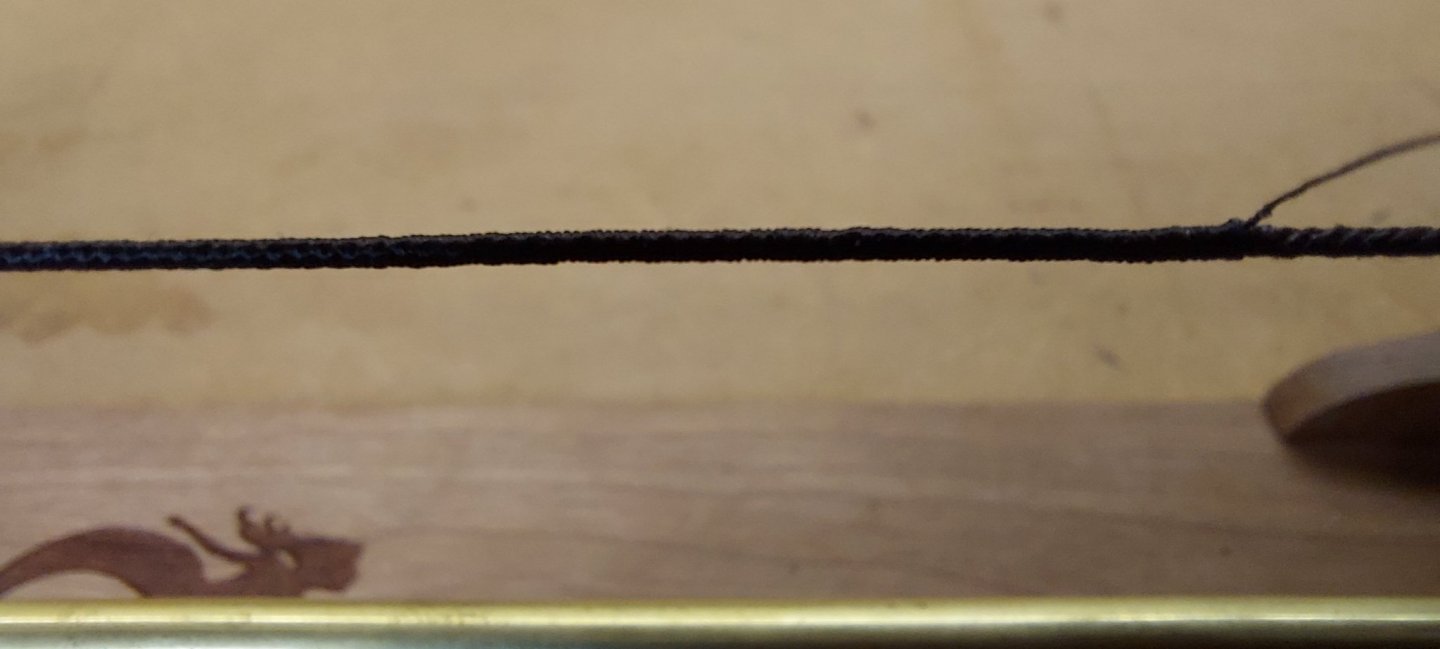

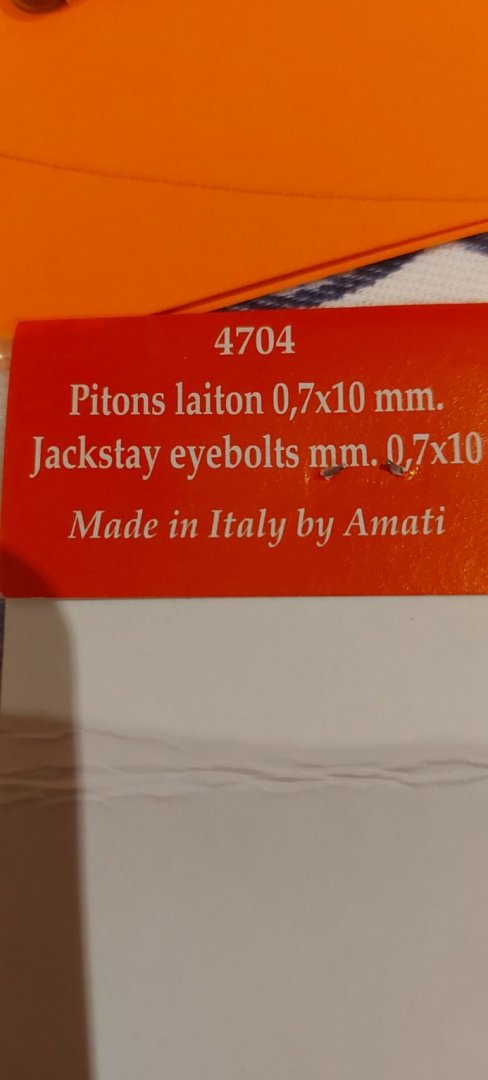

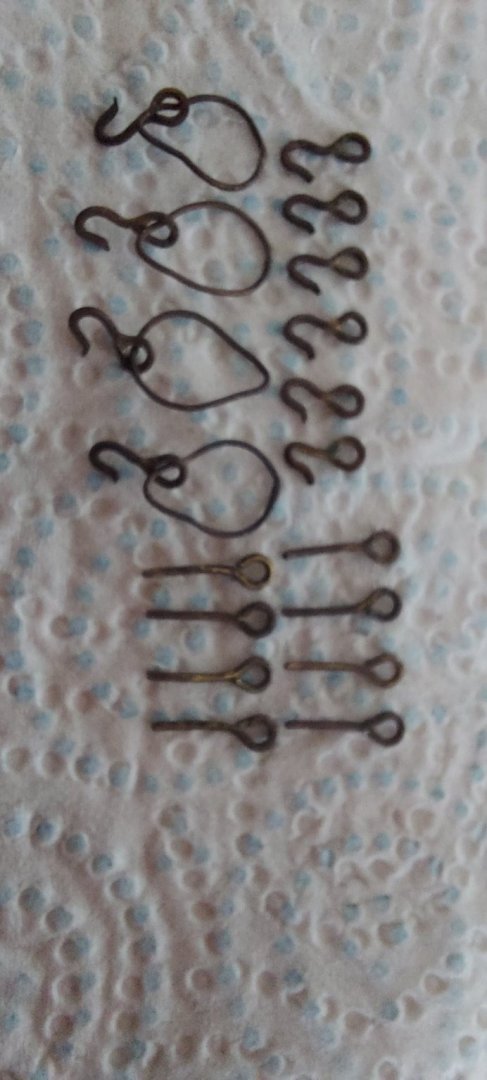

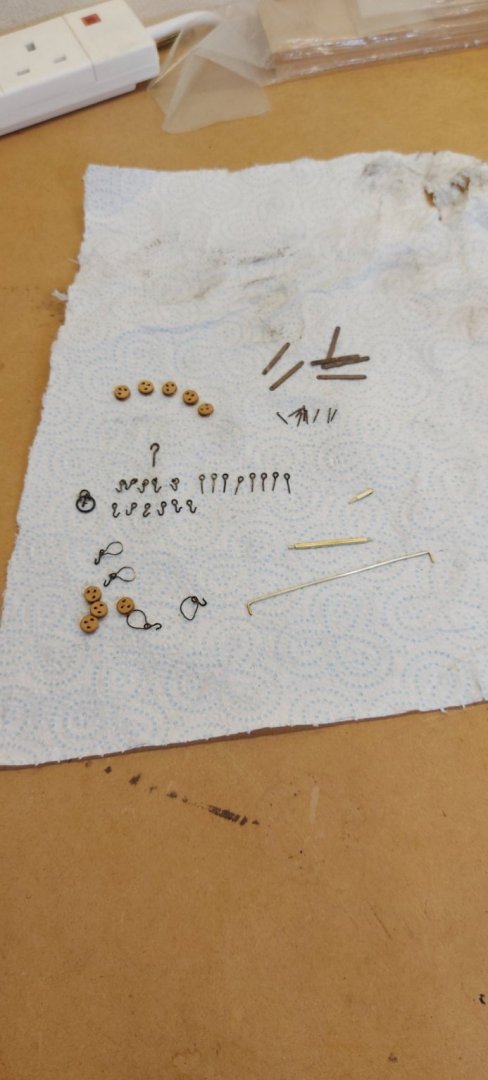

I wasn't happy working with the black wire supplied in the kit, (personal preference, and nothing to do with the quality supplied). What i wanted to do was use brass wire and some baught eyebolts so that i could shape and solder my own parts and then blacken them with Carrs blackening for brass, Here are the results.

-

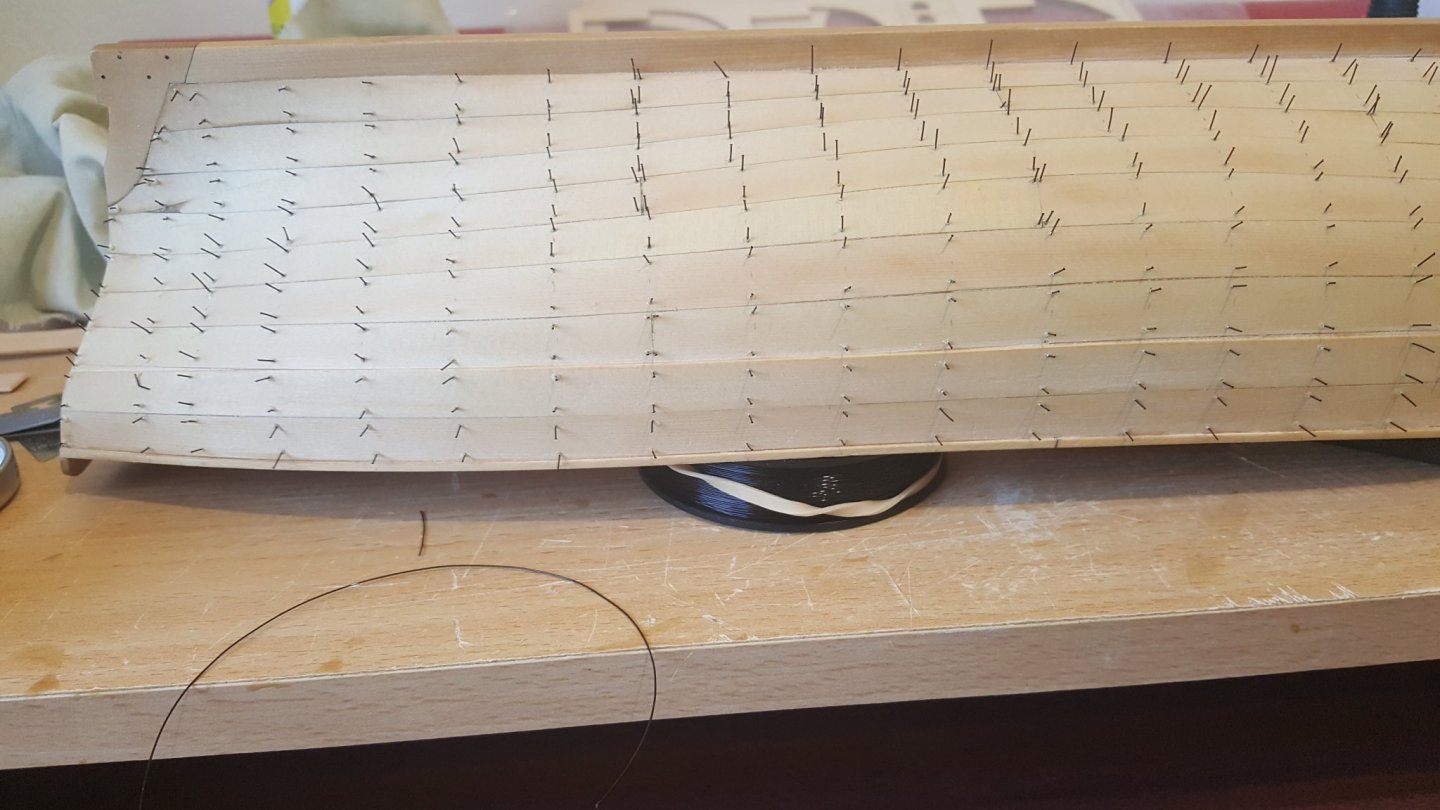

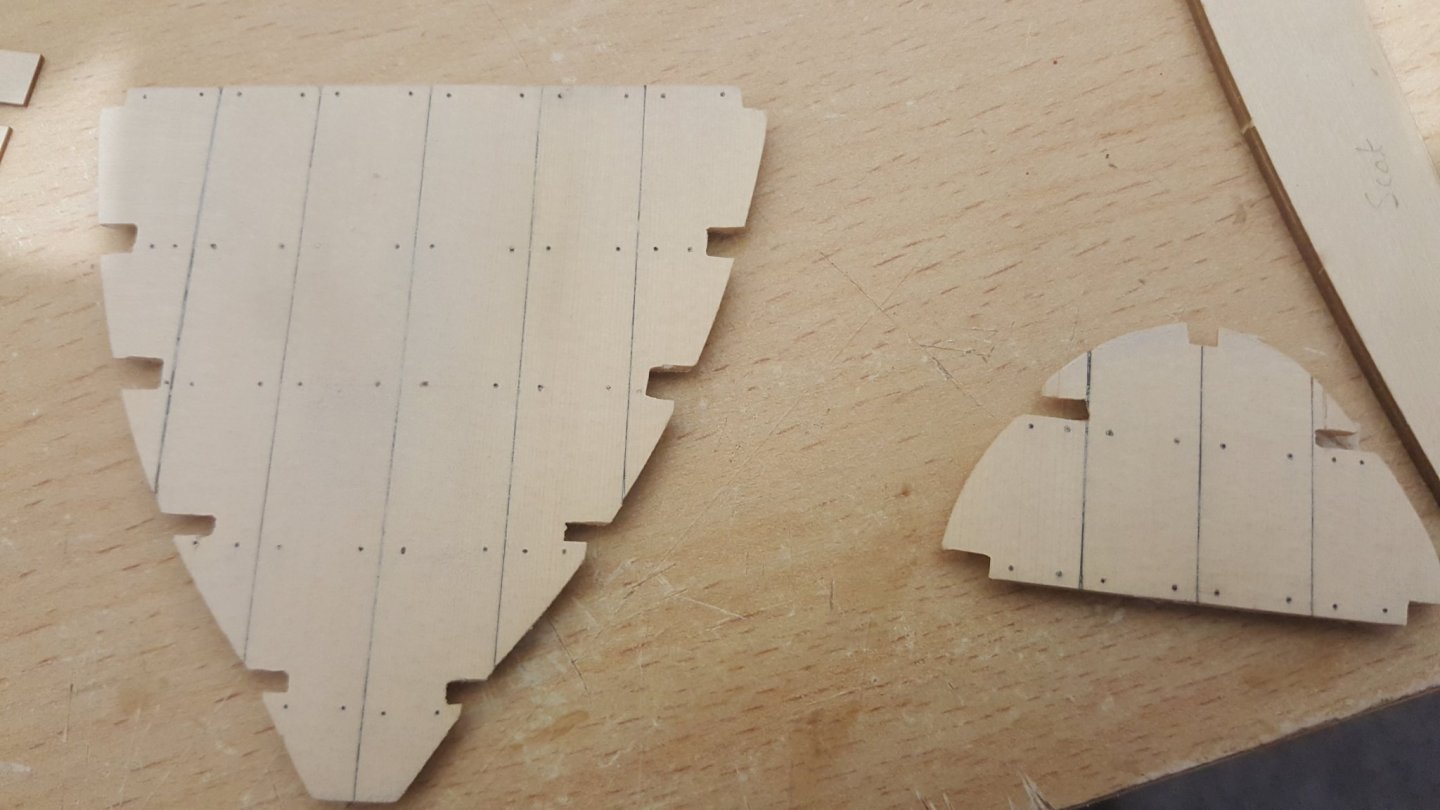

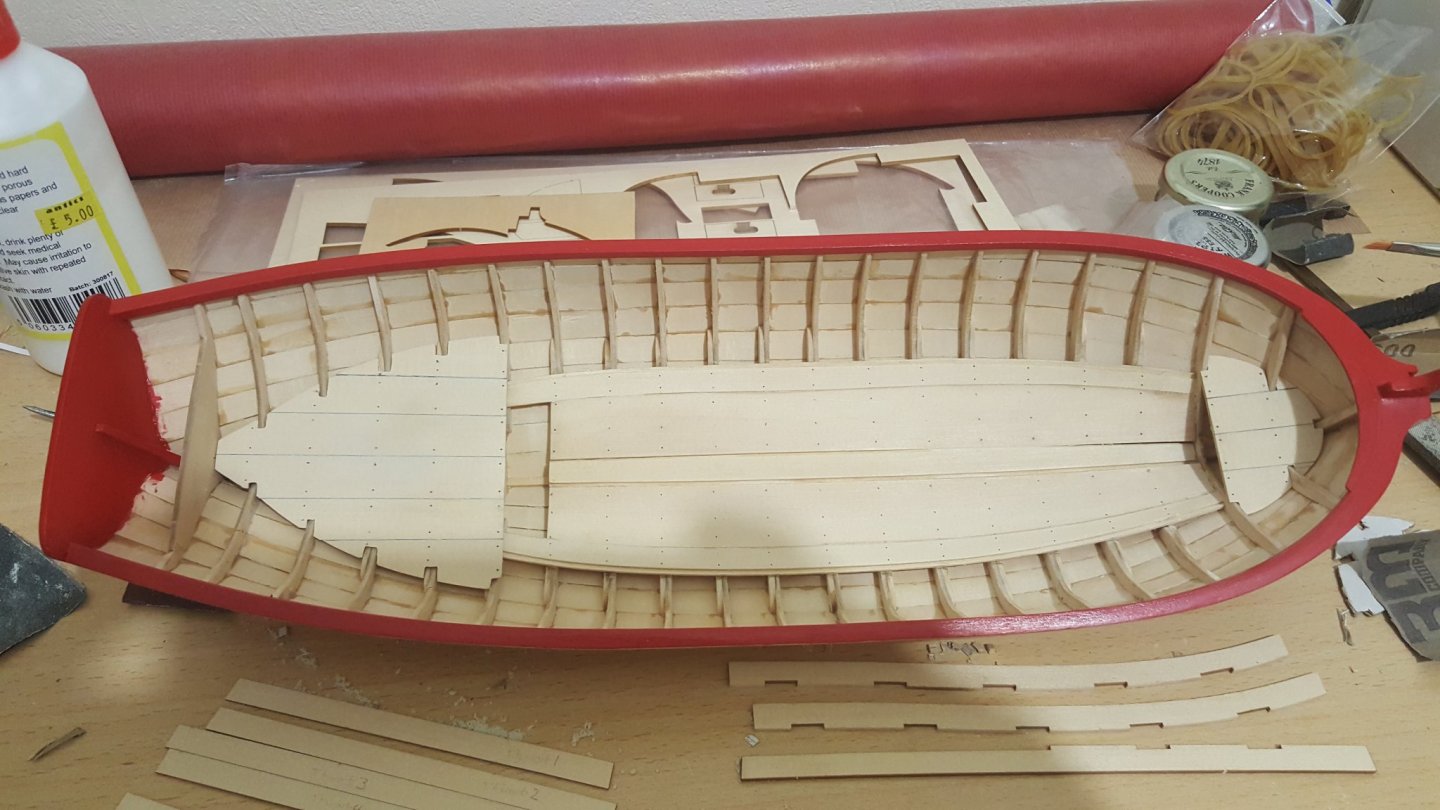

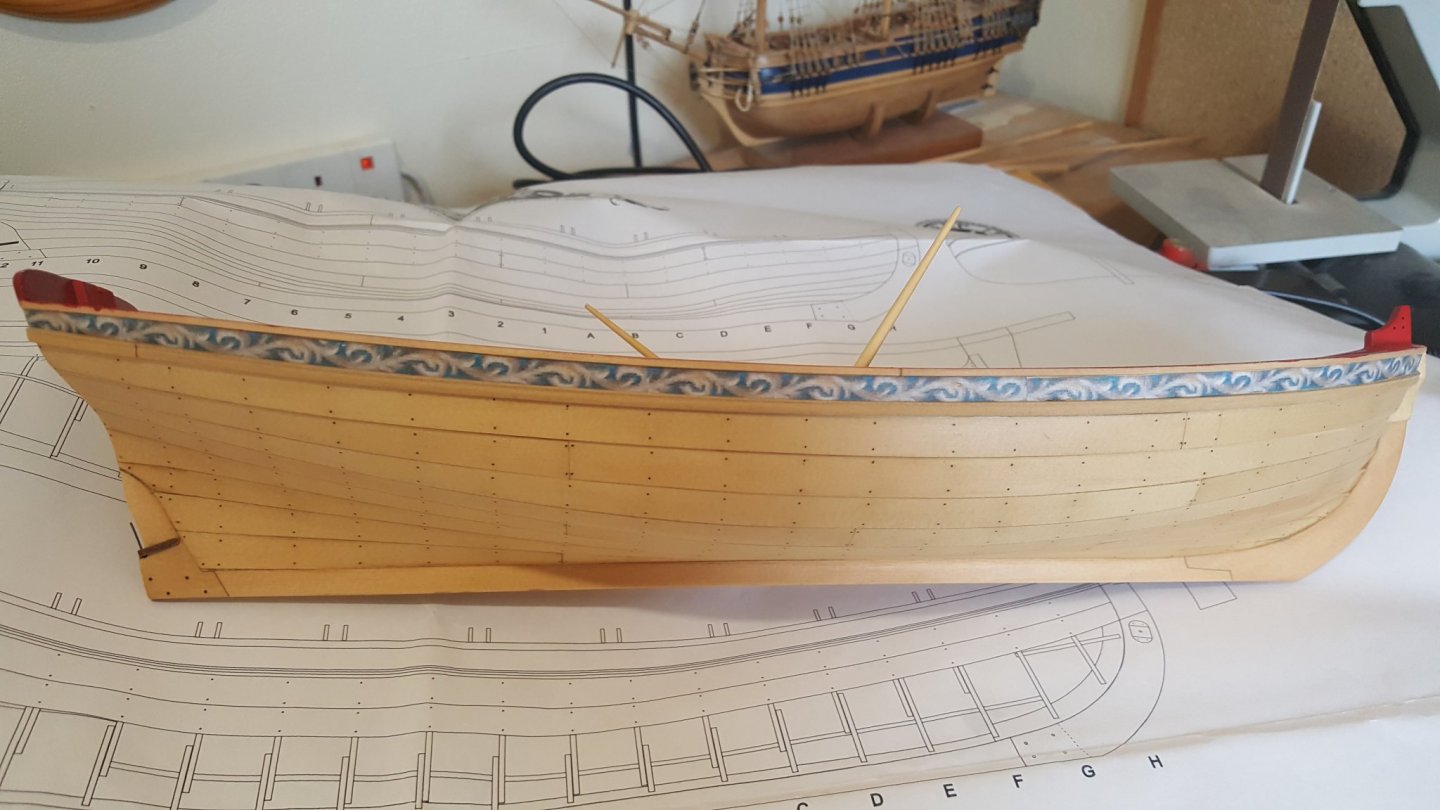

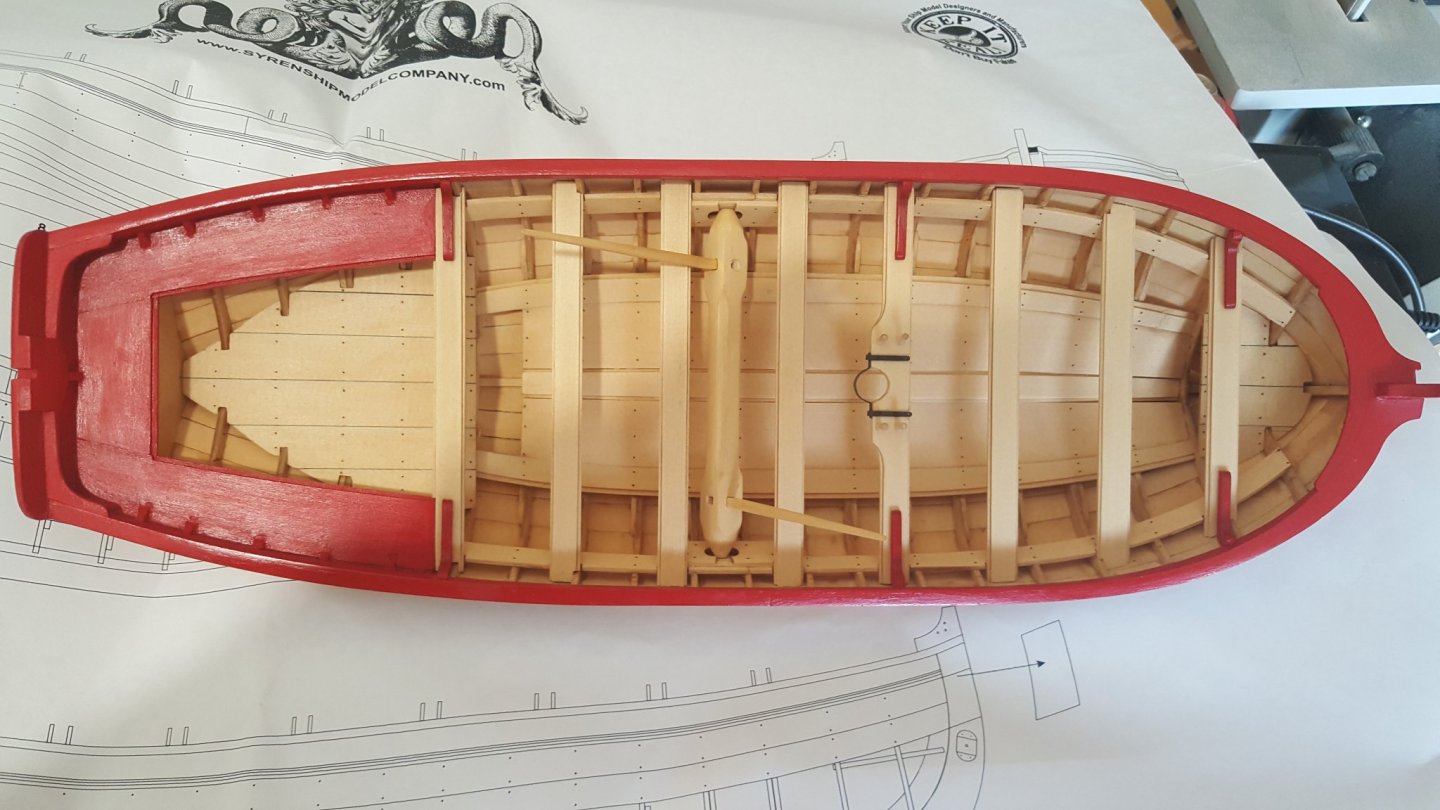

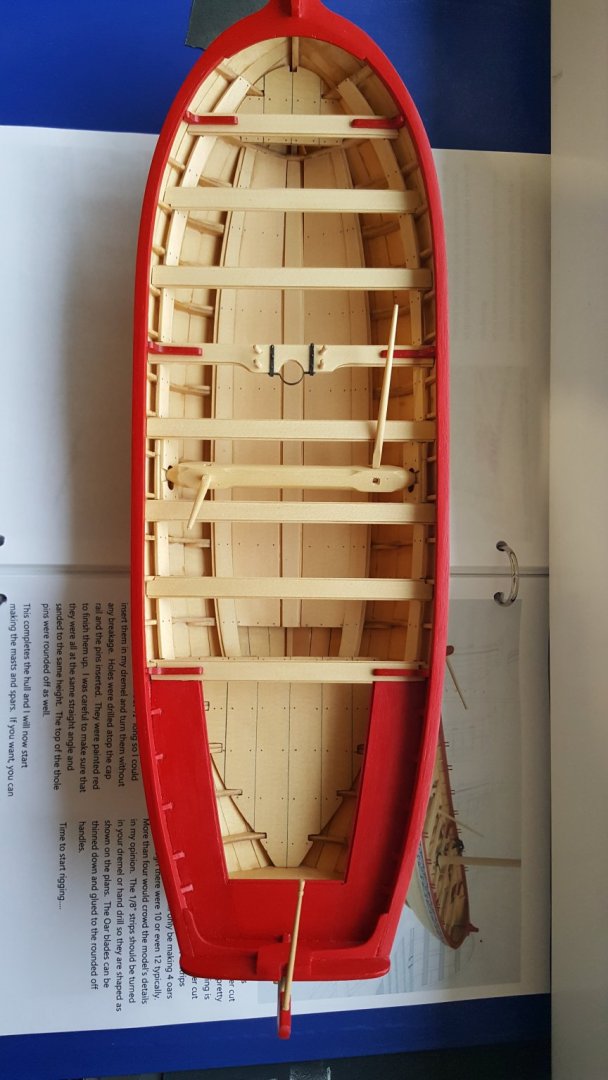

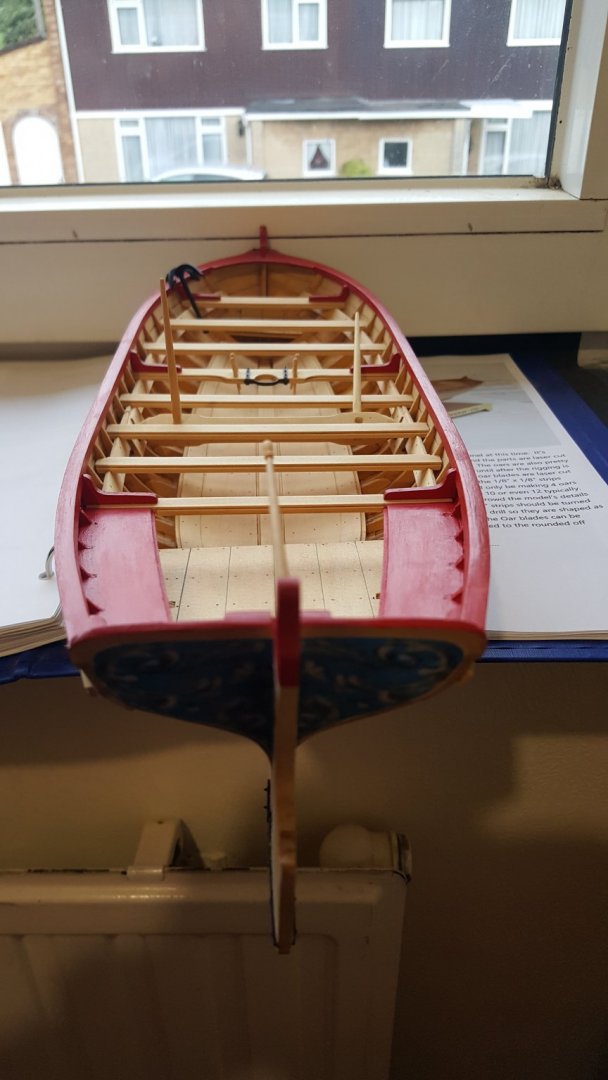

Hi guys. Been a long time since i posted anything . Had a few issues with my laptop, but got a new one now, so all sorted. The model is all but finished as regards the boat itself but i am waiting for the go ahead to purchace the masting and rigging set and a serving machine from Chuck just as soon as he is able to despatch overseas again. I'll post all the photos that i took and then answer any questions that you guys may have. The only problems that I had while making the kit was during the planking of the hull. Because it was my first time of doing a single planked hull i found it a little difficult bending the planks to shape using Chuck's method of using heat to bend the planks. I found it easier later on to soak the planks for a couple of hours, bend and clamp them in place and then glue them up once dry. I didn't think of doing this until half way down the hull. Because of these dificulties at the begining some of the planks didn't quite line up and when i came to the sanding stage some planks were paper thin after sanding and in a couple of places even went through particularly near the bows. Oh well, never mind, lessons learned. Also, i had trouble cleaning up wet glue on the inside of the hull as i went along as the full frames were in the way and it was very difficult to clean up once dry and the frame filling pieces were removed. Did anyone else have these problems or was it just my inexperience. Apart from that, everything else went well and i had great fun building the kit. choose files... Click to choose files

-

Now for the first plank. 😱 Managed to bend the plank to shape with the boss's hair drier with good results, but decided to use a couple of clamps to keep it in place while the glue dries. used a toothpick as an improvised clamp to put upward pressure on the plank against the keel at the very aft end.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.thumb.jpg.6d6ee4bdbfaac2c58ecc77e7b80ae374.jpg)