-

Posts

32 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by steven sturgis

-

I've put a hold on the clamps for now. The nails didn't thread deep enough to hold the strain on the clamps so they stripped out. Ill have to redesign them. Im still working on the sail design but was told to get out of the dinning room for Easter (Admiral's orders). I was losing my patients with them any way. Lots of test pieces and no clear answer yet. The planking is continuing on the Flying Fish slowly but i think it looks good. Boy i leave the room to work on the ship and Misty takes control of my chair. The snow is starting to melt in the north east. Good thing to I was getting cabin fever. With the sun staying up longer it will be harder not to go out side . This may slow down the build a little.

- 34 replies

-

- flying fish

- model shipways

-

(and 1 more)

Tagged with:

-

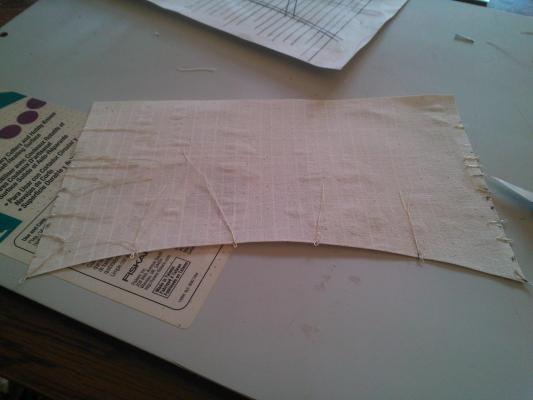

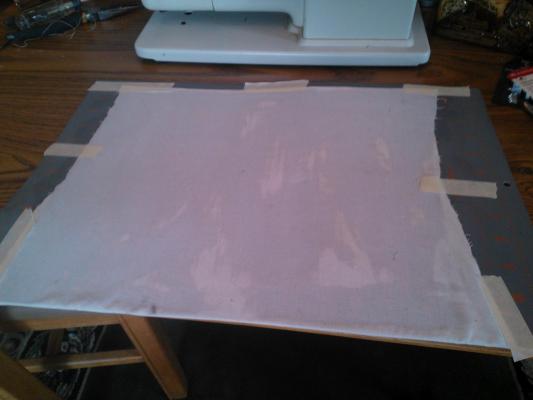

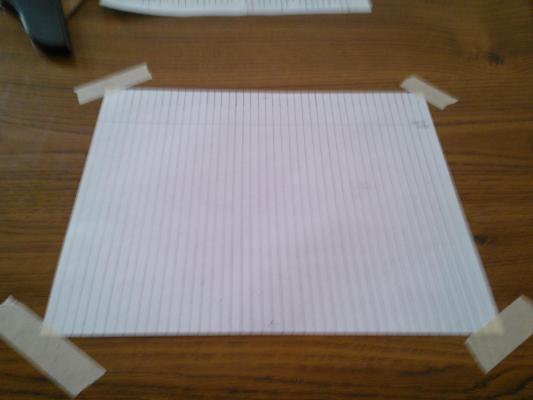

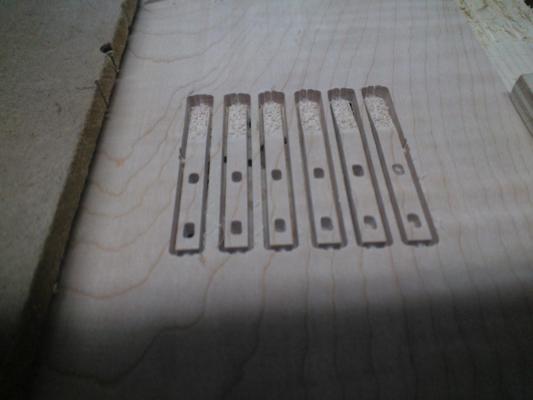

Well I've been prototyping my sails with the input from my sail making forum. I ordered silkspan and muslin to try out. The silkspan although nice and light did not stiffen as well with the GAC 400. The silkspan shrunk and took out the curve of the sail. I drew lines for the seams on the muslin with a white pen before coating it with GAC 400. The pen marks come out light but darken with the stiffener to a nice shade. I draped the cloth on a cut out of a piece of cardboard to set the shape. I made the cloth wider all the way around as it seamed to get a better shape to the sail this way. I plan to add strips for the hem and bands after it sets. I added the stiffener to a piece of cloth before cutting up the strips. This aides in cutting small strips. I will add the reef points before gluing the strips on the edges to help hold them in place. I am it tn the process of making some small wooden screw clamps from maple. The maple fingers where cut out on my CNC. I used # 6 finish nail for the threaded rod sections. They have to be threaded half way across from both ends with a right and left thread. I made the barrels with a 3/16 piece of brass threaded for left and right barrells. You need two each for a clamp. Make sure you put the barrels on each side opposite it counterpart I broke my milling bit because i was stupid so the assemblies will have to wait. Keep the barrels in tack as long as possible because they are easier to handle for threading.This clamp can put a lot of pressure to bear on a small spot be careful. These are a bit more complicated then just threading one side but are much more useful in the long run.

- 34 replies

-

- flying fish

- model shipways

-

(and 1 more)

Tagged with:

-

walnut has a specific grain to it. You need to look for the direction that it will lay. Also if you try to bend it or add stress from not forming to hull it will crack. If you stream it and get it to form to the hull you should be able to hold it in place with out claps. Then it will not have stress built in as you cut your gun ports. I believe it would be better if you cut the planks around the gun ports as you plank.

-

I've been doing some research on ships my ancestor captained and sail design with different materials in another forum. I would like to build one of these ships. The work on the flying Fish is continuing. I made some progress on the planking today. I also have been doing some mock ups of the display case I will build. I can't make up my mined on the style. I also ordered some tap and die to make some neat clamps I found in another forum. There like the wood screw clamps I use in my shop but very small. I will put up photos and instructions when I get the parts in and build them. I also like the display that was done on this model. It looks like the ship is under sail at sea. Ship in waves disply http://modelshipworld.com/index.php/topic/152-le-superbe-by-blue-ensign-heller-plastic-built-as-le-praetorian-after-boudriot/ sails http://modelshipworld.com/index.php/topic/9979-your-best-sail-cloth-and-technique/ reserch on ships http://modelshipworld.com/index.php/topic/9958-i-need-help-in-finding-these-ships-in-plan-form-elizaulyssescarolineatahualpa/

- 34 replies

-

- flying fish

- model shipways

-

(and 1 more)

Tagged with:

-

Your best sail cloth and technique

steven sturgis replied to steven sturgis's topic in Masting, rigging and sails

I believe its just a different brand butt lets let the experts handle that question. -

Your best sail cloth and technique

steven sturgis replied to steven sturgis's topic in Masting, rigging and sails

Thank you all this is good stuff. I hope I can still get silk span I would like to try it out. -

Your best sail cloth and technique

steven sturgis replied to steven sturgis's topic in Masting, rigging and sails

I like the look of the silkspan and the layering of the cloth details. What weight silkspan do you use? -

Your best sail cloth and technique

steven sturgis replied to steven sturgis's topic in Masting, rigging and sails

Good stuff. I have seen some members using silkspan and modelspan. Any thought on this material. I'm not familiar with thermal transferring paper. can you elaborate. How do you use textile adhesive with out making a mess? Is it diluted in any way? -

Your best sail cloth and technique

steven sturgis replied to steven sturgis's topic in Masting, rigging and sails

Thank you twintrow. I did look at that but some one needs to go back and up date the links. About 80% don't work any more. I was going for full rigged full sails. Can you do that in paper? 1/8 scale Im sure this is old hat to the expert modelers but passing on that knowledge is needed by the next generation of builders -

Very nice sail work.This will help me on the Flying Fish. (what a tangled web we weave).

- 126 replies

-

- le superbe

- heller

-

(and 2 more)

Tagged with:

-

Hi every one. I have been looking for the best sail cloth for my Flying Fish build. I would like to get a lot of suggestions that I can look at. Please include where the cloth can be bought. Do you change the color with dyes? do you age the cloth some how? How do you add detail to the sails? All sail makers are welcome to post their designs I know a lot of you don't put on sail because it covers the rigging so anyone that does would be a great asset to the topic. Looking forward to seeing your tricks and designs.

-

Cutty Sark by Keith B

steven sturgis replied to Keith B's topic in - Build logs for subjects built 1851 - 1900

The copper looks good I cant wait to do it on the Flying Fish -

I am looking to build a ship from scratch. I Am a descendant of William F Sturgis of barnstable Massachusetts. He was the captain of many ships and I would like to build one of them. I have been looking around the internet and can't find the ships. I think I want to build the Atahualpa but need to find one of these in plan form. I hope some one with experience in researching ships could guide me on where to find these ships. Eliza,Ulysses,Caroline,Atahualpa http://modelshipworld.com/index.php/topic/9958-i-need-help-in-finding-these-ships-in-plan-form-elizaulyssescarolineatahualpa/

- 34 replies

-

- flying fish

- model shipways

-

(and 1 more)

Tagged with:

-

I have looked at this and found nothing that would help. I think all try writing to the sturgis library.

- 2 replies

-

- ship researching

- plans

-

(and 2 more)

Tagged with:

-

I am looking to build a ship from scratch. I Am a descendant of William F Sturgis of barnstable Massachusetts. He was the captain of many ships and I would like to build one of them. I have been looking around the internet and can't find the ships. I think I want to build the Atahualpa but need to find one of these in plan form. I hope some one with experience in researching ships could guide me on where to find these ships. William F. Sturgis (February 25, 1782 – October 21, 1863) was a Boston merchant in the China trade, the California hide trade and the Maritime Fur Trade. Eliza,Ulysses,Caroline,Atahualpa all are merchants I think around 1800 In 1809, his ship the Atahualpa, owned by Theodore Lyman http://en.wikipedia.org/wiki/William_F._Sturgis

- 2 replies

-

- ship researching

- plans

-

(and 2 more)

Tagged with:

-

The New Clipper Ship Flying Fish, of Boston. This is the fourth clipper which Mr. McKay has built during the past year, and all of them may be regarded as experiments, for they bear little resemblance to other vessels, or to one another. The Stag Hound, the first, has round lines, and 40 inches dead rise at half floor; the Flying Cloud concave lines, and 30 inches dead rise; the Staffordshire, though fuller in the ends than the others, also has hollow lines, but only 20 inches dead rise, and the Flying Fish is the sharpest of all in the ends, though her bow is not so long either that of the Flying Cloud or the Stag Hound, and her dead rise is but 20 inches. All these vessels are timbered round the sterns and planked up flush to the covering board; but as will be seen by the variations in the angles of their floors, they are all of a different model. To this variation, which is peculiar to all our scientific ship-builders, may be attributed the matchless speed of our ships. Mr. McKay is one of those who believe that a perfect model for speed, with fair carrying qualities, has not yet been discovered, and hence, in every ship he designs, he tries to make some improvement. The Flying Fish is the embodiment of his idea of swiftness, with good stowage capacity. She registers 1566 tons, and stows a very large cargo for her register. The variation in the angle of her bottom and the form of her ends gives her greater capacity, and more buoyancy; and as her bow, towards the extreme, is even sharper, she is expected to sail as fast as the Flying Cloud. The Flying Fish is 202 feet long on the keel, 210 feet between perpendiculars on deck, and 220 feet over all. Her extreme breadth of beam is 40 feet, and is precisely at the centre of her load displacement line; the angle of her bow at the same line is 17 degrees, and her stern 20 degrees, and her whole depth at the main hatchway is 22 feet including 7 feet, 10 inches height of between decks; but as she is carried up boldly forward, her depth at the fore hatchway is a foot more. Her sheer is about 3 feet, and the rounding of her sides about 12 inches. In outline she is plain but beautiful. The representation of a flying fish for a head, neatly carved and burnished with gold and green, is her only ornament on the extreme, for she has neither head nor trail boards, nor even chocks around the hawseholes, nor is the bow lumbered with rigging, for all her head stays lead inboard and set up under the topgallant forecastle. Her name is carved into the monkey bulwarks along the curve of her bow, and is gilded, and the ends of her cat-heads are also ornamented with gilded carved work. Her bow, as already remarked, rises boldly, and is most beautiful in its form and outline. The moulding of her planksheer is carried around the stern, and the run planking is carried up to it. She is three degrees fuller on the load line aft than forward, but still her run is very clean, and faultless in form. A beautiful arch of carved work, and her name, etc. ornament the stern. She is sheathed with yellow metal up to 18½ feet forward, and to 19 feet aft; the rest of her hull is black outside — a color peculiar to clippers and the clergy. Inside her bulwarks, etc., are painted pearl color, and the waterways blue. She has a topgallant forecastle the height of the main rail, and in the wings are companions, which lead to the sailors' quarters below; and before the companions are water closets, and along the sides, lockers, etc. The accommodations for the crew occupy the angle of the bow, are lofty, well lighted, and ventilated. Abaft the foremast is a house, 33 feet long, 15 wide, and about 7 feet high amidships. It contains the galley, sleeping quarters for the cook, a sail-room, store-room, and aft, quarters for ten or twelve boys — the juveniles of her crew, and state-rooms for the petty officers. She has a trunk cabin, built into a half poop-deck, with ample steering room aft, and good gangways. She has two cabins. The first contains three state-rooms, the pantry, and a bread locker, and is neatly painted and ornamented. The after cabin contains six state-rooms, and a water closet, with a recess on each side, and a companion, which leads to the deck aft. It is splendidly finished, with mahogany, rose-wood etc., has a large centre table, sofas in the recess, and mirrors, which multiply its beauties at every turn. The space abaft, under the poop, is a store-room, with a skylight over it, which also answers for a hatchway; and the space along the wings in the officers' and steward's rooms, are fitted with drawers, suitable for stores of various kinds. Her accommodations forward and aft are all that could be desired for safety or comfort, and correspond well with her other arrangements, leaving ample deck room for working ship. She has a strongly secured patent windlass, and Crane's patent chain stoppers, which, by the way, ought to be adopted in every ship. They are simple in design, economical in their cost, and of the highest utility in saving every link of chain as it is hove in. They are secured to a breast-hook close inside of the hawsehole, and the chain passes over an iron ridge, and every link as it is hove in is nipped by a paul which falls upon it, consequently its fleeting or surging upon the windlass will not lose a single link. It supersedes entirely the use of the devil's claw. When the chain is required to be paid out, the paul is triced up out of the way, leaving fair scope for running. She has two beautiful mahogany capstans, brass mounted, one on the topgallant forecastle, the other on the quarter deck, Litchfield's patent pumps, and Reed's patent steering apparatus. Abaft the mainmast she has a cylindrical iron tank, nearly her whole depth, and capable of holding 5000 gallons of water. She has five boats of the most approved models, either for braving a heavy sea or landing in a surf. Her ground tackle in weight and length comes up to the highest requirements of Lloyd's. In every detail of her furniture no expense has been spared to make her perfectly complete. As the above will convey a fair idea of her hull, in its outline, and some of its appointments, we will now give the leading details of her construction. Her keel is of rock maple and oak, in three depths, which combined, moulds 3 feet 2 inches, and sides 16 inches. The floor timbers are moulded 18 inches, and sided from 10 to 12, and over them are two depths of midship keelsons, each 15 inches square and alongside of these are sister keelsons 14 inches square. The floor timbers are bolted alternately through the first keelson and the keel, so that there is an inch and a quarter bolt through every floor timber and the keel. The upper keelson is bolted through every navel timber — the bolts driven blunt into the keel, within three inches of its base. The sister keelsons are bolted horizontally through each other and the lower depth of the midship keelson, and diagonally through the navel timbers into the keel. The ceiling on the floor is 4½ inches thick, and over the first futtocks are two bilge keelsons, each 14 by 15 inches. Above these there are four strakes of 10 by 14 graduated to 8 inches thickness, which continues the same in substance up to the deck. To avoid repetition, we may as well state, once for all, that she is square fastened throughout, from the keelsons to the covering-board, the fastening varying from 1¼ inch to 7/8 of an inch. Under the lower ends of the hanging knees is a stringer of 14 by 12 inches. The hanging and lodging knees in the hold are of oak, and the former have 18 bolts and 4 spikes in each, and the latter meet and scarph in every berth, and are closely bolted. She has 4 oak pointers for ward, and the same number aft, and all are filled in with hooks. Some of the pointers extend nearly 30 feet on each side, along the skin, and none of them are less than 12 inches square, except where they taper at the ends. The hold stanchions are 10 inches square, kneed above and below, in the wake of the hatchways, and elsewhere they are clasped with iron to the beams and keelson, and bolted through both. Her deck beams are of Southern pine — those under the lower deck are 15 by 16 inches, amidships, and those under the upper deck 10 by 16. The between decks waterways are 15 inches square, the standing strake over them 10 by 16, and that inside of them 9 by 12, closely bolted vertically and horizontally. The ceiling above is 5 inches thick. Her ends in the between decks are spanned by massive hooks, alternately bolted from both sides, that is, from the inside to the outside, and vice versa. The between decks hanging knees, like those below, have in the body of the vessel 18 bolts and 4 spikes in each, and the stanchions are turned and secured in the usual style. Her upper deck waterways are 12 inches square, with two 4½ inch strakes inside of them, let into the beams below. The lower deck is of hard pine, 3½ inches thick, and the upper deck of white pine of the same substance. Her garboards are 7 inches thick, let into the keel, and are bolted through it and each other, and upward through the timbers. The bottom planking is 4½ inches thick, and her wales, which are 6 by 7 inches, are carried up flush to the planksheer. Her treenails, bilge and butt bolts, have been driven with more than ordinary care. Her planksheer and main rail are each 6 inches thick, and the latter is strengthened by a 5 inch rack rail, which extends from the bluff of the bow to the turn of the stern. Her bulwarks are 4½ feet high, amidships, surmounted by a monkey rail of 16 inches and the poop is protected by a rail supported on turned stanchions. Her bulwarks are neatly tongued and grooved, and her sides are smooth as glass, the planking fair and regular, and her outline, as a picture, faultlessly beautiful. Her frame is mostly of white oak, and her planking and ceiling of hard pine. She is seasoned with salt, has air ports below, ventilators along the line of her planksheer, and Emerson's corresponding ventilators forward and aft. In materials and fastening, she is second to no ship of her size, and in workmanship and finish, she has no superior. She is a full rigged ship, and her masts rake alike, viz., 1¼ inch to the foot. The distance from the stem to the centre of the foremast is 52, thence to the mainmast 62, thence to the mizzenmast 52, and thence to the sternpost 44 feet. The following are the dimensions of her masts and yards: MASTS. Dimensions, Inches. Length, Feet. Mast-heads, Feet. Fore 38 82 14 Top 18 46 8 Topgallant 13 24 0 Royal 11 16 0 Skysail 9 12 pole..6 Main 40 88 15 Top 19 49½ 10 Topgallant 14 27 0 Royal 12 18 0 Skysail 10 14 pole..7 Mizzen 26½ 78 13 Top 15 38½ 7½ Topgallant 12 21 0 Royal 10 14 0' Skysail 8 10 pole..5 YARDS. Fore 21 70 yard arms..4½ Top 16½ 55 5 Topgallant 12 41 3 Royal 9 32 2' Skysail 7 25 1½ Main 28½ 80 4½ Top 17½ 64 5 Topgallant 13 49 3½ Royal 10 39 2½ Skysail 8 31 1½ Crossjack 16½ 59 4 Mizzen topsail 13 44 4½ Topgallant 10½ 34 2½ Royal 8 26 2 Skysail 6½ 20 1¼ The bowsprit is 28 inches in diameter, 18 feet outboard and 27 feet inboard, with two sets of bitts; jibboom 18 inches in diameter, divided at 20 and 15 feet for the two jibs, with 5 feet end; spanker boom 58 feet, gaff 40 feet, including 5 feet end; for and main spencer gaffs, each 24 feet long. Her fore and main masts are fished on every square, and closely hooped, and the fishes extend two feet below the lower deck partners. No ship belonging to this port has such massive lower masts. A glance at the length of her mastheads, and the diameter of her topmasts, will show that she is unrivalled in her sparring. Her yards, too, are stout in proportion, and are secured in the first style of workmanship. Instead of cheeks to her topgallant yards she has regular iron parrals, similar in design to those of the topsail yards; and she has double topsail ties and halliards. Her topgallant, royal and skysail masts are of single spars. Her mast-heads are crowned with gilded balls and spires; her yards are black, and booms bright and her lower masts white. Her heavy standing rigging is of four stranded, patent rope, made to order of the best Russian hemp, and varies from 10½ to 8 inch. The running rigging is principally of Manila hemp. Her iron work is the same as that in general use, but stout in proportion to the other details of her rig. She has chain topsail sheets and ties, and iron trusses and futtock rigging. Her fore stays set up to the knight heads, and all her other stays lead through the bows and set up inboard. The main stays set up to the bitts before the foremast, and the main topmast stays in the fore top. Her lower rigging sets up with dead eyes on the line of the main rail, outside of the monkey rail, and the topmast rigging upon the ends. She has all the fancy sails peculiar to a clipper, such as royal studdingsails, staysails, water sails, a ringtail, etc., and 8250 yards of canvass in a single suit, and if her standing rigging is as good as it appears to be, we apprehend no danger from her being crippled in her spars, for she is the best fitted out ship aloft belonging to this port. Her masts and yards are stouter in the diameters, than those of the largest clippers belonging to New York. Their positions and proportions are beautiful, and fill the eye of the observer with admiration. Her sails when set will make a glorious display. The leaches of the square sails will form a continuous line from the head earrings of the skysails to the clews of the courses, and her fore and aft sails will set like boards. The sails were made by Mr. Porter, of East Boston, and she was rigged by Capt. Brewster, of the same place. Mr. J.W. Mason executed her ornamental work, and Mr. Mendum was her blacksmith. All employed upon her have done their work well. She was designed in all her details and built by Mr. McKay at East Boston; and he confidently expects that she will sail as fast as the Flying Cloud, if not faster. Her commander, Capt. Edward C. Nickels, a gentleman of long tried experience and intimately acquainted with the California and China trades, superintended her construction and equipment. No man knows better how to handle a ship, and as he has had the Flying Fish fitted out precisely as he wanted her, he will be expected to make her astonish the swiftest New Yorkers. Messrs. Sampson & Tappan, of this city, own her. She is now laden, and will sail in a few days for San Francisco. Good luck to her, and may she prove to be the swiftest ship afloat. Boston Daily Atlas, November 4, 1851. Transcribed by Lars Bruzelius. Sjöhistoriska Samfundet | The Maritime History Virtual Archives | The Boston Daily Atlas | Search. Copyright © 1997 Lars Bruzelius.

- 34 replies

-

- flying fish

- model shipways

-

(and 1 more)

Tagged with:

-

Hi Jean-pierre The reason I was going to use paint is that it is what the plans shows. I assume that means it was done on the real ship. I don't want this kit to become overwhelming to me. It is my first kit. I plan to put a lot of detail in the rigging and sail work. I found a very good forum about sail making on the site. I'm also looking in to building a ship from scratch after reading a PDF on the subject. I made a DXF file from a set of plans for the Foochow a clipper ship that was not built that I know of just proposed. With that image I scaled it into an auto cad program Sketchup 7. I then traced the bulk heads and made an STL file that can be feed in to my home made CNC machine to cut out the bulk heads. I only did a few test pieces. I will have to allow for the planking and other things on the real attempt when I decide what to use. I want to make it a 1/5 scale. that would make it about 37" on the hull. sail work http://modelshipworld.com/index.php/user/3035-jerseycity-frankie/ I took the time to make up some black walnut planks to get a feel for making my own materials. What is the consensus of using different type of wood on a scratch build.

- 34 replies

-

- flying fish

- model shipways

-

(and 1 more)

Tagged with:

-

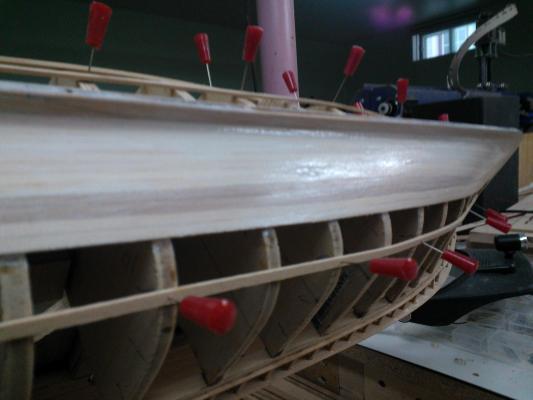

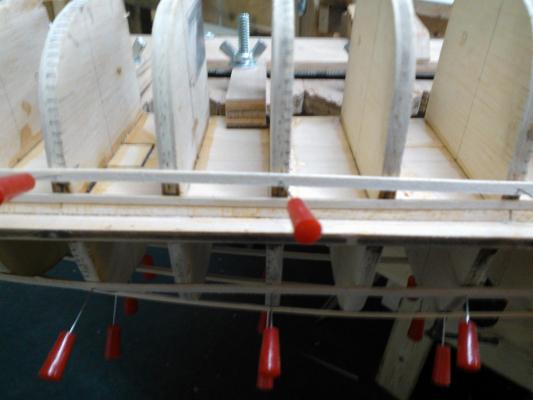

Some more photos. I had to adjust some planks to get in aliment with the battens. You can see it as a darker band in the photos.I still don't know why it happen. I also put hobby filler on the planks that are completed. This is used to fill grain in balsa and fill imperfections. It can only be used if your going to paint or cover it in some way. I used this when I built RC planes it fills good , seals the wood and sands easy.

- 34 replies

-

- flying fish

- model shipways

-

(and 1 more)

Tagged with:

-

welcome to the build bhermann and schooner. I need to find the right cloth for the sails. Does any one have any suggestion on materials and where to get them? On the topic of the deck is it possible to paint the deck planks before the installation so I can add caulk lines. I'm afraid it would get all glue and I cant sand it afterwards? The planking is progressing but photos would look all the same for a while. Ill take more when you can see some progress.

- 34 replies

-

- flying fish

- model shipways

-

(and 1 more)

Tagged with:

-

Thanks for the answers Jean-pierre. I just remembered I bought the paint kit so the deck will be painted. I assume in this instance the caulk lines wont work. I started to put on full strips of planking because the lines where getting out of alignment. I'm going to use the copper to cover it any way. I might scribe them in later. I know I should be practicing it but I need to get straight again first. When I get to the top of the copper all try again. Ill add the bolts before I get to far. I have to go buy some. I had a lot easier time when I did the full scale Guide boat. Using such small parts is trying for me my hands shake bad know. dgbot thanks for the advise Ill try that with the rest. Nenad M It looks like your building several kits a once?

- 34 replies

-

- flying fish

- model shipways

-

(and 1 more)

Tagged with:

-

I have been looking at other members post and had some questions. I see some members adding some type of bolt before the planking for the pedestal. Do I need to do this for the flying Fish? I was also using thin super glue for the hull planking as it dries fast. Will this be a problem long term? I had planed to add thick supper glue on the back of bulk heads. I don't have any long term experiences with there affects to the model to go by. I also would love some feed back on adding to the kit detail. I see a lot of deck planking with some thing to look like caulk. What would be a good procedure for this scale. I have nerve pain and the detail is very small at this scale for me to keep my hands steady. I also thought I mite get an artist to pant a sea scrape on the bottom of the display case and on the back to look like its at sea. Dose any one remember any one else doing this. I would like to see it to get an idea if I like it. When I sand the planking and paint the upper hull will the planks still show. Is there such a thing as to smooth eliminating the details? I just bought a cheap air brush for this build. I'm just full of questions today. When you solder the fitting of brass how do you hide the discoloring of the solder.

- 34 replies

-

- flying fish

- model shipways

-

(and 1 more)

Tagged with:

-

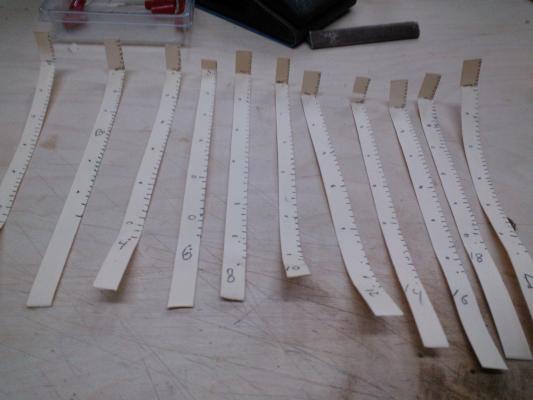

Thank you for the compliment scottrc. I do have a back ground in wood working. I have built a number of furniture pieces and a full size Adirondack guide boat. I had a woodworking school for awhile. I've now moved on to the planking after fairing the bulk heads. I used the tick method to mark the planks in bands. I also did the battens like the plans show. I hand no idea how long this was going to take. I spent four hours just to do 2 rows of planks. I hop it will get easier as I go. I also planked the forecastle ceiling to add some strength to the thin bulk heads. I made a new jig attachment to hold the model in my home made vice upside down. I got used to using the vice to move the model in any direction. I couldn't live with out it.

- 34 replies

-

- flying fish

- model shipways

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.