timboni

Members-

Posts

52 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by timboni

-

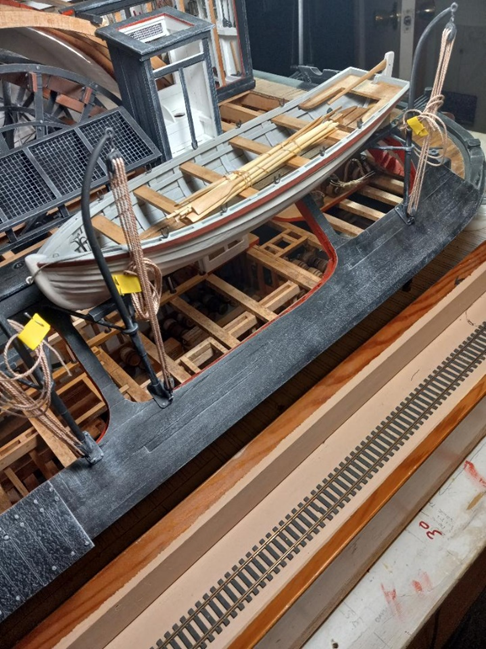

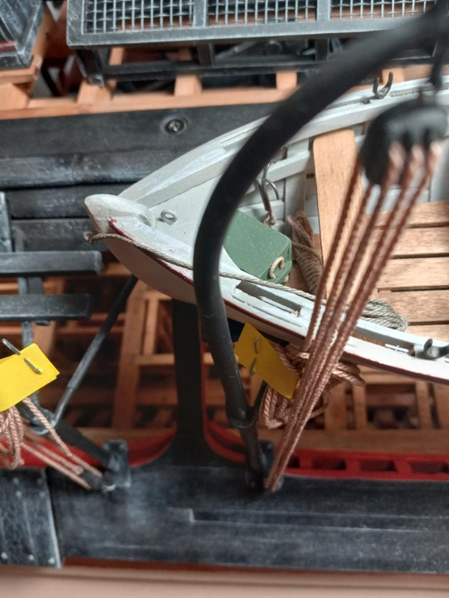

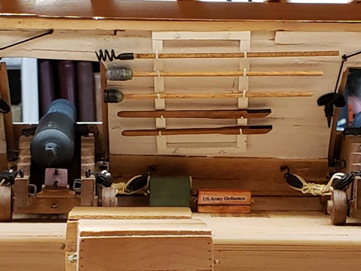

Hi all, and Happy New Year! Bill is still working on the figurines, but in the meantime, here are some pictures of one of the ship's boats on davits, with tackle, and also some items such as oars, a boat hook, a box for smaller items, a grappling hook, an axe, and several lengths of rope. (The "railroad track" is in fact part of a ropewalk device made by Bill) Tim

-

Don, this project was commissioned by the Missouri Civil War Museum, located on Jefferson Barracks (now a veterans' cemetery) in St. Louis. To be honest, there have been some communication problems between us and the Museum's director, so we're uncertain if and when the installation will be done. Hopefully it will come to pass, and if so, I'll be posting some pictures of the dedication/installation ceremony. Thanks for asking. Tim

-

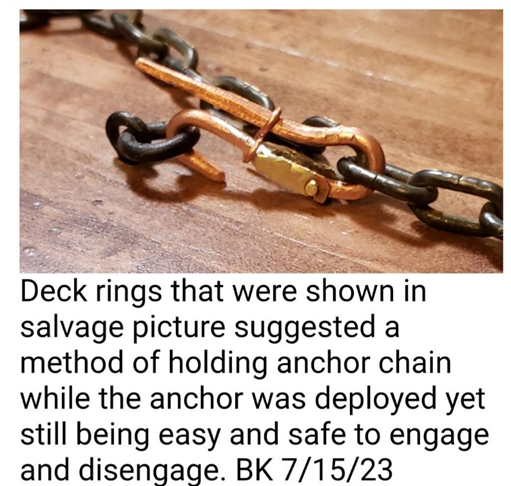

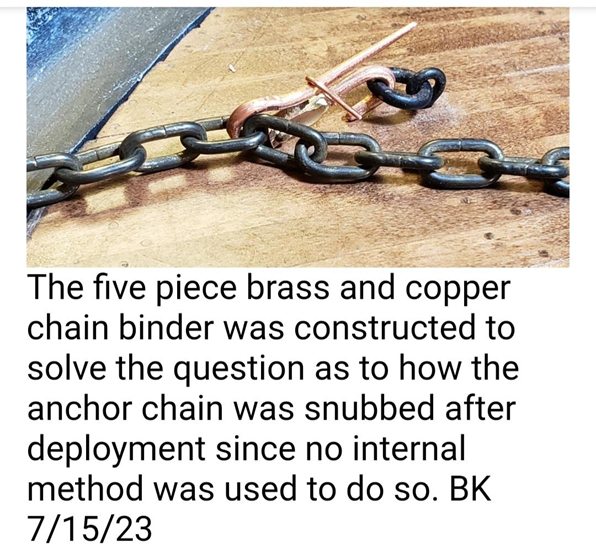

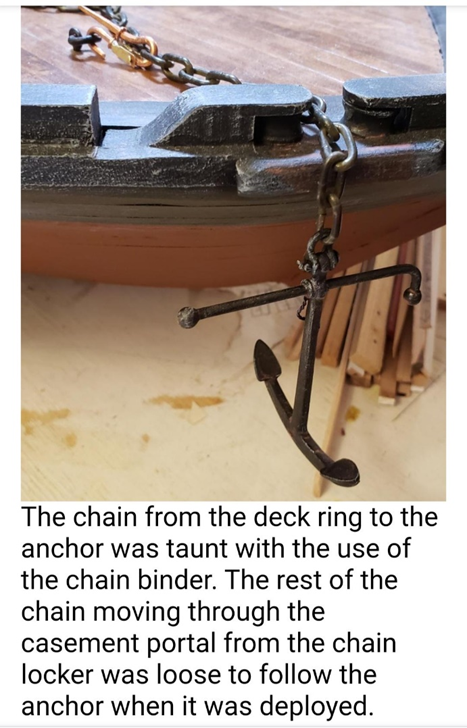

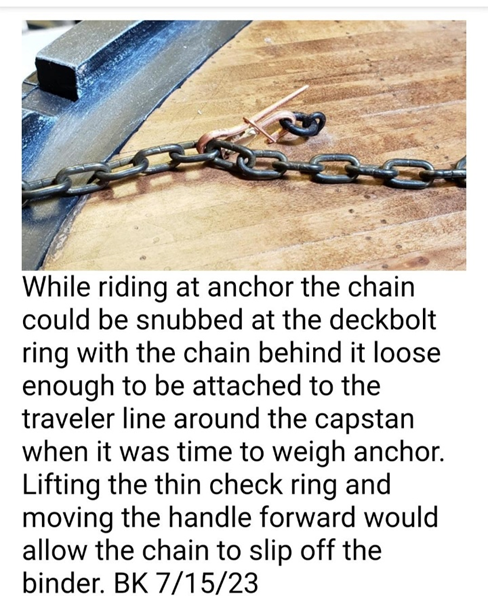

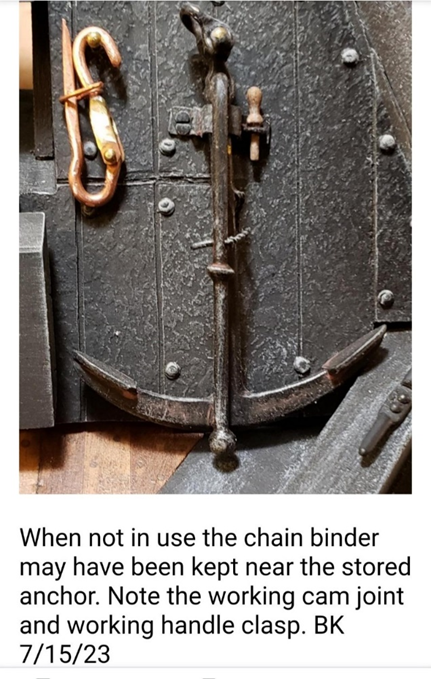

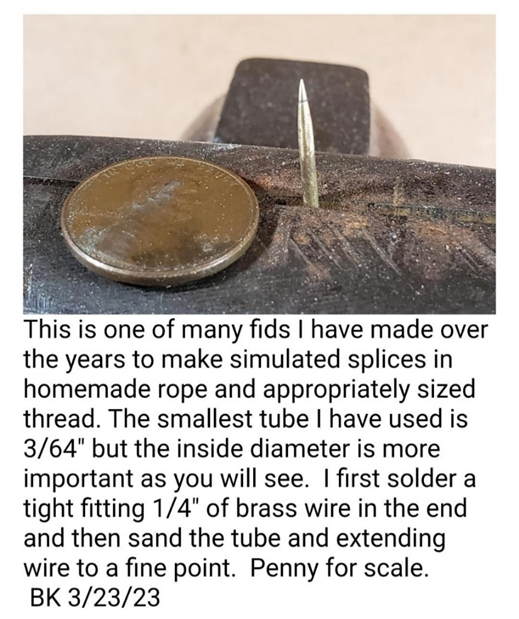

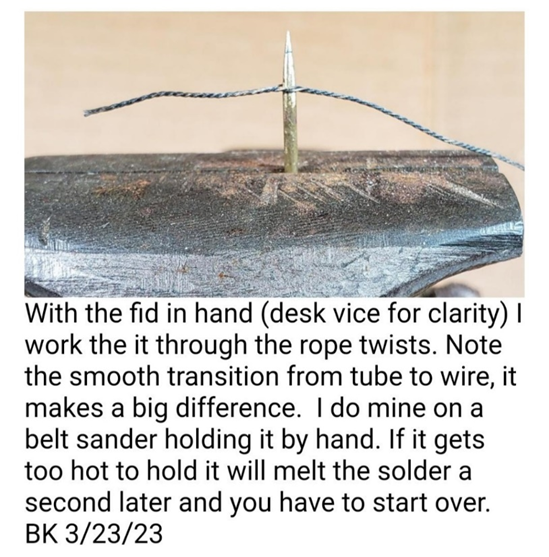

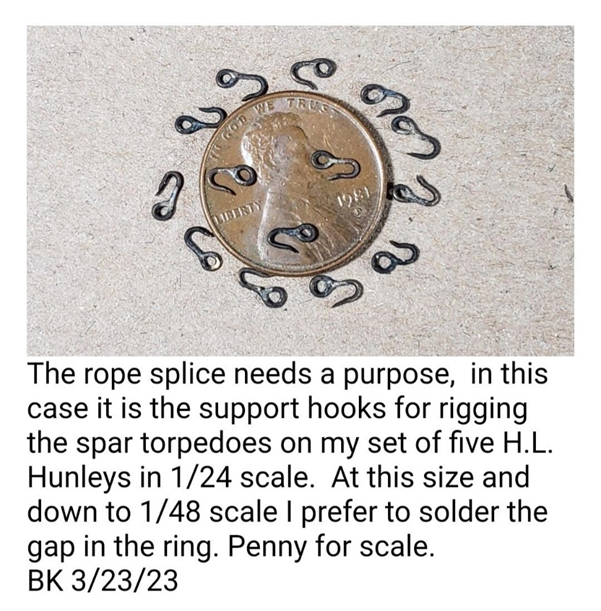

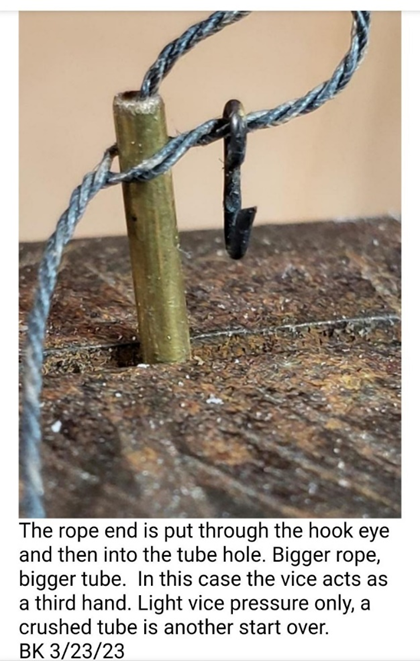

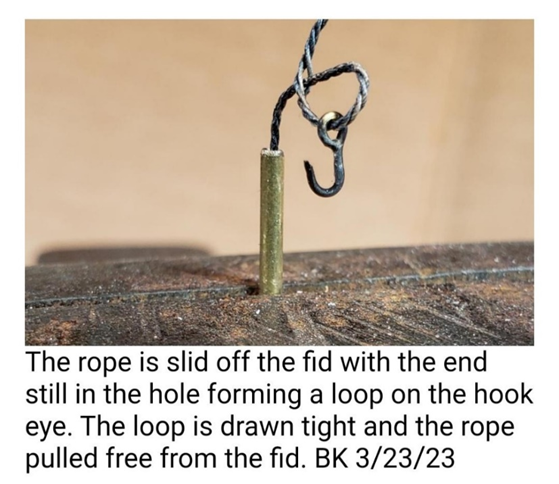

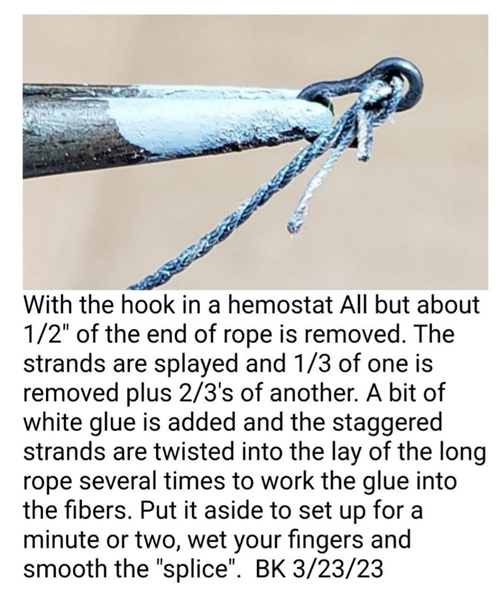

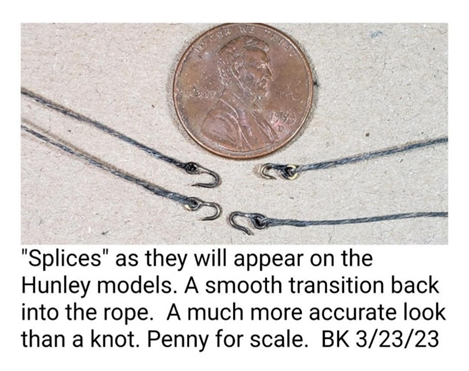

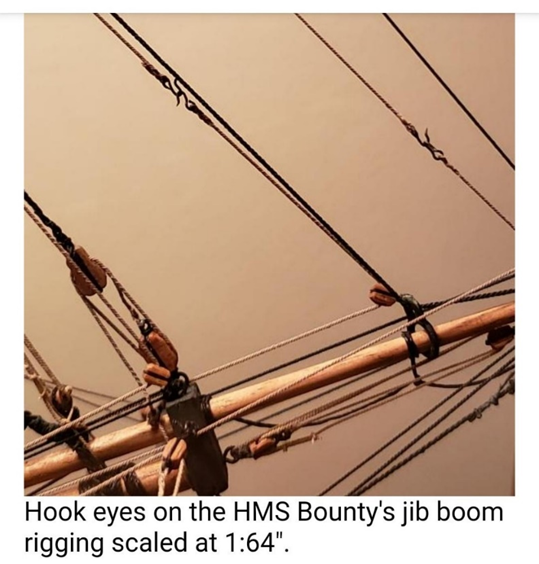

Hi all, This entry is from July, 2023 and looks at making a chain binder w/ slip handle, and how to do splices using a homemade fid: LEVER CHAIN BINDER WITH SLIP HANDLE This device answers two questions on the fore deck of the St Louis. Number one, what was the purpose of the large ring bolt in one of the salvage pictures? Number two how did they control the anchor chain when deploying, it snubbing it, and weighing the anchor? This type of lever chain binder may have been used in this period of time. MAKING SPLICES IN ROPES, with illustrations of their uses on Bill’s C. L. Hunley and HMS Bounty (Pictures and captions by Bill Kammermeyer). While not technically OK, folks, we're caught up! The project is almost finished, with most of the effort going to making figurines 1/24 scale. Previous entries have looked at making armatures, heads and some clothing, which will be supplemented by adding specific figures in various poses around the gunboat. Tim 314-761-5435

-

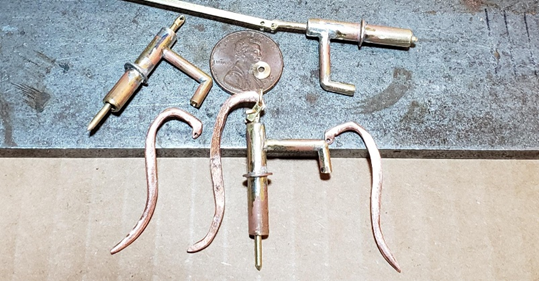

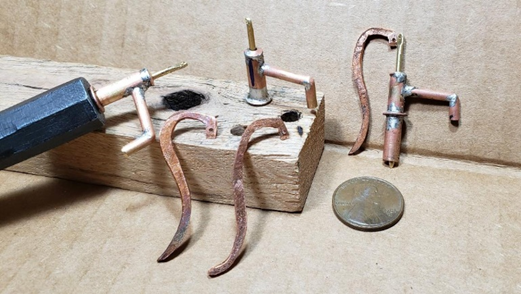

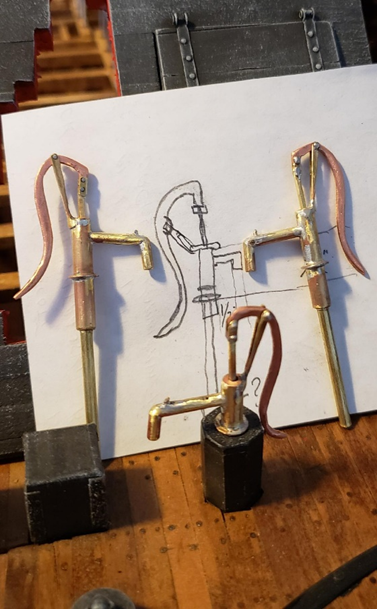

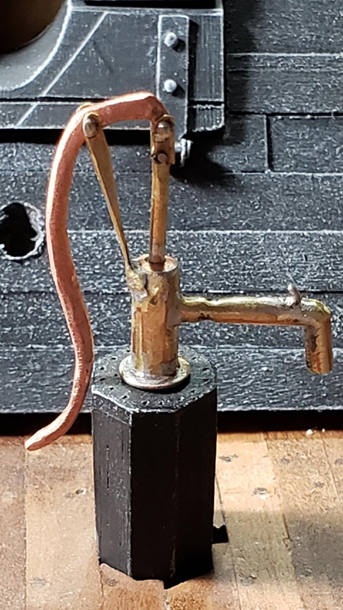

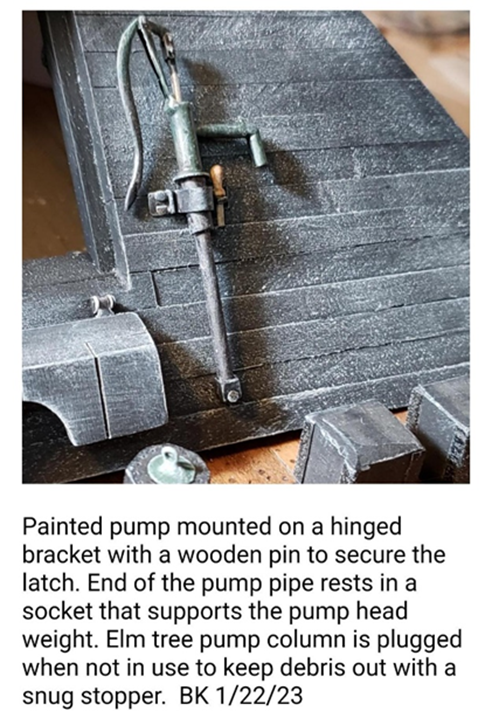

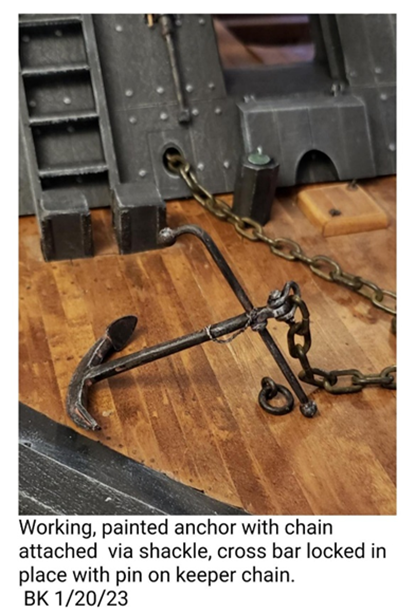

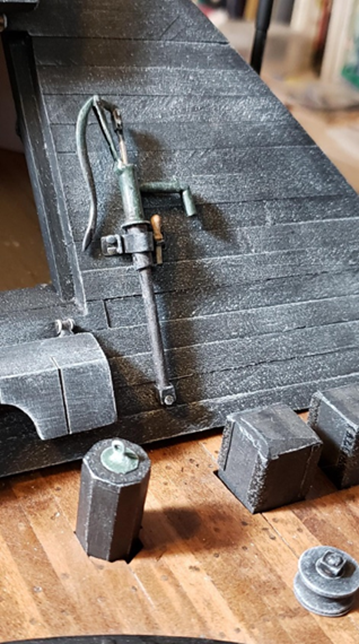

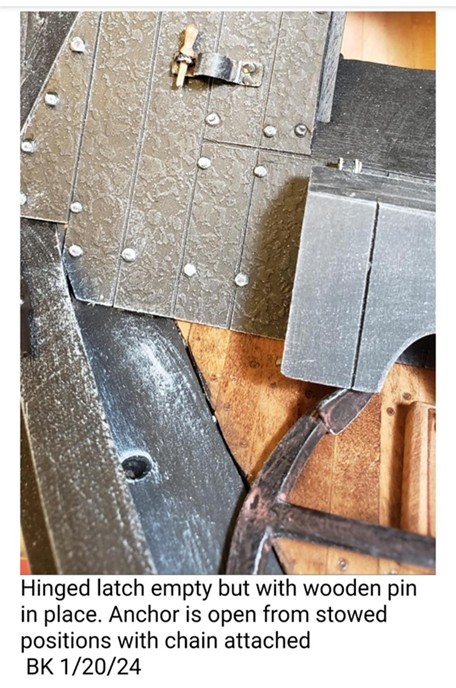

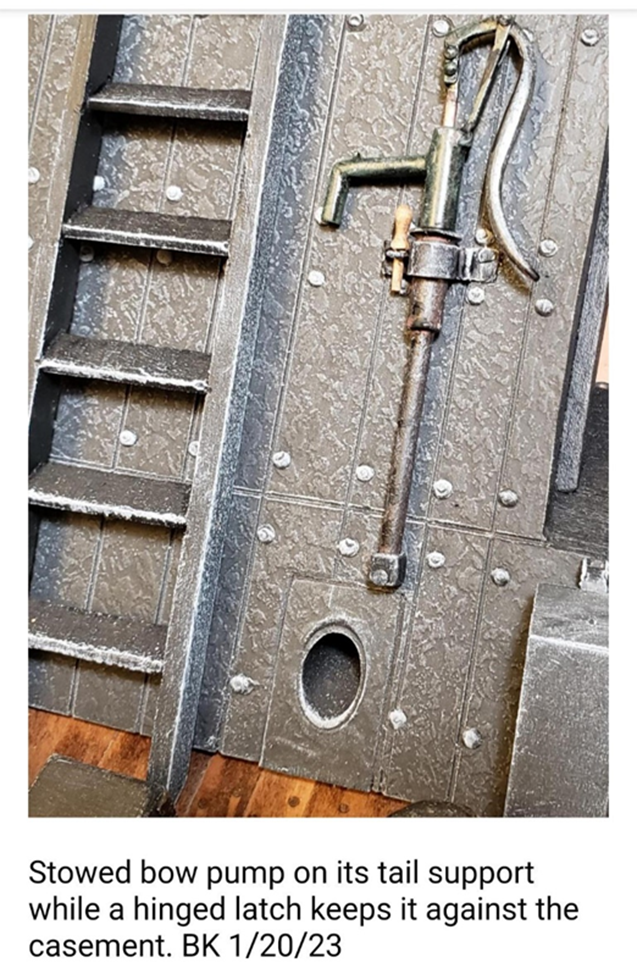

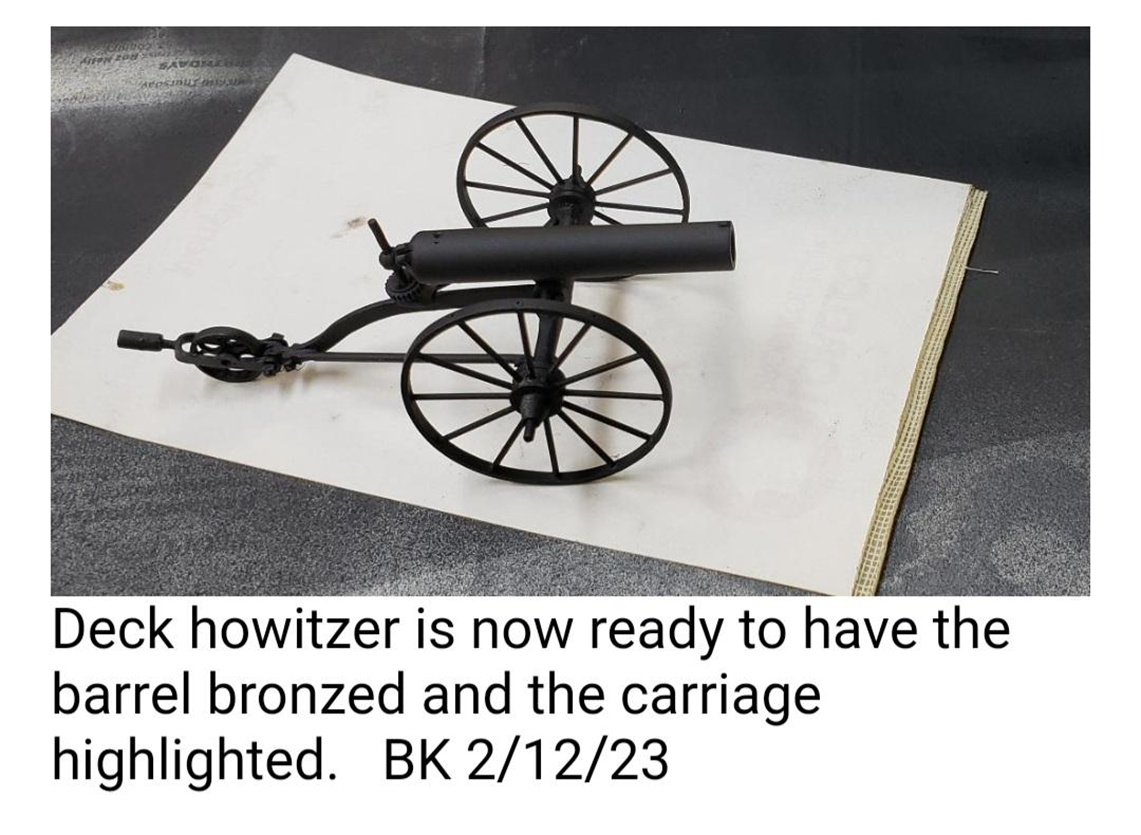

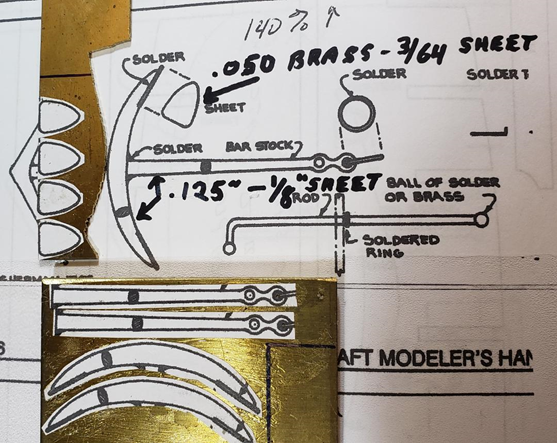

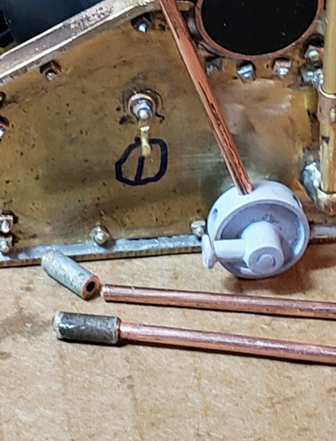

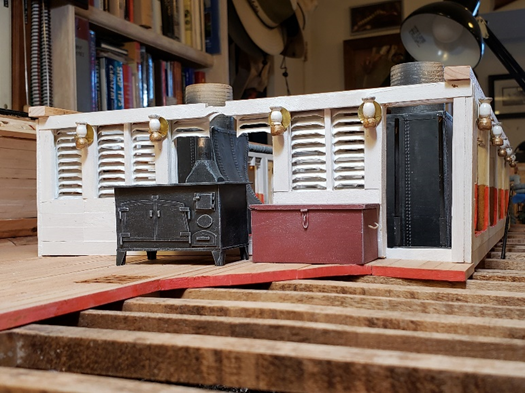

Hi all, This next installment is from January/February of 2023. 12 Pound Deck Howitzer BK 11/23/22 Deck Pump Heads Three octagonal "oak tree pump" shafts were made 4 years ago by Vince and Tim and installed in the bow and stern decks as per the Cairo plans. No pump heads were shown on the plans. Research shows that hand pumps were removable and stored on deck casements. I found a number of period pumps and drew plans for plausible type. These were used to empty the bilges, not as emergency water removal. In an emergency, the ship was run aground and the emergency addressed. Brass tube, rod, sheet stock and 14 guage copper wire were cut and soldered. The hardest part was attachment points so the pump handles would work the internal pump rod. BK 1/4/23 Plan that I drew as guide for pump construction behind the finished pumps. The 2 in back will be mounted on the casements. The tail pipes will fit into a water-tight fitting to create a vacuum after the pump is primed. BK 1/11/23 The mechanism that drives the pump rod works well, and all pivot points pins are soldered in place in a fashion that allows movement. When they are painted this feature may disappear. BK 1/11/23 The pump heads rotate 360° with a nib on top of the spout to hold an attachment for a leather or heavy waterproof cloth hose to take the foul water over the side. No internal discharge was shown on the plans. BK 1/11/23 Our scale figure shows relative size of the pumps. When in action, the pumps needed to be stowed to avoid damage by cannon discharge. BK 1/11/23. Painted pump mounted on a hinged bracket with a wooden pin to secure the latch. End of the pump pipe rests in a socket that supports the pump head weight. Elm tree pump column is plugged when not in use to keep debris out with a snug stopper. BK 1/20/23 Painted, working pump head in the elm tree well that goes into the port bilge. The plug is stored in the pump tail support on the casement. BK 1/20/23 Port anchor painted and stowed against the bow casement in its hinged latch with a wooden pin to secure it. BK 1/20/24 That's all for this time. Next will be the fashioning of anchor chain binders. See you then! Tim 314-761-5435

-

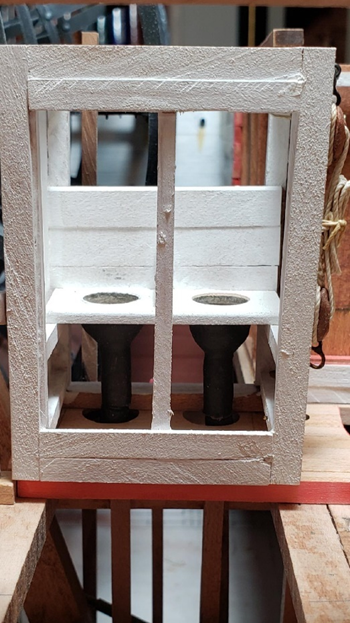

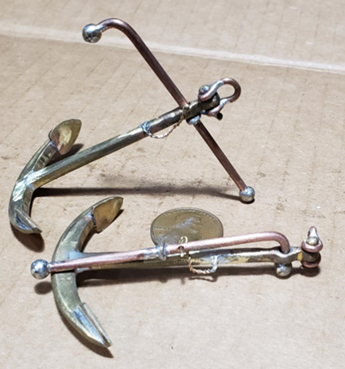

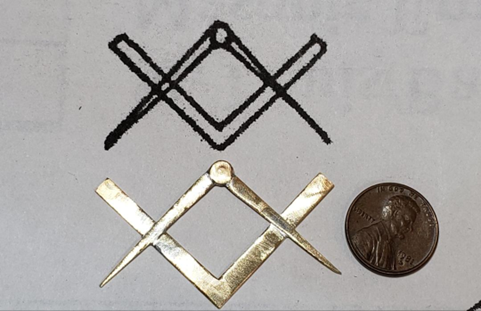

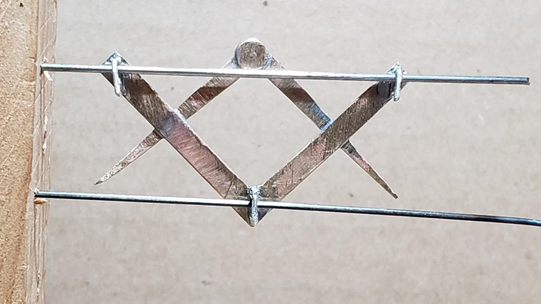

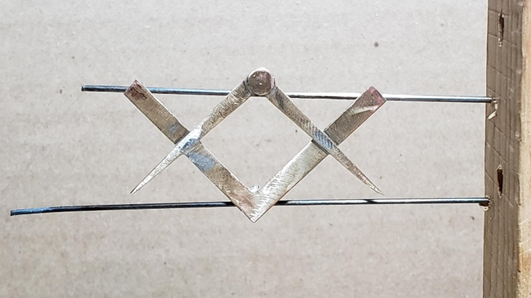

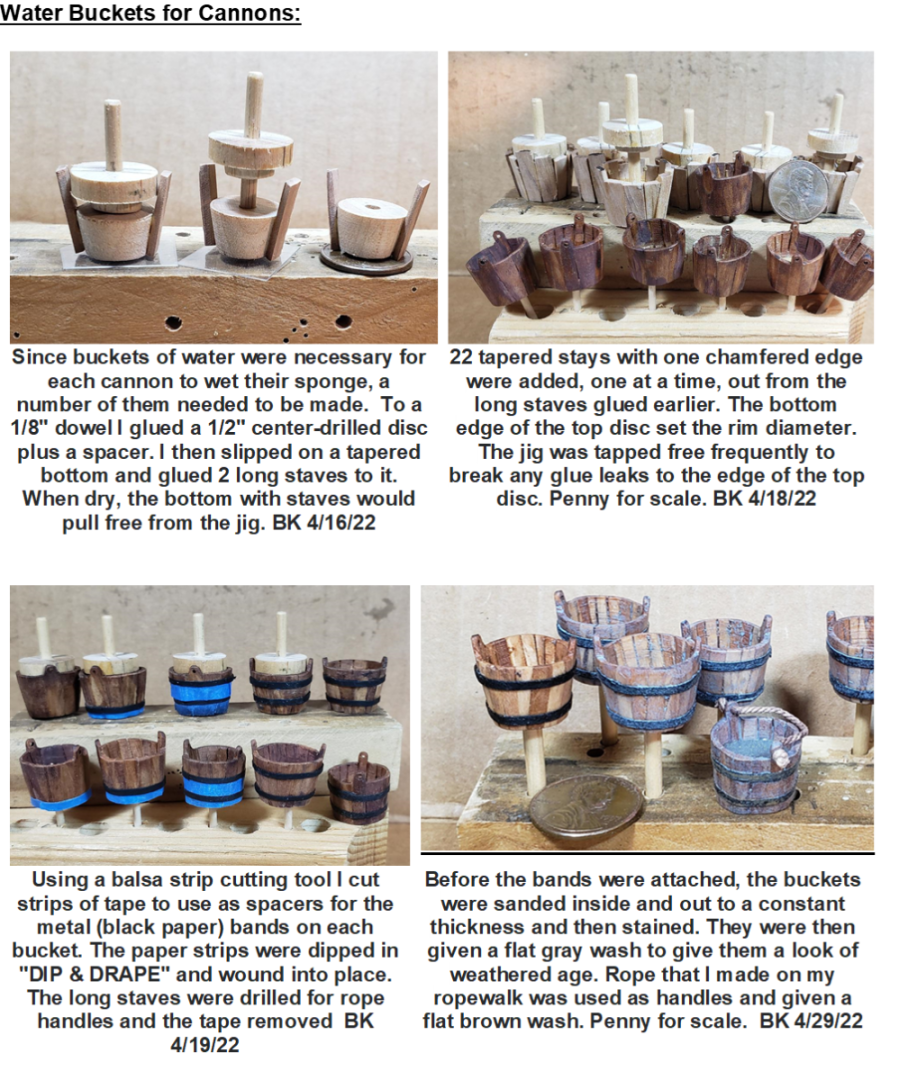

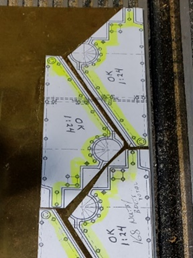

OK, this next session cover much of 2022, and covers not only further progress on the USS St. Louis , but also progress on the accompanying Mortar Barge built by Bob Keeler. USS ST LOUIS (Photos and text by Bill Kammermeyer unless otherwise noted) In the pilot house, the lanyards for holding the armor plate window lids open are put in place around their pins. LED lighting has been put in place as a trial. Fred and I are looking into fiber optics for the candle flame. BK 3/21/22 CREW HEADS: The difficult mechanism for building the plumbing apparatus for the crew heads was as overcome by turning Styrofoam molds to be covered with liquid epoxy in the shape of a bowl and pipe using a pattern and duplicator. BK 4/24/22 The Styrofoam mold was trimmed and then removed from the dry epoxy bowl shapes using a moto tool with a round bit. After most of it was removed, a drop of acetone melted the rest. The rims were sanded flat. BK 4/26/22 The bowls were painted copper on the inside and black outside. The flat edges of the bowl were glued to the underside of the seats of ease with the pipes making a right-angle turn into the waterway. A drain from the starboard upper head may be seen with a stain in the background. BK 4/28/22 MASKING AND PAINTING OF THE CASEMENTS: Blocks of Styrofoam were cut, with Vince and Tim’s help, for a tight fit in the gun ports and open viewing cuts. BK 6/9/22 With Styrofoam plugs in place and masking complete the casements and the upper portion of the hull are ready to be painted. BK 7/27/22. Bow and stern casements were painted off the ship and the side casements are ready to be painted. Aluminum foil works very well with irregular surfaces. BK 7/27/22 Painting went off without a hitch. The Styrofoam plugs worked very well. The use of a flat red paint to designate removed sections of casement were applied. BK 8/4/22. All the edges of the gunports as well as well as the removed area had to be painted flat black and flat red respectively. BK 8/4/22. SPITOONS, CHICKEN COOP AND LADDERS: Using beads as the base and paper as the rims, Vince and Tim made a number of spittoons for placement around the ship. Pegs were attached to the bottoms of the spittoons so they could be placed solidly in holes drilled in the decking. They were painted brass. (see below regarding “straw” for the flooring of the coop) Chicken coop (unpainted), and ladders for bow and stern casements, made by Vince 1/25 scale chickens (hard to find, gotten from a Canadian company) white (see on right), painted brown, in preparation for their becoming residents of the coop. They came with pegs on the feet, for anchoring on the coop floor, and these pegs were placed in the end of a piece of corrugated cardboard while the paint was drying. VM/TJ 9/9/22 Coop painted black. Floor had standing chickens (including one rooster). Upper shelves had “nests” made from buttons. The legs were cut off these and the hens placed in the “nests” as if they are laying eggs. The “straw” for the floor and shelves was made from scale “rough grass’ and “dirt.” ANCHORS: Research plans for an Admiralty anchor were printed to the proper scale, cut to rough shape and rubber cemented to brass sheet. 1/8" for the arms and shanks. .0218" for the palms. BK 10/28/22 The brass parts were cut to pattern size, filed, and sanded to final shape with a notch in the top of the arm and a shoulder filed on the end of the shank for a stronger soldered joint. These parts were pinned to scrap wood with a hole under the joint so the wood would not act as a heat sink. BK 10/30/2 The joints were fluxed and then overwhelmed with torch heat. Silver bearing solder was touched to the joint and I was done. A solid joint that just needed to be cleaned and filed. BK 10/30/22 The finished joints after filing and sanding were smooth and true. 12-gauge copper wire was cut and bent as per plans with balls added to the ends. Balls were from an old brass bead chain with the links cut and one end drilled for the cross arm. BK 10/30/22 The palms and notches in the arm tips were fluxed and tinned, then spring clamped together and torch soldered while in a vise. The clamp was removed and palms were finish set using pliers and torch. Balls were soldered in place. Penny for scale. BK 10/31/22 Shackles were made from 14-gauge copper wire. Stop rings and retaining pins were made of 22-gauge brass wire. Pins were drilled and 28-gauge brass wire was twisted and soldered to simulate the keeper chain. Anchors shown in working and stowed positions as they will be displayed on the bow deck. Penny for scale. 11/5/22 Anchors displayed on bow deck, top view View from the bow. The anchors store more easily with the cross bar stowed. MASONIC SYMBOL: The existence of a Masonic symbol located hanging from the support rods between the smokestacks is seen in some period pictures, although it has been difficult to verify. It is known that the USS St. Louis was renamed the USS Baron DeKalb (named after Johann DeKalb, a French military officer who served as a Major General in the Continental Army) in September of 1862 when it was transferred from Union Army service to Union Navy service. Her last Captain, Lt. Commander John Grimes Walker, was known to be a Mason. It is also known that during combat, Masonic members would not fire upon other Masons, even if they were the enemy. (thanks to Casey Jovick and Keith Dockins for their research assistance). Thus, despite the speculative nature of this symbol, it was decided to construct one, which could be removable but still part of the display if need be. Sheet brass .021" from an old award plaque was cut to make the square, compass, and hinge buttons. Buttons were made with a Whitney #5 jr. punch. Penny for scale. BK 10/26/22 Assembled parts were tinned, clamped and then flash soldered with a propane torch. Excess solder was sanded and filed away. The result was pretty close to the plans I used. Penny for scale. BK 10/26/22 20 gauge brass wire hooks was soldered to the back for optional mounting between the stacks. It will be firm but not glued, giving us the option of removing it if proof is presented that in fact it was not historically accurate. BK 10/26/22 Finished Masonic symbol as it will appear on the stack support rods viewed from the bow. BK 10/26/22 Buckets to be used on Bob Keeler's 1:24 scale 13" mortar barge (see below). Long rope attached to retrieve bucket when thrown over the side to refill the sponge tub. Stained water in buckets is liquid steel. It dries level and has a water sheen. Penny for scale. BK 4/21/22 MORTAR BARGE, Continued (photos and text by Bob Keeler, 06/03/22) Shows .04 in x 1.25 in x 3.25 in styrene shielding representing 1 in x 30 in x 7 ft iron shielding on wooden supports. Side view View showing Bill’s mortar and supporting hardware with our scale man for perspective. No, I didn’t paint the shields black; just the lightingeffect. It does show the rifle ports to advantage. Another view showing the interior details Tool for cutting styrene into 1.25 in wide strips Tool for cutting strips to 3.25 in length. Right hole is for drilling 1/8 in rifle holes; left hole is for locating hawser holes in 4 pieces. After doing all this, it didn’t look right. When I went back to the plans, I found out that I had made wrong calculations. The supports should have been 1 in. high instead of 1.75 in. high, and the shields should have been 1 in. wide (24 in wide) instead of 1.25 in. wide (30 in wide). So I will remove these supports and shield and build new correct ones. WHEW! Lotta stuff there! Next installment will be from January/February and will look at the deck howitzer and the pump heads. Tim 314-761-5435

-

Hi again all, More from February 2022, this time focusing on making and displaying tools as well as ceramic jugs. The former involved several people, including Bill Kammermeyer, Fred Heckr, Bob Keeler, Vince Murphy and myself. Making Shovels I formed blades and soldered tubes to them to make collars. Penny for scale. BK 5/18/21 Using the same size tube with teeth filed into the end (as seen on the penny) a peg is formed that fits perfectly into the socket. BK 5/18/21 Old brass weatherstripping was repurposed into shovel blades with tube shafts soldered to them. BK 5/18/21 Tools, Lanterns, Brooms, etc. Axes built and painted by Bob Keeler 8/9/21 Push brooms by Tim (VM 9/15/21) Oil cans by Vince (VM 10/6/21) Tools for the deck storage sheds and the engine room. Lanterns by Fred. Saws, shovels, sledgehammers, clinker rakes and hook and most painting by Bill. Brooms, mattocks, hammers, wrenches and tool boxes by Vince and Tim. Axes by Bob. Penny for scale. 10/14/21. FH / BK / VM & TJ / Bob K. View into forward work shed with tools in place. BK 10/21/21 Forward work shed corner detail. Front boxes had bottoms reduced to cover "L" of cardboard that was glued to the bottom of the walls to allow the crates to be removed intact when the shed was removed from the hurricane deck. BK 10/15/21 Rear shed tool and equipment placement. BK 10/20/21 Tools and lanterns by everyone, selection and placement by Bill. BK 10/20/21 Detail in rear shed. Rope, sledges and shovels by Bill. Tool box and tools by Vince and Tim, lantern by Fred. 10/21/21 BK /VM-TJ / FH Shelving attached to the curve of the wheel house made sense for added storage in the deck sheds. Canvas sun shade would have been stored here along with miscellaneous everyday ship needs. BK 10/10/21 Unlit and empty lanterns along with beans and general supplies. FH/BK 10/10/21 All sacks, boxes, canvas tarps and barrels are attached to shelves and surface of the wheel house so they will stay in place when the wheel house and sheds are made into one unit that can be removed. BK 10/21/21 CERAMIC JUGS FOR PLACEMENT AROUND THE USS ST LOUIS First I turned them by hand. Penny for scale. BK 1/31/22 Then I attached handles, painted as with a ceramic glaze, and corked them. BK 2/3/22 I made 1/2 gal.,1 gal. and 2 gal. size. Lookin' pretty good! Penny for scale. BK 2/3/22 OFFICERS’ STARBOARD QUARTERS Covered mockup by Vince with thin planks and added doors and corrected after gap. VM/BK 10/28/21 Framed the doors and painted as the casement. Using the fit/sand/fit/sand method I was able to get a tight fit. BK 10/27/21 Using a punch, I was able to make door hardware. BK 10/29/21 Detail of door handles made of bent and worked copper wire with plates made wIth punch. BK 10/20/21 View aft with officers’ cabins installed, painted, doors framed and handles attached. BK 10/19/21 I spent more time than I should for a snug fit for this curved wall. I forgot that boxes would be blocking my handiwork. BK 10/29/21 That's all for now. Next entry will be from October, 2022. Please to enjoy. Tim

-

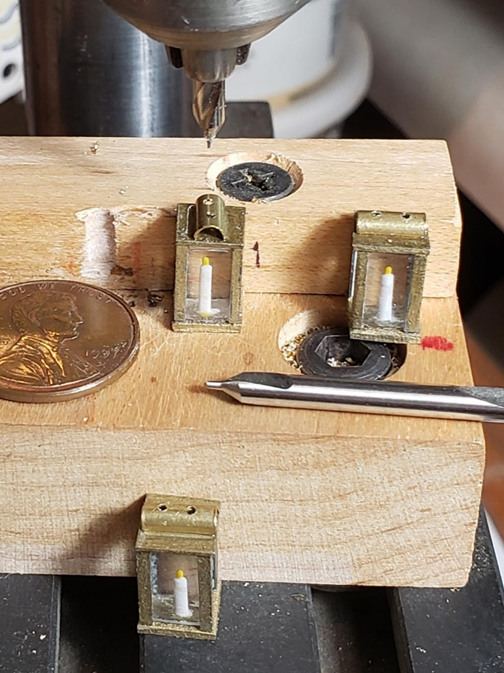

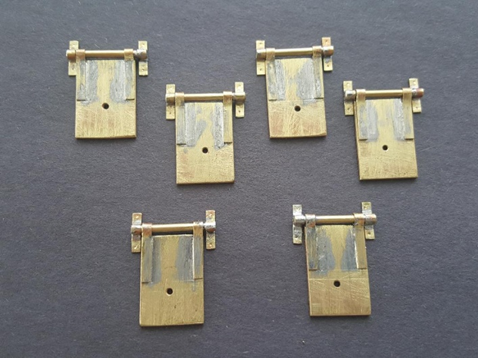

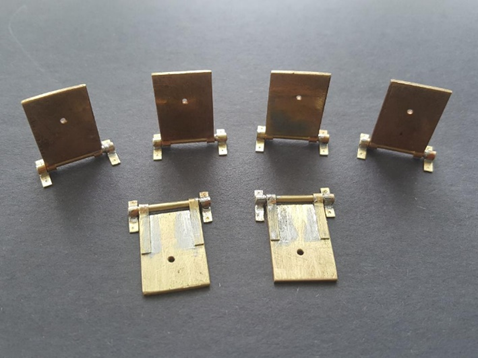

Hi all, Here's the next installment, which is from February of 2022: MAKING SMALL BRASS LANTERNS (built by Fred Hecker and Bill Kammermeyer; photos and captions by Bill unless otherwise noted) An alternative method of making the lanterns was developed by Fred using square, clear, acrylic rod as the glass. The edges were the same plastic angle with a brass tube cut in half for the vent. The bottom of the rod was drilled with a tiny bit, frosting the side of the hole-- PRESTO!, a candle! Some were “lit” by using an even smaller bit for the wick and a bit of paint on a thin wire for the flame. Great job, Fred ! FH 5/28/2021 Drilling holes in the brass lantern vent for wire bail handles was Bill's job. The use of a special bit allowed the holes to be drilled without the use of a center punched mark. This is a good view of the candles with their lit flames. these will be used in the lower working part of the engine room and storage holds. Penny for scale. BK 8/10/2021 Use of a machinist’s centering bit allowed for pilot holes to be drilled quickly without damaging the glue joints and then they could be slightly enlarged later to fit the 20-gauge brass wire used for the bails. the relatively heavy shank of this type of bit relative to its tip keeps the tip from wandering on the surface as would a standard bit. Penny for scale.. BK 8/10/2021 The 20-gauge wire handles add a touch of realism to the look and will be added to a few of the crew below deck as with the 1/24 figure that I use as a gauge for my figure sculpting. Penny for scale. Fred made a total of 21 lanterns that will be used around the "dark places" of the ship as well as in the deck storage sheds ready for night maneuvers. BK 8/11/2021 OPERATING PILOT HOUSE WINDOW ARMORED COVERS (MADE BY FRED HECKER) Operating pilot house window armored covers. 2 will be in closed position, 4 will be open and 2 will be left off of open viewing sections. Another outstanding job done by Fred. Hinge plates have been punched for Bill to drill to appropriate size for attachment pins. FH 10/13/21 MAP CASE FOR PILOT HOUE (made by Fred Hecker) When Fred Hecker sent these photos of a map chest to me, I thought it was for my approval. I thought they were pictures of an antique chest. I wondered if they would fit in the pilot house. FH 10/4/21 Fred said this was what he built. It looks so good I thought it was a photo of an antique. It looks great in place and there is still room for officer and crew as well as floor hatch use. FH/BK 10/7/21 That's all for today. Next time, also from February 2022, many many tools. Tim

-

Hi Bruce, Beautiful picture of your Whaleboat! You can be sure Vince and I will be visiting your build log for it when we start our build. Tim

- 245 replies

-

- model shipways

- Finished

-

(and 1 more)

Tagged with:

-

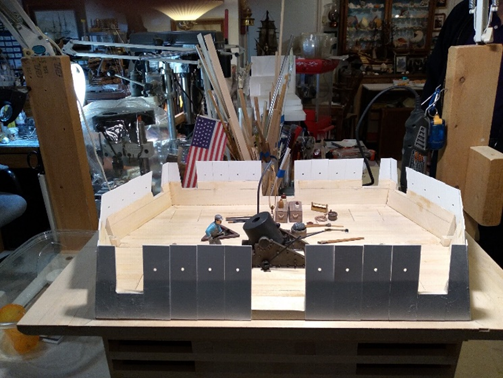

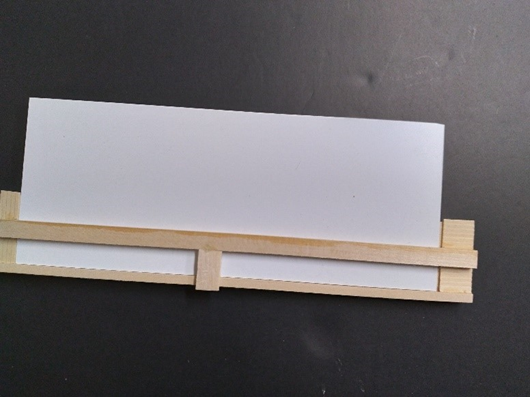

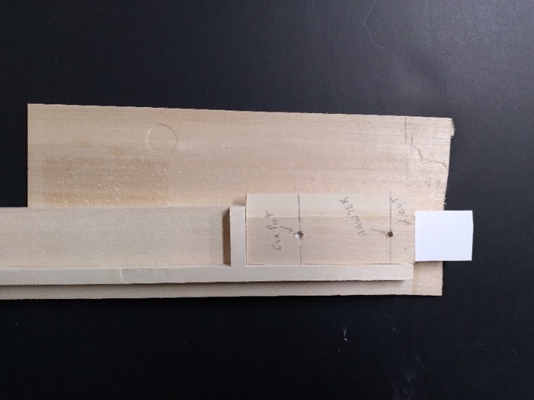

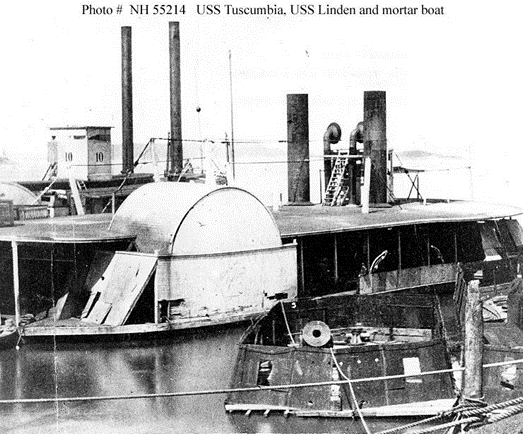

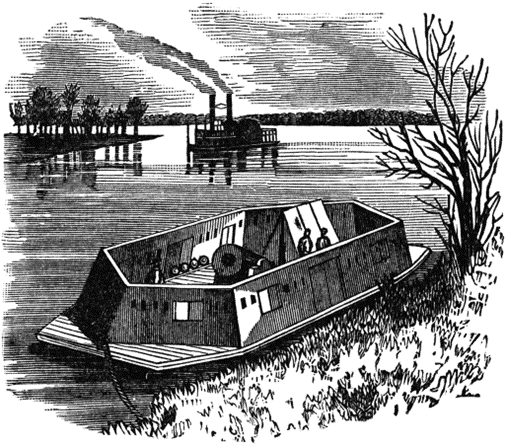

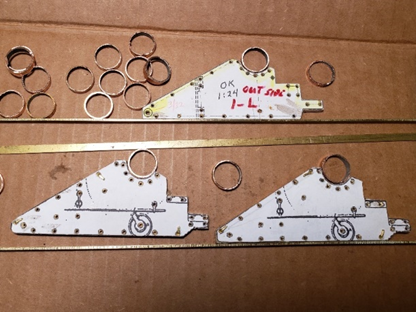

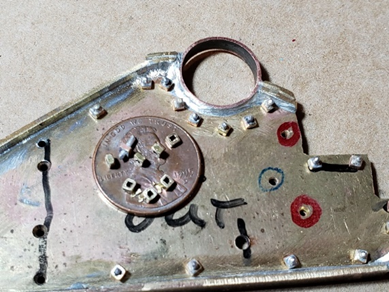

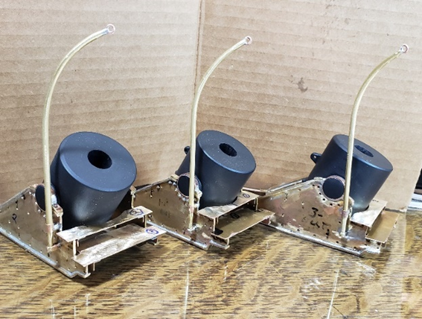

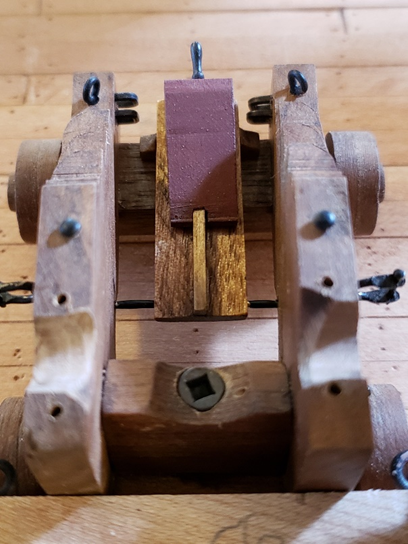

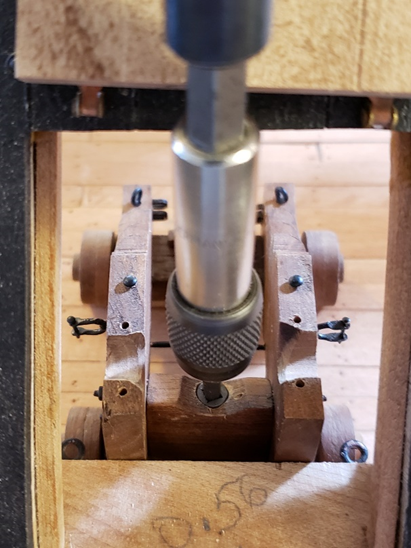

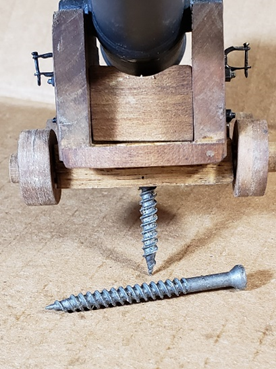

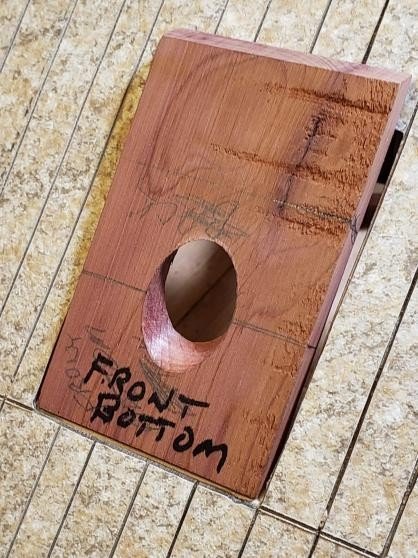

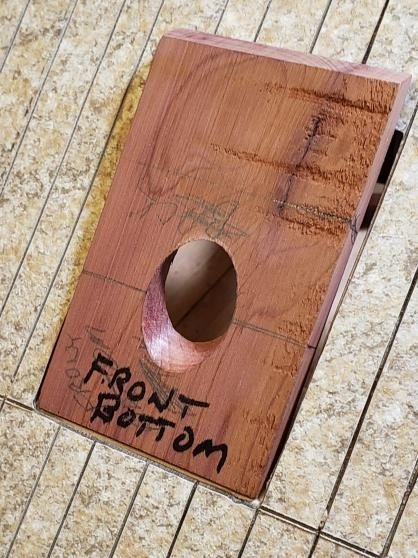

OK, now, here we go with April of 2022, which concentrates on the building of a mortar barge and the mortar itself: This month’s focus for the USS St. Louis will be on a 1/24 scale mortar barge, which is being built by Bob Keeler. The mortar itself was built by Bill Kammermeyer. These mortar barges typically accompanied larger steamships or gunboats, and has been discussed for possible inclusion in the USS St. Louis Display. MORTAR BARGE (photos and captions by Bob Keeler) The mortar barge was 45 ft long x 30 ft wide. Building at 1/24 scale gives a model that is 22.5 inches long by 15 inches wide. Mortar barges were not built for long life as you can see by condition of this barge. Civil War sketches of mortar barges were not consistent with photos and each other’s sketch configurations. Tool used to build interior structural beam layers Building the lower skin first layer of beams and start of interior cribbing which would support the mortar's weight and recoil of mortar. Looking down at the lower skin (,5 in wide by .25 thick planks), structural beams and interior cribbing made of alternate layers of .75 in x 1.00 in beams. Notice strips used to keep things aligned. View showing interior beams made up of .75 in by .75 in beams and .5 in x .5 in beams Adding the support beams for the Exterior cribbing after skinning sides and . Cribbing on mortar barges was1 foot on sides and 2 feet on ends. Model with the side skinned, the upper deck in place and the exterior cribbing. The upper deck is removable for access to the interior. One side is exposed to show interior. This is current status of model. Next step is to add supports for .04 in armor shielding. (It was 1 inch thick iron plate.) MORTAR (photos and captions by Bil Kammermeyer) As part of our build of the USS St. Louis, one of our members Bob Keeler decided to build a mortar barge in the same 1:24 scale. This non-powered raft of timbers had a 13-inch costal mortar mounted amid ship and was pushed where needed by a powered member of the fleet. I had seen these mortars at White Garden near the Battery in Charleston SC and was impressed with their squat bulk and the 200+ shell they fired over 2 miles in a big arc. I decided to build 3 scratch built models, one for Bob's barge, one for me and one for my son-in-law, Lance Carlton who lives outside Charleston and grew up on Folly Beach, the site of a lot of the action during the civil war. Just thought those who had no idea what I am building might like to see a period photo c.1863. BK I drilled hard maple blocks for the bores and trunnions. BK 4/16/21 Turned the barrels on 3 different types of lathe. BK4/23/21 I cut the carriage sides out of sheet brass as per plans that Bob obtained. BK 6/8/22 Parts were cut and soldered together. BK 6/25/21 Flash soldering required the use of a propane torch, heat sinks and clamps to join brass of different thickness without unsoldering previous joints. BK 13/27/21 Using the carriage as a guide i cut a groove for the elevating lugs on my bandsaw. BK 12/31/21 Using a horizontal jig i cut the lugs in the strip of hard Maple I had glued in the slot. BK 1/3/22 Over time I made 300+ "nuts" for the "bolts" that joined the 2 sides of the carriage half that clamped the "t" strip around the edges of the carriage half. BK 1/5/22 The mounting hardware for the loading cranes as well as the cranes (gibbets) themselves were made. Penny for scale. BK 1/9/22 Parts of the cranes as sub assemblies (7 parts for each crane) soldered together. BK 1/9/22. The front loading steps we're soldered to brass angle using a spacing jig. The full crane is in place and functional. BK 1/11/22 The triplets are moving right along. It is a constant situation of fit and file. BK 1/12/22 The small wheels on the side and the internal cam operated by the tube on the axle allowed the wheels to lift and hold the 8 tons of mortar and carriage a fraction of an inch and then with iron rods in the wheel holes, rotate the mortar left or right. Penny for scale. BK 1/23/22 Making the cam sockets required soldering small brass rings to the ends of small brass tubes. Penny for scale. BK 2/23/22 Using an indexing jig I drilled 6 equidistant holes in a half inch brass tube. I inserted a wheel that I had turned to the exact internal dimensions of the tube to form the cam section of the wheel in the cut ring of drilled brass. BK 1/22/22 All the wheel parts were permanently attached to the axle and bars were made to switch the cam mechanism as well as turn the wheels. All parts were primed before painting. BK 1/25/22 All of the parts had to be finished and attached on the right side and free and open on the left side so I could pull the carriage sides apart and insert the cannon barrel. I did this due to the strange size and configuration of the cap squares that cover the trunnions on the cannon. I will never do this again. In retrospect the significant amount of time and effort needed to make the 2 sets of steel jigs for the cradles and cap squares would have been well worth it. BK 2/27/22 Since only one of the mortars will be in a mortar barge the other 2 will be on a hard surface platform. As per period photos I built 2, scale 12' x 12' heavy timber platform with heavy skids. I then tried different methods to show the use of the crane, 200 lb. shells and tools needed to load and service the mortar. BK 2/12/22 MORE TO FOLLOW Extra Added Bonus! Bill’s very own CIVIL WAR CANNONBLL!!! (pictures and text by Bill) As I was leaving a garage sale with my 50 cent purchase I noticed a small dark object at the corner of the driveway and the street. It was convex and about 4 inches in diameter. I asked the homeowner if it was a cannon ball and he said "That's what the guy who gave it to me said". I asked if he wanted to sell it for $5 and he said yes. I borrowed a shovel and kept hitting iron as I worked outward. the ball was much bigger than I thought and I needed help getting it out of the now 10 inch hole filled with wet mud and slick leaves. I just could not grip it with my finger tips. Turns out that it was not only wet and slick but weighed 65 pounds. It was a shot for an 8 inch Civil War cannon. Oddly enough the 3 largest cannons on the USS St. Louis that I am building at 1:24 scale happen to this same gun. This 65 pound hunk of iron could be fired over 2 miles with devastating effects to fortifications and troops, and was! The ball was heavily rusted and large flakes of scale from about the size of pinheads to that of quarters distorted its shape. (Penny for scale, no pun intended). After about 3 hours of chipping with a brick hammer at the scale I was able to remove most of it. A steel cup brush on an angle grinder removed the rest of the flakes. After rinsing it with water, this is its current condition. I have no idea how long it was in the ground or its origin other than the fact that they were stored aboard the City Class gunboats built in Carondelet, south St. Louis and Mound City, and were fired at fortifications in mass south of St Louis. BK 11 / 1 / 21 To be able to more easily move and store my treasure, I built a carrier of white oak boards, which were cut, glued and screwed together at cross grain with a tapering hole in the center. The ball rests securely in the pocket and stays where I put it. Holes were drilled through both boards at the corners, with the bottom hole being enlarged to hold the knot for the ends of the nylon rope handles. A piece of copper tubing was flared at the ends and used as a handle with both ropes passing through it to comfort the hand while lifting the 65 pounds. It is great fun watching the reaction of friends and family as they give this relatively small sphere a lift. One-inch, rotating casters were screwed to the bottom for easy movement. It is a lot easier to roll it than lift it. It is a neat conversation piece and I am pretty sure I am the only guy on the block that has one, BK 12/12/22 Hope you have enjoyed this little tangent. Back to the USS St. Louis proper in the next installment, which will look at all manner of things, such as lanterns, multiple tools and ceramic jugs. Tim

-

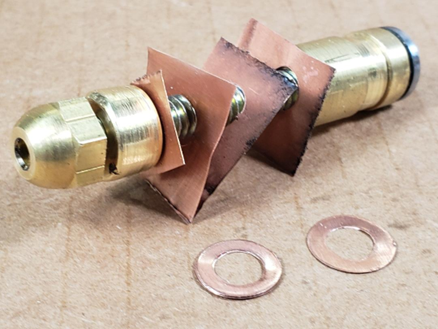

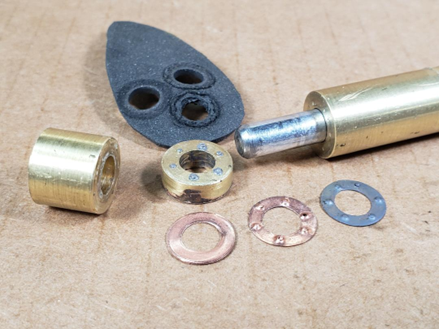

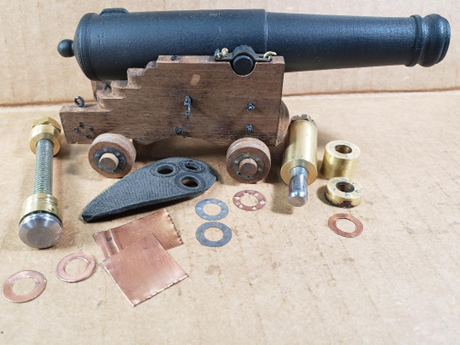

SUCCESS! Just needed a battery. OK, on to: CANNON WHEEL HUBS The 2 parts to a cannon carriage wheel (truck) were set cross grain and bolted together to dramatically increase their strength under the pounding they endured with 1 to 3 tons of iron above them being bounced around the deck by large amounts of gun powder. Over 100 of the hubs with bolts were needed to outfit the wheels, plus extras. Over 100 sheets of .005 copper sheeting were center-punched by Mike Orgel and slid on a 1/4" bolt (we later found that a smooth shank threaded at the end would work better). He compressed them into a solid rod, adding spacers as needed. He ground a special cutter and cut them to a uniform size on his lathe with the lathe live center in the drilled end bolt. (MO 02/25/21) Mike and Bill made the center die of brass ring and indexed pins soldered in countersunk holes. When it is placed on the rod, a blank (left) is added, followed by the black neoprene. The brass tube (left) is added and the unit is pressed in a vise, end to end. The result is the embossed hub (center) and blackened to the right. (MO / BK 03/1/21) Materials and tools needed to make hubs. (BK/MO 03/6/21) Detail of finished hubs and homemade tools. (BK/MO 03/6/21) OK, wanted to make sure to finish up the March 2021 issue. Next is fully a year later; although we weren't meeting due to COVID, plenty of work went on. Stay tuned! Tim

-

SUCCESS! Just needed a battery. OK, on to: CANNON WHEEL HUBS The 2 parts to a cannon carriage wheel (truck) were set cross grain and bolted together to dramatically increase their strength under the pounding they endured with 1 to 3 tons of iron above them being bounced around the deck by large amounts of gun powder. Over 100 of the hubs with bolts were needed to outfit the wheels, plus extras. Over 100 sheets of .005 copper sheeting were center-punched by Mike Orgel and slid on a 1/4" bolt (we later found that a smooth shank threaded at the end would work better). He compressed them into a solid rod, adding spacers as needed. He ground a special cutter and cut them to a uniform size on his lathe with the lathe live center in the drilled end bolt. (MO 02/25/21) Mike and Bill made the center die of brass ring and indexed pins soldered in countersunk holes. When it is placed on the rod, a blank (left) is added, followed by the black neoprene. The brass tube (left) is added and the unit is pressed in a vise, end to end. The result is the embossed hub (center) and blackened to the right. (MO / BK 03/1/21) Materials and tools needed to make hubs. (BK/MO 03/6/21) Detail of finished hubs and homemade tools. (BK/MO 03/6/21) OK, wanted to make sure to finish up the March 2021 issue. Next is fully a year later; although we weren't meeting due to COVID, plenty of work went on. Stay tuned! Tim

-

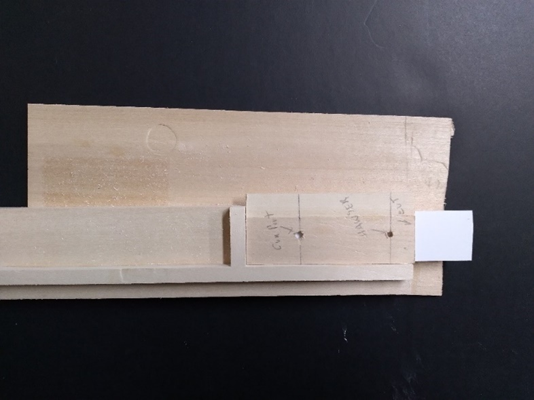

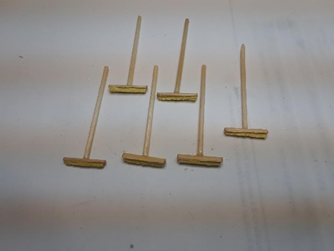

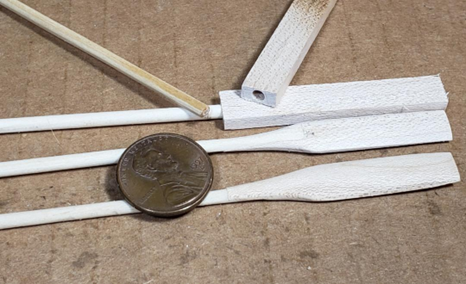

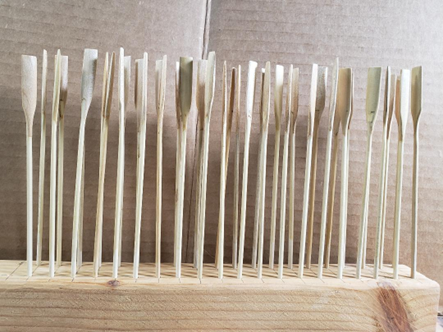

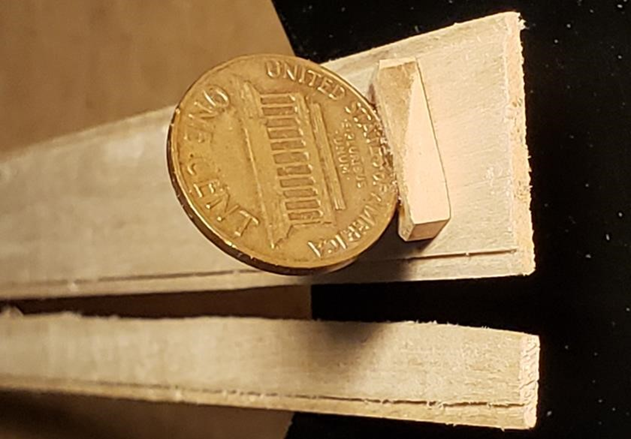

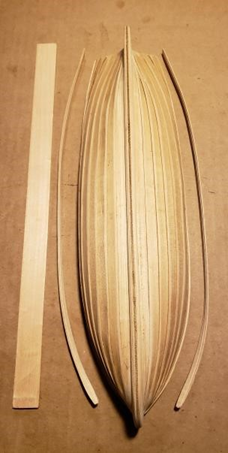

Hi all, A few from the March 2021 Newsletter, looking at construction of the cutter and launch, as well as making cannon wheel hubs. Here we go. (N.B. For the most part, Bill has been working on this on his own, with assistance from Bob Keeler, Dr. Mike Orgel and Vince Murphy. Unless otherwise noted, all pictures and captions are by Bill Kammermeyer) STEPS IN MAKING OARS FOR THE CUTTER AND THE LAUNCH FOR THE USS ST. LOUIS Hard Maple blocks were center-drilled in a jig to accept 1/8" hardwood dowels. The blades were then tapered and formed using a bench top belt sander with fine grit abrasive cloth and an oscillating tube sander for the side rounds. Penny for scale. (BK 02/24/21) 2 different homemade core drills were used to make the handle at the end of the oars. Penny for scale. (BK 02/24/21) After sanding to shape on the bench sander as well as the oscillating sander, the 40 oars were hand-sanded and then varnished to be sanded again to remove any fuzz, so as to be very smooth and ready for painting where needed. (BK 03/6/21) Enough oars for 4 boats, all double varnished and sanded, ready for paint. A far cry from the blocks and sticks with which I started. (BK0 3/7/22) Problem with my mouse. Will resume when I figure the )^&^%^&&* thing out. Tim

-

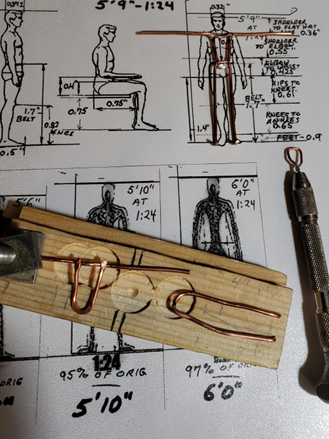

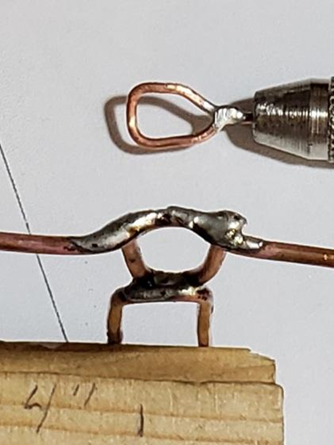

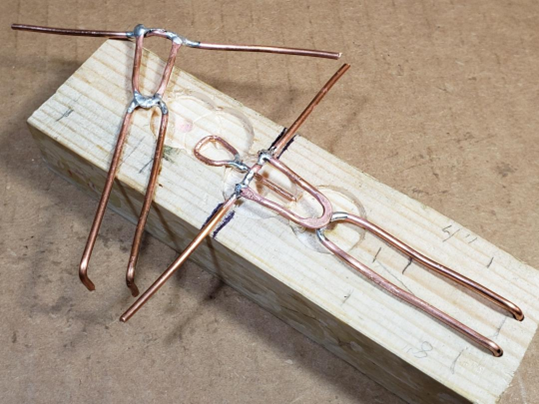

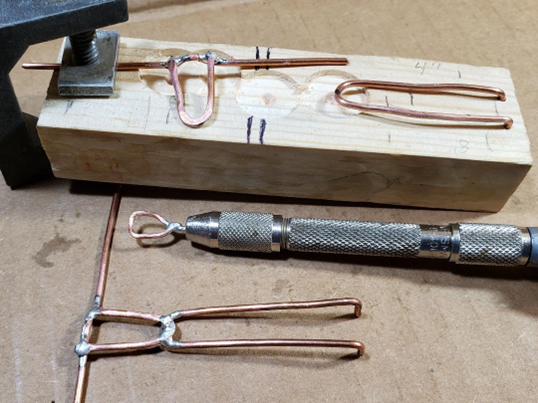

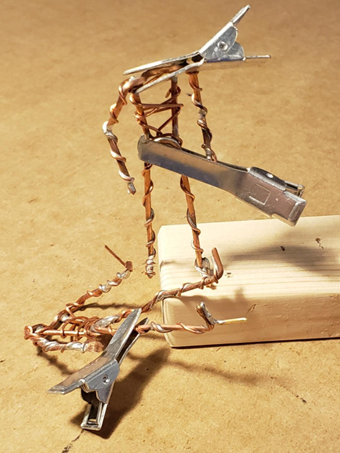

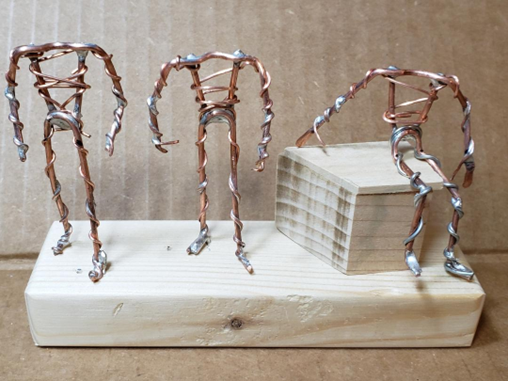

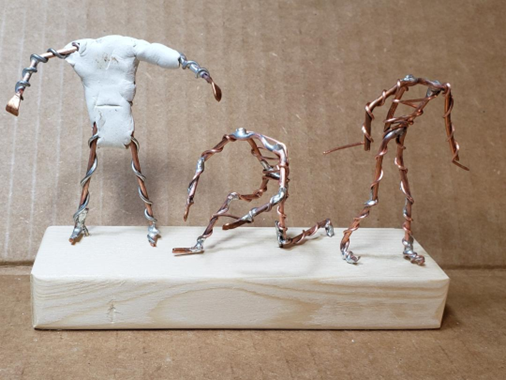

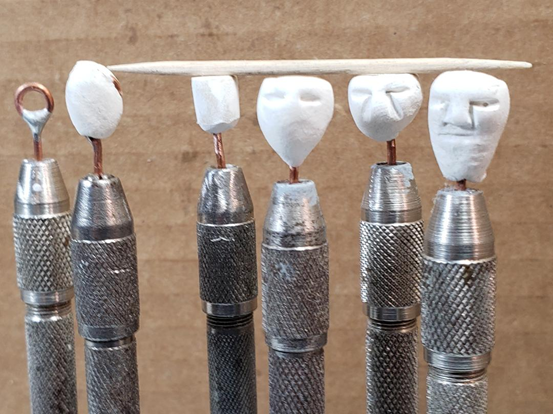

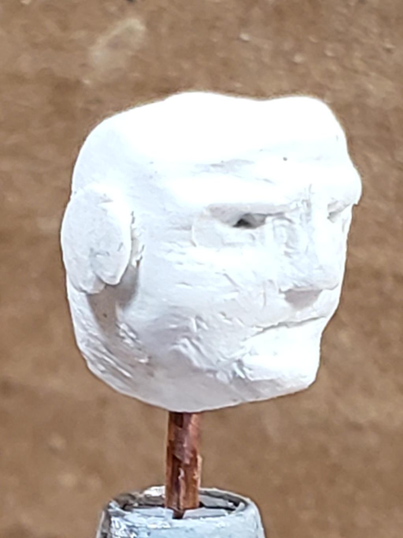

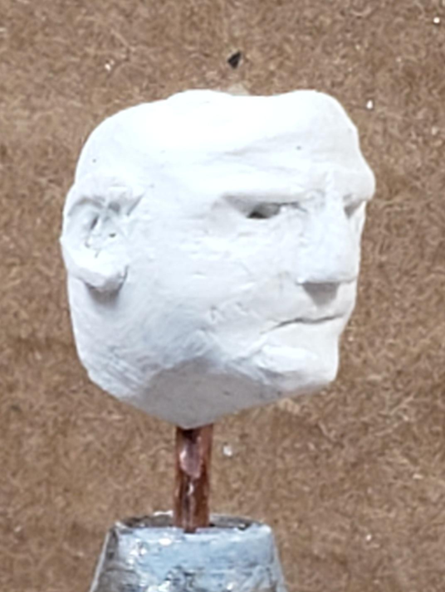

Hi all, here's the next installment of making figurines: again unless otherwise noted, pictures and captions are by Bill Kammermeyer: (MAKING FIGURINES, CONTINUED) Another method was to build armatures for the “skeleton” out of wire, and then fill out the body and clothing with Sculpey. The heads could either be provided by those cast from the 1/24 purchased figurines or made from Sculpey using a toothpick as a tool for details. Bill has done that work. A simple wooden jig used for maintaining scale consistency for the wire armature used in my figure construction. (BK 1/6/21) Torso is 14 Gauge copper wire bent into a "u" with the ends and bend flattened. It is soldered to an arms-and-shoulder wire with a yoke bent into the center for the neck hole. (BK 1/6/21) Yoke for neck hole shown, and head armature in a pin vise. (BK 1/6/21) Lower figure in the soldering jig, the upper armature is ready for animation. Note the recess holes beneath the solder joints. This allows the wire to heat to soldering temperature without the wood acting as a heat sink. (BK 1/6/21) The torso is first tinned at the soldering points and then soldered to the arms-and- shoulders wire with the yoke facing the figure back. That assembly is then removed from the clamp and laid on the pre-bent legs, and soldered at the tinned touch points. (BK 1/6/21) Shallow notches are cut at the backs of the knees at the mark on the jig. Bent and filled head Let the animation begin! (BK 1/8/21) 22-gauge bell wire was wrapped around the 14-gauge scrap copper wire armatures to give the clay more purchase surface. (BK 1/8/21) An L shaped 3/64" brass rod was soldered to a foot with an aluminum clip heat sink in place to protect previously soldered joints. (BK 1/8/21) Protective aluminum heat sink clips made from old hair-styling clips. Nothing fancy, but they protect the previously soldered joints. (BK 1/10/21) The foot pegs in a hole make animating the armatures much easier. Bell wire extending beyond the flattened hand sections will be a support for a thumb when figure is gripping an object. I will now start bulking the bodies with clay as in the figure on the left. (BK 1/9/21) SCULPTING CREW HEADS Steps for sculpting crew heads, left to right. 16 Gauge wire is bent into a 1/4-inch eye and soldered. Sculpey clay is packed into eye and heat-hardened. That is then sanded into a plug and wrapped with a thin layer of clay. Using only a toothpick at this time, horizontal eye dents are made, followed by vertical nose dents. Horizontal dent is made below nose and rolled up creating basic nose and upper lip. (BK 1/22/21) (view progress from right to left) Pupils are set with a toothpick end, in line with corners of the mouth. All movement of clay at this time is made by rolling the toothpick lightly on the surface of the clay. Excess clay is rolled down neck and cut off with an X-Acto knife. Rolling toothpick in a trial-and-error fashion creates facial features. I have about 6 minutes of sculpting time invested in the head on the left at this time. (BK 1/21/21) Ears are now added by rolling a 1/8-inch ball of clay, cutting it in half, balling it again and sticking each small ball to the side of the head about eye height. A rounded rod is touched to the center of the disc and worked out in an ear shape, the front of the ear flat with the face. All clay at this time is moved by rolling the toothpick or tapping with the rounded rod. (BK 1/21/21) A pin on a stick is used to tease out the whiskers on his pork chops and hair. A thin strip of clay is added under the nose and teased with a pin to make his mustache. (BK 1/21/21) The soft clay is hardened with a heat gun and the top is sanded flat to the top of the copper eye. Penny for scale. (BK 1/21/21) Oversized card stock is cut and glued to the flattened head. (BK 1/23/21) A small ball of clay is packed on top of the hardened head. With an "L" shaped, 1/8" wide tool, the band is pressed in, the top is rolled with my toothpick, and detail is stamped in. (BK 1/23/21) After hardening head with the heat gun, the cap bill is sanded to shape with a moto tool and fine disc. Pin vise is a real aid in sculpting these small heads. (BK 1/23/21) These are the tools I used to make this part of the crew. (BK 1/26/22) All heads are made with flat tops, to which I may build hats after the lower portion has been heated and hardened. This allows the facial features to stay intact when the hats are pushed around on the heads. (BK 1/17/21) The five heads in the back row are actually a bit too large to use. While they are nice heads, I will have to find another project for them where the scale is not so important. I had made them before I developed a constant armature for the head (the small copper ring at lower right). I covered this with clay and hardened it as a face base (white object in center). Penny for scale. (BK 1/16/21) Keeping to a true 1/24 scale became much easier when Vince Murphy provided plastic train figures in that scale to me. I removed the heads from several and drilled an appropriate counter-sunk hole in the neck. While the clothing on the figures is not appropriate, it does give a great feeling for the scale. Thus, to maintain the proper scale, I built the heads on small rings of 22 gauge copper wire covered with Sculpey clay. Using mostly a round double-pointed wooden toothpick and a pin vise by which to hold the wire aperture, I pushed and poked the soft clay into face shapes and inserted them onto the neck of the figures (BK 1/10/21) OK, that's all for January, 2021. The next entry will be from March of 2021, making oars for the cutter and launch, and cannon wheel hubs. Hopefully in the next few days. Tim

-

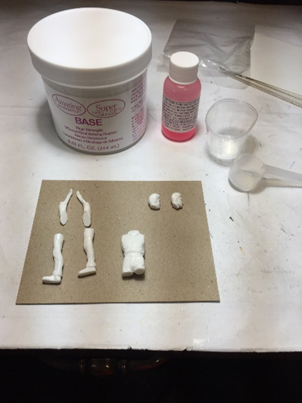

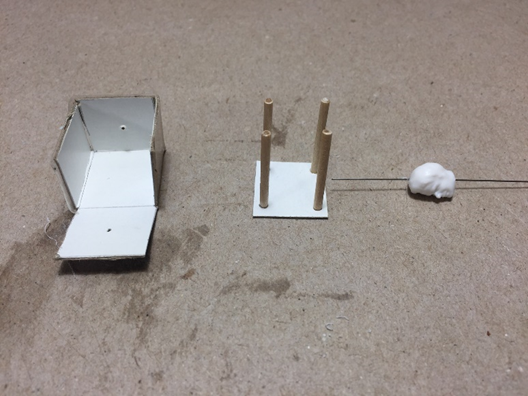

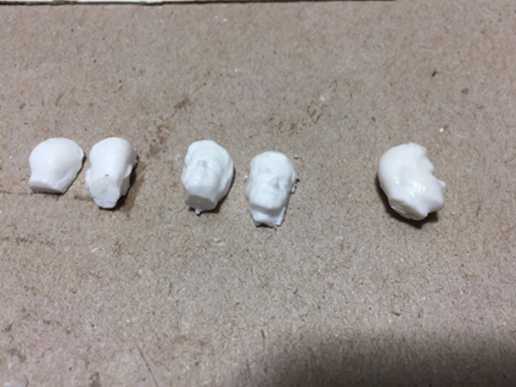

More stuff from January 2021: CANNON TRAINING TACKLE: Jig that I used to hold blocks while rope is rove through them and then gathered and tied in ship shape fashion in the center. (BK 2/20/20) While still on the spreaders, the rope is dampened with Aleene's Fabric Stiffener and tied with lighter cord. (BK 12/17/20) In just a few minutes, the stiffener dries to a flat finish and holds the rope in a very natural fashion. BK 12/17/20 When I am ready for the final installation of the cannon, I will wet the rope near the blocks with more stiffener and push down until dry to give the appearance of natural weight. (BK12/19/20). HURRICANE DECK LIGHTING 1/8" wide LED light strip in "beam trough " that hides the strip from view, yet focuses the light down onto the deck. (BK/BobK/MO 12/26/20) The amount of light generated from the LED strips makes a dramatic difference on the detail in the interior of the ship. (BK 12/26/20) This view of the LED strip is completely blocked from normal viewing by the trough built around it. (BK/BobK/MO 12/26.20) CANNON TOOLS: Cannon tools that I previously made were attached to racks that Tim Jovick and l made last year. The tools were fit and glued to the racks and then the racks glued and nailed to the 45゚ inside casement as a unit. Ready to use and out of the way. (BK/TJ 12/27/20) View of bow cannon tools, ammunition boxes, and tool boxes. Open padlock on green chest while the yellow chest is locked. Fused bombs are in the blue ammunition chest for the 8" smoothbore at the center bow casement. (BK 1/2/21) View down the starboard gun deck showing the angle at which the racks and tools are attached. Also, how they are attached and out of the way. Scale man at right. (BK 1/2/21) AMMUNITION CHESTS AND LOCK MANUFACTURE: Ammunition chests with 32- lb. cannon balls (green) and 8-inch fused bombs (blue) in racks. Bright and blackened padlocks showing how I made them. (BK 12/31/20). After painting chests with craft acrylic paints and a period of drying time, they were given a coat of walnut stain to darken them and give shadow definition to all recessed areas. (BK 12/28/20) Padlocks were made by punching discs from 3/64-inch brass plate. By moving the punch a bit into the last disc hole, a clip was made in the current disc. The center dimple is part of the punch process. An added punch point, with luck, makes the bottom part of the keyhole. Flattened ends of 18 Gauge brass wire were soldered to the back of the blanks to make the shackles. #45 drill bit formed the i.d. of the shackles. BK 12/30/20 These shots show how well the stain picks up the detail on the wood and hasps. The padlocks look relatively realistic considering the penny for scale next to them. (BK 12/31/20). MAKING FIGURINES 1/24 SCALE We have been using a couple of 1/24 modified figurines for reference over the course of this build (you’ve likely seen the guy with the shovel at various places around the boat). The plan is to make perhaps 25 uniformed figurines (both officers and seamen) at a number of places around the gunboat doing various functions (e.g., cannon crew). As mentioned previously, we learned how to make figures from Bob Temper, by fashioning “skeletons” out of scrunched-up aluminum foil, with clothing and heads made from Sculpey. More recently, we purchased a number of solid 1/24 male figurines from Schaefer’s, a local Hobby Shop, with the intention of cutting off the heads, arms and legs (in two parts) and then casting them with the intent of reassembling them in whatever position we wanted. Vince Murply has made a number of such heads, with the help of Fred Hecker. 1/24 solid male figurines, purchased from Schaffer’s Hobby Shop (VM 01/20/21) Cut-apart (head torso, arms, legs) 1/24 figurine (used by Bill, for reference), along with Alumilite brand silicone mold kit, including high-strength mold material, mold-release solution, and measuring cup and scoops. (VM 01/20/21) Early attempts to make molds. The clips on the device are to hold the heads in the mold (which is in two parts) so they won’t sink. The syringe holds the casting solution. (VM 01/20/21) 2-part mold box with holes in front and back panels. The head from the figurine is suspended by a wire passed through the holes to keep it in place. The insert with pegs is to align the two halves of the mold. The insert is put into the box, then the head is suspended, and the mold material is poured in, only half-way. This half is allowed to completely dry, then the red solution is brushed on before the second half of the mold solution is poured in, so the mold halves will not stick to each other. (VM 01/20/21) Silicone molds for two-part casting, along with two heads cut off the 1/24 scale figures (VM 01/14/21) “Smooth-Cast” two-part casting solution, provided by Fred Hecker (VM 01/14/21) Silicone Casting forms for two-part heads, plus completed heads (VM 01/14/21) Cast heads, formed from two pieces (front and back), separately cast from silicone forms (VM 01/14/21) One-piece heads (longer necks) (VM 01/14/21) Both one- and two-piece heads, with their silicone molds. Penny for scale. (VM 01/14/21) OK, that's all for today. Next submission will look at an alternate method of making figurines using wire armatures for the "skeleton," if you will, plus more about making heads. Tim

-

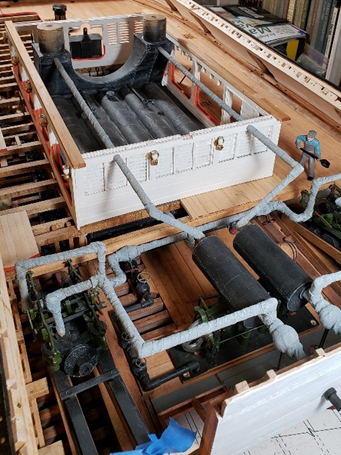

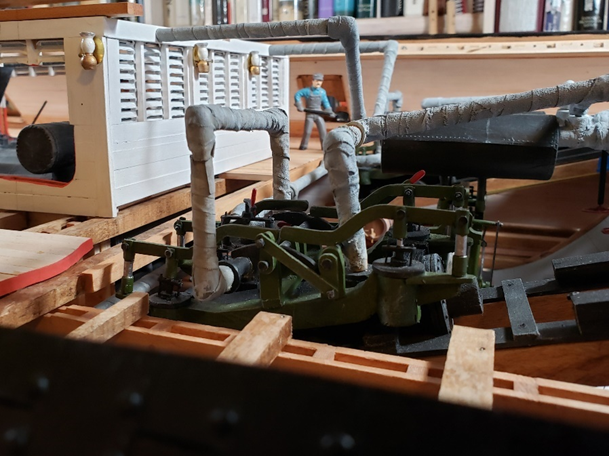

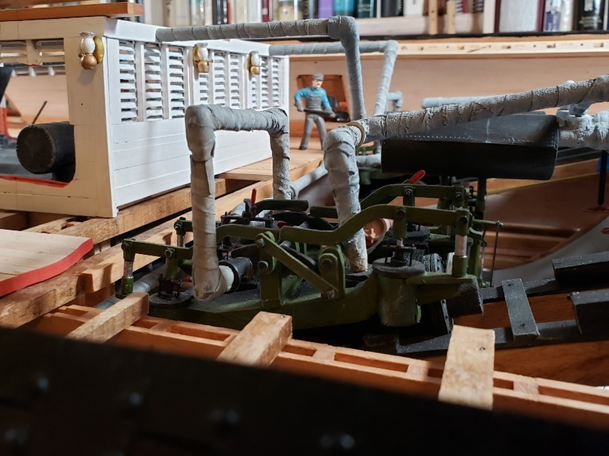

Again apologies for the delay in posting these pictures and captions. These are from January, 2021 and entail a variety of smaller projects, such as engines, hurricane lanterns described in the previous post, using rope splicing fids and rigging of the cannons. These projects were done by Bill Kammermeyer (who is the source of the pictures and captions), with assistance from Bob Keeler, Mike Orgel and Vince Murphy. ENGINE REWORKED I had the steam engine positions reversed and needed to place them in their proper positions with new live steam wrapped pipes in their proper positions. Entry points of live wrapped steam pies on outboard sides of engines. Oil lamps may be seen on the backside of boiler room ventilating screen (BK 12/07/20) OIL LAMPS Hurricane lamps that I made earlier are now in position around the boiler room ventilating walls. (BK 11/18/20) DETAIL OF ENGINE ROOM LADDER Detail of engine room ladder and walkway rail. (BK 1126/20) ROPE SPLICING FIDS Rope splicing fids made of brass tubing and brass rod, soldered and ground to a fine point make faux splicing a snap! (BK 12/01/20) CANNON ATTACHMENT TO DECK Breast plate and deck 1/8" drilled, breast plate 5/32" drilled then 7/32" top counter sunk for 1-1/2" X 6" finish screws. (BK 12/15/20) Carriage being attached to deck through the gun port. Screw will not show and cannon will be reock solid. (BK 12/15/20) Now, barrel, cap squares and pins may be installed. (BK 12/15/20) Maple grating that Mike cut and I assembled and sanded to fit all the gundeck hatches. (BK 11/11/20) LOCK PINS ON CAP SQUARES 18 Gauge brass wire, on left, bent, flattened, and drilled. Same wire bent, crushed, fit with a fid, trimmed and soldered. Penny for scale. (BK 12/12/20) Since barrels and cap squares must be installed through the gun ports after the carriage has been screwed to the deck, fid is soldered in place and unit acts as a nail. Finished on top, rough at bottom. Penny for scale. (BK 12/13/20) INTERIOR GUNPORT DOOR LIFTS 12 Gauge copper wire flattened, punched, drilled and end rough shaped while on long wire. Shaped with 80 grit sanding disc. Wire cut and other end finished in the same way while in a clamp. (BK 3/4/20) Cleat attached to inside casement with gun port lifting rope in place. (BK 12/20/2020) That's all for now, more coming in short order. LOT of stuff in this January 2020 edition, Tim

-

Forgot to add, we also have the Philadelphia by Model Shipways, should be an interesting build. But more immediately, we have the Model Shipways New Bedford Whaleboat, which we got for an obscenely low price on sale. These miniature whaleboats for the Morgan will be good practice for that one! Tim

- 245 replies

-

- model shipways

- Finished

-

(and 1 more)

Tagged with:

-

Hi, Bruce. My friend Vince Murphy and I are building the Morgan and have gotten to installing the boat slides and starting to build the whaleboats. I came across your build log and it Blew My Mind! Wow! You did a bang-up job on those whaleboats, so I took the liberty of downloading those sections of your log for reference and inspiration. I'm the Secretary for a local (St. Louis) shipmodeling group, the Gateway Shipcrafters Guild, and also the editor of its Newsletter, so you will be acknowledged when we post the "whaleboats" section of our own build. However, you may also be interested in our Build Log for the USS St. Louis, Civil War Gunboat, 1/24 scale, which was one of seven built in St. Louis, designed by James Eads, who also designed the Eads Bridge. It is a sister ship to the Cairo, which was sunk and recovered 100 years later, and is now a museum in Vicksburg. Our group was commissioned to build it (model is 8 feet long and about 2 1/2 feet wide), been working on it for some 6 or so years, "nearing completion." This is a Scratch Build, lot of details, lot of research, lot of frustration and fun. I'm behind in posting our progress, but getting back in the saddle, starting with early 2021. Let me know what you think. Thanks. Tim Jovick 314-761-5435 timboni7263@att.net

- 245 replies

-

- model shipways

- Finished

-

(and 1 more)

Tagged with:

-

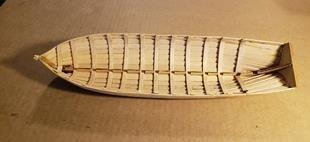

OK, here we go with the continuation of the building of the ship's boats/cutters. Again, pictures and text by Bill Kammermeyer. Strakes were cut from the rabbeted stock and attached to the ribs. Each set of strakes was wet and tied to the form The next day, they were glued to the ribs and each other, port and starboard at the same time. Tapered bamboo chopsticks were used through the jig to hold lashings while the glue dried. The tapered chopstick ends were used under the lashings as wedges to add force to glue contact points, making for a tight fit. Cutter on mold was given three coats of varnish, more as an adhesive to the rabbet joints than as a finish. I cut the ribs as the sheer line and the cutter came off the mold just as advertised. It has virtually no flex or spring and will finish nicely. I now have to add the gunwales, seat rails and decking, to finish the build. All of this seems so reasonable, now that I have results of my first attempt at this type of boat building. So not bad for a first try! Making oarlocks; Brass strips 0.12" wide were cut from a 0.03" thick brass sheet. These strips were center-drilled with a small centering bit and then again with the #56 bit to match the diameter of the brass rod for the stem. They were bent into a rough U shape using a jeweler's pliers. The hole was re-drilled with the #56 bit. Brass rod 3/64" in diameter was soldered into the hole. Pin vises were used to hold the oarlocks for final shaping and finishing. Grinding with a burr in a moto tool was used to remove rod tip inside the oarlock. 329 bit was used as a center mandrel. ,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,, Oar locks, before and after finishing. Penny for scale. Oarlocks as they appear on the gunnels of the cutter. Boats ready for painting: Boat at right and in the center were made on the solid bread-and-butter mold. The boat to the left was made on the open rib form. Using the rabbet on the straight side of each plank before cutting them to shape made for a very stable glue joint. Rudders under construction. They are of mortise-and-tenon construction so that the tiller tenon may slip in-and-out of the mortise, so it may be stored when not in use. The finished rudders with early stge of gudgeons (the socket) and pintles (the pin), still in manufacturing stage. I made extras while I was at it, in case I build any more boats in this scale. The rudders were attached by inserting the pintles into the gudgeons, which were then mounted to the hull of the boat and the transom. The tillers were cut with an angled tenon and set into an angled mortise in the rudder. They may be removed for storage by pulling the holding fid on the top starboard side of the rudder. The rudders are prevented from floating free of their gudgeons with the use of a swivel block above the top pintle. It is moved up and to the side so the rudder may lift off for storage. The bottom lift clearance slot is left open. When the swivel block is in place, the rudder is locked to the sternpost. All straps are held in place by 0.026" brass pins cut and drilled into the hull and rudder. Super thin cryo was used as a last bath to hold the pins in place. Checking for height for the boat supports from the casement to the davits, with temporary supports in place. Measurements are made for the V supports for the boats that go from the casement to each davit. The horizontal supports will be installed into the casement permanently and will not be affected by removing the Hurricane Deck. (somehow this got rotated in the process of transferring to this build log; turn the picture 90 degrees clockwise) The V supports were joined to the casement with 3mm tubing slid over their bars on 3/32" pegs in the casement. This made the lower portion rigid while the upper curved portion of the davit could swivel freely. This made all of the davit support/boat support arms the same height. Note the Y support in the casement accommodating the sleeves from the center davits. One of the primed launches resting on its supports. Two timbers will run parallel to the keel to support the weight of the boat. Starboard launch and cutter resting on their storage supports. They also will have a beam on each side of their keels on which to rest when in storage. The portside launch is for demonstration purposes only. It would block too much of the ship's interior if left in place. ! WHEW! That's all for the ship's boats. The next entry will be from January 2021. And again, please to enjoy. Tim

-

The following entries are from about June or July of 2020. Again there were not meetings due to COVID, but Bill Kammermeyer continued to work on his own. Pictures and captions are by Bill. Making Internal Lanterns: Using my pattern duplicator on my Sherline lathe, I cut 25 lamps from 5/16" dowels. The ends were countersunk to make the internal taper. I finished their shape with files and sandpaper. Leaving them on their dowels made it much easier to varnish, re-sand and paint the lamps. A 1/2" punch was used on a strip of brass weather stripping to cut the reflecting backs for the hurricane lamps. Pins were pushed through pre-drilled holes in the lamps as well as the reflective plates and super-glued in place. This made not only the wick-adjusting knob for the lamp, but also the attachment for the back plate as well as a mounting fixture to go into the walls along the inside of the ship. Penny for scale. Painting and drilling accurate pin holes were easily done while the lamps were still on their dowels. Cutting them on the bandsaw table was also easy with the dowel rolling on the surface of the saw table. Constructing Ship's Boats/Cutter: There were two different methods I was considering for making the ship's boats. The top shows a solid mold over which the ribs would be bent. The bottom one has lifts to which the ribs were bent. in both cases, the longer ends of the ribs woul be glued to the boat jig. To form the solid mold shown in the previous picture (top), I took the plan lifts and glued them to 1/2" wood boards that were cut and then glued together. The high edge of the top board was removed down to the high edge of the next lower board in a fair fashion. this transformed the plans into a 3-D shape. Lifts stacked and glued on center line with keel, stem and stern slots cut. Lifts filed and planed almost to completion. A boat form is developing. t was cut on each edge of the 1/16" basswood strips thaA 1/2A A 1/32" rabbet was cut on each edge of the 1/16" basswood strips that I cut as strake stock for the cutter. Penny for scale. This shallow rabbet was enough to position the edge of the plank in a uniform fashion to the curved edge of the previous plank. It also gave a good surface for gluing. It was very simple to do on my 7-1/2' saw with the rip fence and a thin carbide blade. I put a block of wood over the plank back at the cutting point to keep it in contact with the saw table. The run of the planks was at the lower plank edge. With the building of each boat, I became more adept at fitting the planks. Even at that, my first attempt turned out to be pretty good. More to come on the building of the ship's boats/cutter in the next entry. Please to enjoy. Tim

-

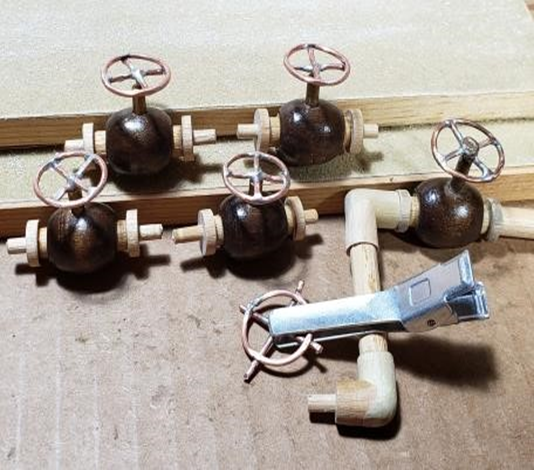

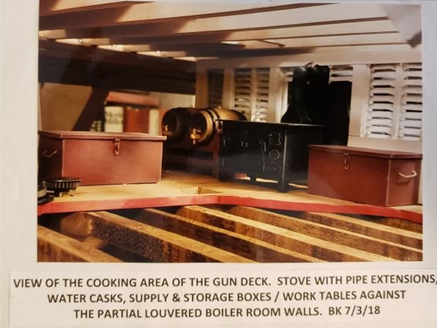

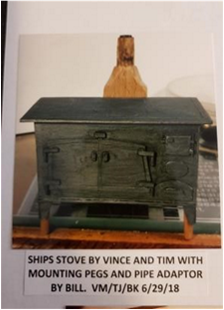

(more March 2020) Illumination in the Captain's Quarters Making water and steam valves in 1/24 scale: 1/4" Macrame Beads, 1/8' and 3/8" dowels, plus 16-gauge copper wire, and you are ready to become a steamfitter! Live steam pipe layout; Steam pipe elbows and T's measured, cut and assembled to form the live steam loop. Portside view of live steam loop. Main river water intake port through the hull. Valves control the direction of the river water in, and cleaning water out of, the system. Turned wooden support for goose pen valve just to add interest and color versus a block of wood. (Left Picture): Main water valves for the boiler and doctor engine: Inflow valves and water pipes to the doctor engine. (Middle Picture): Main in-flow valves and tap between them through the hull for river water. By opening and closing specific valves, this system could also be used to clean out a mud drum as well as the doctor tanks. (Right Picture:): Overview of the river system. Mud drum connection to main water valve and offshoot to water supply for goose pen. Valve to control flow of water to structure under the hot fire boxes (goose pen). Goose pen (loose brick in a tray with water circulation) kept the deck from being scorched by the high heat of the fire boxes. Quarter-inch dowel center drilled and cut in jig to fit at a right angle to a quarter-inch dowel making an elbow or a "T". Simple teeth cut on the end of a quarter-inch (O.D.) brass tube makes an excellent cutter when used with a simple wooden jig. Wooden jig and brass tube cutter cutting dowel. This was a demonstration cut. The real ones were center drilled first on the lathe with an 1/8" bit. Penny for scale. That's all for March 2020. The next entry will be from June or July of 2020. The Club did not meet as such for the next year or so due to COVID. However, Bill Kammermeyer posted photos and captions from work he did on his own. These will be posted in the next entry. Hope you enjoy these. Tim Jovick

-

(continuing with March 2020) Making track lighting: Extra hands needed to hold 1/8-inch-wide LED light strips for tiny lead attachment. Detail of tiny lead attachment to 1/1000" thick foil strip on 1/8" wide LED slight strip. LED strip is immobilized in wooden track by glued block at foil contact points and glued 1/16" wood strubs between lights. Block covers heavier wire and protects the thin foil contact points from being torn from the light strip during installation. These 3 shots were just to determine what illumination level that would look best with cannon and propulsion equipment in place. (sorry for the fuzzy images) More light testing, this time in a darkened room. Center line of lights was in three parts. Connecting wires went to the starboard track under the Hurricane Deck planking and then as a common line to the Hurricane Deck terminal. One line went from here to a junction box on the Gun Deck. The long wood channels were screwed to the underside of the Hurricane Deck and then the LED strips were installed with glued wood blocks at the connection points and glued wood stubs between the LEDs. Lighting the forward storage room. Illumination in the steam capstan gear room. Illumination in the bulk coal storage bunker. Illumination of loose coal in wheelbarrow and bagged coal in coal bunkers of boiler room. Posting now so as not to lose the photos. More March 2020 coming below.

-

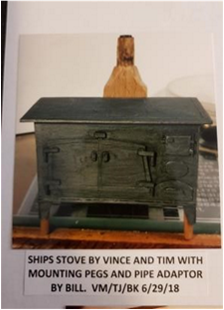

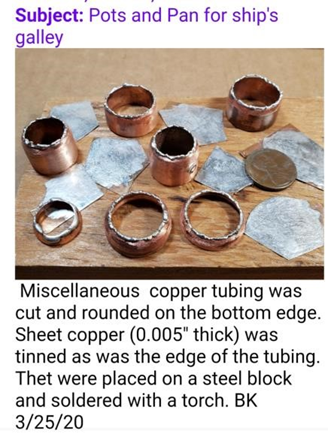

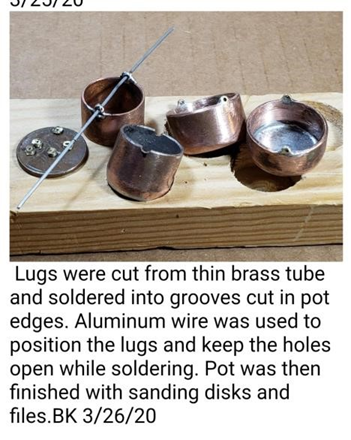

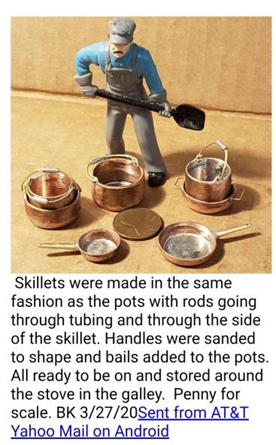

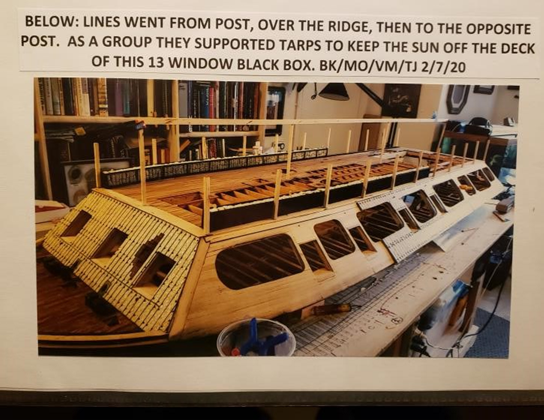

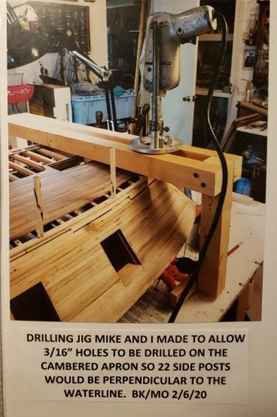

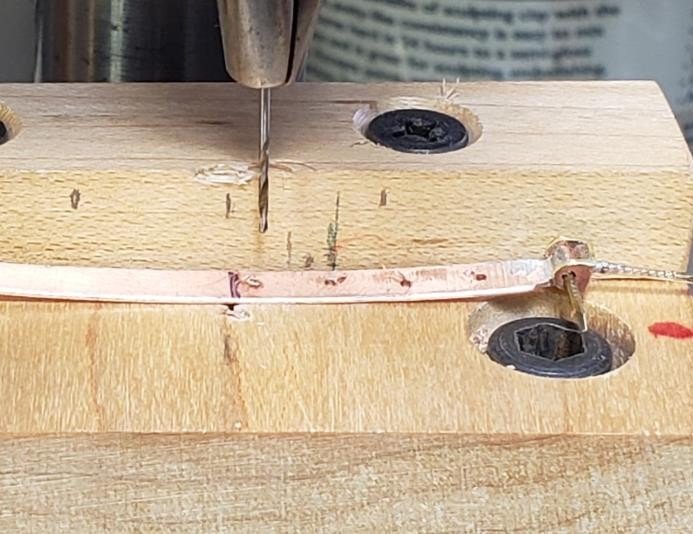

Hi all, Again apologies for my delay in posting entries from the Gateway Ship Crafters for some time. We've made a lot of progress since February of 2020, and indeed we're (maybe) getting close to the end, we'll see. So now we start with March of 2020 As the photos show, much progress has been made in designing and installing the micro-LED track lighting strips to illuminate the interior of the USS St. Louis. Stanchions for a canvas cover and the fashioning of pots and pans for the cook stove are also being planned. Work will also be done on building the launches plus other side projects. (Note that photos and captions are by Bill Kammermeyer) Making posts for a canvas cover on the Hurricane Deck. 3/16" dowels were cut into the ends of the posts for a centered, snug connection for the posts. This was the same procedure that I used for making axles on the axle trees of the cannons

-

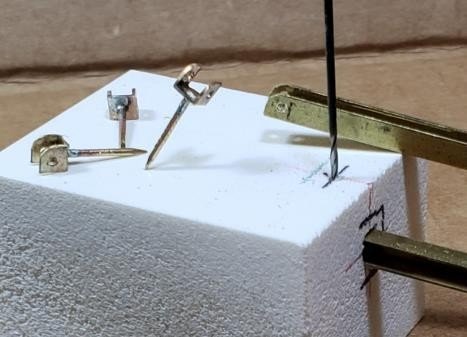

More from February 2020: When painted and dry-brushed, the seams should look quite realistic. Using a jig on the drill press and following pre-made marks as per plan, holes for the armor bolts were drilled. Modified brass pins with a washer and hex head pounded into them were placed in each hole and pushed flush with the surface. The bolts were placed in each hole for the lower band of armor, hammered flush and then cut and sanded flush on the back side. Every 6th bolt was omitted so that a full long nail could be inserted for extra strength after gluing. Mike and I attached Mike made the weather deflectors for the smokestacks that would run rainwater off the top edge of the insulating collars for the Hurricane Deck. They were center board pieces of maple that were then shaped to the plan dimensions by hand. I then enlarged the center hole on a spindle sander for a snug fit on the smokestack pipe. It will attach snugly to the smokestack and have no contact with the heat insulator below it. It will be covered with metal foil and rivets. Hard foam block used with a drill press to make uniform repetitive holes for hinge cups. After drilling center holes in bottoms of cups, holes were drilled for flat head pins which were soldered into place. One end was rounded while still on the brass stock, then they were cut to uniform size using a stop on my Mini- Chop Saw. The heads of the brass pins were tinned with solder and placed in pre-drilled bottom holes and heated with a soldering iron. There was instant attachment. Hanging a clip from the bottom of the nail caused it to drop down flat in the hole as soon as the solder was liquid. Other side of the cup was rounded holding it by the pin in a pin vise. Holes were evenly spaced on the hinge strap. Referencing mark on back of the wooden guide made for even spacing of holes Brass pin joined the strap and the cup with a brass hinge pin cut and peened to finish the assembly. Only 50 more to go! Bow gun port doors Working gun port doors. Making cleats out of 1/8” brass rod, for the ropes to the gun port doors. Sorry for the small size of photo and fuzziness OK, that's all for February of 2020. March 2020 comin' up!

-

OK, more from February 2020: again, pictures and captions are by Bill Kammermeyer. Outboard horizontal plank scribe lines to be cut for gun port lids. Used a vibrating multi- tool and a Square to scribe the lines. Using a strip holder for the gun port lid stock, vertical inboard scribes were made with the multi-tool and jig. Wood at center was used as a straightedge guide for the jig using the adjustments front and back. Strip at side was a guide for both outside scribe lines. The jig was then used for the center line cut. Use of a foot control on/off switch made cutting the lines much easier and safer. Detail of fine scribe lines in gun port lid stock. Each took about 4 seconds to make and were very accurate with controlled depth. The gun port stock represents a two-layer lid construction. Horizontal planks on the outside and vertical planks on the inside. A differentiation line needed to be run down the center of the quarter-inch stock. The multi-tool in its jig was clamped to the side of the workbench. The lid stock was run along the side of the workbench at the correct height and the line cut into the stock in about 5 seconds. This type of construction was chosen to eliminate the need of laminating individual strips of wood and trying to keep them square and true. Also, there is no worry about delamination 45-degree holes are drilled in the centers for cannon barrels. View of the cutting blade 1/8-inch above the surface of the workbench surface. Center line cut may be seen on the facing edge of the stock. The lids will be pre-cut and the cannon holes drilled individually for the specific height of the cannon caliber. All doors will be painted black so the sugar burn on the Maple will be irrelevant. Gun port doors rough-cut to size from pre- scribed strips. 45 degrees at both top and bottom. Rough cut doors are checked for fit. Mike and I measured and marked the gun port blanks for the 45-degree-angle hole for each cannon. The doors will be cut across at that horizontal center line so cannon may stick out. Practice blank to establish center height for each caliber of cannon. Hole was drilled at 45゚ angle for proper alignment in casement. Actual gun port doors cut and rough fit for each caliber of Cannon. Bottom portion of gunport doors on casement sides will be in a closed position while the top portion will be open and held at a horizontal plus angle. Strap hinges will be added later. Before doors were made stops had to be placed inside each port. A jig (right) Was made to match door thickness and then stops were applied from the inside against the back of the jig. Stops were installed, glued and clamped (left). Using a 4-tooth vibrating blade on the modified on the multi-tool, I was able to cut controlled horizontal seam lines as seen here in a freehand practice session. I set up a straight edge on the seam line and cut every other armor plate in a very controlled fashion using a tool on/off switch. The tool again worked very well, and no extra blade need be purchased. I just ground out a flat spot on the 300-degree “half-moon” blade that left 4 teeth that moved only a few thousandths of an inch per stroke. OK, moe from February 2020 hopefully coming shortly. Please to enjoy. Tim

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.