-

Posts

728 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Seventynet

-

Beautiful job, Doc! I greatly enjoyed watching this progress. Ian

- 143 replies

-

Paul, just a beautiful job. You should be very happy with the result. Can I ask what’s next? Ian

- 72 replies

-

- Glad Tidings

- Model Shipways

-

(and 1 more)

Tagged with:

-

Honestly Chuck with these endless innovations you are making it is hard for me to continue with my nascent build of the Speedwell. I think I may just have wait until your kits are available. Outstanding work! Ian

- 778 replies

-

- speedwell

- syren speedwell

-

(and 1 more)

Tagged with:

-

Swan Class by Stuglo - FINISHED - 1:48

Seventynet replied to stuglo's topic in - Build logs for subjects built 1751 - 1800

Beautiful work! I enjoyed following your progress. Thanks for sharing. Ian -

Thank you, Bob! Every time I visit my daughter’s place and see the model displayed I think it has to be one of my favourite builds. Ian

- 107 replies

-

- brazzera

- marisstella

-

(and 1 more)

Tagged with:

-

Beautiful work Chuck. So innovative. I’ve started mine but not enough work to report yet. Ian

- 778 replies

-

- speedwell

- syren speedwell

-

(and 1 more)

Tagged with:

-

Very, very well done, Bob. Congratulations you should be very proud. Ian

- 111 replies

-

- Nonsuch 30

- Model Shipways

-

(and 1 more)

Tagged with:

-

Absolutely masterful job, Greg and beautiful carvings David! I look forward to building this and hope I can come anywhere close to this. This build log and your books will certainly be a massive help. Ian

-

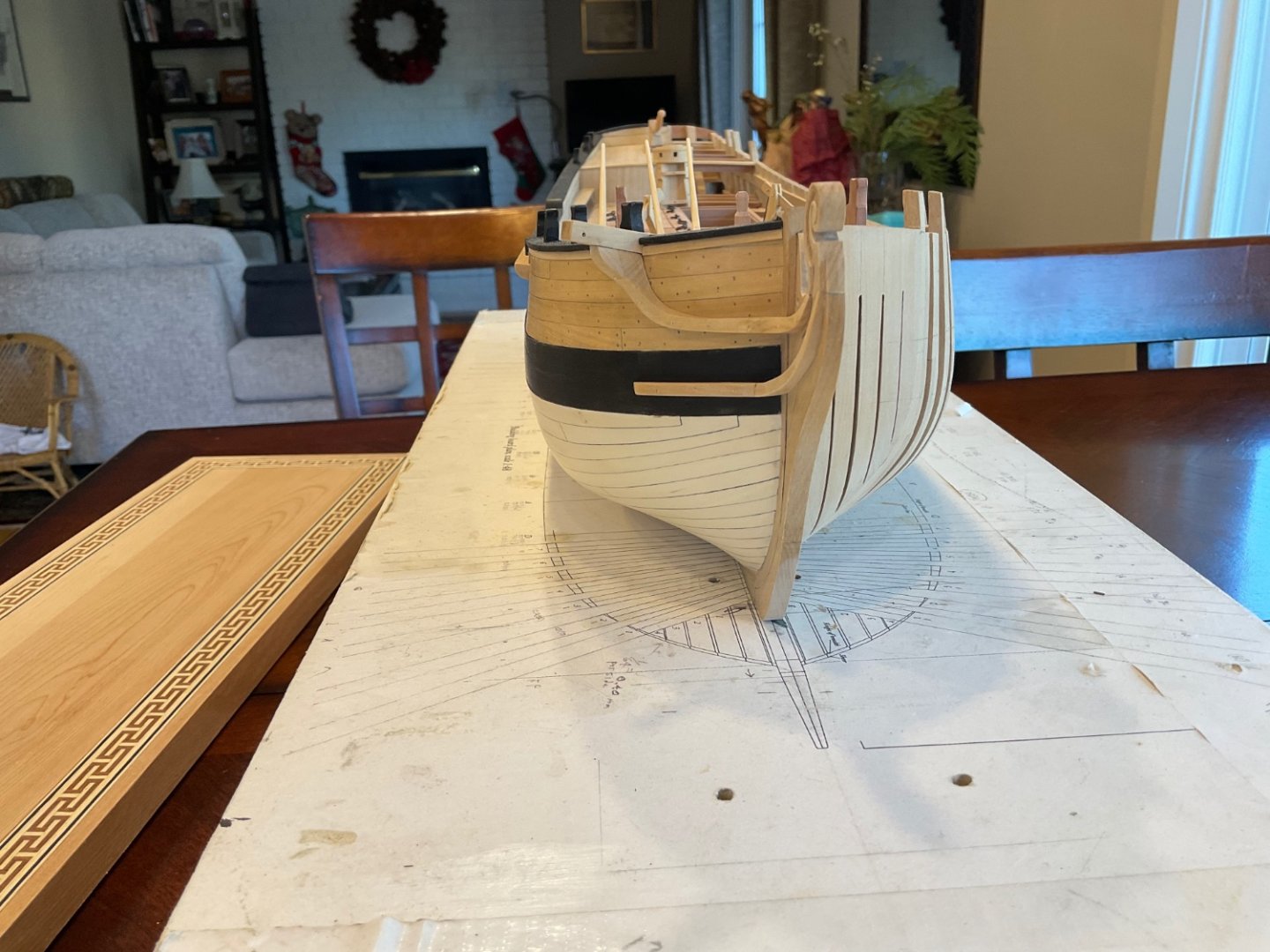

Hi Jim, thanks a lot. I am going to tackle David and Greg’s Speedwell scaled up to 1:32, the same scale as Chuck’s but fully framed. I am hopeful that I can make use of some of Chuck’s add-ons but I’ll have to keep an eye on my build and his to maximize the potential for that option to work. Anyway, the building board today. Ian

-

Thanks all for your praise: Chuck: thanks but I’ll say it again, building your models was no small influence on my ability to get where I did! Yves: thanks so much. Greg: thank you kindly. Now I will be held to your and David’s standard again as I start the Speedwell. VTHokiEE: And I continue to enjoy your Echo build! Keith: thanks for following my build and all the likes and comments. They really make a difference. Paul: Many thanks and keep up the superb craftsmanship. Chris: thanks a lot, much appreciated! Captain Hook: thanks for saying so! Mike: thanks! jpalmer: Thanks again! Vladimir: thanks and thanks for following along! David, yes I will have to get a case down the road. Ian Ben: thanks indeed!

-

This is beautiful! I assume you used your mill for the lights? I’m interested in your next steps to finalize them (my own attempts frustrated me!). thanks, Ian

- 885 replies

-

La Palme by Tobias - 1:36 - POF

Seventynet replied to Tobias's topic in - Build logs for subjects built 1501 - 1750

Beautiful work Tobias. I’m really enjoying your build. ian -

Hi Alan, thanks a lot. That headboard has come in handy for I don’t know how many projects. It just keeps giving. Paul thanks, it is but a shadow of your work. Thanks for following. Hi billocrates, keep at her. It’s nice to hear that I’m not the only one building this beautiful ship and look forward to seeing yours soon. Thanks Jim, good luck with your Mayflower. I appreciate it Tobias and I will continue to follow your superb build. Thank you of course druxey. I have a very specific idea of what’s next but will need your advice before I finalize my plans. You’ll see a pm soon. Ian

-

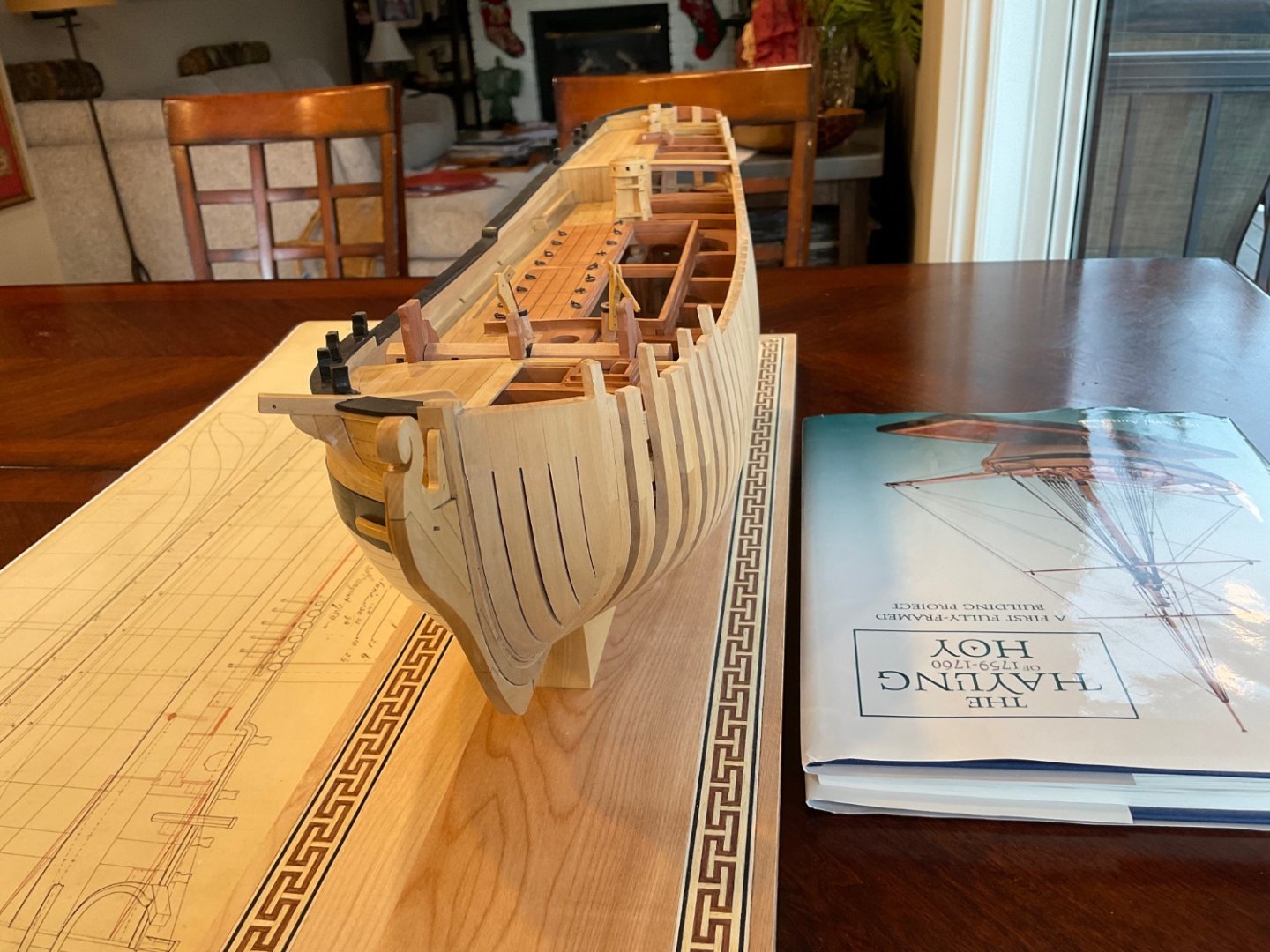

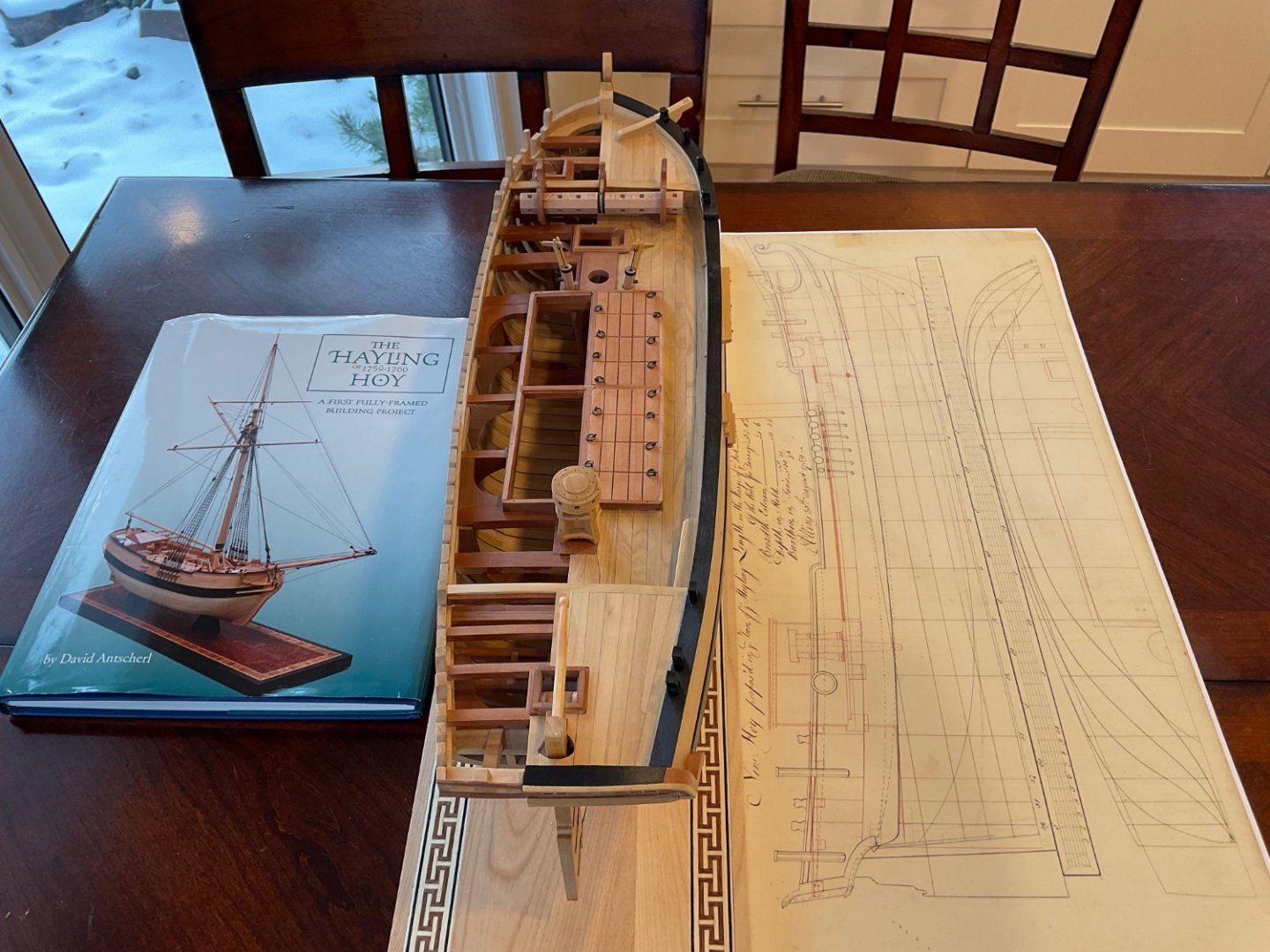

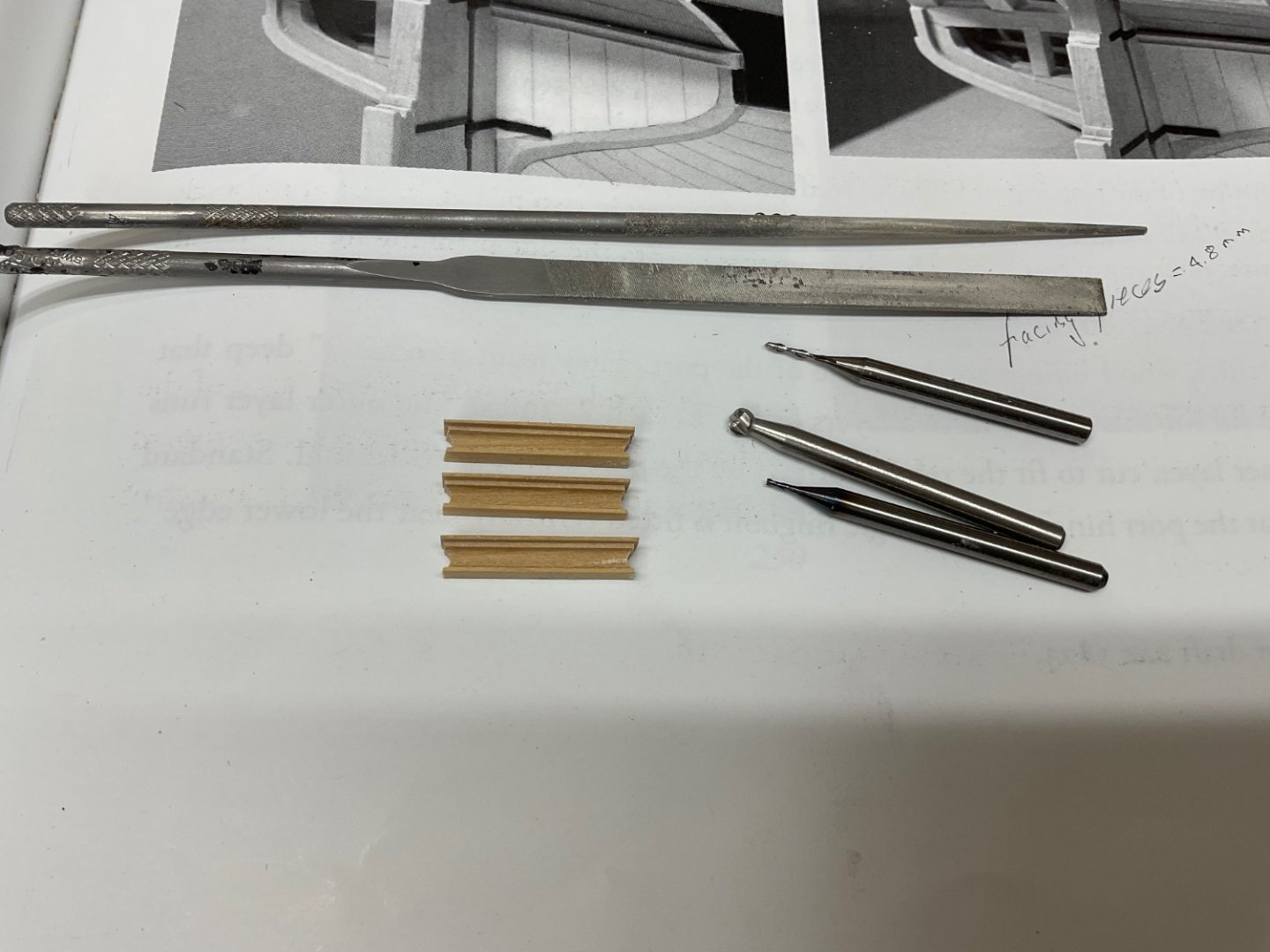

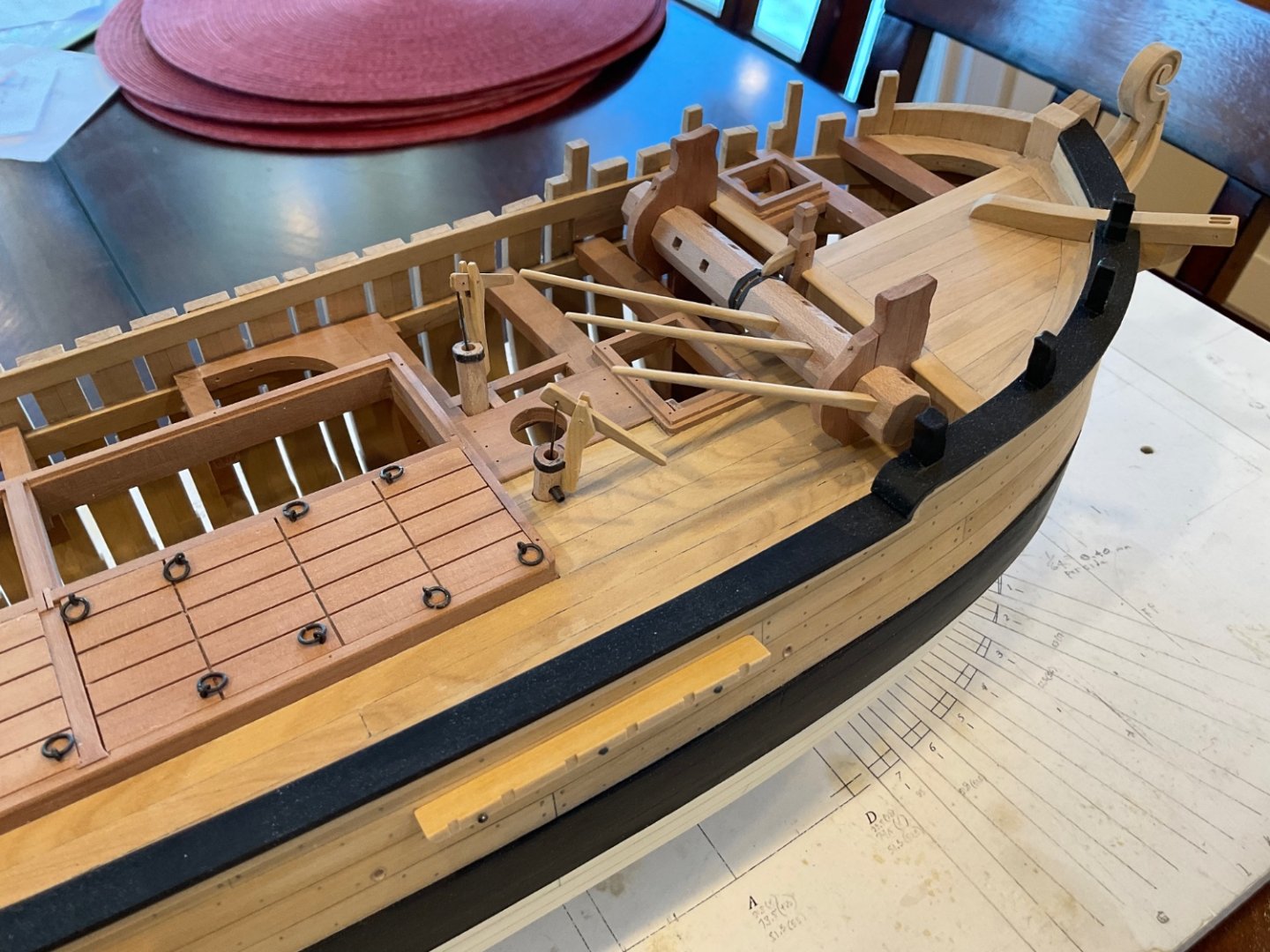

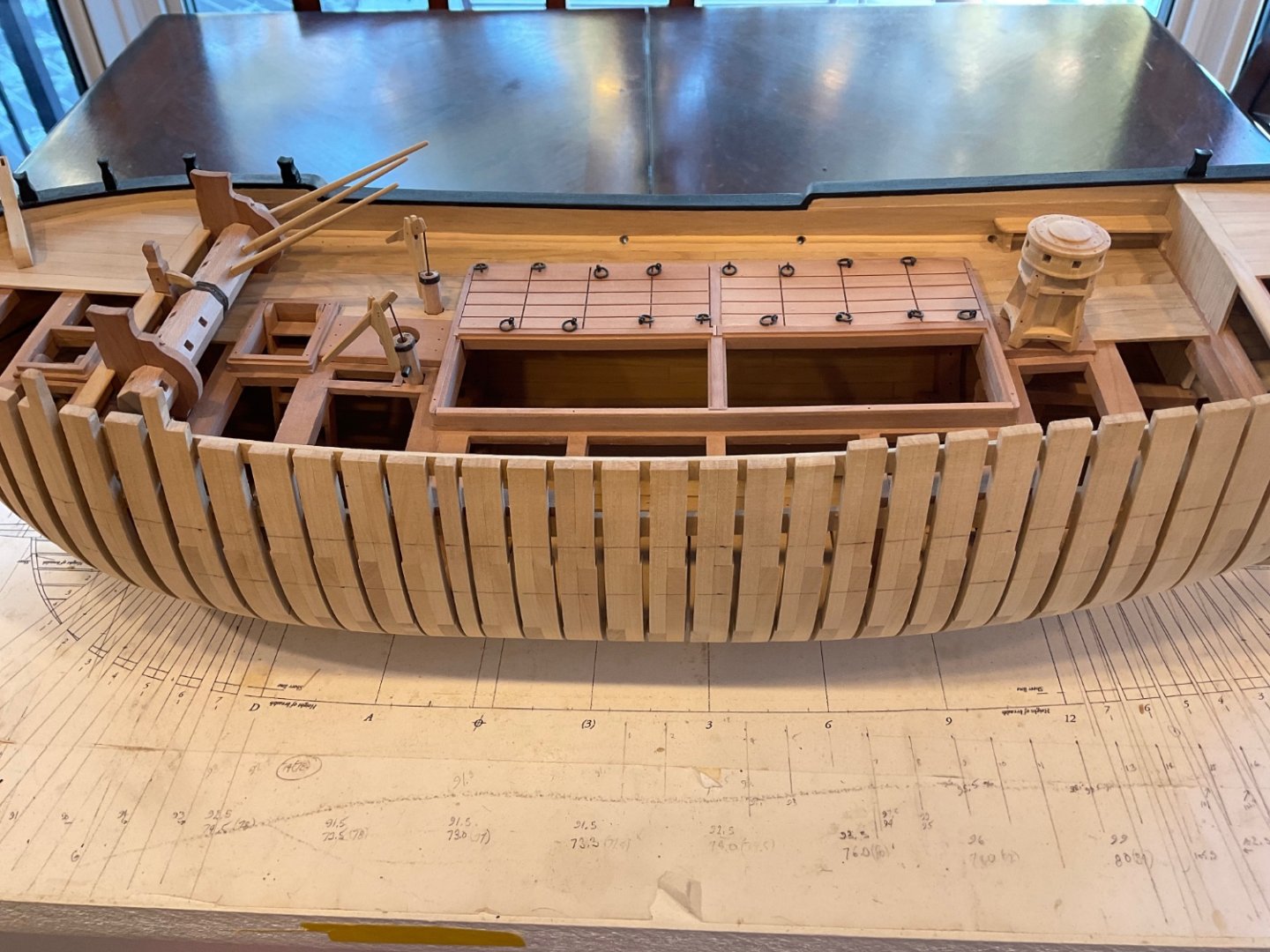

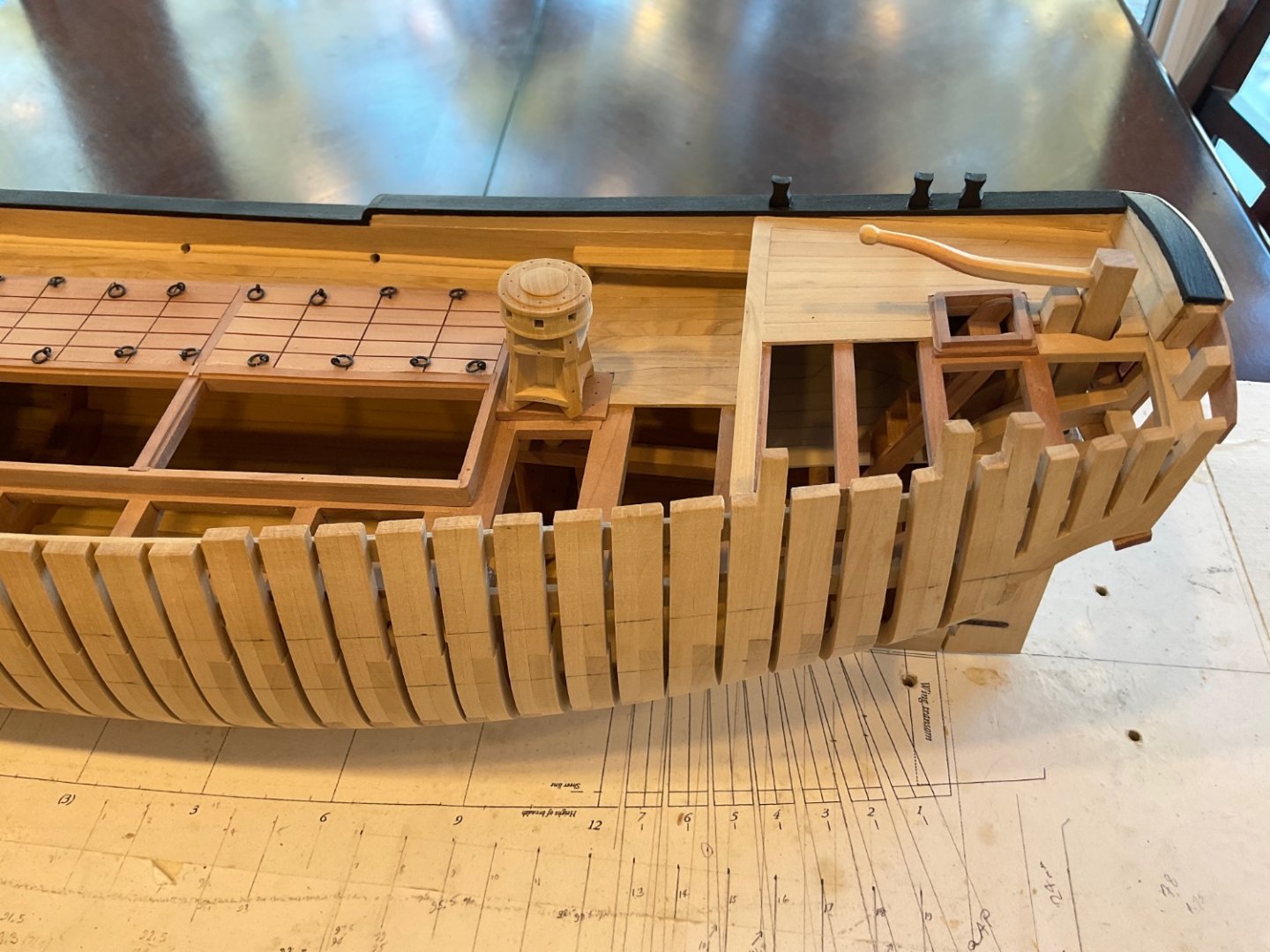

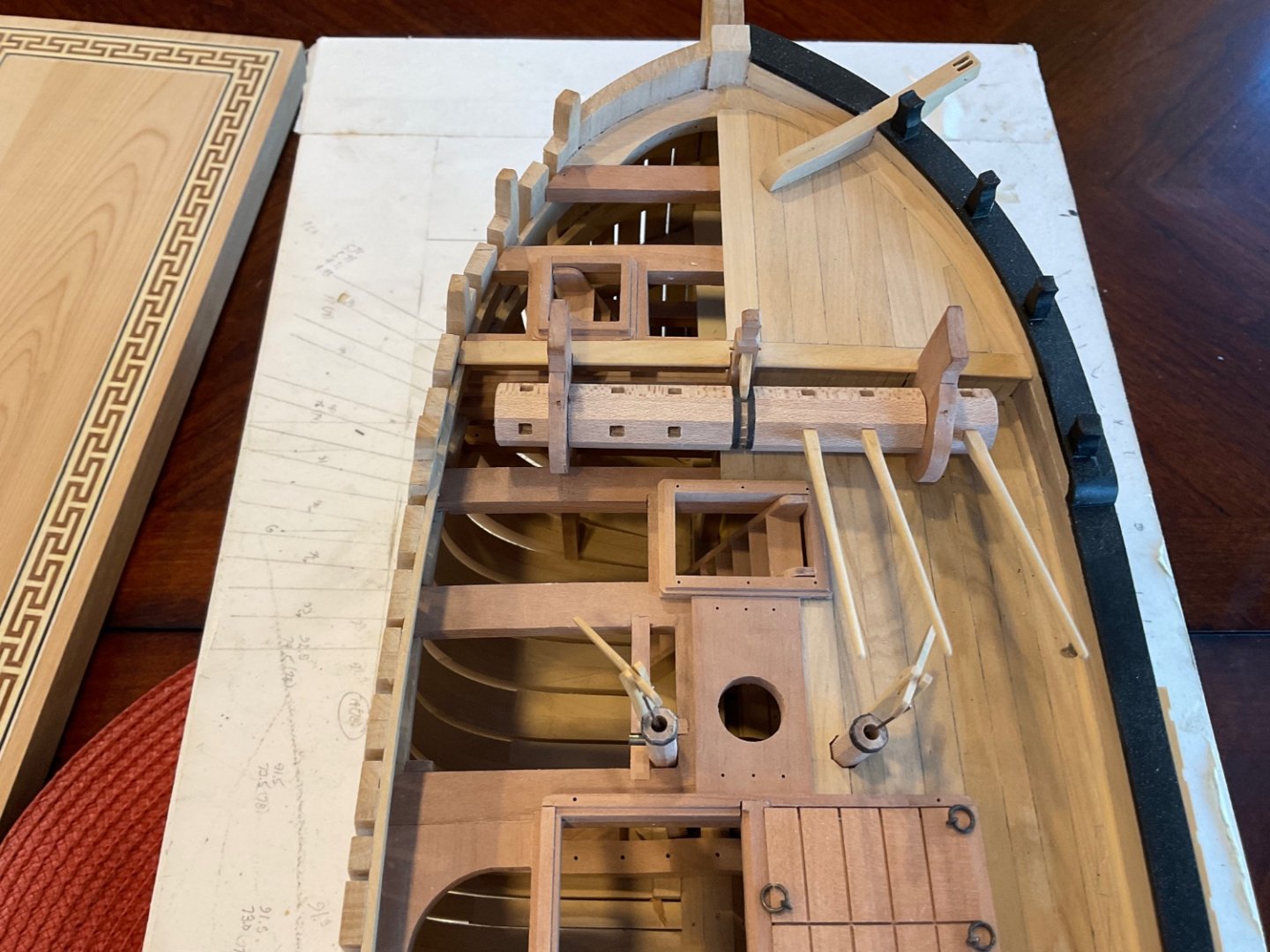

Good Day, and thank you very much for the comments and likes. I am just about finished this project. I don’t plan to rig it, I just don’t have room. Let me start by giving a short review of what I did since last time. I have very little in the way of photo documenting the steps I took for each operation because for the most part they are unremarkable and probably of little interest…with one exception. That is the stern lights. I struggled mightily with those and after at least three tries using different approaches for each light I succumbed to frustration and plugged in my last pathetic version. The one positive thing I will share is discovering that old negative film (my wife’s idea) works great as windows. It readily glues to the wood with CA and the edges actually sand well. Now I will confess I actually made a single light that was close to perfect with the exception that I constructed it backwards so it wouldn’t fit. That was the last straw. The method I used for this last successful but abandoned attempt was to trace the outside of the opening insitu onto a piece of scotch tape, then trace the location of the borders and mullions. I lay the tape upside down sticky side up on the bench, fixed it in place with tape. I added the required impossibly narrow frames (0.4mm as I recall) directly onto the sticky tape marked out lines, progressively re-dimensioning the pieces until they were a perfect fit ready for glue. The sticky surface made offering up and fixing the pieces much more feasible. The stern work started with the taffrail covering board of Holly. I cut a curved single piece which sufficed. Facing pieces of pear were placed between the lights to make the aft face of the outer counter flush. A quarter piece was made to conform to the top of the wale and the edge of the stern. While guidance suggests doing it in two pieces and I can see why that may hold some advantages I decided to start with a single piece. That worked out ok. Once those were finished and the lights installed, I added small pear strips to the lights base to round out the pear framing. I then added an ornamental rail (drip rail) to run along the knuckle of the counter. I see I still need to add treenails to it. The ornamental scroll was made to fit the external curve of the stern. Big head scratch for how and where the timber port stops and lid are to go…? The planksheer was more challenging than I initially anticipated but it’s all about patience. The first step is to card shape the curve (I cut all pieces to curve; no edge bending) and the holes for the timberheads. Incremental filing is the name of the game here. There just doesn’t seem to be any point in painting the timberheads beforehand as the paint will just be scraped off after the thousandth fitting. The rest of the effort is to get a flush fit to the interior plank and to the top of the frames and planking. I painted the interior edge before installing. The thin finishing strip of Castello underneath the cap rail, the planksheer rail, was straight forward and glued on after I finished painting the planksheer and timberheads. The channel for the chains and deadeyes was made from a quarter round cut from a lathed piece of Castello, notches milled and a very slight round up sanded in to conform to the hull line. Three bolts were installed. The entry steps were milled using an end mill and a burr as shown. The bottom piece was glued on and the the length cut for the three steps and the ends filed. A tiny round up was necessary. The break pumps were fashioned as described in TFFM. I still need to file home the brass ends and blacken. I made the stand out of an old maple headboard and routed in the inlay which I got from Lee Valley. What’s next and final? Basically a lot of cleaning up, varnishing, some trenailing, make the pedestals and mount the Hayling Hoy. Sorry, no real sequence to the pictures. See you next time.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.