-

Posts

12 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Vtwoods1027

-

I think I made some progress!!! The hull structure is in a pretty good shape and I think I can actually move on. I faired the deck surface and then moved on to the bulkhead. There was a LOT OF GAP between the bottom of the bulkhead and the rabbit line. I added some filler wood and sanded them down using little dowels with sandpaper glued to them. They look pretty good now. Also, I carved (actually sanded) the filler block into position on the stern of the ship. As I stated before, the plans and parts don't quite match up, but a little extra work makes everything smooth. Hope you all are having fun!

- 17 replies

-

- pride of baltimore ii

- model shipways

-

(and 1 more)

Tagged with:

-

Hi there everybody, Kind of a shotgun approach to the update today... I have been working on two different aspects in parallel, this ships boat and fairing the hull. I used the plans to make hull aspect guides... Applied to the sides of the ships boat, I did a lot of sanding and got the outside of the hull in pretty good shape. The inside needs more work but some wood filler and lots of sanding/patience should get it in decent shape. That's next weeks work. Traced out the transom filler blocks and installed them. Please note that I am receiving help from the next generation of model shipwright. One nice thing that I kind of learned.... I placed extra braces in just about everything (see help from 2 y.o.) to make things much more robust. Sanding them down proved to be challenging, but I learned that by alternating between a 1 bulkhead, 2 bulkhead and 3 bulkhead sander, the taper angle just kind of 'averages out'... so some repetitive work, but the shape is basically forming itself.

- 17 replies

-

- pride of baltimore ii

- model shipways

-

(and 1 more)

Tagged with:

-

A more light hearted post... first of all thanks to Karl for the links. I am working on the boat a bit now... I'll post more a bit later. But in the meantime. Its Saturday morning, wife asleep (she is a night NICU nurse), toddler occupied with siblings and I have a few hours of boat building. I am working on frames to shape the hull of the ships boat, watching a documentary on early jet development and generally really enjoying model shipwrighting. Such a great hobby that lets you be creative, work with your hands and still be pretty technical. Enjoy your day all... oh yeah... I am also cooking up french onion soup for dinner!

- 17 replies

-

- pride of baltimore ii

- model shipways

-

(and 1 more)

Tagged with:

-

Hello all - Just a quick update. I spent the weekend re-enforcing the false keel and bulkheads with some scrap that I had from the last model. Probably overkill, but I was concerned that the bulkheads seemed to move quite a bit when I was sanding the edges to get the taper edges more symmetric. I will generate a lot of saw dust in the next week, but the center keel/bulkheads are 'iron-tight' now. Oh yeah, please note that I have to do all this in the kitchen so my little klein tool bags are my life line to being organized (I love tools).

- 17 replies

-

- pride of baltimore ii

- model shipways

-

(and 1 more)

Tagged with:

-

Hi everyone, Quick question. Is there a POB-II build log that covers the ships' boat? I want to get a head-start. Thanks -vincent.

- 17 replies

-

- pride of baltimore ii

- model shipways

-

(and 1 more)

Tagged with:

-

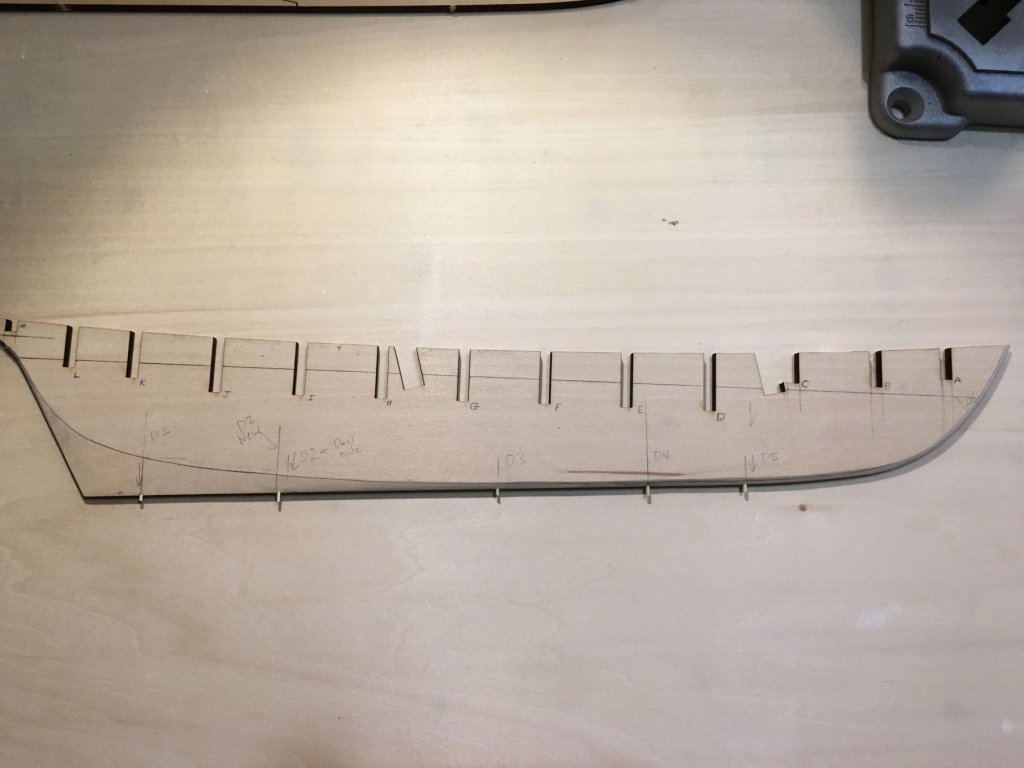

Lots of fun on the 3 day weekend! The first job was to place (again) the reference line on the bulkheads. This is tricky because I want them to be symmetric on both sides of the bulkhead. Making a measurement on one side and then flipping the bulkhead over to repeat the measurement is asking for some sort of systematic error. So, I used the machinist parralel blocks and plates on scanned plans to create a frame to make the marks. Also, I got the building board started (and finished). I was super happy to find some machinist parrallels in 3/16" thickness. They were really cheap and make so many tasks easy now. Bulkheads are going on one at a time with a square and the reference line matched up. I will post later on this, but the plans and pieces are really off.... by at least a 1/16". I can shim up the parts later, but its remarkable that they are so far off. Not complaining, just observing.

- 17 replies

-

- pride of baltimore ii

- model shipways

-

(and 1 more)

Tagged with:

-

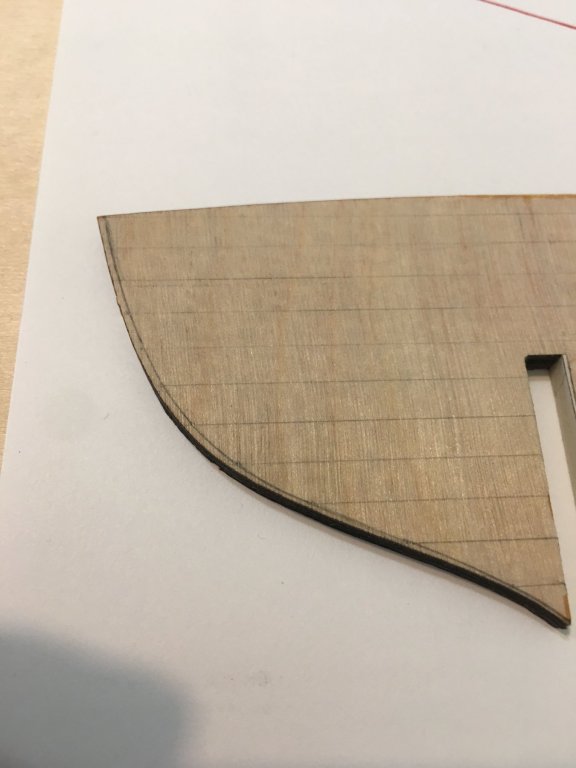

Hi there Everybody. Thanks for the kind words of encouragement. I appreciate it. My family is lovely and can feign a certain amount of excitement, but its so good to hear from fellow enthusiasts. Here is the latest update. I have completed the tapering of the keel!. It was a little tricky and I am pretty proud of how I got it accomplished. The plans show the tapering of the keel, so I made a rough sketch in my build log. I glued together 1/64" thick engine valve lifter shims, which I could then use to mark both sides of the keel to define the profile of the taper. At several points, I made reference tapers... using a super soft pencil mark (5B) on the top of the keel to indicate if I was sanding on the top of the keel. Repeat, repeat, repeat and then carefully sand the remaining parts of the keel to make a smooth symmetric taper down the center. Lots of saw dust (man glitter) but its done.

- 17 replies

-

- pride of baltimore ii

- model shipways

-

(and 1 more)

Tagged with:

-

Greetings to all fellow model shipwrights. I am working on Model Shipways Pride of Baltimore II. I have done a few previous kits from Dumas and MidWest, with some rather nice results and have decided to make this a lifetime hobby. I'm throwing this build log up to get some help as I go along and provide some inspiration to others starting out. I am thinking that I am a younger member here (43) and love that this hobby is still going on. A little about me, so that all other readers can get where I am coming from. I am a nuclear physicist. I grew up on the chesapeake bay and my father had a Morgan 28' outisland that I learned to sail on. I'm a bit of a perfectionist and love how this hobby combines the meticulous nature of a technical build with the final result of a beautiful piece of what I would call architectural art. Here is where I am at... early stages. I got the kit and set out to getting started. One thing that struck me was the imperfections of the cuts and plans... A lot is off by ~ 1/16th". I know that this is art, not technical designs, but my machinists would have kittens if I provided parts this far off. That being said, I have been consulting a great book that my wife gave me; "Ship[ Modeling Simplified" by Frank Mastini. So far, it has been crucial in getting the bulkheads symmetric and centered. Here are the current pictures. I have tapered the false keel and used machinist blocks to get dowels (I filed down tooth picks) centered. I glued the keel/stem assembly to the false keel. Also, I have marked (the now centered and symmetric) bulkheads for tapering. One extra note that makes this build a little more difficult and unique. I have a 2 y.o. son who thinks that the most important thing in his life his to get his hands on the parts and 'help.' My wife is a NICU nurse who works nights so I have a lot of parenting time, and building this model is a little harder with a toddler trying to crawl up your leg.

- 17 replies

-

- pride of baltimore ii

- model shipways

-

(and 1 more)

Tagged with:

-

I took the deck and made a false deck mold.... added on top 3/32" by 1/16" planks... doing a four offset butt setting. It's getting there... I will mix up flat white paint and thinner to simulate a newly holystoned deck. Sorry about the delay in updates. My wife and I are expecting our first child (together) in a few weeks and she has a large "honey do" list.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.