-

Posts

202 -

Joined

-

Last visited

About liteflight

- Birthday 02/24/1949

Profile Information

-

Gender

Male

-

Location

Melbourne, Australia

-

Interests

Scale sail, model flight

Recent Profile Visitors

-

druxey reacted to a post in a topic:

Paddlewheeler Golden City by Louie da fly - Scale 1:50 and 1:25 - solid hull

druxey reacted to a post in a topic:

Paddlewheeler Golden City by Louie da fly - Scale 1:50 and 1:25 - solid hull

-

mtaylor reacted to a post in a topic:

The San Marco mosaic ship c. 1150 by Louie da fly - 1:75

mtaylor reacted to a post in a topic:

The San Marco mosaic ship c. 1150 by Louie da fly - 1:75

-

mtaylor reacted to a post in a topic:

The San Marco mosaic ship c. 1150 by Louie da fly - 1:75

mtaylor reacted to a post in a topic:

The San Marco mosaic ship c. 1150 by Louie da fly - 1:75

-

Cathead reacted to a post in a topic:

The San Marco mosaic ship c. 1150 by Louie da fly - 1:75

Cathead reacted to a post in a topic:

The San Marco mosaic ship c. 1150 by Louie da fly - 1:75

-

Thukydides reacted to a post in a topic:

The San Marco mosaic ship c. 1150 by Louie da fly - 1:75

Thukydides reacted to a post in a topic:

The San Marco mosaic ship c. 1150 by Louie da fly - 1:75

-

liteflight reacted to a post in a topic:

Mistydeefer by Louie da fly - FINISHED - RESTORATION - decor yacht

liteflight reacted to a post in a topic:

Mistydeefer by Louie da fly - FINISHED - RESTORATION - decor yacht

-

BANYAN reacted to a post in a topic:

The San Marco mosaic ship c. 1150 by Louie da fly - 1:75

BANYAN reacted to a post in a topic:

The San Marco mosaic ship c. 1150 by Louie da fly - 1:75

-

BANYAN reacted to a post in a topic:

The San Marco mosaic ship c. 1150 by Louie da fly - 1:75

BANYAN reacted to a post in a topic:

The San Marco mosaic ship c. 1150 by Louie da fly - 1:75

-

Egilman reacted to a post in a topic:

Scrappee Liaison by chadwijm6 - Microaces - RADIO - Finished

Egilman reacted to a post in a topic:

Scrappee Liaison by chadwijm6 - Microaces - RADIO - Finished

-

mtaylor reacted to a post in a topic:

Scrappee Liaison by chadwijm6 - Microaces - RADIO - Finished

mtaylor reacted to a post in a topic:

Scrappee Liaison by chadwijm6 - Microaces - RADIO - Finished

-

Canute reacted to a post in a topic:

Scrappee Liaison by chadwijm6 - Microaces - RADIO - Finished

Canute reacted to a post in a topic:

Scrappee Liaison by chadwijm6 - Microaces - RADIO - Finished

-

Mmmmm. Scrappee requires very light radio gear and servos and flies on a single lithium polymer battery ( 1S, or a nominal 3.7volts). Your Heli gear may well be “standard” radio, where the servo plugs alone weigh more than a micro-servo ( about 1.5 gms) Unless you are seeking the ultimate in lightness, the equipment does all plug together, and probably requires no soldering at all. For anyone interested, all the equipment to fit out Scrappee is available on the Microaces website as well as the rest of their model range I’m an indoor flyer, but have no relationship with Microaces, other than as a future customer ( I fancy their DH Dragon Rapide) andrew

-

Amusing; close, but no cigar! Named after lord Melbourne (?) Brit foreign Secretary, who took his title from the village of Melbourne in Derbyshire. Melbourne means the place of Melde Melde is Chenopodium Album, commonly known in UK as Fat Hen, and was cultivated in the Middle Ages as a vegetable and eaten a bit like spinach. Note: there are dozens of Melbournes in Britain, as the stuff grows everywhere It could have been worse. He might have taken the title of Lord Fat Hen! sorry to have hijacked your thread, Steven. I’ll climb back under my flat stone andrew

- 379 replies

-

Steven If your travel plans included Melbourne* in the foreseeable future, I have about a pint (imperial) of Matt Acrylic Medium, and you are welcome to a dollop ( as well as a box of box) I believe that the pouring medium is relatively very runny, and so contains a lot of acrylic solvent. The Matt medium is more pasty than liquid, and for the application of seams to sails would have to be diluted a bit ( acrylic thinners) or applied with a weeny roller Fwiw, I use a satin acrylic varnish as an adhesive for tissue/cloth, etc, . Most probably it comes as a matt version as well * As far as I am aware the only State Capital named after a vegetable. I exclude Brussels as that was t’other way about andrew Pumped from looping a Concord model today, indoors and by accident!

- 379 replies

-

liteflight reacted to a post in a topic:

21' Fisherman's Launch by Vaddoc - Scale 1:10 - Plans from Howard Chapelle's "Boatbuilding"

liteflight reacted to a post in a topic:

21' Fisherman's Launch by Vaddoc - Scale 1:10 - Plans from Howard Chapelle's "Boatbuilding"

-

In a Blinding Flash of the Obvious I have just realised the wakeboard is the modern embodiment of the green plastic foot-base on toy soldiers! Steven’s comment above triggered the BFO The rudder/tiller combination is fully reversible - all wave forces, shocks and running into dead second-hand hippppopotomi will kick back into the tiller and the steersman’s ribs if the stance is correct. Big regular forces (waves) could probably be resisted by a good lateral stance. Additionally there would be frequent small shocks from the hydrodynamic forces and possibly these would make the steersman’s ribs painful, calloused or both None of the above is unique to the trailing tiller system, it is just that ships of this era had, essentially, very short tillers (compare with the length of tiller of say a Naval Cutter or Brixham Trawler) which would make the steersman’s strength a necessity. As a spokesman for the Department of Useless Information (DoUE) I can observe that the an old term for the Steersman was Gubernator ( Latin) from which we get the terms Governor (US) fly-ball governor ( engineering and frequently US) “Guvv’nr/ Gov” ( London Cabbies) Parthian thought: you could carve yourself as photographed*, Steven, to make the model truly distinctive *with or without wakeboard andrew

- 379 replies

-

Wire will make the strongest, especially if you use steel wire. I’m not sure of the diameter of the stanchions and rails but at the scale I would guess they would be in the 1 to 1,5 mm region, You could consider different materials like plastruct extruded sections ( ABS material ) which can be joined by solvent welding, but they might not be strong enough take even light handling. Brass is easy to cut, solder and finish. If you use steel wire - do not use the wire available in model shops, as this is Piano wire ( music wire to our US cousins) which is high-carbon, very hard and stiff and therefore quite difficult to cut to identical lengths, bend to repeatable curvatures, etc. Engineers would say it is almost glass-hard. Soft iron wire is probably too soft, but is easy to work, bend and solder*. Samples are florists wire and some fence wire. Bunnings do big hanks of garden wire - might be worth a look. Piano wire can easily be tempered back to a useful hardness - same as your Uhfbert sword, but much faster ‘cos of its thinness. Heat to dull red and allow to cool in air will produce very soft temper *With the correct flux! Sorry, I have rabbitted on too much. soldering easily learned - especially when shown the method. Probably Pat’s resistance soldering setup is readily controllable and he might share his wisdom about it 4 secrets** of good soldering: Cleanliness Cleanliness Right Flux Cleanliness Enough Heat! **. Like the Garden of Five Surprises

- 29 replies

-

- Paddlewheeler

- Paddleboat

-

(and 6 more)

Tagged with:

-

Yes, but the staples then rust. Me, I use masking tape to hold the covering material to frames made of 1/4 square hard balsa ( 6 mm in newfangled money) I have heard of people buying old pictures in Op Shops ( Charity Shops, Thrift Shops) and scrapping all but the frames. If made in the last 30 years the frames themselves are probably Ramin Thank you for the glimpse into carving real chaps from fruit-wood. We can just hope that you find a source of boxwood. I like the photos of You-as-steersman. Good way to visualise the stance. I do wonder how much the tillers would kick back in choppy weather and do the steersman’s ribs a power of no good. He would also probably ( my speculation) need one foot thwartships to brace him against the kicking of the tiller Were there two steersmen, one per rudder? And how did they communicate and coordinate the steering? Two independent quarter-rudders make it possible to get considerable braking by turning both inboard (or outboard, but that would require longer arms!)

- 379 replies

-

Good knees, Steven and blocks and owners/crew/cabin boy

- 379 replies

-

Nice idea of the jig ensemble - it works in principle even if it may need modifying in detail. AND At least the frame squarifying jig will work on any future ship that has frames and a reasonably parallel keel.

- 379 replies

-

Lovely work Steven, and fascinating research and evidence from the massed ranks of MSW stalwarts. My belated tuppence worth: All that has been said about curved keels is true and very valid. I can attest to the fact that even the slightest rocker in a keel improves turning ability enormously ( I used to race R/C yachts for amusement) Better turning = less rudder movement to get the required turn Less rudder movement = greater boat speed I remember reading the detail of the keel of one of the big, excavated Viking burial ships (almost certainly Oseberg) and learning that the main keel member was a single riven oak log. What boggled my tiny mind was that the overall length was iirc over 80 feet ( 24M) with over a foot ( 300mm) of rocker. ( as well as the complex cross section to accept the garboard strake) Good jig for the mast steps! andrew

- 379 replies

-

liteflight reacted to a post in a topic:

Henry Grace a Dieu (Great Harry) by Louie da fly - FINISHED - Scale 1:200 - Repaired after over 50 yrs of neglect

liteflight reacted to a post in a topic:

Henry Grace a Dieu (Great Harry) by Louie da fly - FINISHED - Scale 1:200 - Repaired after over 50 yrs of neglect

-

liteflight reacted to a post in a topic:

Stagecoach 1848 by John Bartley - FINISHED - Artesania Latina - 1/10

liteflight reacted to a post in a topic:

Stagecoach 1848 by John Bartley - FINISHED - Artesania Latina - 1/10

-

Steven, Blast from the past, which might be answered while you are gathering your equanimity The shallop/ chaloupe/ ships boat. it appears to be about the size of a ladybirds wingcases ( ladybug to our US cousins) could you give me the overall length, please. I have just looked back through your build and the wonderful pics of the finished boat. Judging by the scale on your cutting board, and the VAST match, it seems to be close to 45mm long I have a sudden fancy to (try to) make one, or more. Once I have a form, I aim to try planking with thin pine (0.007”, 7 thou), paper and perhaps papier-mâché, oh and plunge-forming. tia, Andrew

- 739 replies

-

- Tudor

- restoration

-

(and 4 more)

Tagged with:

-

Steven The cloth of Gold sails are magnificent, they will be the eye-catching “stars” of the show ( and probably outshine Hal) I’m sure you have documentary evidence for the Tudor clothes-peg andrew

- 739 replies

-

- Tudor

- restoration

-

(and 4 more)

Tagged with:

-

liteflight reacted to a post in a topic:

Henry Grace a Dieu (Great Harry) by Louie da fly - FINISHED - Scale 1:200 - Repaired after over 50 yrs of neglect

liteflight reacted to a post in a topic:

Henry Grace a Dieu (Great Harry) by Louie da fly - FINISHED - Scale 1:200 - Repaired after over 50 yrs of neglect

-

HMCSS Victoria 1855 by Banyan - 1:72

liteflight replied to BANYAN's topic in - Build logs for subjects built 1851 - 1900

Pat This supplier stocks the Bergeon range of Watchmakers supplies, might be worth a call after the holiday. https://www.australianwatchclocksupplies.com.au/tools.html andrew- 973 replies

-

- screw

- gun dispatch vessel

- (and 5 more)

-

liteflight reacted to a post in a topic:

Starlight by AJohnson - FINISHED - Paper Shipwright - 1:250 scale - CARD - Clyde Puffer

liteflight reacted to a post in a topic:

Starlight by AJohnson - FINISHED - Paper Shipwright - 1:250 scale - CARD - Clyde Puffer

-

HMCSS Victoria 1855 by Banyan - 1:72

liteflight replied to BANYAN's topic in - Build logs for subjects built 1851 - 1900

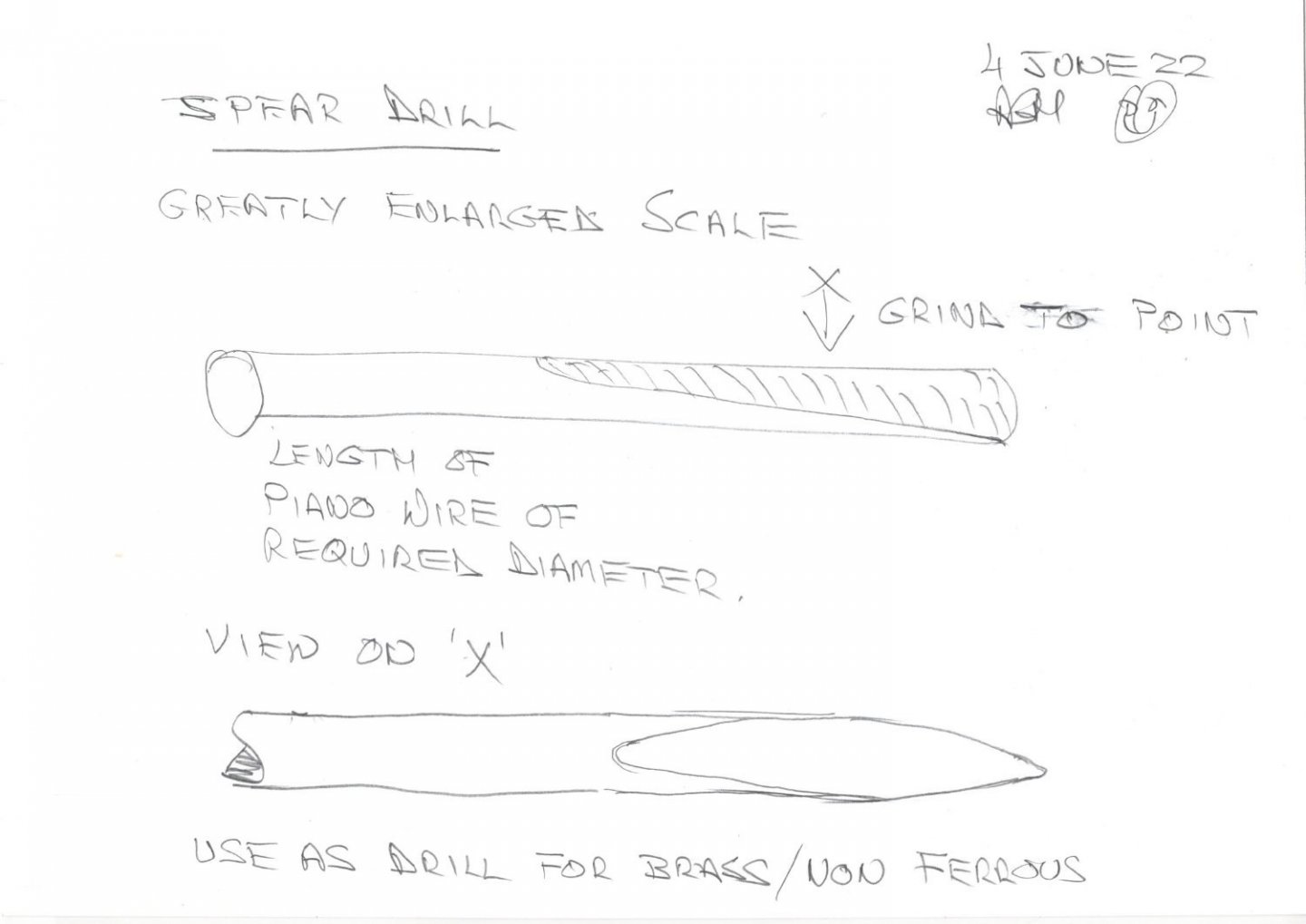

Hi, Pat Noted! AND Following Welfalck's excellent suggestion of watchmaker's Pivot Drills https://www.esslinger.com/drill-press-drills-and-more/ https://watchmaking.weebly.com/drill-bits.html and, as it happens they are precise spade drills, available in sets or singles (see first reference) Googling the Bergeon (No. 1713) reference will extend your horological linguistic skills not a little And yes, the homemade piano wire reamers/drills make a wire-size reamed hole which is not necessarily on the centreline of the gadget that turns them but for thin brass they follow the centre-pop! andrew- 973 replies

-

- screw

- gun dispatch vessel

- (and 5 more)

-

liteflight reacted to a post in a topic:

Henry Grace a Dieu (Great Harry) by Louie da fly - FINISHED - Scale 1:200 - Repaired after over 50 yrs of neglect

liteflight reacted to a post in a topic:

Henry Grace a Dieu (Great Harry) by Louie da fly - FINISHED - Scale 1:200 - Repaired after over 50 yrs of neglect

-

HMCSS Victoria 1855 by Banyan - 1:72

liteflight replied to BANYAN's topic in - Build logs for subjects built 1851 - 1900

Hi, Pat Don't want to be a nuisance on your thread, nor was I suggesting that you make a fluteless drill by forging and quenching in the blood of a red-headed virgin (the best type) Its probable/possible that you already have the necessary tools! Alternatives are: High-speed (preferably Carbide) burrs (liberate from your friendly dentist, if necessary) Diamond Burrs Needle files or a home-made spear drill - see sketch attached I hand-drill small holes using an Archimedean drill as a holder - generally centre-pop them with extremely sharp point (think compass point ground from a masonry nail or dead small drill shank) then turn over and needle file the back to remove the pip. This often leaves a pinhole to be enlarged Then any of the listed gadgets (and rotary broaches) will enlarge the hole to your desired diameter without applying much torque Note 1 - the spear drill is an excellent reamer of holes in sizes up to 5 or 6 mm (I use a dead drill shank rather than Piano wire as cutting piano wire in these sizes is very little fun) Note 2 - grinding a spear drill in 0.5mm (20 thou) diameter needs to be done slowly and with copious cooling as you grind to avoid overheating the high carbon wire. Have a deep mug or water and keep cooling the wire before it needs it. Note 3 - If you get the whole end red hot - heat it white hot with a blowlamp and quench in the water ! Viola! Glass hard again! Note 4 - You COULD grind both sides to a chisel point, then grind it elliptical like a glass drill but IMHO life is too short and I, for one would not presume to measure the diameter or cylindricity of your holes (which will no doubt house a shackle pin, or similar)- 973 replies

-

- screw

- gun dispatch vessel

- (and 5 more)

-

HMCSS Victoria 1855 by Banyan - 1:72

liteflight replied to BANYAN's topic in - Build logs for subjects built 1851 - 1900

Pat, I can see the problem! As usual I do not know the whole answer, but can suggest some directions which might lead to the answer! When a twist drill breaks through, it has a strong and inevitable tendency to “grab”, especially in brass. Quite possibly it is this grabbing, in association with heat, that breaks the solder joint. Perhaps use a drill which does not grab - ie, not a twist drill. Examples of this are the centres of spade drills, glass drills and/ or make your own from a length of piano wire of the correct diameter (I will sketch and send later) Solder in a less breakable way. Silver solder with the correct flux and a micro flame torch ( together with extreme cleanliness) will make the joints in seconds ( and as a bonus anneal all the material so that it is softer to drill) . Drop the hot assembly into pickling solution and viola! - soft pink and strong spider band! Cheat royally! - make the lugs of the spider band of small “U” shaped wire bends so that they are born with a hole. Solder as above and if necessary flatten after pickling to flatten the wire and reduce the size of the hole. I made the jib traveller on my Thames Sailing Barge by a modification of (3). One radial hole drilled at each lung position to fit wire lug. U shapes bent with one Longer leg which went in the hole. All jigged and solder soldered, pickled and cleaned up. Bore cleaned up removing the longer legs of wire I have rambled a bit. Hope some part may be useful. Underwood’s book on rigging shows his method of making these - essentially a hybrid os 2and3 above with a drilled hole in the band and a nib on the Sheet lug to fit in the Hole. Jigged with a twist of wire to hold all the lugs compressed into place and silver soldered on charcoal block andrew- 973 replies

-

- screw

- gun dispatch vessel

- (and 5 more)

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.