Dee_Dee

Members-

Posts

286 -

Joined

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Dee_Dee

-

A method for making panelled sails using paper

Dee_Dee replied to Cathead's topic in Masting, rigging and sails

Cat, Very nice sails. For sewing on the bolt rope, I would like to make two product suggestions. I totally understand why your using the needle threader instead of a needle. There are needles with fine / small eyes, but threading them is a real pain. For the needle, I would like to suggest using "Beadalon Collapsible Eye Needles". The eyes collapse to the same size as the needle. These come in multiple sizes and should be faster to sew with. These are readily available, this link is to confirm the exact product. https://www.michaels.com/beadalon-fine-collapsible-eye-needles/M10427044.html There are other 'collapsible eye' needles, but I find these best for actual sewing. For the thread, Nymo is a beading thread that is a single ply and very fine. It's a nylon fiber and very strong. What's nice about this thread, it does not fray (untwist) very easily and if it does, nearly impossible to see. This needle and thread combination would allow sewing 'thru' the bolt rope instead of around it. Nymo Thread Size Thickness OO ? O 0.15mm / 0.006 in B 0.20mm / 0.008 in D 0.30mm / 0.012 in F 0.35mm / 0.014 in This link will provide info on available colors https://www.firemountaingems.com/search?keywords=nymo+thread .- 49 replies

-

- sails

- sail panels

-

(and 1 more)

Tagged with:

-

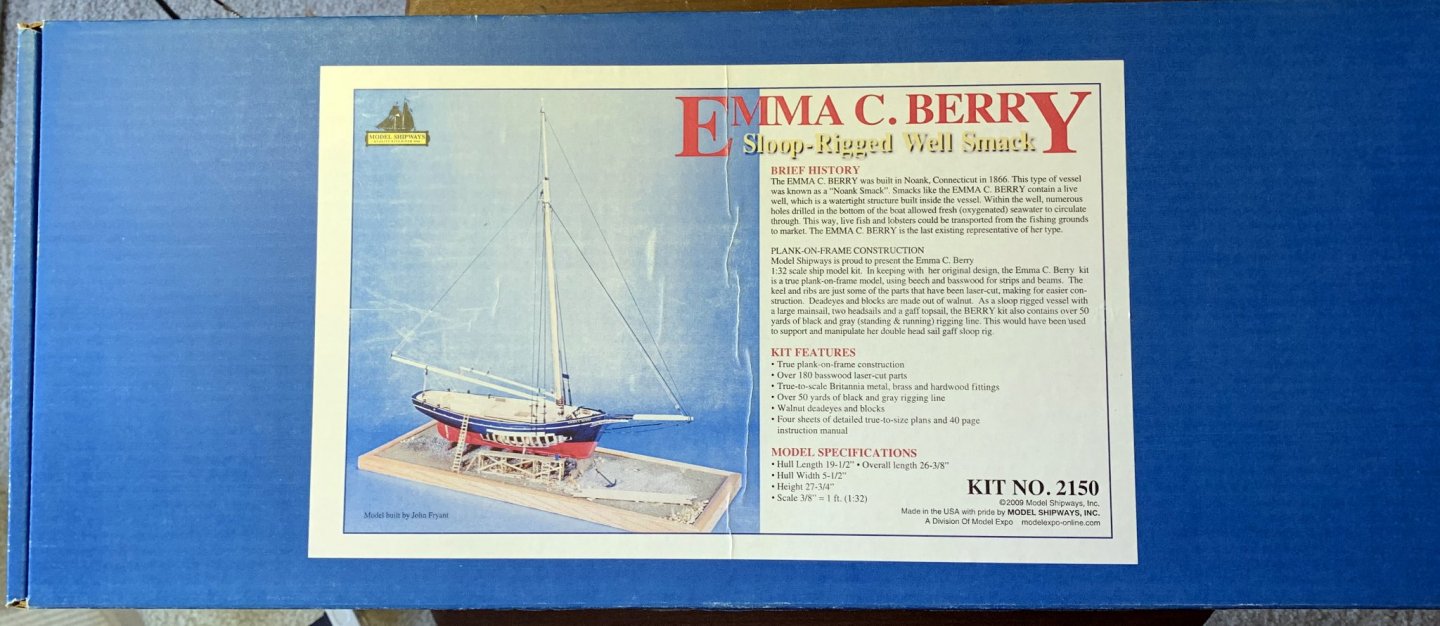

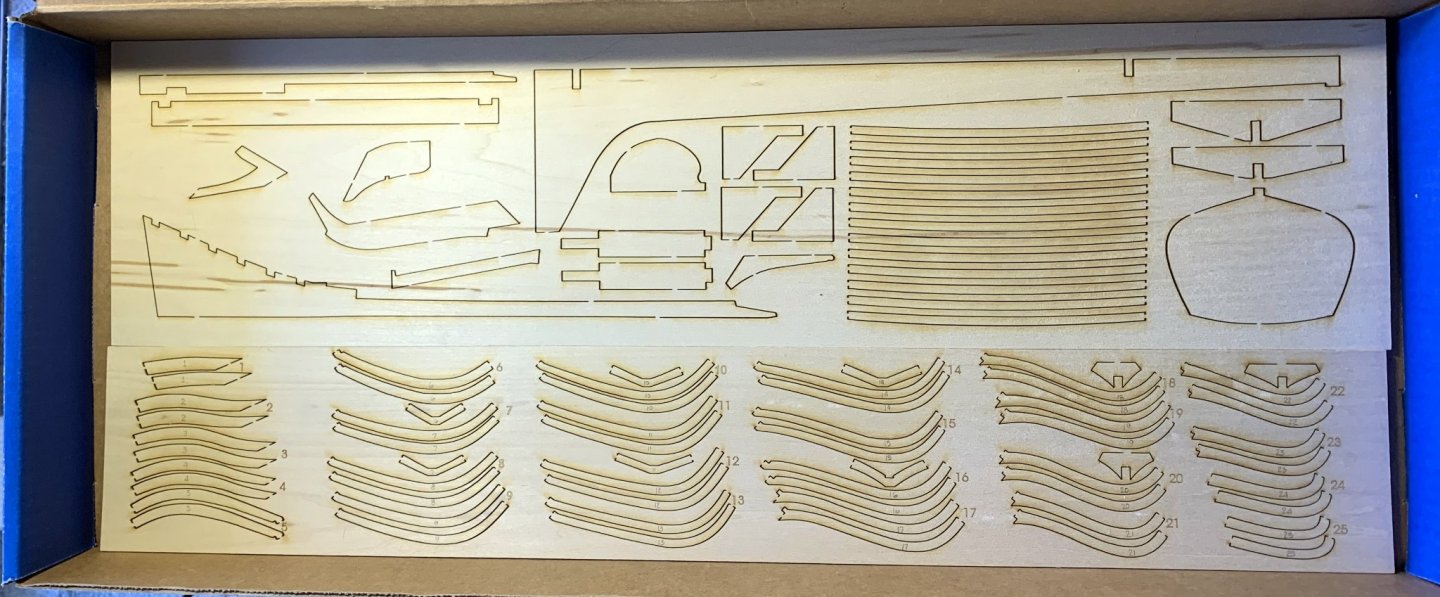

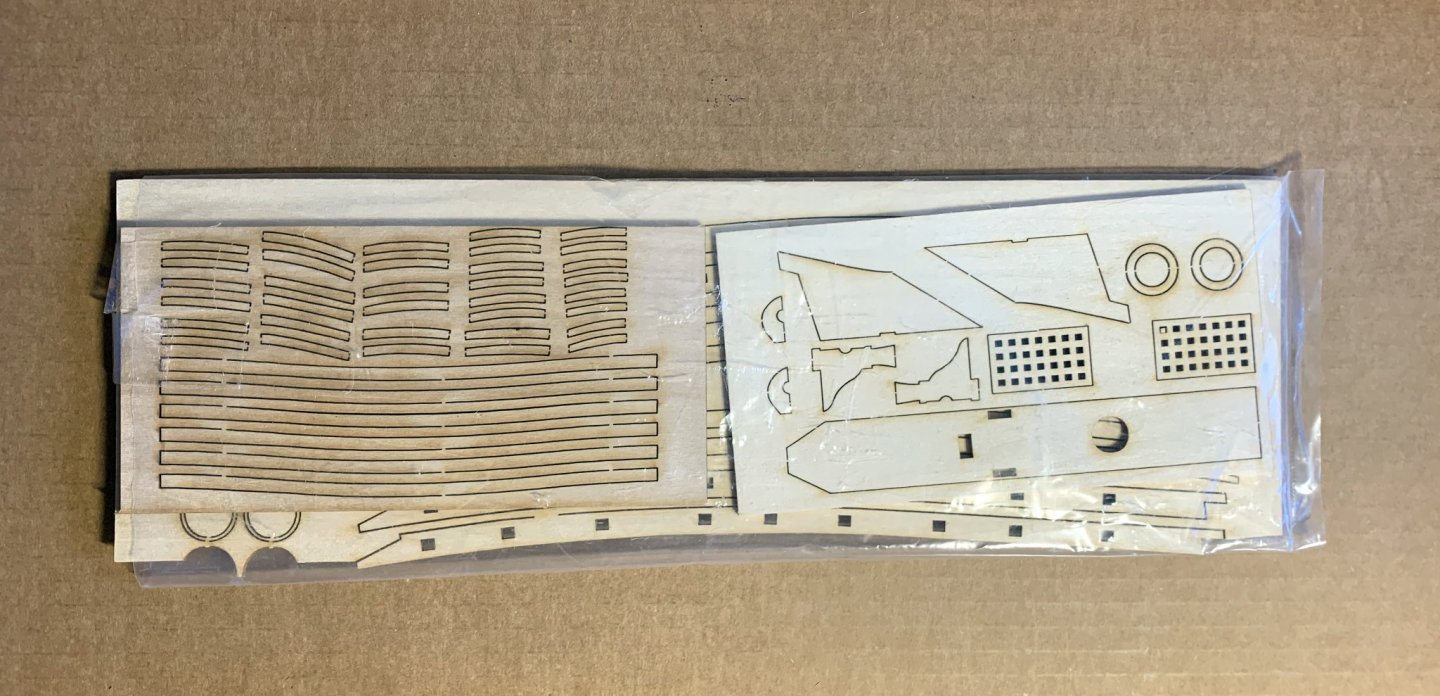

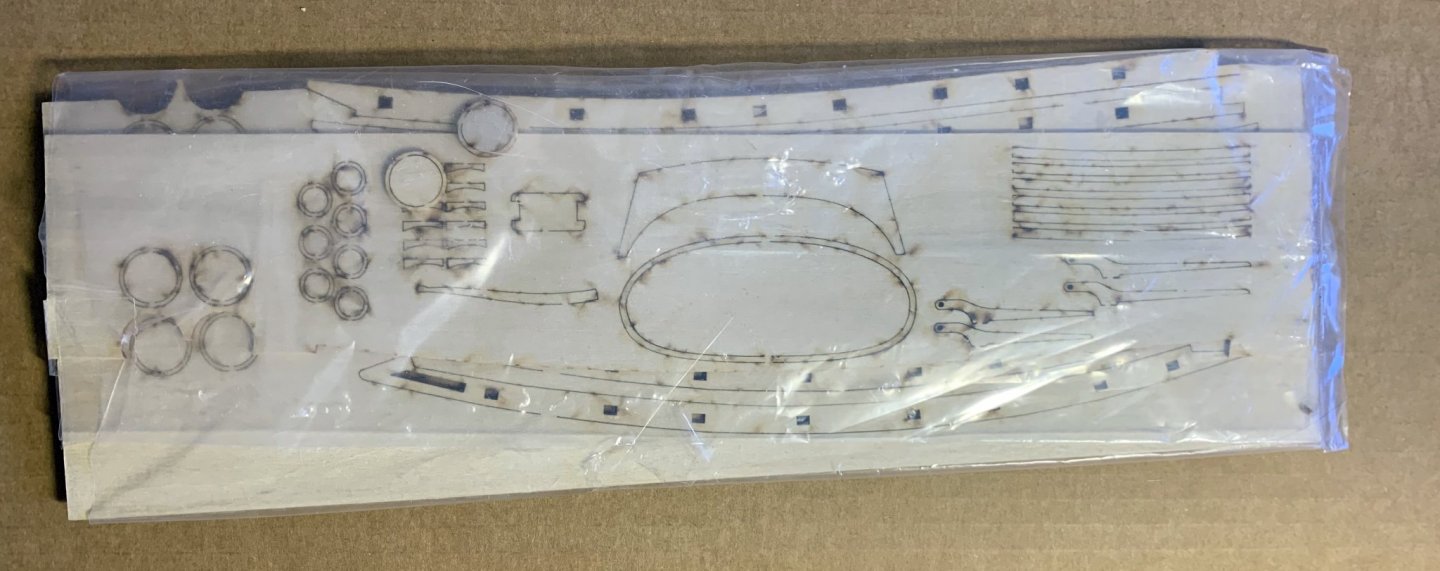

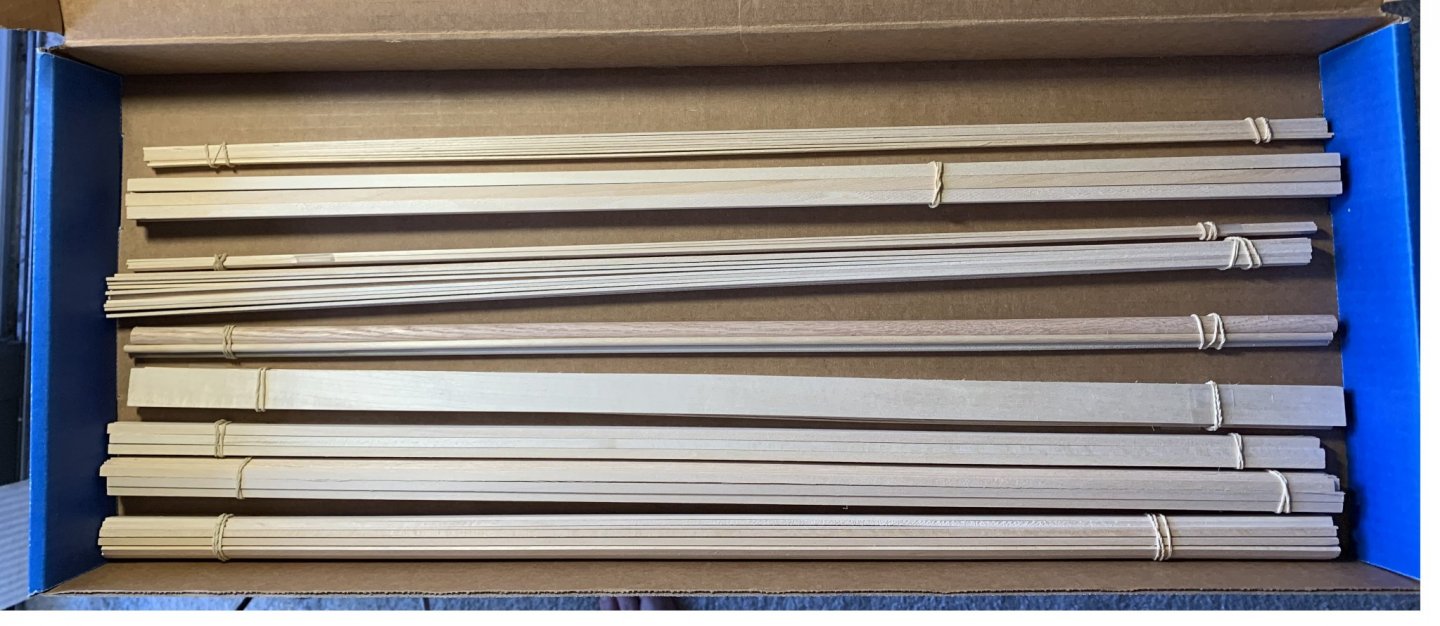

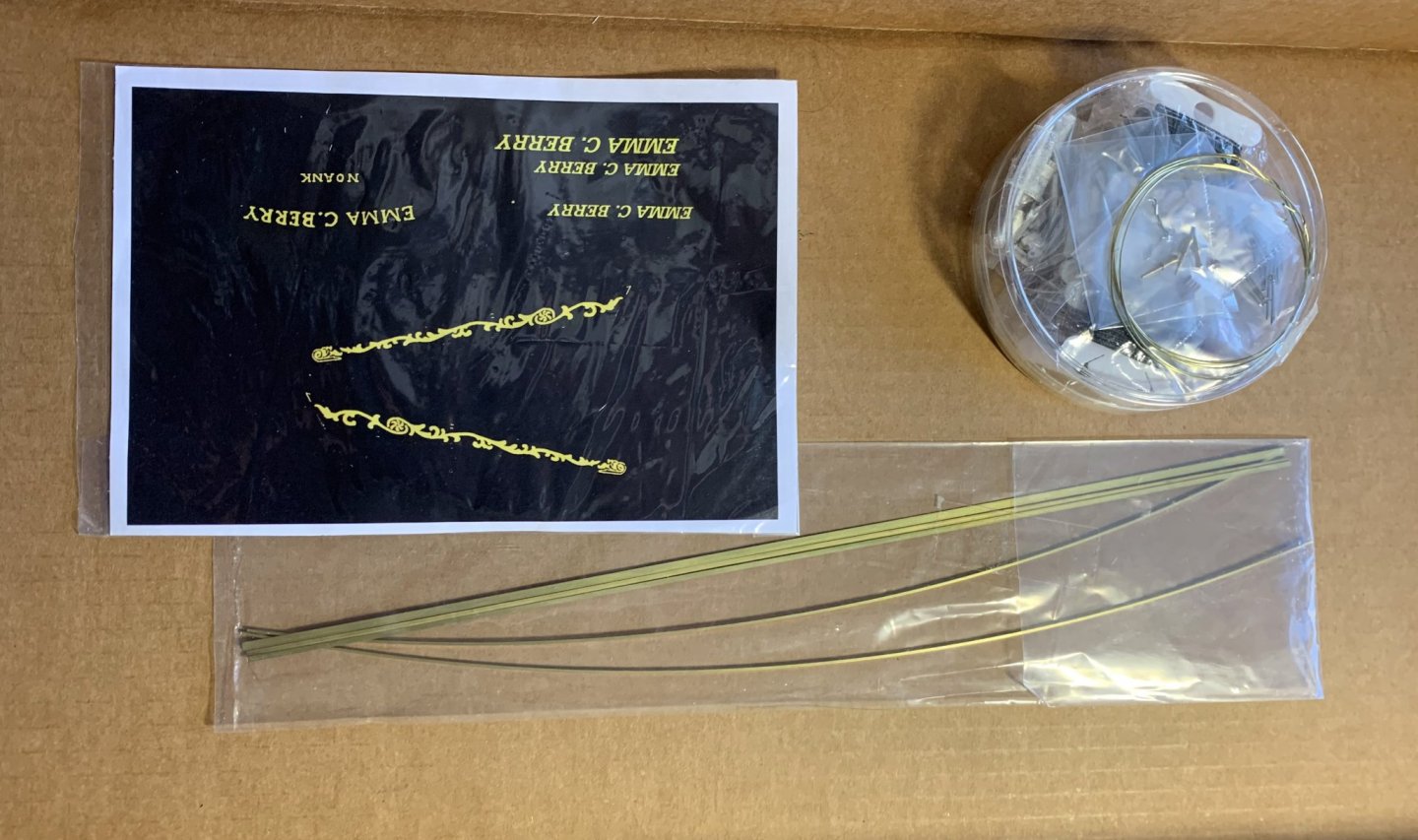

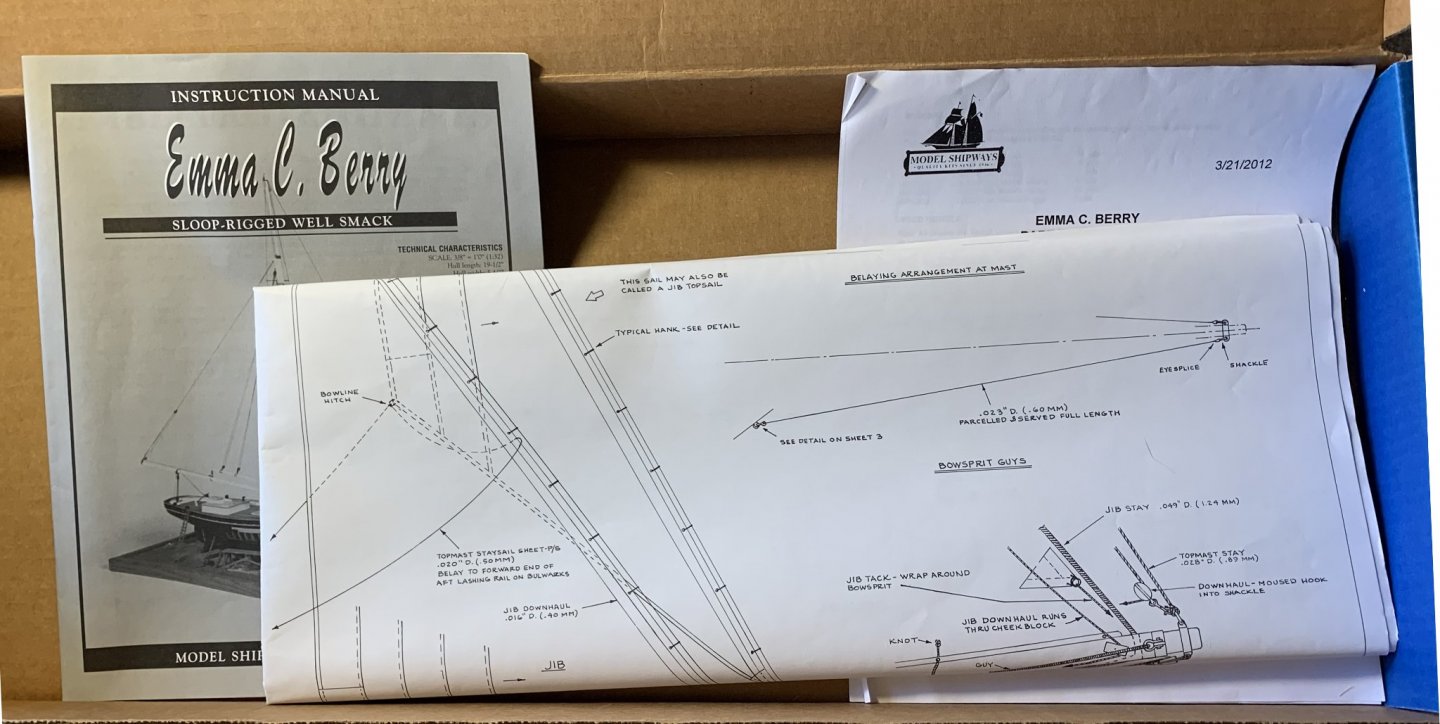

FOR SALE - EMMA C. BERRY by Model Expo - Blue Box I was looking forward to building ECB. But while building Glad Tidings, I came to the realization I need to dedicate more space to continue building Glad Tidings and that's not going to happen. The kit has been sitting on the shelf and the box has some shelf wear - 1/4" laser cut sheets are all intact - Thin laser cut sheets have been stored in a plastic bag One sheet was carefully cut to fit and avoid accidental loss of parts. - Small Parts are in the original small plastic container - Brass strips in plastic bag - Decal sheet has been stored inside the instruction book - Wood strips were sorted and taped together I think I might have used one or two strips, not sure what size. I've added some walnut, mahogany and basswood strips to make up for this - Prints were opened once - Instruction book was read through a few times Current Model Expo Price is $169.99 including postage $140 - shipped to the lower 48 only.

-

There are all sorts of ways to do this, but the least complicated is using better quality wax colored pencil, like Prismacolor, Staedtler, or Blick Store brand - these can be purchased individually. Cheap colored pencils have poor color pigment, icky wax and will not give the desired results. Simple How To: Using a very sharp colored pencil, lightly trace / outline the number, then, with a light touch fill in the outline GOING WITH THE FABRIC GRAIN. Hold the fabric taught with you other hand, to keep it from stretching / pulling. Wait 30-60 seconds, then add a second light layer of color pencil. Next is burnishing - place a 2" x 2" piece of paper over the color and lightly burnish in the color, 6-8 passes. Use paper heavier than copy paper and don't let the paper slide! The end of a medium size Sharpie works great for burnishing. Add two more layers of color pencil and burnish again. Repeat until you get the desired opacity. Colored pencils are a great way to add 'aging' and details to fabric sails, build depth by using color variations. Practice on the same fabric to be sure the colored wax does not get pushed thru the fabric. There is no real need to 'seal' the color pencil (unless you plan on washing your sails) and the wax will keep the pigment from fading. I've used colored pencils to add detail to art quilts - 20 years later, the detail is still there! .

- 8 replies

-

- small boat

- sails

-

(and 1 more)

Tagged with:

-

Chuck, There's a fabric glue that has not been previously discussed on MSW, called "Beacon Fabri-Tac" It's used by the fashion industry, applications include costume design and gluing sequins to wedding gowns. I've experimented with it and I'm really happy with the results: It's quick drying, doesn't stain / discolor or spread like CA glue does. When it cures, there is a very slight amount of stiffening, but the fabric remains fully flexible. A plus feature of this glue, it's acid free. It comes in 2 oz, 4 oz and 8 oz bottles and mini tubes. I purchased it at JoAnne Fabrics or it can be mail ordered. https://www.beaconadhesives.com/product/fabri-tac/ Dee Dee

-

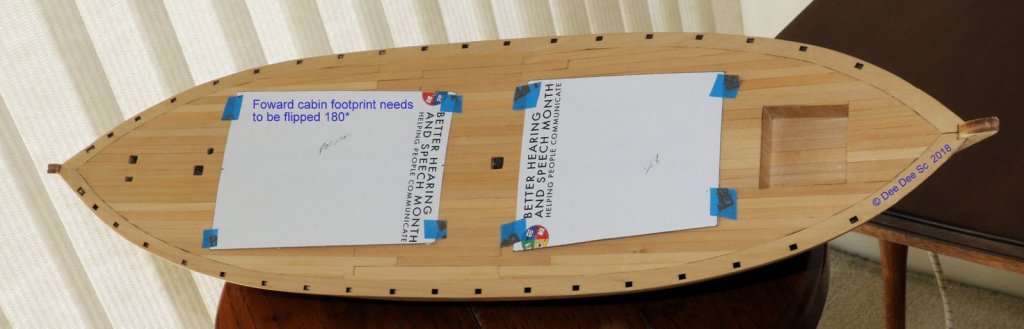

The decking is done! To get a level decking, I did a lot of scraping with a razor blade, some light sanding with some sandpaper and a sanding sponge. Then finished up with vacuuming! I wiped on a thin coat of shellac to act as a sealer, it's easy to scrape off where needed. The black lines are reference lines for the cabin placement. I'll glue on a 'cleat' to help align the cabin. These are the cabin footprints - Ooops! The forward cabin should be flipped 180* I'm disappointed with the lumber in the kit - Almost every piece had significant saw blade marks that had to be sanded down to get a tight fit. I coated the edges with some shellac before sanding and sanded just enough to get a flat edge. The kit was designed to use 12 planks on each side, covering just under 60mm. However, since each strip had to be sanded, 12 planks left me with a 2mm gap on both sides. I did some creative press fitting to fill the gap. I still need to figure out the personality and color scheme. I've decided to not use the round portholes, instead, I'll make rectangle shaped windows and skylights. I really like what John Earl did with his pinky, check out John's pinky here and here. Thanks for stopping by. Dee Dee

-

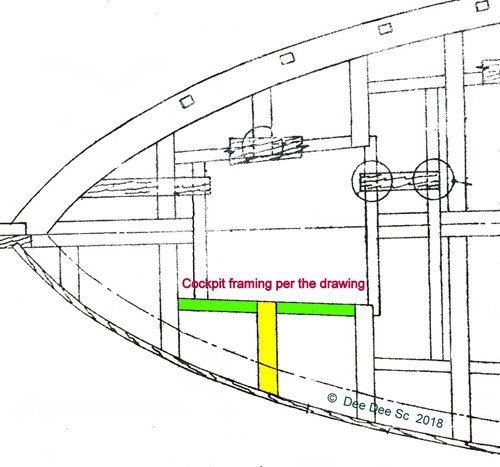

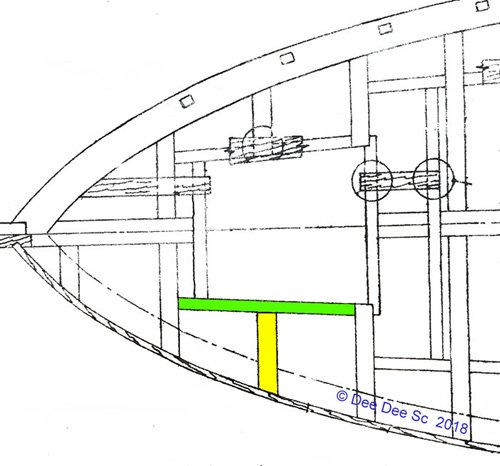

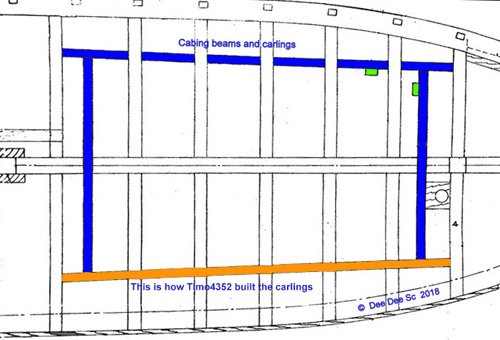

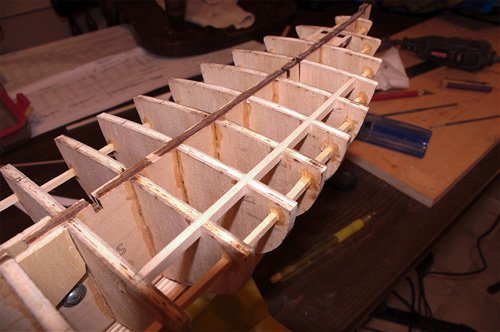

Glacial Boat Works is moving along..............slowly...................................... I made a small change with the framing for the cockpit. I lopped off a small section from bulkhead #17 (shown in yellow), and used one piece of 1/8" x 1/4" for the cockpit framing (shown in green). For the cockpit walls, I glued the pieces together, then backed each section with a strip of paper to give it some strength while sanding to size. The final height sanding was done after gluing. If you zoom in on the photo, you can see the paper backing. Silly me! I forgot to add the drain in the cockpit flooring. If I can find some thin black tubing, I'll add it. Deck Beams and Carlings The deck beams and carlings for each cabin (shown in blue) are not really needed. But if you're bashing the heck out of this build, you will need these and I suggest adding these as timo4352 did in his build here .... shown in orange. This is where I got the idea to do the cockpit as I did. The waterways are a bit 'delicate' and both broke due to the wood grain, an easy fix. Both ends needed sanding / shaping to fit the curves of the bow / stern stems and I heard a couple of 'crack's as I was gluing them on, but I don't see any cracks or lines. Phew!! Next up is planking the deck, I'll use the 1/16" x 3/32" basswood. Thanks for stopping by, questions, comments welcome. Dee Dee

-

Hey Eamonn! It's really nice to hear from you! Hope you are well! GT may be a small craft - but it's more than twice as long as my last build, with an overall length of 29.5" / 75cm. I need to make a big space on the shelf for this one! Joshua! Thanks for stopping by. Yep! I'm an anal analytical with lexdysic tendencies. It's not supposed to be overwhelming, rather, it's meant to be a simple way to sand each plank to size. When I plank my next build, I'll try a different approach, with less analysis. Your "Prince" is looking great!

-

Linen yarn is available for ropewalk stock

Dee_Dee replied to Jaager's topic in Masting, rigging and sails

Londonderry linen thread is a high quality linen thread with a smooth finish and also comes in sizes as small as 80/3 and a few colors in 100/3 and sold in small spools of 12-50m, each spool costs less than $3. It's available online from Threadneedle Street, located in Issaquah WA. Their website has numerous pages, this is the direct link to the page with the linen thread. Scroll to bottom for colors to make rope. https://www.threadneedlestreet.com/linthrd.htm There's also have a pdf guide for rigging: https://www.threadneedlestreet.com/LINEN RIGGING.pdf -

Kurt, I have two of these straight fairleads. They measure 12mm, made of white metal with an aged bronze plating or painting. I believe they came with the Blue Jacket 1:30 Endeavour J boat, but they were packed with two pair of oar locks that were 6mm long. If it will help, I can send these to you to make a mold / copies Also, check out this page at BlueJacket: http://www.bluejacketinc.com/fittings/fittings17.htm Dee Dee

-

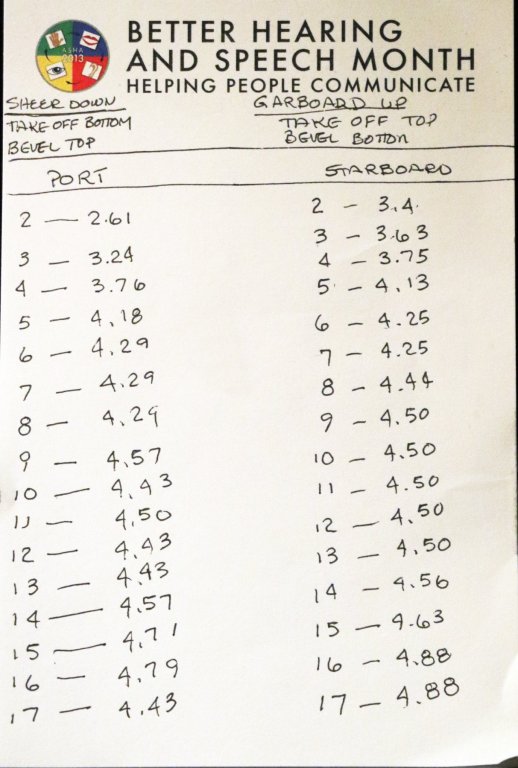

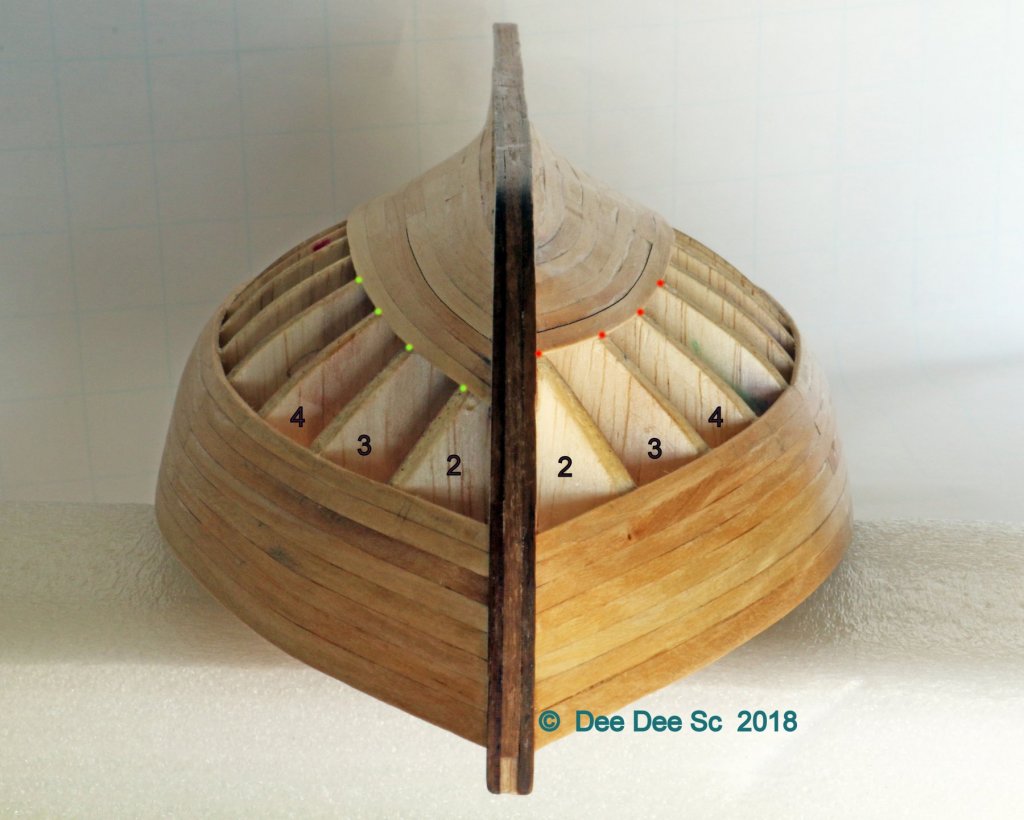

Don I like planking, but yes, it's always good to complete it. Now, I have to 'get back on the paper' and start reading the instructions and drawings............ Rob, I'm one of 'those' crazy analytical type personalities, where numbers need to make sense to me to confirm I'm staying on track. If I So if I go over the top, just tell me: "There you goes again! Getting all crazy and analytical again!" When it came time to actual planking, I keep it simple: What's the width of each plank at each bulkhead, then I wrote those numbers down on a note pad. The photo below answers that question for the eight planks of the starboard B Belt. After four planks, I redid the measurements and again wrote those numbers down. This hull was fun to plank and I hope you will still consider building Glad Tidings. Dee Dee

-

I posted this in reply to your thread on Naval history: I built the Corel sloup kit using photos from all of the above links; I bashed the heck out of it from the very beginning. When building this kit, it became apparent that EVERY Brittany sloop is different; a lot of it depended on what is the primary fishing, oysters, lobsters, sardines, location and more. The link to my build is in my signature. A place to start is with the 'Bergère de Domrémy, hull # B 5929', a scallop dredging sloop / coquillier built in 1936. It was rebuilt and now a French National Treasure. The French An Test website contains some details and history. There's lots of info on this website. http://bergere.antest.net/le-bateau/description/ Info on Auguste Tertu, who built the Bergère de Domrémy and many other boats http://bergere.antest.net/2013/12/auguste-tertu/ Page through Sophie's link for numerous photos and good info on the Bergère de Domrémy and other sloops: http://sophie-g.net/photo/bret/brest/bergere01.htm A blog with lots of photos of Bergère de Domrémy http://www.laroyale-modelisme.net/t9662-la-bergere-de-domremy The Brittany sloop is similar to the Irish Galway and Kinsale Hooker and many other Channel / Atlantic fishing boats. More info on these Irish boats here: http://www.tradboats.ie/index.php The "Douarnenez Festival" held every other year features numerous variations on the Brittany sloop / coquillier. Here are links to photos from the 2006 and 2012 festivals. Google 'Douarnenez Festival' for more photos. 2006: http://www.pbase.com/image/65376766 2012: https://www.flickr.com/photos/valendrevarzecois/7623197092/ Videos from 2012 Douarnenez Festival https://www.youtube.com/watch?v=8bwdXWwGRbY https://www.youtube.com/watch?v=lcetV8QmPGk This Pinterest page did a good job of assembling various fishing vessels from the Channel and Atlantic coast and includes some basic drawings. https://www.pinterest.co.uk/tomedom/french-traditional-boat-types-of-the-channel-and-a/

-

A place to start is with the 'Bergère de Domrémy, hull # B 5929', a scallop dredging sloop / coquillier built in 1936. It was rebuilt and now a French National Treasure. The French An Test website contains some details and history. There's lots of info on this website. http://bergere.antest.net/le-bateau/description/ Info on Auguste Tertu, who built the Bergère de Domrémy and many other boats http://bergere.antest.net/2013/12/auguste-tertu/ Page through Sophie's link for numerous photos and good info on the Bergère de Domrémy and other sloops: http://sophie-g.net/photo/bret/brest/bergere01.htm A blog with lots of photos of Bergère de Domrémy http://www.laroyale-modelisme.net/t9662-la-bergere-de-domremy The Brittany sloop is similar to the Irish Galway and Kinsale Hooker and many other Channel / Atlantic fishing boats. More info on these Irish boats here: http://www.tradboats.ie/index.php The "Douarnenez Festival" held every other year features numerous variations on the Brittany sloop / coquillier. Here are links to photos from the 2006 and 2012 festivals. Google 'Douarnenez Festival' for more photos. 2006: http://www.pbase.com/image/65376766 2012: https://www.flickr.com/photos/valendrevarzecois/7623197092/ Videos from 2012 Douarnenez Festival https://www.youtube.com/watch?v=8bwdXWwGRbY https://www.youtube.com/watch?v=lcetV8QmPGk This Pinterest page did a good job of assembling various fishing vessels from the Channel and Atlantic coast and includes some basic drawings. https://www.pinterest.co.uk/tomedom/french-traditional-boat-types-of-the-channel-and-a/ I built the Corel sloup kit using photos from all of the above links; I bashed the heck out of it from the very beginning. When building this kit, it became apparent that EVERY Brittany sloop is different; a lot of it depended on what is the primary fishing, oysters, lobsters, sardines, location and more.

-

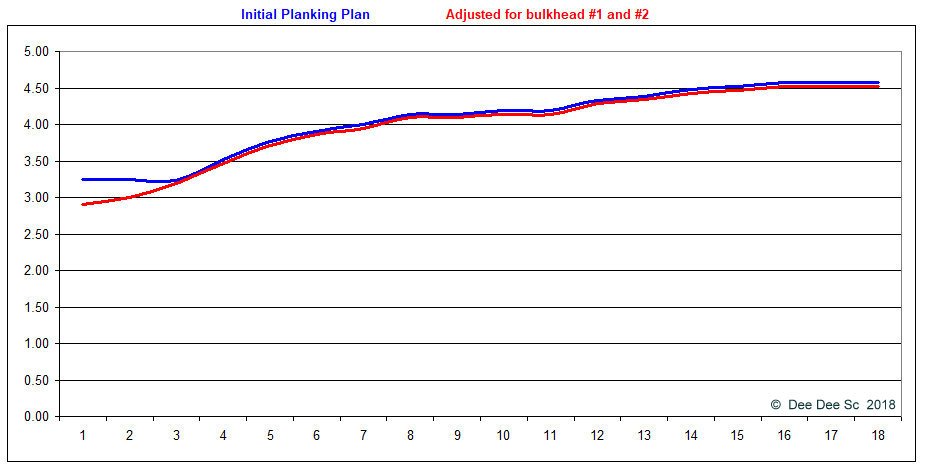

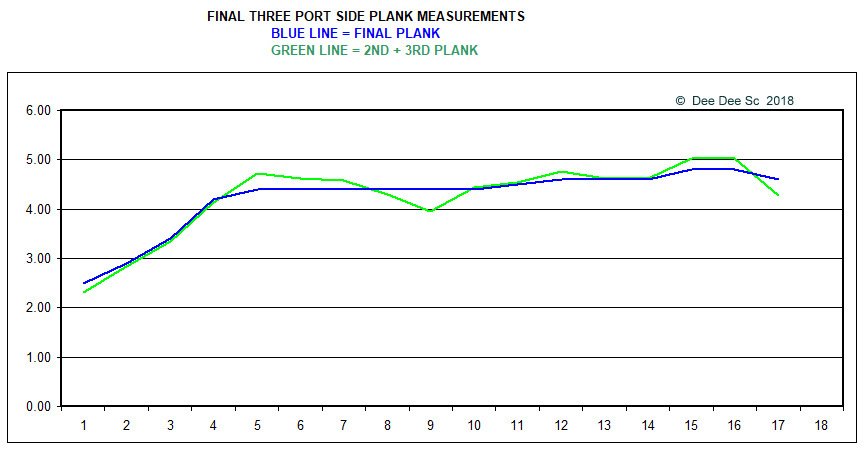

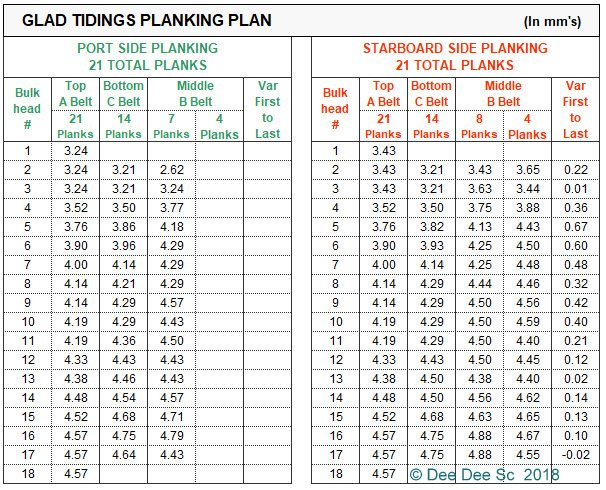

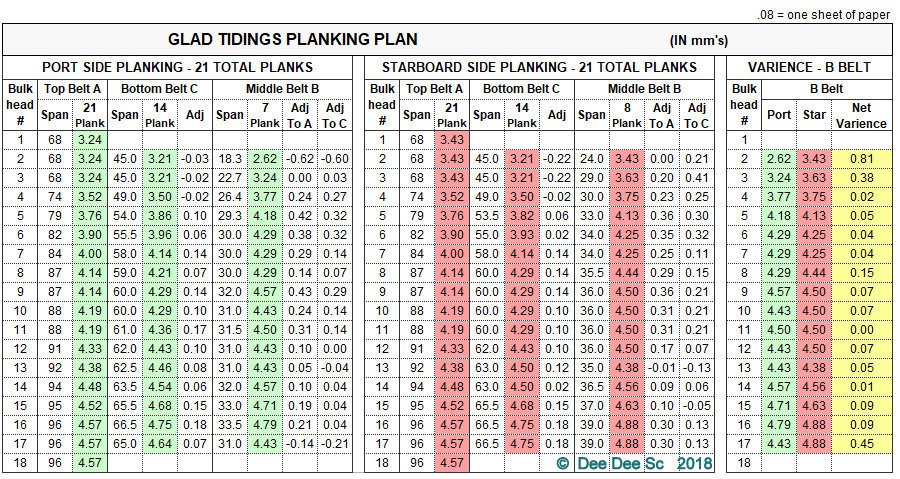

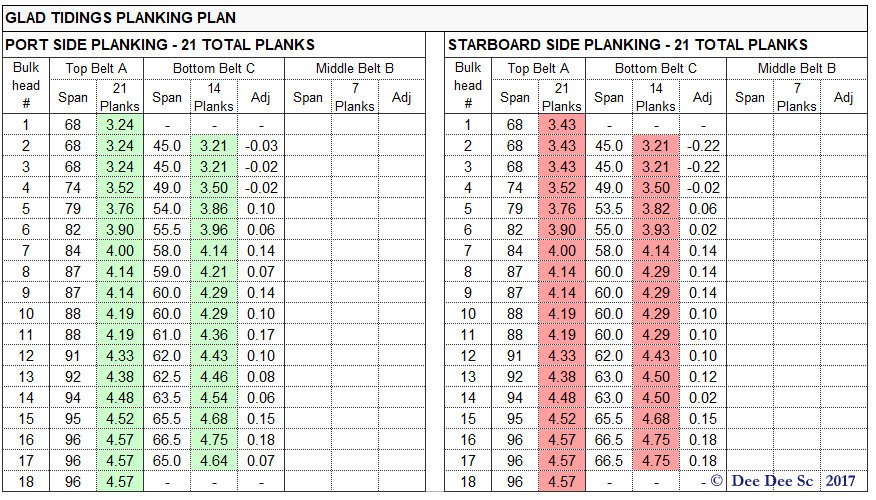

The planking is done! Yeah! After the last plank, I spent a few hours on each side with scrapers, sand paper and vacuuming! Also, mixing and adding epoxy to a few thin spots for support. Time well spent. When I started planking, I didn't have a planking plan, so belt A is different on each side. But somewhere I settled on 6 / 8 and 11 / 13. Thinking I should have had a third set of joints to break it up a bit more. The stern stem planking and the stem itself needs a little bit of filler. In the original plan, the planks at the bow stem were 3.24mm on the port side and 3.43 on the starboard side. Needless to say, I was a bit off. By the port side C belt, this measurement was down to 2.62mm. I contemplated "adding a plank" for about 10 minutes, I stayed with the plan of narrow planks. In this close up, you can see the difference in size as the planks hit the bow stem. When I did the original planking plan, I thought I was measuring correctly. To figure out where I went wrong, I 'charted' the planking plan. In the chart below, the blue line is the original planking plan - the plan flat lined for the bowstem and second bulkhead. Going back to basics, I 'smoothed' the numbers to follow the general line of the hull, the bow stem to 2.90 mm and 3.00 mm for bulkhead #2. These measurements would have been a better start until I was able to get a 'solid' measurement. OK, now I now better. THE FINAL THREE PLANKS!!!! I wanted to make sure the last plank would be easy to shape and get a tight fit. I remeasured and came up with a plan for the final plank, then worked backwards to get the measurements for the 2nd and 3rd to last planks. These measurements are highlighted in gray in the spread sheet below. In the chart, the blue line shows the smooth shape / plan of the final plank and the green line shows the wonky shape of the other two planks. It took time to get the 2nd and 3rd wonky planks shaped, but the last plank was really easy to make and fit. And THAT's the last of the charts and graphs! Need to do a bit more work on each side, then some sanding sealer and some covering to protect the hull from me adding unwanted nicks and dings in the hull. I still need to decide on paint colors Thanks for stopping by! Dee Dee

-

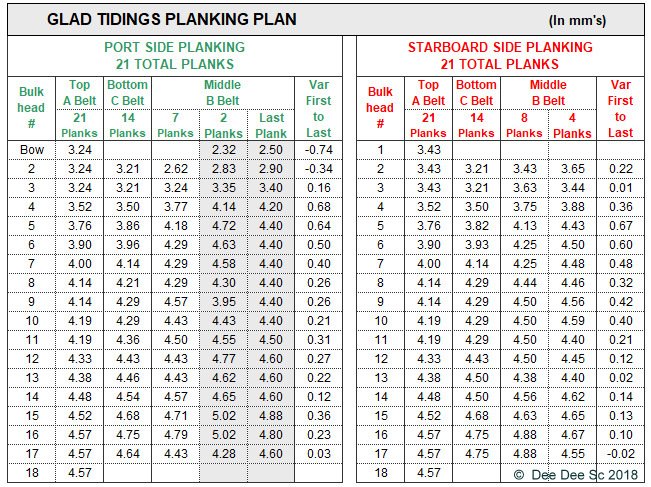

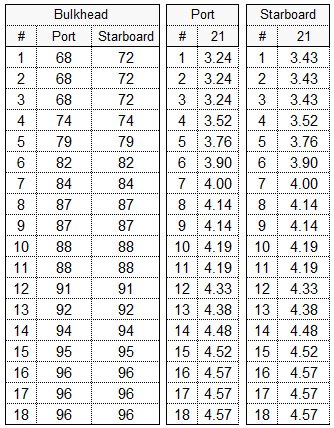

The starboard planking is done! Yeah! My thumbs were sore, but my planking fingers were working. I minimized the beveling and that solved the 'thin spots', but there are a few paper thin 'gaps' that were filled by the glue. The starboard Middle B belt was 8 planks. After the first four planks were added, I measured again. To avoid a 'skinny whiskey plank', I slightly undersized the these planks by 0.05 - 0.1mm. I added a couple of black lines to denote the individual belts and shows the difference in planking skills. Now I need to work on aligning the joints. I'll cover this side in blue tape again to prevent the basswood from eroding from handling and dinks when I drop something heavy, like a set of calipers, on the hull. To keep the blue tape from sticking, I wiped on a thin coat of poly. Below is the summary of measurements for the starboard side. With the exception of the 5th, 6th and 7th bulkhead, the measurements for the last four planks varied were within 0.40mm of the first measurement. Later today I'll start planking the port side per the plan below. This is the side where the planks for the 2nd and 3rd bulkheads are going to be thin. So this will be 'interesting........' Thanks for stopping by!

-

Another section of planking is done! The plank measurements for the second and third bulkhead were reduced to adjust for the too wide planks in Belt A. I drew the seams on each side to show that with the thinner planks, each plank needed more edge bending. By the fourth bulkhead, both sides are the same. It's been a while since I last planked. The top section was the first section I planked, I really want to redo this section, but paint will cover it. My planking has improved and I learned how to do the butt joints. Some planks need to be beveled. But I've been over beveling every plank resulting in more than a few thin spots. I'm shinning a light through these planks to show how thin it got. On the top two planks, I reduced the beveling by 95% and there's no light shinning through these seams. Since this hull is single planked, I'll be adding some epoxy on the inside to give it some strength. The Plan I re-measured both sides, starboard side with eight planks to go and port side with seven planks to go. The chart below shows the plan for the Middle B Belt. With the exception of #2 and #3 and #17, the measurements for the 'Middle B Belt' on the port and starboard side are within 0.15mm, about the thickness of two sheets of paper (highlighted in yellow). I'll spot check the measurements after every plank, then check all of the measurements with three to go. But first, cover the planking with some blue painters tape and mix some epoxy....... Thanks for stopping by!

-

Steve, Thanks for stopping by and hitting the like button. The scrapers are 'Lynx Mini Scraper Set', they're small, ranging in length from 1.75" to 2" and not too expensive. Here's a link to Woodcraft: https://www.woodcraft.com/products/lynx-mini-scraper-set-4pc?via=573621f469702d06760016cd%2C57641b8969702d65930008c9

-

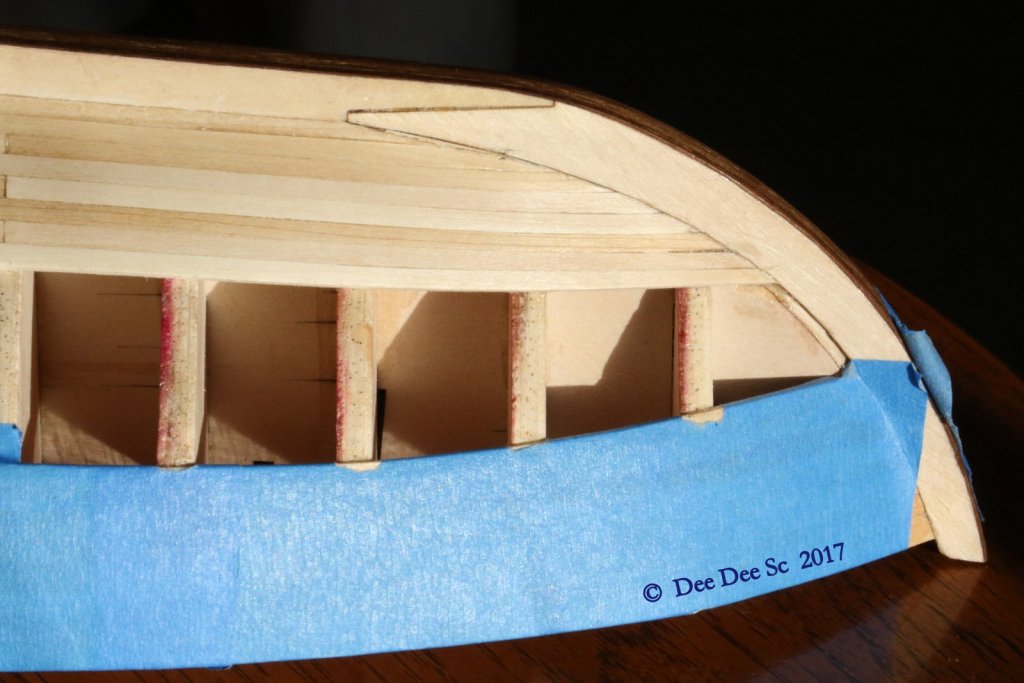

Glad Tidings planking continues! Belt C on the port side is done. Each strake had three planks, that were sanded to size using the chart in prior post. Previously, I was using a razor blade to knock off the edge and small files shape the plank. I purchased a set of mini scrapers and I'm hooked on using them! They're faster and produce less air borne saw dust. I learned real quick to be careful with the sharp corners of the scrapers. The garboard strake had a bit of a gap in the rabbit, so after adding the first strake, I filled the gap in with a sliver of wood. Once it's painted, no one will see it. The first strake hit the third bulkhead and the measurement I was using was on target. To help get a good fit, the bow planks needed edge bending. I'm using basswood which is easy to edge bend; I marked the start / end of the bending, soak the plank in a glass of water for a couple of minutes, then used a hot iron on a piece of thick cardboard to bend. At the bow, the bending was close to the end of the plank, so I didn't cut the plank to length until after the plank was bent. I do a little bit of edge bending on almost all of the planks. It's not a lot but makes fitting each plank a lot easier. Stern planking. For the second and third bulkheads I had to measure them using a line I drew on the keel. The measurement is good on the third bulkhead, but after the fourth strake, it's off on the second bulkhead, I mean really off - argh!!!!!!!!!!!. Deep breath! I'll make adjustments on the starboard side for the C belt. On the port side B belt, I have two options: Seven strakes that are narrow at the bow or 6 strakes at the bow and add the seventh half way down the hull. I'll think about it. I'll give this section a coat of poly, then when dry, cover it with more blue painters tape (to protect it and prevent erosion) then start on the starboard side. Thanks for stopping by!

-

Re-measured all the bulkheads (in millimeters). I was a bit off on #2 and #3 on the starboard side, but the others look OK. After I complete planking the C belt, I'll check all the measurements again before starting the middle belt. Now, it's add some blue painters tape to keep the basswood from eroding and start planking!

-

Finished planking the A belt on the port side . . . . . . . . . . . . . . . . . . . . The first sheer strake was a bit wonky, so I gave it another try and this one turned out much better, especially at the stern post Made some adjustments to the location of butt joints (yes, they should be offset by at least three strakes, but the hull will be painted). I didn't do any edge bending on the starboard bow planks, but I did on the port bow planks, I think this side turned out a bit better. I paid a lot of attention to the edge bending, where it starts / finishes and getting the bend just right. The planking was taking a wonky curve (between the two orange lines) and I thought did something wrong. I took a couple of bulkhead measurements and they're still good for the next belt. So I'm thinking it's just the shape of the hull. Again, I sand as I go to about 90% done, this helps to ID any high spots. For example, there's a slight bump on the bulkhead #17 on the third and fourth plank. When I do the final sanding, I'll know not to go crazy trying to sand out that bump. Also, to keep the soft basswood from eroding, I added a coat of poly wipe on. Next up, I'll check all the bulkhead measurements, make any adjustments, then start planking the C Belt, seven blanks starting at the garboard and going up. Thanks for stopping by

-

Don, Al, Steve, thank you for your vote of confidence and thanks to all who hit the like button. Estoy, hope my build log adds to the info already provided in prior build logs! Rob, Thanks for your interest in my build log. I used a red sharpie to mark the right side bulkheads. When I was gluing the bulkhead spacers, the first one was at the top of the bulkhead where there's red ink. For some reason, the CA glue would not cure, the glue turned into a red, runny blob! On the planking, I use CA to glue on the bulkheads and edge to edge. When gluing, I glue one bulkhead at a time, if the plank is straight, sometimes I'll plank two bulkheads at a time.

-

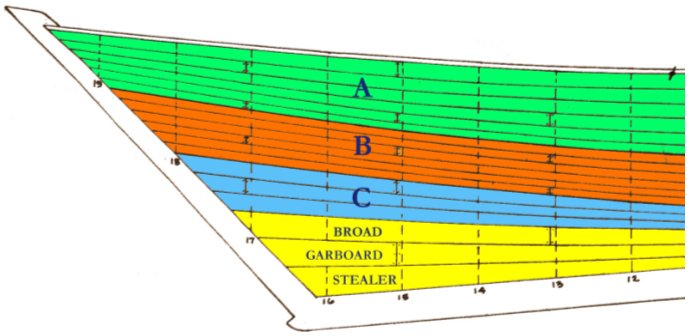

It's been a while................ Part 2 - Planking Glad Tidings The kit comes with instructions and drawings on how to shape each plank. It's a nice feature and a great way to learn how to plank. However, the planks at the stern post range in width from 3.5" for the top twelve strakes in belt A and B, 6" for the three planks in belt C and 9" - 10" - 10" for the three bottom plank, broad, garboard and stealer. These bottom three strakes are a bit out of scale. Instead, I'll plank the hull using a technique similar to the 'Fan' method. Instead of 'tic' marks on the bulkheads, I divided each bulkhead measurement strip by the number of strakes per side. The chart below shows the width (in mm) of each strake at each bulkhead. The Glad Tidings bulkheads are space ~1", making this process a bit tedious / nervous. After the first strake, I decided to smooth it out a bit and only use the measurements for bulkheads #'s 1, 5, 7, 13, 15. Changed my mind again, I'm measuring every plank at every bulkhead. After adding the seven strakes on the starboard side, I measured the total distance covered and I'm off less than 1mm at each bulkhead. I've finished planking belt A on the starboard side. It took a few strakes to figure out how to do the butt joints. When I plank a hull, after adding each strake, I remove the excess corner sticking up. These seven + one planks are sanded to about 90%. To keep the basswood from 'eroding' away or getting dinged while working on the model, I did a light coating of wipe on poly, then covered it with blue painters tape. Close up of the bow. Close up of the stern. The iron was a bit warm when edge bending this planks. ooops! But it gives me an idea for the deck planking.......... Next up is planking the A belt on the port side. But first I need to remove / replace the sheer strake and do a better job. Hopefully my next post will not take as long........ Thanks for stopping by. Dee Dee

-

Londonderry linen thread is a high quality linen thread with a smooth finish. It's available online from Threadneedle Street, located in Issaquah WA. It's expensive, but you get what you pay for. Their website has numerous pages, below is the direct link for the page with the linen thread. Scroll to bottom for colors to make rope. https://www.threadneedlestreet.com/linthrd.htm

-

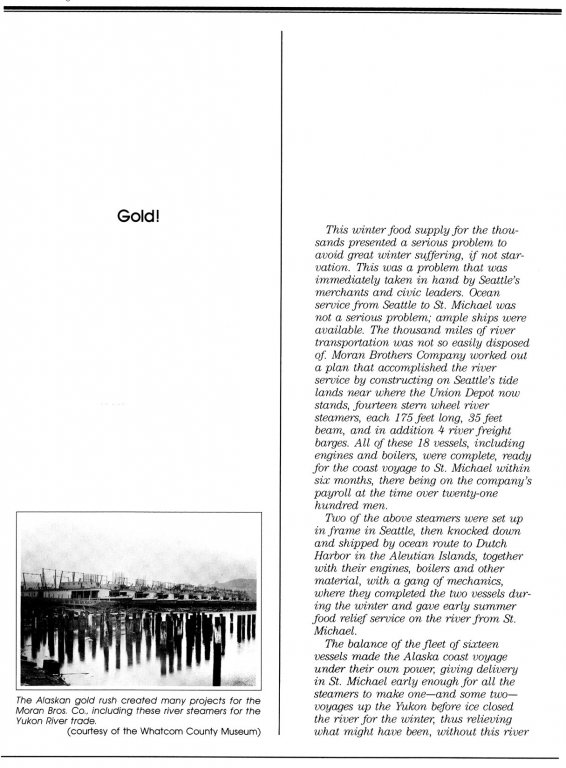

Steamboats and other rivercraft - general discussion

Dee_Dee replied to Cathead's topic in Nautical/Naval History

Robert Moran (1857-1943) and his three brothers were Seattle ship builders. The Moran boat yard was located about where Safeco Field is today. In 1887, at 30 years of age, Robert Moran was elected to the City Council and in 1888 elected Mayor of Seattle. Seattle was destroyed by the great fire of June 6, 1889. A number of years ago, I vacationed on the San Juan Islands. Highly recommended! I visited Rosario, the estate of Robert Moran. What really caught my eye and interest, were the tiny details and the mechanics within the estate, especially the butterfly door hinges. After hiking up Mt. Constitution on Orcas Island, I purchased a book in the tiny gift shop, titled "Rosario Yesterdays", by Christopher M. Peacock. The first half of this 72 page book detailed the Moran Ship building business, the second half detailed the Rosario estate. Library of Congress Catalog Number: 85-51170 ISBN: 0-9614970-0-9 Published: 1985 Peacock's book "Rosario Yesterdays" contains extensive quotes from Robert Moran's Memoirs from 1939. These four photos are of text from "Rosario Yesterdays", specific to Robert Moran's Memoirs, about the gold strike in the Yukon and the riverboats the Moran Brothers built to carry supplies.- 269 replies

-

- Steamboats

- riverboats

-

(and 3 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.