-

Posts

38 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Davy Jones

-

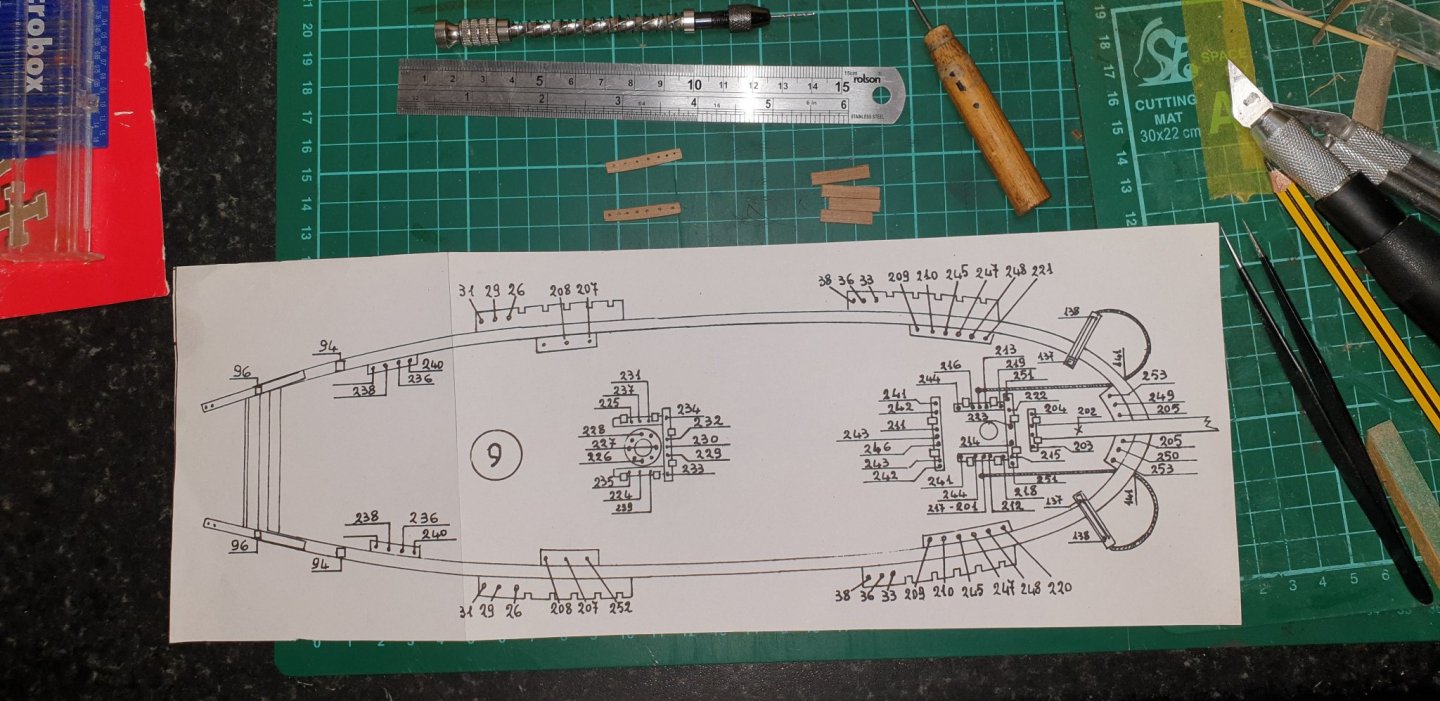

Reading/decoding Mamoli Rigging Charts

Davy Jones replied to robnbill's topic in Masting, rigging and sails

Thank you for the explanation Robnbill. I was just looking at my rigging plan for the Mamoli Lexington Brig and swiftly put it away again. As it won't be long when i am at the rigging part of the build, your explanation of the Mamoli rigging plans are a god send. As a newbee at ship building my knowledge of the terms and understanding the plans is a huge learning curve. Thanx again. Davy. -

Great looking model. With good attention to detail. Good job sir. Davy.

- 52 replies

-

- model shipways

- new bedford whaleboat

-

(and 1 more)

Tagged with:

-

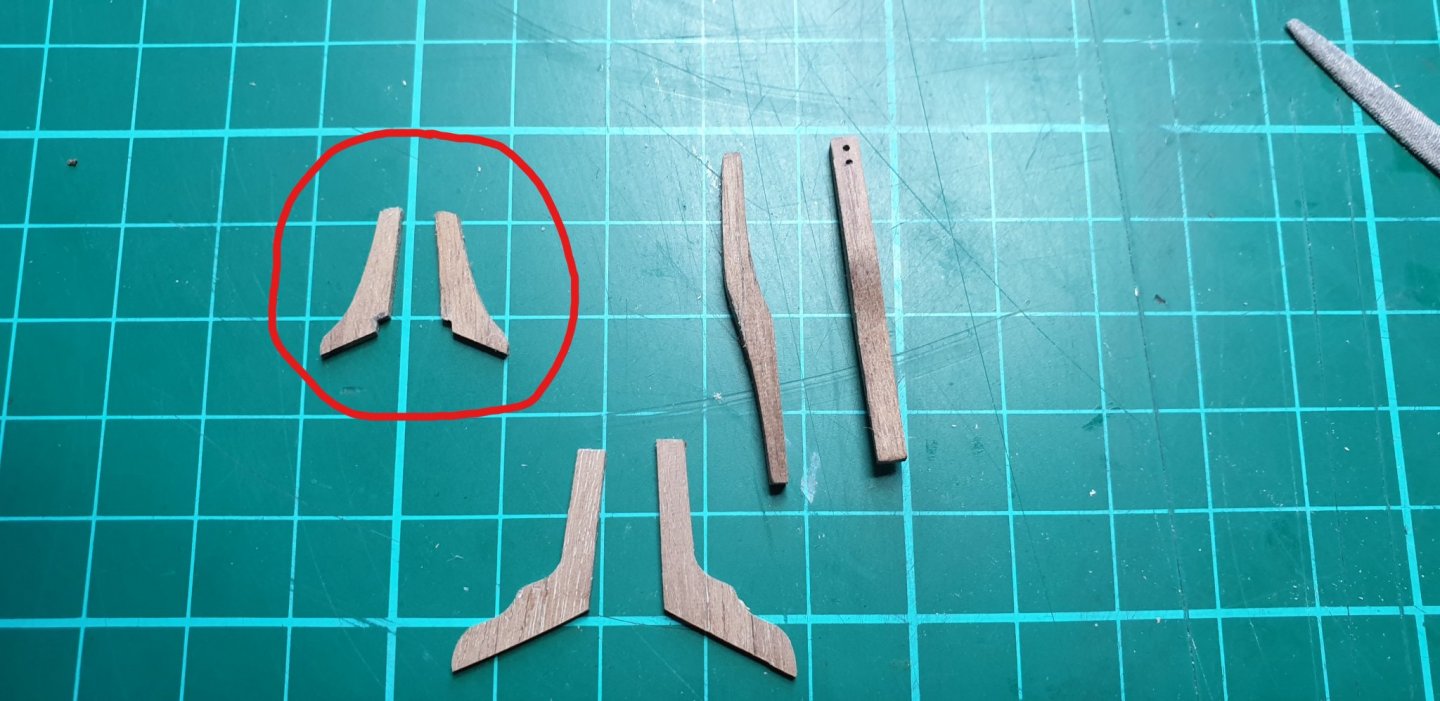

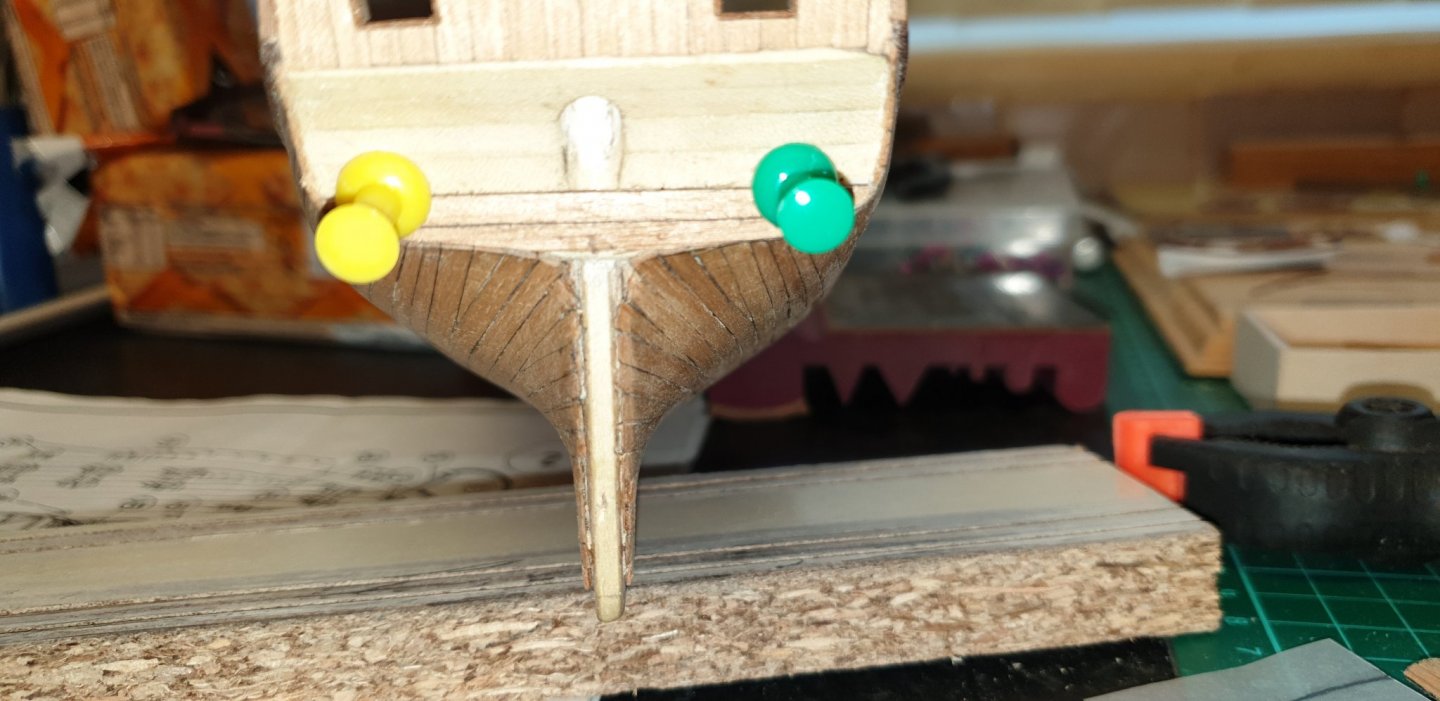

Thanks for the replies Edward & Charles. I to like the natural wood effect and the stealers were quite hard for me as this was my 1st go at it, but thankfully with time and patience it went better than i expected. Now I think this is the figure head, basically just a curl on the bow of the ship. They supply you with a gold colored metal curl, but i don't like it very much so i made my own out of walnut. As you can see the right side of the curl's base is missing and the detail is not very good. To me the new one looks better. Davy.

-

Finished the keel. I think it looks ok now its sanded. I also attached the rudder This was quite fiddly, it took alot of fitting the re-fitting but all went well I had to be quite carefull with the rudder Gudgeons i think thats what they are called, These are made out of a lead type metal and marked very easily. Davy.

-

Now to do the Hull planking below the transom. THis was easy enough apart from the 45 degree angle around the edge. Now to cut the rudder hole, sorry not sure of the term for this. Now to do the keel covered with 0.5mm walnut strips, the bow part of the keel has horizontal strips as per the instructions I dont realy like the look of the bow part of the keel but she will be painted so not to much to worry about. Davy.

-

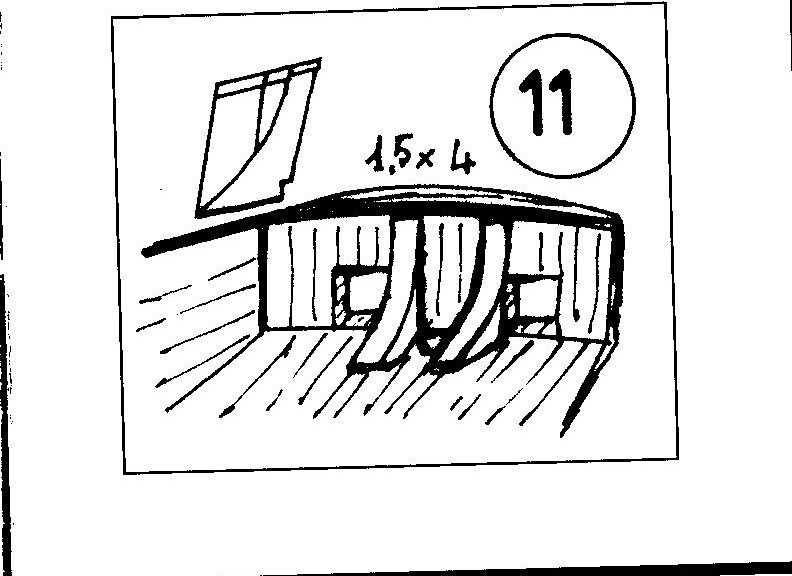

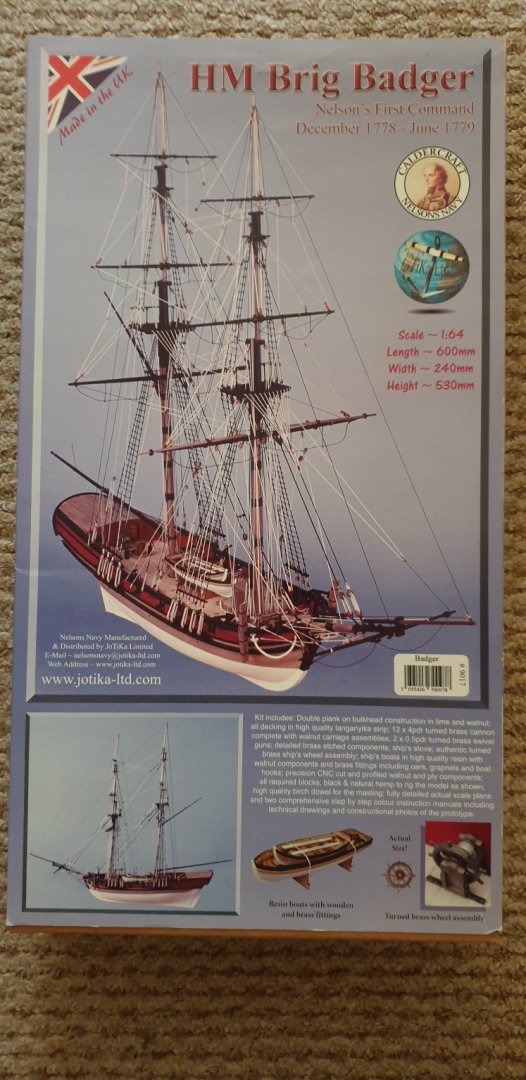

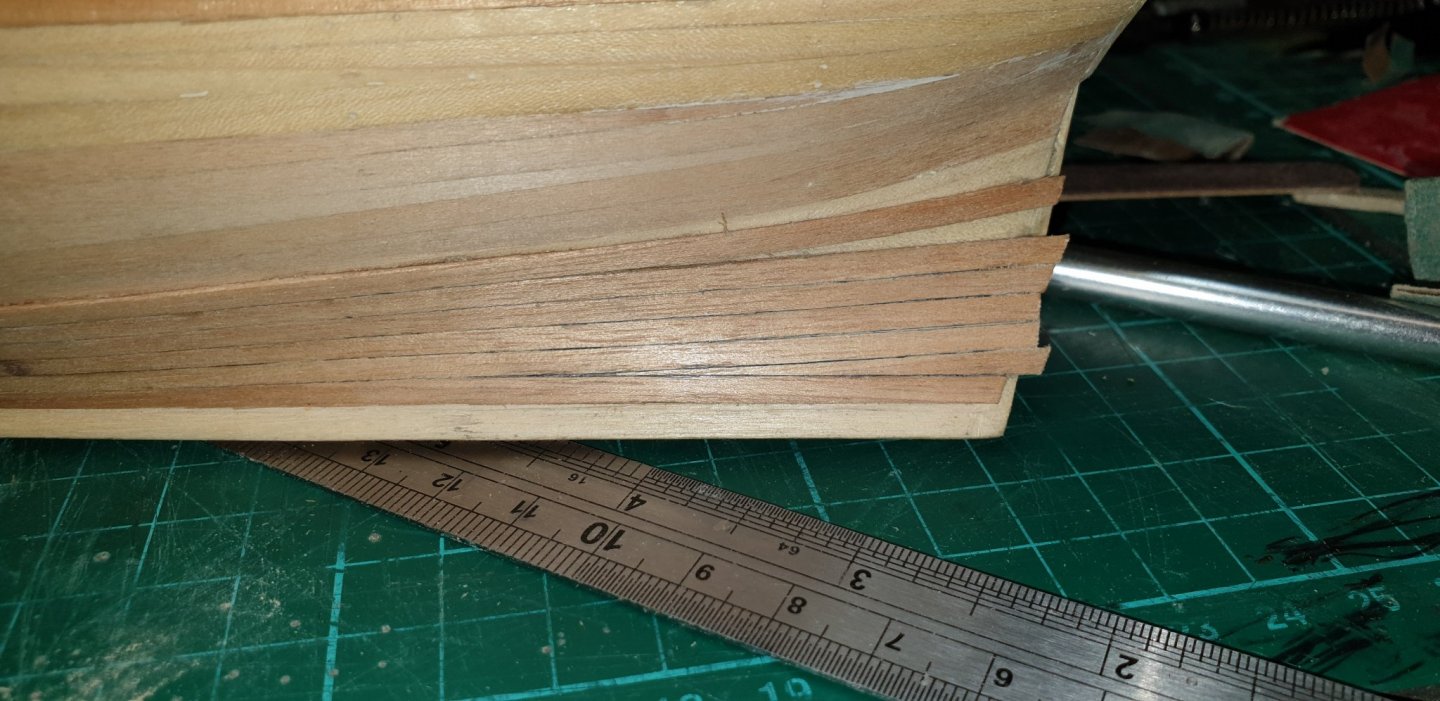

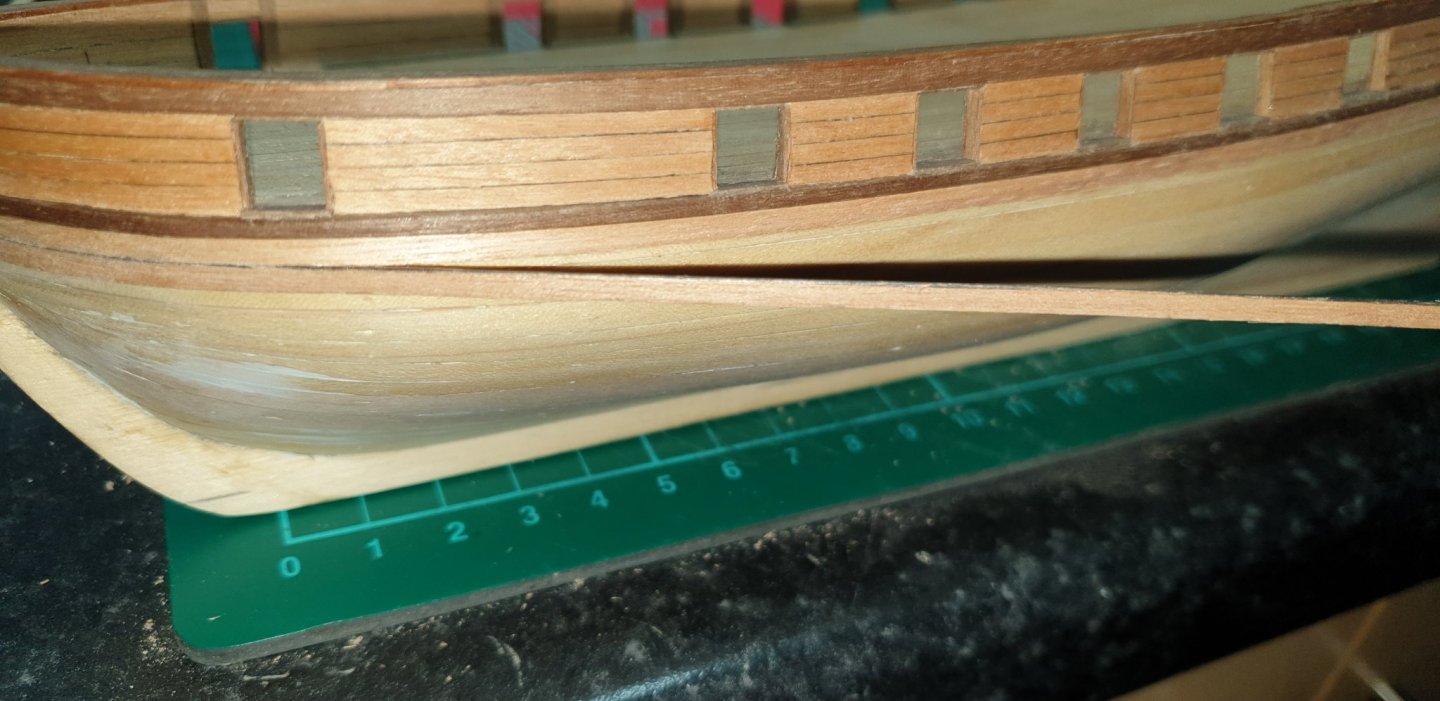

Well i was up till 4 am this morning. so my brain hurts now. but i have worked it out ( I think ) I have a 4 plank width on the bow and an 8 plank width in the middle of the ship, so if i shamfer the planks to half the width which is 1.5 mm. My planks being 3 mm wide i should theoretically < ( Big word for today ) be able to fit 8 in the bow at 1.5 mm width and the stern will get the usual Fill the gap treatment with triangular pieces. this is the point i am at after 4 am this morning. I think the hardest part of this build is going to be finding a big enough bottle to put this in lol. But seriously this I think the 2nd layer of planking is going to be the most difficult part of this build as I have never done it before. What I have noticed this Tanganyika wood. There are a lot fo splinered edges it also has a tendancy to splinter very easily on the edges even with slight bend. I found the solution to this is to run a little bit of CA glue on the edge then quickly wipe it off with my finger that seems to cure the problem. As these planks are only 3mm wide I could not aford to sand much This is when you bend. Befor glue. After glue. Then Sanded. As a side note when i bought the lexington in 2012 I thought it was going to be easy, just before i realised how hard it was going to be I purchased another kit I bought the HM Brig Badger 1/64 by Caldercraft. This will be interesting Davy.

-

Now at 6 planks up from the keel. Seems i read something in one of the posts or seen in a video that if you get the, I think its the garboard strake shaped and fitted good then the rest of the planking will be ok, and so far so good. I can see that there is a lot of space between the middle hull planking and the bow Planking. It looks like I need to research more to see how i can fill this gap. Davy.

-

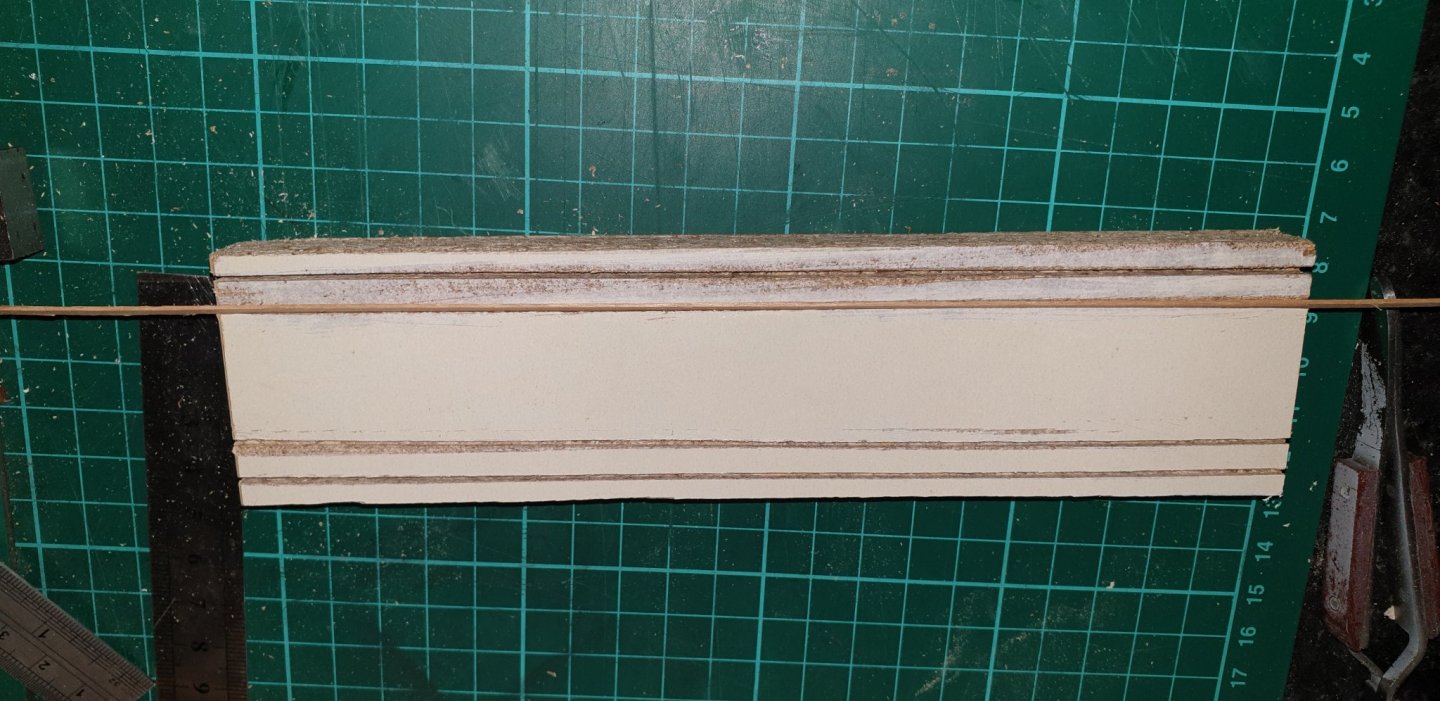

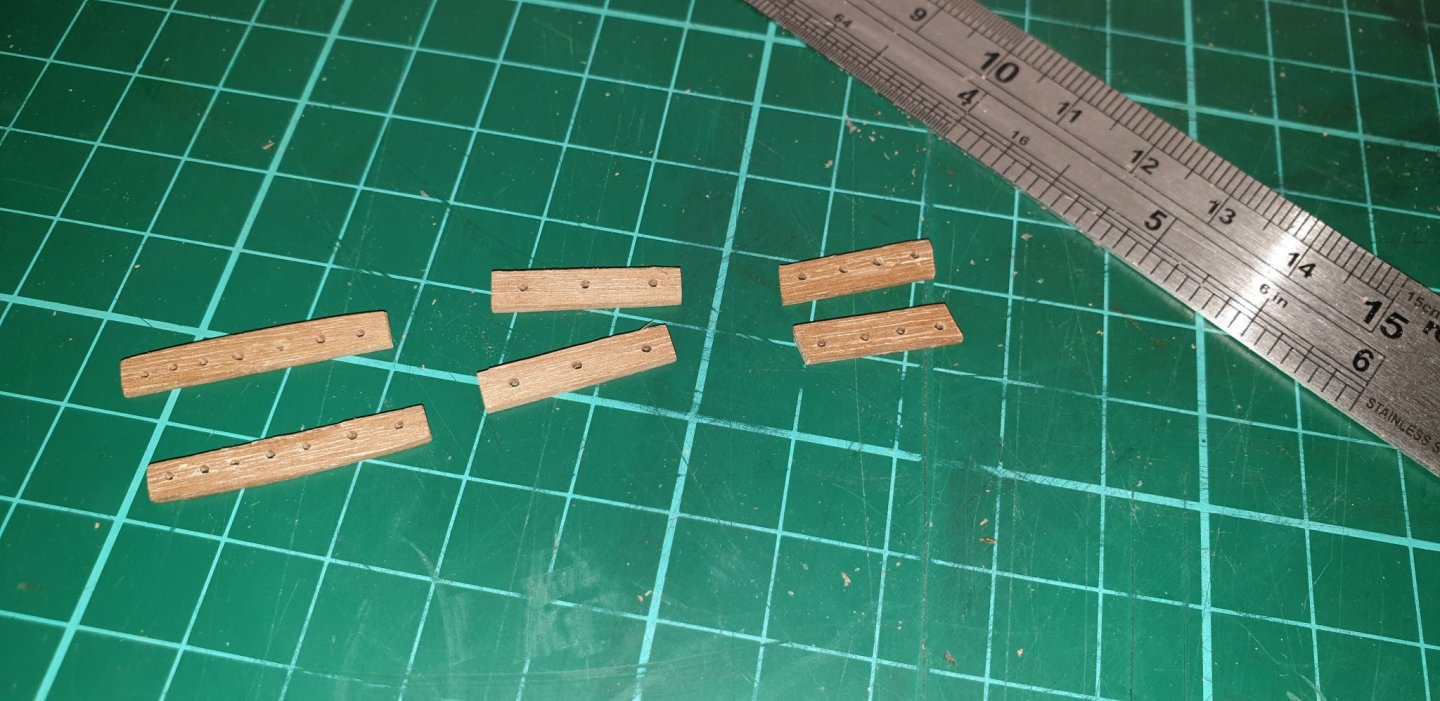

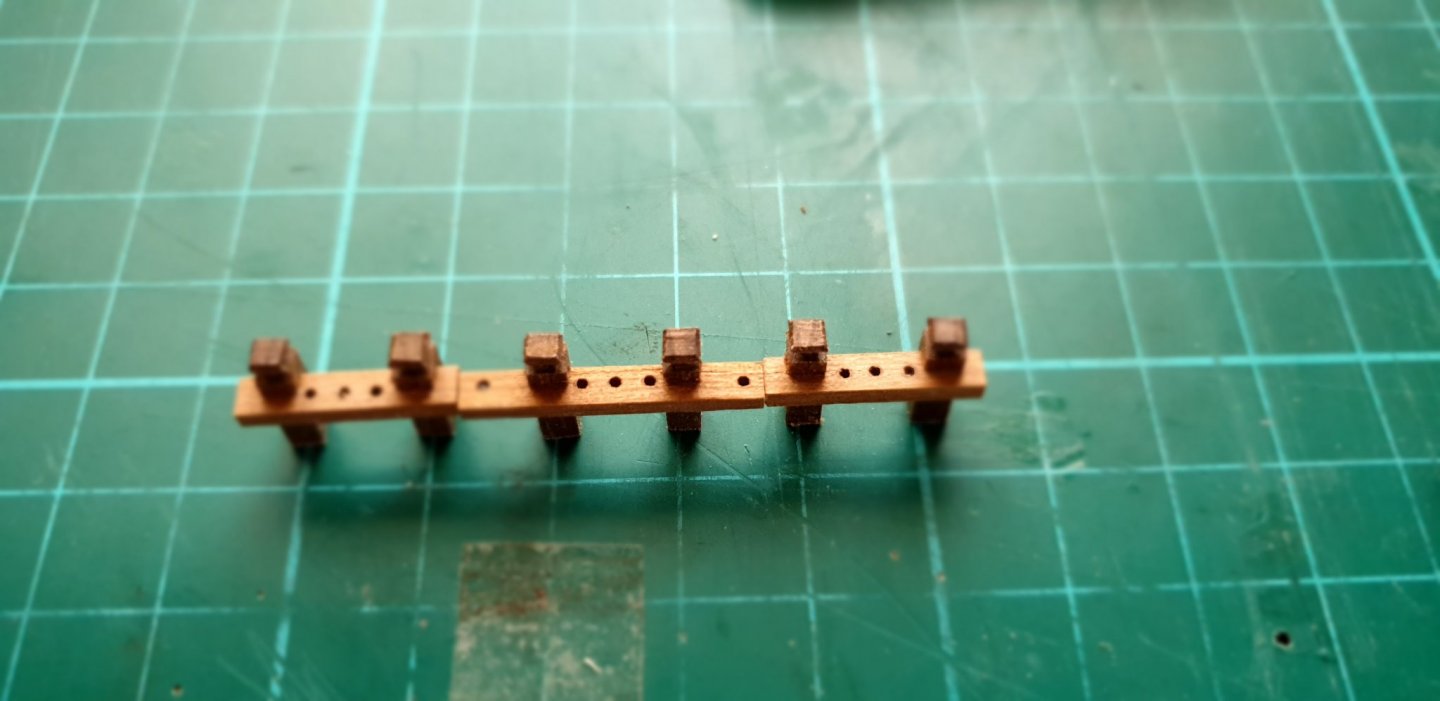

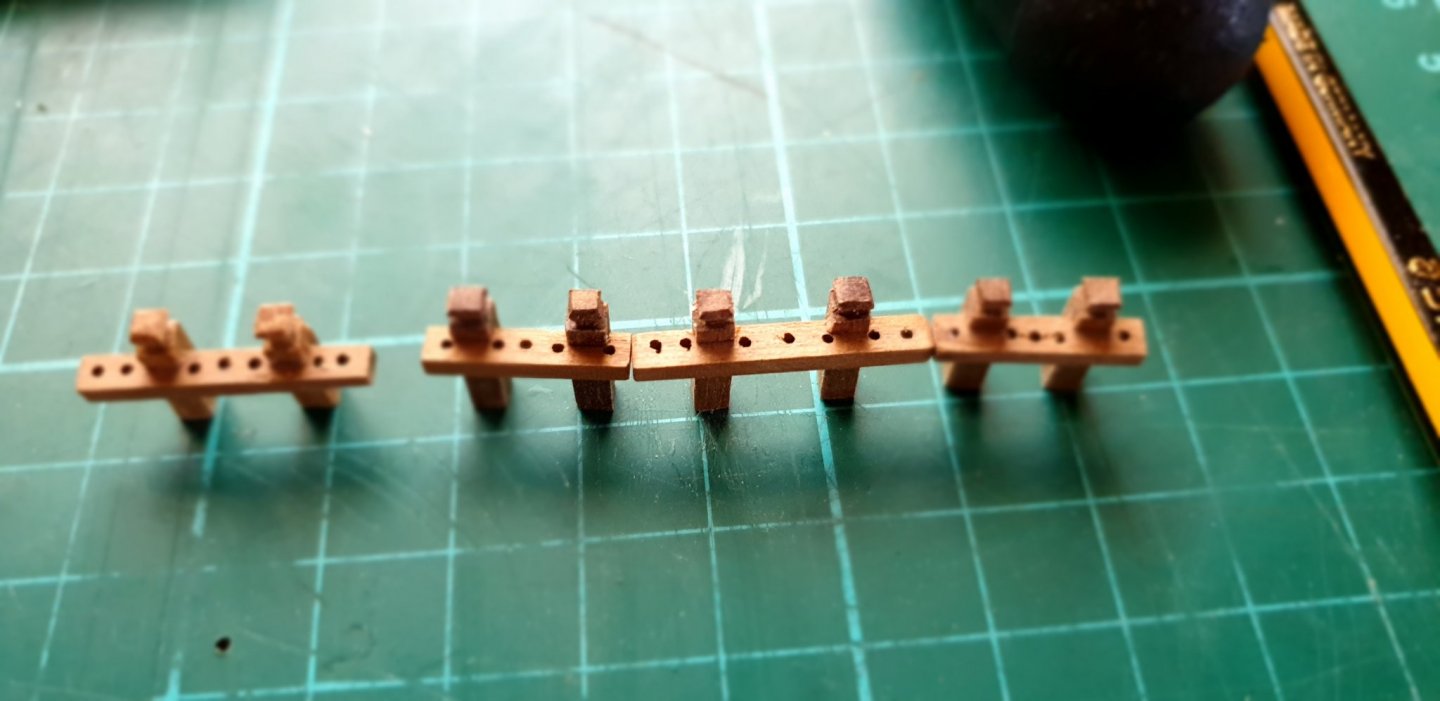

My wood arrived this morning, Thanks Cornwall model boats for your prompt service. so i finished the 2 bow belay pin racks. The pencil line in the 1st pic is how much overhang the handrail has so i know how far out to drill the 1mm holes. Now to start the second planking, I have no idear which technique to use so I'm just gonna wing it. my idear is to start from the top and work down then from the keel and work up as far as i can tell if I shape the plank nearest the keel i think is called the garboard strake. As long as the bow end of the garboard strake does not curve upwards and isa level the rest should just fall into place. This is a little jig I made to hold the planks so i can bevel and shamfer them. Well thats 2 done. I'm going to leave it there for today, but so far so good. Davy.

-

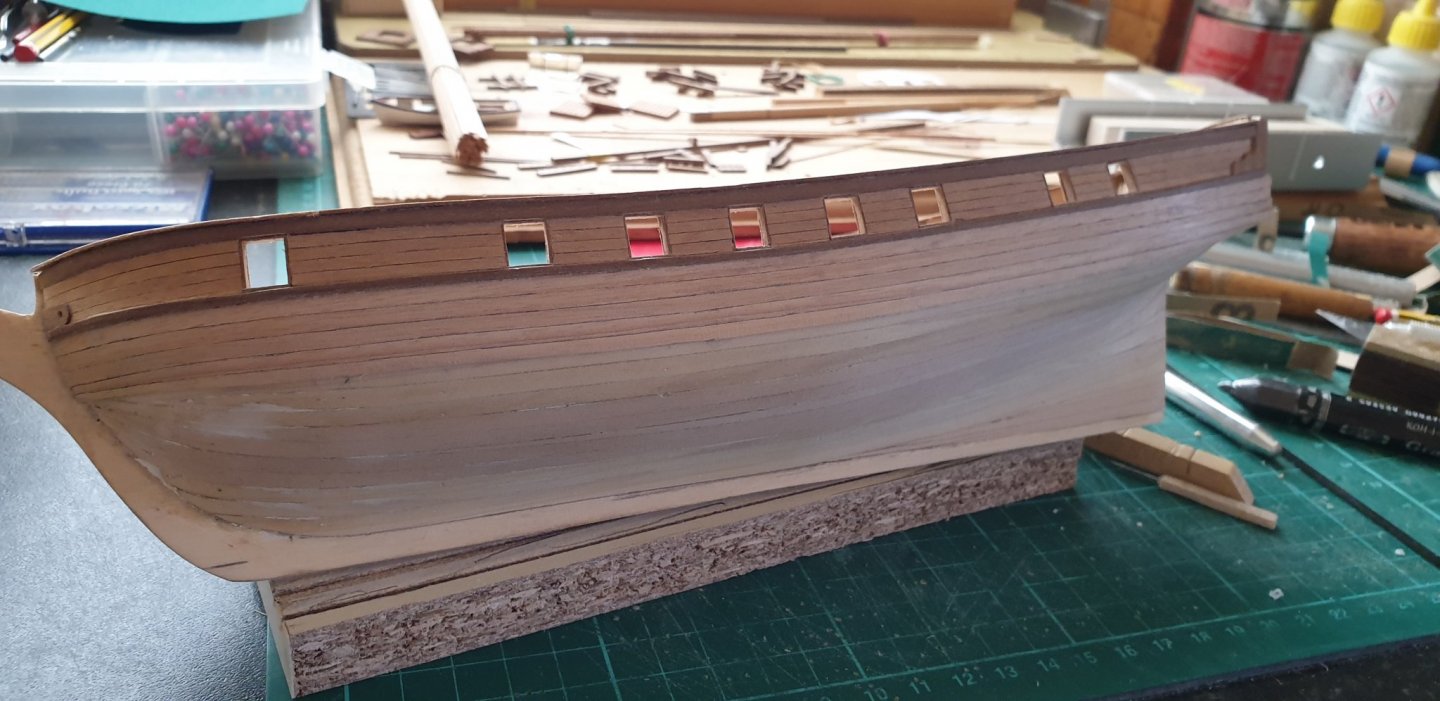

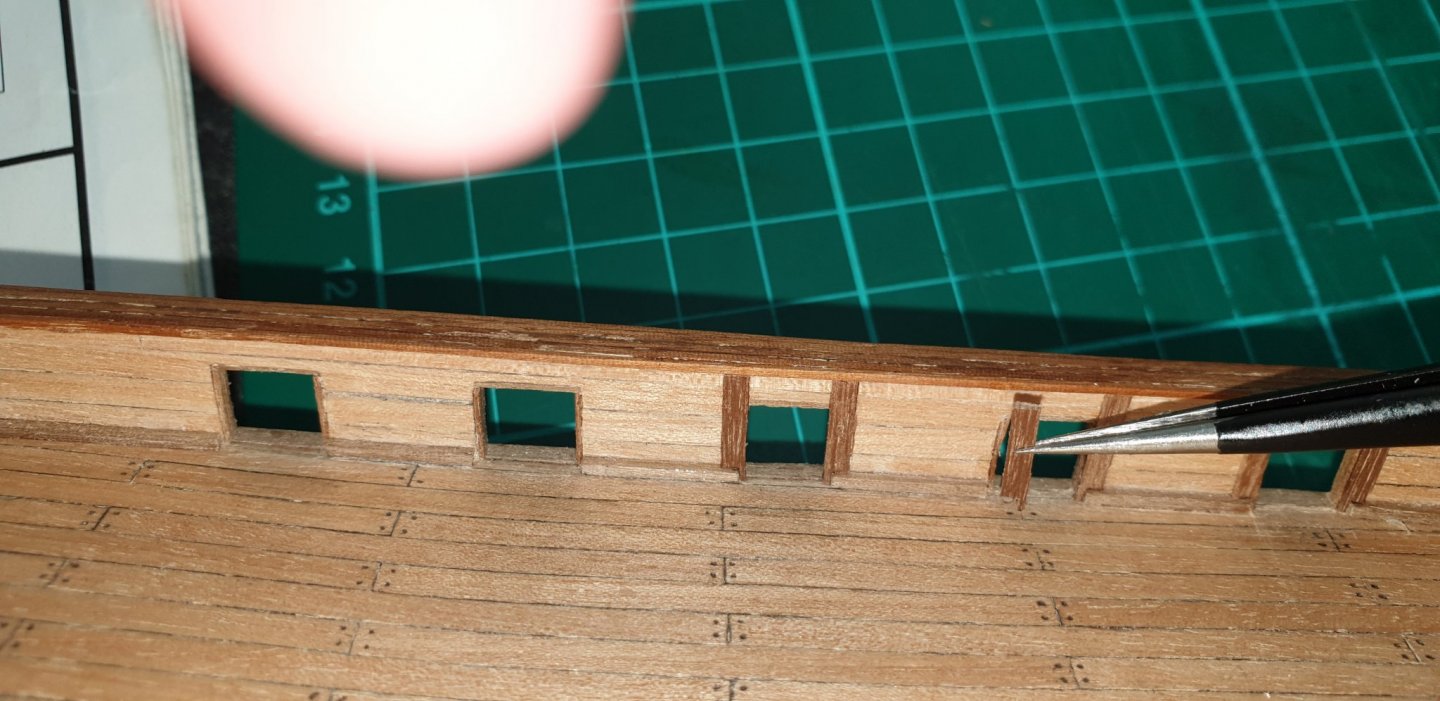

I love my Archimedes drill. Well thats them done I have finaly stuck the 1st planking and the handrails back on that i removed erlier to make the deck planking easier. I also started on the gun ports Now to make a start on the outer planking above the sheerstrake. I thought about gluing a whole plank from bow to stern but i thought it would have been a waste of wood, so I did it in short planks. Its not going to save a rain forrest but it helps. I would love to know how you guys do this, do you use a whole plank from bow to stern, then cut the gunports out afterwards. Or use small strips. then the inner planking. Also the consoles at the stern of the ship atached to the bullwarks, and 2 1.5mm x 2mm strips of walnut to cover the top of the transom. As this is my 1st build log. Please leave comments if you think i'm doing something wrong or if there is an easier way of doing something. any help will be greatly appreciated. Davy.

-

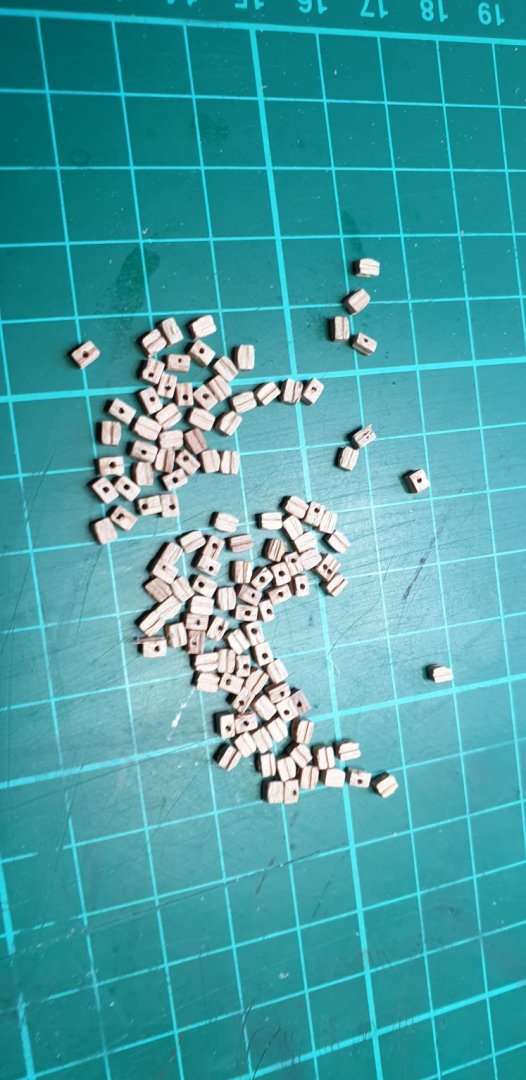

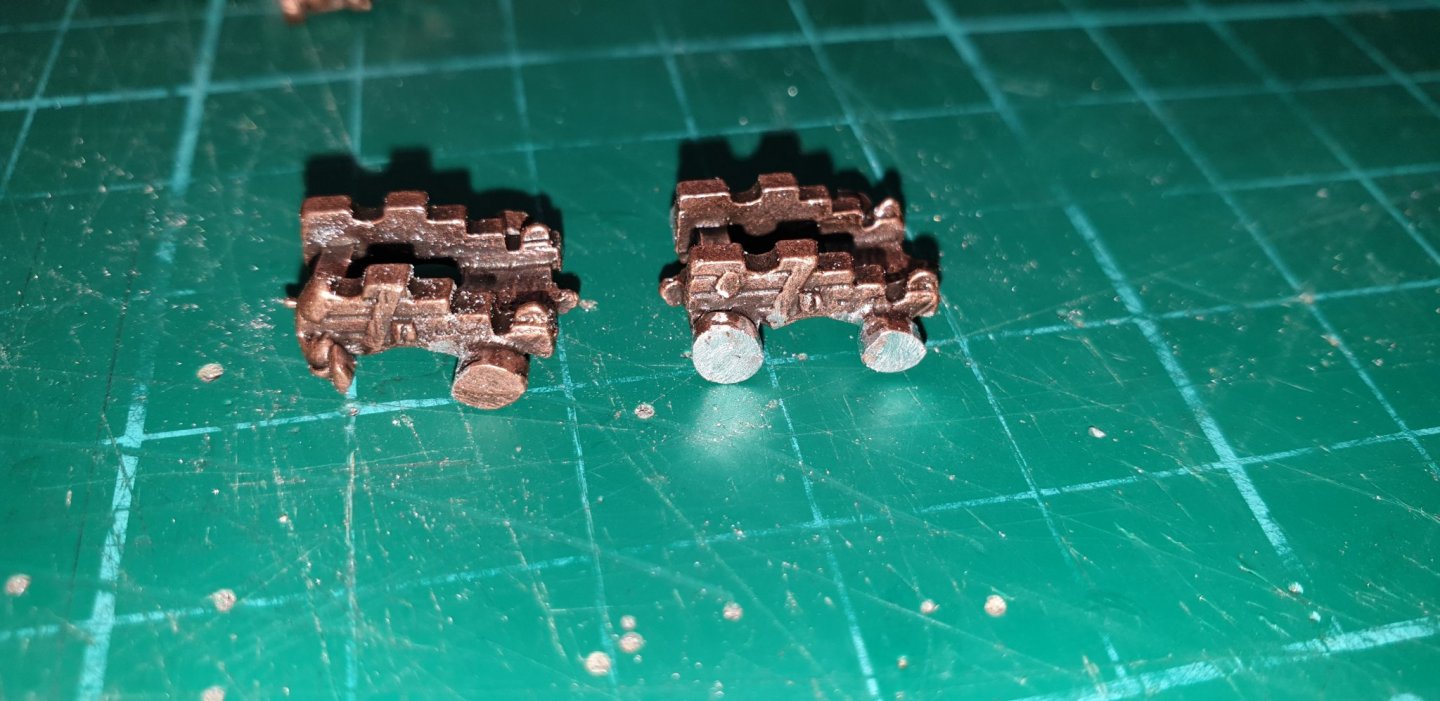

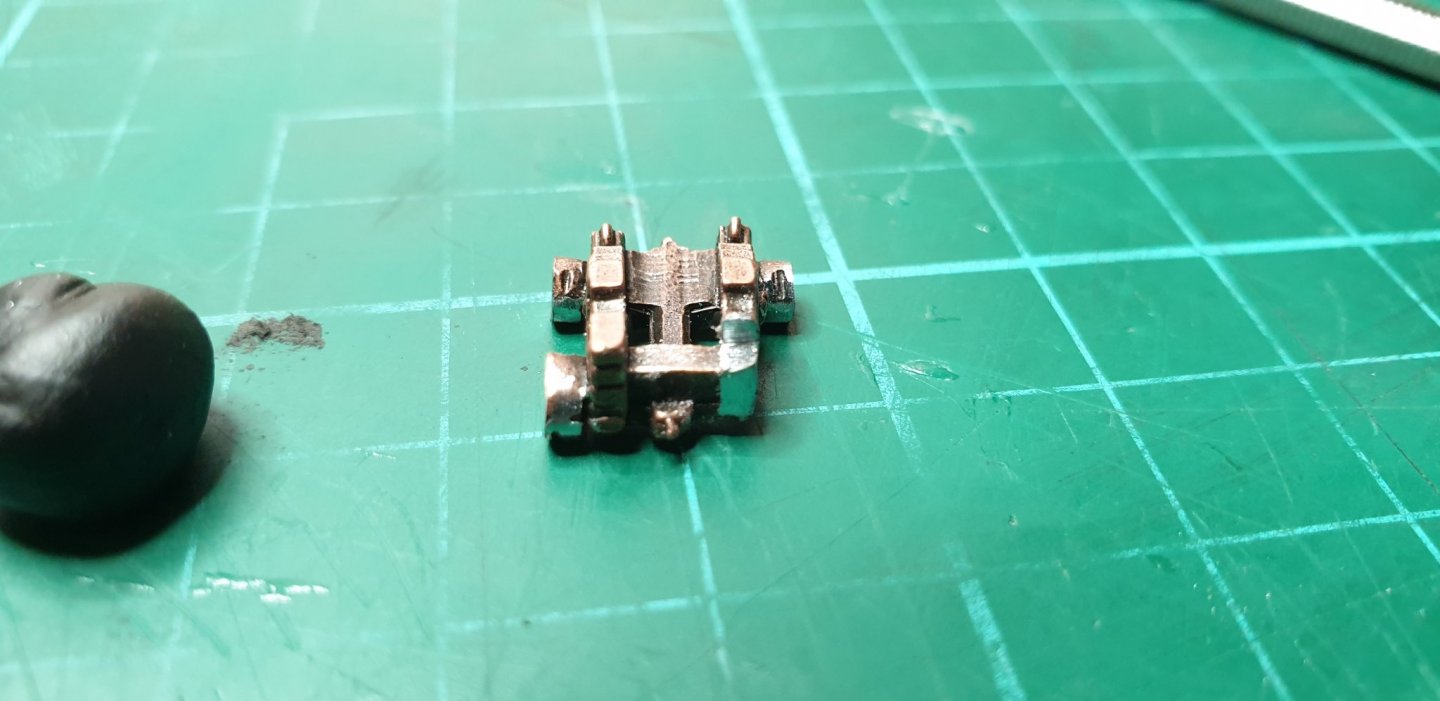

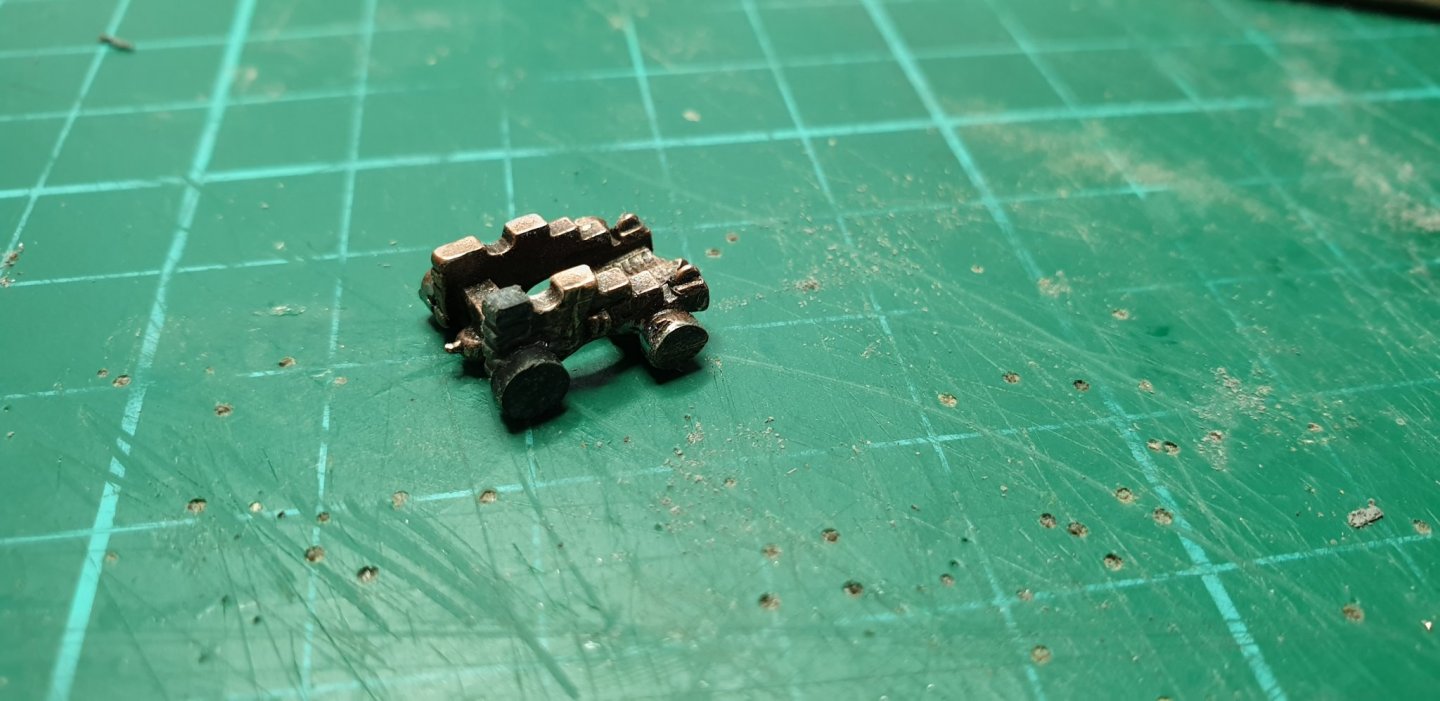

I have finished the planking on the outside of the transom. Its starting to look more even now. Now for some of the smaller parts like the transom supports . Then the lifeboat bracket for the stern of the ship also walnut, and the sides of the transom above the sheerstrake. Then the blocks which come square so they need rounding off to make them look a bit like the real thing. All 152 of them, this took me a long time to do. I found the best way to do this was to use a cocktail stick or a pin to hold them down then a small file to round them and a v shaped curved file to cut the grooves.

-

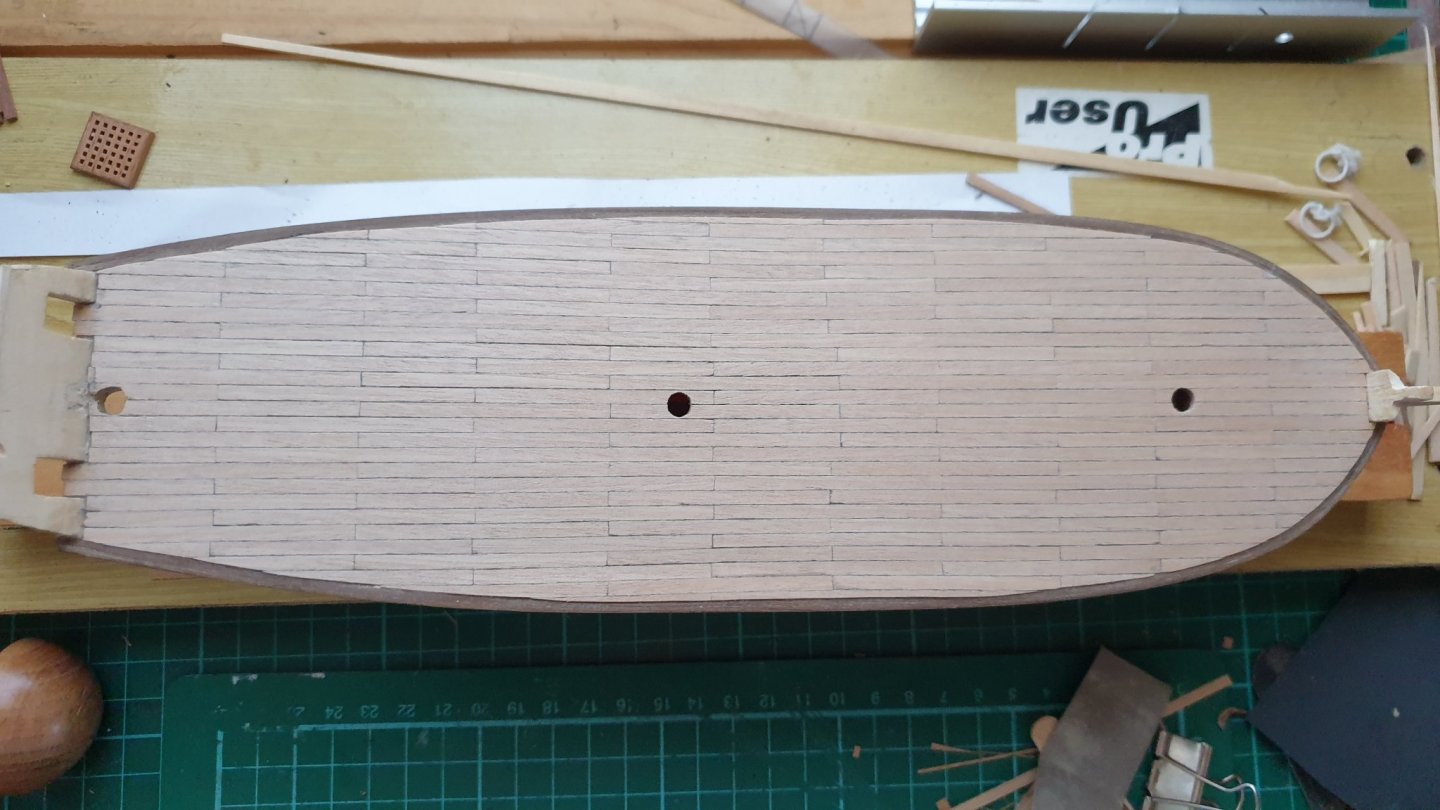

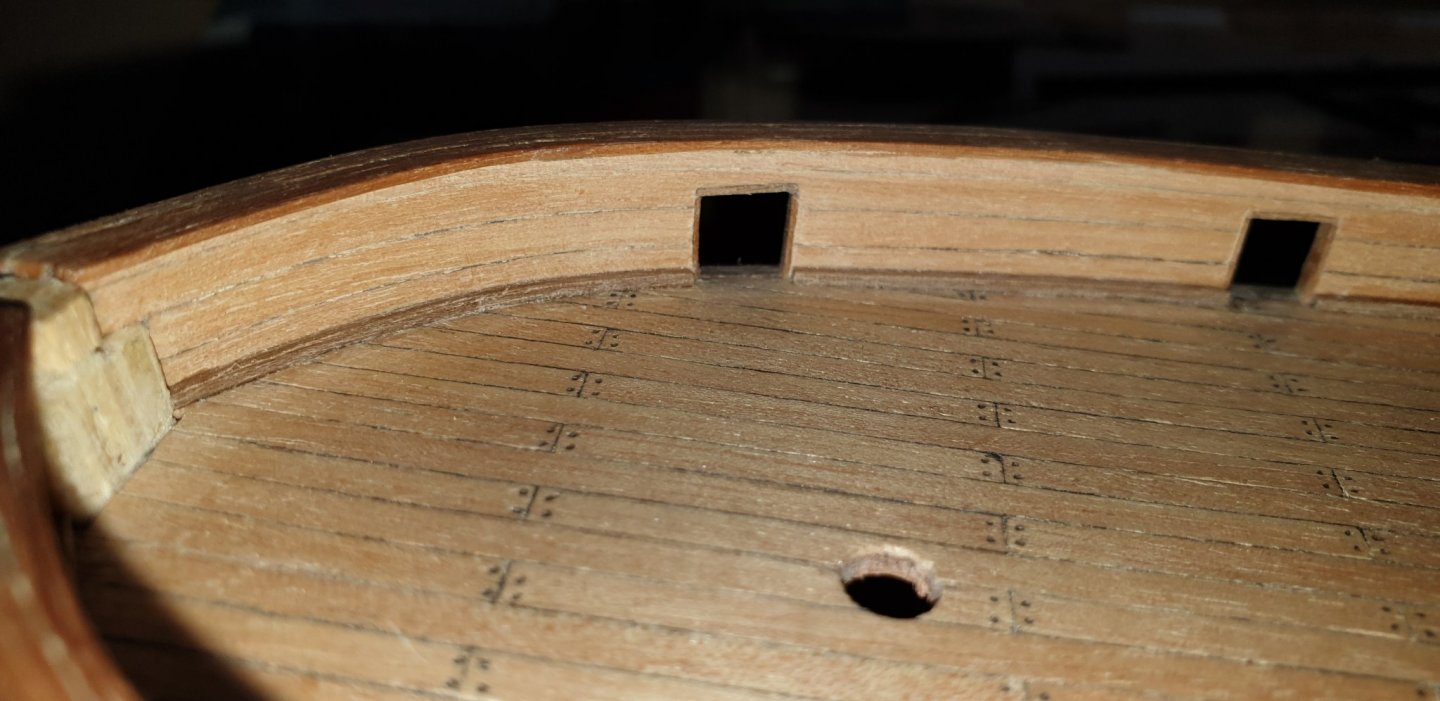

After the 1st planking I made a start on the deck planking. For this i followed the plan instructions. 50mm long 3mm wide 0.5 thick, for the calking i used a 4b graphite stick. This went well As you can see from the above picture i have no sides to the ship above the sheerstrake, which i removed to make the planking of the deck easier for me. little did I know this would be a challenge to put back as i already cut the tops off the bulkheads. Now the deck is planked a bit of a mess at the transom end of the deck, but I have 1mm x 1mm walnut to cover any mistakes. Now its just a case of making the edges nice ready for the sides to go back on

-

Well it's time to get this build log underway. Thanks to mtaylor who put the idear into my head. I bought The Lexington American Brig by C.Mamoli kit back in 2013, I started it then ran into some real life problems. I started on the Lexington, and soon ran into my 1st problem as the instructions in my mind are awfull. I have made a lot of plastic models, ships, tanks etc. but never a wooden ship. So as per instructions i start with adding the bulkheads to the keel, once that was done i started on the mahogany deck sheet. Then added the transom where my 1st problems started. So i fixed that with a bit of cutting and sanding but never thought of measuring so it ended up slightly off as you can see from the pic. After the Transom I started on the 1st layer of planking where my real life problems started. This is the point of the build where i was stuck and mothballed the kit until i sorted the real life stuff and researched alot about planking and looked for all i could find on the Lexington, which puzzled me a bit because I found that there were a few versions of the ship. Some had 4 windows above the 2 gunports in the transom, some had 2. Mine has just 2 gunports.I also found 3 build logs here and 2 of them are different to mine I know The Lexington was renamed from Wild Duck to Lexington and was re-fitted to be a war ship in the continental navy. So the years passed and i forgot about the ship, Then came covid 19. So took her back out and with the research and some help from you guys I started again. So i finaly finnished the ist layer of planking. Which i can say was a chore but an enjoyable one. I found i did'nt need much filler as the planking came out quite good.

-

Thanks guys. I think my problem is solved. But i can see with the instructions for this model there will be many more. Davy.

-

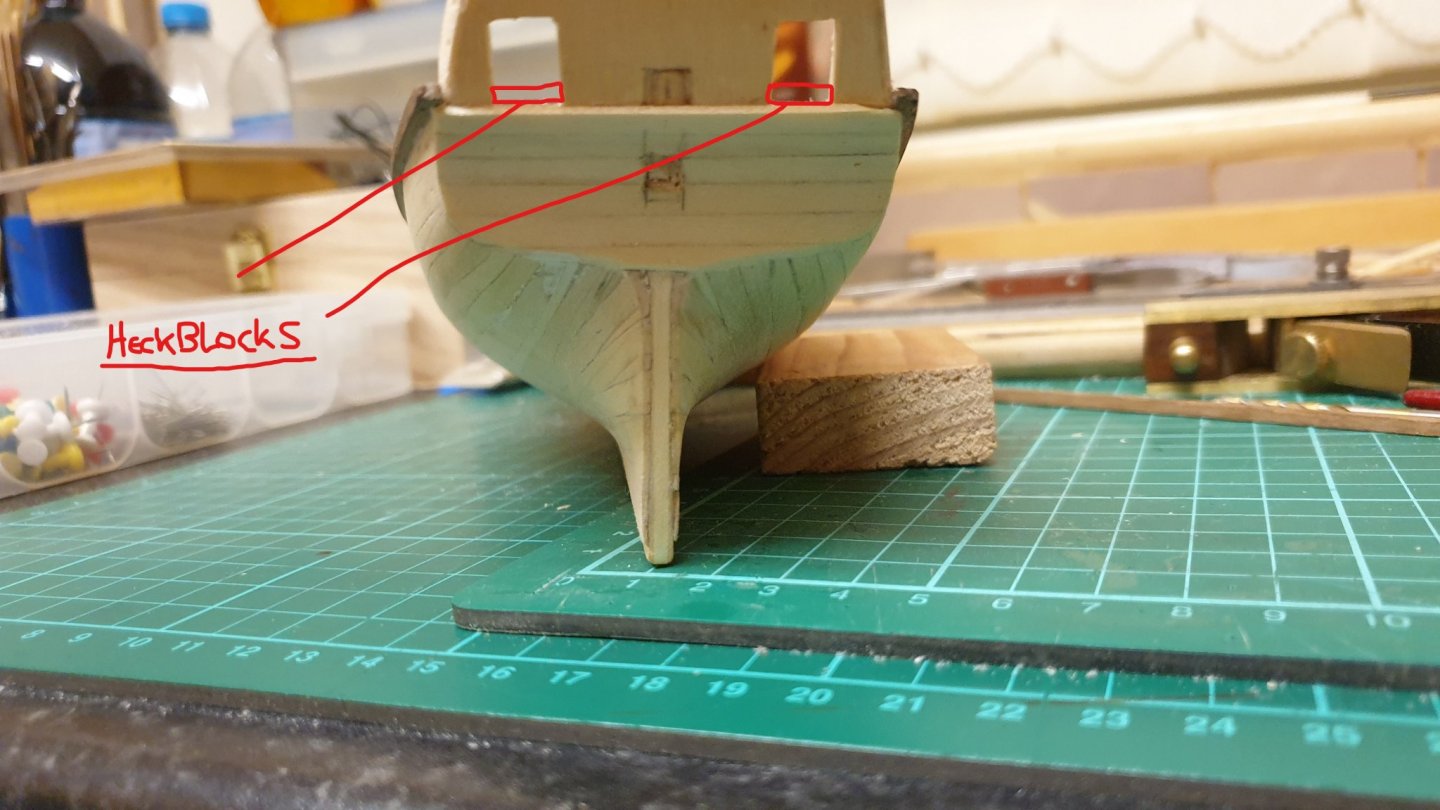

Thankyou Bruce. So what your saying is the Heckblocks is a Transom Pully block. So basically i'm supposed to plank the Transome pulley block. I just love puzzles lol. I also Google translated the word heckblocks and in German it means Stern blocks. Anyway i think i have the solution to this puzzle after looking at Zappto's build log. If you notice on the 1st picture my transom gun ports go all the way to the bottom of the transom. But if you look at Zappto's transome finished they do not which makes me think there must be a block under the short planking at the bottom of the gun ports. I wonder could these be the heckblocks

-

Hi Bruce. Yes. I have already made those but as you see they are on the otherside of the transome. I dont mind telling you that the instructions for this kit are not very good. Davy.

-

Hi Keith. The kit manufacturer is Mamoli. Davy

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.thumb.jpg.1d7bfdb395a6cc6b9afdb9ef3325766c.jpg)