-

Posts

44 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Engineer57

-

Bob and Canute, Turns out I still had some of the Micro Krystal Klear that I have used for model railroad structures and vehicle glazing. It worked great. Thanks! Zapto, Thanks for the compliment. Just the single layer of planking for this model. I am nominally following the kit instructions with some deviations/mods per Bob Rafine's version. If you have not read his log please do so. The difference is that I am working with a newer "corrected" kit. So some of his notes about how he had to fix parts in his kit have been accounted for in the newer kits. More pictures to come,

-

Bob, or anyone else with experience, how do you glue the wood window frames to the "glass" without making a mess? If the window glass is plastic (acrylic or styrene) sheet using CA adhesive will fog it. I don't think the elmer's wood glue will stick to plastic very well (unless you have experience otherwise...) so I am not sure what to use. Thanks everyone for the likes. Thanks!

-

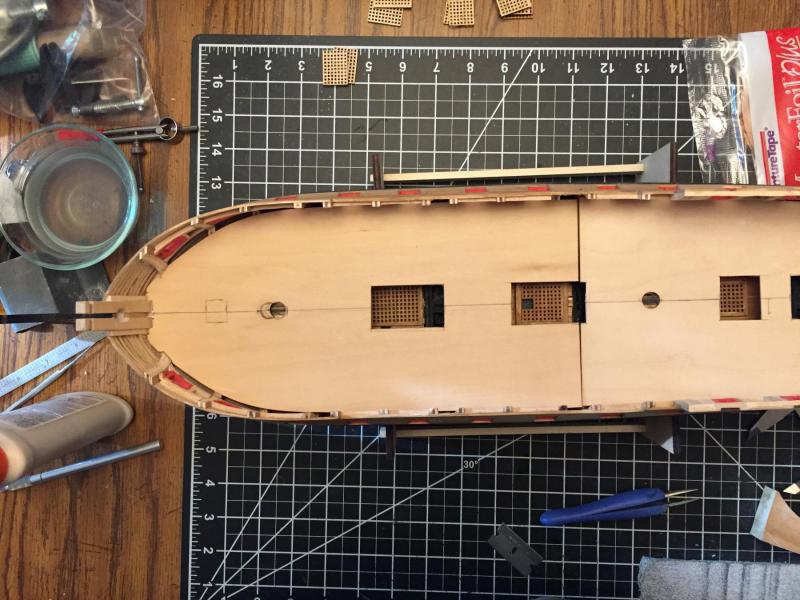

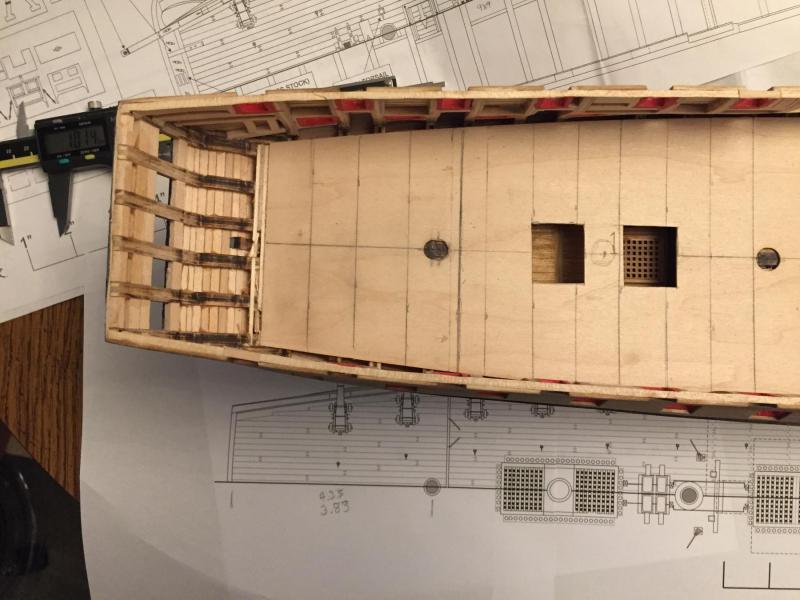

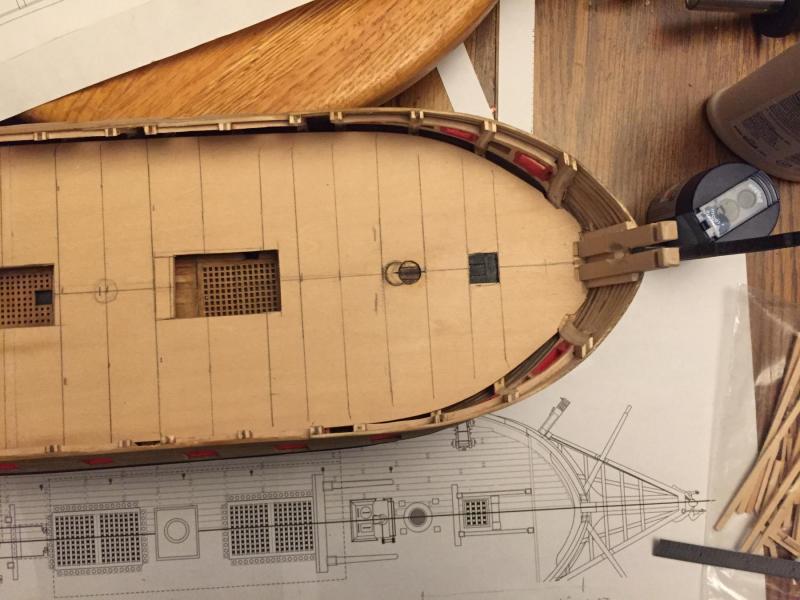

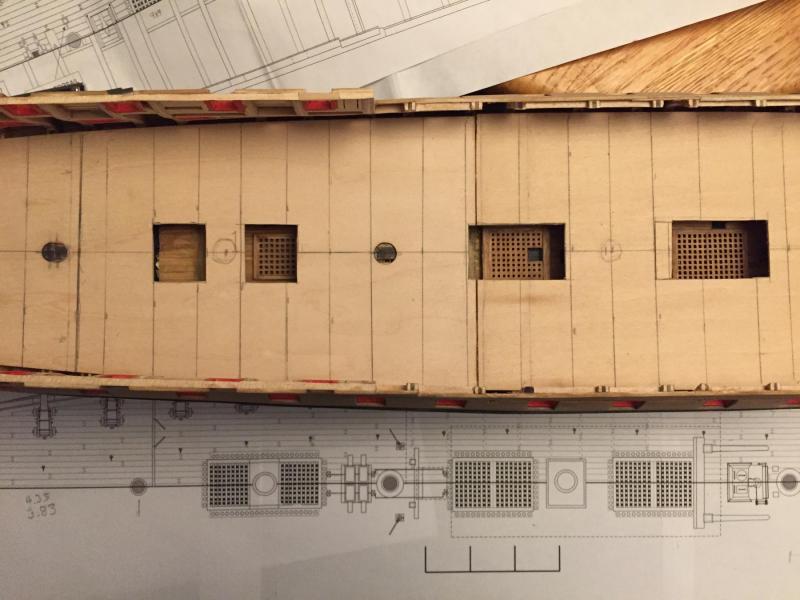

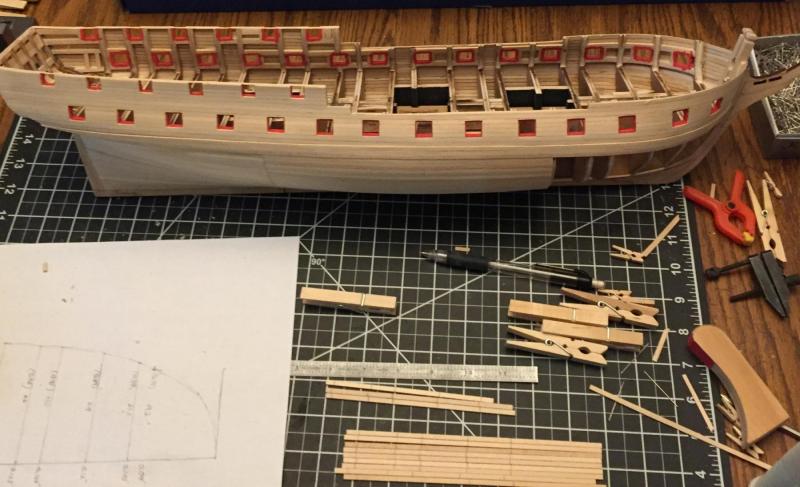

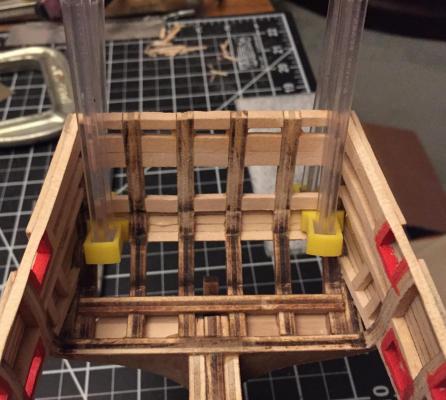

Hello everyone, Longer break than I planned due to increased time doing PT on my shoulder. That is officially done now. Vacation was very enjoyable, we covered Niagara Falls to Bar Harbor and I got to see the replica of the Gun Boat Philadelphia at the Lake Champlain Maritime Museum and watched the 4 masted schooner Margaret Todd sail in Frenchman's Bay. I have made some more progress. After a lot of measuring and comparing notes across multiple sources I decided to shift a few features and go forward. The mizzen mast shifted forward slightly and the foremast stayed where the false deck located it. The length of my gun deck to the bottom of the window frames at the centerline came out approx 0.43" short. I do not know why but suspect a combination of things including not getting the stern frames at precisely the correct angle. There may still be something off in the kit, but at this point I cannot prove what if anything that might be. After gluing the false gun deck in place I used two metal angle blocks with a right angle block and set the drilling angle for the masts to match the drawings. I mounted the hull on a board on my drill press and shimmed the back part of the cradle upward until the drill was parallel to the angle blocks. I carefully marked the location of the beams that would be under this deck so that I could use the marks to cut the planking to length. I decided to cut individual planks rather than follow the instructions to do full length and mark them after the fact. I think this way you get a more realistic looking deck. I started in the center and worked outward after the margin planks were dried. It took some creativity at the bow to fit the margin planks around the knight heads. Then it just takes patience to cut and bond the planks in the correct pattern. Continue the pattern working outward until you hit the point where you have to joggle the planks into the margin planks. A really sharp small chisel helps here. At the port and starboard edges you need to custom sand planks to fill the remaining gaps to the margin planks. After sanding the deck I started the bulwark planking. First the board under the gun ports was carefully positioned and allowed to dry. They I used a variety of tools to make sure the plank below that was pushed up against the first plank. I split the planks at the first row near the sixth and the second near the eighth gun ports to allow me to soak and bend the bow sections and then apply the rest to the stern. Where the gap to the deck was less than 1/16" I did not fill it since the waterways will cover them. The I worked my upwards and ended by applying the waterways. Next will be planking the inside of the stern.

-

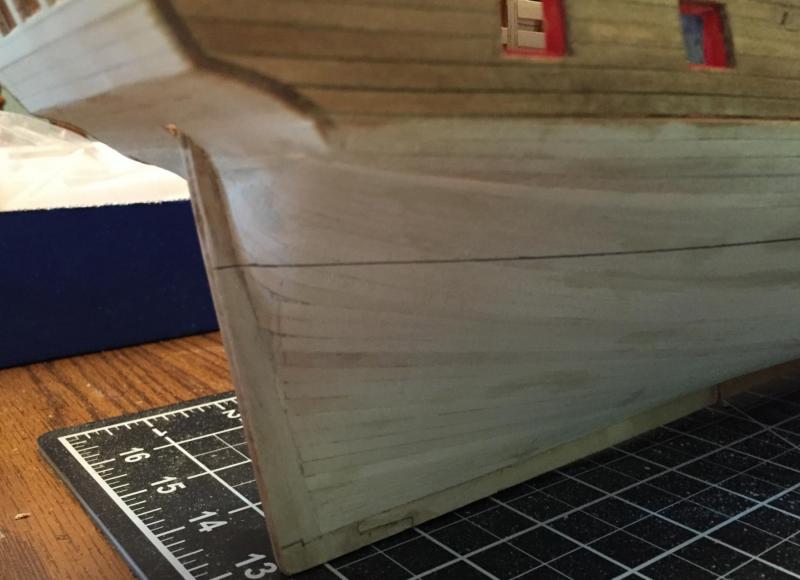

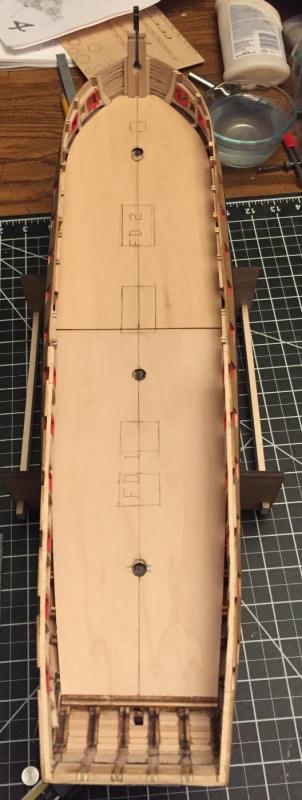

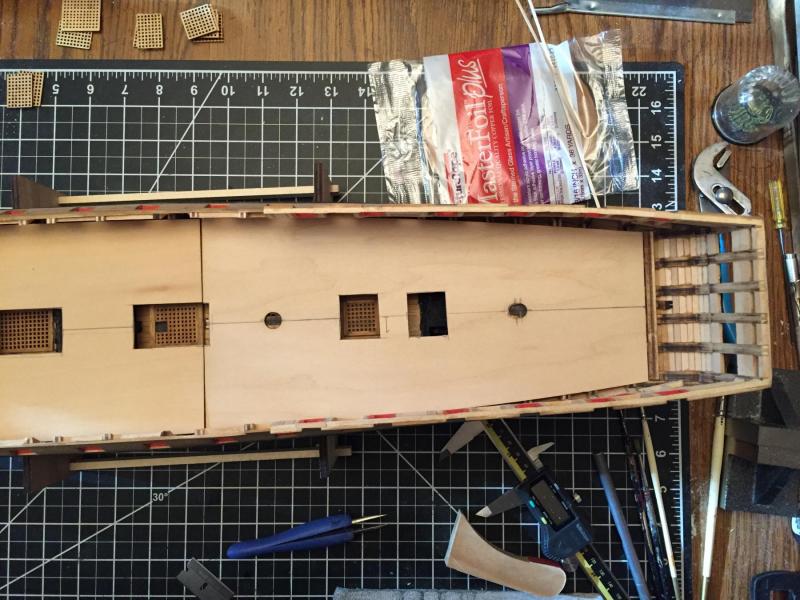

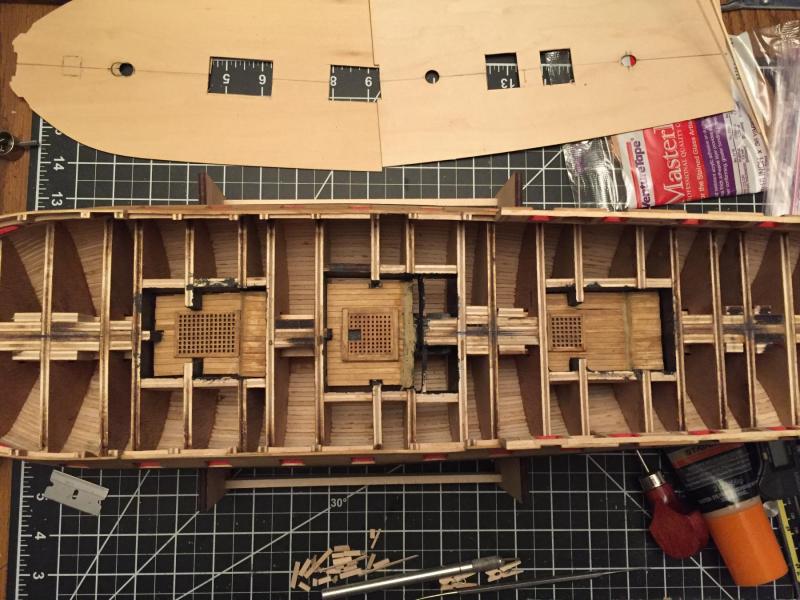

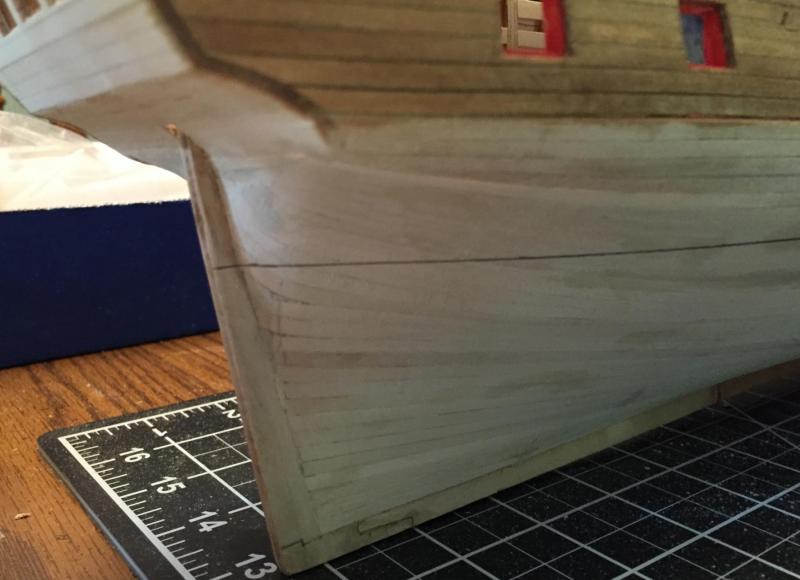

Thanks everyone for the likes! And here is the next set of pictures of my progress to date. I used a vertical caliper as a scribe for the hull lines by taping a pencil to the arm. The hull (keel at the front) has to be propped up in front to get a correct run for the top of the copper plates and the blend point for the lower to mid runs of copper plates. Then I painted the areas of the hull black that would not be copper plated.starting below the gun ports, as well as the stem and stern areas. Amazing how that changes the appearance of the model. The false deck was giving me fits because I could not get things to line up correctly. After much measuring and some helpful feedback from members here I determined that the fore and main mast holes in the false deck fit correctly but the distance from the mizzen mast hole and the main mast are off slightly. I ended up moving the mizzen mast hole 0.15" forward. Also when I laid out the grating positions and cut them into the false deck I saw that my earlier attempt to show the lower deck and gratings was short by various distances on all three areas. I modified the frames by cutting and reframing the lower areas and extended the planking to match. None of this will probably be visible, but I wanted to try and get it right. After more adjusting and fitting I decided it was as good as it was going to get, so I glued the false deck down and then marked the lines for the under framing to help me cut the decking to the correct lengths when I get to that point. I will be taking a couple of weeks off for vacation, more when I have progress to report.

-

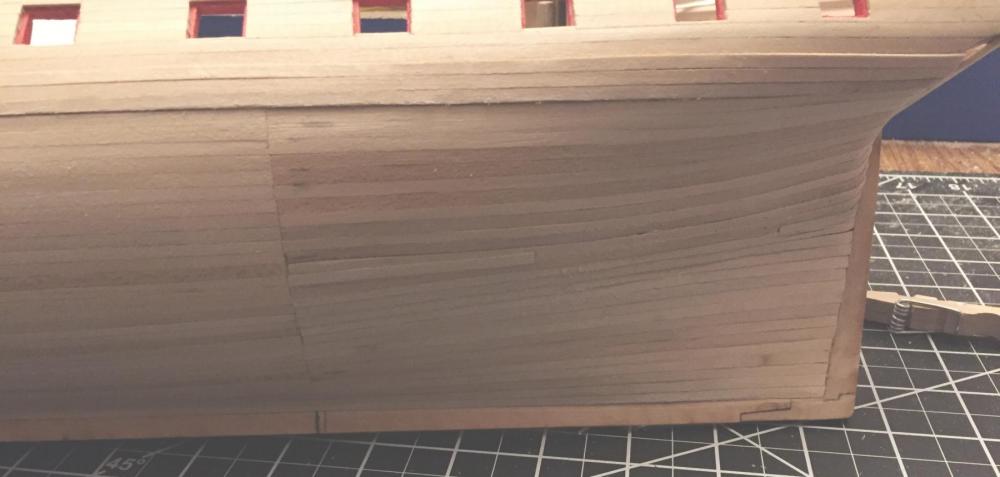

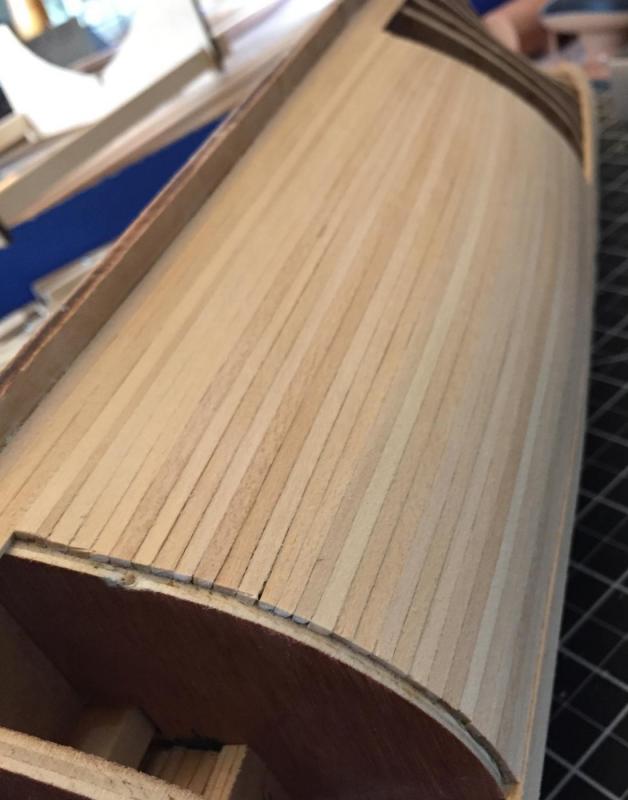

Here is the belated update of my progress so far. I finished planking the port and starboard sides of the bow. Since I had never done this before it was a lot of experimenting and I did each side a bit differently. I was not worried that they would look too different since I am planing on painting and copper plating the hull per the model instructions. By this point I had gotten better at tapering and bending each plank. You can see where I simply tapered some planks to points to make it all fit about 1/3 of the way up from the keel. On the other side I tried to taper each plank more but still could not get it all to lay in the way I wanted. However when looked at next to each other it came out looking pretty good. After sanding and a bit of filling it looked much better. Then I went to work on completing the stern above the rudder. As you can see there was not a uniformity to the two sides at the stern with planking stopping shorter on one side than the other. I did some creative fitting and filling and in the end (pun intended) it came out fairly acceptable. That's it for now, more tomorrow.

-

Hello everyone. I am finally to a point in my recovery from the shoulder surgery that I have started building again. I will post pictures soon, but I have finished planking the outside of the hull and am trying to fit the false deck. I am having problems getting my model measurements to sync up with the drawings. Mast positions do bot match the spacing of the laser drilled holes in the false deck, etc. Does anyone have similar issues and how did you get things to line up? Do I trust the drawings fully?

-

And finally the stern planking. This is more challenging due to the need for fillers. It looked rough at times but it all sanded out pretty well with minimal need for filler. The clamping became more of a challenge. This catches everyone up to where I am except for the few bow planks I have tried. That requires carefully tapering each plank to fit and is driving me a bit crazy so far. once I start up again I will post progress. Thanks for the likes and encouragement.

-

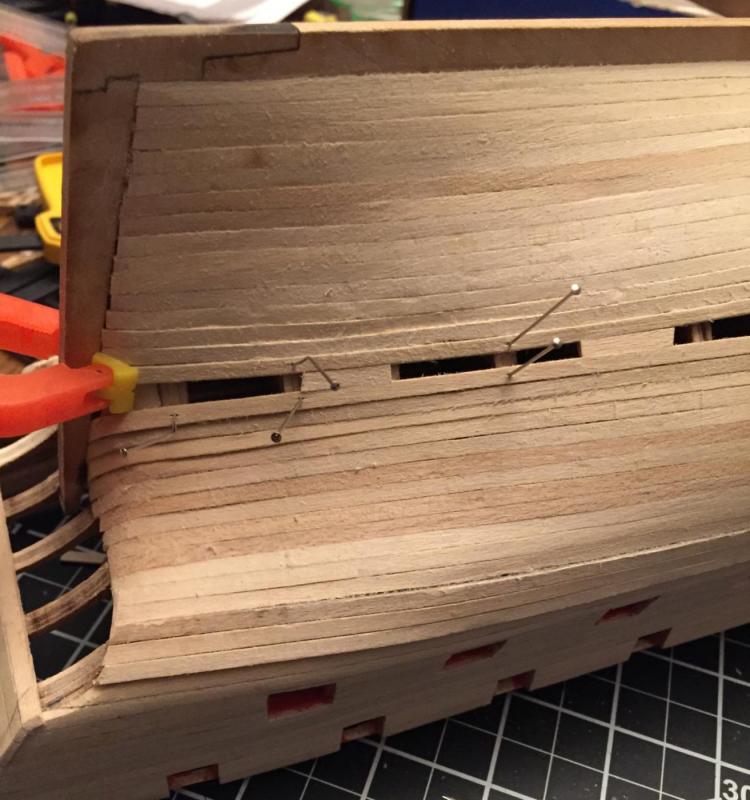

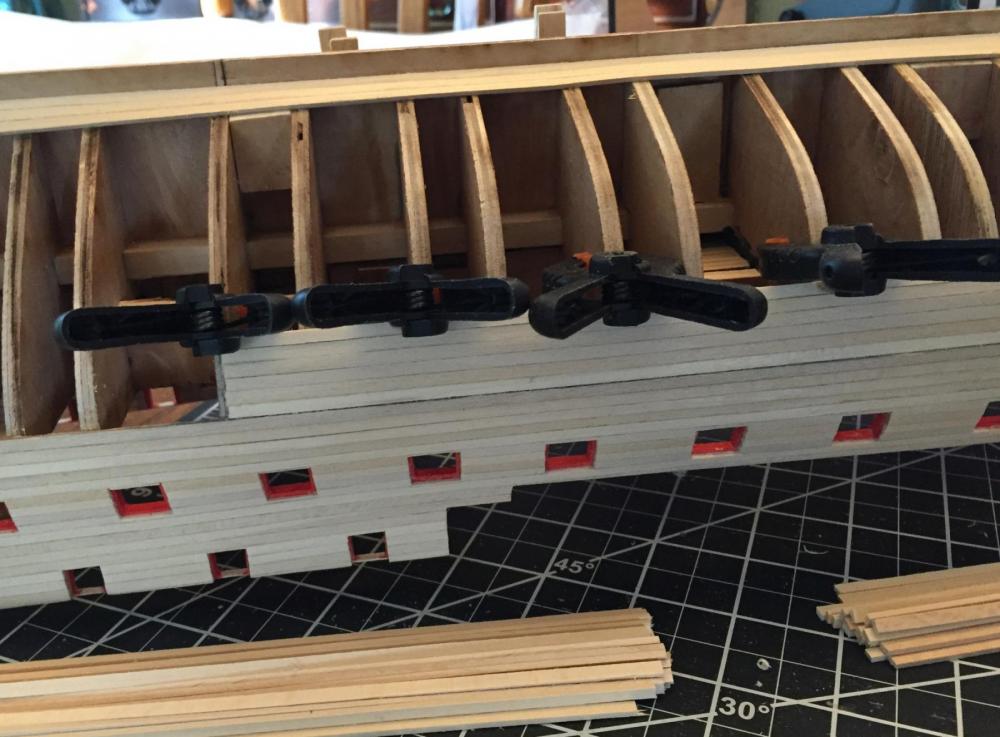

I did not do anything on the ship for a couple of weeks after the injury since the arm hurt too much. Then I started working on the lower hull planking. I decided that since I was both painting and putting copper on the hull I would follow the kit instructions and apply the planks in three sections: Center, Aft and Bow. Center and aft went pretty well. The bow is not done yet because of the surgery. Hope to start back up soon. You will see that I varied the clamping depending on where I was in the process, having to go to smaller ones and finally pins to hold while the adhesive cured. You should also be able to see where I tapered planks on the lower portion closer to the keel to get everything to fit correctly. These pictures are of the center section work. I will post the stern section next.

-

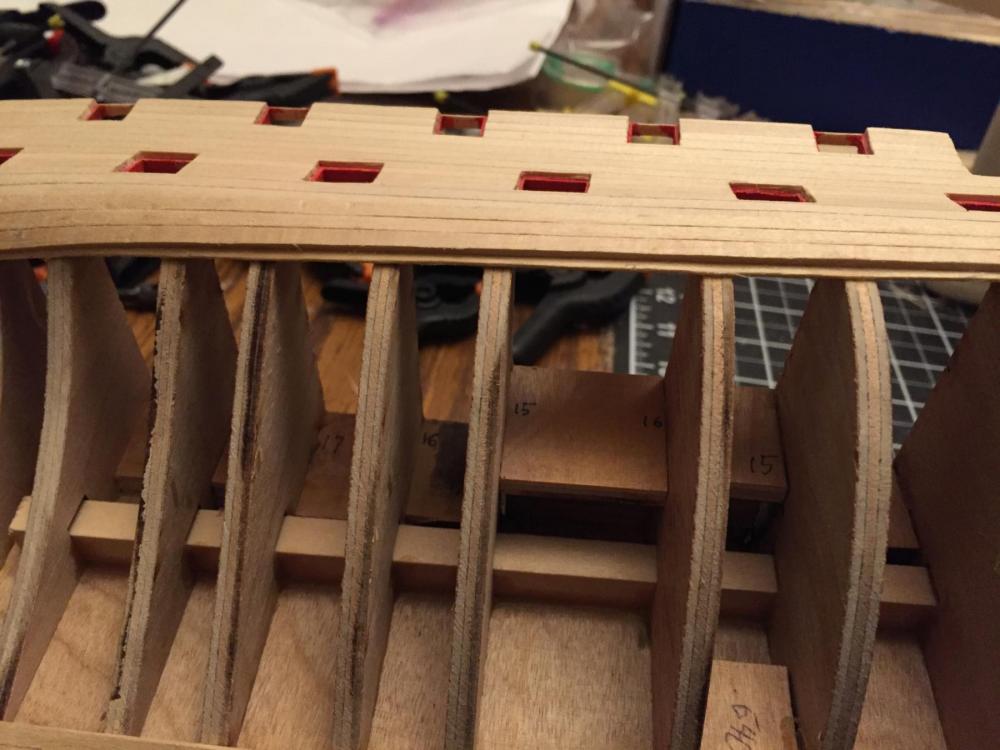

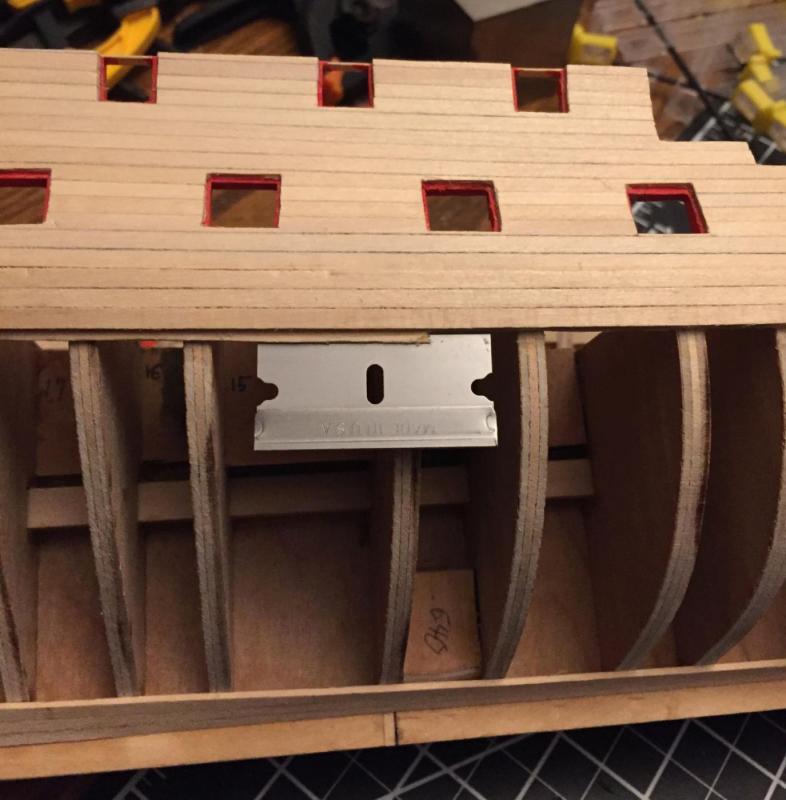

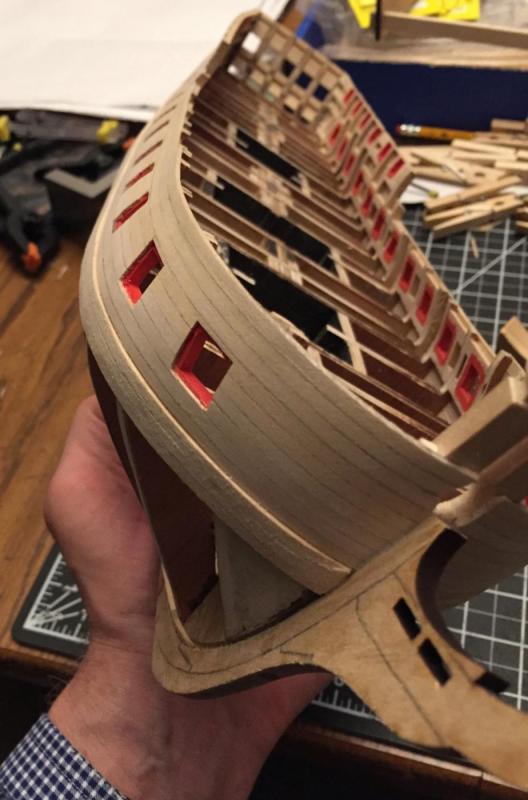

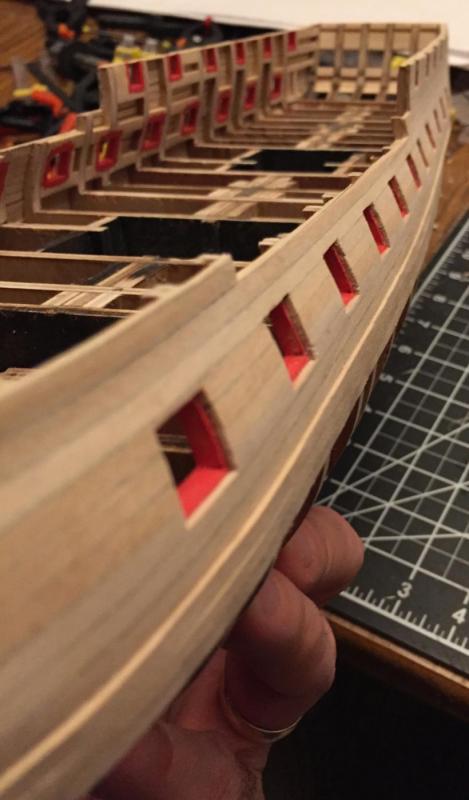

Hello, So it has been 5 1/2 weeks since my shoulder surgery. Hope to get cleared to go back to work by this Friday. Here are the pictures of the progress I had made up until the day before I was injured. I was completing the application of the wales. The images show the three planks being completed on each side over the 1/32 strips to bump the wales out. The images with the razor blades show the excess 1/32 material extending beyond the lower wale planks that I carefully trimmed off after everything was dried. I did use some filler to handle a few gaps and results look pretty good. The next time I will bevel the edges of the planks even more. I will post further progress soon.

-

So, it turns out my shoulder injury was really bad and I only got a few planks put on before I had to stop. I tore 3 of the 4 tendons in my right rotator cuff. I had successful repair surgery 3 weeks ago and now cannot use the arm for 3 more weeks and then can start physical therapy to get it back to normal. So the Essex sits patiently. I will post pictures to catch up to where I am. To quote MacArthur' "I shall return," just not yet.

-

1/24/16 – 1/25/16 In between shoveling and other chores I managed to start bonding the wale planks. I switched to clothes pins as clamps because I was noticing that on very water soaked planks I was leaving impressions with the plastic clamps. That is even after using the plank bender to “dry out” the wet planks during forming. Seemed worse on some boards than others. So here is the progress to date. Have to go back to work Tuesday, so it may be a bit before I have more progress to show.

-

J T Lombard, I bought my kit in October and it is a new one. All of the bulkheads fit into the bulkhead former unlike the earlier kit. Also there was a sheet of paper labeled Optional Instructions showing how to feed the two strong backs through the notches in the bulkheads that run along side the bulkhead former. The old bulkheads did not have those notches or the strongbacks. The parts list will be dated 1/26/2015 and it will also have the strongbacks listed (5/16" x 3/8" x 24"). Since I did not have the old kit I am not sure what other differences there may have been. Hope that helps.

-

1/23/16 Snow! Lot's of it. We got 22" to 27.7" depending on where in town you were located. My first thought was that I would get more time in the shipyard, but there is that little problem of shoveling..... I did take time to upload the work so far as seen in the three previous posts. Maybe I will get some more before we dig out.

-

1/17/16 – 1/23/16 I am still trying to use materials from the kit wherever possible, even if I go outside the standard build. The pictures from the kit instructions show all of the hull planks the same thickness and rely on the black paint to “pop” the wales. However if you look at the picture of the prototype from the instructions cover it appears to show a lip or bump out at the top of the wales below the gun ports. So I decided to try and bump out my planks for the wales. I took the unused material from the sheet of 1/32” material that the false deck comes from and cut 6 planks, 3 for each side. I then tried to bond them into place as an under layer similar to the effect if you were to double plank a hull. Since the thin planks would be hidden below the final wale planks I felt free to use pins to hold them in place during the bonding steps. The result looked pretty good except up front between bulkheads 1, 2 and 3. There some of the boards seemed to run too straight between the bulkheads giving a “connect the dots” or straight tangent line effect. I wanted a more uniform curve, but they were so thin it was hard to make them follow the line intended. As a result I found that I had to fill in with a combination of wood glue, wood filler and water to make a paste. It was a bit gritty and took multiple applications but it seems to have done the job. Once sanded it looked good. Next step: Once everything was dried and sanded the next step was to bond the wale planks in place.

-

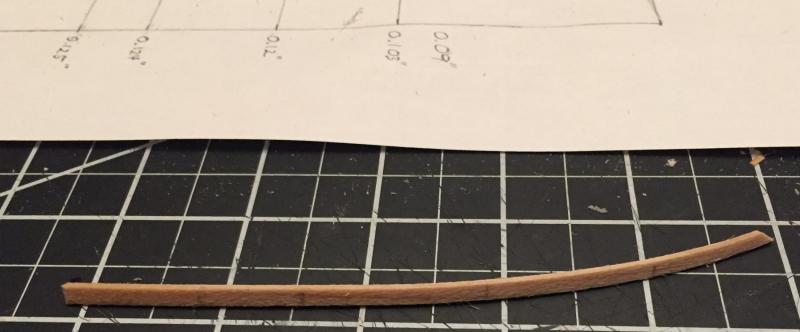

1/11/16 – 1/15/16 The shipyard has to slow down a bit when real life intrudes. Anyway here are the results of my trying to follow the kit directions for the Garboard Strakes. I could figure out how to bend the planks and how to cut them to size, but getting the first one next to the keel to stay there while the adhesive dries was a bit trial and error. Finally used the edges of the clamps to trap it in position. Initially the front tapered point of the planks came too far up the bow, so I waited till they were fully dried and then trimmed them back using a single edged razor blade and a chisel. Then I bonded the second plank in place and repeated the process. As you can see the clamping was mixed by location. I think the final result looks pretty good for a first timer. I am looking at the wales and as I noted in my question to Bob, while the drawings show wider and thicker boards for the wales, the kit does not appear to provide thicker planks to get the correct protrusion of them relative to the rest of the hull planks. I think I am going to use thinner material to bump them out. Time to deviate a bit from the kit.

-

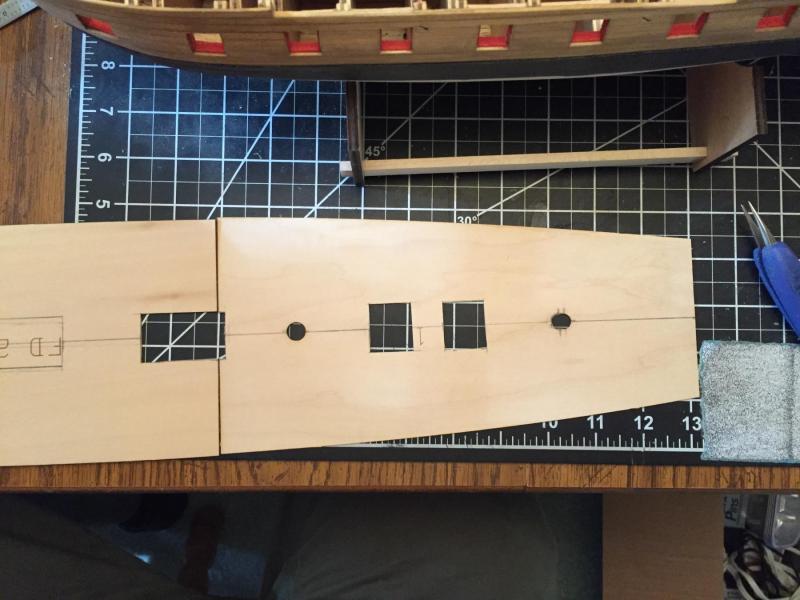

1/9/16 – 1/10/16 Thanks for the positive feedback Spongbob. Are you building the Essex also? I followed the kit directions for the stern. Looked a bit rough initially, but after it was all bonded and trimmed it looks OK. The window openings are uniform and were checked dimensionally multiple times. I have not trimmed the outside edges fully to the outer dimensions yet. Next comes the Garboard Strakes.

-

Thank you Bob, that is high praise. I do have a question, the kit drawings show wider planks for the wales and they appear to protrude a bit on most drawings and models I have seen, but the instructions have you planking the entire hull with the same size/width planks. Is that how you did it? Thanks,

-

12/30/15 – 1/8/16 – Holidays are over, back to work. Progress slows but here is the latest result. I have completed planking the upper hull on both sides. I had to re-do two planks on the bow area but now it looks pretty good. Sanded the results and trimmed away around the gun ports. On to the next step, the stern.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.