-

Posts

41 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by vann

-

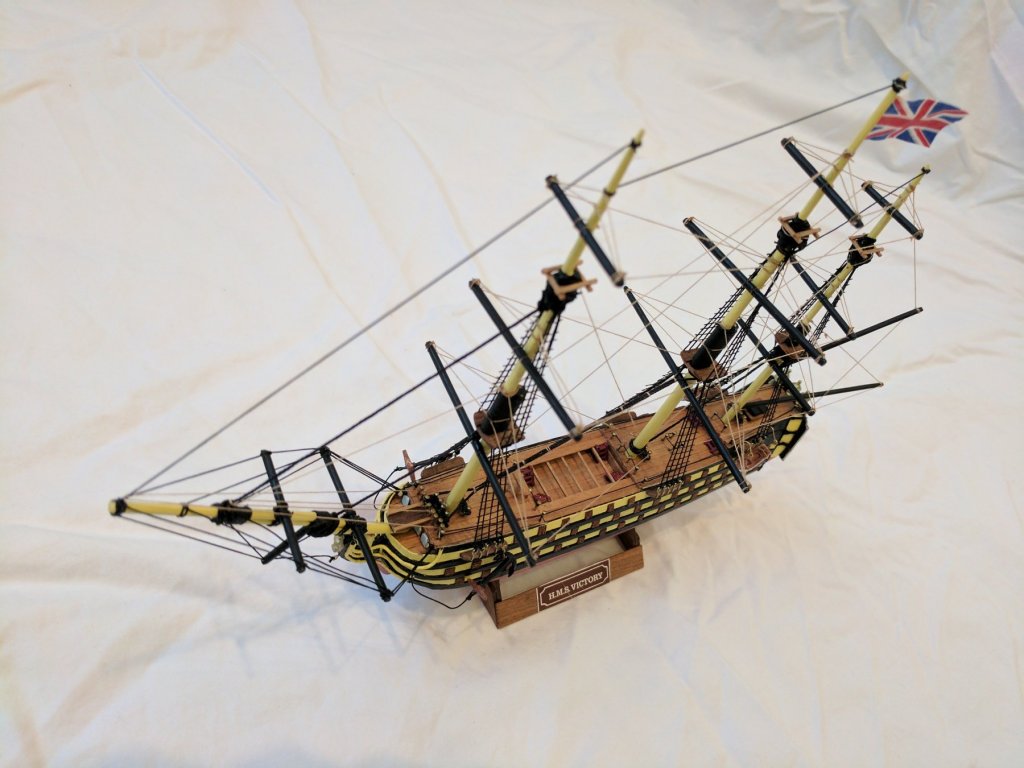

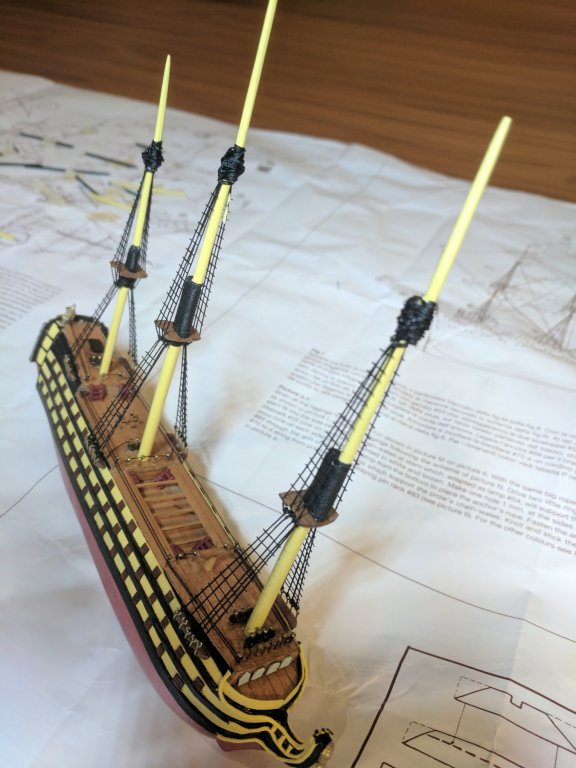

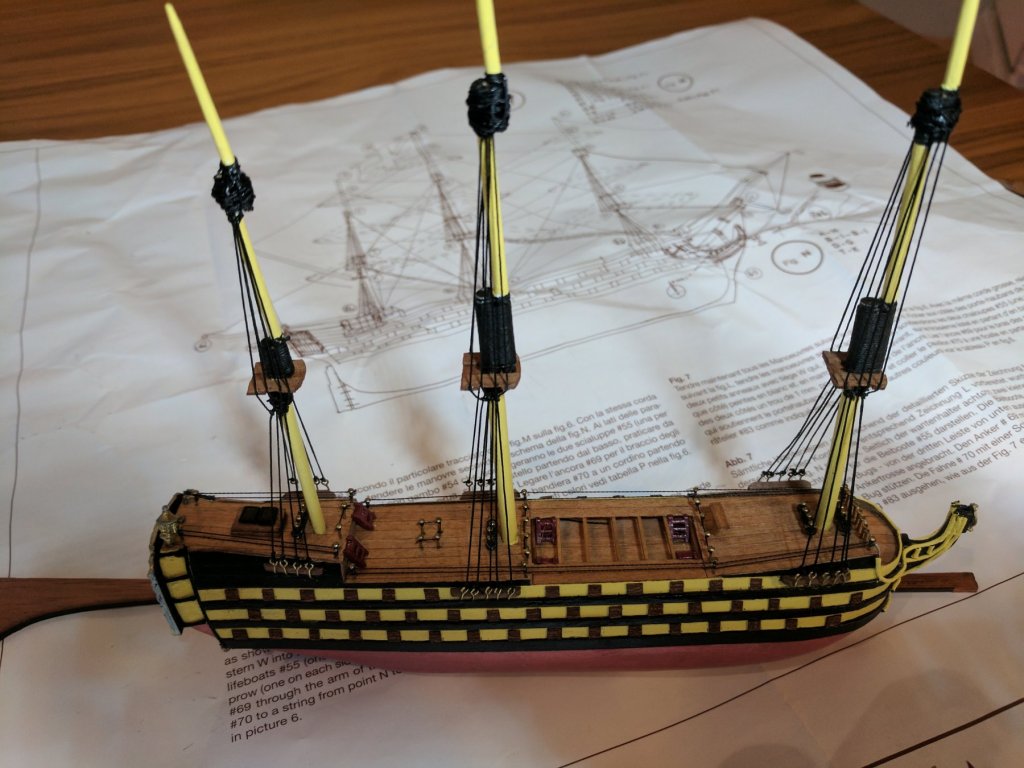

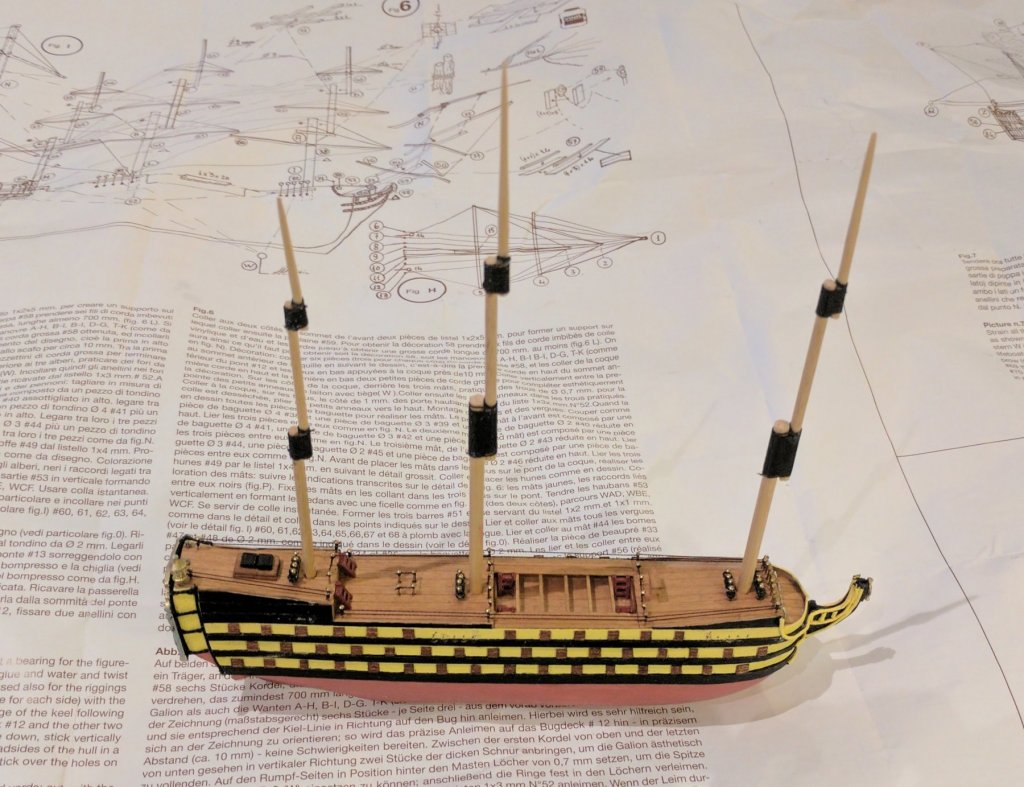

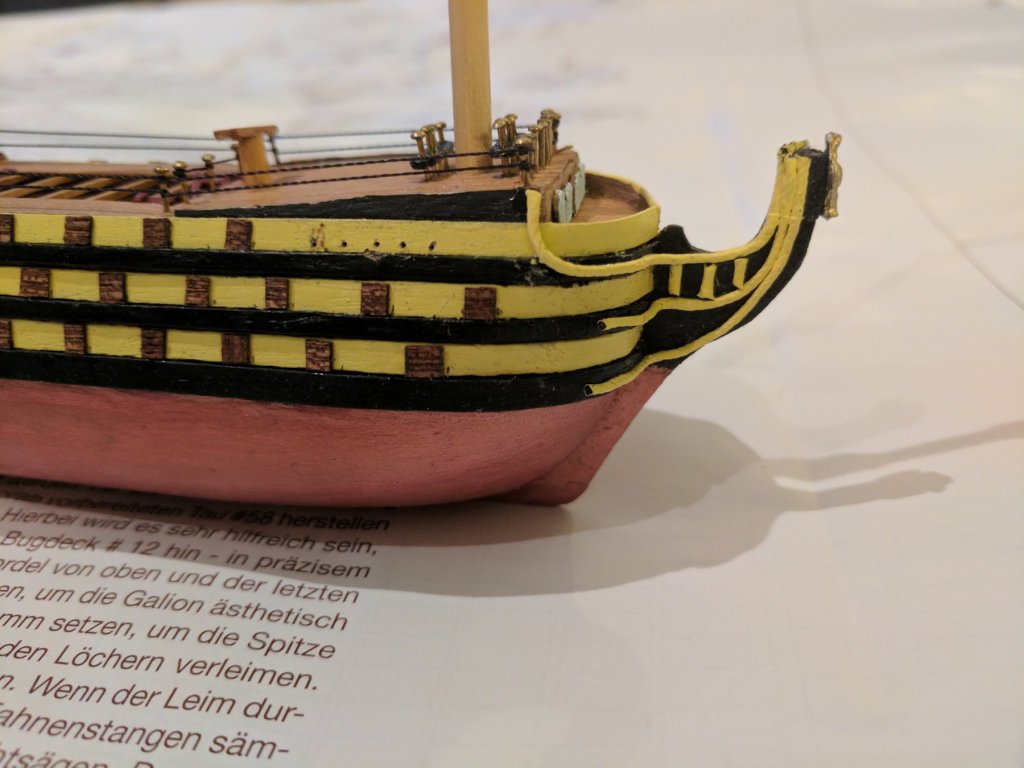

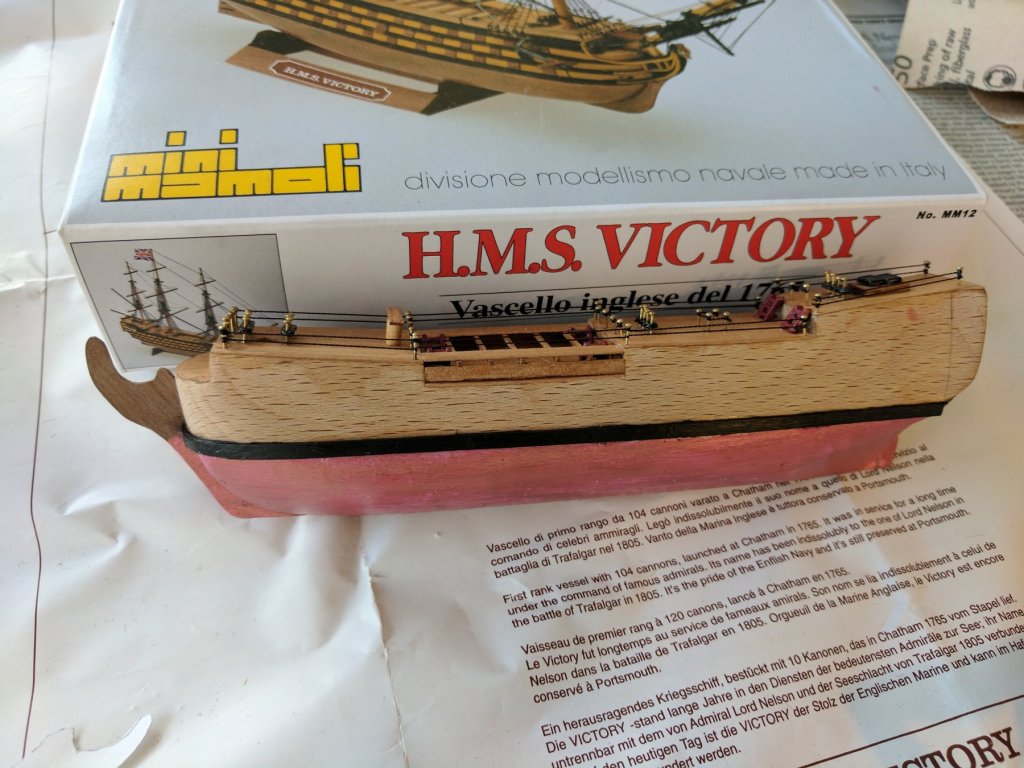

The Victory is done! All in all, I think it came together pretty well. The instructions aren't as bad as I thought they might have been on the first read. It does take a bit of creativity. Interestingly you can see that the builder of the model for the box photo didn't follow the instructions very closely at all! I believe my model is actually closer than theirs. For anyone deciding to take this on, be prepared to make a few extra purchases. I made several orders for: * cordage - get a bunch, you'll go through it! Different sizes of black thread. * nails - you may be able to leave off a couple of the ones along the front of the deck at the bow, but if you follow their plans you'll run out * paint - of course! * 3mm x 1mm strips - this is odd... not sure if it was just my kit, but they didn't provide enough to complete the decking sides. There were probably a bunch of things I would have done differently, but the two that mainly come to mind are: * Positioning of bands on side - the instructions have you measure from the keel. But, this ends up completing the strips too early - I'm guessing that somewhere along the way the size of the hull itself changed. I'd recommend measuring *down* from the deck such that you know you'll get the right amount. You can use the keel to make the strip level, but start from the deck. * Make a jig for cutting the wood pieces for the gun ports. Cutting 3x3 mm squares without a guide is nearly impossible to do consistently. In the end it doesn't look too bad, but I would have been happier if they were more consistent. I'd definitely recommend the build. It was a lot of fun and enough of a challenge for a beginning modeler like me. It does take some time - I'm sure I have over 100 hours into it over a two month period. I think I saw somewhere that mini-mamoli's were 15-20 hour projects. Evidently not for me! @Daniel Dusek is bringing these kits back into production, so there should be opportunities to get new kits.

- 23 replies

-

- Victory

- Mini Mamoli

-

(and 1 more)

Tagged with:

-

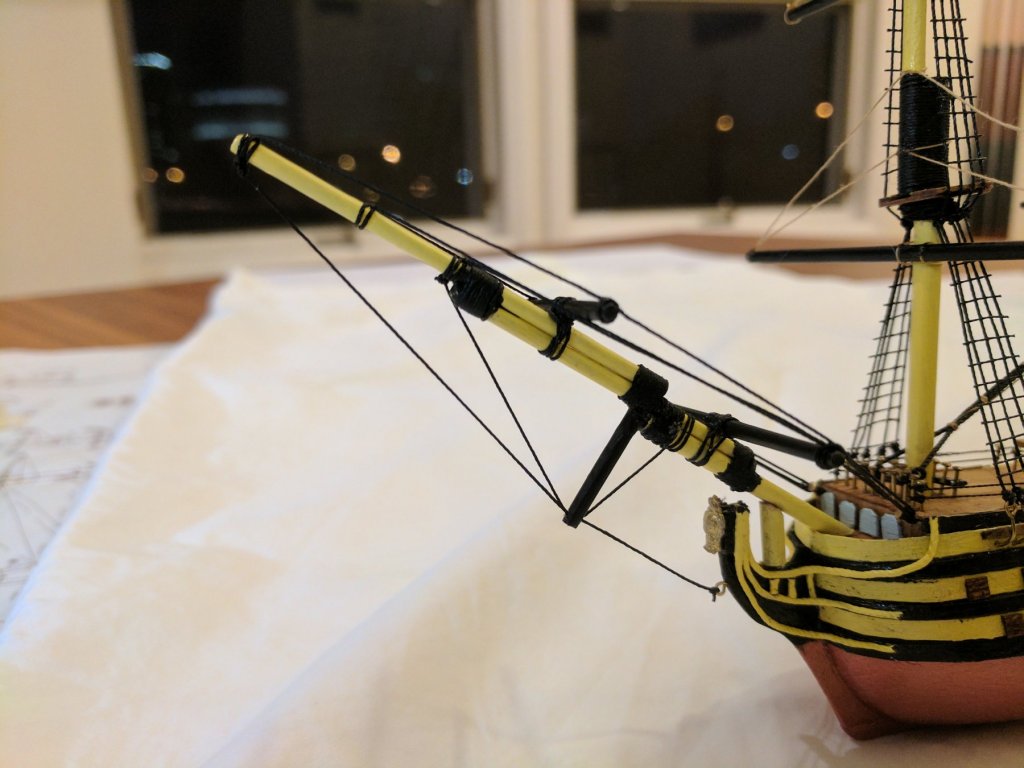

@DSiemens with the suggestion of the build! Wow - How did I not have these scissors before? I had what I thought were ok scissors that came from a sewing kit - they aren't remotely comparable. Thank you! The build continues and I have begun rigging. The spars are on. The bowsprit assembly is done. Really starting to come together, despite my continual attempts to destroy what I've already created. I'm convinced that rigging is there to teach us just how clumsy our giant hands really are. And, my thread seemingly has become self-aware - it certainly seems to go where it wants as if it had will anyway (and apparently it is none too happy with me). But, beat it into submission, I will. Lots of progress, but still a fair ways to go before it is done.

- 23 replies

-

- Victory

- Mini Mamoli

-

(and 1 more)

Tagged with:

-

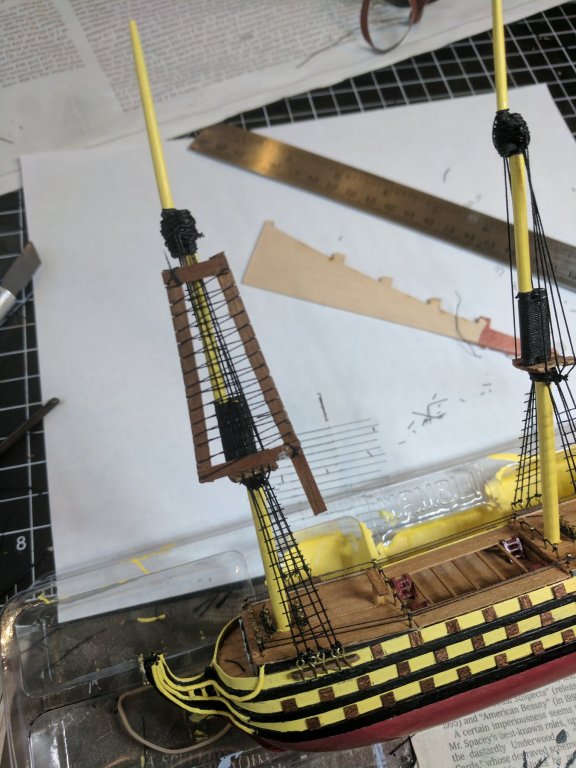

I saw the method that Alex had used (with Antony UK) for ratlines in their build of the Black Pearl: and copied it. The jig worked nicely and made reasonably short work of the ratlines. You probably could trim them closer, but I decided it was close enough for me. And, the risk of accidentally cutting a shroud was a bit too much to take. Ratlines are done! Now to put on the tops and then I believe it is off to work on the bowsprit. Progress!

- 23 replies

-

- Victory

- Mini Mamoli

-

(and 1 more)

Tagged with:

-

The shrouds are in place. Next step - ratlines. I'm going to try the glue method as @S.Coleman mentioned above. Clove hitches would be a bit of overkill on such a small model.

- 23 replies

-

- Victory

- Mini Mamoli

-

(and 1 more)

Tagged with:

-

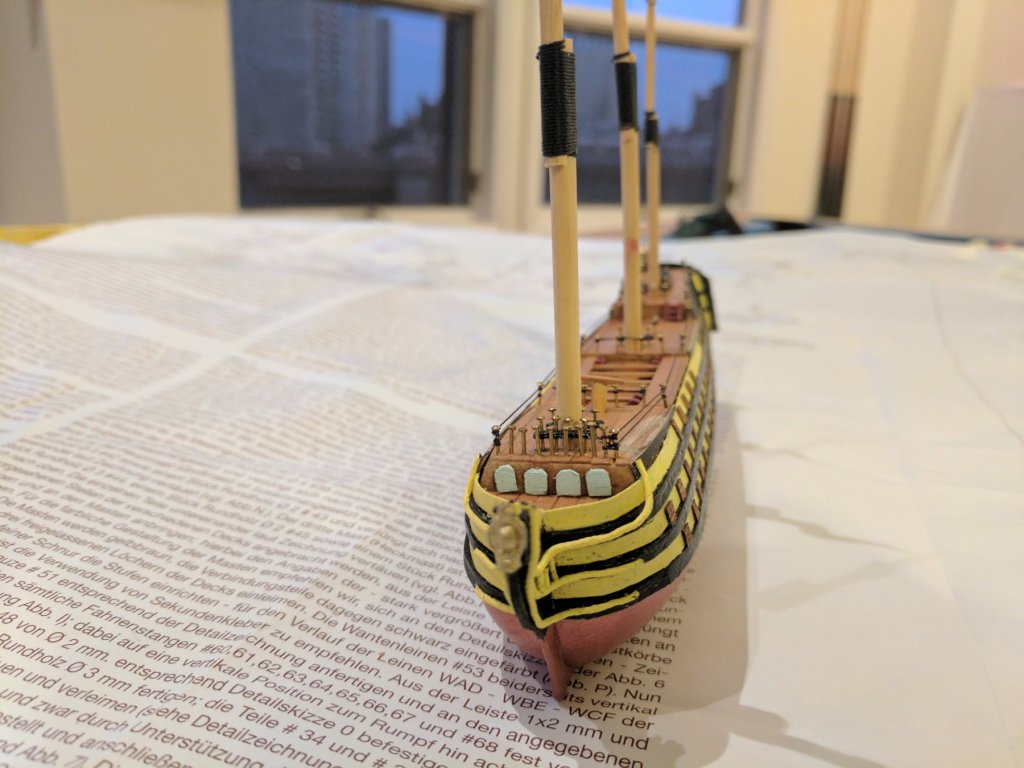

Completed the bow decorations and it is time to start the rigging! Which unfortunately hit an immediate setback as I broke my #75 bit while drilling for the shrouds. While the replacement is being shipped, I can get started with preparing the masts.

- 23 replies

-

- Victory

- Mini Mamoli

-

(and 1 more)

Tagged with:

-

Progress continues! With the extra parts in hand, the deck is finished, side boards have been placed, transom fitting added, and gun ports made. The gun ports are a little all over the place in sizes, but hopefully, when the whole thing is complete it won't be that noticeable (along with my other, many mistakes!). Unfortunately, I broke the stem of one of the aft lanterns. I'm going to try and drill a hole and put a new stem in - fingers crossed that goes ok. Next step is to complete the decorative work around the bowsprit, then it is off to rigging!

- 23 replies

-

- Victory

- Mini Mamoli

-

(and 1 more)

Tagged with:

-

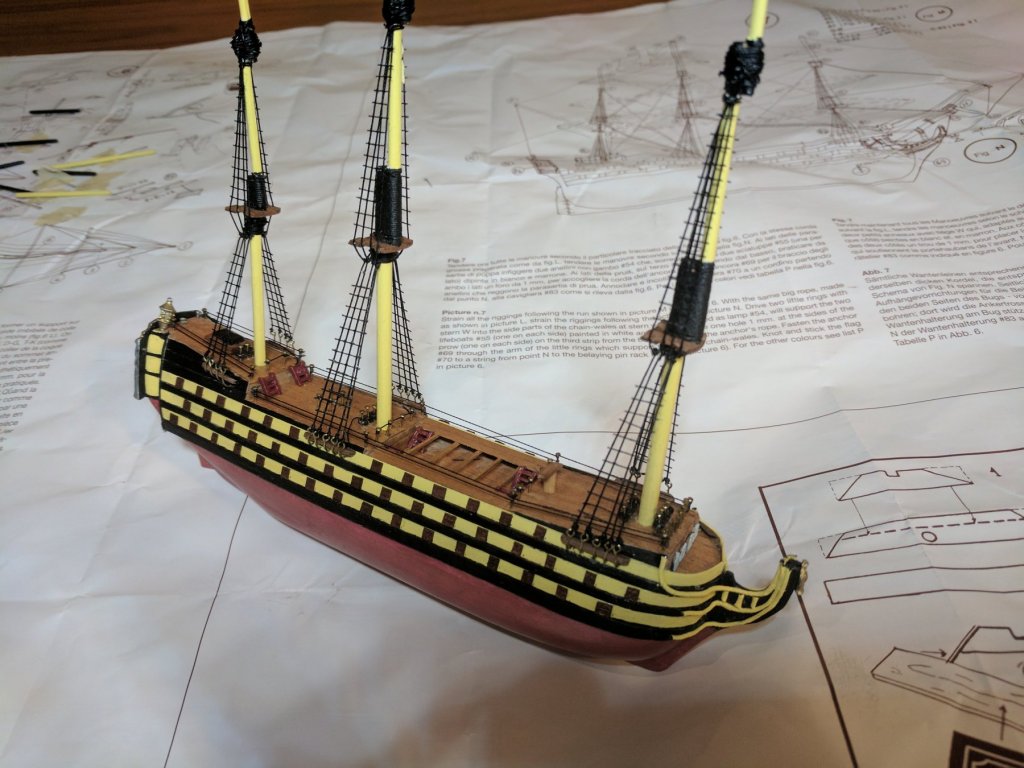

Yes, no deadeyes! But, those ratlines will be a challenge. I may end up with something approximating something approximating the shrouds and ratlines! Additional progress. The first couple coats of paint are on the bottom. I'll add one more before it is done. And, while I'm still waiting on lumber, I went ahead and started with the port side as I had enough to get it done. Coming together reasonably well. I followed the instructions carefully, but think I should have started my sideboards lower on the hull. There isn't really space to have another black strip over the top yellow. But, I think I can make it look reasonable anyway.

- 23 replies

-

- Victory

- Mini Mamoli

-

(and 1 more)

Tagged with:

-

The next big step is to add the planking on the topsides which will provide the black and yellow bands and gun ports. But, alas, I'm still waiting on my planks to arrive. In the meantime, I've started working on the copper paint for the bottom. I'm not much of a painting expert (well - I'm not much of an anything expert in ship modeling!), so hopefully, this will come out ok. The copper paint I have looks a bit to copper colored to me, but perhaps it will work out.

- 23 replies

-

- Victory

- Mini Mamoli

-

(and 1 more)

Tagged with:

-

Made some more progress. The additional lines and brass tacks arrived from ModelExpo, so I was able to complete the deck. Added a couple coats of polyurethane to the deck - fortunately I was thinking a slight bit and did so *before* I rigged all the lines. The deck is looking reasonably good.

- 23 replies

-

- Victory

- Mini Mamoli

-

(and 1 more)

Tagged with:

-

Thanks, Antony! I'm enjoying it so far, but see some challenges ahead. The rigging is going to be interesting! Some progress over the last couple days. I've almost finished the deck fittings, but have run into a couple issues: 1) There aren't enough nails to fill all the spots in the plans. I've ordered some more which will hopefully look close enough. 2) I seem to be short one 1x3mm plank. Ordered more walnut planks. I may run close on the 0.5x3mm but as Model Expo is backordered, I'm going to see how far I can stretch what I have. I may be able to get it done with scraps. A bit annoying - particularly since I'm running into the issues one by one. Model Expo is making a fortune in shipping fees off of me! But, at this point I'm committed... Next step is to start working on the painted sideboards which provide the form of the gun decks. Should get interesting from here!

- 23 replies

-

- Victory

- Mini Mamoli

-

(and 1 more)

Tagged with:

-

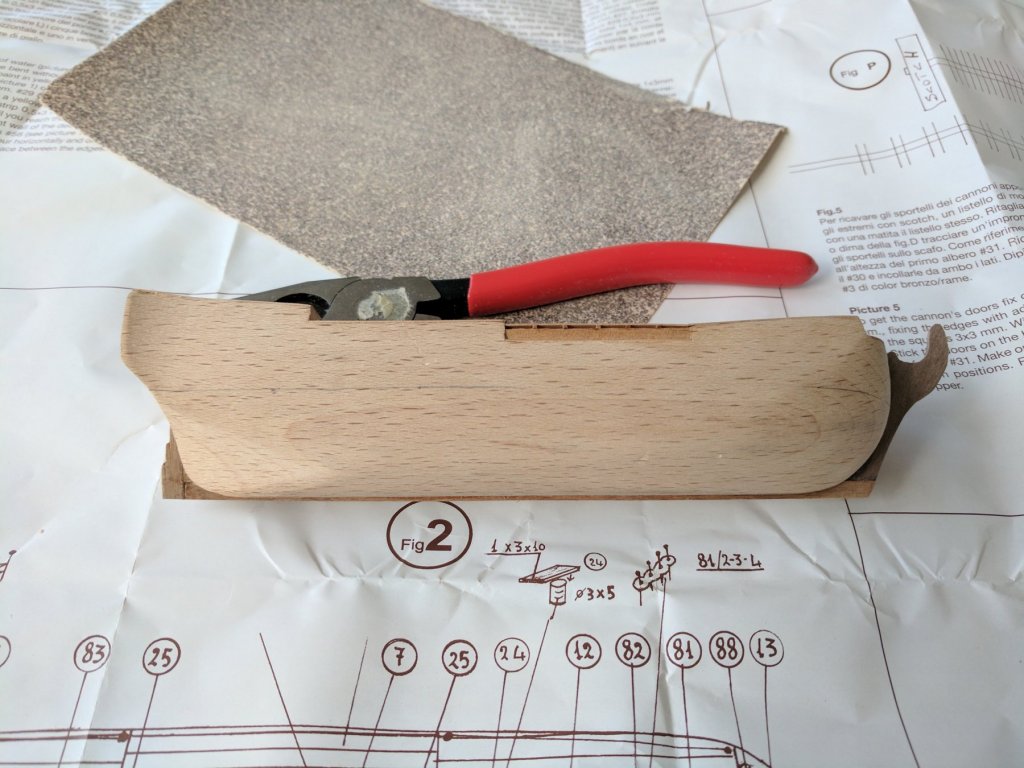

And constructed the keel. The transom/rudder didn't quite line up like the instructions indicated they should, so I improvised a bit. I think it looks close enough for my standards.

- 23 replies

-

- Victory

- Mini Mamoli

-

(and 1 more)

Tagged with:

-

Completed the decking. I considered cutting the boards down into smaller lengths, but considering that the scale is already crazily off, I decided that full length was good enough.

- 23 replies

-

- Victory

- Mini Mamoli

-

(and 1 more)

Tagged with:

-

Step 1 - Sanded down the transom to the right angle and created the "box" for the open part of the deck.

- 23 replies

-

- Victory

- Mini Mamoli

-

(and 1 more)

Tagged with:

-

I thought I'd take on another relatively quick project and picked up a Mini Mamoli kit for the HMS Victory off eBay. I had been excited to hear that @Daniel Dusek was bringing the Mini-Mamoli kits back, but didn't have the patience for the supply pipeline to get rolling again. For the moment, they seem to be fairly available on the second-hand market and hopefully, Daniel gets the new kits rolling along soon. The Mini-Mamoli kits are billed as being for complete beginners, but while they clearly aren't full-scale models, I'm skeptical that many people would finish in the 15-20 hours that I've seen claimed. I'd spend that long on just the painting! But, in theory, I should be able to advance to the rigging reasonably quickly - and then we'll see how long that takes! Another thing for which to be prepared - The instructions are pretty poor. They are translated from Italian which doesn't help, but I'm pretty sure that even in Italian they leave out a lot of details/steps. So, be prepared to be a little innovative. Hopefully Daniel will be able to improve on the instructions with the new kits. Also - I feel like doing the project "right" requires more materials. The kit comes with a single diameter manila cordage, but the kit will look a lot better with some varied thicknesses of black cordage. I've ordered some from ModelExpo which hopefully should be here soon.

- 23 replies

-

- Victory

- Mini Mamoli

-

(and 1 more)

Tagged with:

-

Oh. And, @GuntherMT's build log:

- 11 replies

-

- indian girl canoe

- Midwest Products

-

(and 1 more)

Tagged with:

-

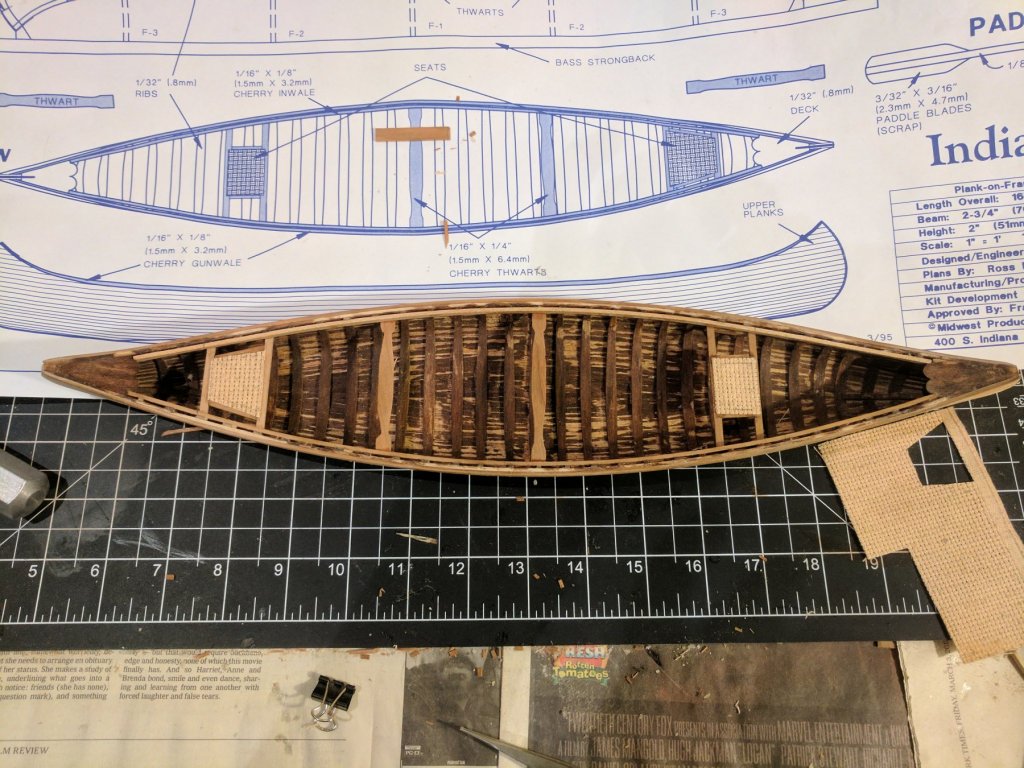

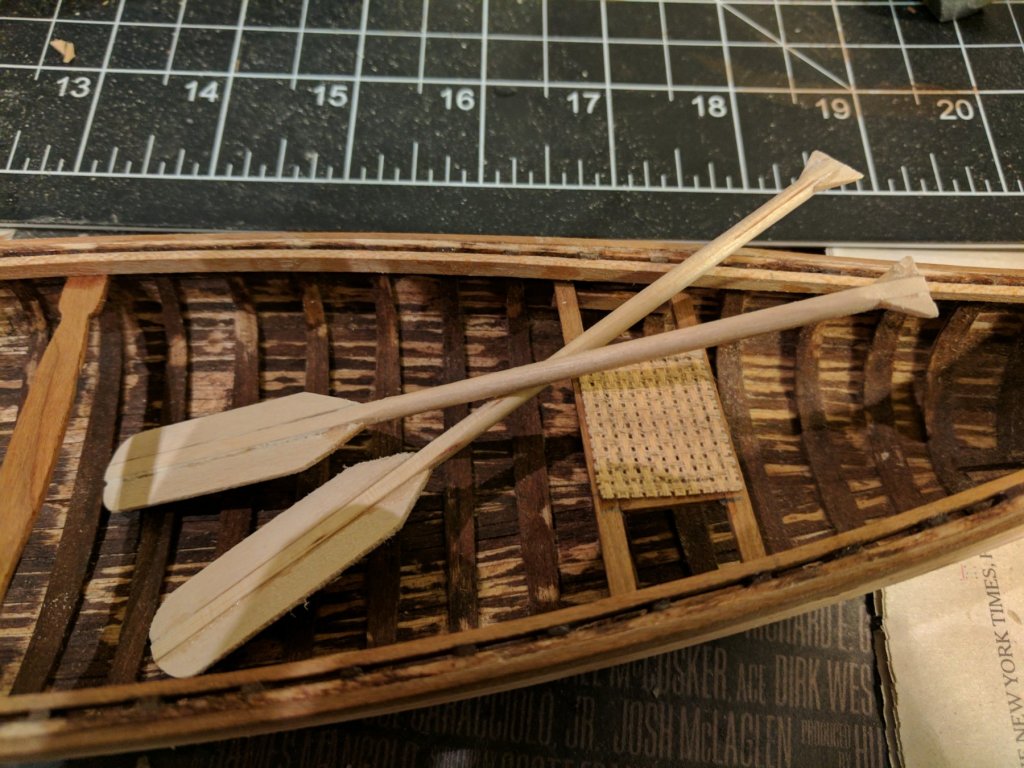

Strangely it seems to have reversed the order of my photos. But, I'm sure the people of MSW can figure that out!

- 11 replies

-

- indian girl canoe

- Midwest Products

-

(and 1 more)

Tagged with:

-

All done! And my Dad after opening his surprise present. I think he was quite happy with it. It brought back great memories of canoe camping and summers on the river. I'll put some more photos in the finished build gallery.

- 11 replies

-

- indian girl canoe

- Midwest Products

-

(and 1 more)

Tagged with:

-

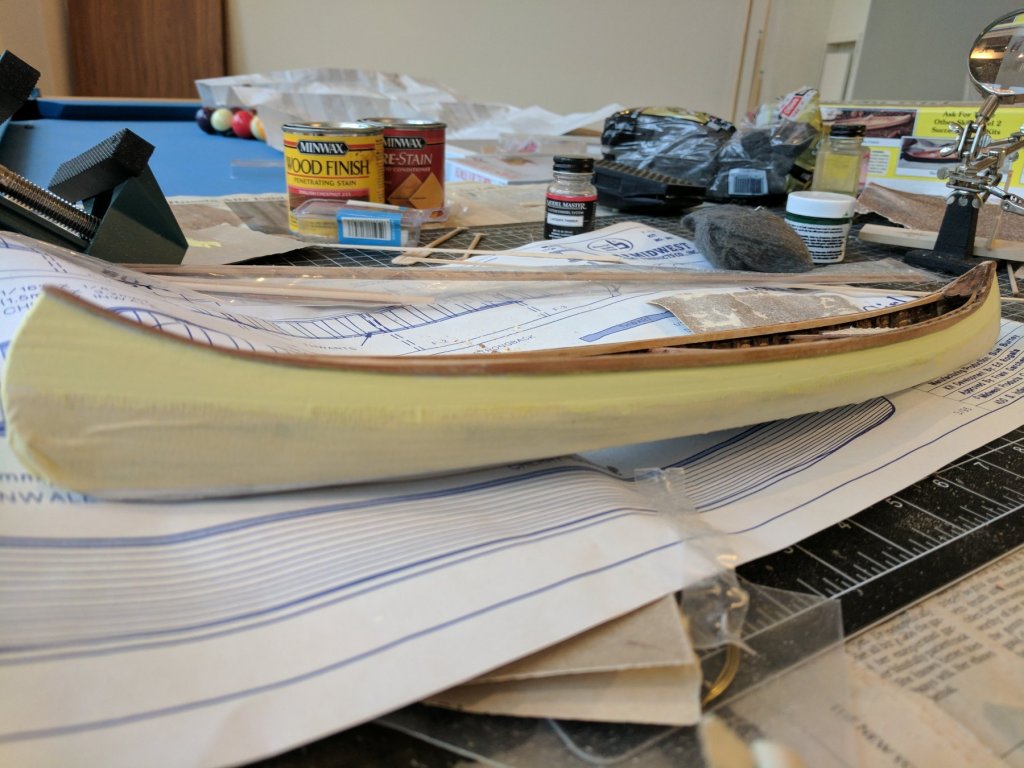

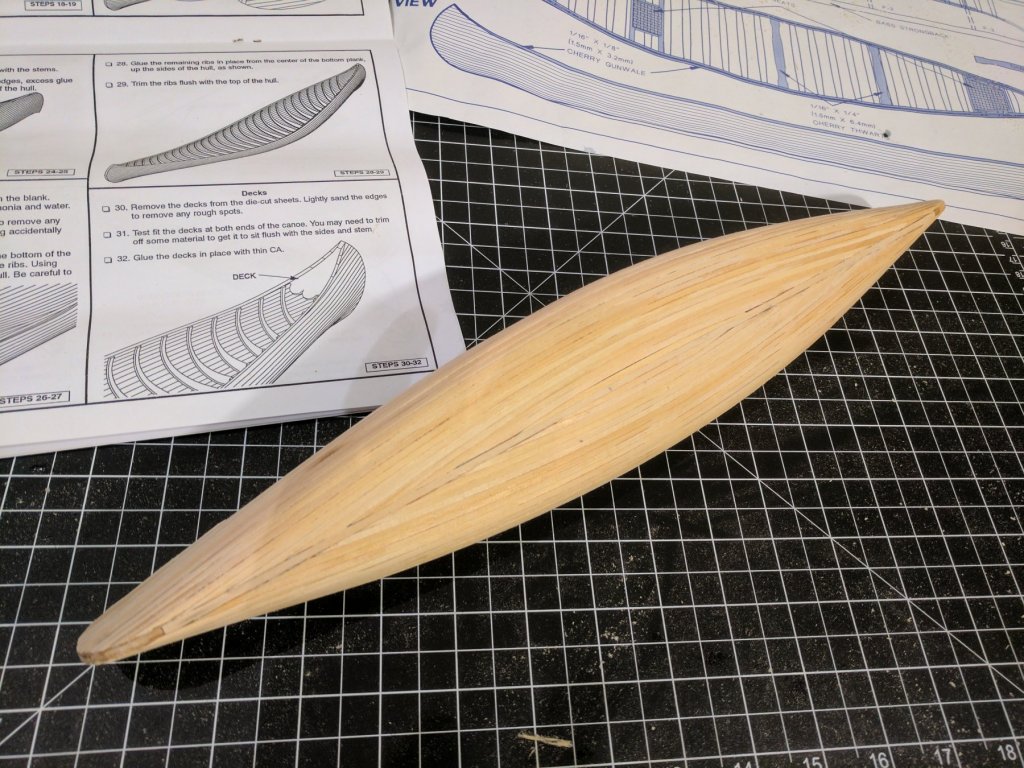

Now on to the painting. I was super nervous that I wouldn't be able to get the two tone look right. But the masking worked out better than I could have imagined.

- 11 replies

-

- indian girl canoe

- Midwest Products

-

(and 1 more)

Tagged with:

-

Here is the next place I went awry. I decided to stain the interior to try and match the dark wood look of the Old Town. Unfortunately, the CA prevented the stain from taking over much of the area. It is something of a disaster compared to what I intended, but I decided to move on. The funny thing is that people who have seen it after completion think that it was a deliberate attempt to make it look old/authentic. So, perhaps I got away with it. Lessons learned - staining with CA is risky! Use CA sparingly. And, work with a substantial representative test piece before starting on your model. I did a test, but it clearly wasn't indicative of the actual model.

- 11 replies

-

- indian girl canoe

- Midwest Products

-

(and 1 more)

Tagged with:

-

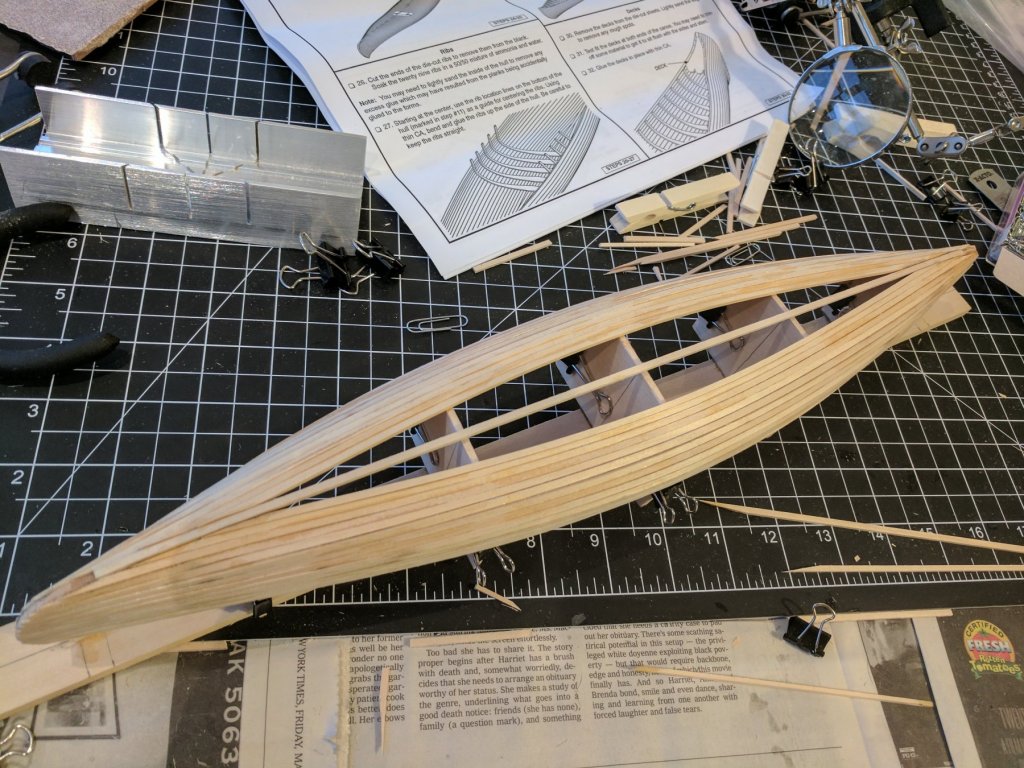

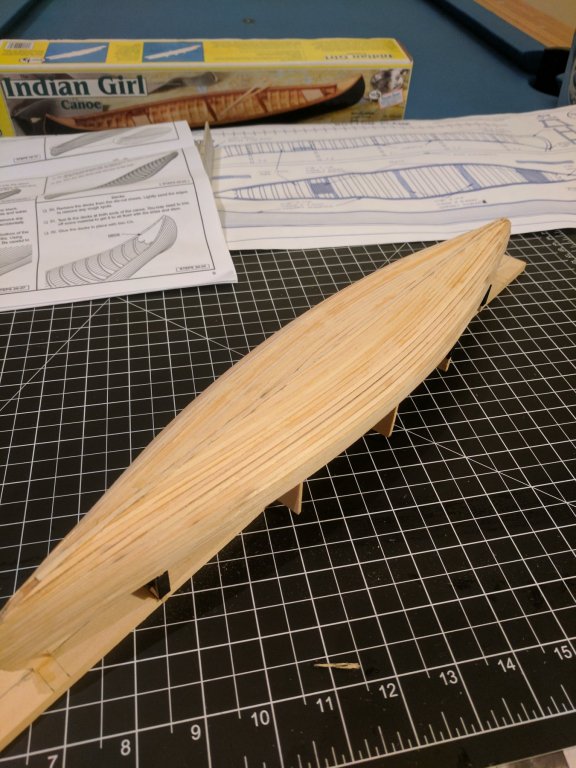

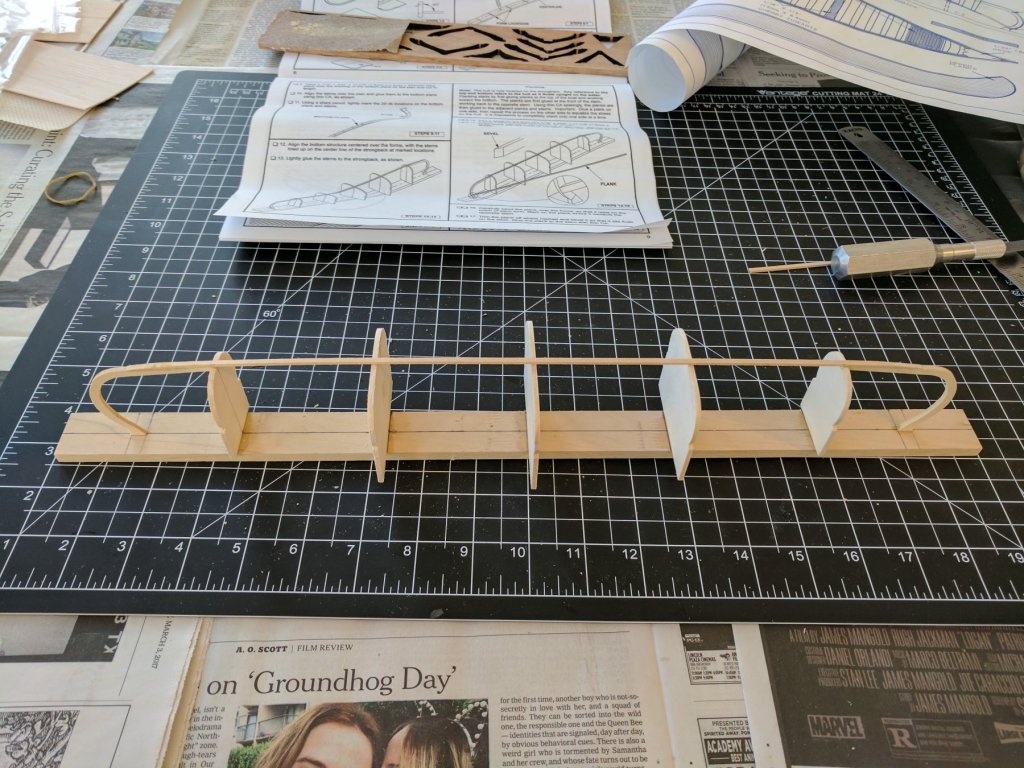

Formed the bow and stern. I hadn't looked at the Old Town photos in a while and just went with the Indian Girl look. If I had to do it again, I would have tried to match the rounded ends of the Old Town. The framing was *far* from perfect with them not being particularly straight and evenly spaced. But, somehow when they are all in place your eye tricks you into thinking they're pretty good. Just don't look too close!

- 11 replies

-

- indian girl canoe

- Midwest Products

-

(and 1 more)

Tagged with:

-

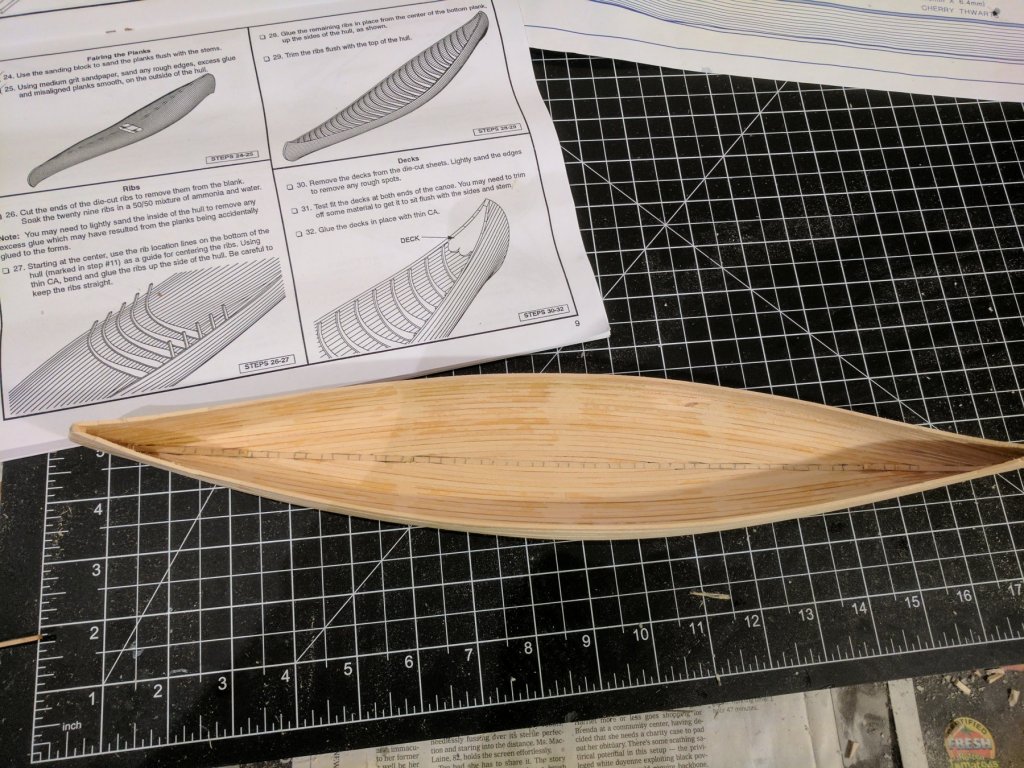

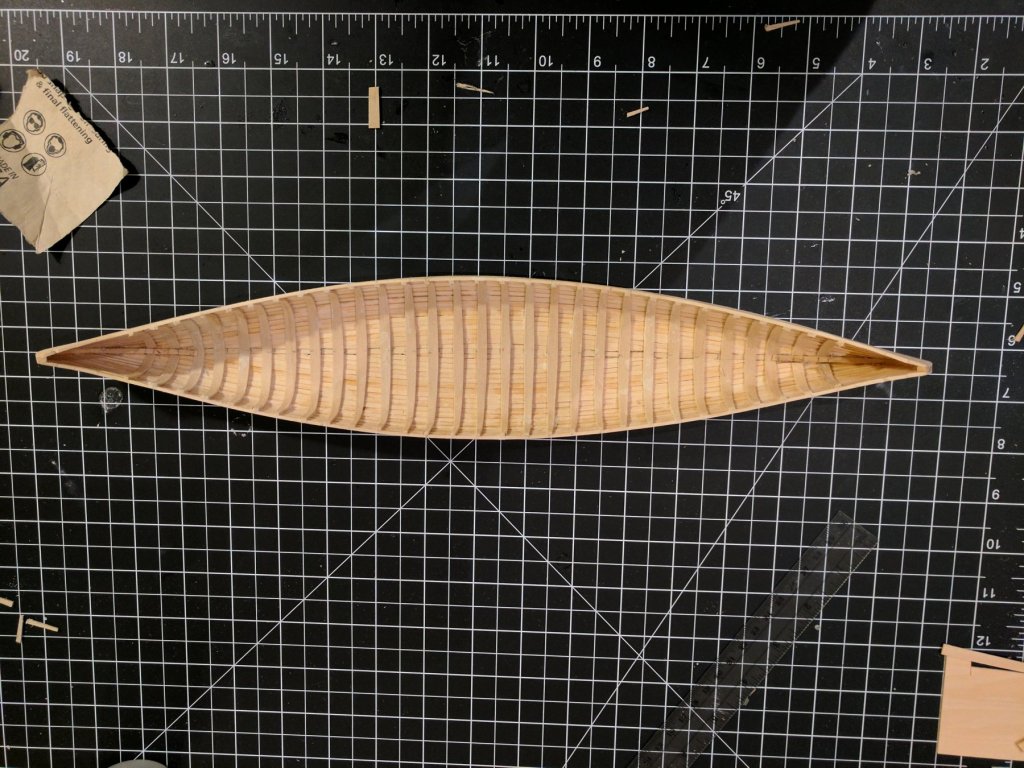

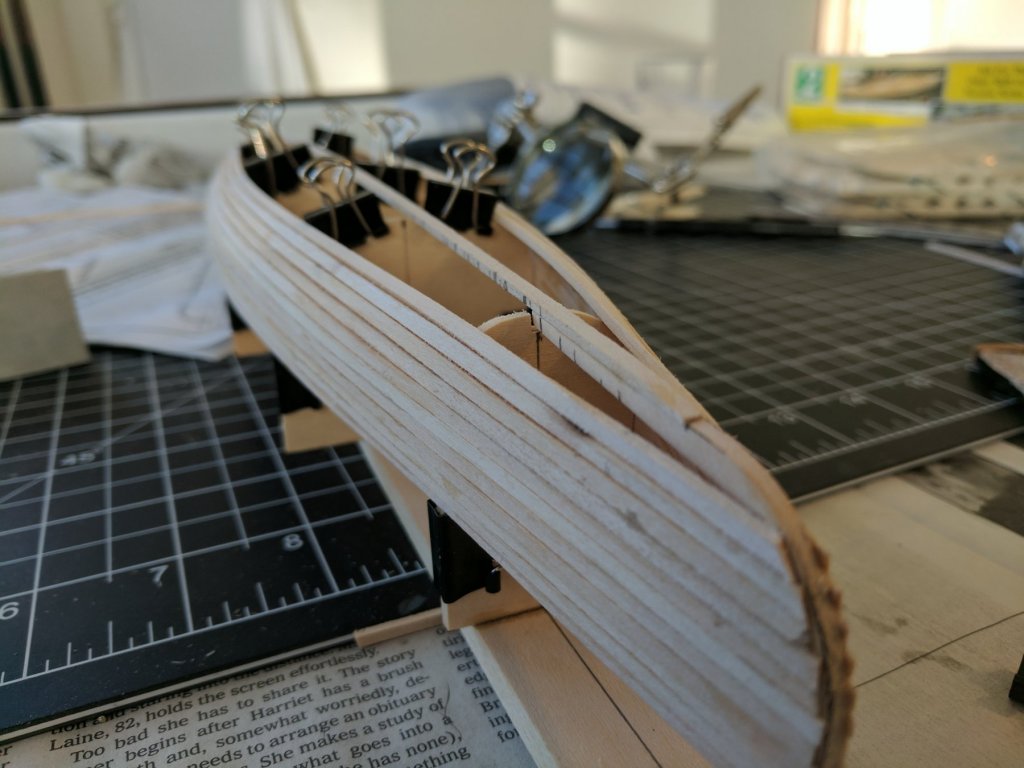

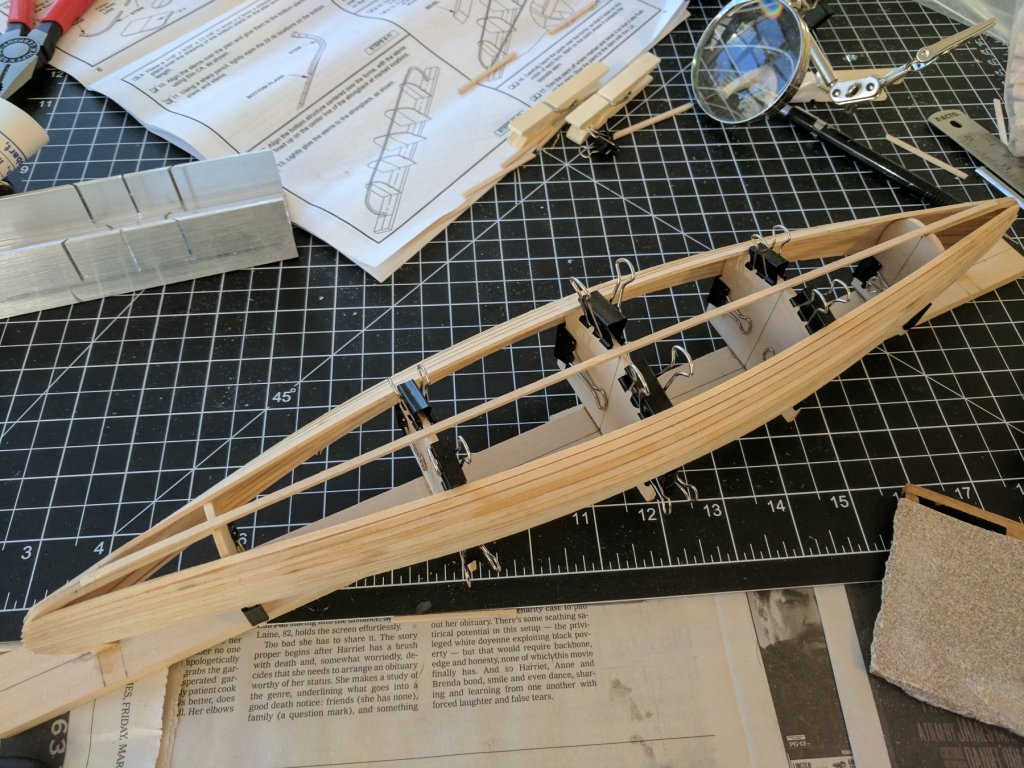

With kit #2 things progressed much better. I used CA per the instructions rather than PVA like @GuntherMT. CA has the advantage of being faster and not requiring Gunther's expertise in clamping, but it does have is disadvantages (see later).

- 11 replies

-

- indian girl canoe

- Midwest Products

-

(and 1 more)

Tagged with:

-

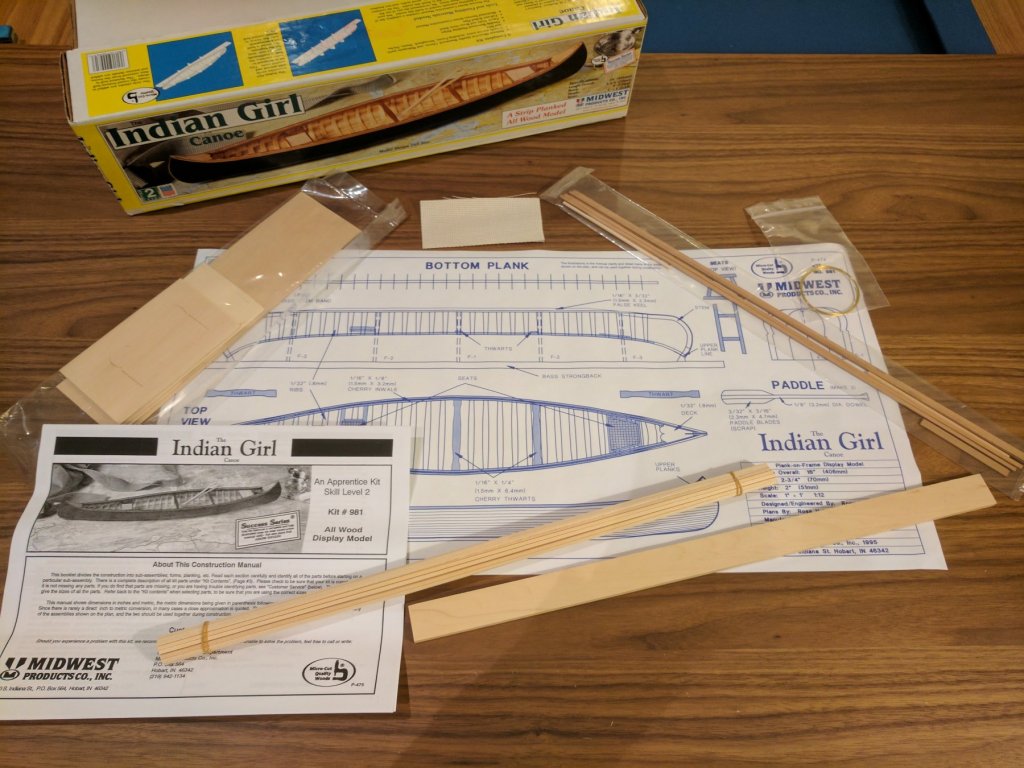

Unpacking and initial construction. All seemed to be going well up until this point. But, around the last photo, I realized I had a big issue. When laying the planks, the board has to go from vertical at the bow and stern to nearly horizontal as it forms the bottom. Normally you would have a lot of glue surfaces on a model (at each frame), but with the removable mold for the canoe, you can only glue to the plank next to it. I did my best to "glue" them to the right shape but failed somewhat miserably. Each plank would more or less stack on the one above it. With such huge overlaps, there is no amount of sanding that would have made a good bottom. At this point, I reached out to GuntherMT who gave me the secret - using a hot air blower / hair dryer to pre-bend the planks. This is probably obvious to an experienced modeler but was not present at all in the instructions. (Thanks @GuntherMT!). I purchased another kit off ebay and started again. This time things went much better. (Somehow I always seem to run through two kits in the building of a model!)

- 11 replies

-

- indian girl canoe

- Midwest Products

-

(and 1 more)

Tagged with:

-

I was inspired by GuntherMT's build log of Midwest's Indian Girl Canoe kit and decided to try and recreate the family canoe from my childhood as a Father's Day present for my dad. It was an Old Town canoe, but the Indian Girl seemed close enough. The model is completed as I did it completely in secret as a surprise, but I thought I'd share some photos of the build here. (I wasn't patient enough to actually wait until father's day!) The build was a lot of fun and I'd definitely recommend it. Unfortunately, Midwest no longer produces this kit, but there are still some available on eBay. Some recent photos of the inspiration below. Note, for anyone attempting the kit, definitely check out GuntherMT's build log. He is a *much* more experienced and talented modeler than I am and has a bunch of helpful pointers. His log was invaluable to me for my construction, but I have a few additional tips (and warnings!) to pass!. Gunther also gave me the critical trick to getting the bend in the planking correct.

- 11 replies

-

- indian girl canoe

- Midwest Products

-

(and 1 more)

Tagged with:

-

Thanks Gunther - Exactly the pointer I needed. I believe these are the videos mentioned... Good news is that a hair dryer should be easy to acquire.

- 43 replies

-

- indian girl canoe

- Midwest Products

-

(and 1 more)

Tagged with:

-

Gunther - I'm trying to construct this kit and fear that my novice skills may not be up to your level. I seem to be particularly challenged to rise to your levels of creativity with clamping. Things have been going reasonably well up to the point where the planks start making the mid-ships bend after departing the stems. I don't have a lot of confidence that I'm going to be able to keep this bend in by just using beveling, edge glue, and clamps. On a normal model you would be gluing to each frame which would provide plenty of strength to hold the bend into the plank. But in this case it seems that the plank will naturally tend to align itself with the fore and aft points (vertical). Did you do any pre-shaping to the planks? I could imagine soaking them and getting it close to form before putting in place, but that seems like a lot of work - and isn't in the instructions (although the instructions are pretty terse in this area!). It seems clear by the smoothness of your hull that you did a proper planking job, beveling the length such that the planks fit the curve of the hull - This isn't covered in the instructions either, but seems very necessary. Thanks for your insights - This is a fun, small project. And, for someone as inexperienced as me, still provides some challenges!

- 43 replies

-

- indian girl canoe

- Midwest Products

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.