Eric W

Members-

Posts

133 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Eric W

-

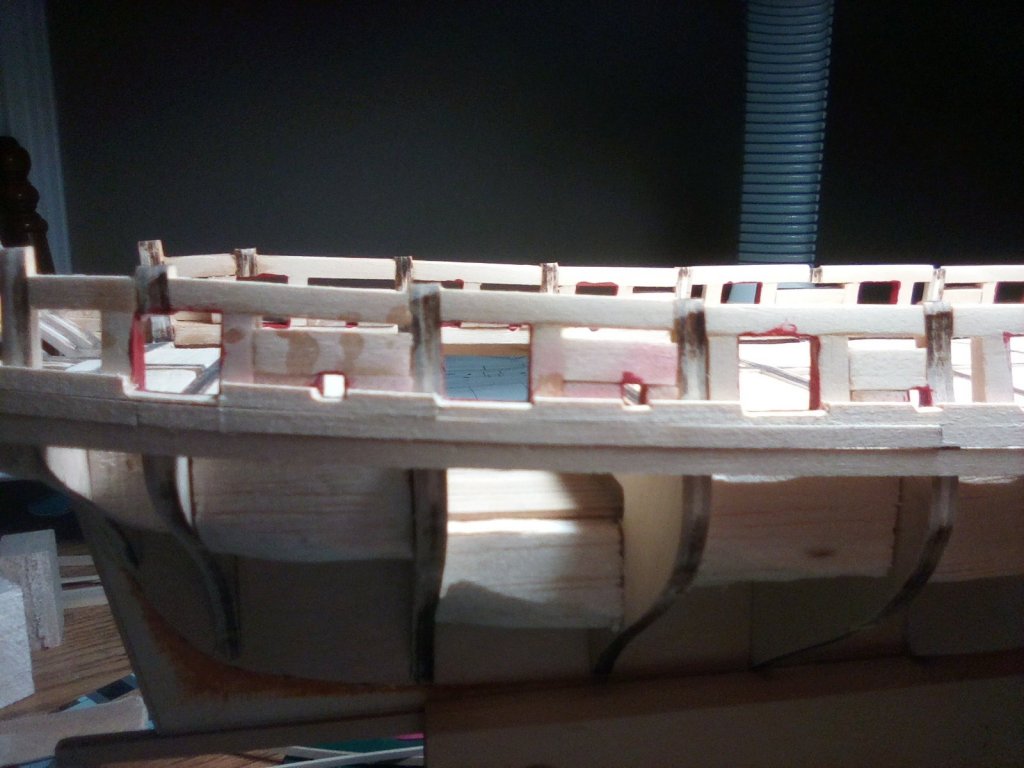

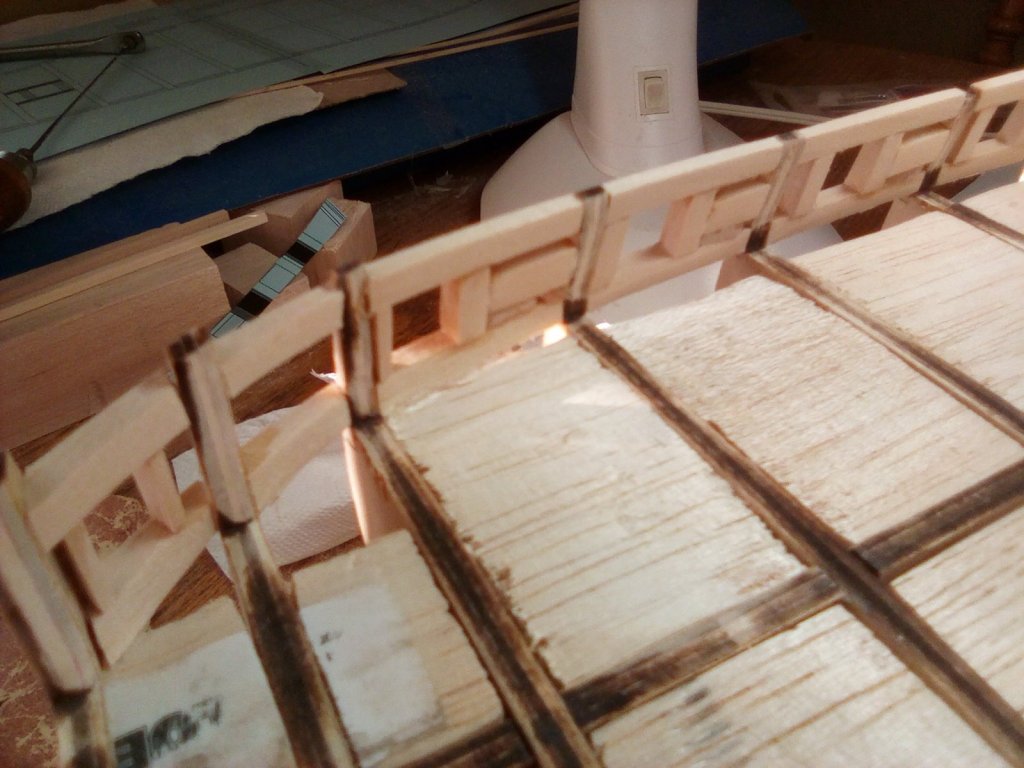

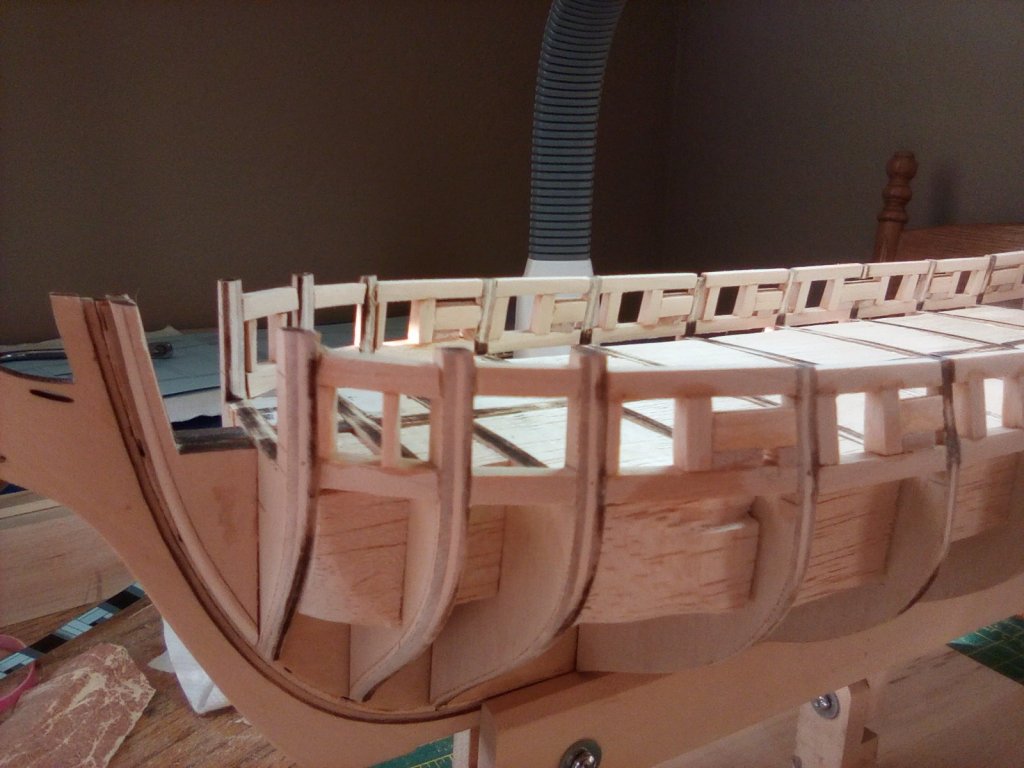

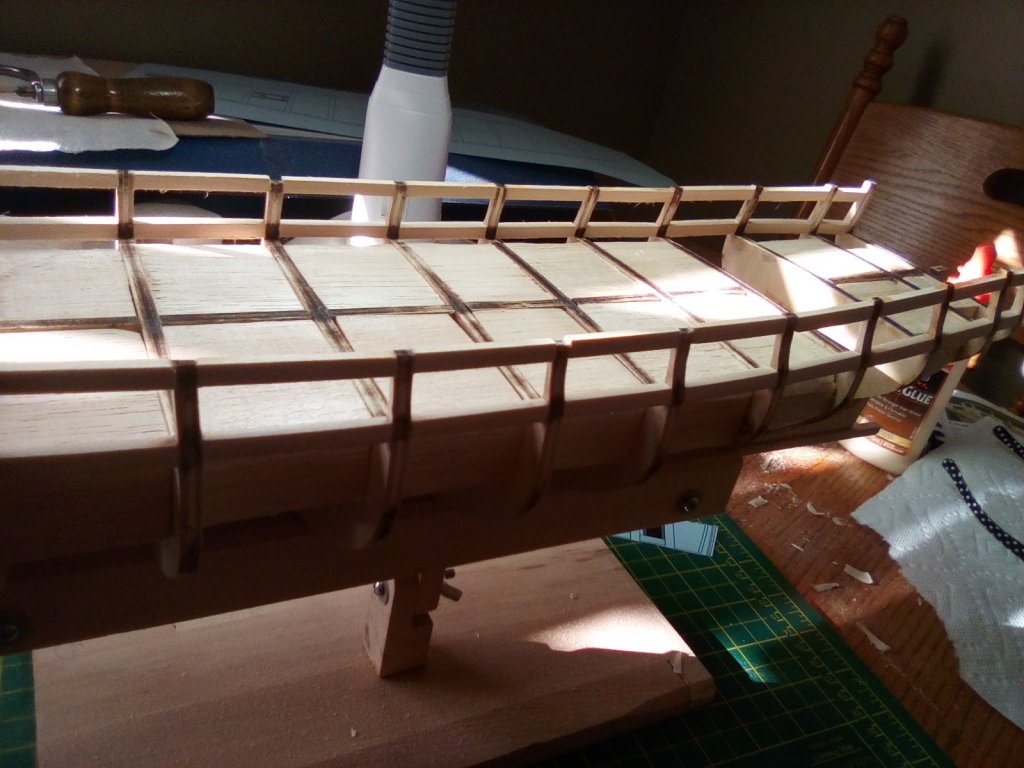

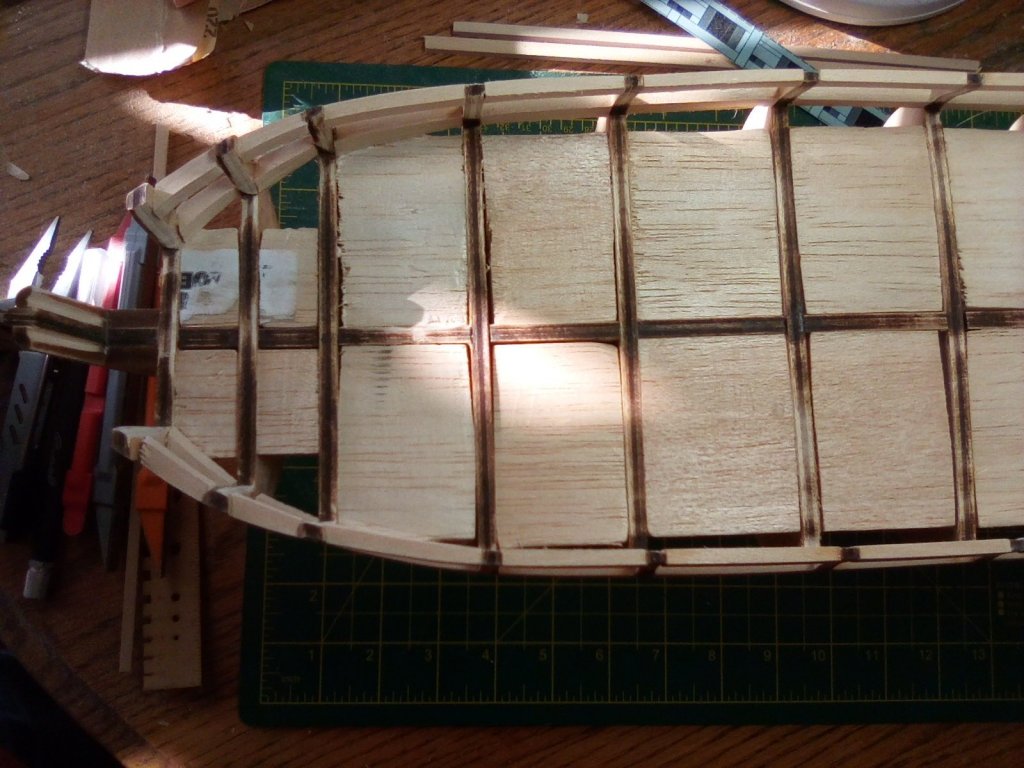

As this is my first POB build, I think I have discovered a certain "zen" in planking. I am really enjoying the process. Don't get me wrong here, I suck at it am making copious mistakes, but it is totally taking away the stress. Also, I am using the hull itself as my "jig" , and bending planks to the hull prior to cutting them. You can see this with the top plank still damp from soaking. So far this has worked fairly well. I will probably be painting vs. Staining to hide some of the gaps and nicks. I was going to lightly sand the planks once in place to also mitigate some of the fitting issues.

-

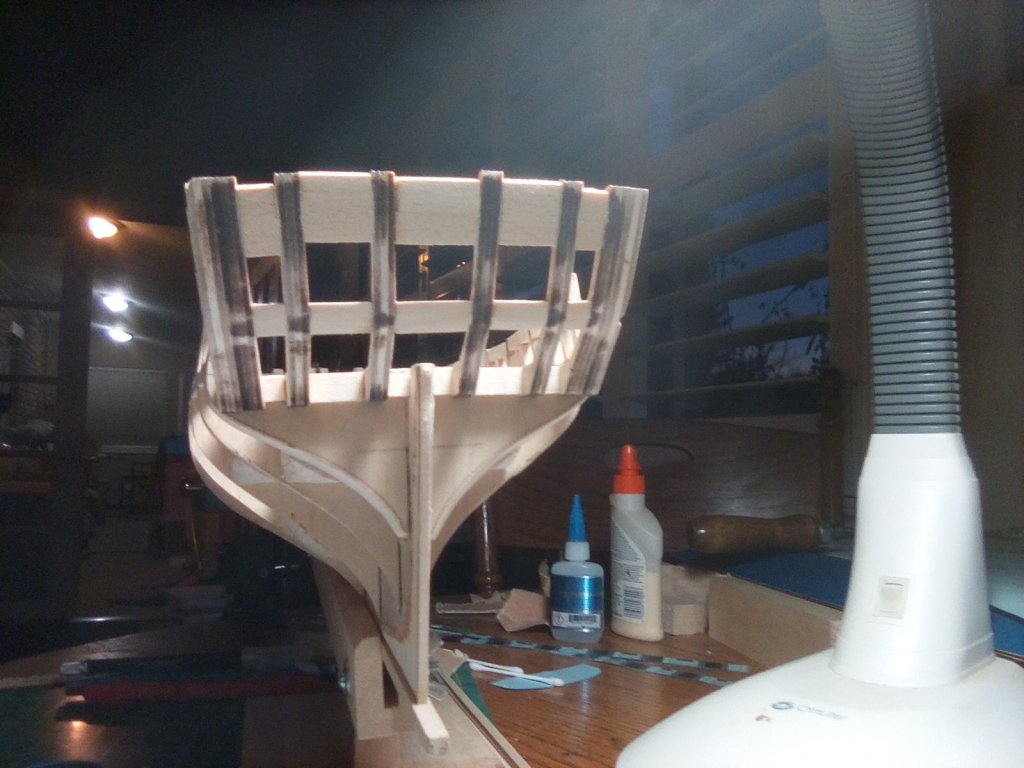

All Hail to the wales! Sorry couldn't resist. Love Chuck's practicum. So far it has not led me astray. However, I was a bit concerned when he starts Chapter 5 with a statement assuming. The builder has previous POB experience......NOT this guy. I did look at a couple of POB guides, but Chuck's instructions and photos are too notch, so forward!

-

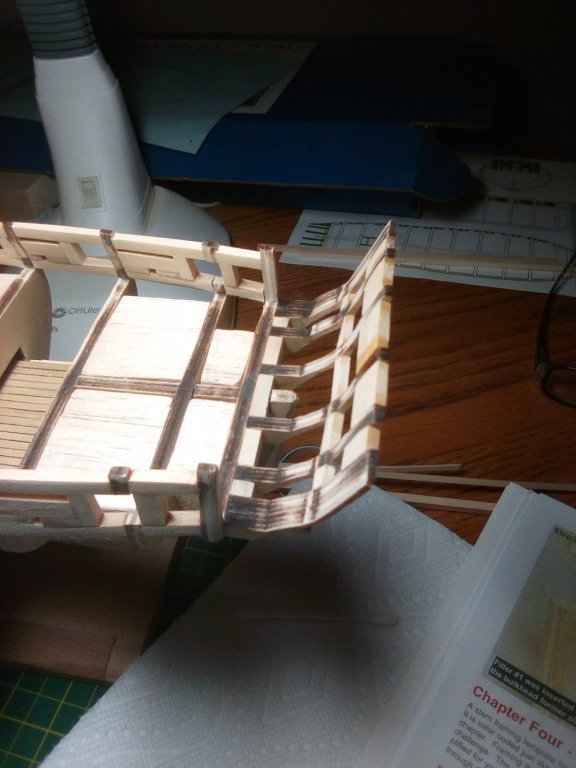

Stern framing....egad! Most of the pieces on this kit have been excellent. My stern frames were a bit warped, though. When I first had everything fitted, it looked about as straight as an eight year -old's mouth. I should have taken a photo then. After sanding and re-gluing some pieces, I have the following result. Better, but there is a slight curve aft on the port side. I am using "hope" as a method, and hoping it will come into line once I start paying planks. It is pretty flexible.

-

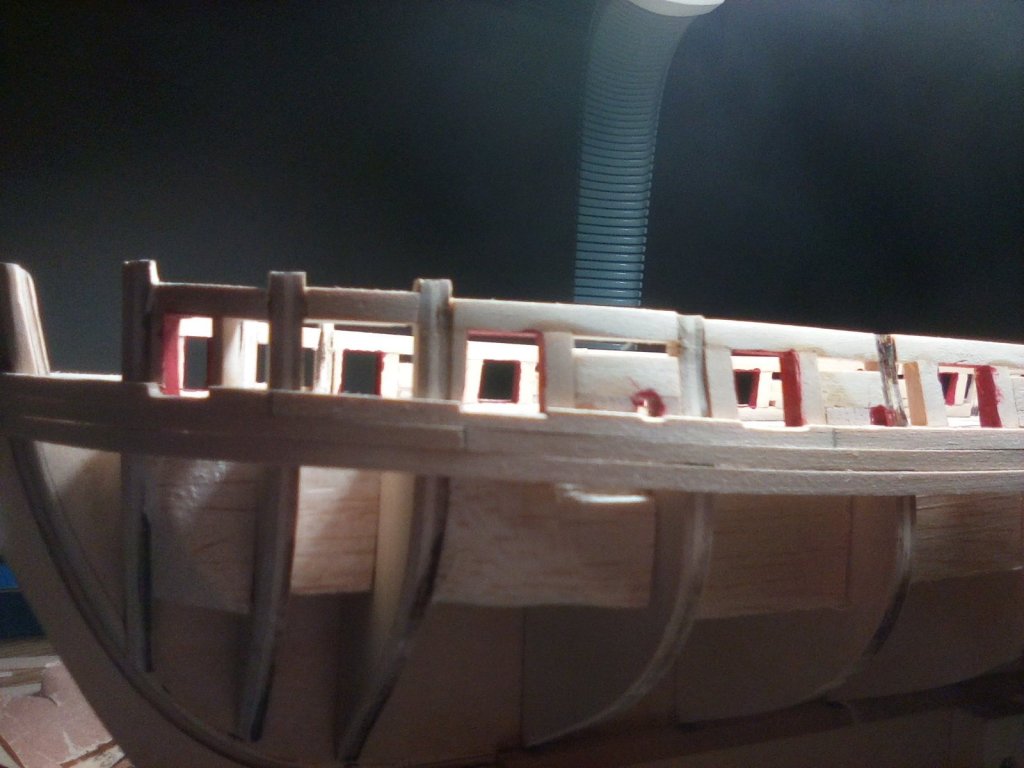

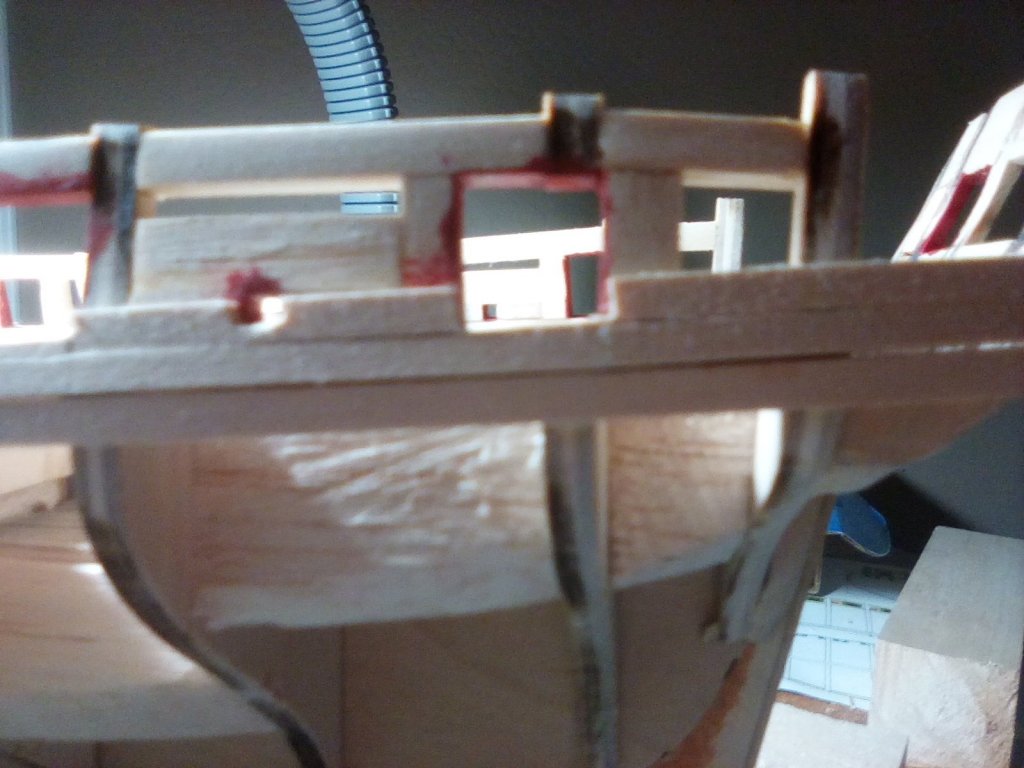

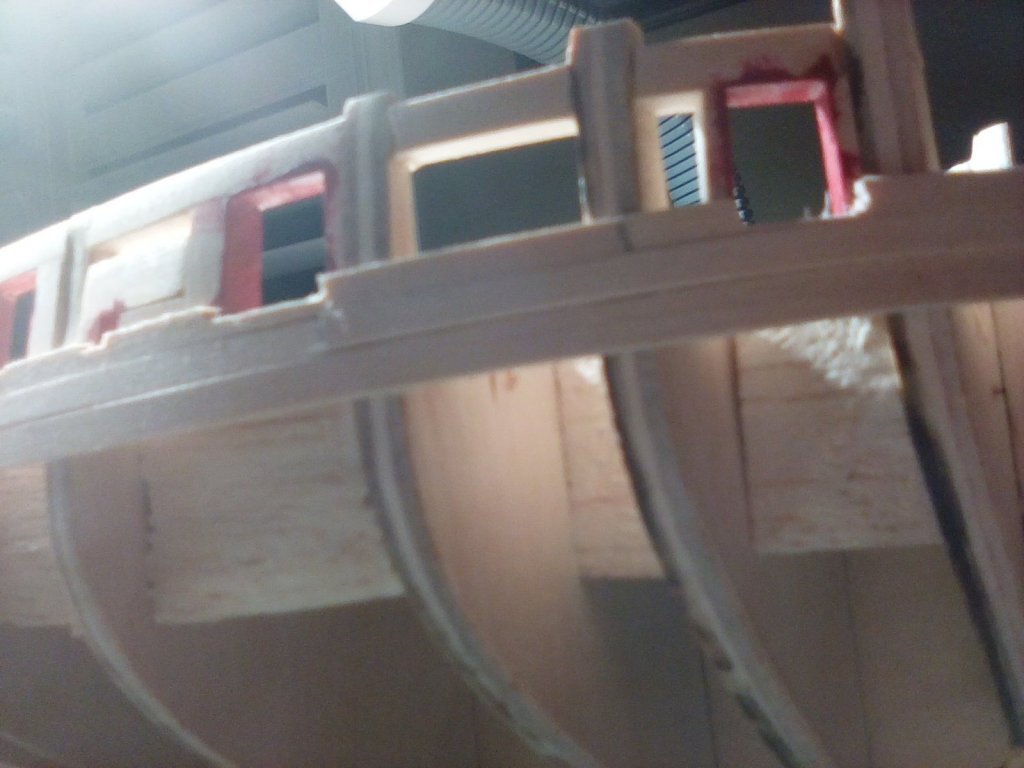

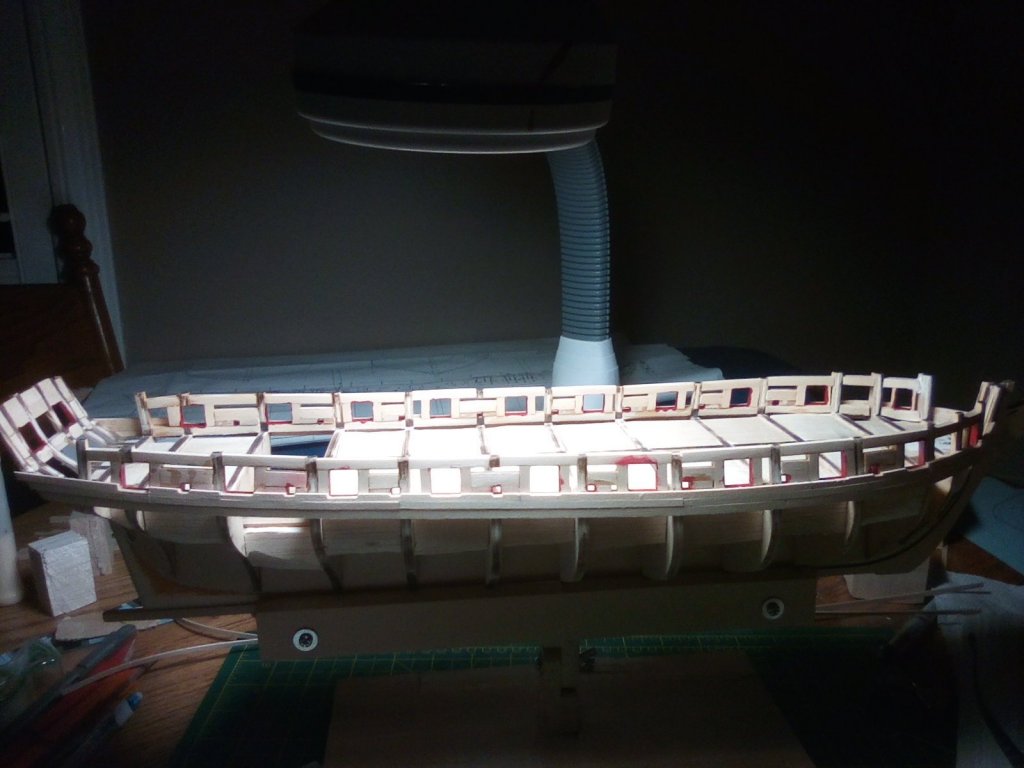

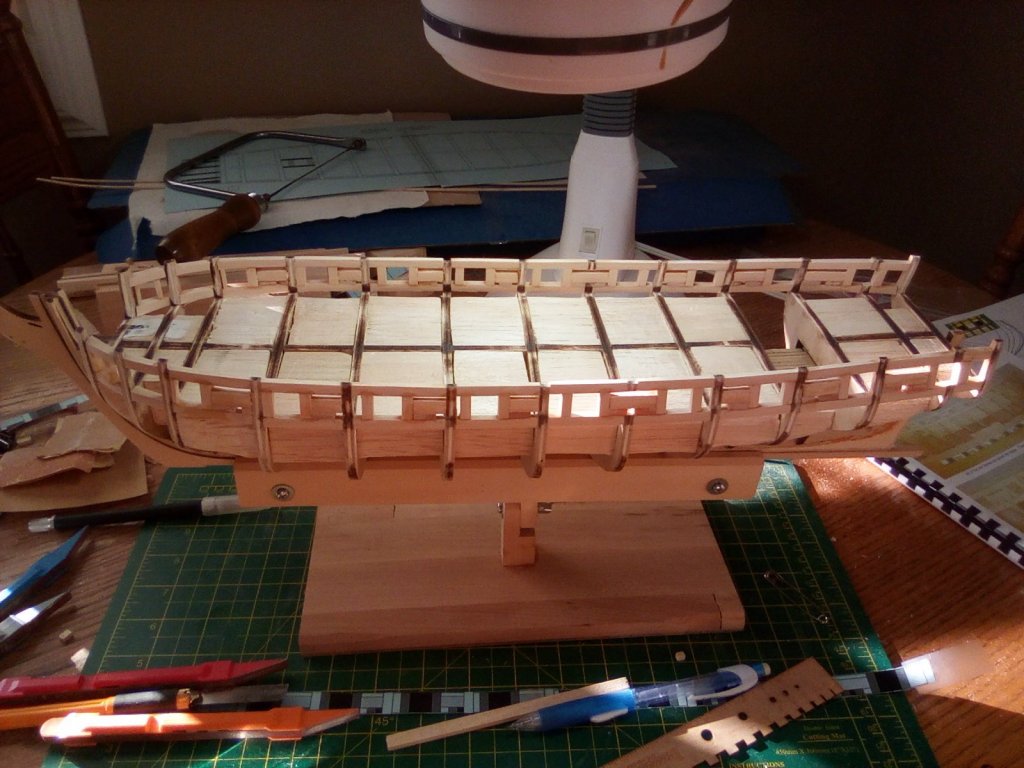

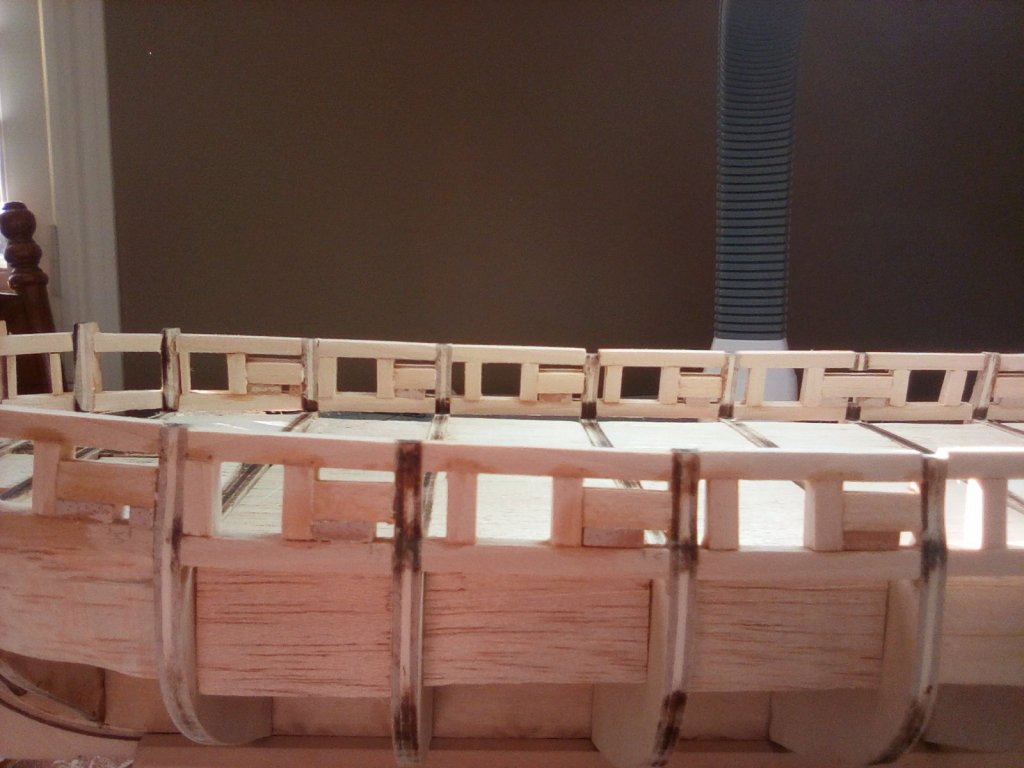

Closing out the weekend with the gun ports and sweep ports framed. I also started the initial sanding on them. I took Chuck's advice and sanded a bit in between each color frame. This gradual process definitely works well. Also, for the sweep ports, I used some leftover 1/8 x 3/8 basswood. Cutting at 3/16 gave me the perfect width. With that, I just had to sand or cut for length.

-

I like the paint booth.

- 104 replies

-

- revenue cutter

- BlueJacket Shipcrafters

-

(and 1 more)

Tagged with:

-

Looking great. I'm my humble opinion, the hardest part was the hull, but the templates are sound....trust them. This is a great starter kit for rigging. My biggest issue was reading the plans closely and getting the blocks in the right position on the masts. Also, recommend you leave the skylight clear and put in a false bottom. A piece of lightly stained basswood worked well for me. Oh, and I did not like the waterline tracing tool. I went with a piece planking material and traced it referencing the plans. I found that much easier.

- 104 replies

-

- revenue cutter

- BlueJacket Shipcrafters

-

(and 1 more)

Tagged with:

-

Suprise, I did not in fact quit the build, just had a bit of a hiatus over the summer. Spent last couple months building the port sills and lintels and sanding them in place. I think I may have sanded myself into a bit of a corner on the two forward most gun port sill pieces on the starboard side. Specifically how they are bowed around the second bulwark. Can that be hidden by the inner planks later, or should I try to fill it now?

-

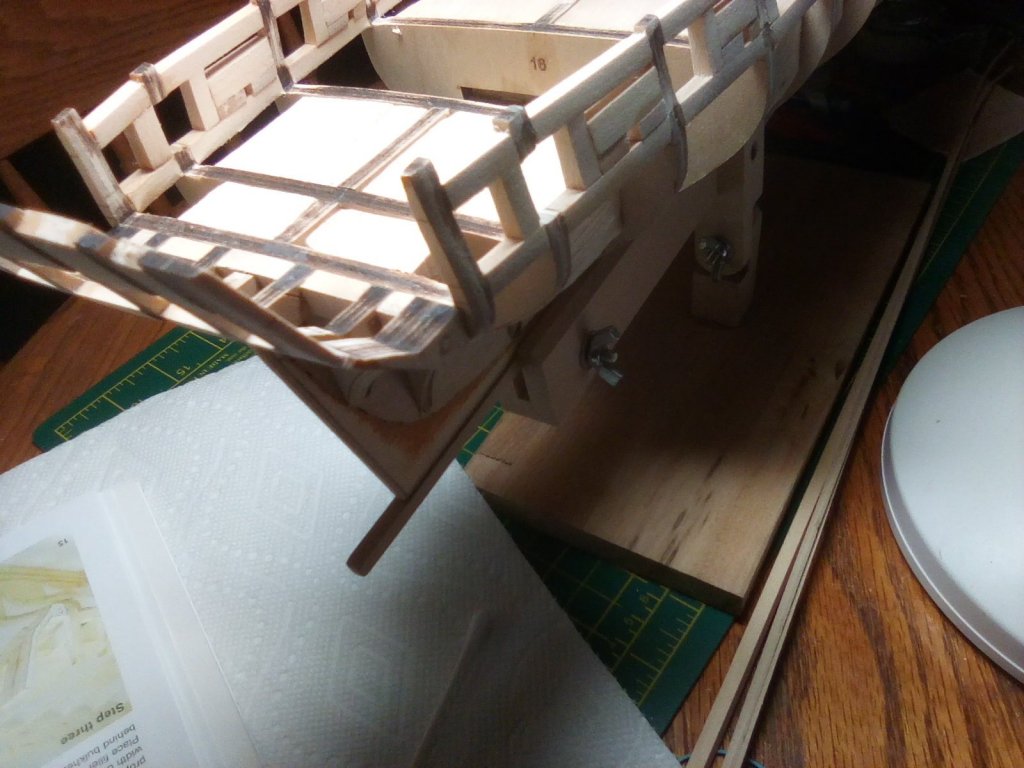

Here are a couple shots of the bulkhead fillers that I was able to get done over the weekend. I am going with balsa since it is pretty malleable and light, yet I think it will sufficiently stiffen the bulkheads. I am sticking with the praticum's suggestion of about 1" by 2" for the filler blocks. These are only dry fitted so far.

-

I am using these great sanding stylus from Lumberton Industries. They come in four different grades of coarseness. I think several people have come up on the net in various build logs with trepidation about going at the bulkheads with chisels. I am definitely in that camp. The sanding belts on each stylus are about a quarter inch wide, so they work great on the bulkheads.

-

So, after reading through a couple of logs, it seems quite a few folks are gluing the bulkheads to the BF prior to bevelling and fairing them. Yet the instructions say to bevel prior to installation. I also have quite at bit of play in my bulkheads, but I think that will be fixed with the filler pieces. Be happy to get some opinions on this issue.

-

Jgrace, my only other build prior to this was the Revenue Cutter. With two ensign builds under your belt, you should be fine. The only area I struggled with was the running rigging plan, because it was mis-labled. I sent my questions to Nic at Bluejacket and he sent me back photos of the edited plans. I believe Al redrew them based on this edit. The hull required a bit of sanding, but the stem and stern moulds were good.

- 58 replies

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.