-

Posts

114 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Hill202

-

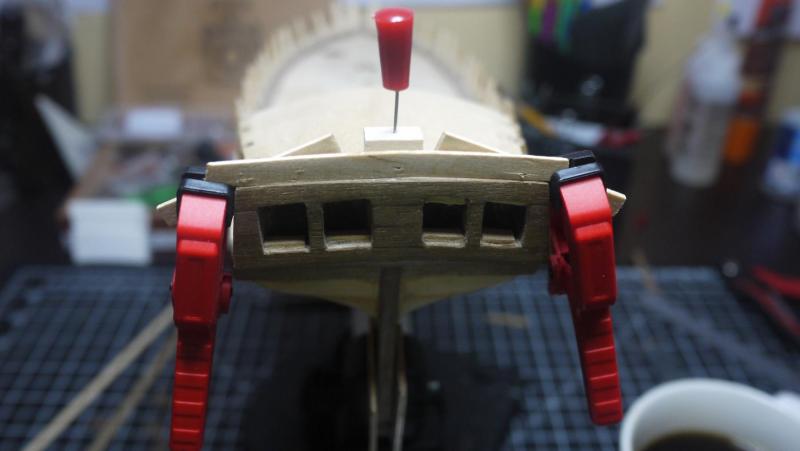

The temporary braces worked. The top planks are on. I have to reinstall one window stop on the port side. I somehow managed to install the window stops after I painted the window cavities. I have no idea why I did that. I'll have to carefully paint those. It's time for the fashion pieces. All of you guys did great on those. I hope mine looks as good as ya'lls. Edit -As usual the pictures help to find the flaws. I have a little more sanding to do on the edge of the counter on the port side. I would like to sand that top plank a little more to flatten it on out but I'm concerned that I will sand thru the walnut.

-

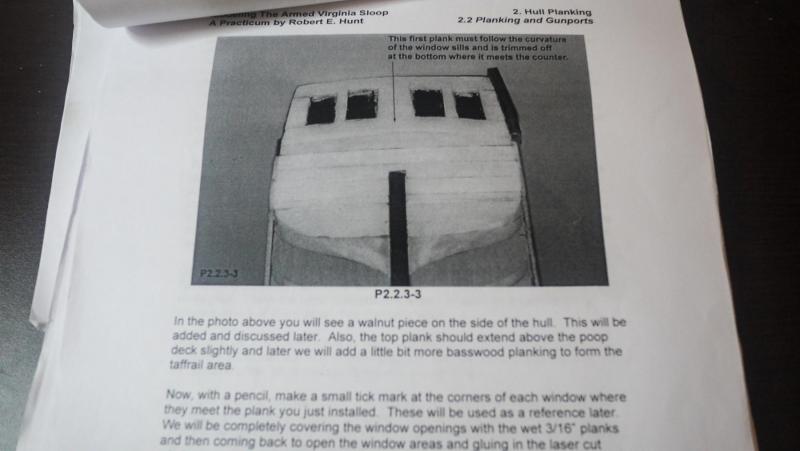

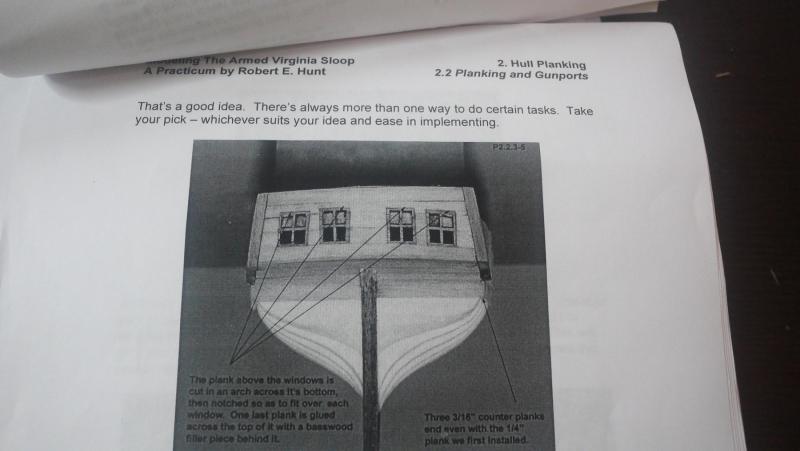

That would probably work. Tact glued to the side and then removed. I'm getting pretty good at un-glueing stuff. Edit- The more I think about, I'm convinced that its the solution.The top plank has" wings" that extend above the deck. I can install a temp vertical brace to the back of it, on each side, to clamp to and keep the additional planks aligned. Thanks David B!

-

This is a dry fit with the windows. My problem is there is supposed to be another plank on top to extend above the cabin deck. There is nothing to glue to, other than edge to edge. How did you guys do that? I don't have the windows pushed all the way in yet. I also still need to sand the edges on the port side to match the starboard side. I think the gold paint on the windows will stand out more after the walnut has been sealed.

-

The practicum says to install an additional plank above the windows to extend above the cabin deck. There is nothing to glue to there. How did you guys glue that top plank edge to edge and keep it all lined up? The only thing I can figure out is to install the fashion pieces first to help line the planks up.

-

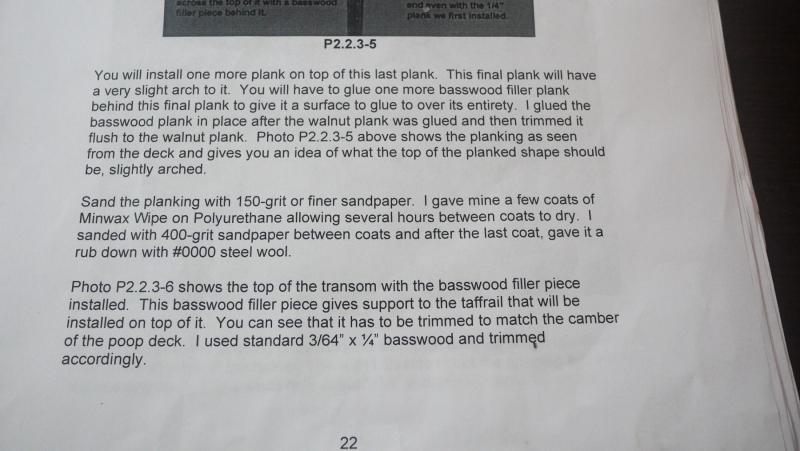

Thanks. There are too many variables for me to be able to put a time frame on it. I'm going on 2 months and I'm only half way through chapter 2 of 9 chapters. The rest of chapter 2 is planking the hull and I could see that easily taking 3 weeks or longer. Everyone builds at a difference pace. (edit, after thinking about it) - Three weeks? who am I trying to kid? It took me 2 weeks to glue 6 planks on the stern. I glued and unglued one plank 3 or 4 times, before I was satisfied.

-

Thanks guys. Come on in Greg! I've referred back to your thread quite a bit. Your AVS is looking great. I really like the way your stern looks. I realize in the pics that you have already applied a satin finish to the walnut on the stern but for some reason the walnut planks in my kit do not look as good. I hope the satin finish brings out the grain in mine. I'm talking about the really thin planks. My parts lists states that they are .030. The plans and practicum say .020. After looking at yours more, your planks look thicker. Maybe I have been looking at the wrong ones.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.