-

Posts

901 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by garyshipwright

-

If any one is interested I have a extra book of David Steel plates 1805 from Sim's Comfort that I would part with if any one is interest if they want it. The cost would be Vol 2 of the Naiad Frigate (38) 1797 Volume II by Edward Tosti with CD. I purchase a new set from Sim's after the fire took vol one and don't need two of the same book. Seems that Sea Watch book isn't going to reprint Vol 2 so I would be more then happy to trade vol 2 of David Steel's book of print's if some one is willing to trade Naiad vol 2 for it. If interested let me know. Gary

-

Chuck is it to late to purchased the first Two chapters? Let me know would you please. Thank you. Gary

-

Hi Kevin. You could look into getting a set from Artesania Latina and on there site they call them Micro Shapers and comes in 3 sets, A,B,C. I have all three and get good result's when using them. At least look in to them and may save you from pulling out your hair. Good luck Gary

- 976 replies

-

Hi Mark. Every one is fine and the dog's to. You are so right about this and it will take some time for the repairs. Getting the paper work done is a whole different ball game. Trying to list every thing that you have in your home is very time consuming, but having photo's of the den and the rest of the personal items does help. Never knew I had so much stuff. Thank you again. Gary

-

Hi Allan and thank you. Do believe it was after the big crash. Only thing I can remember is that it was posted to give folk's a ideal of what books one may see what is out there. Some of my most important books were in the den so am trying to find them so I can claim them on the insurance. I do think I have enough info from photo's of the book's in the den but having that list just help me. Thanks again Allan. Gary

-

Hi every one and hope every one is doing fine. Been having a bit of bad luck going on with the house, had a little fire about a month ago and working on getting the house a make over in the up and coming month's. Hopefully we will get to move back in, in about 6 month's or so. Seems like a long time but keeping busy so the time doesn't drag on. Hoping the good crew can help me out. I posted a list of my books but I can't seem to find it and hoping some one will have come across it. Need to turn a couple of my book's in but thankfully the biggest part of the libaray is in the addition in the work shop. Thank you and will be back before you know it. Gary

-

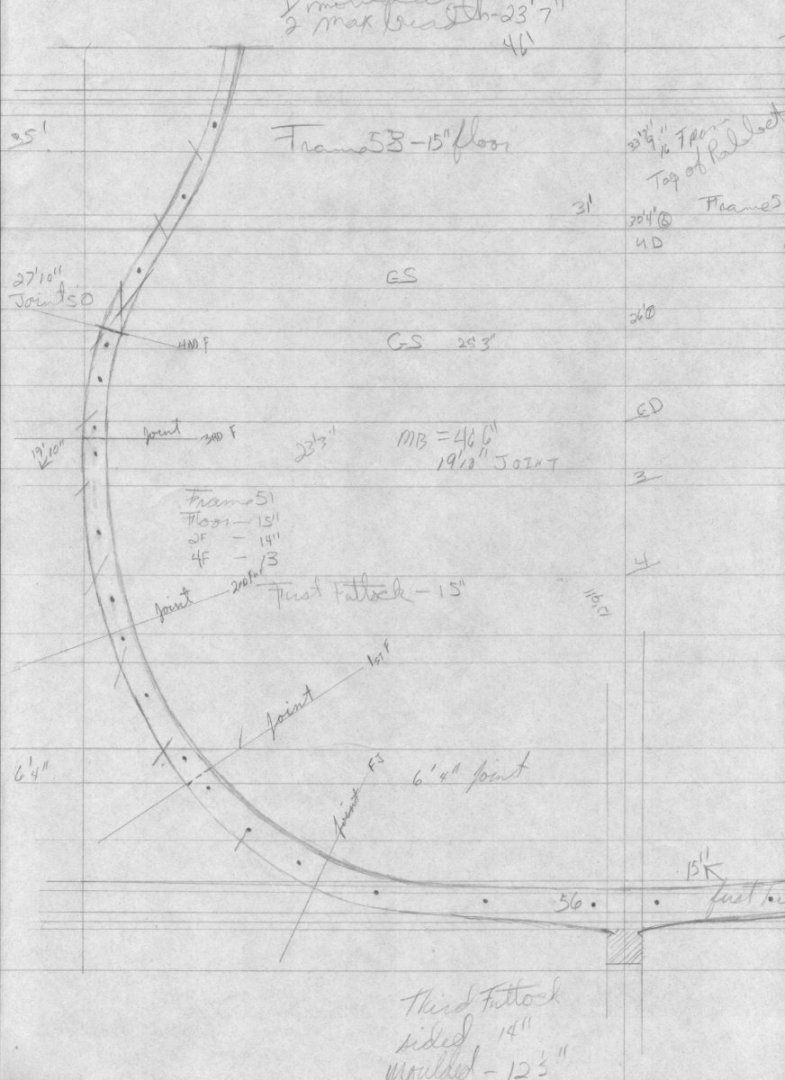

Hi Tobias and thank you for the compliments. Yes I drafted the plans of her, the half breadth plan and then her frames from that. I also drafted the lay out of her deck lines from the shear plans. One does have to be very careful because after many years the plans have enlarge, grown and redrafting this parts, help's straighten this out. Makes her easier to build. I do thank you for your kind words.

-

Thanks guys. Guy your right about that, have been busy that's for sure. Thanks druxey, thought that might add a little detail to her. If you look close at the top of the capstan. I installed some pin's and chain's for holding the bar's in place. Still a lot to do on her, just need to spend a lot more time on her. Once I get the beams installed I may just have some fun and install the stove that I built a couple of years ago.

-

Hello every one. It's been awhile since I posted any thing on Montague/Alfred but wanted to get the the planking done on the Winchelsea and after 6 month's or so of building the bulkhead's and planking her in boxwood I finally went back to work on Montague/Alfred. Been slowly working on adding more beams to the upper deck. I added a few photo's of the Winchelasea and do hope you enjoy the photo's. Sorry about the delay on getting back to her. Gary

-

Hi Johann. Looking outstanding as usually. Have a question for you. You showed in post 2079 your soldering station and was wondering where you got the to tall clamp looking items in the white board for soldering. I have been looking for a set of these but as of yet have not found them. Keep up the great work and thank you. Gary

-

Hi Stevinne. It really depends on what scale you working on. Am sure if you give that bit of infomation a few of us could let you know what size you may need. Gary

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.