-

Posts

2,939 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Hubac's Historian

-

-

King Gustavus Astolphus “liked” that.

-

-

-

This is really wonderful work from both of you. It is an interesting detail that the lower transom planking appears to be let into the aft-most frame, as opposed to overlaying it.

- dvm27, mtaylor, Keith Black and 2 others

-

5

5

-

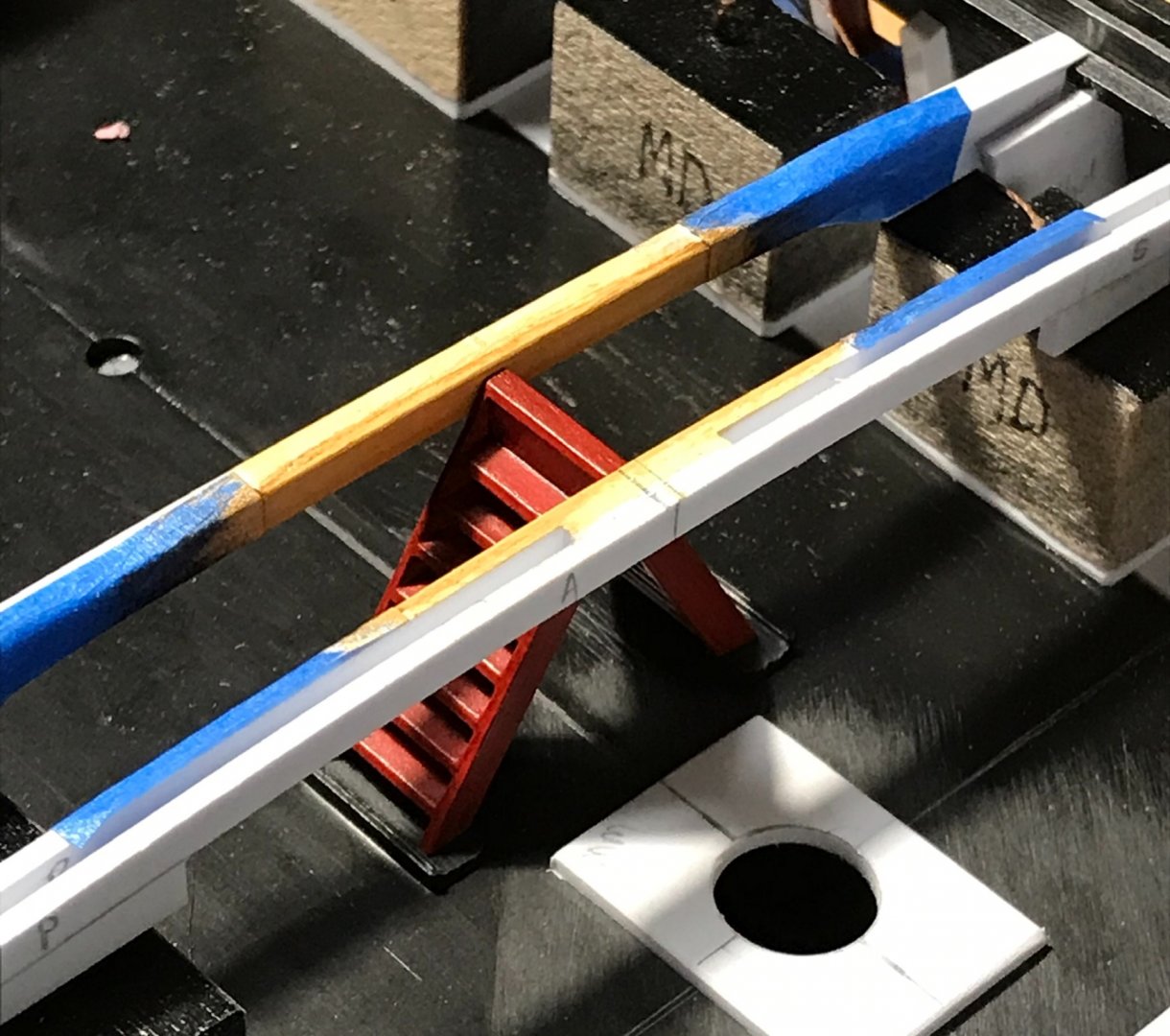

My lid lanyards tie off onto an eyebolt on the top of the dummy carriage. The trick will be shortening the lanyard line enough that it doesn’t look floppy around the barrel. I left myself plenty of excess line to figure it out.

-

Bill, I will make a single eyelet that mounts to the inside (exposed) side of the lid, and I will bend the loop of the eye, downward, so that it seems to hang naturally, like a ring. I’ll seize my lanyard to that.

-

-

It sounds like spalt, but it could also be bug damage of some sort or other. As your exterior hull will be planked, what do you think about injecting epoxy into this void, in order to solidify the material? As you arrive closer to your finished dimensions, you may find it necessary to repeat the process, but that should restore your material integrity.

- FrankWouts, scrubbyj427 and wyz

-

3

3

-

From what I can see in these photos, it looks as though you will have some significant fairing to do between frames 2 and 4. Balsa fillers, throughout, would make the fairing process easier to gauge, as you go. It also will make a realistic plank shift more easy to achieve, as you will not be dependent on landing on bulkheads. The only other way to land a joint between bulkheads, is to back the joint with glue tabs, and even then you might end up with raised peaks at each joint. That seems very tedious to me. Just a thought.

- mtaylor and Bill Morrison

-

2

2

-

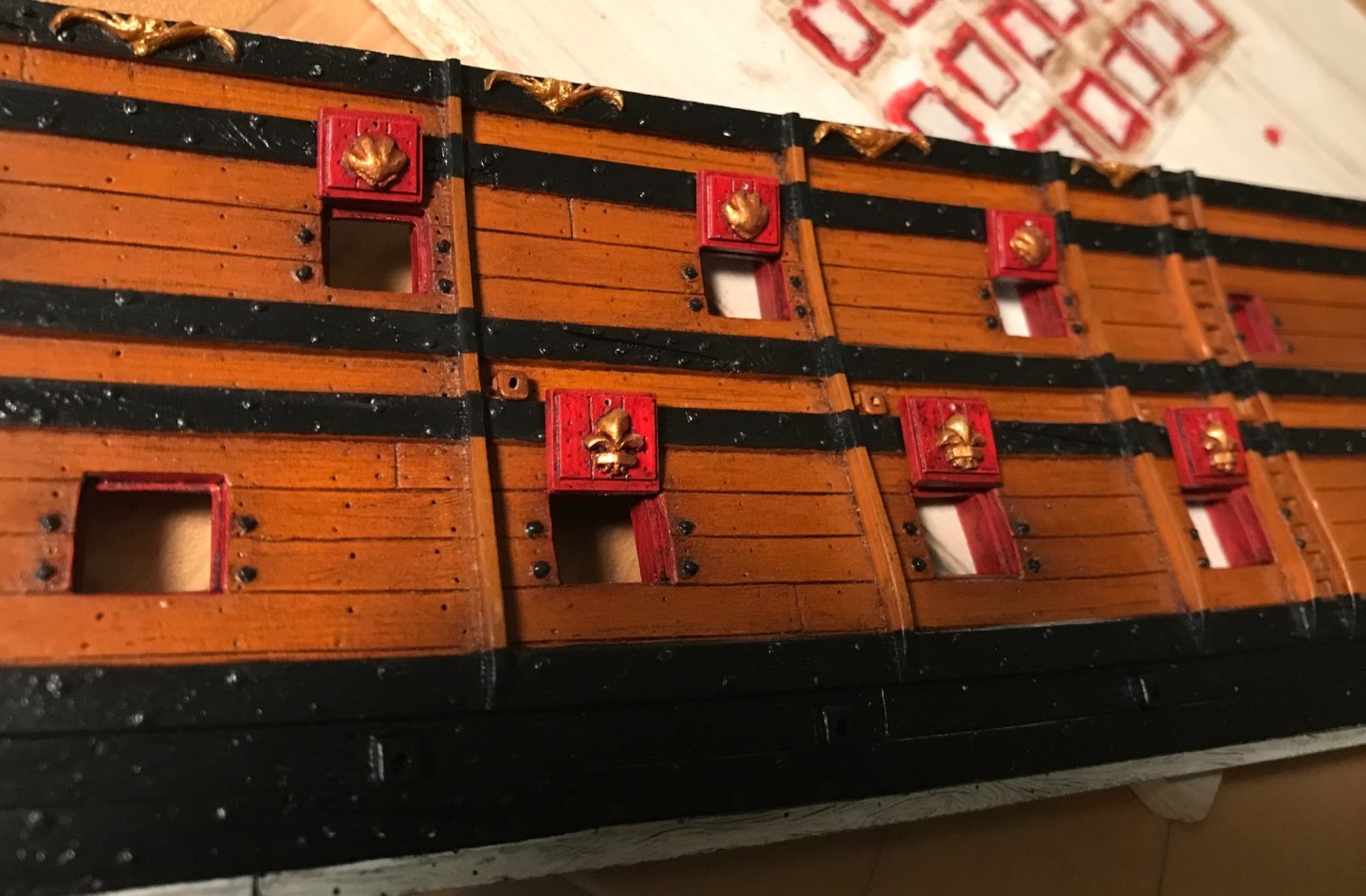

In scales this small, it has been suggested to me to seize your lanyards directly to a single eyelet secured to the lid - rather than an additional ring attached to your lid eyelet.

On my project, I will display the lids in a somewhat unrealistic way - as pulled up against the wales - because I want the lid ornaments to be fully visible.

In this way, I only need to represent the single, interior, closing lanyard.

-

CriCri, when you get to glueing everything together, will you also glue-in filling blocks between the bulkheads?

- mtaylor and Bill Morrison

-

2

2

-

It’s easy to appreciate, here, how beefy the French ships were.

- mtaylor and Bill Morrison

-

2

2

-

Haha! Yes - 08/11🌞

- mtaylor, FrankWouts and EJ_L

-

3

3

-

Congratulations, Marc!! Leos rule! What is your Daughter’s name?

- EJ_L, FrankWouts, mtaylor and 1 other

-

4

4

-

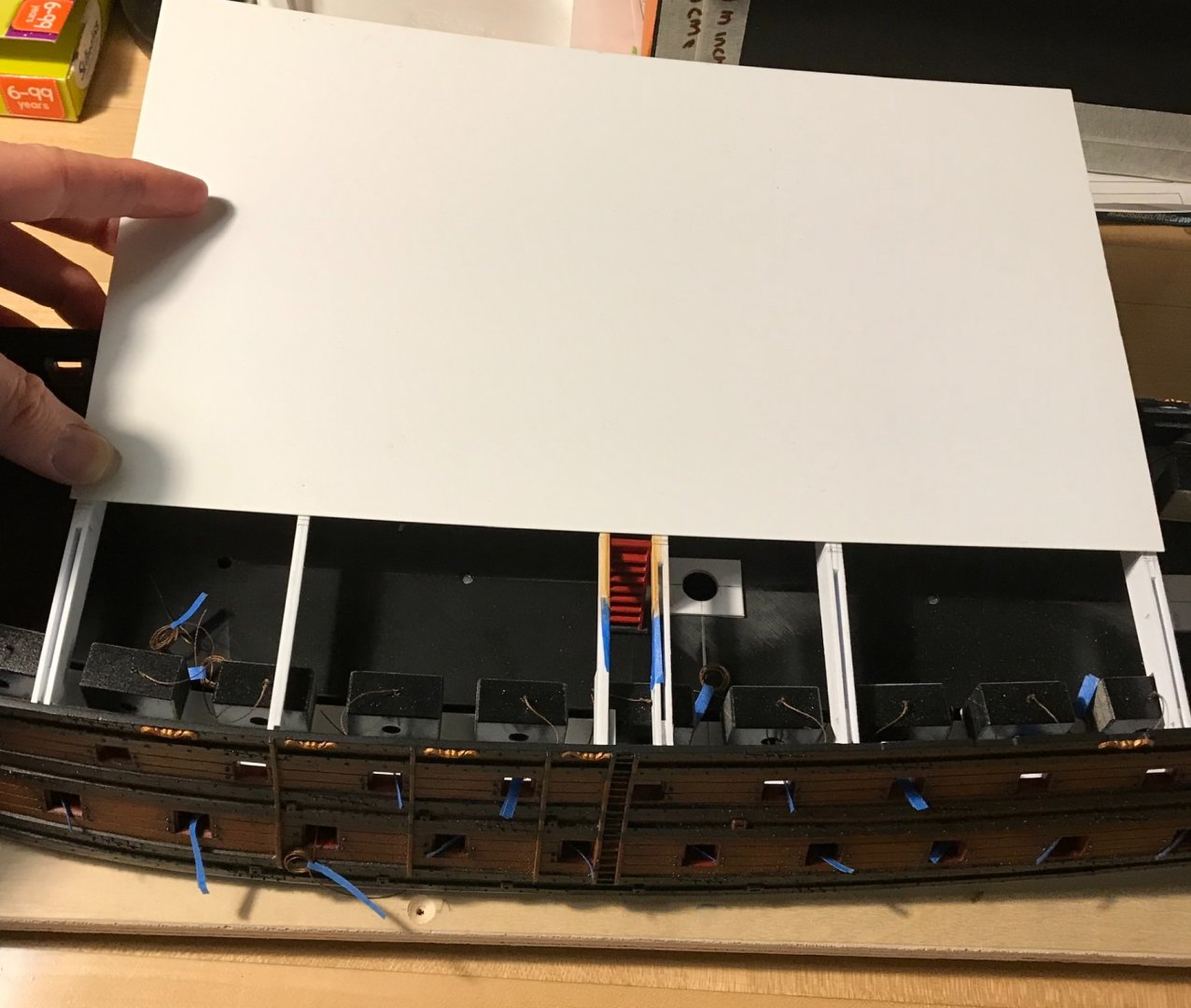

Thank you all for your kind compliments and for continuing to support the project. I know I spend a lot of time on the minutia, but that is where I find the greatest satisfaction and continued investment in the project. It is gratifying that such a good number of you enjoy that level of detail. I may only be guessing a lot of the time, EJ, but I try and do things that make practical sense.

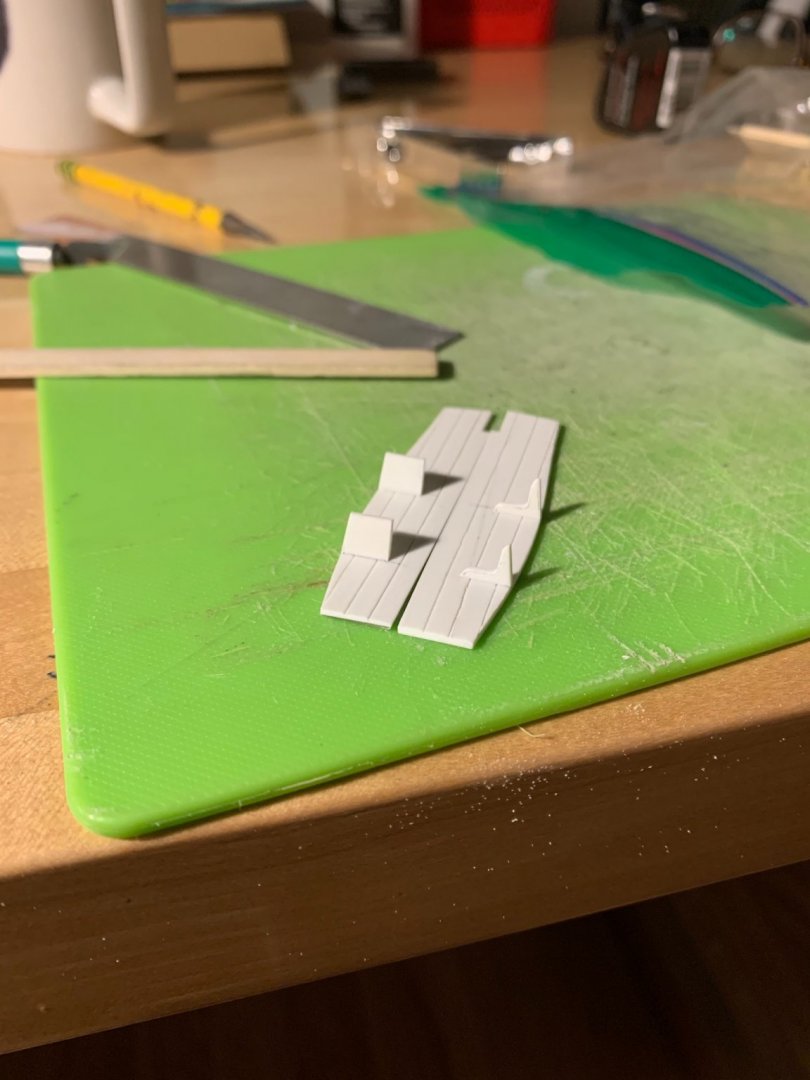

One such example is interior support for the quarter gallery rail. Although, I do not see specific reference to this in Lemineur’s monograph for the SP - or anywhere else, for that matter - it only seems sensible that such a light construction would have additional support. So, that is what I have endeavored to do:

A wooden ship is full of knees, buttressing and distributing loads. The channels have knees. The deck railings have knees. The stern and quarter galleries are particularly vulnerable to rough and battering seas, so I think this makes sense.

There is the added advantage, of course, of having additional glue surface for the railing upright, and these supports will help the part conform to the gentle contour of the gallery.

I received my BSI de-bonder. The bottle says that the product mars most plastics; perhaps not acetate, though. I will experiment. I will also soon be painting again, so that I can install all of these walk parts.

All the best,

Marc

-

Extremely well done, Kirill!

-

Very well said and informative, concerning the alteration of hull shape by moving the smaller bends forward or aft.

- GrandpaPhil, Bill Morrison and mtaylor

-

3

3

-

4 hours ago, Sailor1234567890 said:

Ah. Cool. Thanks. I wonder what the etymology of it is in French. Quarter Galleries are a gallery on the quarter of the ship so that's easy but why "Bottle" in French?

I think they are called bottles because the early baroque silhouette of French quarter galleries were reminiscent of elaborately shaped perfume bottles. The term stuck, through the ages of sail, even as the style of QGs became increasingly austere. Given their function, however, it seems unlikely that they smelled like perfume.

-

I wasn’t sure how you were going to approach this, but I am really impressed that you are tackling an authentic planking job. Your progress looks really great. Yeah, I’d say your process is working!

-

-

I have a few different gauges of wire. A long time ago, I acquired a spool of super fine wire - the gauge of which, I am no longer certain.

In craft stores, I have purchased 28 gauge (upper left) and 32 gauge (upper right). I think for my SR project, I can get away with 32 gauge wire for making eyebolts for my gun carriages in 1:96. I haven’t gotten around to experimenting with that yet.

Online, I found 36 gauge:

I would say 36 gauge is a good starting point, and if you can find something even finer, then I would do so.

-

If you decide to add rings and rig the guns, keep in mind that the ringbolts would be very fine, at this scale. Using wire of too heavy a gauge will look clunky. Most craft stores carry an array of annealed wire; the finer, the better.

-

Chapman, thank you for that super clear image of the Grand Monarque’s bow. I see your point about the relative scantling of timber that the gammoning passes through, in these early First Marine vessels. Twenty years later, though, the head structure of French ships had changed significantly, and the cutwater was significantly more “meaty” in the area of the gammoning. There was a transition from the beakhead style (more characteristically Dutch) to this later style, which is more like the English head structure - excepting the headrails, themselves, which are characteristically French.

- mtaylor and Bill Morrison

-

2

2

-

For reasons I point out in prior posts, doing so creates unnecessary weak points in the structure. These ships were massive, with tremendous dynamic forces working against them all the time; the gammoning really needs to be secured by the heavy timbering of the cutwater.

Anyone, of course, is free to do as they wish. However, if they want to represent authentic reality, then there are some rules of construction that shouldn’t be violated for the sake of aesthetics.

- Bill Morrison, Chapman, PietFriet and 1 other

-

4

4

Spanish Galleon 1607 by kirill4 - Lee - PLASTIC - 1:100

in - Kit build logs for subjects built from 1501 - 1750

Posted

Brilliant work, Kirill!