-

Posts

276 -

Joined

-

Last visited

About Mike_In_RI

Profile Information

-

Gender

Male

-

Location

Lincoln, Rhode Island, USA

-

Interests

Modeling, Electronics, Genealogy

Recent Profile Visitors

-

Keith Black reacted to a post in a topic:

Finding authentic rope looking line for New Bedford Whale boat.

Keith Black reacted to a post in a topic:

Finding authentic rope looking line for New Bedford Whale boat.

-

Hi, It's a little while back, but one reference is from Page 120 of the Erik Ronnberg book. If you squint just the right amount you can count the spiral turns in the large tub and calculate an initial thickness. Then, after making up the line as close as I could to that, it fit within a few turns +/-). The color and shade I settled on most likely came from photos of at the New England Whaling Museum or Mystic Seaport. A really enjoyable reference.... Check the You Tube movie (1922) "Down to the Sea in Ships" around 57 min, 18 sec. You can see the line is soft, right twisted and a very light shade. Good Luck, Mike

-

KARAVOKIRIS reacted to a post in a topic:

Half Hull Planking Kit by Mike_In_RI - FINISHED - NRG - 1:48

KARAVOKIRIS reacted to a post in a topic:

Half Hull Planking Kit by Mike_In_RI - FINISHED - NRG - 1:48

-

KARAVOKIRIS reacted to a post in a topic:

Half Hull Planking Kit by Mike_In_RI - FINISHED - NRG - 1:48

KARAVOKIRIS reacted to a post in a topic:

Half Hull Planking Kit by Mike_In_RI - FINISHED - NRG - 1:48

-

KARAVOKIRIS reacted to a post in a topic:

Half Hull Planking Kit by Mike_In_RI - FINISHED - NRG - 1:48

KARAVOKIRIS reacted to a post in a topic:

Half Hull Planking Kit by Mike_In_RI - FINISHED - NRG - 1:48

-

sakumar reacted to a post in a topic:

Half Hull Planking Kit by Mike_In_RI - FINISHED - NRG - 1:48

sakumar reacted to a post in a topic:

Half Hull Planking Kit by Mike_In_RI - FINISHED - NRG - 1:48

-

GrandpaPhil reacted to a post in a topic:

Hannah by Mike_In_RI - 1:48 scale - Plans by Randle Biddle published by Nautical Research Journal

GrandpaPhil reacted to a post in a topic:

Hannah by Mike_In_RI - 1:48 scale - Plans by Randle Biddle published by Nautical Research Journal

-

JpR62 reacted to a post in a topic:

Hannah by Mike_In_RI - 1:48 scale - Plans by Randle Biddle published by Nautical Research Journal

JpR62 reacted to a post in a topic:

Hannah by Mike_In_RI - 1:48 scale - Plans by Randle Biddle published by Nautical Research Journal

-

The article ... SOME THOUGHTS ON THE RIGGING OF COLONIAL SCHOONERS by McCalip (NRG 32:30-36) is the best single reference I have found. Next to that, William Avery Baker has some thoughts in "Seafaring in Colonial Massachusetts" (online, I think) regarding the Ashley Bowen painting of the BALTICK. Randy's Hannah (45t) is much closer in size to the MS Sultana (53t) and therefore has better scalability for me than the Hahn Hannah (78t). Also, the spar sizes for the Sultana have really good sourcing. It looks like the newest MS Sultana plans include the Harold Puls update of the mast/spar information from the Public Records Office, London. I haven't started rigging yet but I've finally got my head around the nomenclature of the lines. 'Still weak on the contemporary use/position the running rigging so more homework for me. Thank you for checking in, Mike

-

Mike_In_RI reacted to a post in a topic:

HM Cutter Cheerful 1806 by JPR62 - 1:48 scale

Mike_In_RI reacted to a post in a topic:

HM Cutter Cheerful 1806 by JPR62 - 1:48 scale

-

Mike_In_RI reacted to a post in a topic:

New Bedford Whaleboat by kayakerlarry - Model Shipways - Scale 1:16

Mike_In_RI reacted to a post in a topic:

New Bedford Whaleboat by kayakerlarry - Model Shipways - Scale 1:16

-

Mike_In_RI reacted to a post in a topic:

New Bedford Whaleboat by kayakerlarry - Model Shipways - Scale 1:16

Mike_In_RI reacted to a post in a topic:

New Bedford Whaleboat by kayakerlarry - Model Shipways - Scale 1:16

-

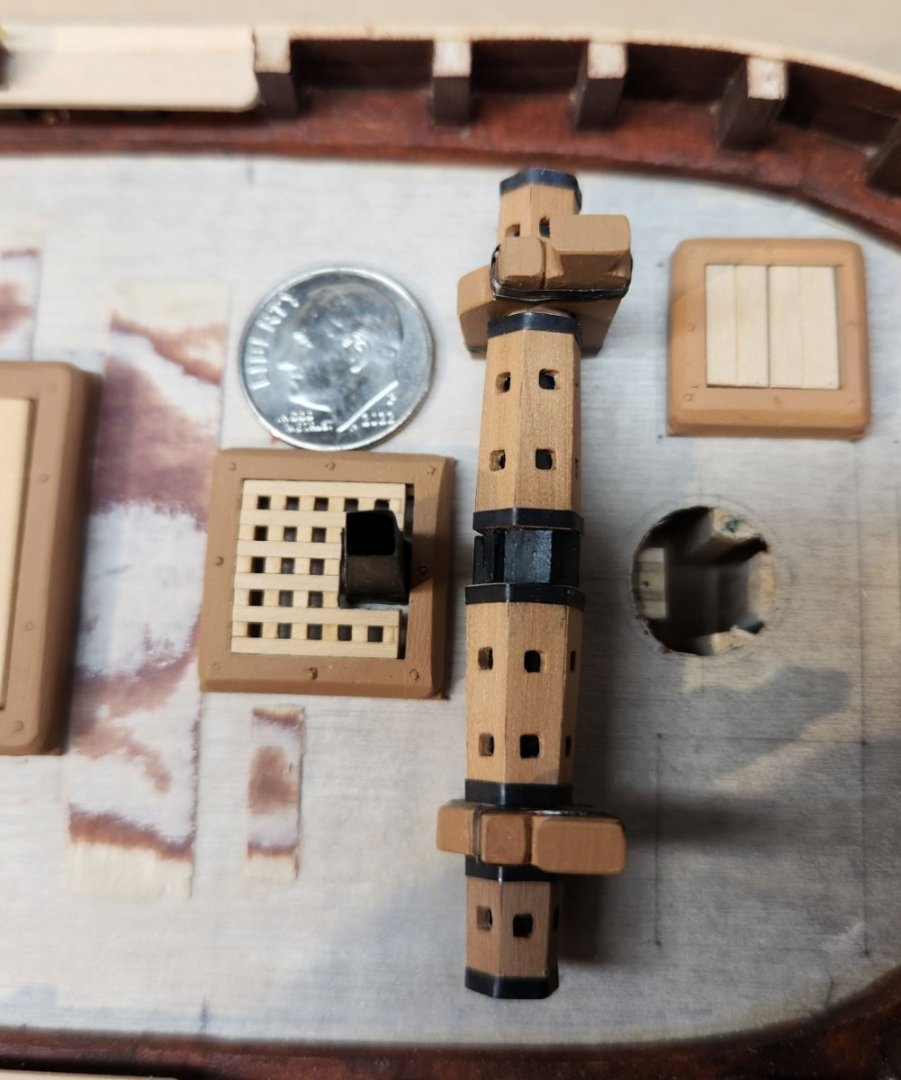

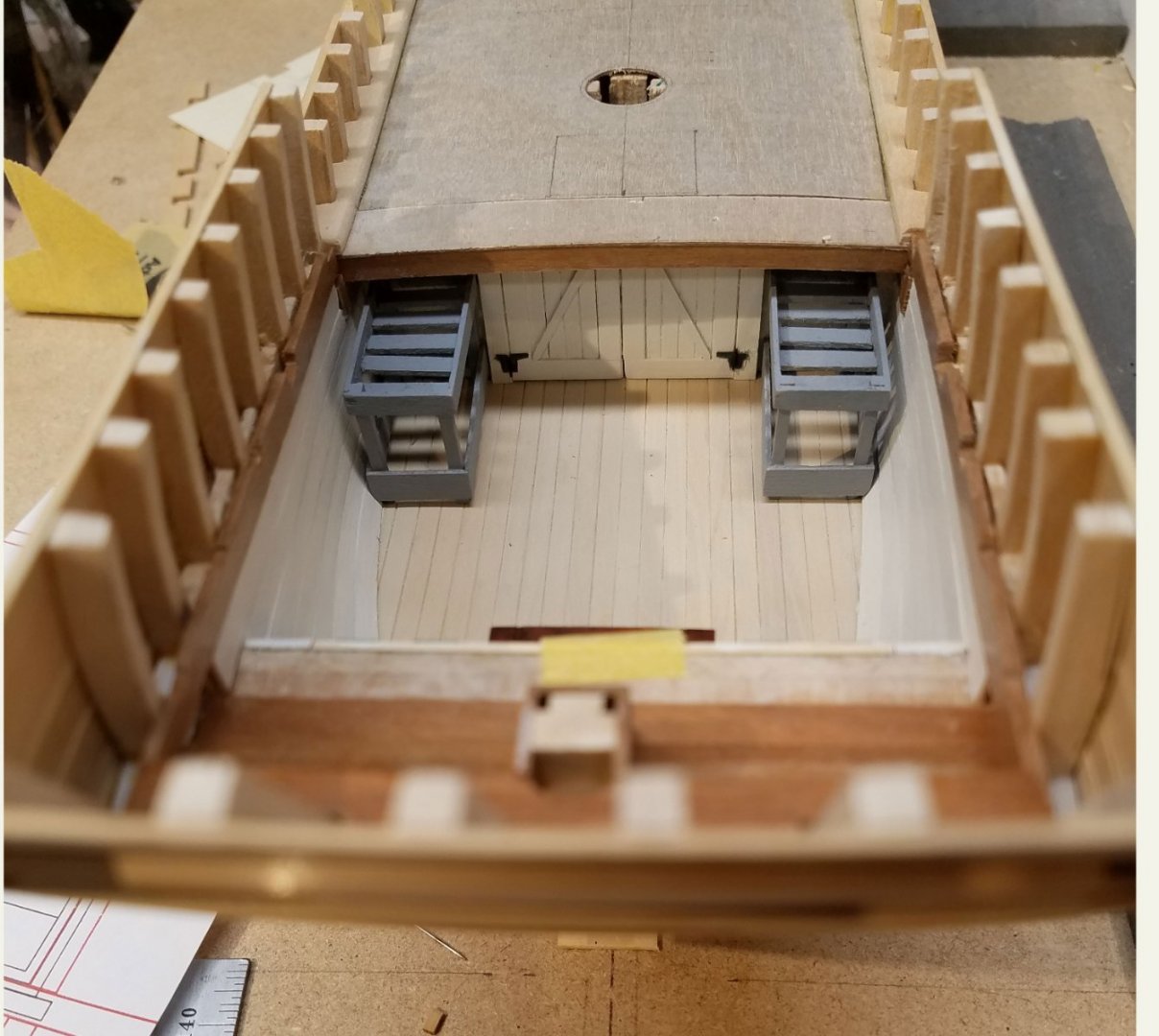

Thank you all for the likes and comments. I appreciate your input. The break pumps are almost finished. At just the right viewing angle down the companionway, the mid-trunks can be seen. The TFFM is a great source for the break pump detail. Thank you again, Mike

-

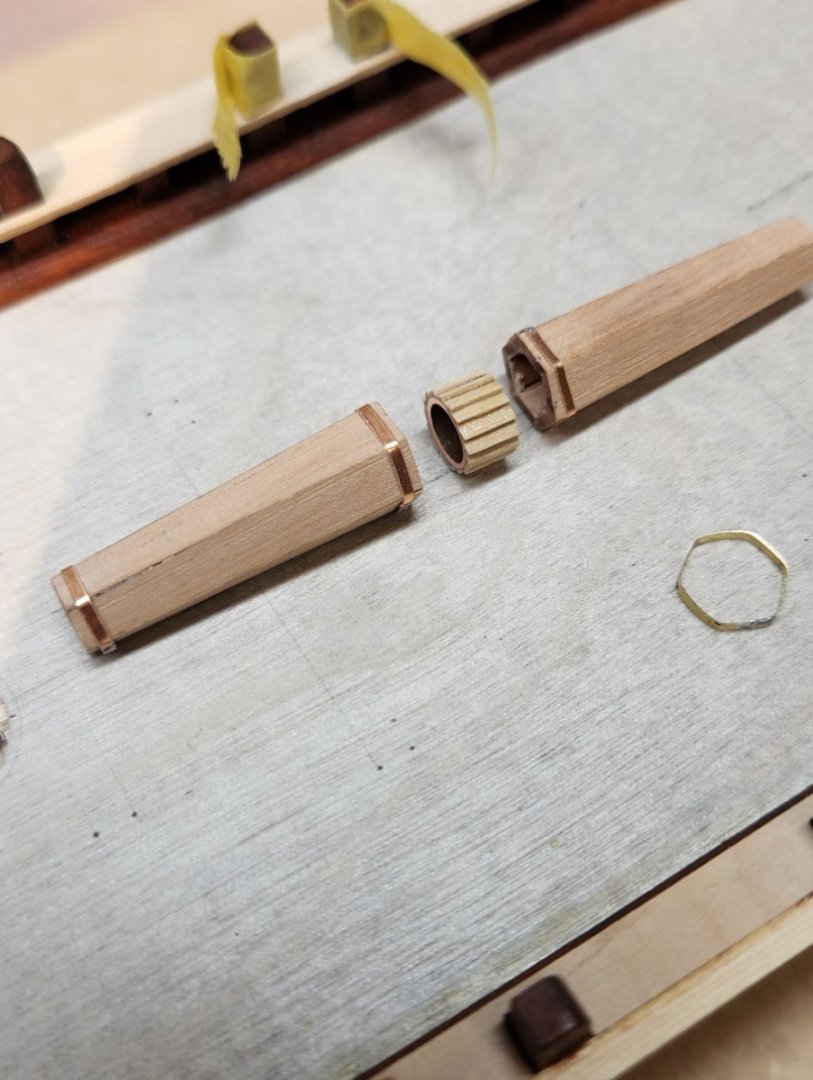

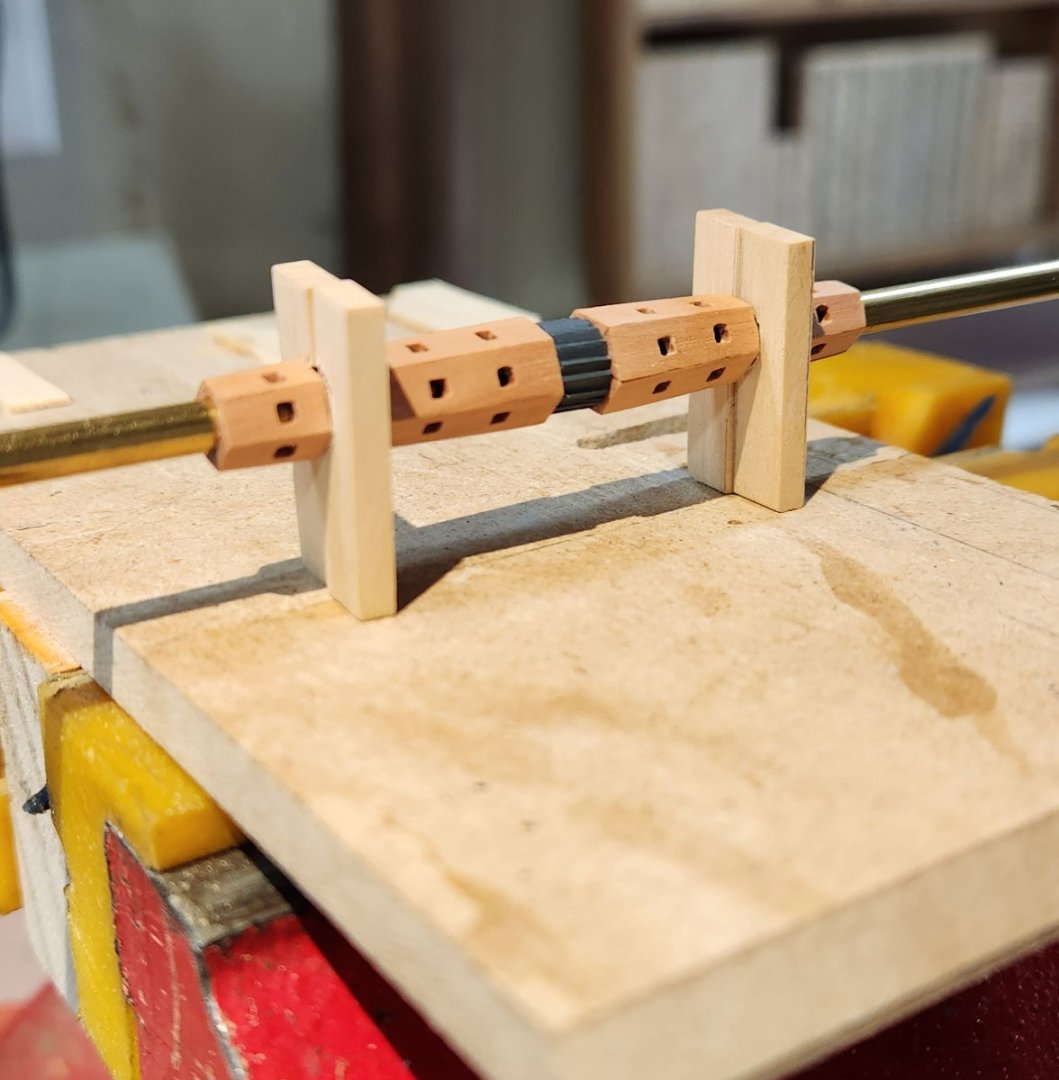

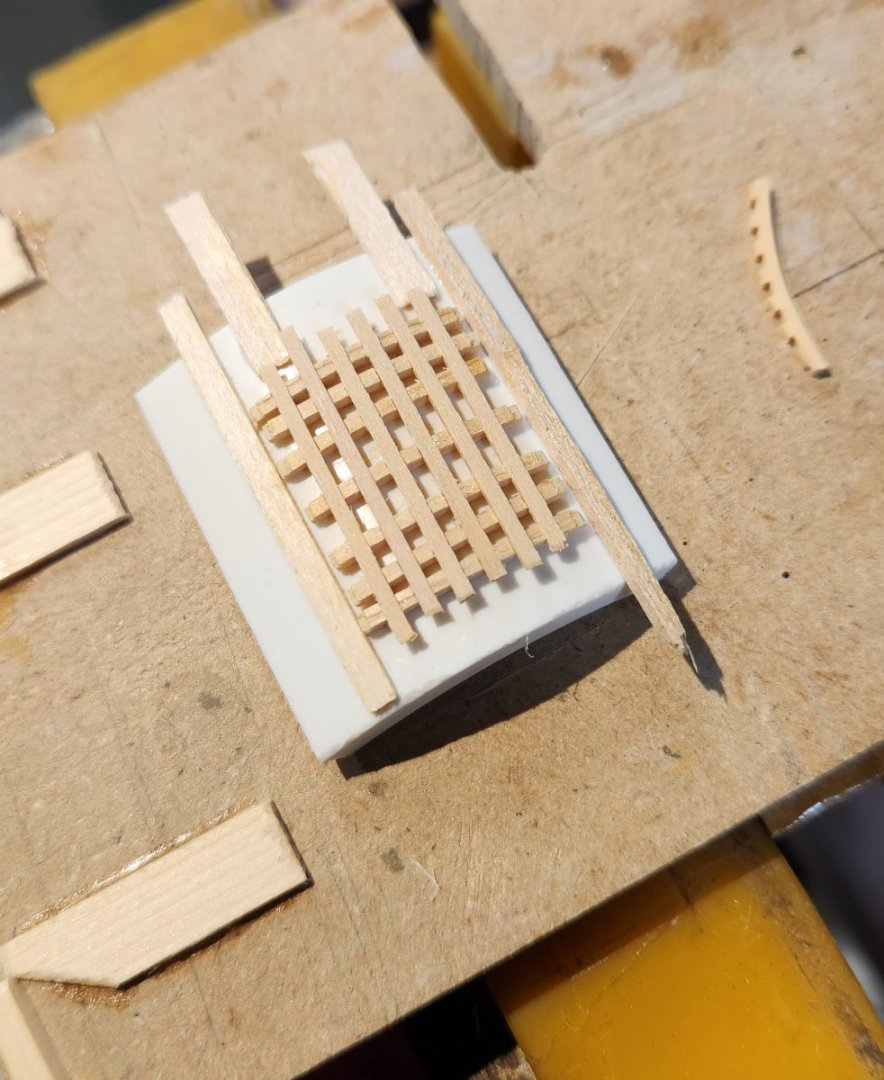

Another way overdue update... no really believable excuses. I continue to enjoy working on this Hannah (designed by Randy Biddle, below) and am putting time in on the scale details as much as I can, either researching them them or sensibly imagining them for the period. The next several shots show the deck furniture where boxwood is used for all the pieces needing fine detail and AYC used for thicker pieces. The binnacle is stick built with one center lamp between two compasses and the lamp and stack are soldered brass. The companionway is also stick built with doors opening inwards to allow closer placement of the binnacle. I want to allow the most open view of the main cabin as possible so the quarterdeck has a very minimal amount of decking... Just enough to support the binnacle, companionway and some rigging eyebolts. Barely visible faux treenails are made by mixing a drop of acrylic paint with thinned wood filler and dabbing that into scale sized holes. I found that too dark or too light filler made the treenails visible from too far away. The compasses are simply two thin brass rings with a barely visible rose. Here is an interesting patent from 1755 on Hathi Trust describing a windlass using a central steel spindle. #62 pg 22. I felt more comfortable making the octagon shape from individual parts than carving them from a "log". Similar to the stick built barrels I made for the whaleboat project, each plank is tapered and then the edges are chiseled to 45 degrees. The pawl shown is not the final version .. it has fewer detents. The steam vent is built following the TFFM where only the grating ledges are notched. A Proxxon MF70 was used to make the notches. The stack is .005" blackened copper. The ledges were bent and assembled over a cut out piece of PVC. The scuffed up look on the deck are small sanded pieces of 1/64" ply that I'm using to round up the deck in those areas before planking. This is how she sits today. The furniture, hatches, masts and bowsprit are just dry fit in place for now. The pump parts are made up following the TFFM and are yet to be assembled. I'm looking forward to finishing the remaining deck pieces then it's a toss up of installing the planking or railing. (???) Thank you for looking in on my Hannah project and please pass along any critiques or comments. They are always appreciated. Mike Randy Biddle's plans for this Hannah are available at NRG online > Journal >> Extended Journal Content > Articles Colonel John Glover’s Marblehead Schooner Hannah (1765 - 1775): Fishing for the Truth

-

Here I am in the basement where it is nice and cool, avoiding the high temperature and dew point outside. 'Just a short update. Today's shots show the Randy Biddle Hannah with the cabin completed sans a rocking chair which I though might make the area look too busy. I had a lot of fun making the cabin but it sure took a while to get it done. The quarterdeck beams are now fixed in place along with the connecting timbers. A rudder trunk rises from the inside counter to the aft-most beam and a sectioned shelf runs along the top of the storage wall... the idea coming from the Charles Morgan. The smaller 2 sections will hold lanterns. The margin planks are also finished with the trickiest being the aft most plank with the 3D curves involved. So, now on to the main parts of the deck area. Thank-you for looking in and keep cool! Mike

-

Hi Larry, I just now found your build site. The whaleboat is coming along nicely. Regarding all the frames: Probably you know this already but just double check that a frame is not in the way of some other piece for future placement. I remember I had to belatedly shift a few frames one way or the other to avoid the centerboard case or a thwart(??). One other planning issue: The temporary plank holding in the stem & stern pieces keep the width of the hull correct until the frames go in. Once that is out, the hull may or may not narrow. Mine narrowed about 1/8" which does not seem like much but the large line tub is a tight fit so I had to make it slightly undersized so it looked OK (not slanted). Keep up the good work. Mike

-

Thanks you all for the likes. I appreciate them. Lou, "time" ... yes, that's the question. Spring has sprung and our neighborhood is sorely lacking teenagers looking for yard work! Mike

-

Time for an (overdue) update. The cabin area needs to be finished in order to follow through with the quarterdeck margin planks. I decided to change out the original dark cherry floor boards and replace them with thinner, white-washed boxwood. For the aft ceiling planks, very thin basswood was used to get enough twist. The lower part of the aft storage wall incorporates a step/seat with drawers. The dark areas on each side are frames that protrude in into the cabin area. The wall has lots drawers for maps, etc. and a drop down table. The horizontal area between the inner counter boards and the storage will have a shelf for lamps and other odds & ends. A barn door look seemed appropriate for the cabin access to the hull spaces. 1/32" x 3/64" box was edge glued with CA and the trim boards were built up to allow for the diagonal brace. The bunk beds are made up of scrap basswood. I stuck with the barn door look for the cut-away privacy walls. There is a small storage shelf just forward of the inner counter planks. At this point, the quarterdeck beams are only temporarily placed. I decided not to add much more to the cabin. It's width is only 3" and I fear it would look overcrowded. OK, maybe a chair :). So, on to the ladder, quarterdeck beams and margin planks. Thank you for checking in and I appreciate any comments. Mike

-

Mike_In_RI reacted to a post in a topic:

Colonial Sloop Providence by KenW - 1:48 - Finished

Mike_In_RI reacted to a post in a topic:

Colonial Sloop Providence by KenW - 1:48 - Finished

-

Beautiful job Ken and something to be very proud of. You have gone the extra mile on all parts of the ship. I see you're showing the port sweeps in this shot. I like that... will you display it the same way? Well done, Mike

- 238 replies

-

- providence

- sloop

-

(and 1 more)

Tagged with:

-

The sternboard and fashion pieces are finished. As usual, the forum is great for finding different approaches to a build. In this case, I emulated a neat way to make the jambs/sill pieces stay square while placing them in the ship structure. I have to apologize in that I lost the link to that site. The port casing is built around a wooden shaft to the correct size, rough sanded to the angle of the stanchions then aligned and inserted into the frame. It protrudes enough to allow for the thickness of three layers of sternboard. The first layer of planking is 1/32" boxwood and will be seen from the quarterdeck. The port planks below the lower curved molding have 3 layers. The middle layer of the sternboard is sanded flush with the jambs. The top layer cases around the port. The plans call for three curved moldings. The jambs .... much smaller than a dime...look off center but are OK with a straight on view. It's nice to see the ships lines come together with the fashion pieces, ports and molding. She's shaping up nicely... another complement to Randy. Thank you again for the likes and comments. Mike

-

The anchor looks great... I like the contrast of the iron vs the stock. Well done.

- 238 replies

-

- providence

- sloop

-

(and 1 more)

Tagged with:

-

The sails furled with the sweeps out is a very attractive, unique look. Those are great shots. Super job on your home made line as well. Mike

- 238 replies

-

- providence

- sloop

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.