mahjong25

Members-

Posts

29 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by mahjong25

-

I think I am finally done! Finished up the base and ordered the acrylic case. Everything sanded and covered with Danish Oil. What a fun project!

- 50 replies

-

- model shipways

- 18th century longboat

-

(and 1 more)

Tagged with:

-

I finally got around to working on displaying my Longboat. I had prepared for the base and drilled 2 holes in the keel during assembly. I cut a piece of walnut and drilled matching holes in them. I used a brass rod to connect the two objects, then slid a hollow brass tube for support. Turned out pretty nice. Also got a piece of curly maple for the acrylic display base. Still need to route some channels for the case. The end is near!

- 50 replies

-

- model shipways

- 18th century longboat

-

(and 1 more)

Tagged with:

-

I was finally able to finish up the rope coils on my model and got all those glued on. I didn't like the fuzziness of some of my rope so I used some wax to clean that up and it looks a lot better. The anchor is also ready to go. I just have to finish a couple oars then i'll be completely done! It has been quite a journey. Still need to figure out the display case situation though. :[

- 50 replies

-

- model shipways

- 18th century longboat

-

(and 1 more)

Tagged with:

-

Continued to rig my ship with some addition. I am really excited being on the last page of the instructions. But I ran out of rope so I'm waiting for the new order to come in to finish up. Now just need to look for a good display case!

- 50 replies

-

- model shipways

- 18th century longboat

-

(and 1 more)

Tagged with:

-

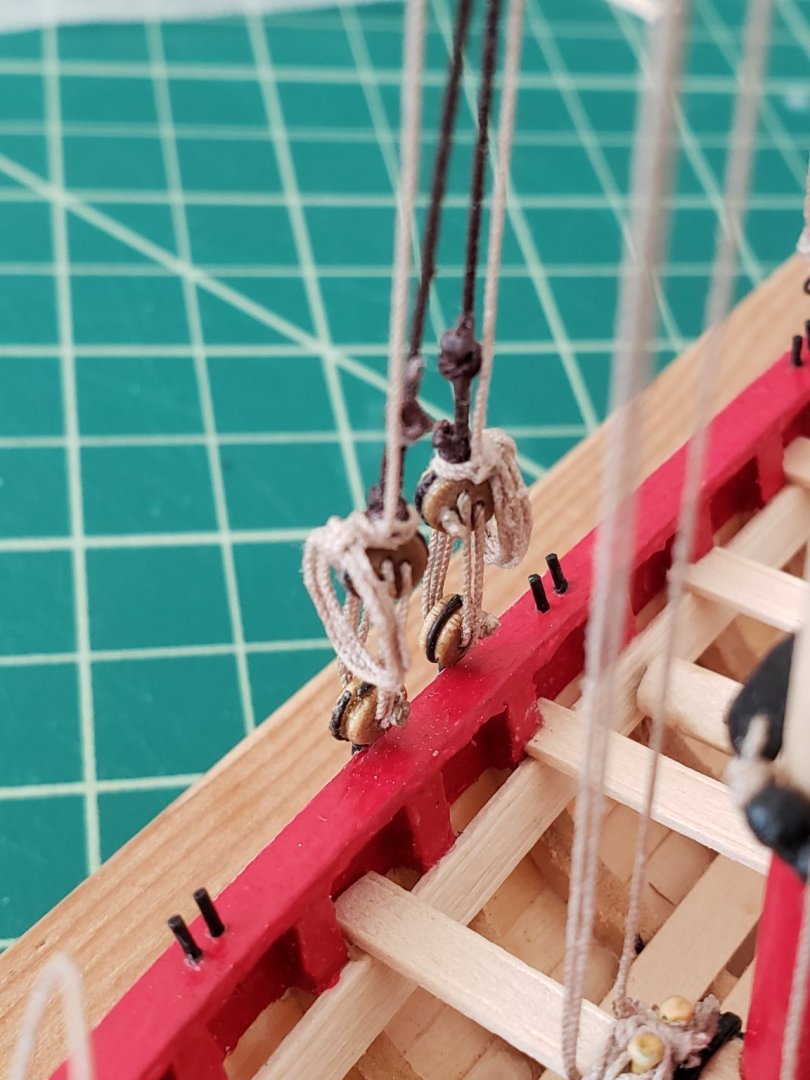

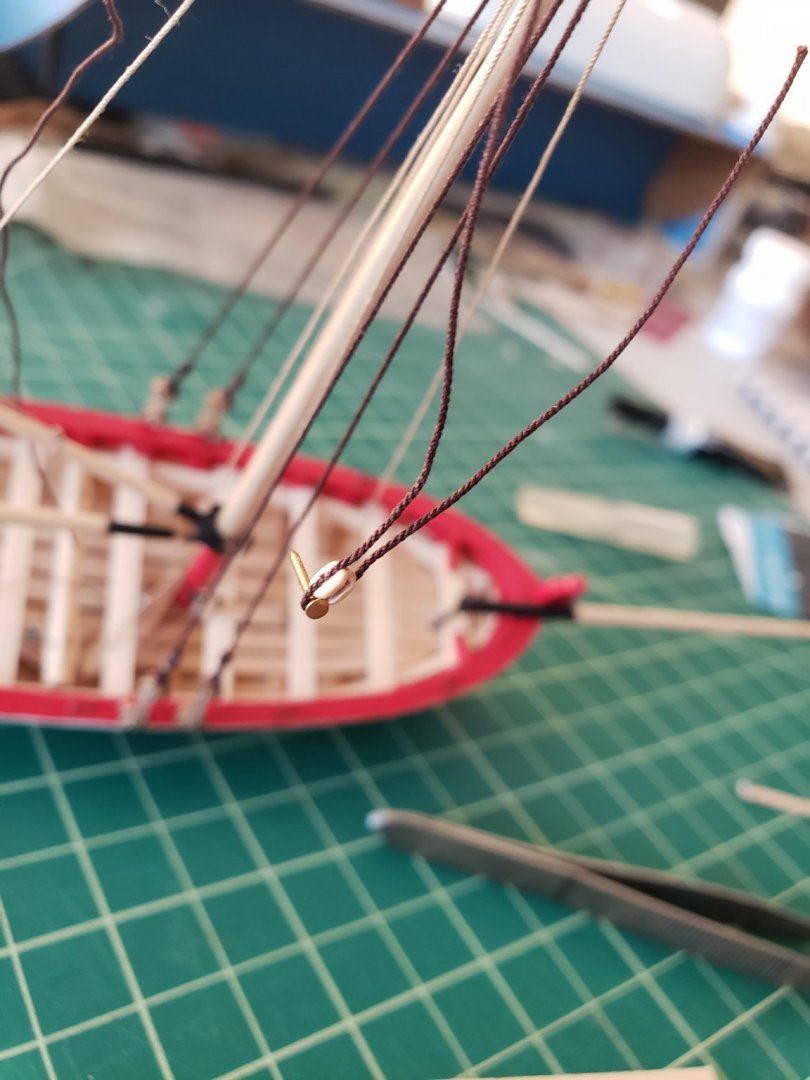

I was able to do some more rigging today, this is definitely my favorite part. I really love working with the Syren ropes and blocks, they make everything so much easier and much more ascetically pleasing.

- 50 replies

-

- model shipways

- 18th century longboat

-

(and 1 more)

Tagged with:

-

- 50 replies

-

- model shipways

- 18th century longboat

-

(and 1 more)

Tagged with:

-

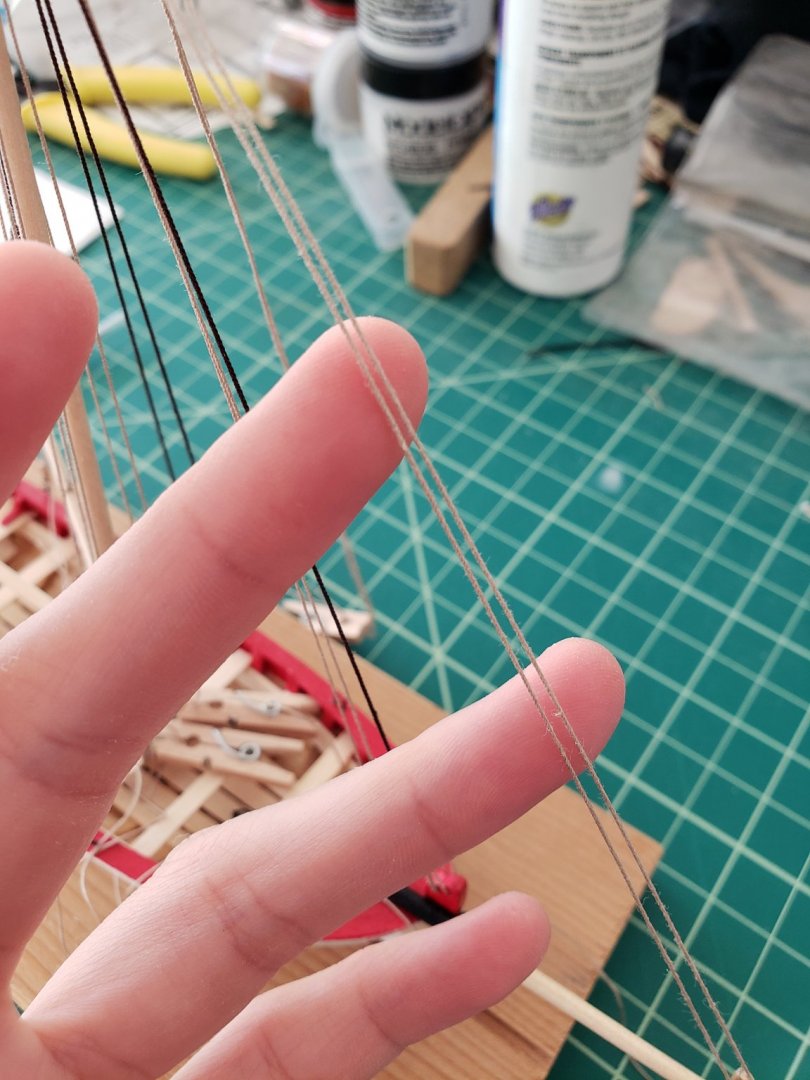

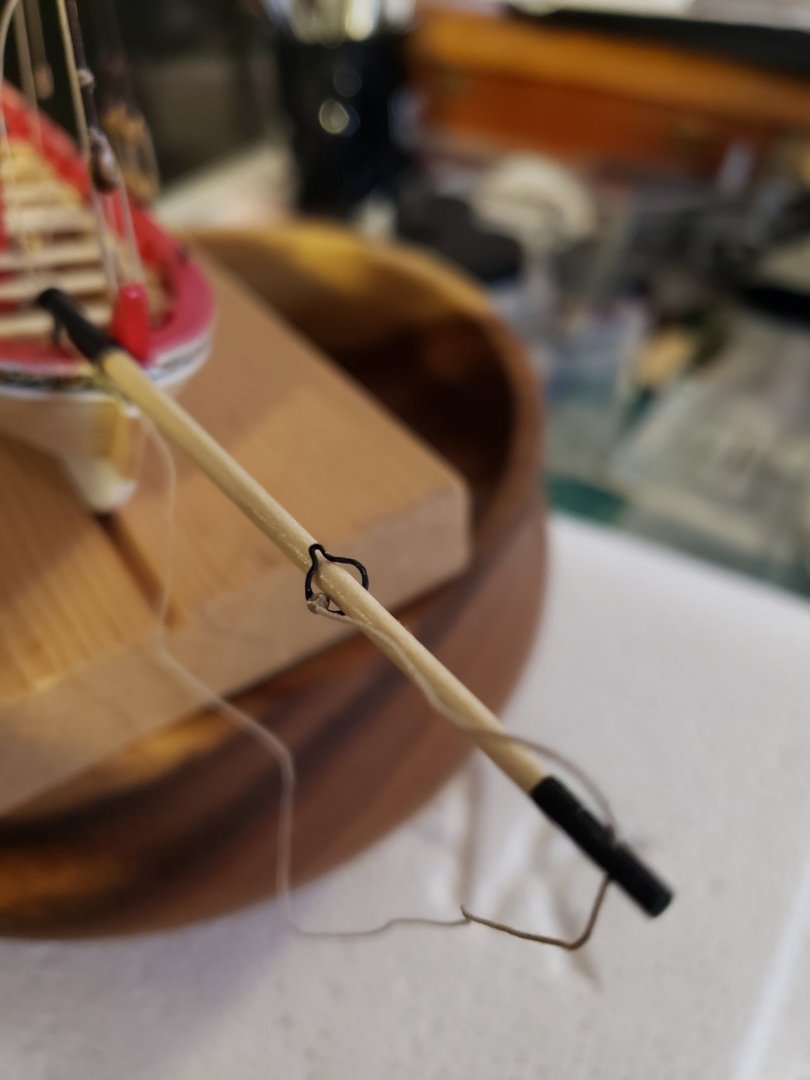

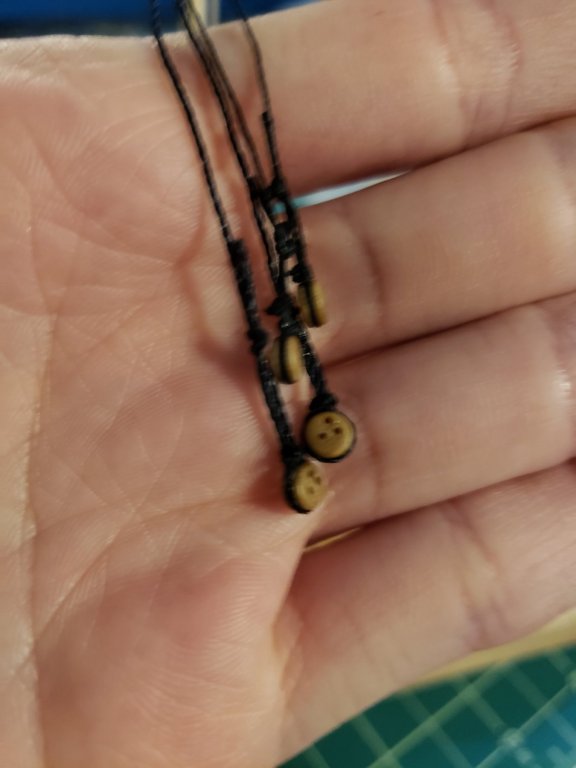

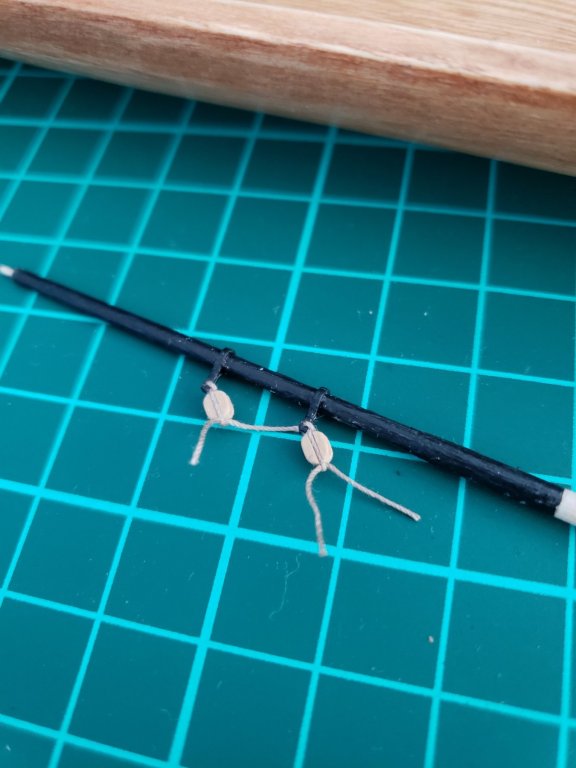

Went with the claw method and started rigging the deadeyes. But there wasn't enough black rope provided in the kit so I raided my Charles Morgan kit. But now looking back, even though both kits are from Model Shipway and say they are the same diameter, they look completely different so I will be purchasing more Syren rope and re-rig this section. I also started on the backstay and made a jig to seize the blocks for it. Does anyone have suggestions regarding display cases? I am nearing the end and should probably start thinking about where to get one. Also any thoughts on how to get closer cuts on the ropes? My seizing looks like a hot mess since I don't own any cutting equipment that can get a close cut on the knots. I am just using an Xacto knife right now.

- 50 replies

-

- model shipways

- 18th century longboat

-

(and 1 more)

Tagged with:

-

@Tector Wow thank you so much! That is such high praise! I really love the details required in model ship building.

- 50 replies

-

- model shipways

- 18th century longboat

-

(and 1 more)

Tagged with:

-

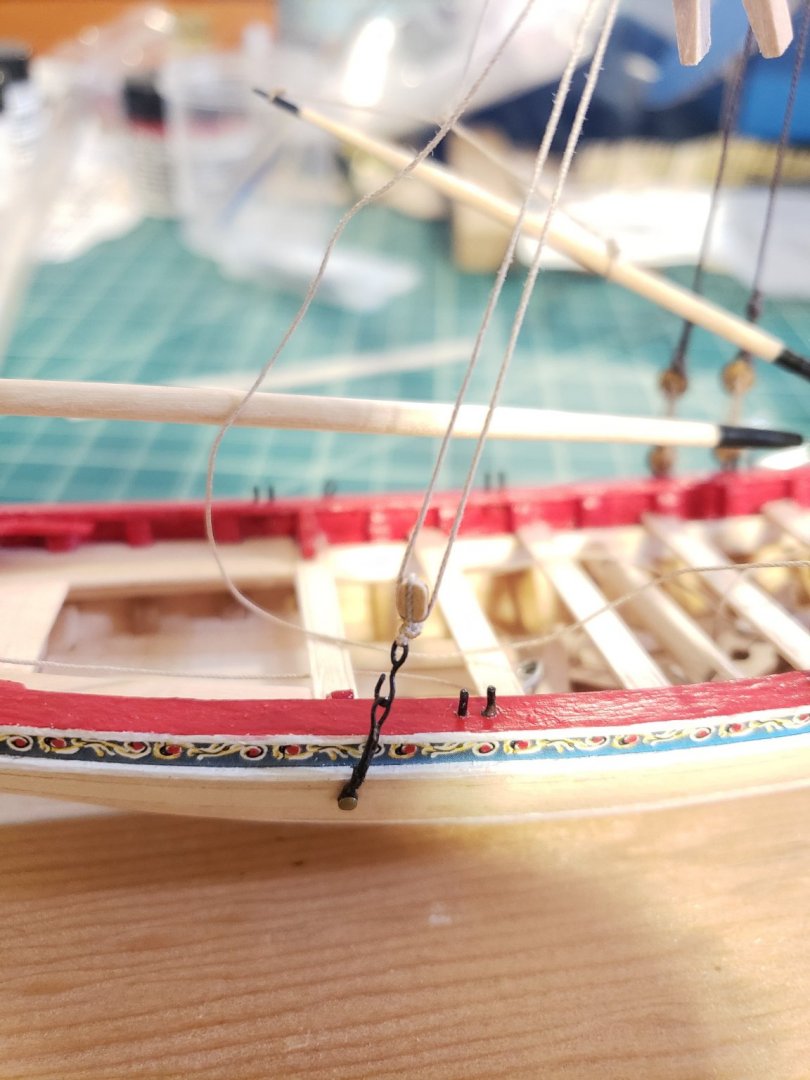

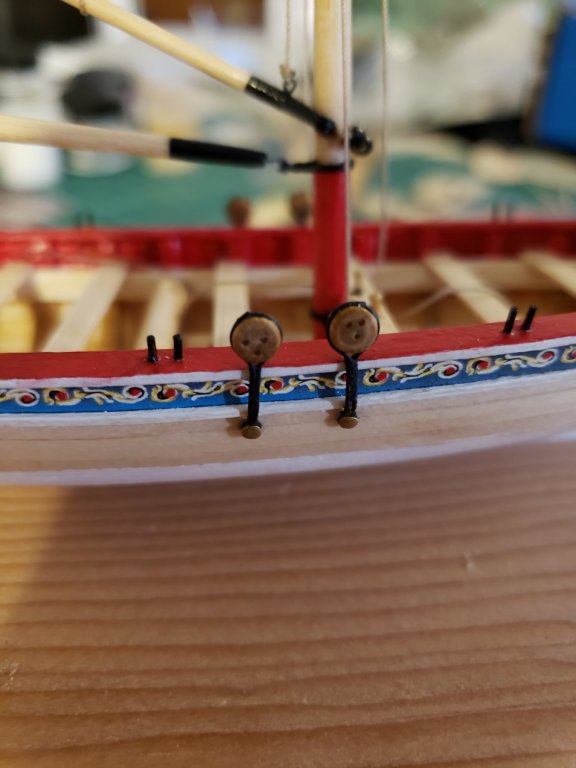

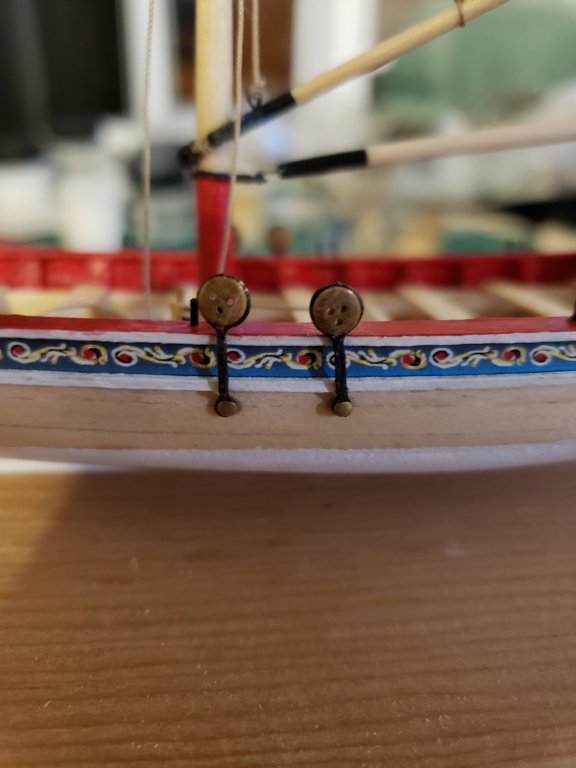

Took a long break from ship building and started doing a lot of ceramics. But I really want to finish my ship since the end is near! I attached the chainplates and will be rigging them soon.

- 50 replies

-

- model shipways

- 18th century longboat

-

(and 1 more)

Tagged with:

-

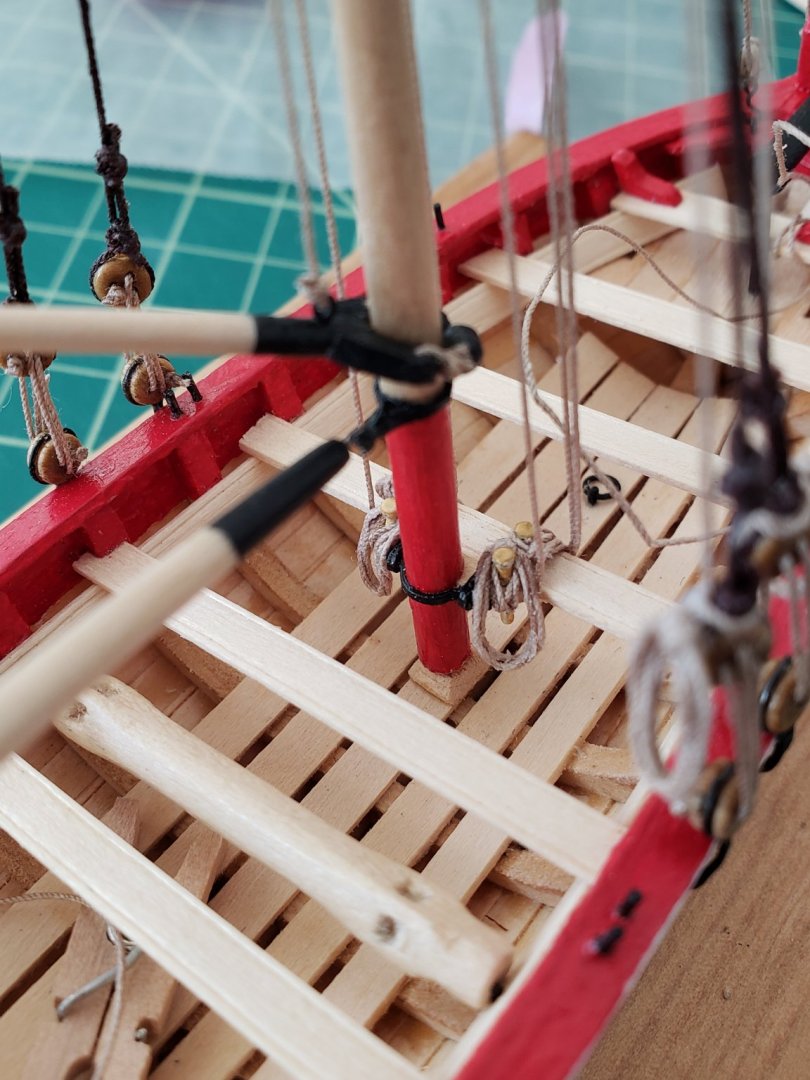

The seizing took a little to get used to, especially since the rope is so tiny. But it got easier over time so the rigging is coming along. I haven't glued anything down yet and I will do that once all the running rigging is completed.

- 50 replies

-

- model shipways

- 18th century longboat

-

(and 1 more)

Tagged with:

-

So I'm nearing the end, and I still haven't used any nails. Am I missing something?

- 50 replies

-

- model shipways

- 18th century longboat

-

(and 1 more)

Tagged with:

-

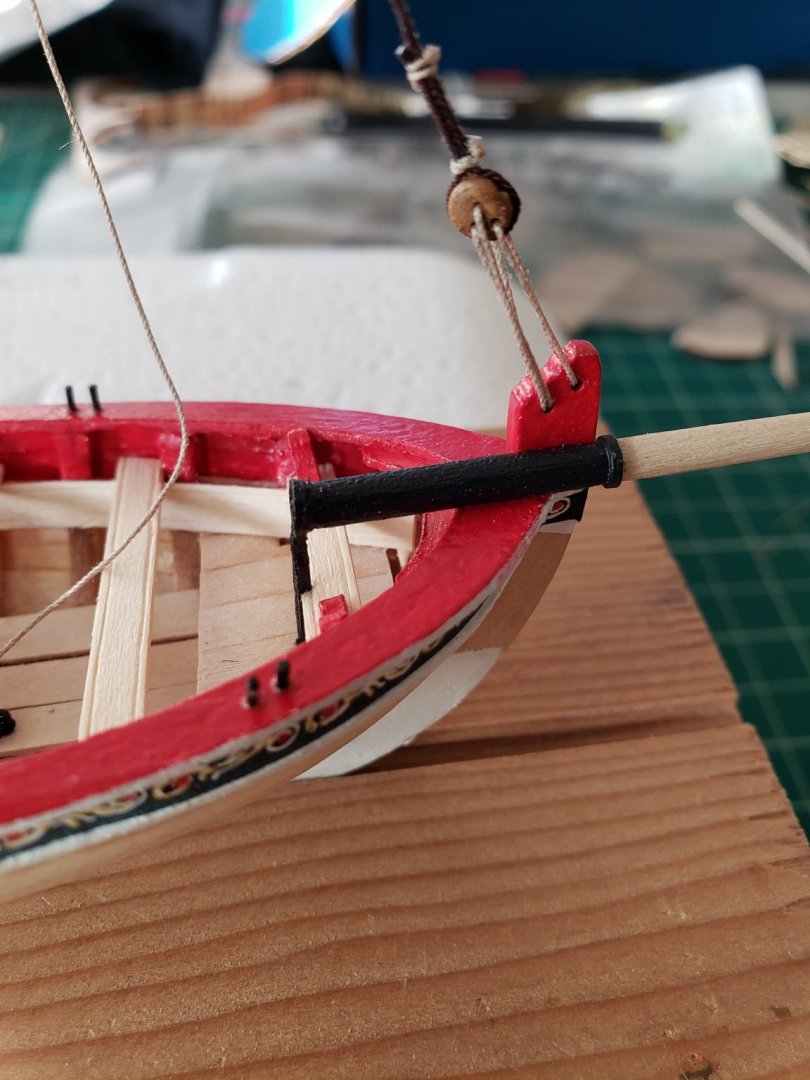

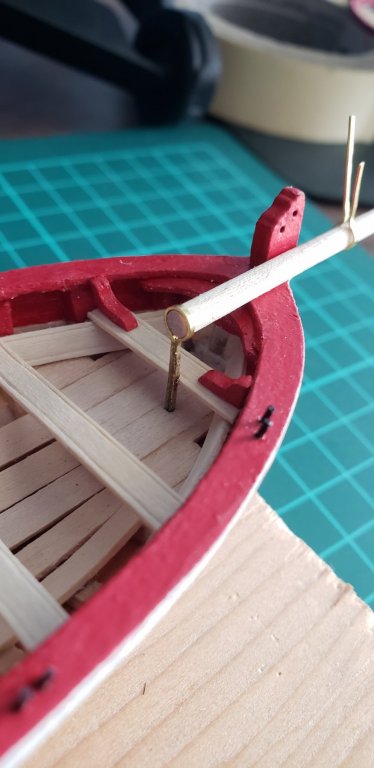

Completed the boom and the gaff. Excited to be nearing the end of construction and moving into rigging!

- 50 replies

-

- model shipways

- 18th century longboat

-

(and 1 more)

Tagged with:

-

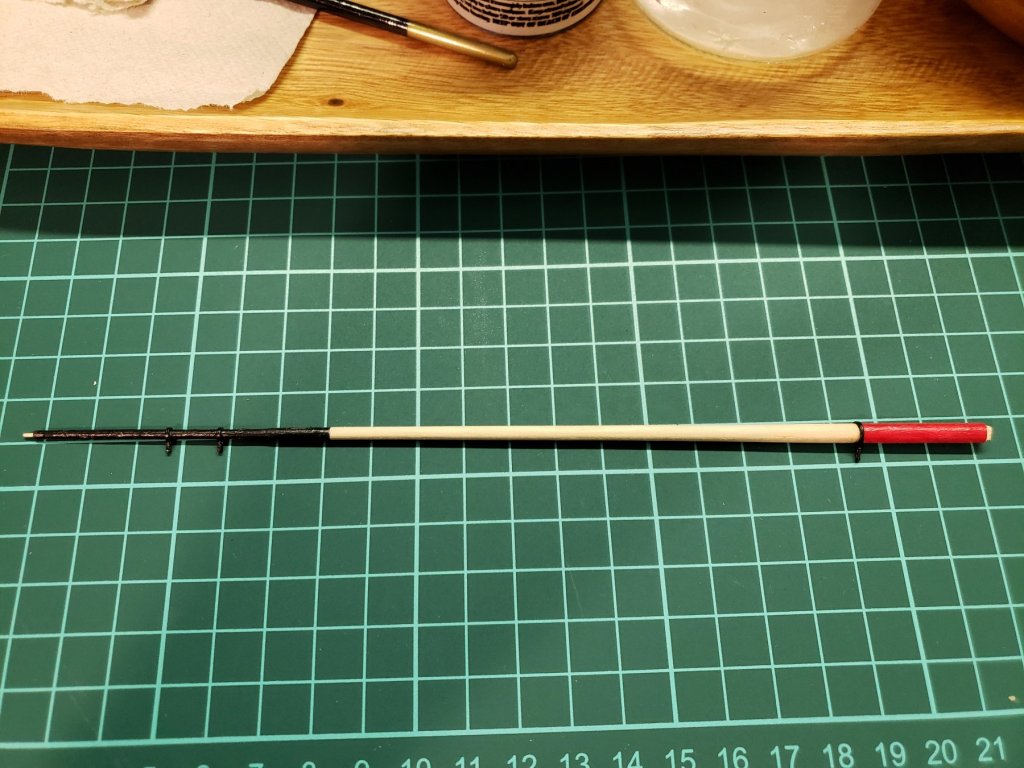

I continued by seizing the blocks. I purchased some new rigging line and blocks for this sections because the ones that came with the kit were not great quality. I am really happy with the way it looks on the mast. Then I shaped, glued and painted the bowsprit on. I am really happy with the way it looks and I will finalize and glue the mast one so I can continue.

- 50 replies

-

- model shipways

- 18th century longboat

-

(and 1 more)

Tagged with:

-

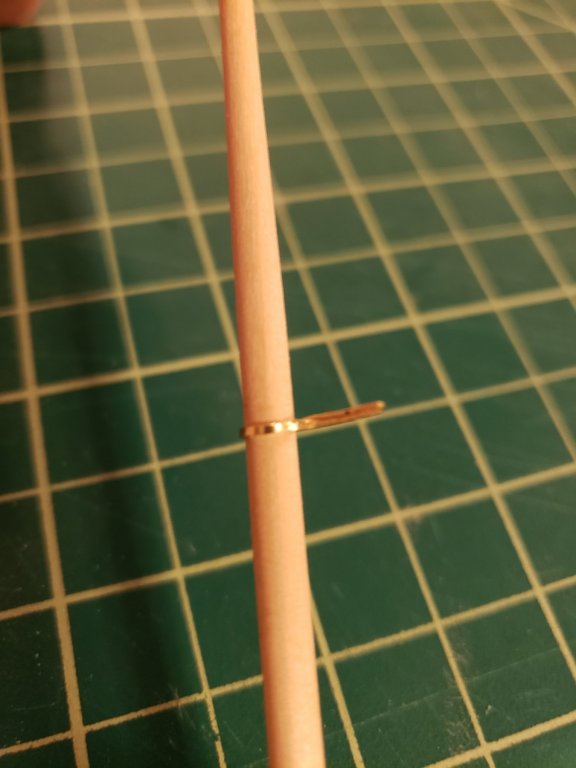

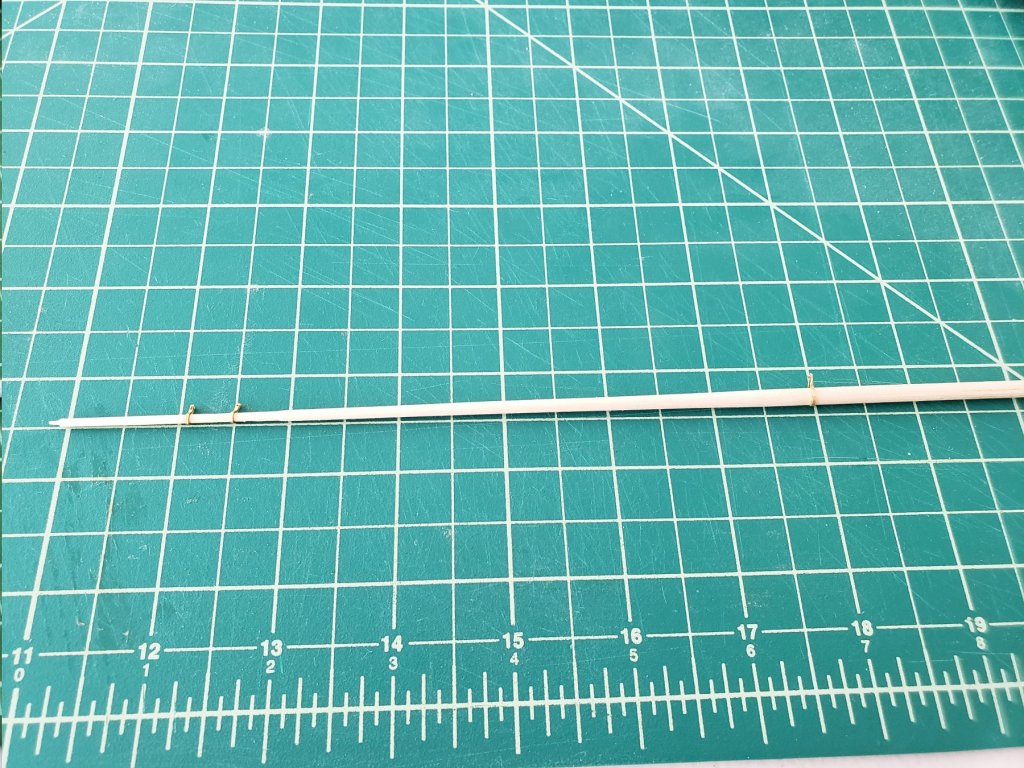

I took a hiatus after being frustrated with my power drill/lathe set up to taper the mast. I just avoided the project and came back to it recently. I ended up tapering the mast by hand which was a lot easier. Making the bands and drilling them broke 2 of my smallest bits but I was able to complete it. I , glued it onto the mast, made the ball truck and mast step, and then painted it. Now I will read up on how to seize blocks and continue on.

- 50 replies

-

- model shipways

- 18th century longboat

-

(and 1 more)

Tagged with:

-

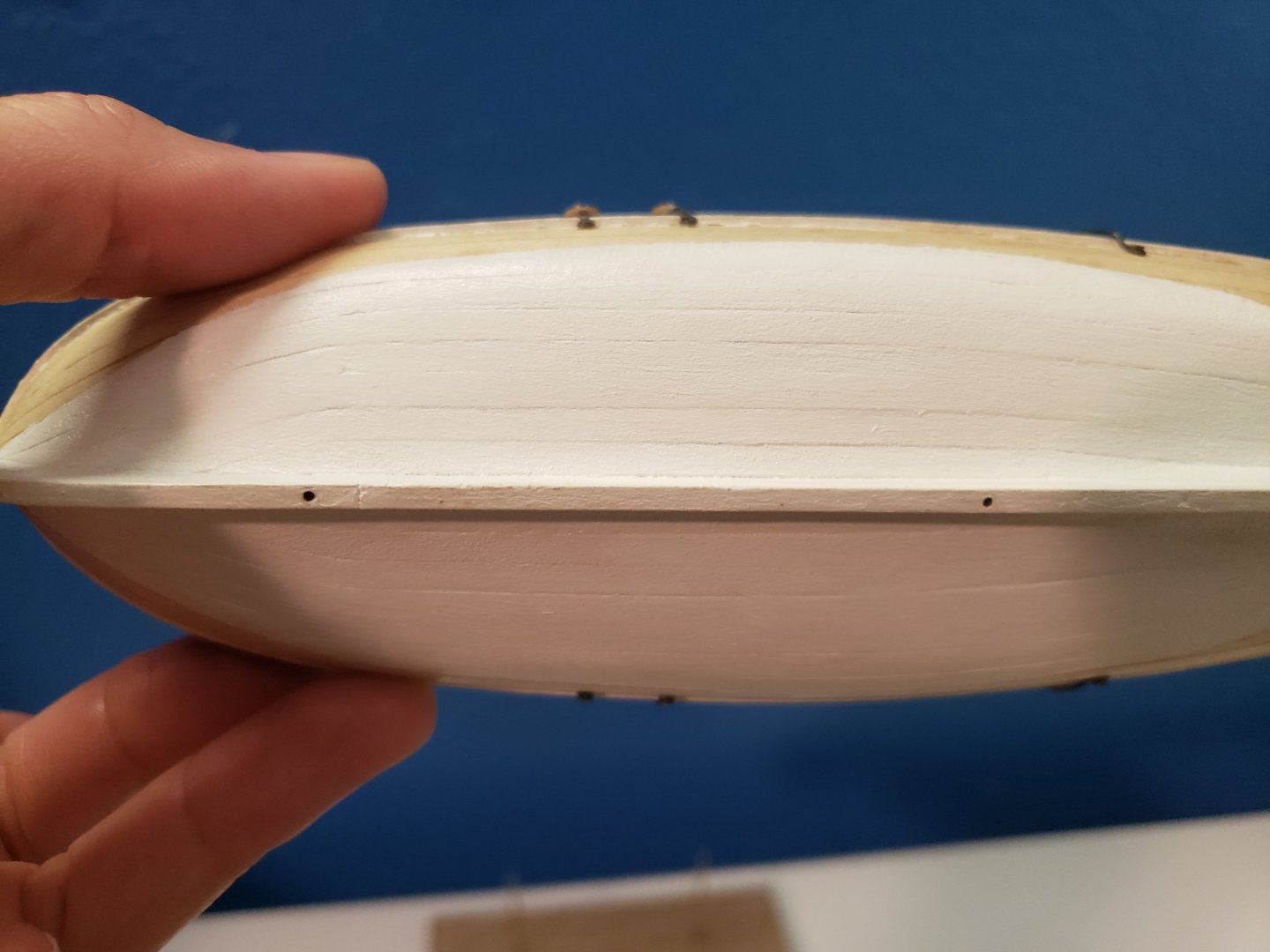

I attempted a waterline jig then taped it up to paint. I still need to figure out how to taper the mast with the make shift lathe/drill since I don't really own power tools. It might be a while before I make more progress.

- 50 replies

-

- model shipways

- 18th century longboat

-

(and 1 more)

Tagged with:

-

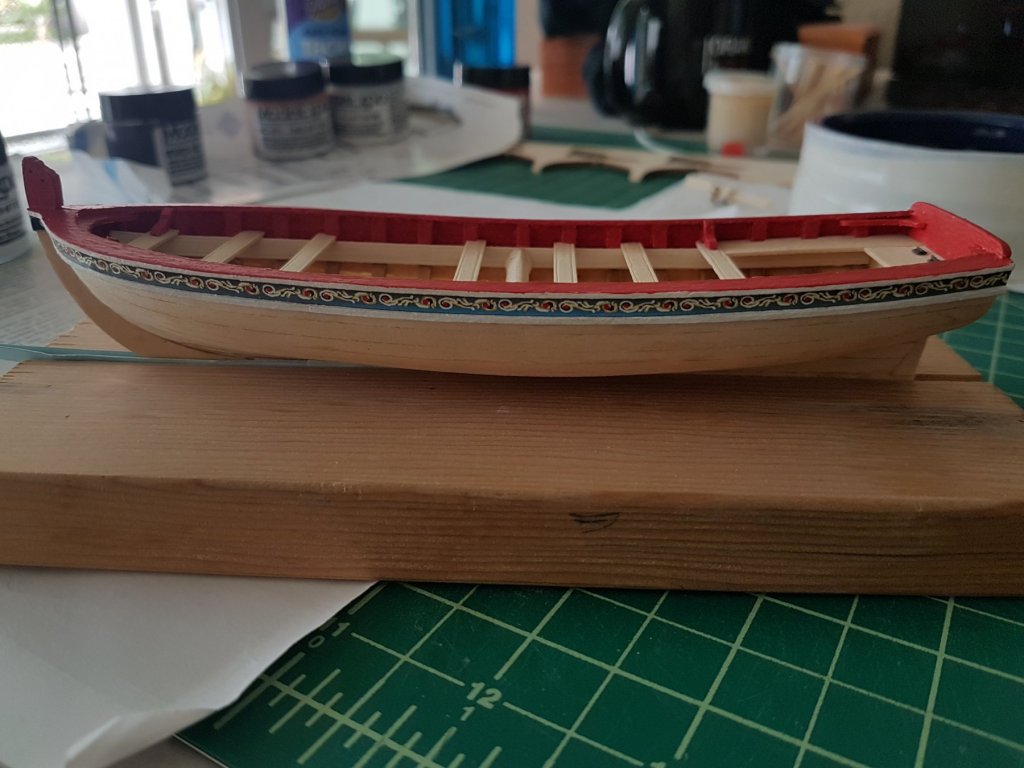

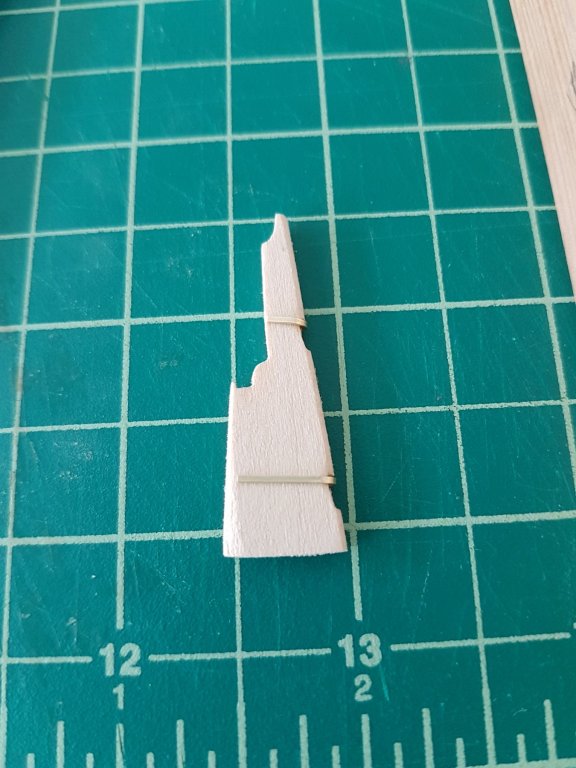

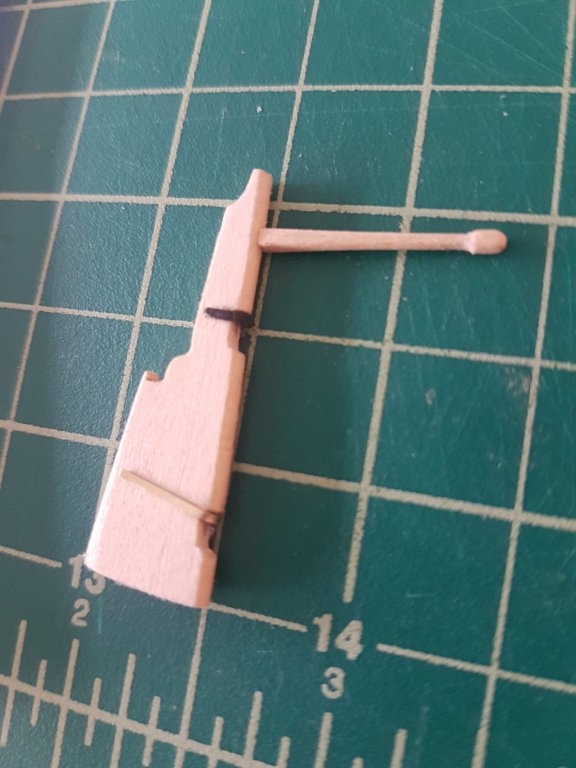

I painted and glued on the knees and it is time to work on the rudder. I cleaned it up then realized I finally have to place the frieze, especially on the transom. I printed out the PDF from Chuck's revision and gave it a couple thin coats of hair spray for protection. Then I cut it out and use some adhesive spray to place it on the boat. I taped a cutout of the transom frieze on so I could paint around it. Then I completed the metalwork on the rudder with gudgeon and pintle. I also shaped the handle. Before I can continue, I have to figure out the best way to draw the waterline on the boat.

- 50 replies

-

- model shipways

- 18th century longboat

-

(and 1 more)

Tagged with:

-

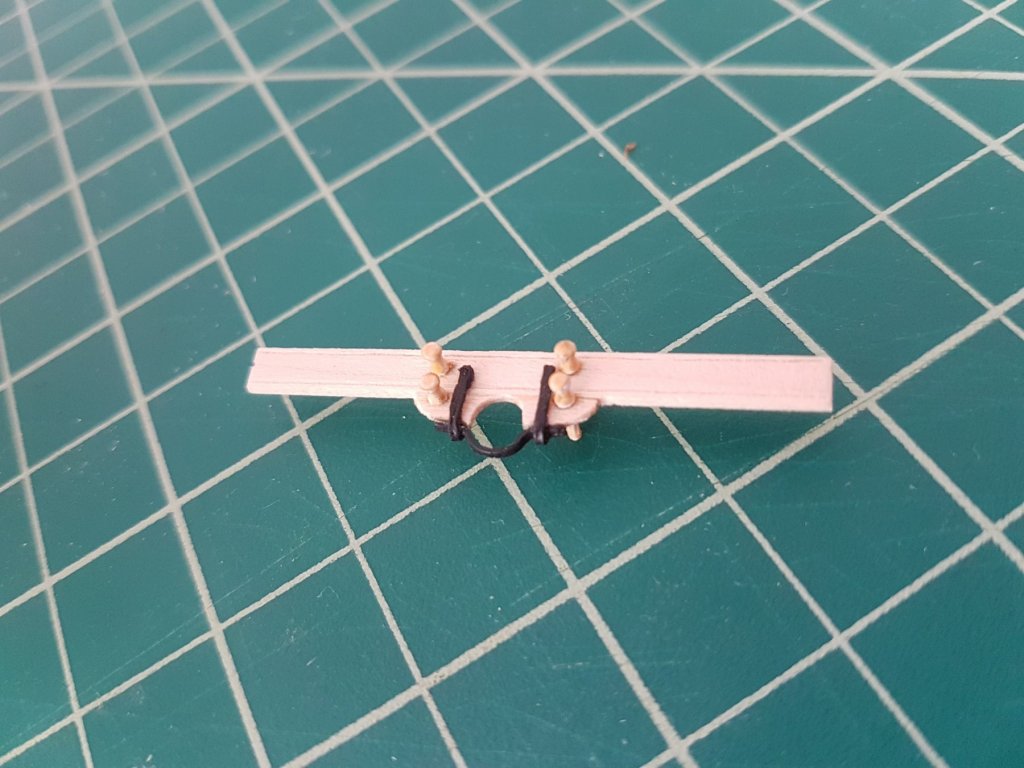

I fixed the caprail and glued on the knee. I also put in the mast bracket and installed the belay pins. Next I had to problem solve the dilemma of the windlass. I couldn't figure out a way to make perfect square holes, so I just drilled the the approximate size and cut the corners out with an Xacto knife. Had some trouble installing it but was finally able to do it.

- 50 replies

-

- model shipways

- 18th century longboat

-

(and 1 more)

Tagged with:

-

I completed the locker hinges and moved onto the knees. That is when I realized that my cap rail is not the correct shape for the knee so I had to do some surgery to repair it.

- 50 replies

-

- model shipways

- 18th century longboat

-

(and 1 more)

Tagged with:

-

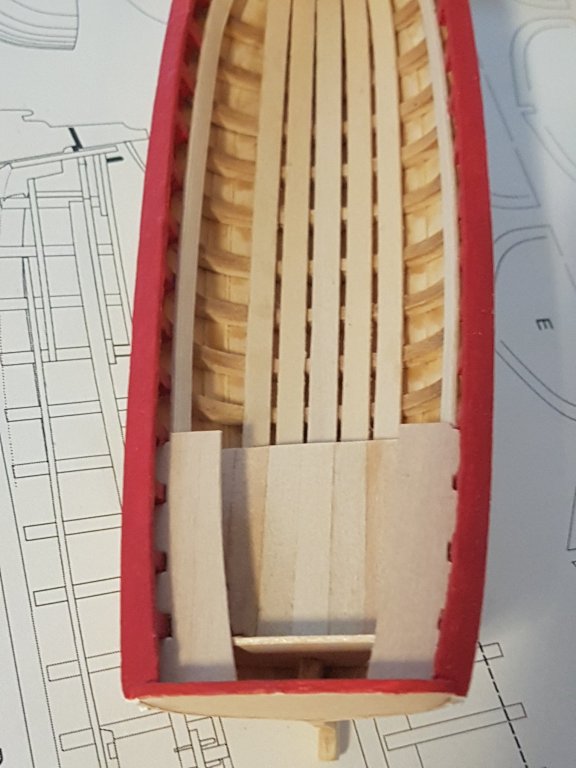

Redoing the thwarts didn't take too long and I moved onto working on the seats and the locker. It took some extra time to make sure it fit the boat appropriately with no extra gaps and it was worth it. Eden

- 50 replies

-

- model shipways

- 18th century longboat

-

(and 1 more)

Tagged with:

-

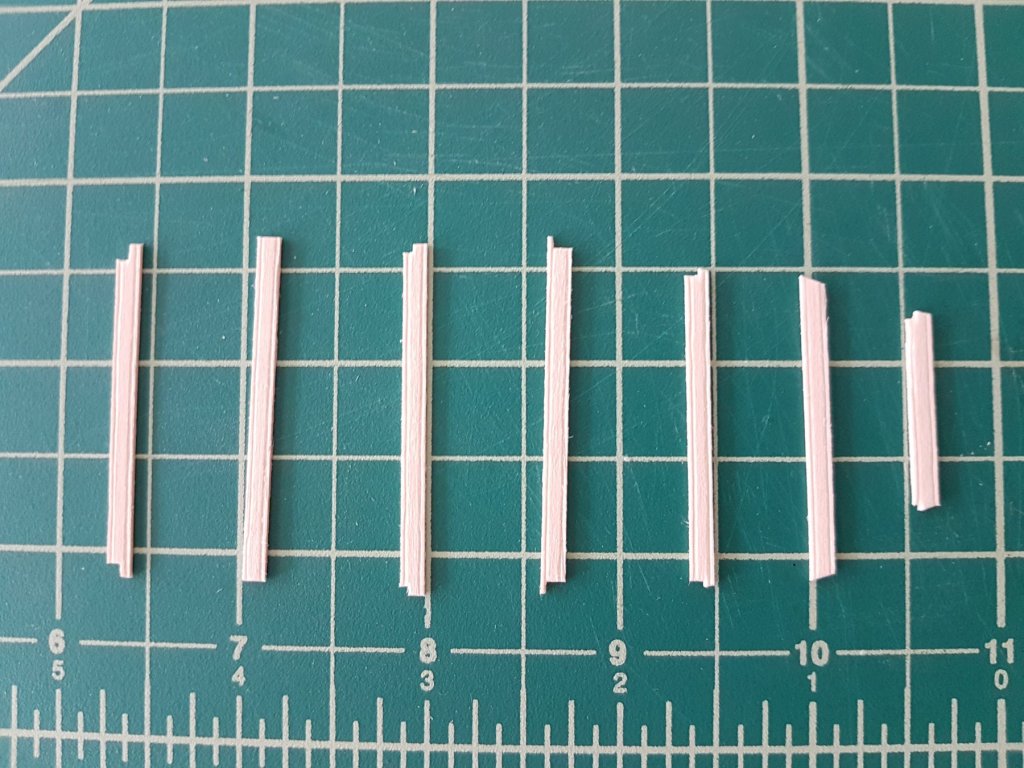

Thanks for such a quick response Steve! I felt it was too thin as well. It is good that I did not glue it on yet. I will work on redoing them. Thanks again! Eden

- 50 replies

-

- model shipways

- 18th century longboat

-

(and 1 more)

Tagged with:

-

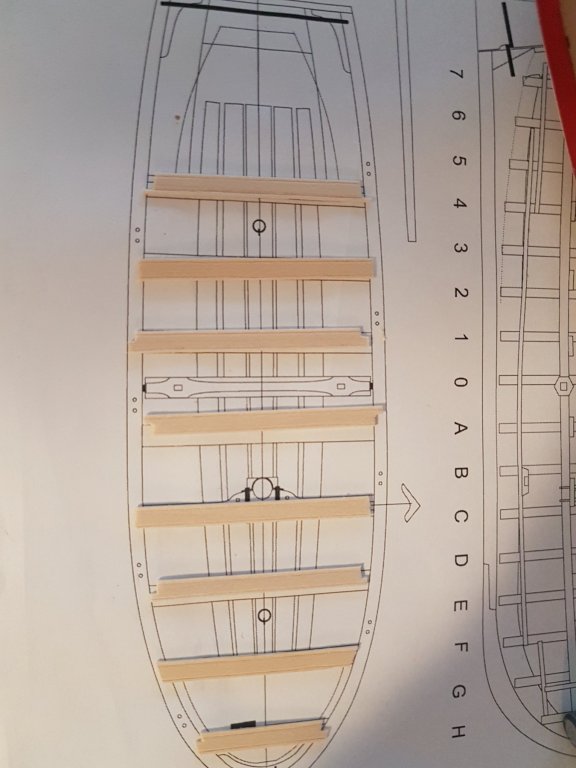

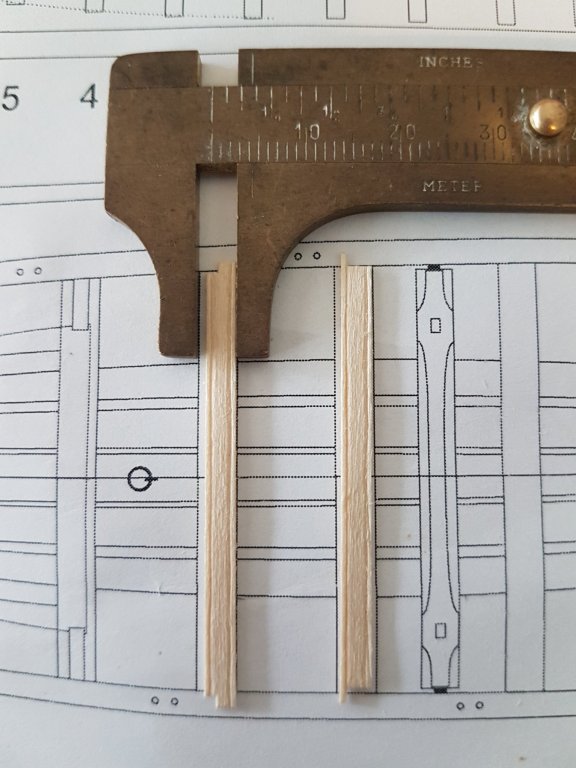

I've glued on the risers and finished working on the thwarts. Did anyone else have an issue with the plans not scaled appropriately? I am trying to work on my thwart with mast, but the plans are scaled just a bit too big so looks like i'll have to eyeball a lot of measurements.

- 50 replies

-

- model shipways

- 18th century longboat

-

(and 1 more)

Tagged with:

-

I have been away on several trips, but I am back with an update on my progress. I have put on my caprails and the molding as well. I've prepared the friezes and will wait to install them later to avoid damaging them. I've also put Polyurethane on my boat then painted. Then I continued onto the floorboards, and the 2 platforms. I also bend the risers but have yet to install them.

- 50 replies

-

- model shipways

- 18th century longboat

-

(and 1 more)

Tagged with:

-

Thank you Derek. I will try and fill in the gaps between the planks. I am not satisfied with the smoothness of the hull and will work on that next. 👍

- 50 replies

-

- model shipways

- 18th century longboat

-

(and 1 more)

Tagged with:

-

I need some help. I've been reading up on multiple ship building logs to make sure I avoid mistakes. I see that the friezes provided in the kit is not the right size and there is a PDF somewhere of the corrected one? Could someone provide me with the link to it?

- 50 replies

-

- model shipways

- 18th century longboat

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.