brad918

Members-

Posts

12 -

Joined

-

Last visited

-

gillianh reacted to a post in a topic:

Flying Cloud by brad918 - 1/96 - Mamoli

gillianh reacted to a post in a topic:

Flying Cloud by brad918 - 1/96 - Mamoli

-

Meriadoc Brandybuck reacted to a post in a topic:

Flying Cloud by brad918 - 1/96 - Mamoli

Meriadoc Brandybuck reacted to a post in a topic:

Flying Cloud by brad918 - 1/96 - Mamoli

-

brad918 reacted to a post in a topic:

Display Cases

brad918 reacted to a post in a topic:

Display Cases

-

brad918 reacted to a post in a topic:

Types of rigging line

brad918 reacted to a post in a topic:

Types of rigging line

-

brad918 reacted to a post in a topic:

Seine Dory by MrBlueJacket - FINISHED - BlueJacket Shipcrafters - 1/4" = 1'

brad918 reacted to a post in a topic:

Seine Dory by MrBlueJacket - FINISHED - BlueJacket Shipcrafters - 1/4" = 1'

-

brad918 reacted to a post in a topic:

Seine Dory by MrBlueJacket - FINISHED - BlueJacket Shipcrafters - 1/4" = 1'

brad918 reacted to a post in a topic:

Seine Dory by MrBlueJacket - FINISHED - BlueJacket Shipcrafters - 1/4" = 1'

-

brad918 reacted to a post in a topic:

Schooner Mary Day by jdbondy - 1:64 scale (3/16" to 1 foot)

brad918 reacted to a post in a topic:

Schooner Mary Day by jdbondy - 1:64 scale (3/16" to 1 foot)

-

Robby The Brobot reacted to a post in a topic:

Flying Cloud by brad918 - 1/96 - Mamoli

Robby The Brobot reacted to a post in a topic:

Flying Cloud by brad918 - 1/96 - Mamoli

-

GrandpaPhil reacted to a post in a topic:

Flying Cloud by brad918 - 1/96 - Mamoli

GrandpaPhil reacted to a post in a topic:

Flying Cloud by brad918 - 1/96 - Mamoli

-

billocrates reacted to a post in a topic:

Young America by EdT - FINISHED - extreme clipper 1853

billocrates reacted to a post in a topic:

Young America by EdT - FINISHED - extreme clipper 1853

-

billocrates reacted to a post in a topic:

Young America by EdT - FINISHED - extreme clipper 1853

billocrates reacted to a post in a topic:

Young America by EdT - FINISHED - extreme clipper 1853

-

Jeronimo reacted to a post in a topic:

Young America by EdT - FINISHED - extreme clipper 1853

Jeronimo reacted to a post in a topic:

Young America by EdT - FINISHED - extreme clipper 1853

-

WackoWolf reacted to a post in a topic:

Flying Cloud by brad918 - 1/96 - Mamoli

WackoWolf reacted to a post in a topic:

Flying Cloud by brad918 - 1/96 - Mamoli

-

dhardy reacted to a post in a topic:

Young America by EdT - FINISHED - extreme clipper 1853

dhardy reacted to a post in a topic:

Young America by EdT - FINISHED - extreme clipper 1853

-

dhardy reacted to a post in a topic:

Young America by EdT - FINISHED - extreme clipper 1853

dhardy reacted to a post in a topic:

Young America by EdT - FINISHED - extreme clipper 1853

-

Jim Byrnes Model Machines

brad918 replied to Mahuna's topic in Modeling tools and Workshop Equipment

Also to add to the benefits of the OSS; in most cases the spindle is normal to the table therfore giving you a perpendicular "cut" on your workpiece which is harder to acheive with a dremel tool, at least in my opinion. If you add a tilt option to the table you can also achieve fairly consistent angles. The "up and down" motion of the spindle also adds a second degree of cutting direction, where the dremel just rotates about its own axis, the OSS not only "cuts" about its axis, it also "cuts" the length of its stroke, i think the biggest advantage to this added motion is the sanding drum will not get as hot and burn the workpiece as if you (or at least i) see with the dremel. Obviously both machines have there place, personally i couldnt live without the dremel, but it sure is nice to clean up frames with an OSS and have the edges square and sharp. Brad -

Jim Byrnes Model Machines

brad918 replied to Mahuna's topic in Modeling tools and Workshop Equipment

See Jim, looks like you already sold at least 10 O.S.S's and you haven't even built one yet, now thats a good reputation to have! Brad -

Ed, thank you for you comments. The plans i have of Champion from Loyalhanna are drawn from E. Hannon. I will seek the Crothers plans for Challenge. I too agree the floor thickness is 17 1/2" on Challenge, i didnt see the floor size for YA however. As for the notch in the floor, i mainly used this to make sure my frames would have somthing to positively align them. Crothers did mention that the floor was sometimes cut into to a depth that lowered the seating of the floor to the bearding line, but as might be expected different yards adopted different procedures. I believe this is on page 148 of Crothers. I do plan on installing the limber notches as you suggested, and i do have the first frame showing how it would have been bolted together. I am actually learning most of these scratch building techniques by referencing your Naiad book (great book by the way, can we expect one on Young America? ) Brad

- 3,596 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

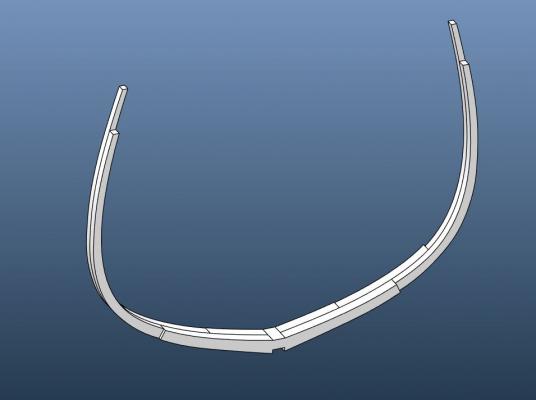

Ed, you are correct that the plans i have are indeed Chapelle's. I will check out the plans from Loyalhanna, i know the last ones i received from them on the Champion of the Seas were fairly poor quality, but maybe just a bad copy. I have attached a rendering of a frame i derived from Crothers book. I am not sure if this was what Webb would have used on his ships or just a generic example of some clipper ships. I wondered if you too were stepping the thickness of the futtock's and top timbers on the square frames as you approach the rail ? I assume this was done to reduce weight in the upper sections of the frame possible to prevent hogging? Hopefully i am not too far off base as i have already completed 4 frames using this theory Brad

- 3,596 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Jim Byrnes Model Machines

brad918 replied to Mahuna's topic in Modeling tools and Workshop Equipment

two votes for O.S.S. Just bought the Grizzly benchtop O.S.S. but wouldn't miss it... Brad -

Ed, this is extremely great to see a fully framed clipper ship being built and with your skills is sure to be another masterpiece. I too am in the early construction phase of building the clipper ship Challenge 1851 by Webb. I have decieded to model a fully framed cross section at 1:48 to capture the framework of these beautiful ships. I obtained drafts from the Smithsonian at 1:48 scale and do agree with you that these large clippers would need a seperate building to be constructed in at that scale. I think your choice of 1:72 scale will be perfect to capture the detail. You will find Crothers book invaluable during your build. I will pass along any info i have or come across on Young America. I will be following your build with great excitement. Great Choice Ed! Brad

- 3,596 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Randy, nice post, i also like to hunt for bowl blanks. My favorite would be cherry burls and spalted beech or maple. A few years back while deer hunting i came across a large cherry blow down which had a 150# burl attached, which i harvested and cut into smaller pieces and still have drying. For me, harvesting your own wood is actually an addiction. Probably like those of us who buy many kits and store on a shelf, just waiting for the chance to open that box and start on a clean slate. Nothing beats cutting into a log and the anticipation of what might be inside and all the possibilites that it can be used for.

-

Pete, i have made a couple of log beds out of aspen (Quaking aspen grows like weeds up here in PA) and i was sort of dissapointed with it, it is very easy to machine, but it is softer than basswood, not as soft as balsa, and you really can't get a good finish when sanding it. Being so soft it does not take a stain or finish well unless you use a sealer. It does have a uniform color however. Brad

-

Pete, sounds like you will have enough black walnut to build a full scale ship! Did you coat the log ends with a sealer? i heard that B.W. should be coated farily soon after cutting. i had some cut a while back and didnt coat the ends, i lost a few inches on each end due to checking but there was still a lot of usable material. You can't beat the color of air dried black walnut though, the big guys usually steam it to even out the color and to me kind of makes the color bland. They say for every inch of thickness you need a year to air dry down to a stable moisture content. I actually have had good sucess drying small quantities of wood in my attic, i let it air dry outside under cover for a couple months, then move into the attic in the summer months, just dont overload your rafters Buck, i would think if the tree hasn't been "dead" very long it should be ok, and if its off the ground your chances improve that it hasnt started to rot yet, you may notice holes in the cherry as bugs often like the dead trees. Brad

-

Hi All, Glad to be back! good to see everyone is reposting their logs. I wanted to repost some pics of my progress to date, its been a slow build but its been a lot of fun. This kit is by Mamoli i have added the ebony planking and the copper plating. Currently im working on the the standing rigging. I've learned so much from everyone here and so glad we have this outlet to share are projects. Brad

- 9 replies

-

- flying cloud

- mamoli

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.