Mr Pleasant

Members-

Posts

43 -

Joined

-

Last visited

-

druxey reacted to a post in a topic:

HMS Mercury 1779 by Mr Pleasant - 1:64 - based on Shipyard paper model

druxey reacted to a post in a topic:

HMS Mercury 1779 by Mr Pleasant - 1:64 - based on Shipyard paper model

-

druxey reacted to a post in a topic:

HMS Mercury 1779 by Mr Pleasant - 1:64 - based on Shipyard paper model

druxey reacted to a post in a topic:

HMS Mercury 1779 by Mr Pleasant - 1:64 - based on Shipyard paper model

-

mtaylor reacted to a post in a topic:

HMS Mercury 1779 by Mr Pleasant - 1:64 - based on Shipyard paper model

mtaylor reacted to a post in a topic:

HMS Mercury 1779 by Mr Pleasant - 1:64 - based on Shipyard paper model

-

GrandpaPhil reacted to a post in a topic:

HMS Mercury 1779 by Mr Pleasant - 1:64 - based on Shipyard paper model

GrandpaPhil reacted to a post in a topic:

HMS Mercury 1779 by Mr Pleasant - 1:64 - based on Shipyard paper model

-

Baker reacted to a post in a topic:

HMS Mercury 1779 by Mr Pleasant - 1:64 - based on Shipyard paper model

Baker reacted to a post in a topic:

HMS Mercury 1779 by Mr Pleasant - 1:64 - based on Shipyard paper model

-

CiscoH reacted to a post in a topic:

HMS Mercury 1779 by Mr Pleasant - 1:64 - based on Shipyard paper model

CiscoH reacted to a post in a topic:

HMS Mercury 1779 by Mr Pleasant - 1:64 - based on Shipyard paper model

-

yvesvidal reacted to a post in a topic:

HMS Mercury 1779 by Mr Pleasant - 1:64 - based on Shipyard paper model

yvesvidal reacted to a post in a topic:

HMS Mercury 1779 by Mr Pleasant - 1:64 - based on Shipyard paper model

-

VTHokiEE reacted to a post in a topic:

HMS Mercury 1779 by Mr Pleasant - 1:64 - based on Shipyard paper model

VTHokiEE reacted to a post in a topic:

HMS Mercury 1779 by Mr Pleasant - 1:64 - based on Shipyard paper model

-

ccoyle reacted to a post in a topic:

HMS Mercury 1779 by Mr Pleasant - 1:64 - based on Shipyard paper model

ccoyle reacted to a post in a topic:

HMS Mercury 1779 by Mr Pleasant - 1:64 - based on Shipyard paper model

-

jpalmer1970 reacted to a post in a topic:

HMS Mercury 1779 by Mr Pleasant - 1:64 - based on Shipyard paper model

jpalmer1970 reacted to a post in a topic:

HMS Mercury 1779 by Mr Pleasant - 1:64 - based on Shipyard paper model

-

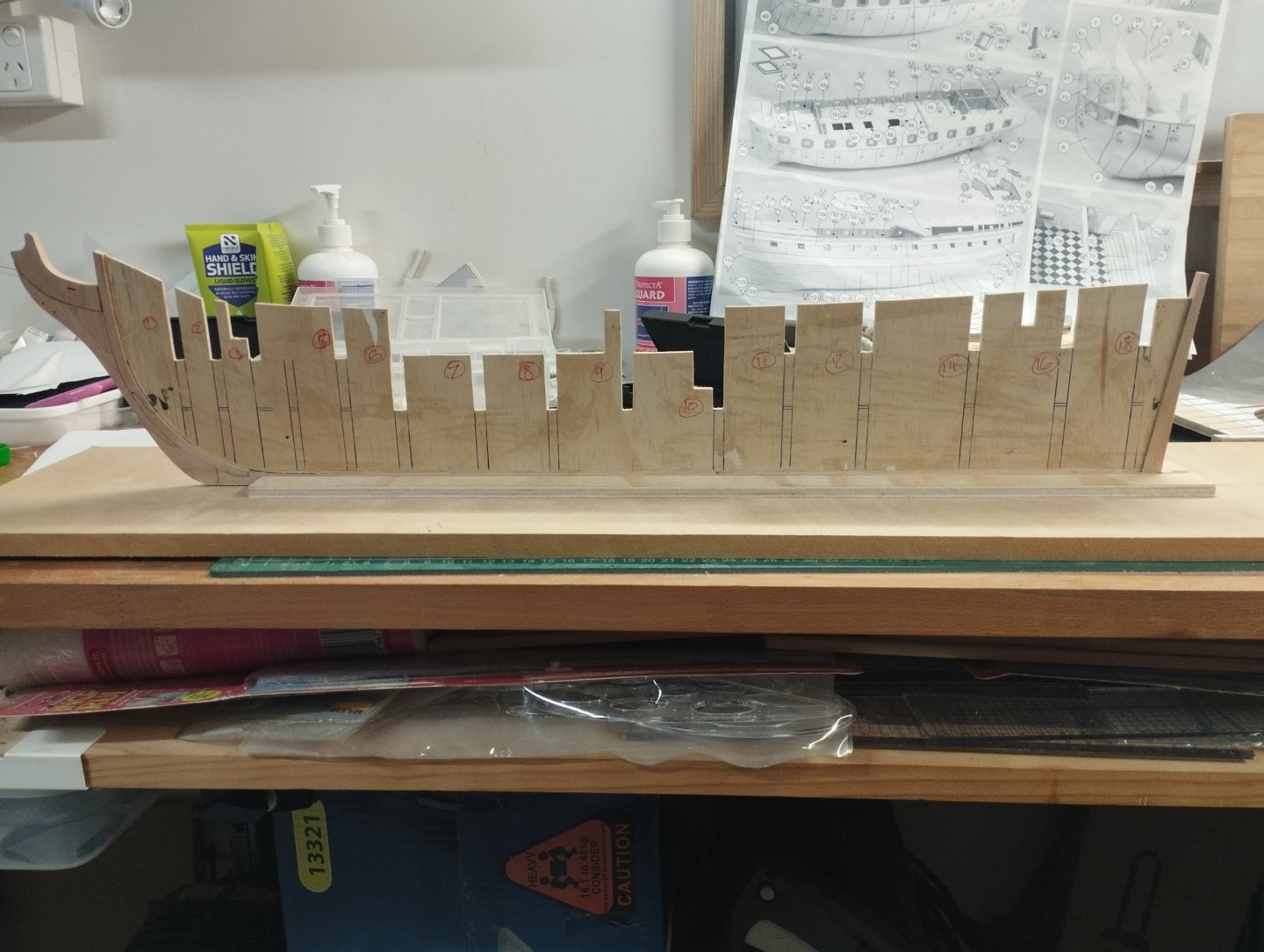

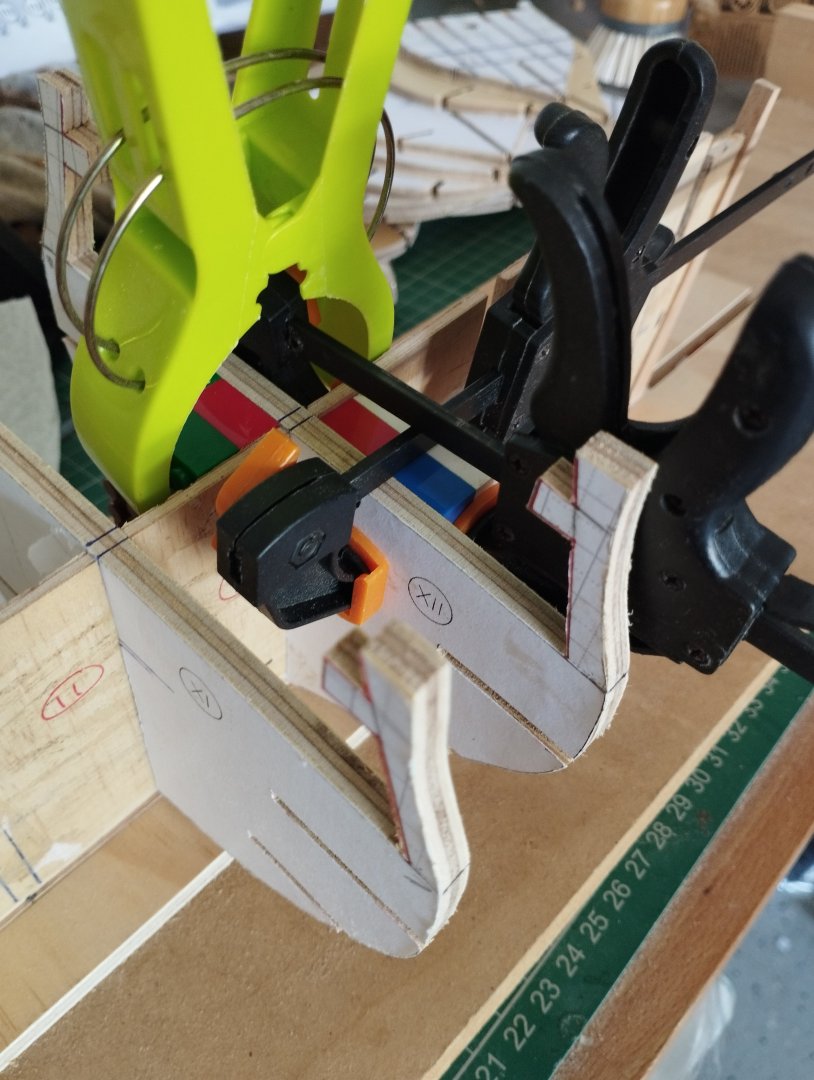

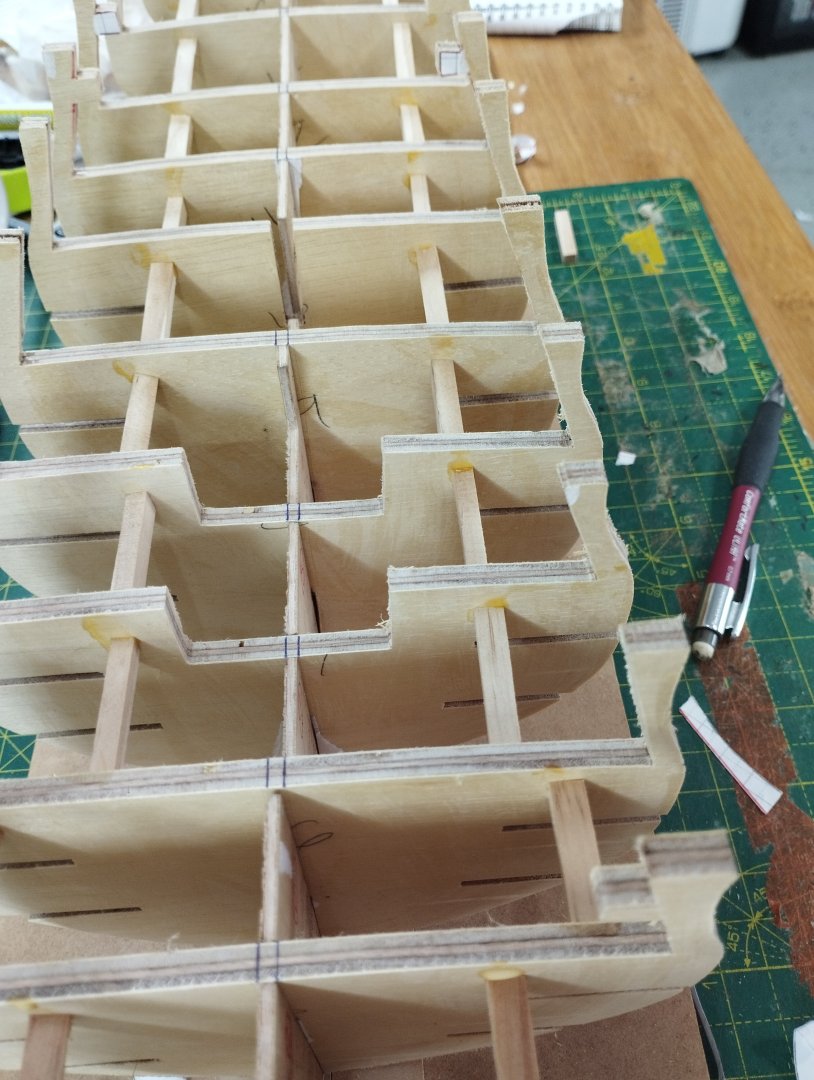

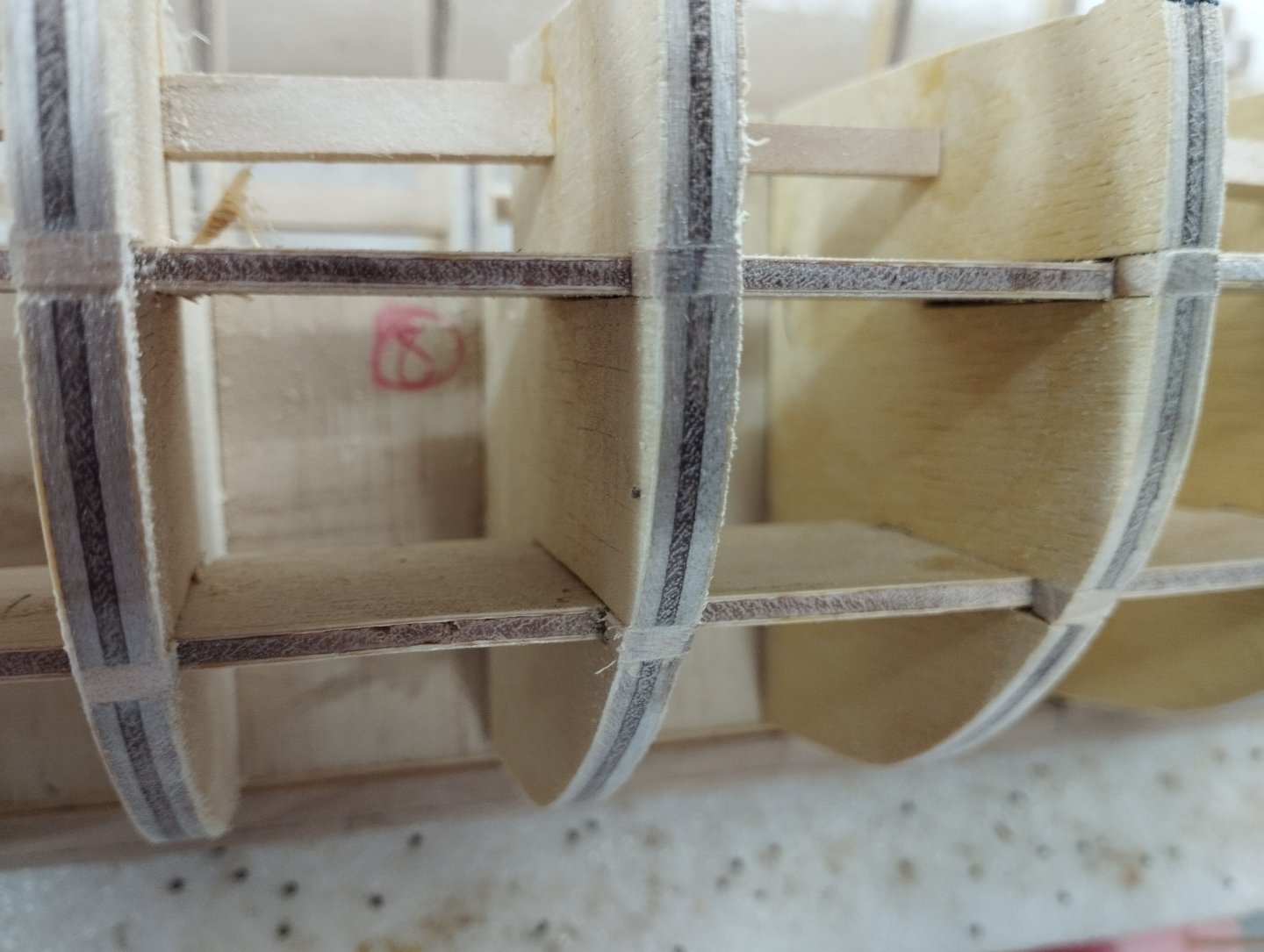

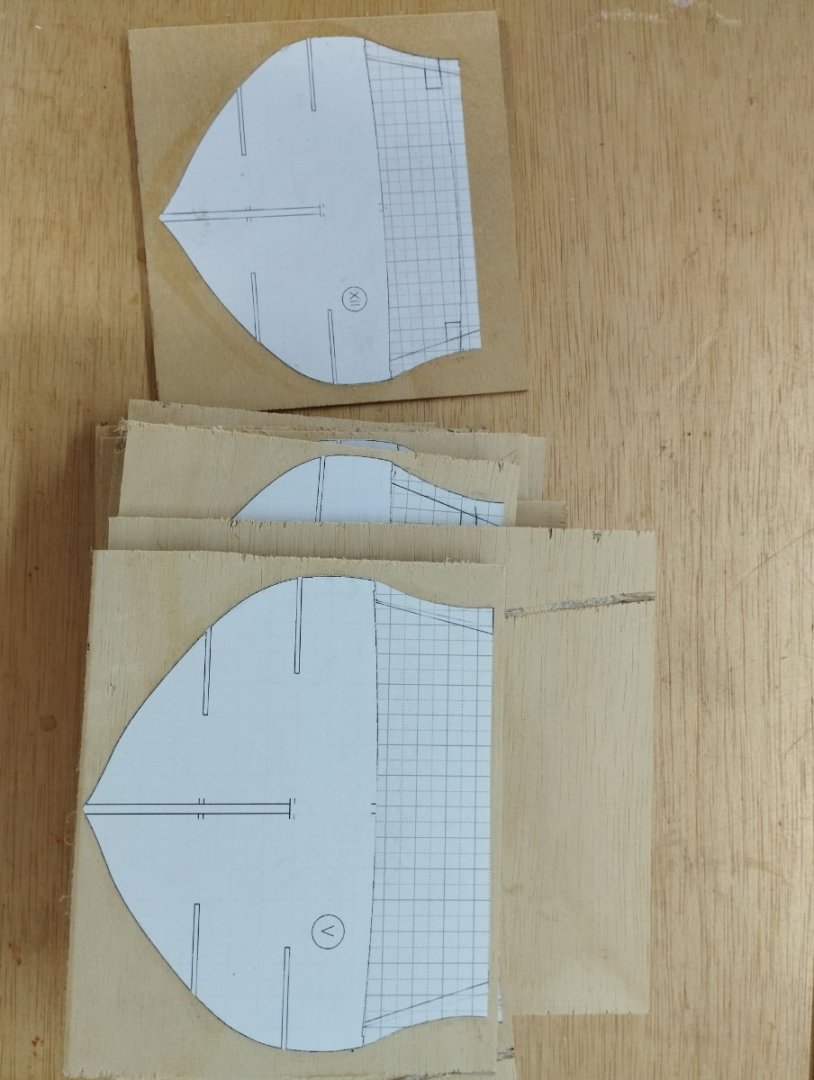

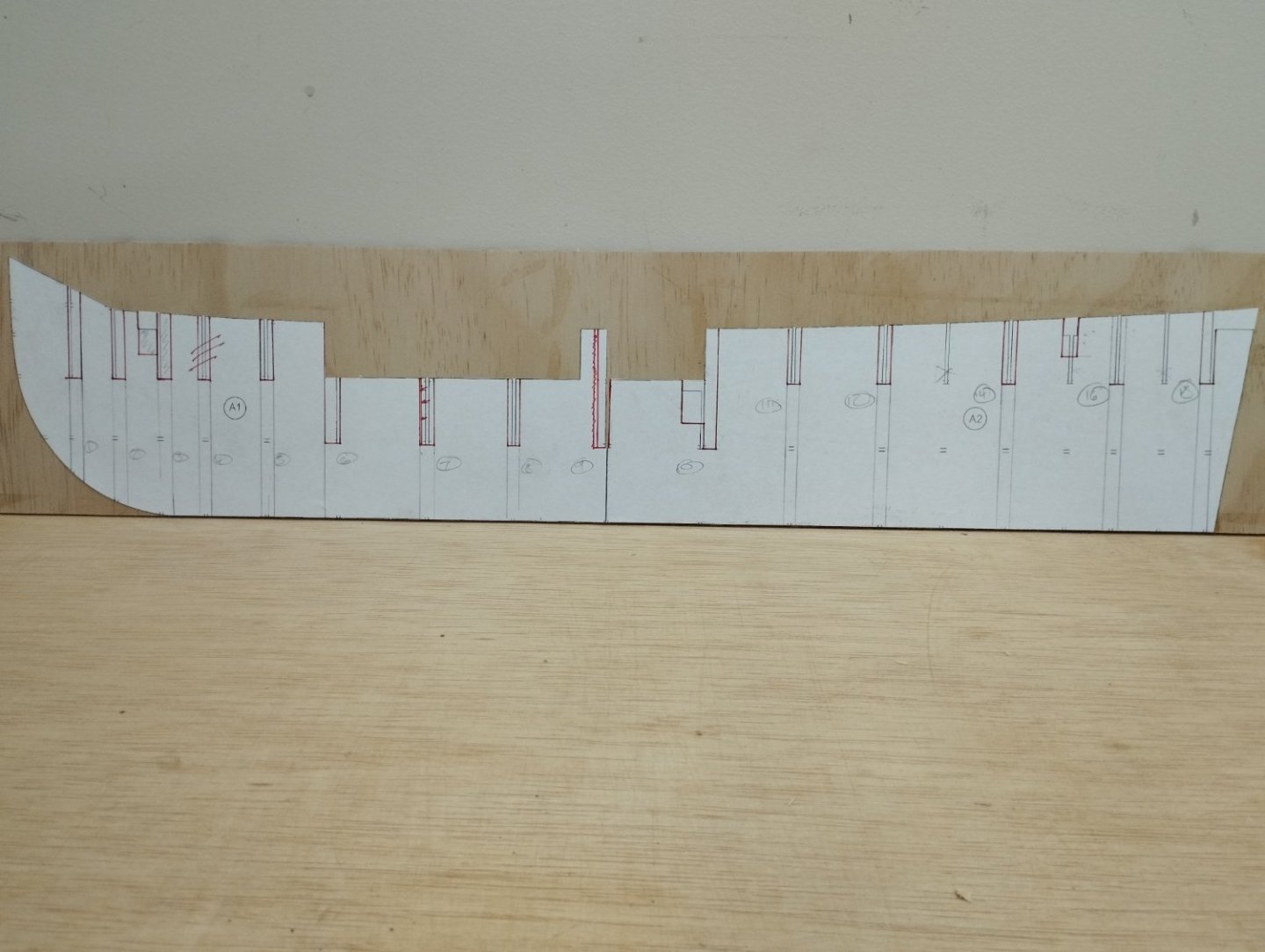

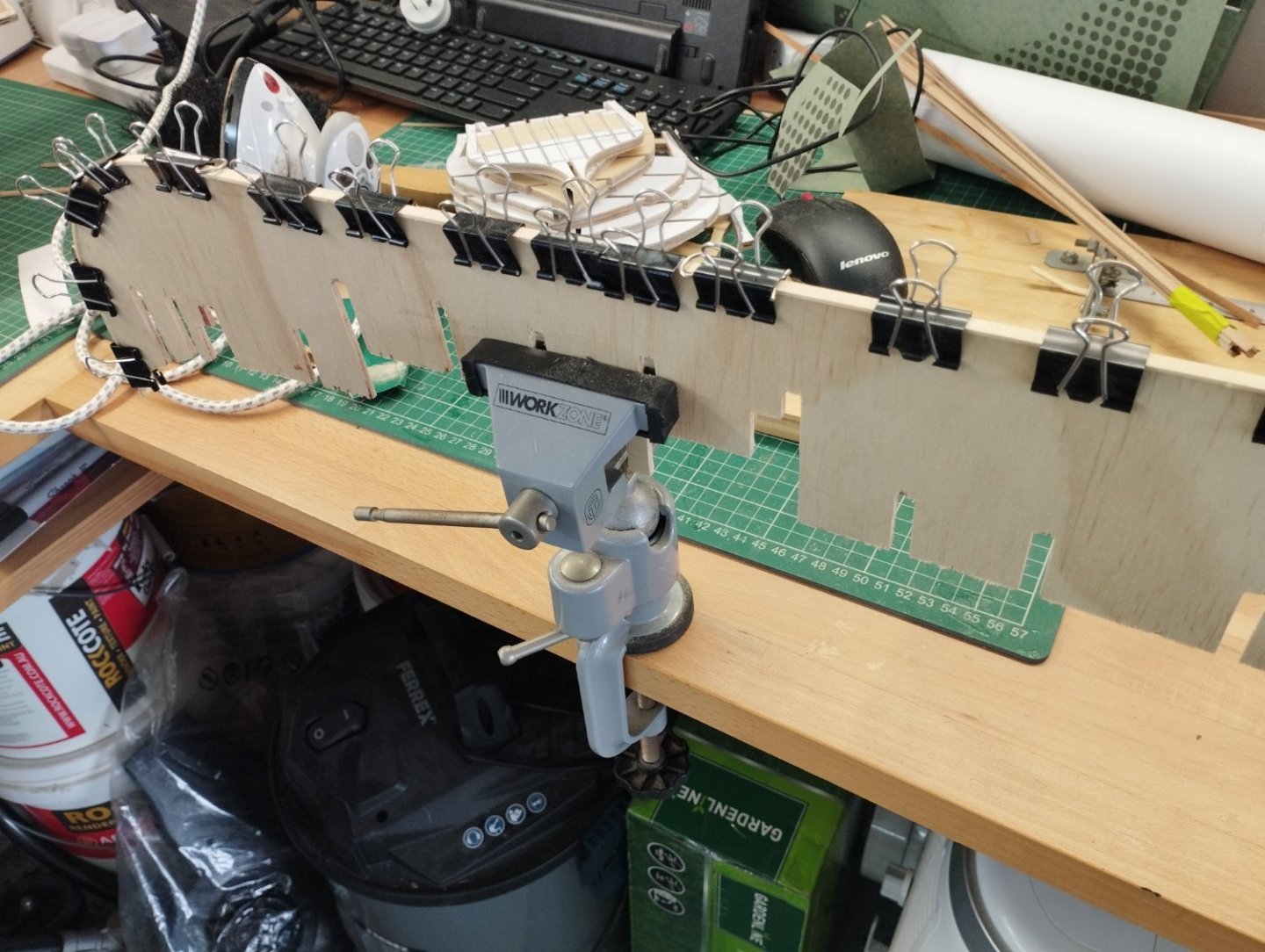

Hi All Thanks for the likes. Onto fitting the bulkheads A quick jig was made to keep the spine vertical whilst the bulkheads were fitted. Bulkheads kept square using Lego and clamps Once all bulkheads were fitted I added spacers to keep everything square, this is simply achieved by taking measurements of the gaps between the same bulkheads on either side of the spine and taking the average, two pieces of stock are then cut to that length and glued in place between the bulkheads The 3mm ply spine is still flimsy at this point so bracing pieces are required. These are cut from the templates provided and 3mm ply is used. I cut the bracing pieces roughly 5mm less wide than the templates so that the edge of the bracing pieces were clear of the bulkhead edges.. Following shows a couple of the bracing pieces cut and installed clear of the bulkhead edges Gaps in the bulkheads are plugged with some pine and sanded flush The frame is now rock solid and straight Thanks for dropping by Mark

-

Mr Pleasant reacted to a post in a topic:

The Hayling Hoy by jpalmer1970 - 1:48 scale - First POF build

Mr Pleasant reacted to a post in a topic:

The Hayling Hoy by jpalmer1970 - 1:48 scale - First POF build

-

Mr Pleasant reacted to a post in a topic:

The Hayling Hoy by jpalmer1970 - 1:48 scale - First POF build

Mr Pleasant reacted to a post in a topic:

The Hayling Hoy by jpalmer1970 - 1:48 scale - First POF build

-

Mr Pleasant reacted to a post in a topic:

Adding a cheap DRO to a Proxxon XY-table

Mr Pleasant reacted to a post in a topic:

Adding a cheap DRO to a Proxxon XY-table

-

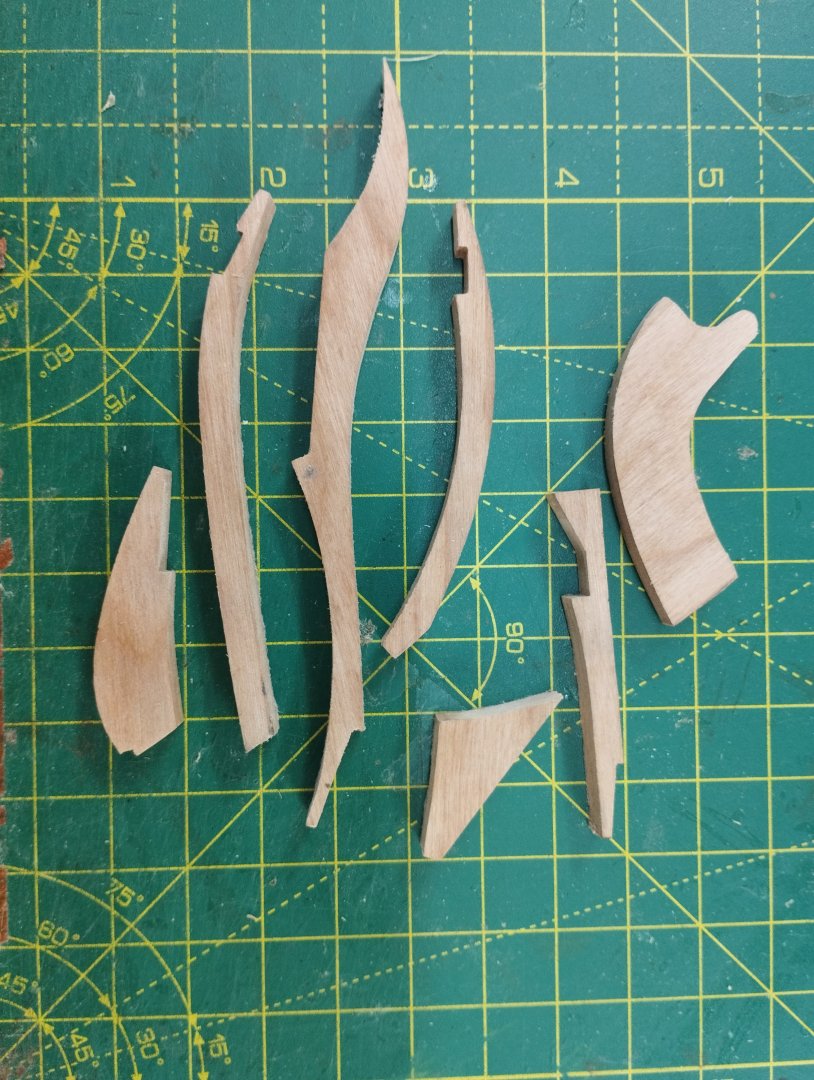

Hi All Thanks for the likes @GrandpaPhil hope you start back on your card version, it's looking good so far @jpalmer1970 thanks, happy to have you along Ok, stem part next....this has been broken down into its component parts and glued up I've milled some cherry to a 6mm thickness for the stem, keel/false keel and stern post pieces and mixed some black acrylic paint into PVA glue for the joints. Some of the joints are not perfectly tight but I'm fairly happy for a first attempt All glued to the "keel" piece I've scored a line along the cherry 1mm in from the "keel" piece (if you zoom in really close you can just see it) , I'll cut this away after the first planking to use as a rabbet for the 2nd planking. I'm hoping the scoring will help in a smooth removal The 6mm cherry is centered on the 3mm "keel" leaving 1.5mm on each side to take the 1st planking which will be.......yeah, you guessed it 1.5mm in thickness. Thanks for looking in Mark Mark

-

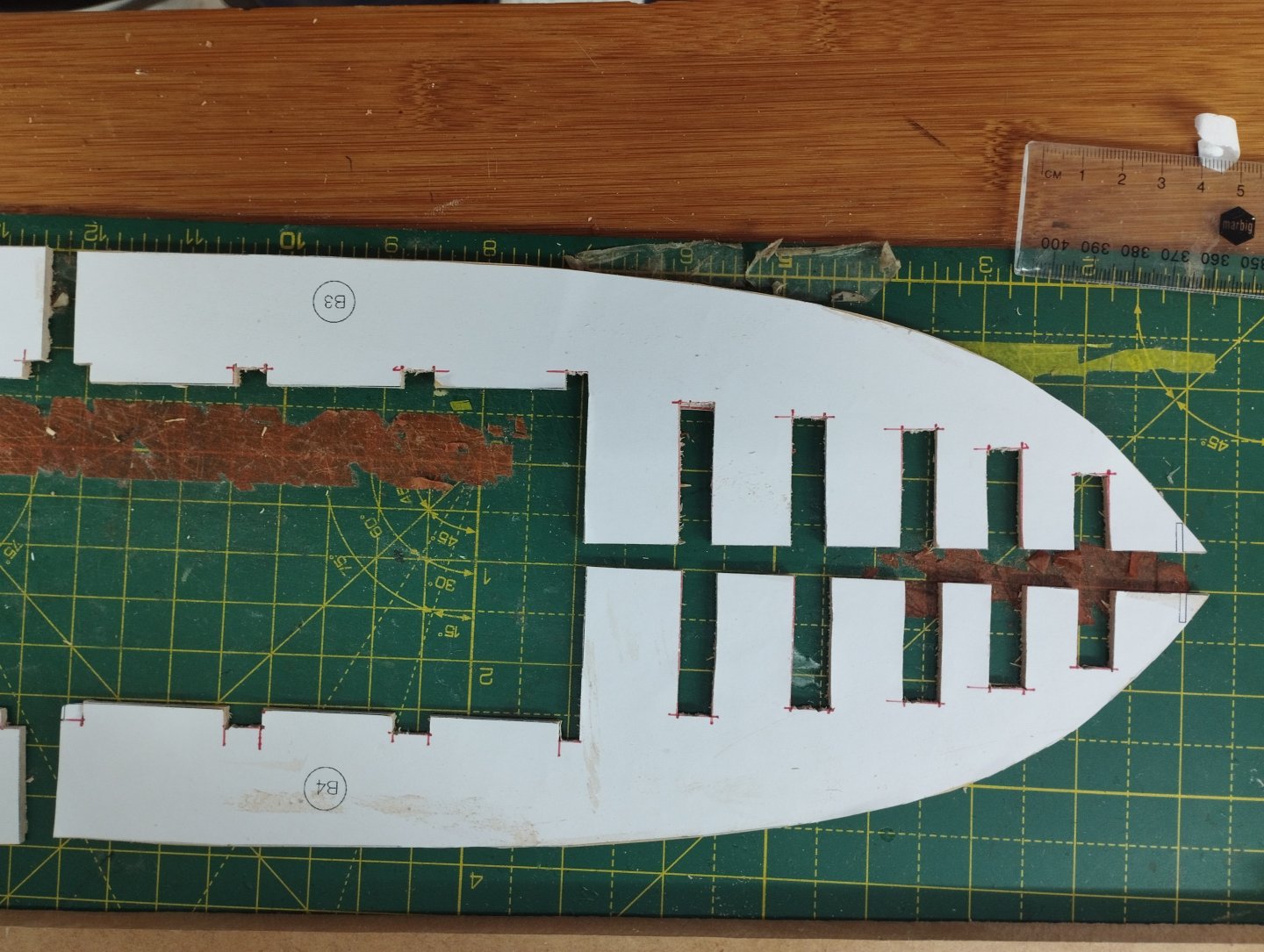

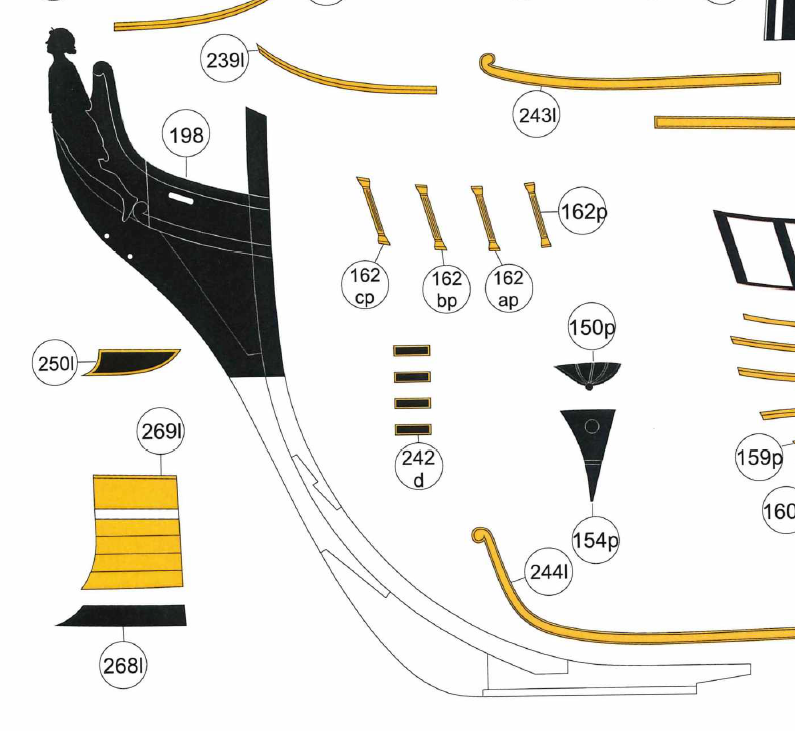

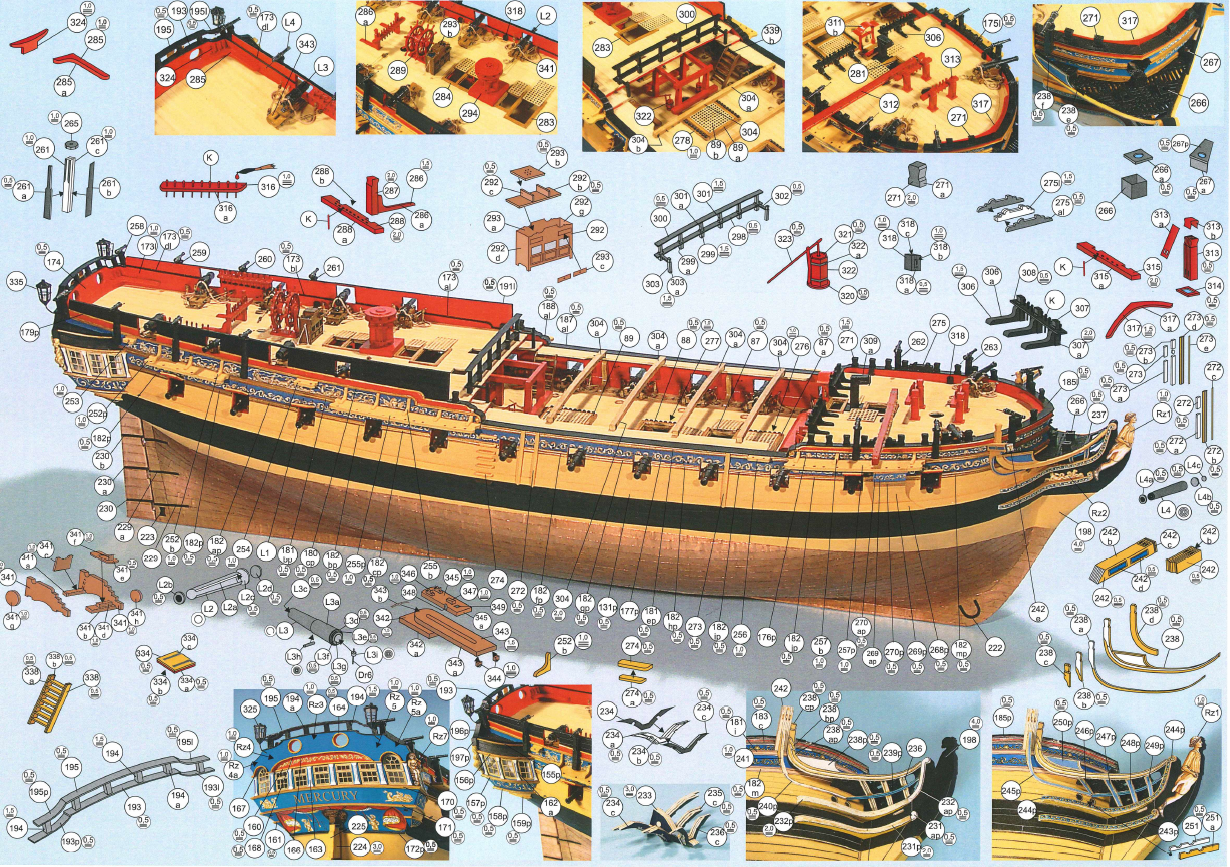

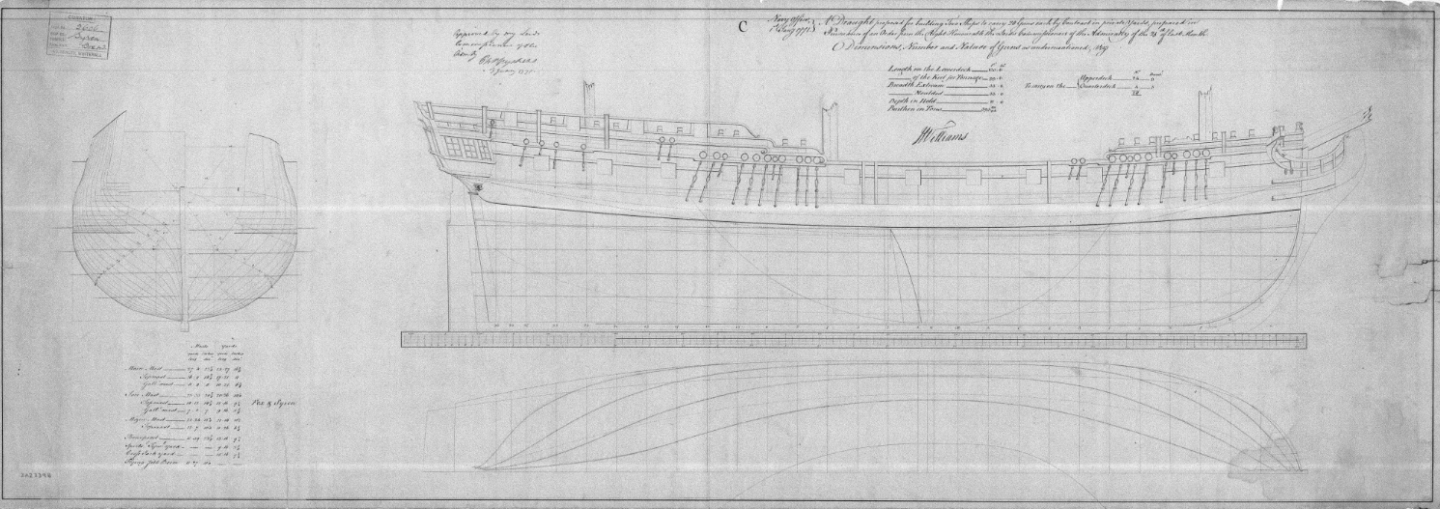

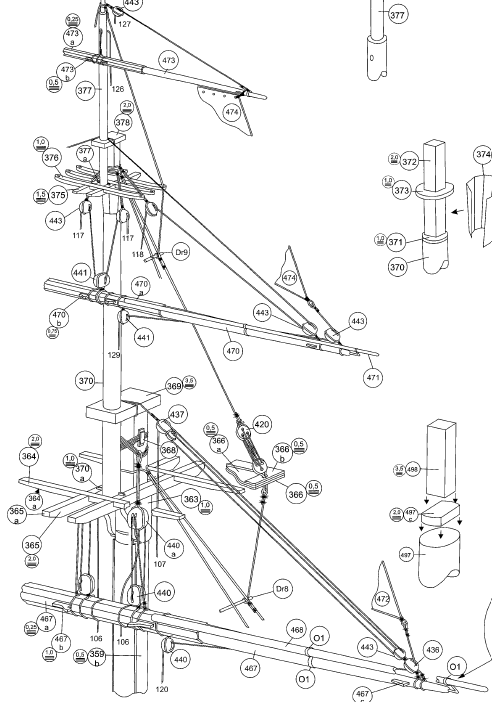

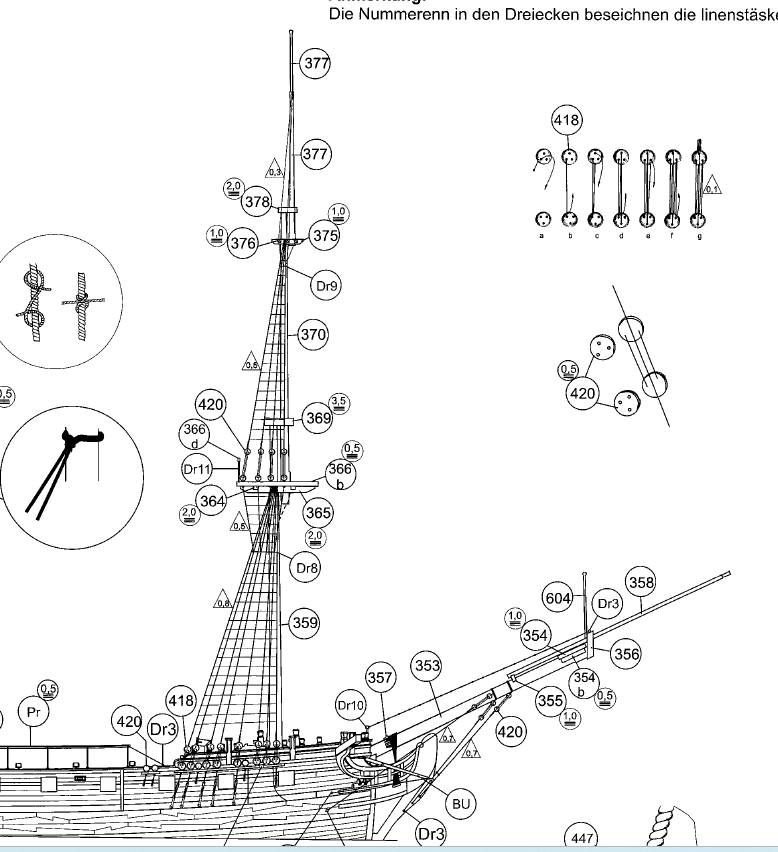

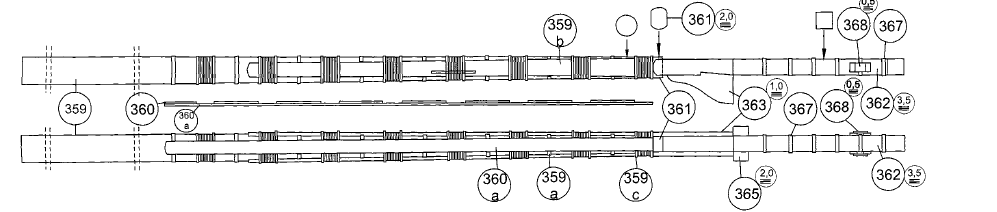

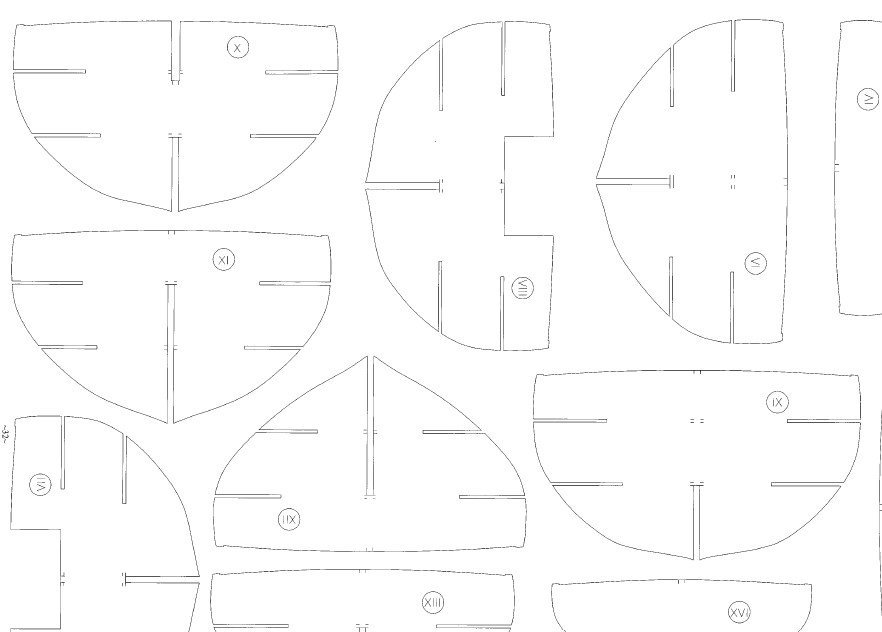

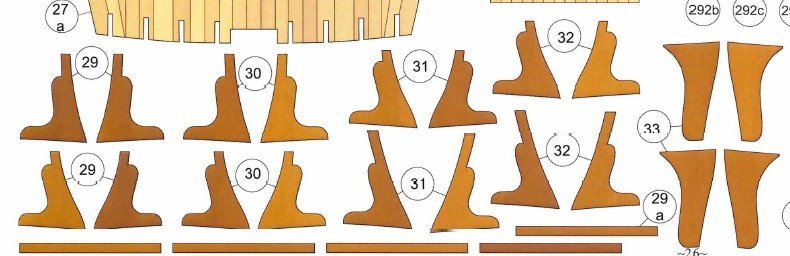

Hi All It's with a little trepidation that I start this build log and as such a word of caution is required..... If you are of a nervous disposition and easily offended by poor quality workmanship, find a complete disregard of historical accuracy extremely upsetting and deem lowering the quality of this forum as morally outrageous then then I beg you to avert your eyes and leave now as the following content is probably not for you. Ok, for those of you that are still with me and made of stronger stuff there are some points that I need to make you aware of before I start a) I am not at one with wood b) tools are not a natural extension of my hands c) I do not see a plan on paper and turn it into a 3D matrix in my mind and compute complex curves and angles instantly d) If there are two ways to do something, I'll choose the wrong one e) If there is an easy way and a hard way, I'll inadvertently do it the hard way e) I was not blessed with any real woodworking skills and I have to make do with my God given abilities f) I enjoy making ship models and I struggle daily to overcome the points above. Let's begin This is my fourth model ship (see signature for details) and my first attempt at a scratch build. I'll be using the paper model by Shipways as the basis of the build and will be using as much as what is contained in the paper parts as templates to assist as I attempt to covert it into a wooden model. I've also downloaded the plans of Syren from wiki commons as an aid as the paper "plans" do not contain plans as such...what is provided is along the lines of Syren download The content of the paper model is really good and has excellent rigging, belaying, mast and yard info and in my opinion is as good as Caldercraft rigging plans...small example of rigging info Masts The paper model is at a scale of 1:96 so the first order of the day was to scan the sheets and print out at a scale of 1:64 and to try and identify what parts are printed on the 30+ A3 sheets and compile into a spreadsheet for ease of location. Bulk heads were cut out of 6mm plywood....this is just normal ply from the local hardware store (Bunnings), I know there is discussion in another topic on the merits of using something better but I've got to work with what I can get easily in my little corner of Queensland.... but first a little manipulation of the templates was required. As below the bulkhead templates only go to the main deck level and make no provision for the bulwarks The way the paper model caters for these is to add internal supports to the deck as shown in the photo below which has been copied from the paper build log of Mercury by @catopower These supports are few and far between and made from the templates I've used these templates to form an extension of the bulkheads I know I could have used the Syren plans to form the bulkheads but I want to use as much as what is provided as part of this build "Keel" piece is made from 3mm plywood....I can hear the gasps now "that won't be strong enough to support 6mm bulkheads....far too flimsy"....I originally considered the 6mm ply but this would result in a loss of definition of the bulkheads once a 6mm slot was cut into them. I've repositioned the bulkheads slightly to centre them over where the thin card bulkheads would have gone. The bulkheads at stem and stern have been positioned so that the face is identical to where the card bulkhead would be as I need to use these as refernece points for the bow and stern works. I've also omitted 3 bulkheads (no's 4, 13 and 17) as I deemed them not necessary with the 6mm ply and closeness to the others A strip of 1.5mm has been glued to the "keel" piece to form a rabbet for the planking. I'm further on than this but will call it a day for this initial post. Thanks for looking in Mark Thanks for looking in

-

Using a card-kit to ¨scratchbuild¨ a ship?

Mr Pleasant replied to ubjs's topic in RC Kits & Scratch building

I'm doing this for the HMS Enterprise using the Shipyard card model kit. Have upscaled from 1:96 to 1:64 and I'm just building a rough prototype to work out the stern and bow areas.....watch this space, build log coming in the New Year once I've worked through some of the issues in relation to converting this to a wood model as to what is provided in the paper plans -

Thanks Patrick I'll certainly be following your build of the Mary Rose

- 50 replies

-

- mary rose

- caldercraft

-

(and 1 more)

Tagged with:

-

Hi All Thanks for the likes and comments and thanks to Fishhooks for posting on the error in the mast dimensions provided in the plans. This is what the forum is about after all, I've learned a lot and continue to do so and hopefully this build log will prove some assistance to those who are in the middle of building this model or who are considering starting. I started this on the 28/12/2020 and finally finished on 05/09/2023. The model out of the box builds fairly well and I think the preceding posts point out all the main pitfalls I came across. The only things I've changed are the making of my own rope and the addition of the two cannons at the stern. The following photos show the end result of a model I've enjoyed building. Thanks again for stopping by Mark

- 50 replies

-

- mary rose

- caldercraft

-

(and 1 more)

Tagged with:

-

Mr Pleasant reacted to a post in a topic:

Mary Rose by Mr Pleasant - FINISHED - Caldercraft - 1:80

Mr Pleasant reacted to a post in a topic:

Mary Rose by Mr Pleasant - FINISHED - Caldercraft - 1:80

-

Mr Pleasant reacted to a post in a topic:

6-pounder, Royal Navy cannon barrel - George III era

Mr Pleasant reacted to a post in a topic:

6-pounder, Royal Navy cannon barrel - George III era

-

Mr Pleasant reacted to a post in a topic:

HMS Diana by DavidEN - Caldercraft - 1:64

Mr Pleasant reacted to a post in a topic:

HMS Diana by DavidEN - Caldercraft - 1:64

-

Will be interesting to see if this solves the problem entirely or if you still need to widen the channels. If you're not doing a build log a pm would be nice when you get to that stage to satisfy my curiosity. Mark

- 50 replies

-

- mary rose

- caldercraft

-

(and 1 more)

Tagged with:

-

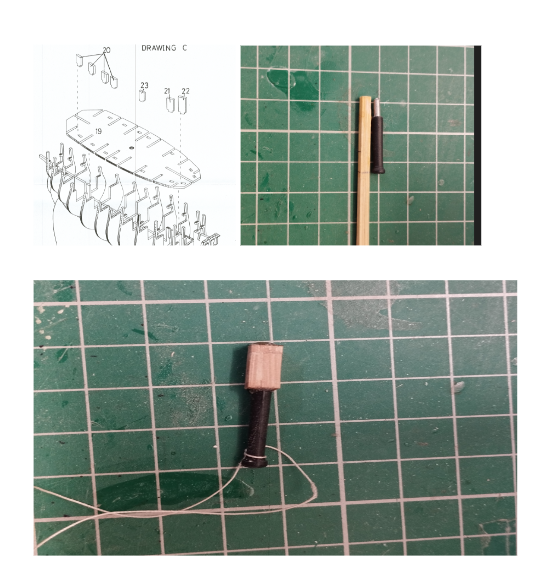

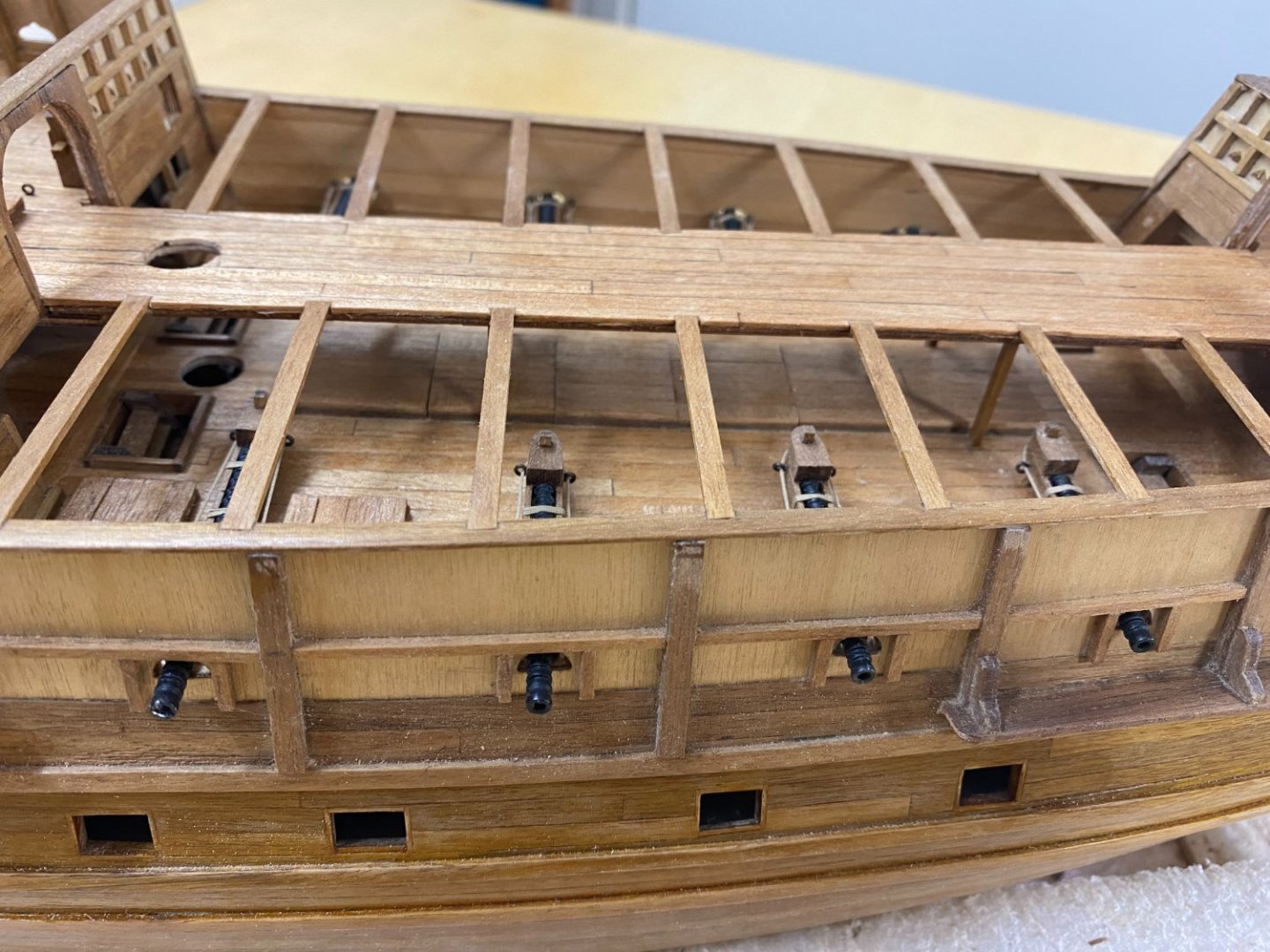

Hi All Thanks for the comments and likes. Small update on progress... Cannons are now installed but not without a few small issues shown below. The plans asked for dummy cannon blocks to be installed at the framing stage in the pre defined slots shown in the top left image with the intent that holes are drilled into the blocks to accept the dummy cannons. Top right image, the wood gauge shows the depth from the dummy block to the edge of the frame (pencil mark). The unpainted part of the cannon is of a lesser diameter than the barrel and is to fit in the hole drilled in the block. However following this course of action would lead to the cannons being far recessed inside the hull. To overcome this blocks were made and the cannons fixed to these to effectively increase the length of the cannon as shown in the bottom image. The assembly was then glued against the dummy cannon blocks....the thread was was used as a recovery mechanism in case the cannons fell inside the hull whilst the glue was setting Cannons are now installed and I'm onto the running rigging Thanks for dropping by Mark

- 50 replies

-

- mary rose

- caldercraft

-

(and 1 more)

Tagged with:

-

Mr Pleasant reacted to a post in a topic:

What are ground toes?

Mr Pleasant reacted to a post in a topic:

What are ground toes?

-

Mr Pleasant reacted to a post in a topic:

Mary Rose by Mr Pleasant - FINISHED - Caldercraft - 1:80

Mr Pleasant reacted to a post in a topic:

Mary Rose by Mr Pleasant - FINISHED - Caldercraft - 1:80

-

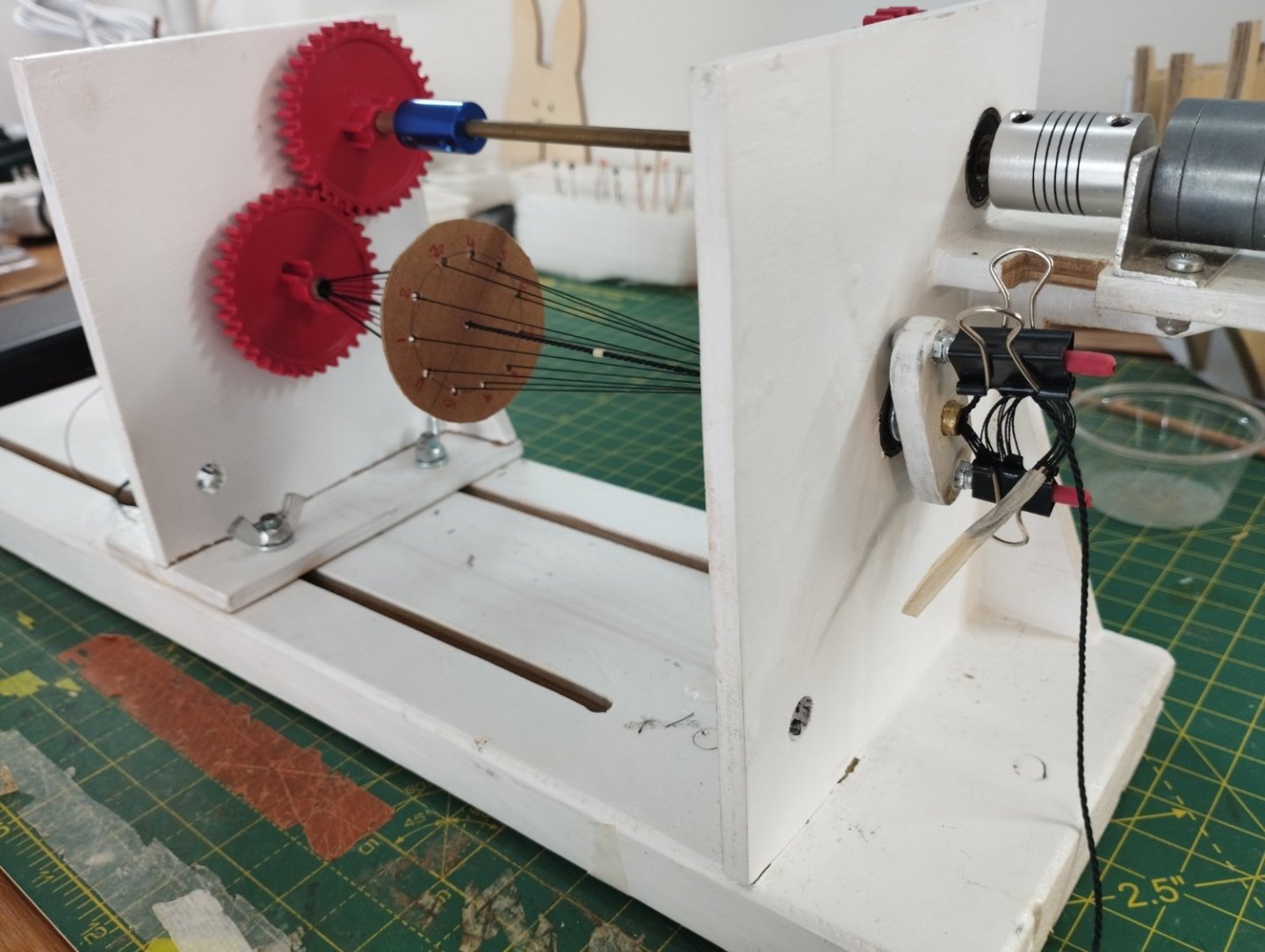

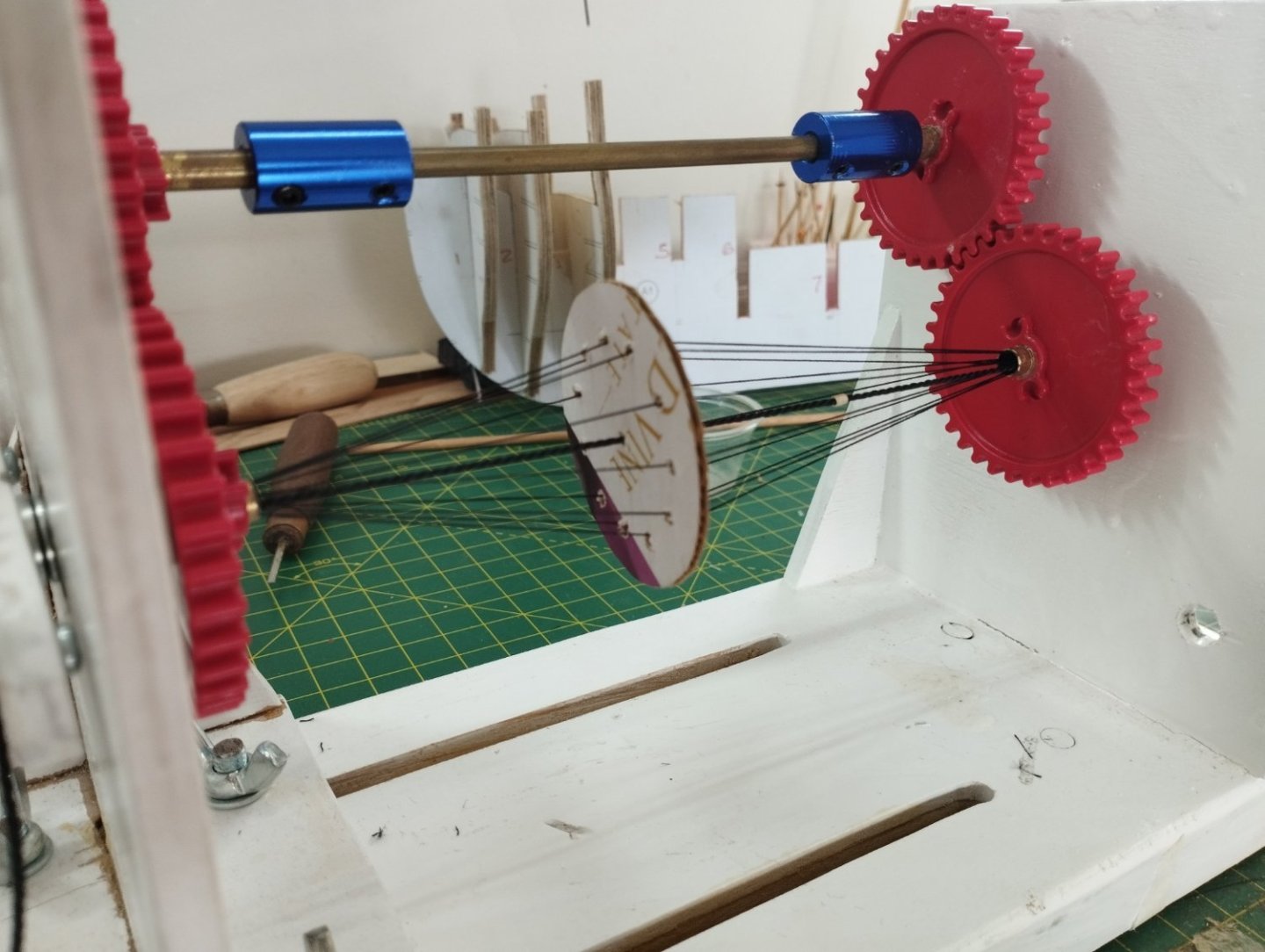

Wow, where did that time go!!!!! 9 month since my last post. Standing rigging and ratlines are now pretty much complete, I've done the stays with "mice" although the instructions didn't call for them and the plans were a little unclear in this regard and the AoTS that I have doesn't have a lot of detail regarding the rigging. There's quite a lot of resource on this site on the making of a mouse and after quite a lot of trial and error I've managed to get something that I'm fairly happy with The setup that I got best results with was to use a serving machine. This allowed me to keep the weaving threads tight but also made the weaving a lot easier than other methods I tried as I could keep turning the weaving threads towards me once I had gone over and under a pair. Thread used was Mara 30 and is probably a little on the large size but was all I had in large quantity as there is a lot of waste, 11 weaving threads were used. The circle used to keep the threads separated is simply a piece of card with the 11 holes punched thorough, I numbered the holes as I found this helped me keep track of the weaving thread as I went under and over the threads. The mouse former was turned on a lathe and is roughly 3mm in length Once this was set up it was "simply" a matter of threading the weaving thread under and over a pair and turning the gears of the serving machine towards me to weave under and over the next pair and so on. Once the former was covered then I served a length of the stay and formed the eye to stop against the mouse. Following photos give an idea where I'm at Thanks for looking in and hopefully my next post won't be too far away Mark

- 50 replies

-

- mary rose

- caldercraft

-

(and 1 more)

Tagged with:

-

Mr Pleasant reacted to a post in a topic:

How an 18th Century Sailing Battleship Works

Mr Pleasant reacted to a post in a topic:

How an 18th Century Sailing Battleship Works

-

Mr Pleasant reacted to a post in a topic:

Mf 70 Proxxon Mill Spindle Mod to take ER11 Collets from 1mm to 7mm

Mr Pleasant reacted to a post in a topic:

Mf 70 Proxxon Mill Spindle Mod to take ER11 Collets from 1mm to 7mm

-

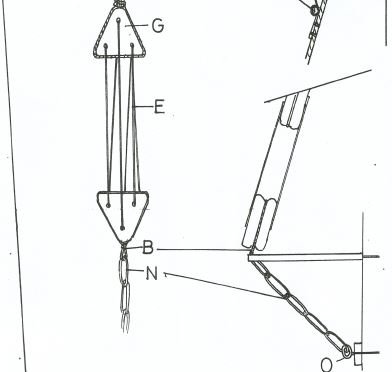

Thanks Steven I have the AoTS book and did consider the chainwork option but the chain supplied in the kit is so soft that I think I would have struggled soldering the ring from the dead eye to it and I didn't fancy making up my own chain so I elected to go with the plans as below where "B" is thread Also, it's not the first time I've had issues with Caldercraft models and the shrouds. I got caught out on the Endeavour and this was a problem with the kit and is discussed by others in a thread in the "masts and rigging section". I think it's something similar in that the main mast should be slightly longer than what is given in the plans and the channels should be slightly wider. But all good, hopefully others who are planning on building this ship can learn from my mistakes. Mark

- 50 replies

-

- mary rose

- caldercraft

-

(and 1 more)

Tagged with:

-

Hi All Must be time for another update..... Had a small issue with the shrouds fouling on the sides as shown below Not sure how this happened as I haven't deviated from the plans and having checked the photo (below) that came on the instruction manual it's not clear if there is an issue with the model itself or not and particularly the shrouds further away from the Main mast and around the Mizzen mast. Regardless, I needed to fix it, the channels are epoxied and pinned so I couldn't remove them, the mast was also epoxied and not moving, the height increase in the mast to clear the sides would have been significant in any case. Only real option I had was to add material to widen the channels, luckily there was sufficient spare wood from where the channels had been cut from. Next was on to fixing the shroud dead eyes and this was accomplished using a jig with a horizontal line drawn on to fix a constant level...I know some people prefer spacers but I find this works for me. The dead eyes for the channels are only held by rope and these had to be stitched prior to seizing as no amount of glue, shellac, varnish would take the strain once the shrouds were pulled tight....following photos show where I'm up to Thanks for looking in Mark

- 50 replies

-

- mary rose

- caldercraft

-

(and 1 more)

Tagged with:

-

Seizings - what am I doing wrong?

Mr Pleasant replied to David Lester's topic in Masting, rigging and sails

Hi All I have quite good results using Floo Gloo from Veniards, it's used in the tying of flies in the fishing world. I was struggling on the dead eyes that sit in the channels on the Mary Rose and having tried nail varnish, shellac, watered down PVA etc the Floo Gloo seems to have solved my problems. Mark -

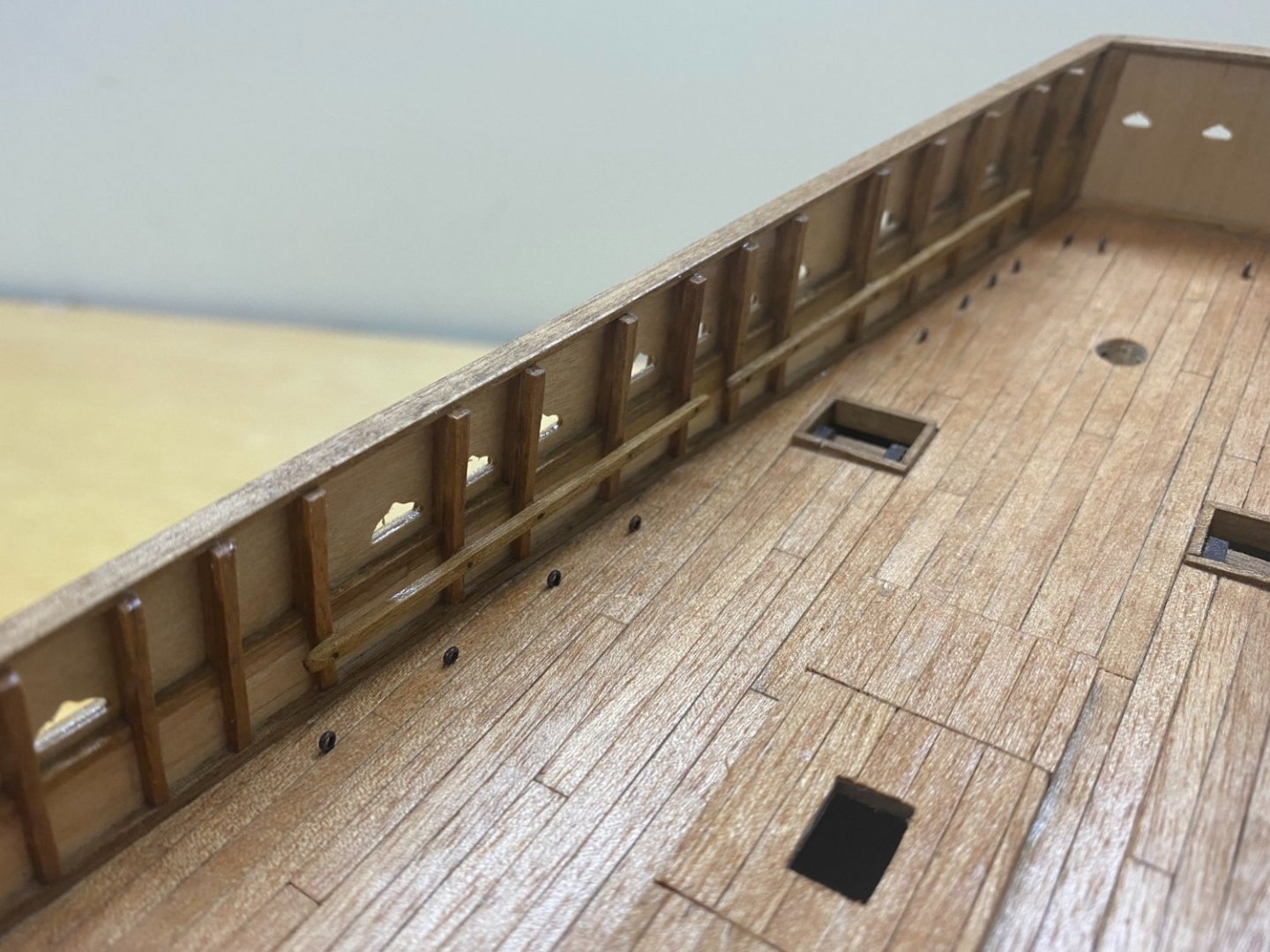

Hi All Thanks for the likes and comments.....really appreciated!!! Just a quick update, deck works are now complete and the gangway installed. Next stop, masts and yards Thanks for dropping by Mark

- 50 replies

-

- mary rose

- caldercraft

-

(and 1 more)

Tagged with:

-

Hi All Small update on progress over the last few months or so. Forecastle is now complete and just a few points for those who may be planning on building this model. The fore beak platform provided didn't really fit and so I had to fashion another out of scrap. The photos below show the kit supplied and my modified version Next was an issue of my own making, when planking the main deck, I planked to the oval provided in the false deck for the bowsprit. This is far too large and I only realised once the forecastle was pretty much complete and I was checking the fit of the bowsprit. The following shows the repairs in a tight space (before and after)....not perfect....but lesson learned for future!!! Cannons are now rigged on the main deck all rope was made on a home made vertical rope walk. Gutermann Scala 200 and 240 thread colour 464 was used Again for those considering the model the centre hatch coverings in the below need to be made narrower than the kit supplied otherwise the support columns for the waist gangway wont fit....don't ask me how I know Some general photos of progress.....looks like one of the cannons has lifted from the deck, time to get the glue out Thanks for looking in Mark

- 50 replies

-

- mary rose

- caldercraft

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.