-

Posts

48 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Ireland

-

Interests

yes

Recent Profile Visitors

-

monstertodd1 reacted to a post in a topic:

HMS Terror by sir francis haddock - FINISHED - OcCre - scale 1:65

monstertodd1 reacted to a post in a topic:

HMS Terror by sir francis haddock - FINISHED - OcCre - scale 1:65

-

Diver reacted to a post in a topic:

HMS Terror by sir francis haddock - FINISHED - OcCre - scale 1:65

Diver reacted to a post in a topic:

HMS Terror by sir francis haddock - FINISHED - OcCre - scale 1:65

-

DaJH reacted to a post in a topic:

HMS Terror by sir francis haddock - FINISHED - OcCre - scale 1:65

DaJH reacted to a post in a topic:

HMS Terror by sir francis haddock - FINISHED - OcCre - scale 1:65

-

consitution reacted to a post in a topic:

HMS Terror by sir francis haddock - FINISHED - OcCre - scale 1:65

consitution reacted to a post in a topic:

HMS Terror by sir francis haddock - FINISHED - OcCre - scale 1:65

-

EJ_L reacted to a post in a topic:

HMS Terror by sir francis haddock - FINISHED - OcCre - scale 1:65

EJ_L reacted to a post in a topic:

HMS Terror by sir francis haddock - FINISHED - OcCre - scale 1:65

-

Keith S reacted to a post in a topic:

HMS Terror by sir francis haddock - FINISHED - OcCre - scale 1:65

Keith S reacted to a post in a topic:

HMS Terror by sir francis haddock - FINISHED - OcCre - scale 1:65

-

sir francis haddock reacted to a post in a topic:

HMS Terror by sir francis haddock - FINISHED - OcCre - scale 1:65

sir francis haddock reacted to a post in a topic:

HMS Terror by sir francis haddock - FINISHED - OcCre - scale 1:65

-

clearway reacted to a post in a topic:

HMS Terror by sir francis haddock - FINISHED - OcCre - scale 1:65

clearway reacted to a post in a topic:

HMS Terror by sir francis haddock - FINISHED - OcCre - scale 1:65

-

clearway reacted to a post in a topic:

HMS Terror by sir francis haddock - FINISHED - OcCre - scale 1:65

clearway reacted to a post in a topic:

HMS Terror by sir francis haddock - FINISHED - OcCre - scale 1:65

-

gieb8688 reacted to a post in a topic:

HMS Terror by sir francis haddock - FINISHED - OcCre - scale 1:65

gieb8688 reacted to a post in a topic:

HMS Terror by sir francis haddock - FINISHED - OcCre - scale 1:65

-

gieb8688 reacted to a post in a topic:

HMS Terror by sir francis haddock - FINISHED - OcCre - scale 1:65

gieb8688 reacted to a post in a topic:

HMS Terror by sir francis haddock - FINISHED - OcCre - scale 1:65

-

sir francis haddock reacted to a post in a topic:

HMS Terror by sir francis haddock - FINISHED - OcCre - scale 1:65

sir francis haddock reacted to a post in a topic:

HMS Terror by sir francis haddock - FINISHED - OcCre - scale 1:65

-

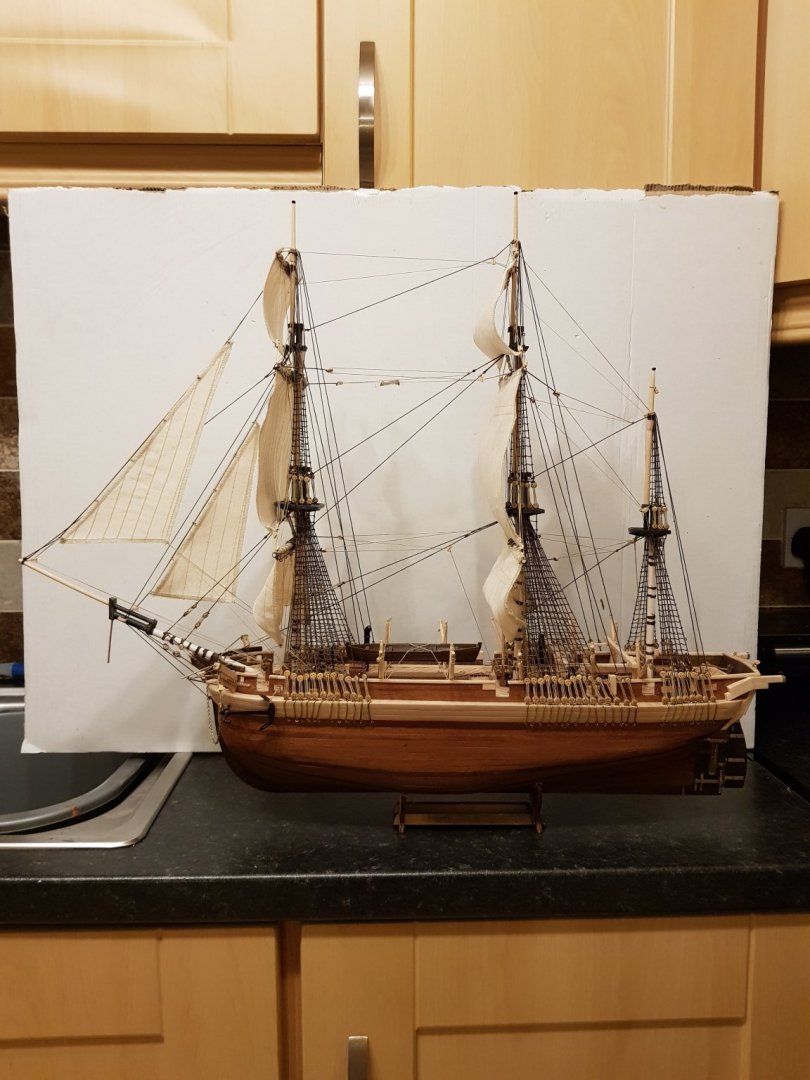

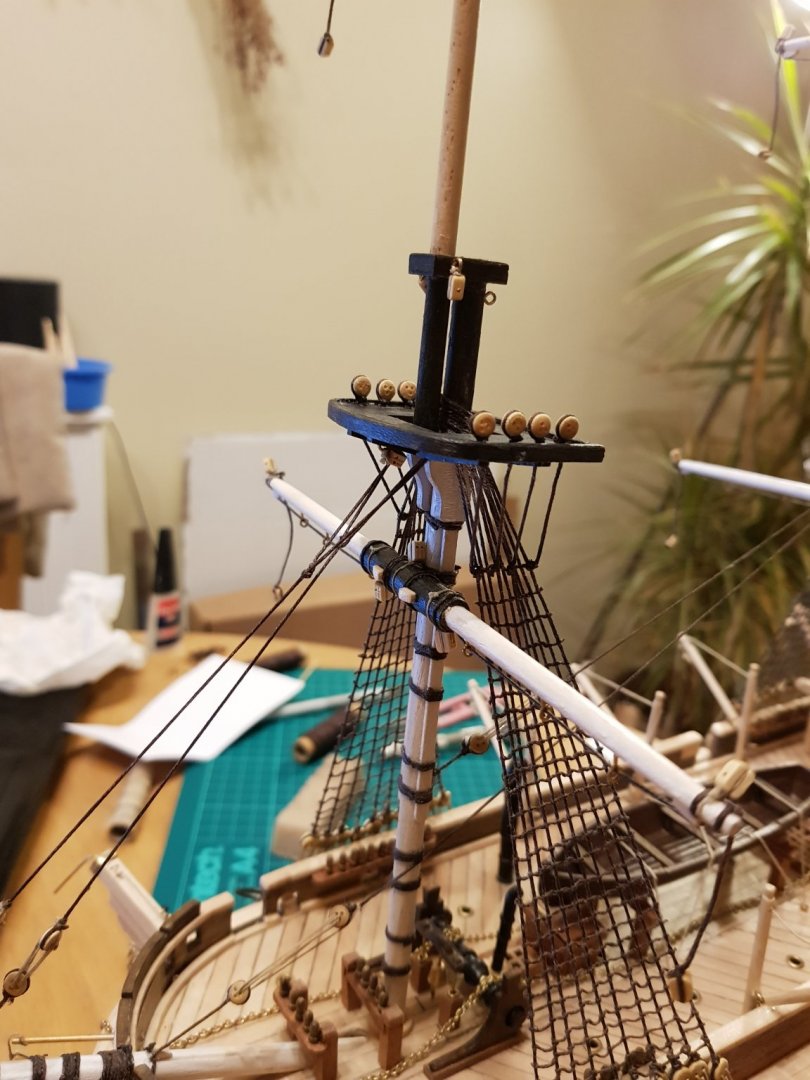

A bit difficult, some of the rigging is not in the instructions. But I think it's ok. Getting close to finishing. 😊

-

Another sail done. Getting faster at these. Thought I would get these peices in before the boom and sails. Must be easier without them in the way.

-

sir francis haddock reacted to a post in a topic:

HMS TERROR by Wahka_est - OcCre - 1:75 - first wooden ship build

sir francis haddock reacted to a post in a topic:

HMS TERROR by Wahka_est - OcCre - 1:75 - first wooden ship build

-

sir francis haddock reacted to a post in a topic:

HMS Terror by sir francis haddock - FINISHED - OcCre - scale 1:65

sir francis haddock reacted to a post in a topic:

HMS Terror by sir francis haddock - FINISHED - OcCre - scale 1:65

-

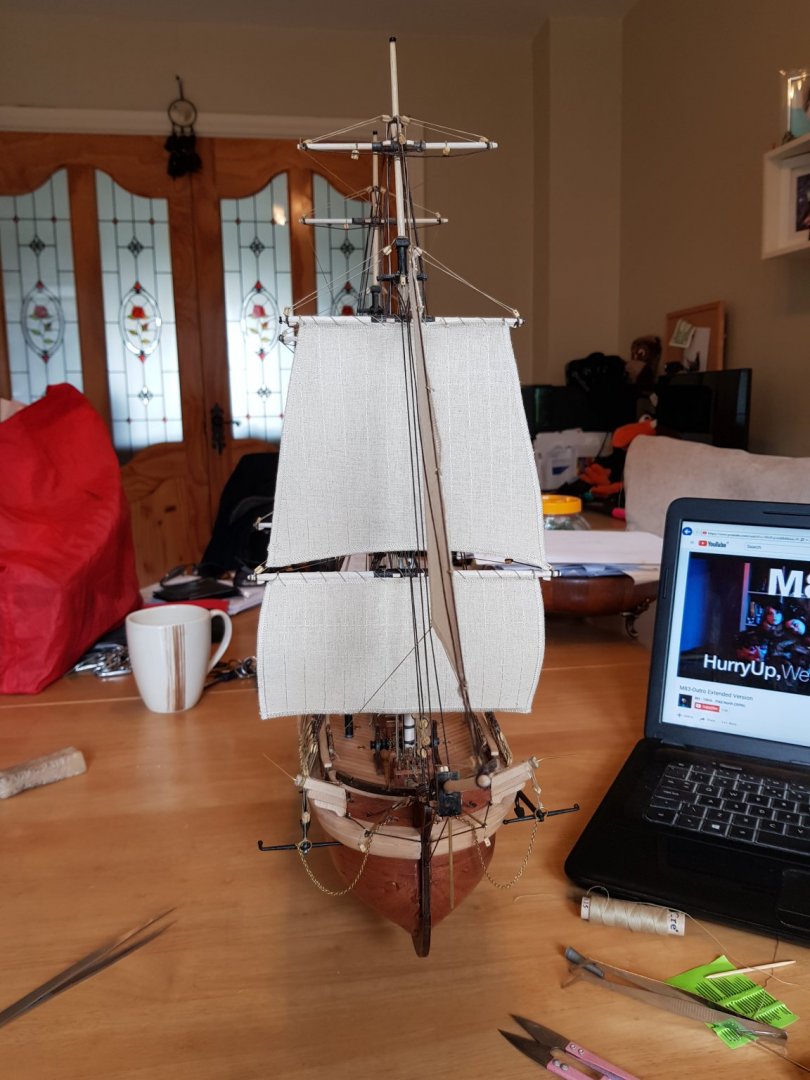

Hi am back after a break. Small case of getting married. Hope to get back in full swing. Some more sails added. 😊

-

sir francis haddock reacted to a post in a topic:

HMS Terror by Mish - OcCre - 1:65

sir francis haddock reacted to a post in a topic:

HMS Terror by Mish - OcCre - 1:65

-

sir francis haddock reacted to a post in a topic:

Greetings from Czech republic

sir francis haddock reacted to a post in a topic:

Greetings from Czech republic

-

sir francis haddock reacted to a post in a topic:

HMS Terror by sir francis haddock - FINISHED - OcCre - scale 1:65

sir francis haddock reacted to a post in a topic:

HMS Terror by sir francis haddock - FINISHED - OcCre - scale 1:65

-

sir francis haddock reacted to a post in a topic:

HMS Terror Video

sir francis haddock reacted to a post in a topic:

HMS Terror Video

-

sir francis haddock reacted to a post in a topic:

Exploring the wreck of HMS Terror

sir francis haddock reacted to a post in a topic:

Exploring the wreck of HMS Terror

-

Been chipping away at the shrouds and the ratlines. So, so many. Tying every rat line takes forever.

-

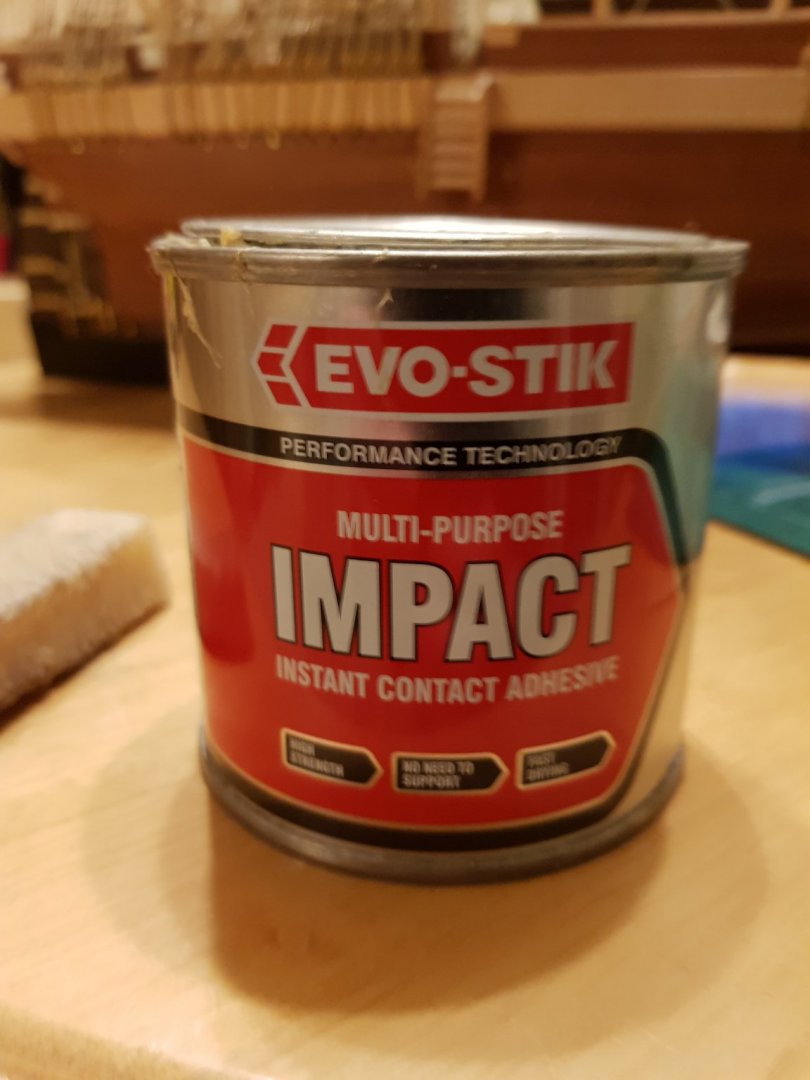

Hi LyleK1, didn't go with the ice shield because I thought not painted it would stand out a lot. I have painted the life boats, anchors and chimneys. These are cast metal so need to be painted. I also painted the masts, I used a very watered down acrylic just to stain the wood. The very pale colour of the dowl seemed to distracting. There really wasn't any logic to it, just what feels right. Good luck with your build. Would be awesome to see a pic. 😀

-

sir francis haddock reacted to a post in a topic:

HMS Terror by sir francis haddock - FINISHED - OcCre - scale 1:65

sir francis haddock reacted to a post in a topic:

HMS Terror by sir francis haddock - FINISHED - OcCre - scale 1:65

-

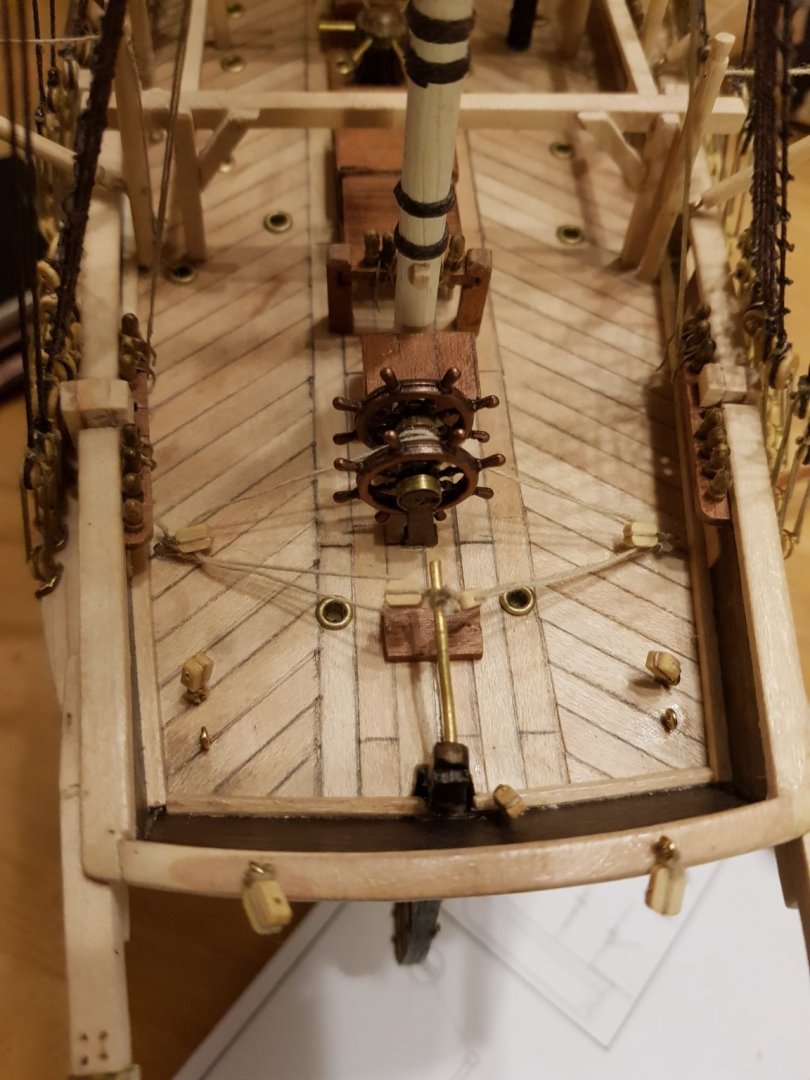

Well spotted, I had read somewhere that the Terror had 2 cannons and 2 swivel guns. When I was ordering some extra parts from occre they had 2 sizes of extra cannons on there website. I did get 2 of the largest size but they aren't right for the age of the ship. (But I now have 2 model cannons do I'm happy) Cornwall models I found later, has a larger range of cannons and barrels. But not sure if I want to add more to the deck.

-

Thank you RickyGene, been away from the project for a couple of weeks due to work and the general heat wave. looking forward to getting back on track and working my way through the rigging. As for the painting, anything from me would be guess work with a wood model. But it would seem likely the thinner the paint/ink the more the grain would remain. Is there a black varnish? I have been form the start looking up everything I can find on line about anything to do with models of the Terror, one was on youtube by a German (I think?) builder. Its not in English but he does show how he coloured and weathered the deck.

-

Thanks Heinrich der Seefahrer for all the positive comments (and every one else). The grating looks very good and would take it to a higher level. Would be a great challenge . with more construction under my belt maybe then would be able to pull it of.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.