Brian Falke

Members-

Posts

64 -

Joined

-

Last visited

Profile Information

-

Location

Jacksonville, FL

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

@g8rfan Thanks for posting this link. I too have been searching for figurines to add to my build and have not had much luck. Even tried 3D printing, and that failed. I did purchase one packet and positioned them around one cannon to see if they would work. And they are perfect - yes, I will have to repaint them since orange coveralls and hardhats were not in vogue in 1812, but their positions and shape are perfect.

-

mort stoll reacted to a post in a topic:

USS CONSTITUTION by Brian Falke - BlueJacket Shipcrafters - Scale 1:96

mort stoll reacted to a post in a topic:

USS CONSTITUTION by Brian Falke - BlueJacket Shipcrafters - Scale 1:96

-

mort stoll reacted to a post in a topic:

USS CONSTITUTION by Brian Falke - BlueJacket Shipcrafters - Scale 1:96

mort stoll reacted to a post in a topic:

USS CONSTITUTION by Brian Falke - BlueJacket Shipcrafters - Scale 1:96

-

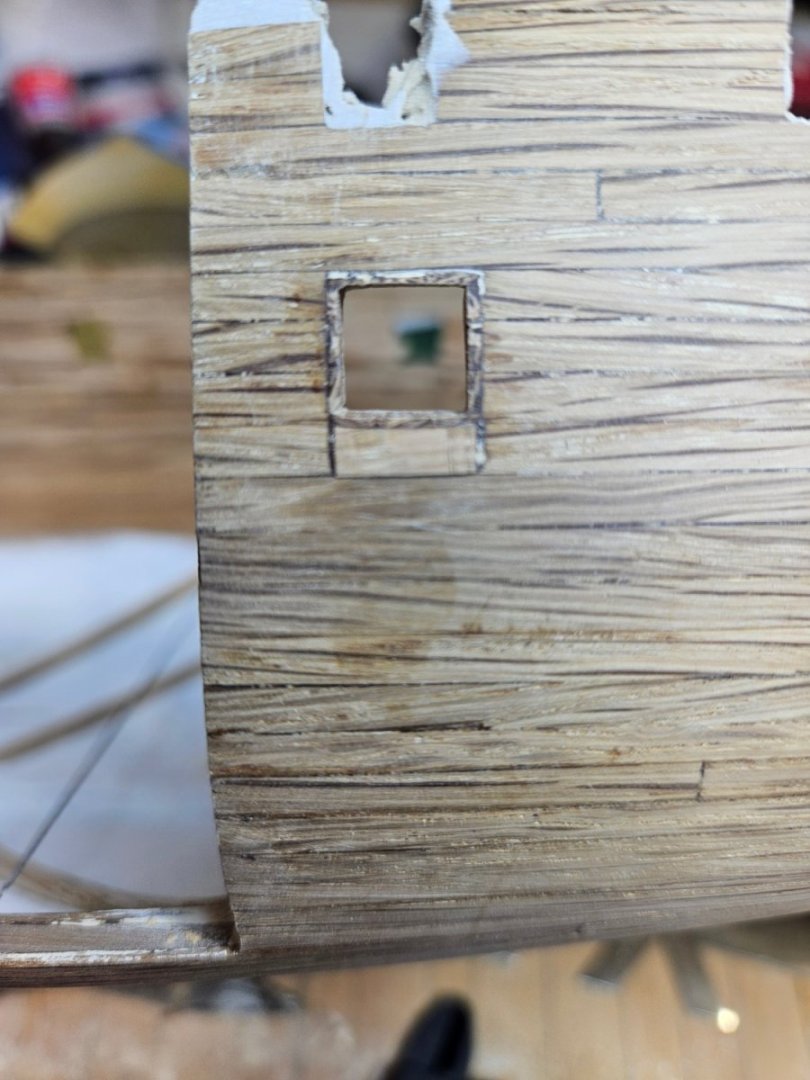

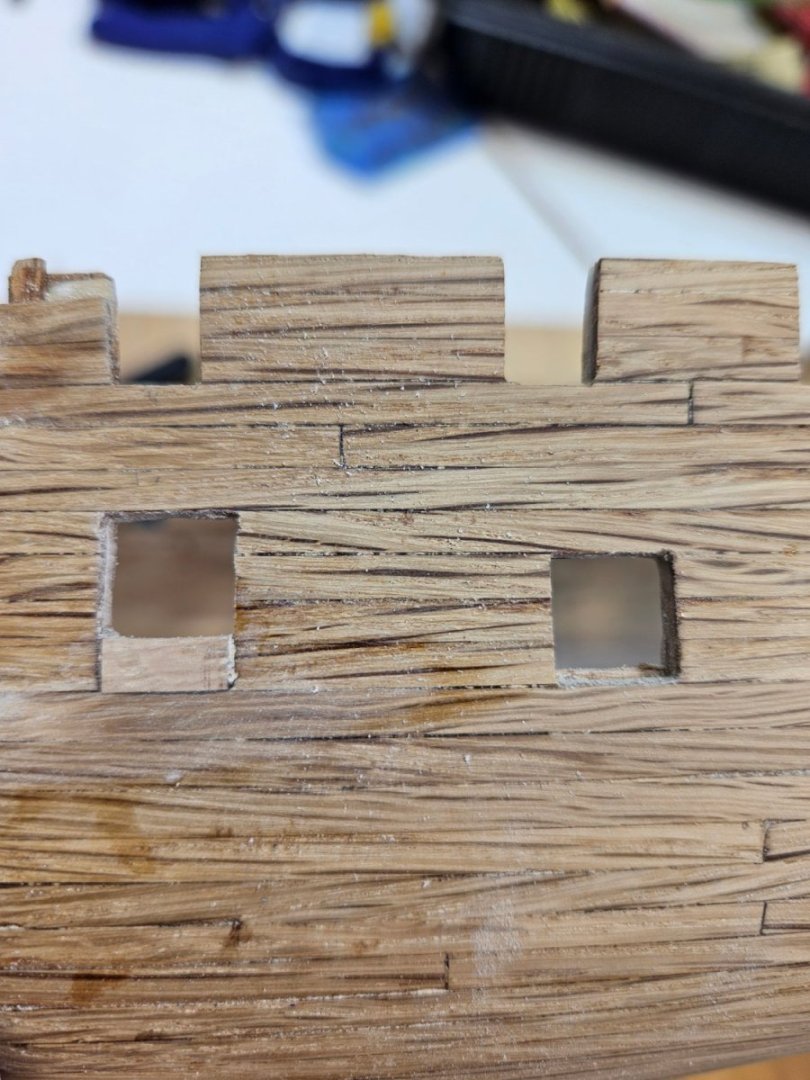

So....scratch all that I posted on on December 17th. It is not working out as I had envisioned. After checking the size of the gun port lids (.36" square) and looking at another Constitution build log, I changed course and lined the sill, header and sides with .02" planks. This finished off the port and gave me acceptable corners. Here is the finished port for the first one.

-

Bill Morrison reacted to a post in a topic:

USS CONSTITUTION by Brian Falke - BlueJacket Shipcrafters - Scale 1:96

Bill Morrison reacted to a post in a topic:

USS CONSTITUTION by Brian Falke - BlueJacket Shipcrafters - Scale 1:96

-

Bill Morrison reacted to a post in a topic:

USS CONSTITUTION by Brian Falke - BlueJacket Shipcrafters - Scale 1:96

Bill Morrison reacted to a post in a topic:

USS CONSTITUTION by Brian Falke - BlueJacket Shipcrafters - Scale 1:96

-

Bill Morrison reacted to a post in a topic:

USS CONSTITUTION by Brian Falke - BlueJacket Shipcrafters - Scale 1:96

Bill Morrison reacted to a post in a topic:

USS CONSTITUTION by Brian Falke - BlueJacket Shipcrafters - Scale 1:96

-

Bill Morrison reacted to a post in a topic:

USS CONSTITUTION by Brian Falke - BlueJacket Shipcrafters - Scale 1:96

Bill Morrison reacted to a post in a topic:

USS CONSTITUTION by Brian Falke - BlueJacket Shipcrafters - Scale 1:96

-

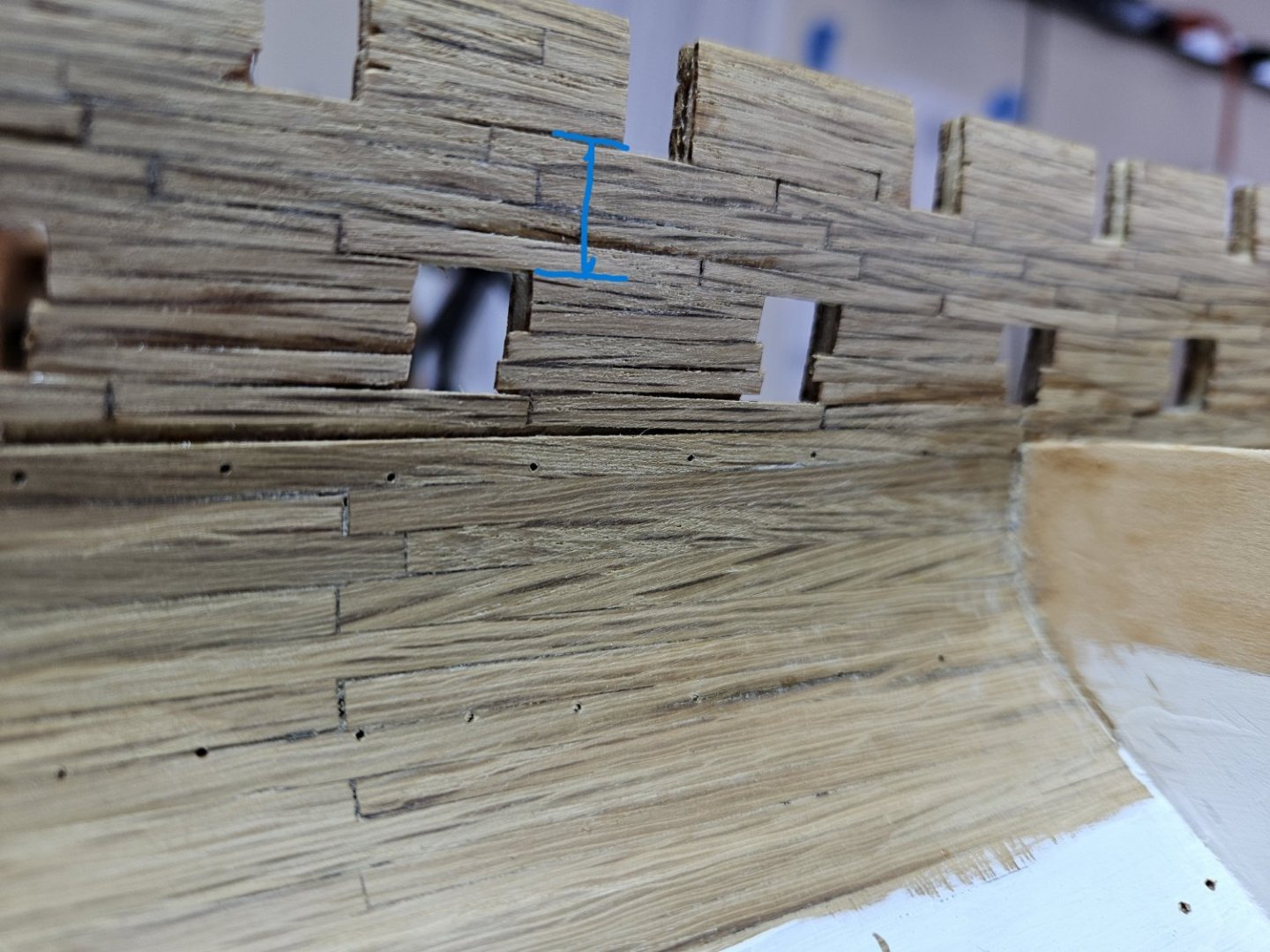

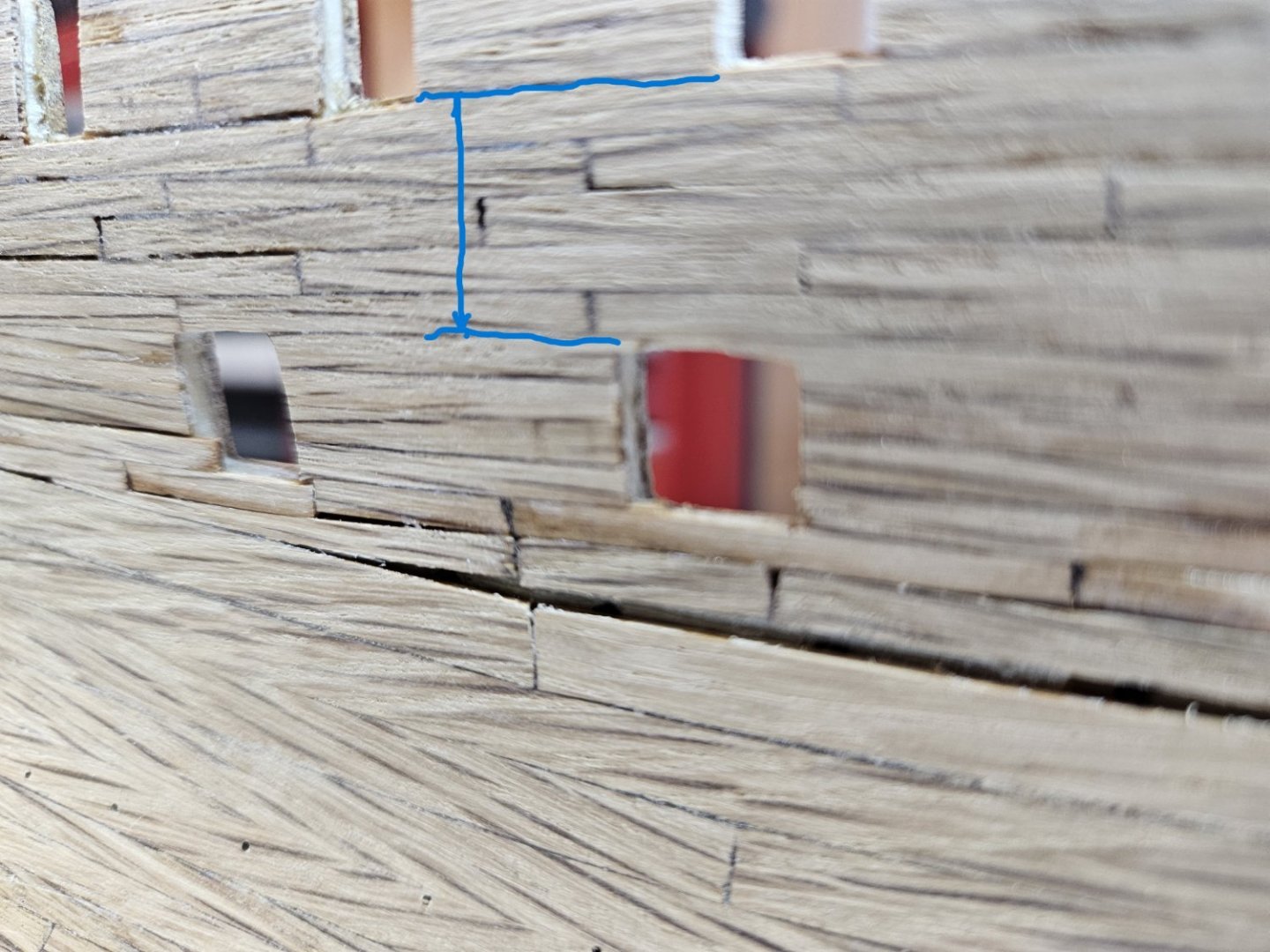

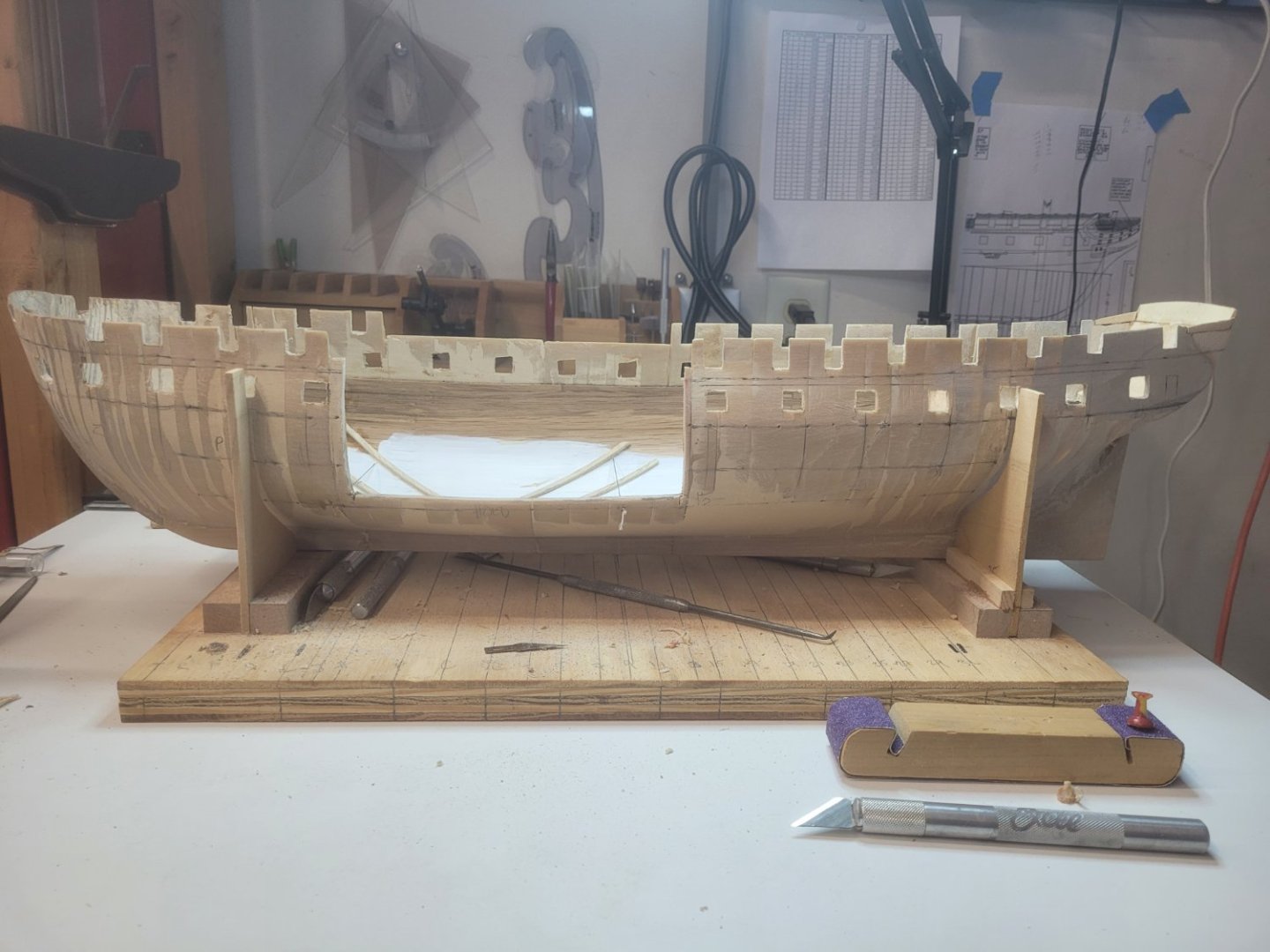

My next challenge after "raising" the gun ports was to square off all gun ports. Those on the gun and spar deck. The openings on the spar deck had a tendency to flare outward at the top of the gun port, and those on the gun deck had rounded corners and, if I tried to square the corner, it would round the side since I would put too much pressure toward forming the corner. I knew that I needed to fill in the sides of the gun ports with plastic wood and sand them down square. But, without a metal template, I would just be repeating what I already have. I did find a metal template that has a 3/8" x 3/8" square and a 5/16" x 5/16" square (through Amazon) which would work perfectly to help square off the ports. Using 80 grit adhesive backed sand paper strip attached to a mini-file, I would sand the side of the gun port until the sandpaper scraped the metal template. I would then increase the grit to 220 and do the same, sanded until it scraped the metal template. To form the corners, I used a triangle shaped file so I would not have to use extra pressure to get the file into the corner. There are some minor touch-ups needed, but the shape is real close to being square.

-

GGibson reacted to a post in a topic:

USS CONSTITUTION by Brian Falke - BlueJacket Shipcrafters - Scale 1:96

GGibson reacted to a post in a topic:

USS CONSTITUTION by Brian Falke - BlueJacket Shipcrafters - Scale 1:96

-

GGibson reacted to a post in a topic:

USS CONSTITUTION by Brian Falke - BlueJacket Shipcrafters - Scale 1:96

GGibson reacted to a post in a topic:

USS CONSTITUTION by Brian Falke - BlueJacket Shipcrafters - Scale 1:96

-

Thanks Jon. Yes, it took me a couple of weeks to come to this solution. Just had to purchase some very fine tooth "keyhole" saw blades to accomplish. As for the wood, it is white oak. I am cutting, planning, and sanding each piece from stock white oak 6"x1" boards. Yes, a lot of waste in the process, but that is what I do best...turn perfectly good pieces of lumber into saw dust 😀. I will be painting as per the specs in the kit and will also copper plate the underwater hull.

-

Geoff Matson reacted to a post in a topic:

USS CONSTITUTION by Brian Falke - BlueJacket Shipcrafters - Scale 1:96

Geoff Matson reacted to a post in a topic:

USS CONSTITUTION by Brian Falke - BlueJacket Shipcrafters - Scale 1:96

-

Mr Whippy reacted to a post in a topic:

USS CONSTITUTION by Brian Falke - BlueJacket Shipcrafters - Scale 1:96

Mr Whippy reacted to a post in a topic:

USS CONSTITUTION by Brian Falke - BlueJacket Shipcrafters - Scale 1:96

-

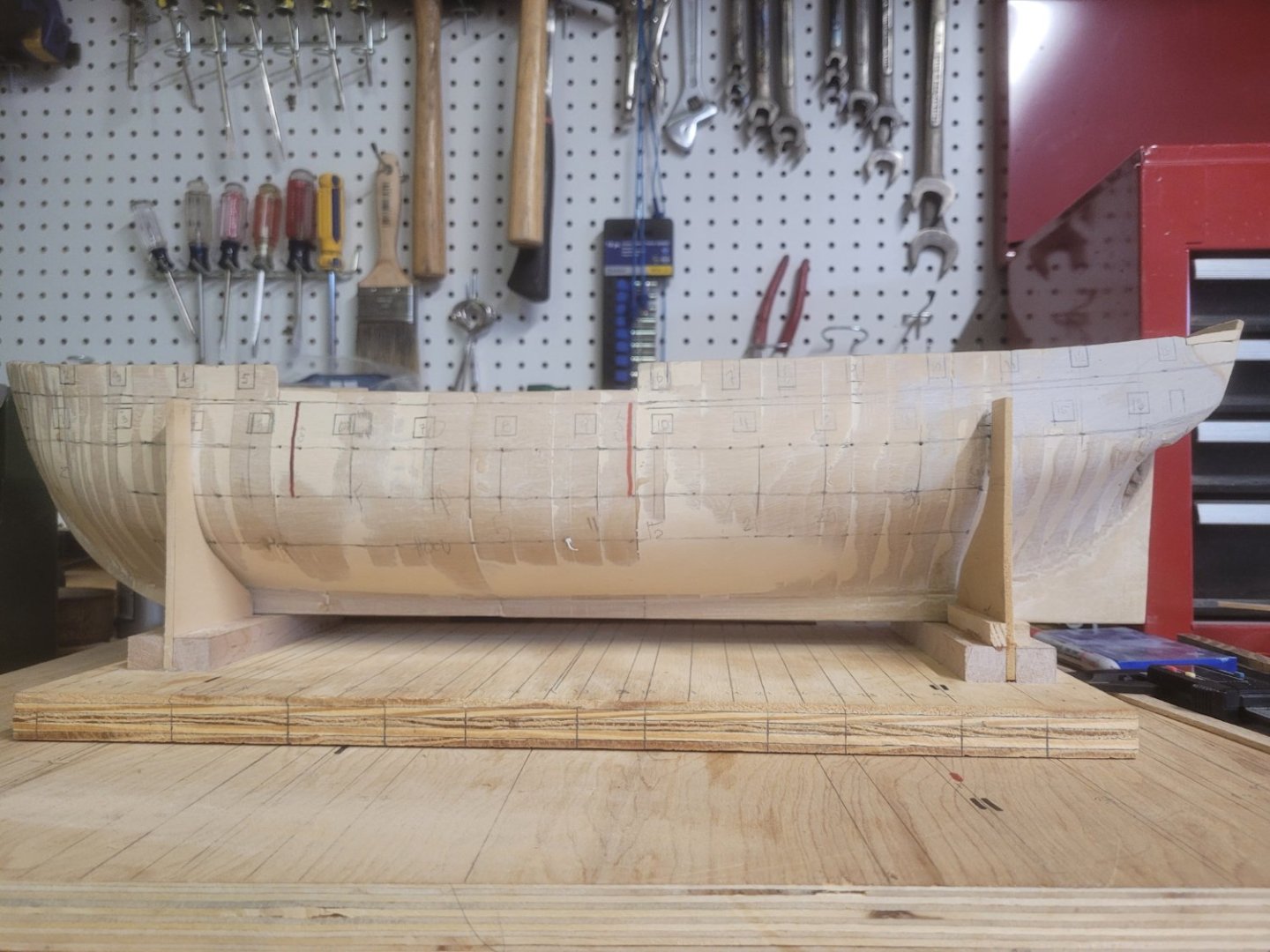

I have for the most part completed the interior planking. Upon inspection I noticed that on the port side, the gun deck gun ports were 1/8" lower than the starboard gun ports. That would be a foot which is significant difference. First picture is the starboard side, the other, port. The port side has 5 planks from the bottom of the spar deck gun ports to the top of the gun deck gun ports. The starboard has 4. Thankfully this was only limited to the gun ports on the aft section of the port side, 7 of them. My dilemma was how can I move them up and would it look good. Taking a deep breath, I cut a 1/8" section out of the top and sanded. Then, I glued a 1/8" piece of oak to the bottom and sanded that smooth with the interior and exterior hull and the bottom of the gun port. There, the gun port is now moved up the side by a foot, or 1/8". Now to do the other 6...

-

Avi, my only recommendation would be to do all you can to ensure the corners are pressed down. I too have given it thought on how to achieve a "smooth" surface with the platting and feel that pressing using a mini-roller would be my best option. Here is what I am referring to https://www.crutchfield.com/S-nanjTCMS645/p_15410005/Dynamat-10005-Roller.html?XVINQ=GZ0&XVVer=23B&awcr=628226750370&awdv=c&awnw=g&awug=9011556&awkw=pla-338049137464&awmt=&awat=pla&gad_source=1&gclid=CjwKCAiAmsurBhBvEiwA6e-WPCWYGGJauK5mjhW1Q49RQkdvHo2oMrQxcw7LQwMYGI3-J_hrBvPk9RoCTQQQAvD_BwE With a slight bit of pressure, you should be able to get the corners pressed down. Brian

-

It has been a slow go this past year. When I last reported, I was preparing to commence the exterior planking. I have finished the exterior, and started on finishing the interior. Since I am electing to use Live Oak as the planking material it does take time. I have 12" long pieces of 1"x 8" pieces of Live Oak stock that I have to rip with a table saw, then plane it down to 1/8" using a table planer, then using Micro-Mark drum sander/planer, down to .09". There is a lot of waste, but I don't have any other means to get the planks out of the wood stock. From there, using a band saw, I cut the planks (.04"). Through the sanding process, I sand off about .01" to get the correct thickness. Here are the pics. As you can see, I have already started on the interior, working from the top to where I left off from the keel up. I apologize in advance, I have no clue why the bow and stern picture are upside down. I have tried multiple times to get it right, but just not cooperating.... Cheers, Brian

-

Avi, I have no recommendation with regards to coppering as I have not gotten to that point yet. But, I do appreciate you asking the question and @MrBlueJacket (Nic's) response. On to your initial question regarding the planking creeping up into the gunport or sagging down into. I just started the interior planking, so again, thanks for the insight. If I were to face this dilemma, I would trim (sand) the plank sagging down into the gunport and fill in at the bottom. My thinking is that once complete, it will be very difficult to view the planks at the top since the spar deck will be hiding that from view for the most part. And filling in at the bottom still leaves you with the option of sanding it down so that the gun is properly centered when run out. I do like the idea of building a mock gun. With that it would give you and idea if you need to fill in or trim the planking at the top or bottom instead of guessing. Brian

-

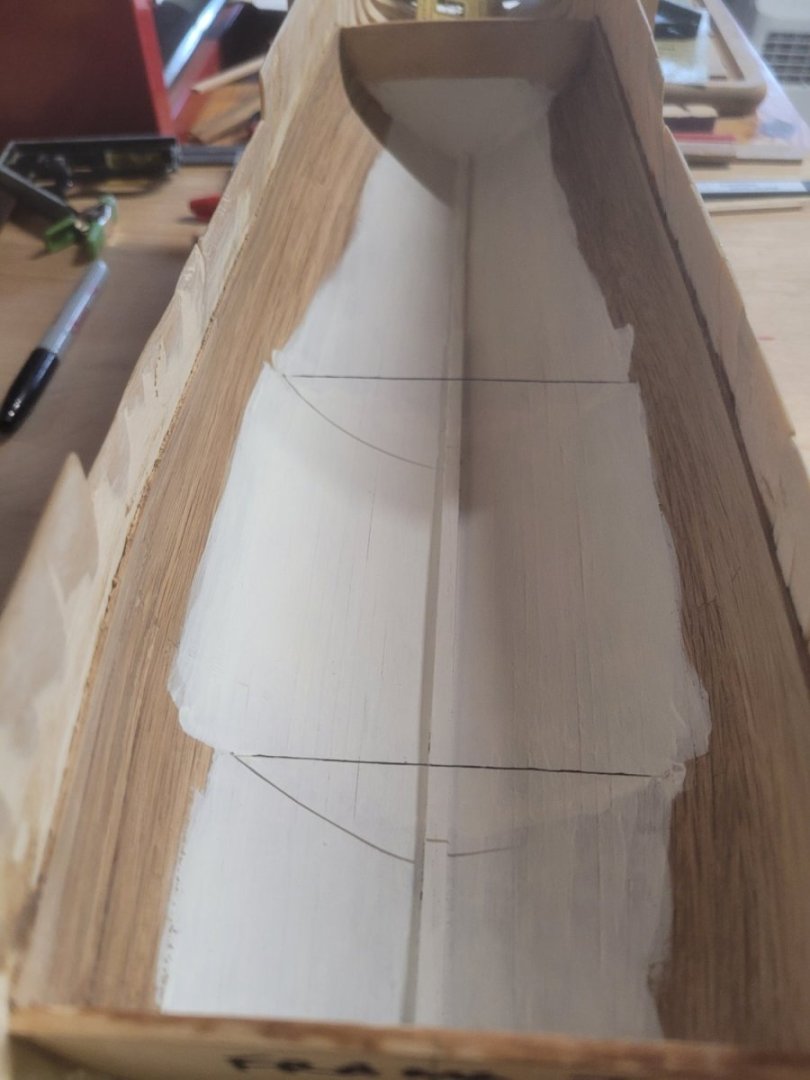

@Mort , those are my thoughts as well. just have to avoid the bright blue and pink gravel 😀 So took a huge step yesterday with the plan of being able to view all decks inside the ship. I cut out the section from the port side. It went easier than the gun ports. Used a Dremel saw to cut through the hull shell and interior planking. Above is a straight on view, below are looking aft and forward to give you an idea of what will be visible.

-

The gun ports have been cut. I will have to say, very nerve racking to go through that. To cut the ports I used two methods. The first was with a high speed drill using a 1/64 drill bit. I would make multiple passes as if I were drawing a line with the tip of the drill bit. The second method I used a hot knife with a 3/8in flat blade. It cut through easily, but left behind melted plastic which I did have to cut either with a knife saw or an exacto knife. Of the two methods, I would recommend using the hot knife. It was not without its problems, but comparing the results from the two, the hot knife was better. I have still to cut out the passageway for the quarter galleys and the port side for interior viewing, and mark the decks on the inside of the hull. Once those are complete, I foresee starting the exterior planking.

-

So, back to the topic regarding pig iron vs. stone ballast. Did a little more research and according to the USS CONSTITUTION Museum during 1812 the CONSTITUTION used pig iron as ballast but also gravel in the hold for the casks to rest on. With this, I will forego the pig iron and just add gravel to the hold before putting in the casks. Now to find 1/96 scale gravel...

-

I felt that I was ready to commence the exterior planking, but, I was wrong. I needed to transfer the gun ports from the 2D drawings onto the hull shell. Additionally, I wanted to mark the deck levels along the hull. This will aid me in the construction of the interior decks. Using the Waterline Marker as previously discussed, I marked out each gun ports lower left corner and using a draftsman's template, I outlined each gun port on the gun deck and spar deck. I found using the template as recommended in the Bluejacket instructions made this process very simple. Here is the port side. The red vertical lines are where I intend on cutting the hull out to see inside the ship. I have not yet decided where the cut out will be for the Orlop Deck. I know that it will include the main hold and aft. But how far aft, not sure yet. So, my next move was to define the main hold on the inside of the ship. I marked the after line of the forward section of the Orlop deck and the forward line of the after section. I drilled a very small hole horizontally through the hull at those location on both port and starboard side. I ran a piece of small stuff through one hole to the other and super glued them in place. Below is a picture of the string through the hull (looking aft). As you can see I also painted the hold areas in preparation of installing the Orlop deck beams. I was already to proceed with that process when I had one of those duh moments. I forgot to install the diagonal riders. So, I need to sand down the paint to bare wood and then install the riders. Now a questions for the group. Constitution's ballast in 1812 - granite stones/boulders or pig iron? I am leaning towards pig iron. Here is why. In my research the initial ballast was pig iron and this was replace in 1813 with granite stones/boulders during a shipyard period. The battles with HMS Guerriere and HMS Java occurred in 1812, before the change and, during the battle with Guerriere is where Constitution earned her motto "Old Ironsides". So, 1812 is the year I am going for. However, I have seen a number of Constitution hull cross section models and they all have granite stones/boulders as ballast. So, I am leaning toward pig iron, but have my doubts.

-

Thank you for the bow on view. I am struggling with wrapping my mind around the tapering of the planks as they approach the bow. It looks as if you did a very fine job with that. The planks meet perfectly at the bow from port and starboard, and have a slight up sweep. To me, it looks great and sure once you sand and paint, you will be pleased with the work.

-

Brian Falke reacted to a post in a topic:

USS Constitution by Avi - BlueJacket Shipcrafters - 1:96

Brian Falke reacted to a post in a topic:

USS Constitution by Avi - BlueJacket Shipcrafters - 1:96

-

Thanks Jon. With the dimensions from the drawings you provided and me stepping away from the problem for a day, I am sure that I have it figured out. The measurement from the deck to the bottom of the gun port is actually from the top of the deck beams, not the top of the finished deck. Subtracting the height of the gun barrel (.38) from the height of the center of the gun port (.4375) yields .0575. Converting that to 1/8in scale is roughly 5-3/4in, which is roughly (close enough) the thickness of the deck planking. I should be good to cut the gun ports now. Thanks.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.