-

Posts

222 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Long9Ron

-

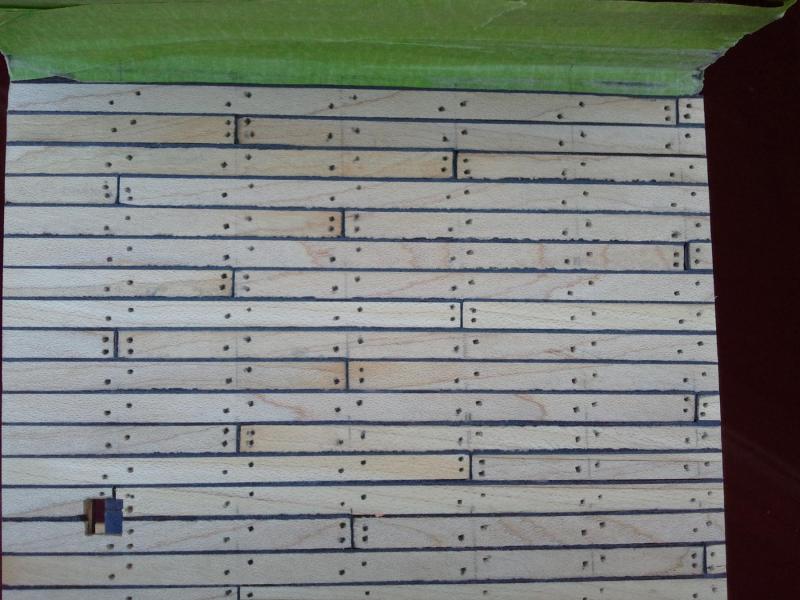

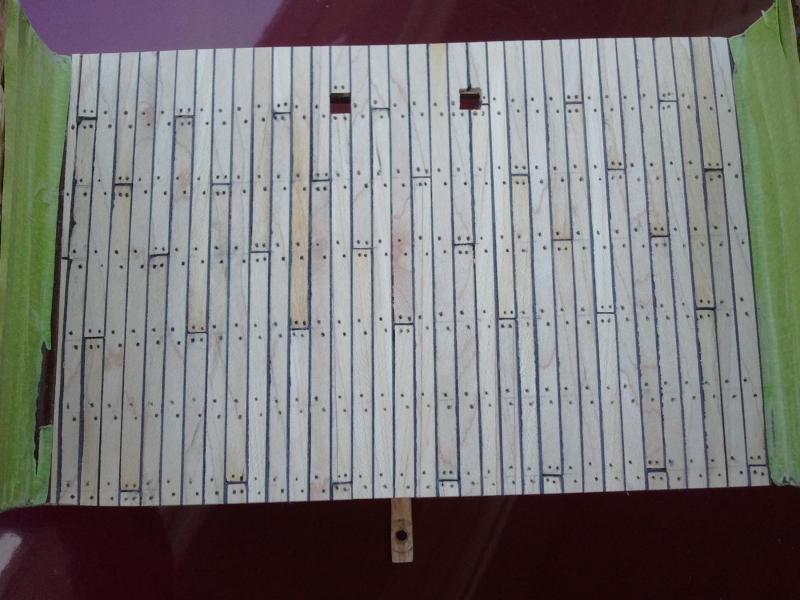

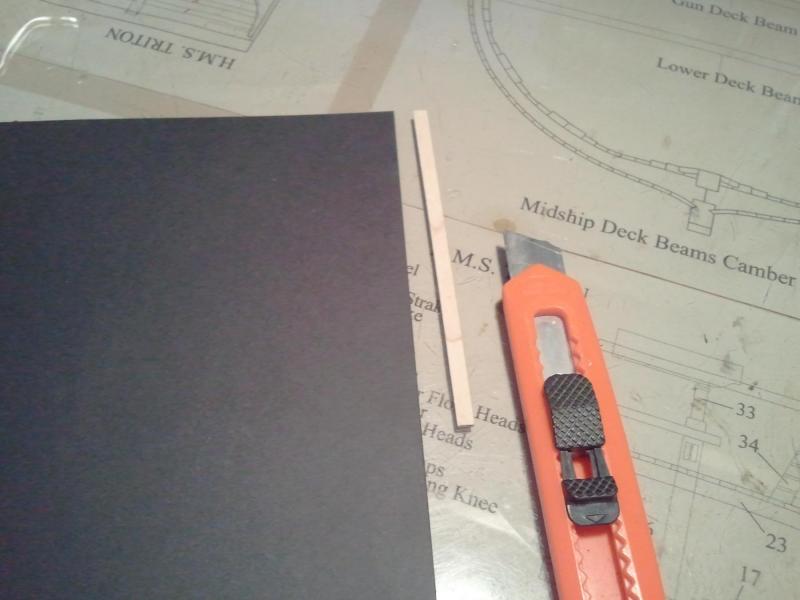

It's been about two years and I'm now in the mood again to work on my H. M. S. Triton (cross section). I want to get it finished. I got very discouraged about the build after I started it because I was being a bit of a perfectionist. I now realized that I don't need to be a perfectionist. I just need to be me and to have fun with the build and want ever the build turns out to be will be alright. Anyway, I'm back and I'm glad. I can't seem to find my build now. I guess I was away to long. Anyway, I will dust off the spider webs and get busy. Ron

-

Wow. Just Wow... Came across your build and starting reading it and I love the way you have added your own ideas to make it your build. You build fast but nice (very nice). You have inspired me to get back to building my cross section. Looking forward to seeing your completed build, and I believe that will be very soon. lol

-

I saw your build and have decided to follow it, but I'm not familiar with the Royal Louis. Is there a little history on the ship that you can past along? It looks like a beautiful ship to build.

- 786 replies

-

- Royal Louis

- Finished

-

(and 1 more)

Tagged with:

-

My Homemade Wood Lathe

Long9Ron replied to Long9Ron's topic in Modeling tools and Workshop Equipment

The drill that I use is an old Sears variable speed drill. It's range is from 0 to 1200 rpm. Running at 3 amps. It's not very fast, but will do in a pinch. It is also hard to hold a square piece of wood in a three prong chuck. When it runs for a period of time it does get a bit hot. Higher speed, with a capability of controlling the speed, would be a better choice in my opinion. I made this when I was first starting out with ship modeling and saw some DIY lathes, so I decided to make one. There are a lot of better DIY lathes out there. I hope your DIY lathe project turns out the way that's best for you. -

Paddy I think you're doing a great job. The framing looks very nice. I think that I will have to start getting some more books on ship building. I didn't know about the copper spikes at all. I will have to start doing more research on the building of wooden ships before the 1800's. I'm learning so much from all the builders on MSW, it's great.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.