-

Posts

337 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Rob S

-

- 392 replies

-

- 392 replies

-

She’s a beaut mate! Very nicely done and a joy to watch!

- 20 replies

-

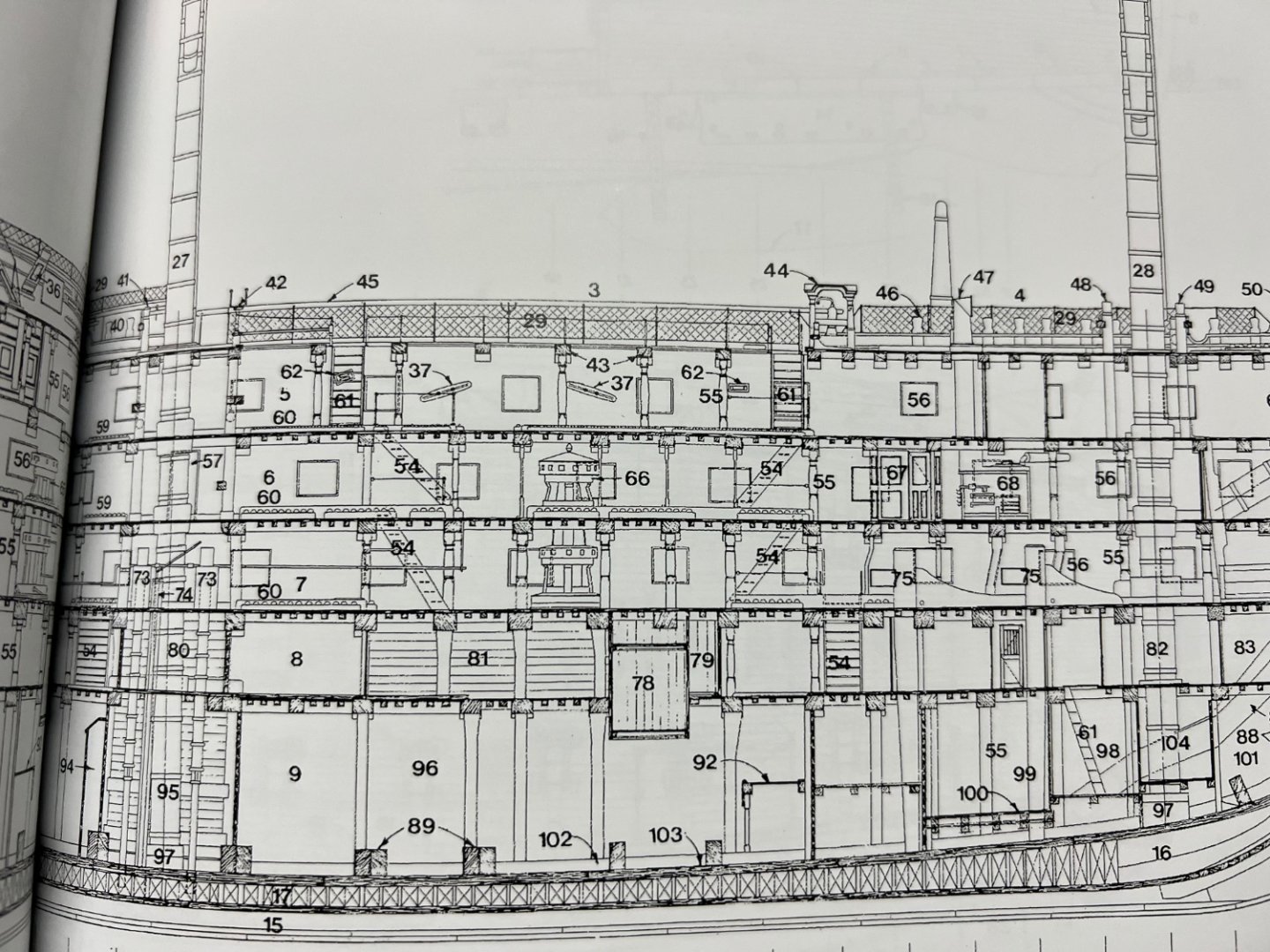

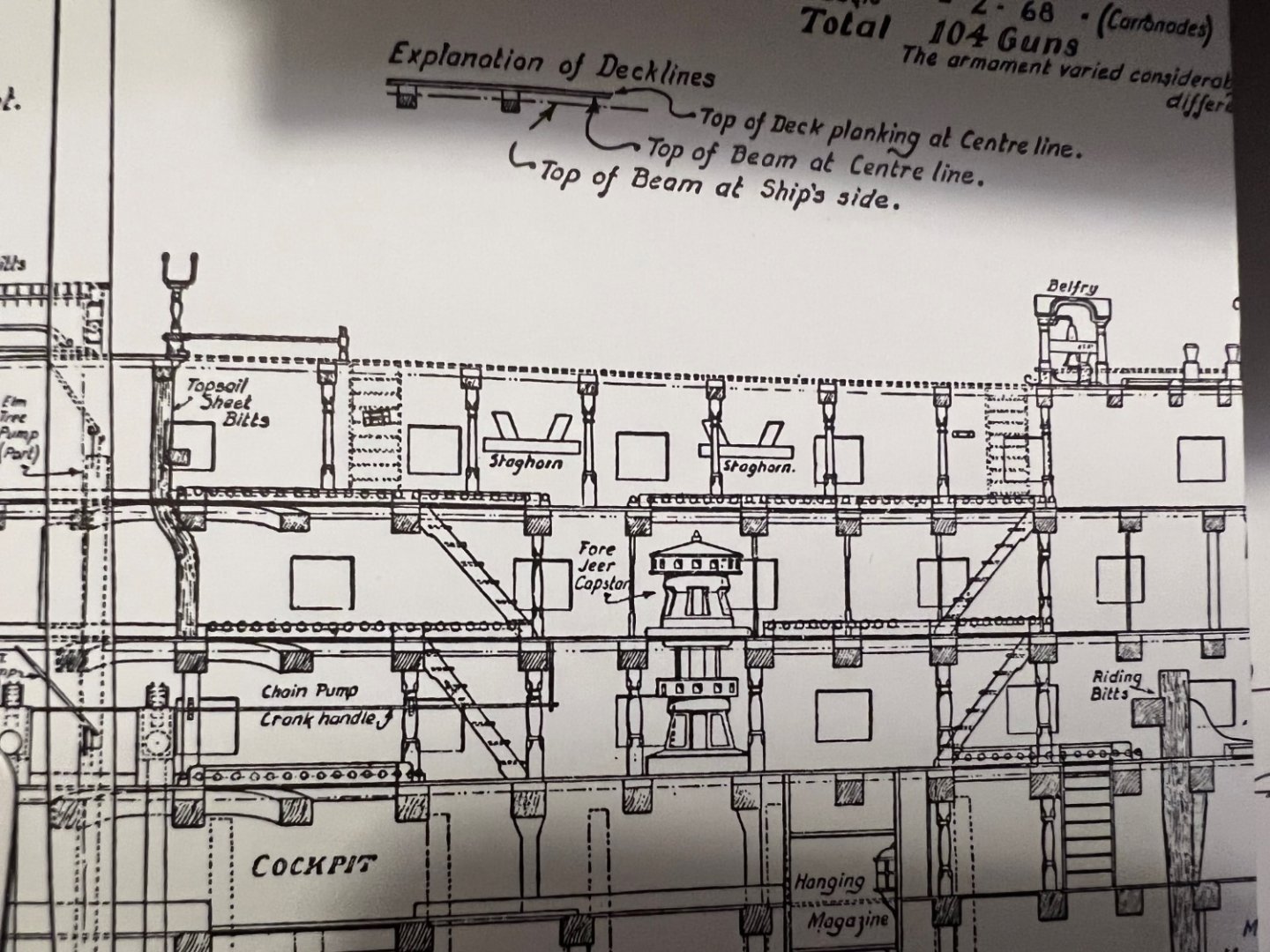

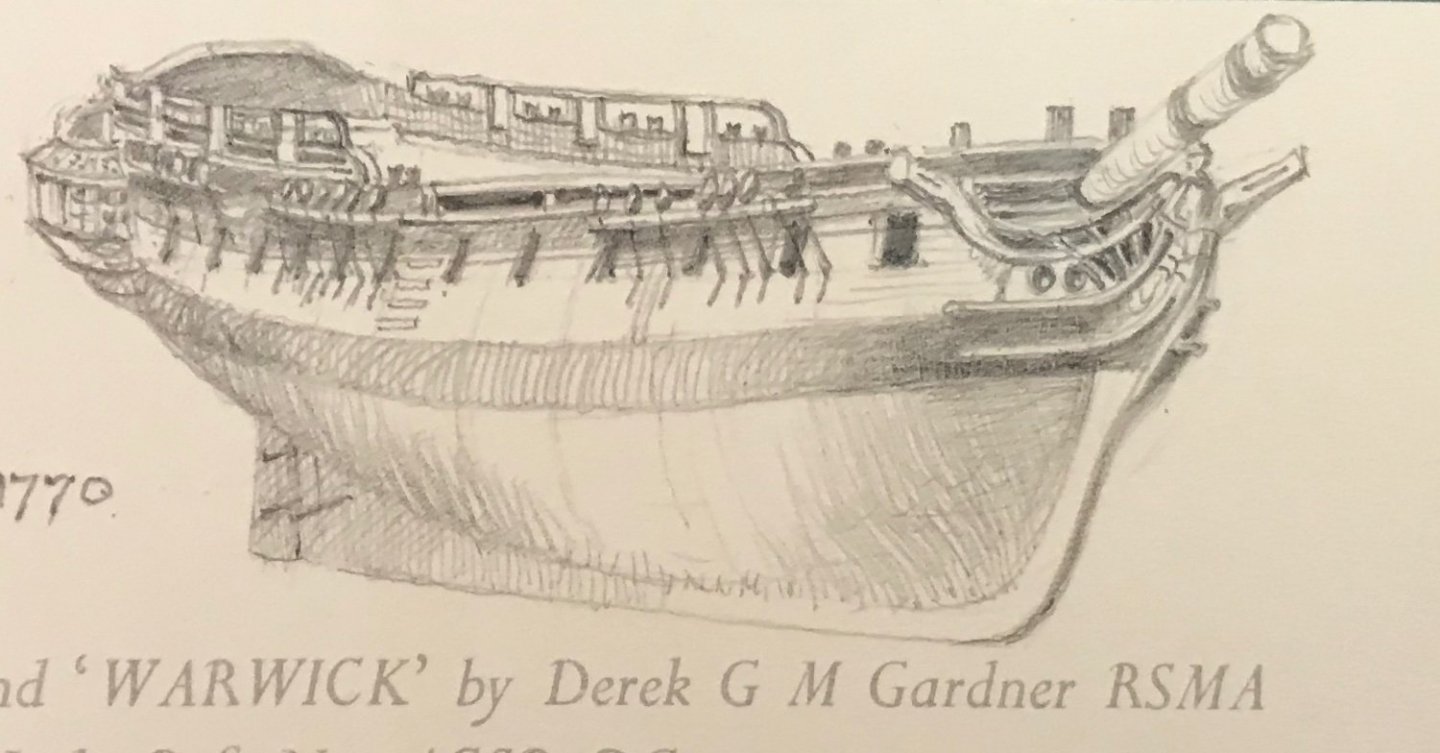

The skid beam pillars are also shown in McKay’s ‘The 100-Gun Ship Victory’, page 38. Rails are depicted on page 40, but the rail material is not specified.

- 392 replies

-

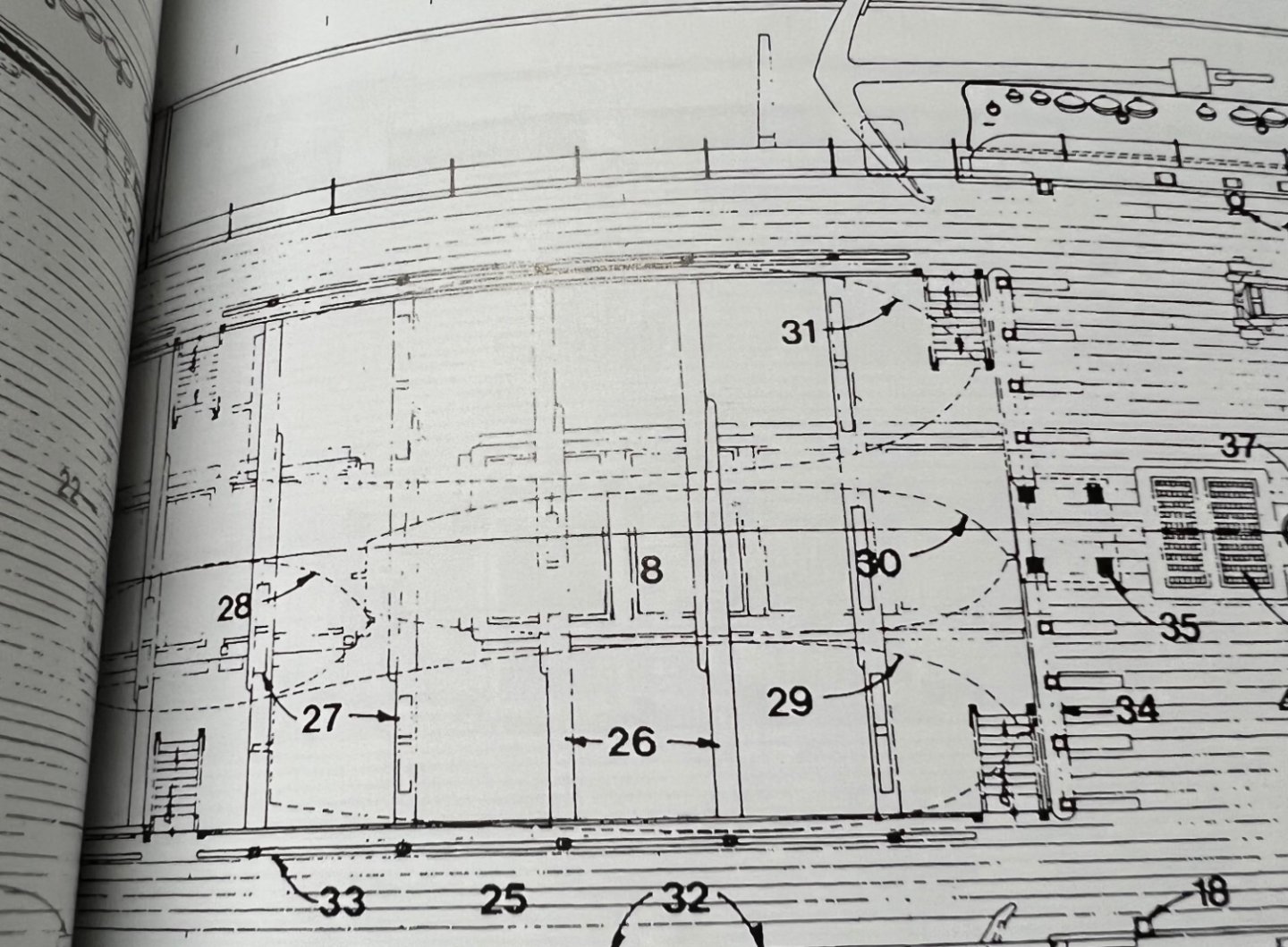

Thanks Allan. The skid beam pillars are shown in Longridge’s book ‘The Anatomy of Nelson’s Ships’, Plan #1. See attached. I’ll look at the railings. In either case, they both were included with the kit and shown in the instructions.

- 392 replies

-

- 392 replies

-

- 392 replies

-

Installing the ropes between the quarterdeck railing. Challenge is keeping the rope taut as I work the knots. Here was the process for the first rope. I’ll look in the rigging section for tips on doing this correctly. Other than that, perhaps YouTube may have some tutorials I can watch.

- 392 replies

-

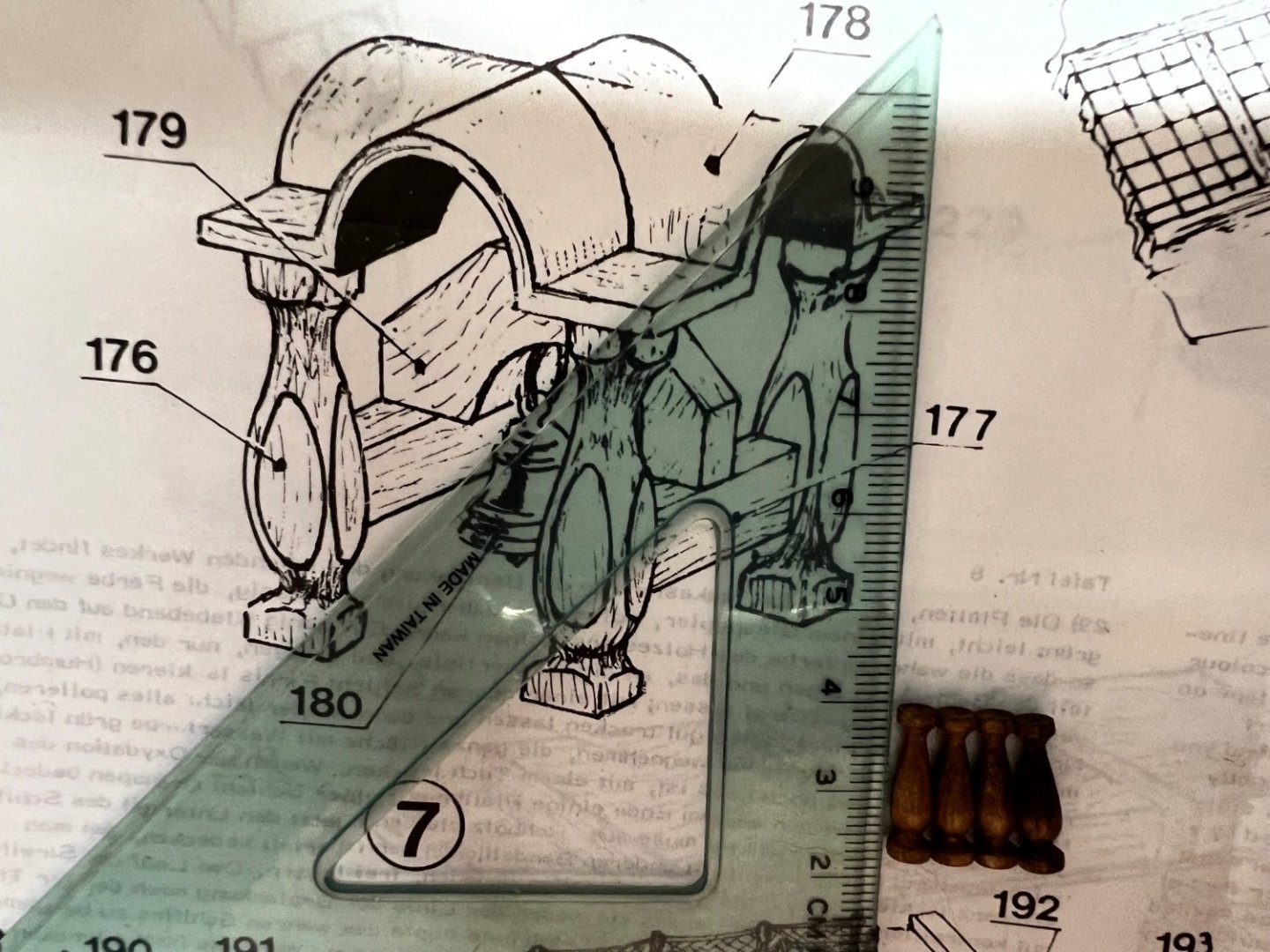

Thank’s for your kind offer Gregory. The balusters match up pretty well per the drawings with the mods shown. I just wanted to ensure I wouldn’t need them later. These 4 should do:)

- 392 replies

-

Looking for some help here folks. I’m starting the belfry buildup and not certain if I should be using the shown columns. It’s not clear in the Mamoli directions shown. I don’t want to use these in the belfry only to find out the pieces are required somewhere else in the build. It appears they would need to be modified as shown. Appreciate any thoughts on the matter. Thanks in advance!

- 392 replies

-

- 392 replies

-

Congrats on completing a beauty! Well done sir!

- 41 replies

-

- OcCre

- Santissima Trinidad

-

(and 1 more)

Tagged with:

-

- 392 replies

-

Tom - Welcome aboard! I started the Heller Victory in the early nineties, but alas never finished it. I’m looking forward to following along with your build. Finally, thank you for your service! Cheers, Rob S.

-

Very nice work! Clearly your woodworking skills and tools will be on display during the build process. It will be interesting to know the percentage of original Mantua kit used when it’s all said & done. My Mamoli Victory was purchased in the early nineties, started in ‘19 and I’m finding some of the wood brittle. Can’t imagine building a kit 20 years older! Anyway, I’m looking forward to watching your journey:) Rob S

-

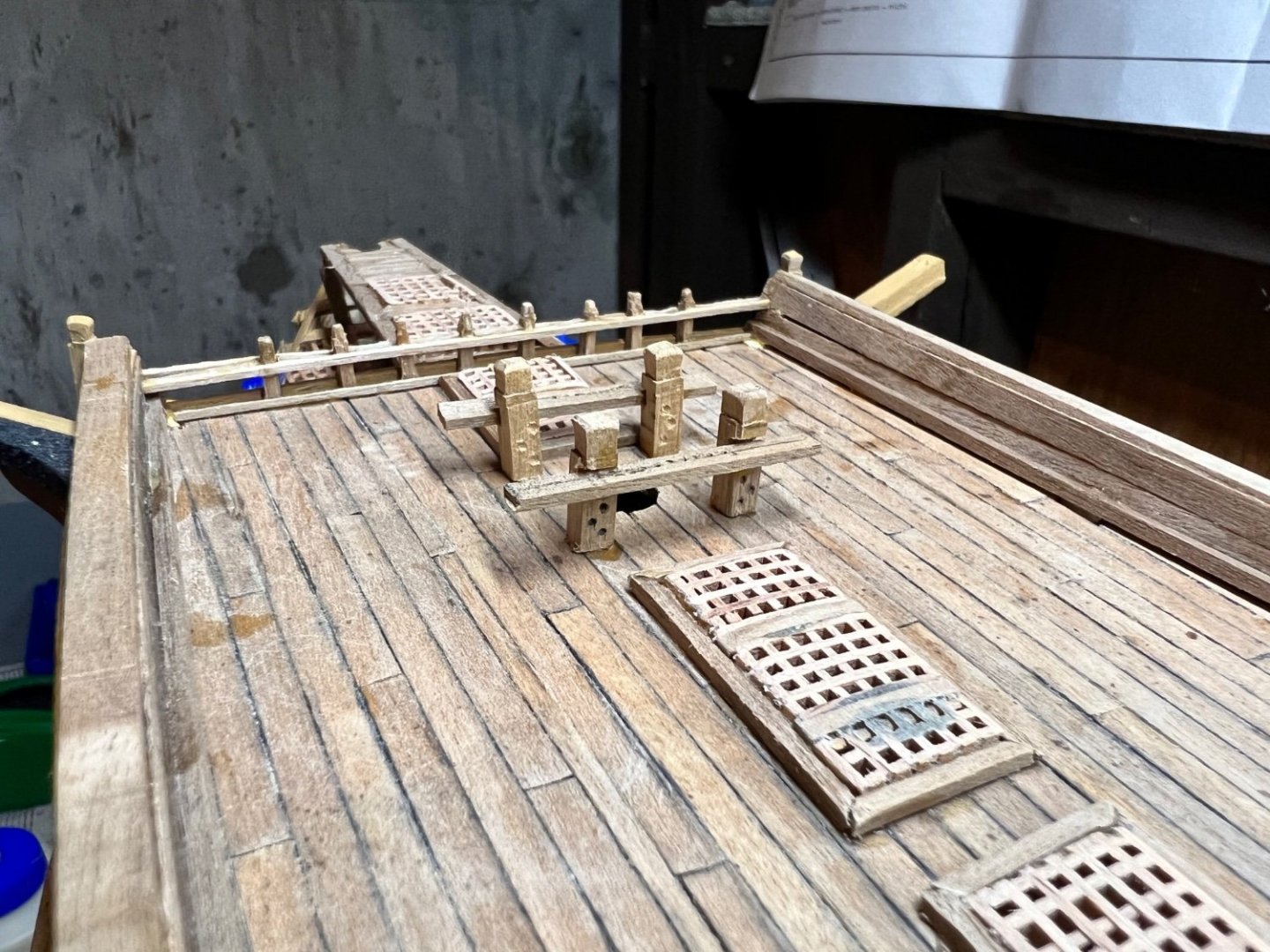

Thank you Allan; I will endeavor to address your comments in future activities. Here is how we stand as of now:)

- 392 replies

-

Measuring, shaping and installing the timber heads. Roughly 2mm x 3mm x 14mm dimensions. Eleven per side.

- 392 replies

-

Eck - You have a very nice ship in progress. You clearly have done this multiple times and know your way around these builds. Looking back I’m sure most of us ( I can!) can identify areas we would like to have done better. The ST is massive and must be a more difficult model to plank absolutely correctly, especially given scale. I hope you will focus on what is going right in your build as she looks splendid!

- 41 replies

-

- OcCre

- Santissima Trinidad

-

(and 1 more)

Tagged with:

-

- 392 replies

-

Looks like an informative place. Great Just Great

Rob S replied to rudybob's topic in New member Introductions

Welcome aboard Rudybob. You will certainly have a lot of material at your disposal. Glad you are here! Rob S -

Next step. Putting the small indents in for cannon balls is difficult because of the wood condition.

- 392 replies

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.