Steve Harvath

Members-

Posts

59 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Steve Harvath

-

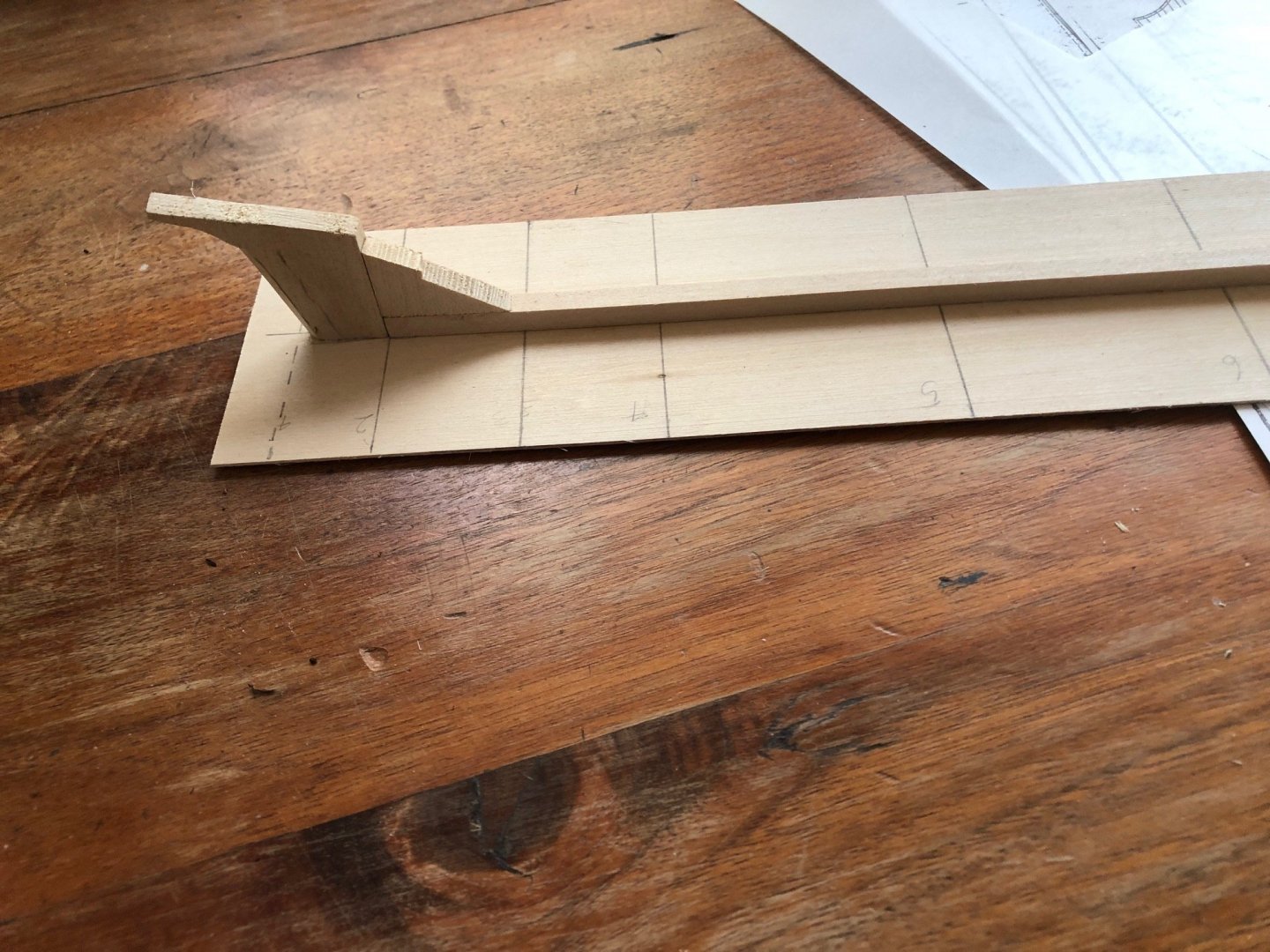

Chris, Stockton CA is still interesting. I love having a deep water port with several bulk carriers a week and a purpose built ship that just carries super long lengths of railroad rail. I traced the stem shape onto some vellum. I used white carpenter's glue to glue it to a 1/4 thick piece of Basswood. Coping saw, sandpaper and knife were used to carve it out.

-

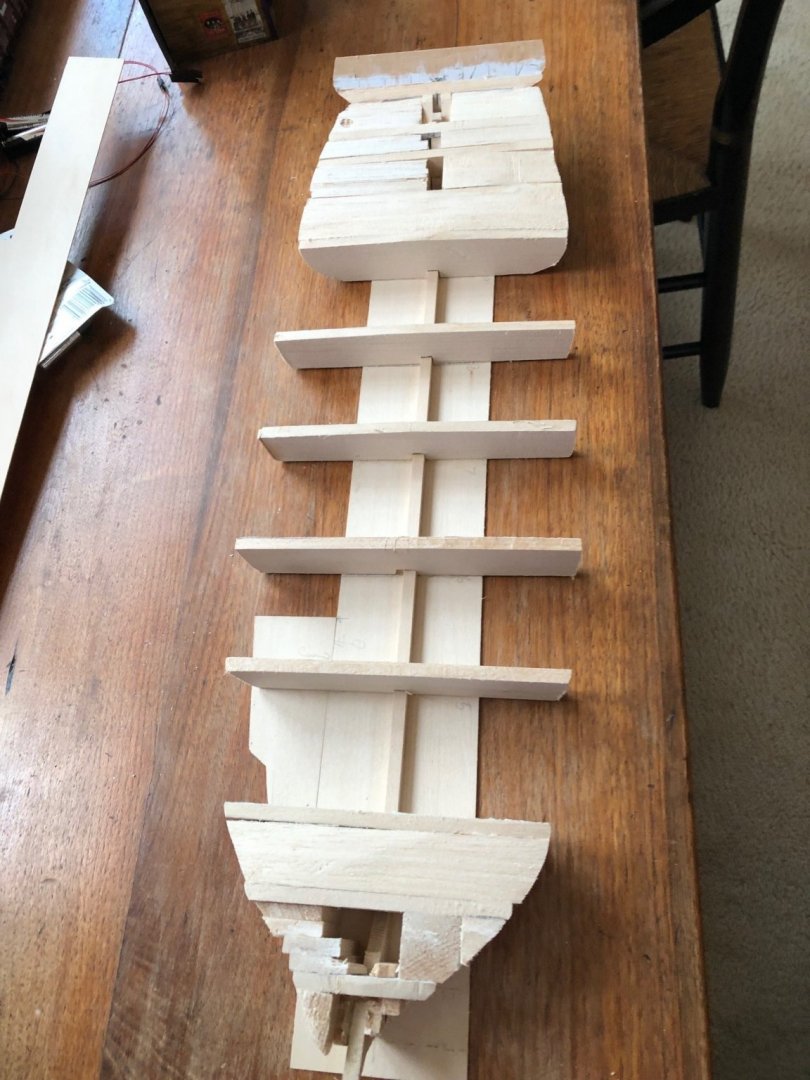

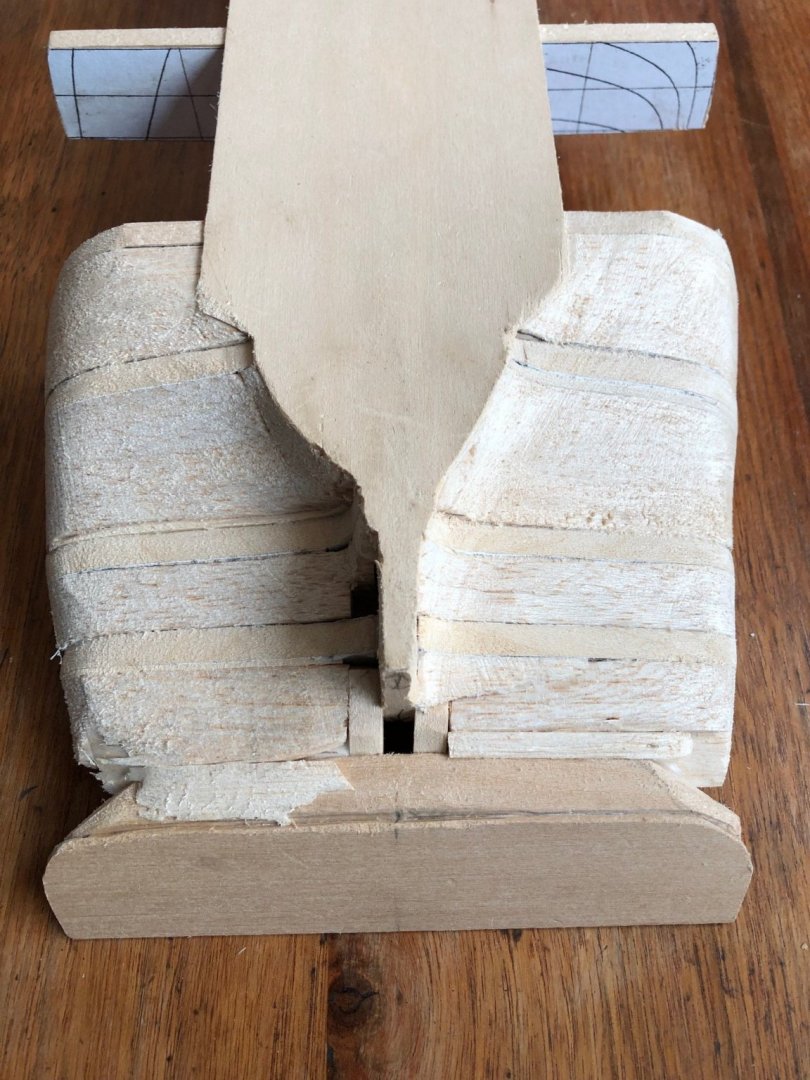

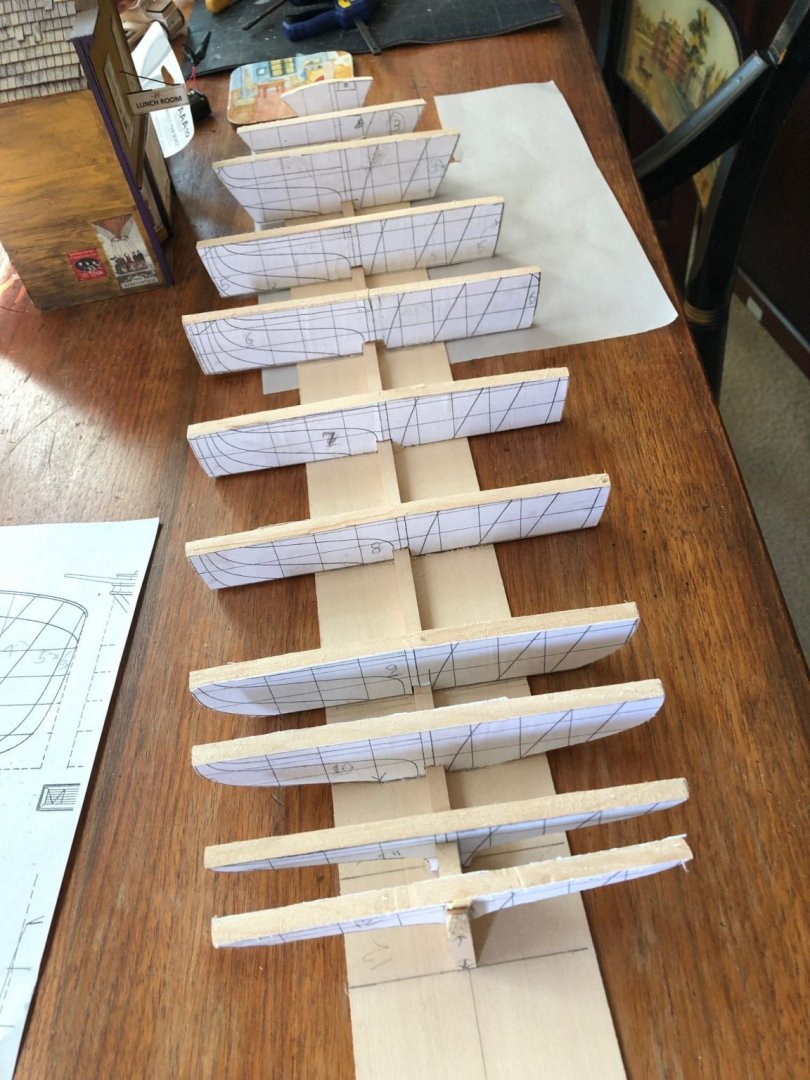

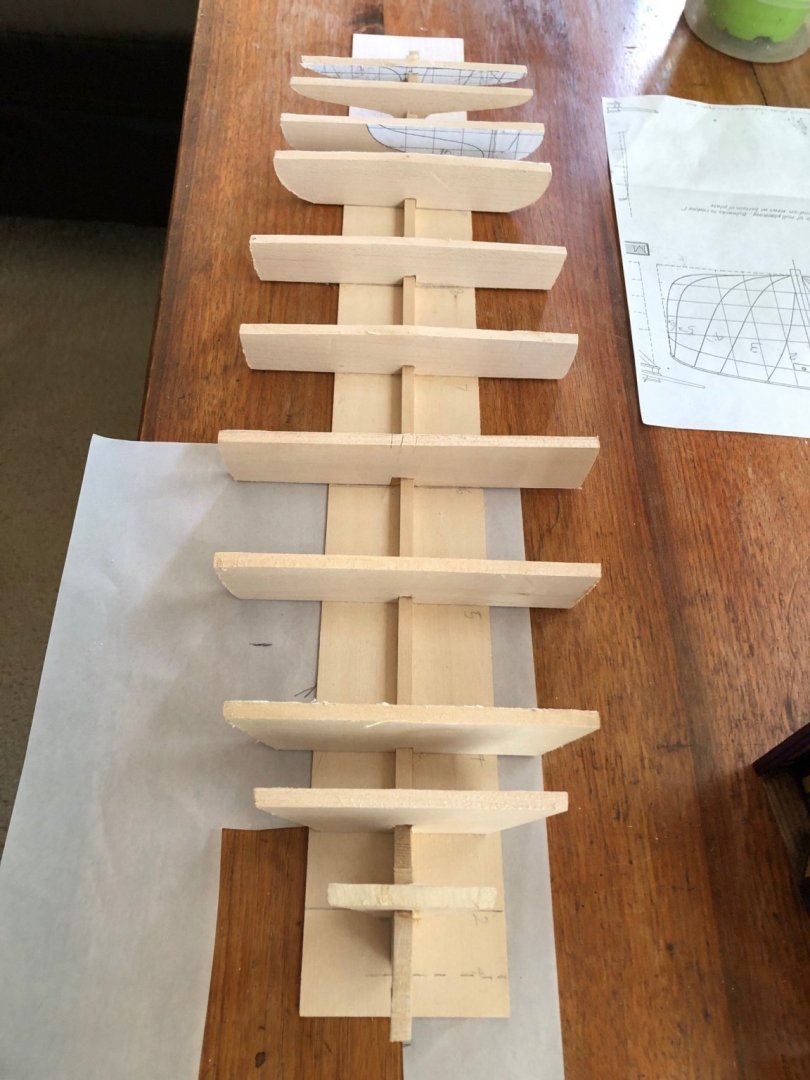

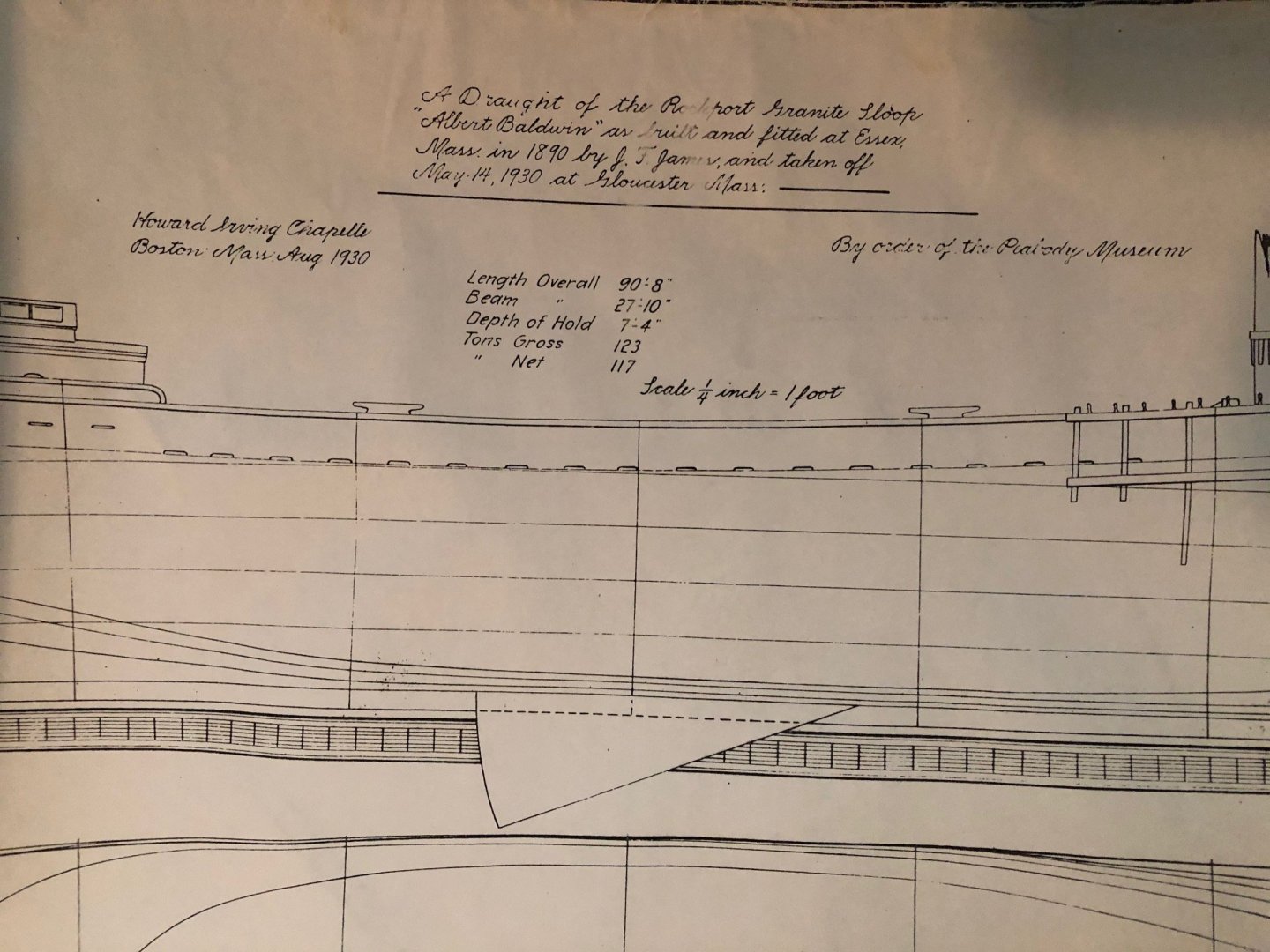

I have decided to build a waterline model of the granite sloop Albert Baldwin ca. 1890. It will fit in my harbor scene of the same period. The other craft and the wharf and railroad transfer bridge in the diorama are built to 1 inch equals 48 inch scale. I have the plans which are conveniently 1/4 inch to the foot scale. These are from 1930 by Howard Chapelle. I am planning on challenging myself and build it plank on bulkhead.

-

Very nice. I love that you are modeling a kind of watercraft would never have been in preservation. Dusty, everyday working craft that are hauled around a harbor. Contemporary commentators paid little attention to them because they were just there doing their jobs on the waterfront. I wonder if those grain barges came from the midwest via the Erie canal.

-

bateau 1881 by Steven Harvath

Steve Harvath replied to Steve Harvath's topic in - Build logs for subjects built 1851 - 1900

-

bateau 1881 by Steven Harvath

Steve Harvath replied to Steve Harvath's topic in - Build logs for subjects built 1851 - 1900

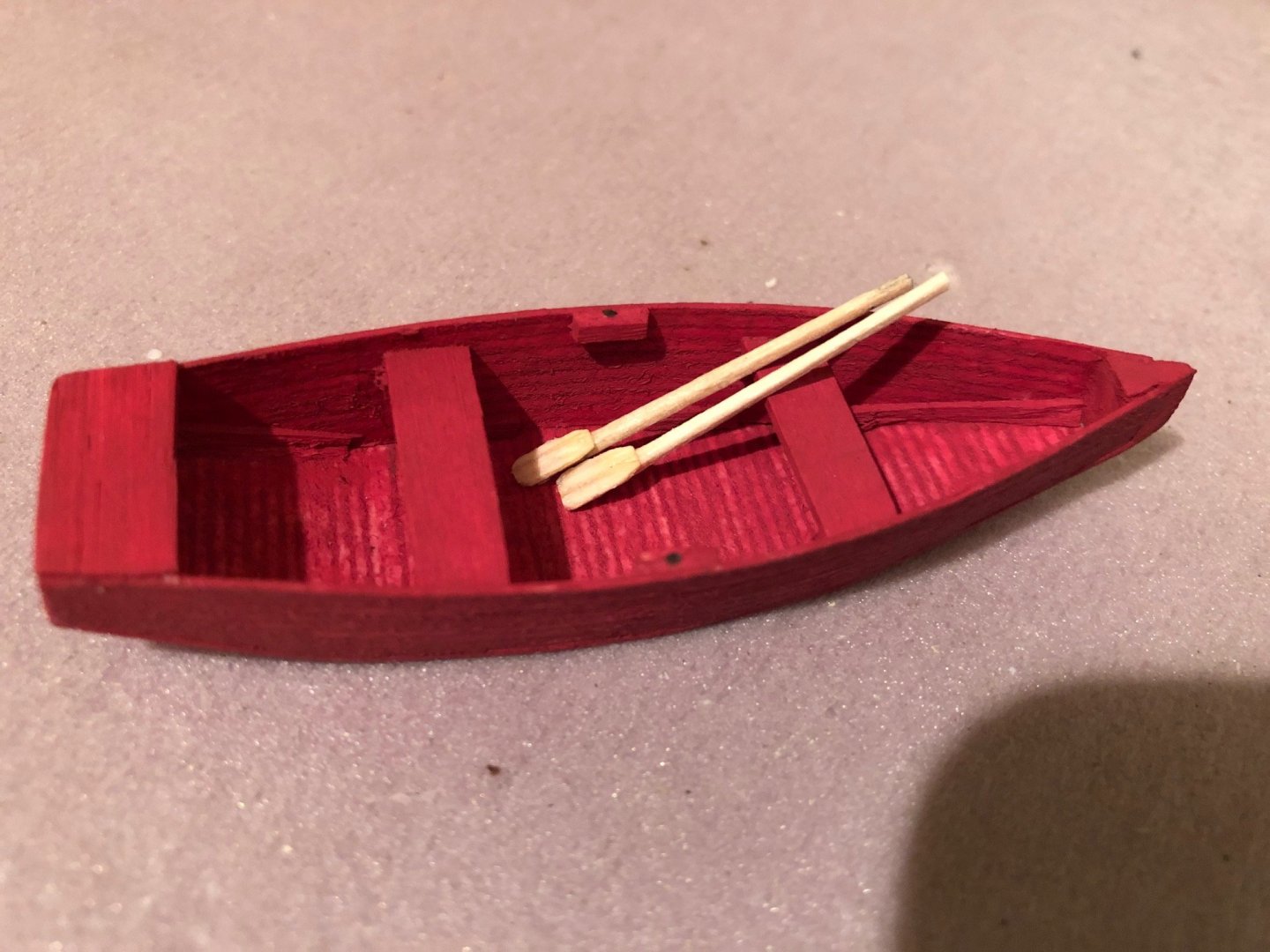

The seats are in. They are made of 1/32 basswood. I made them longer than the width of the boat so that they would serve to spread out the sides in a graceful way. The bamboo sides bent quite easily. Now I need to add some small side boards for the oar locks and make some oars. -

bateau 1881 by Steven Harvath

Steve Harvath replied to Steve Harvath's topic in - Build logs for subjects built 1851 - 1900

I glued the floor on. I added some pieces where the sides and bottom meet so the glue bond would be better. I have been able to thin these back a bit after the glued dried so they are less obvious. -

bateau 1881 by Steven Harvath

Steve Harvath replied to Steve Harvath's topic in - Build logs for subjects built 1851 - 1900

-

bateau 1881 by Steven Harvath

Steve Harvath replied to Steve Harvath's topic in - Build logs for subjects built 1851 - 1900

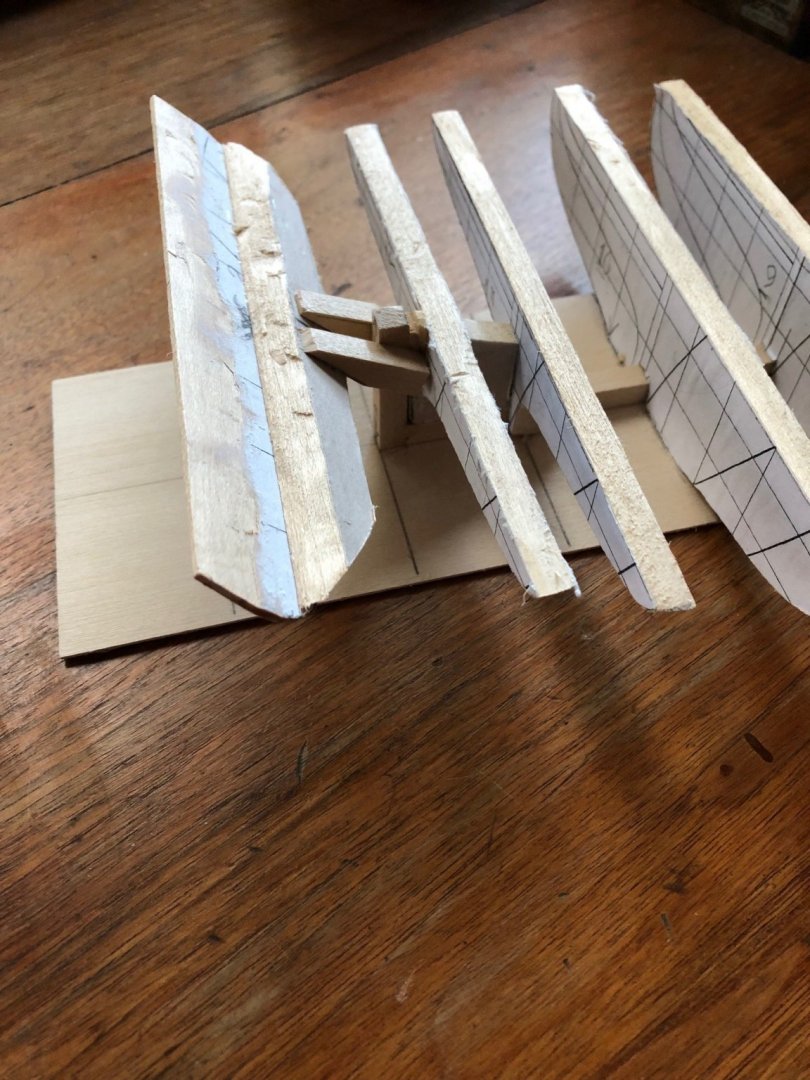

Following the instructions I carved a stem out of basswood and notched it to receive the side planks. The instructions for the boat have the builder attach three foot wide temporary braces at the center of the sides. These will define the shape of the boat when the sides are bent in to the stem and stern. I clamped them in place temporarily while I attach the stem and stern pieces. -

bateau 1881 by Steven Harvath

Steve Harvath replied to Steve Harvath's topic in - Build logs for subjects built 1851 - 1900

I found a piece of bamboo vaneer in my scrap box. It was a 4 by 4 inch sample that I picked up at a trade show a long time ago. It is very flexible and thin and should work for the sides of the boat. -

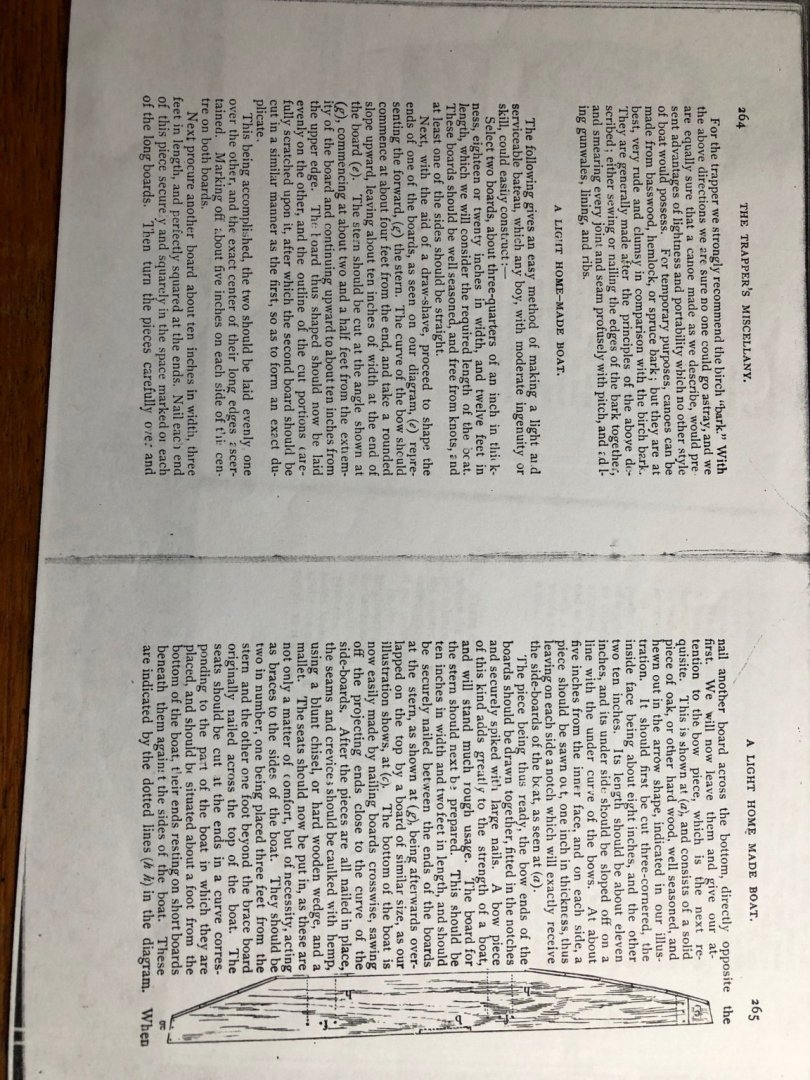

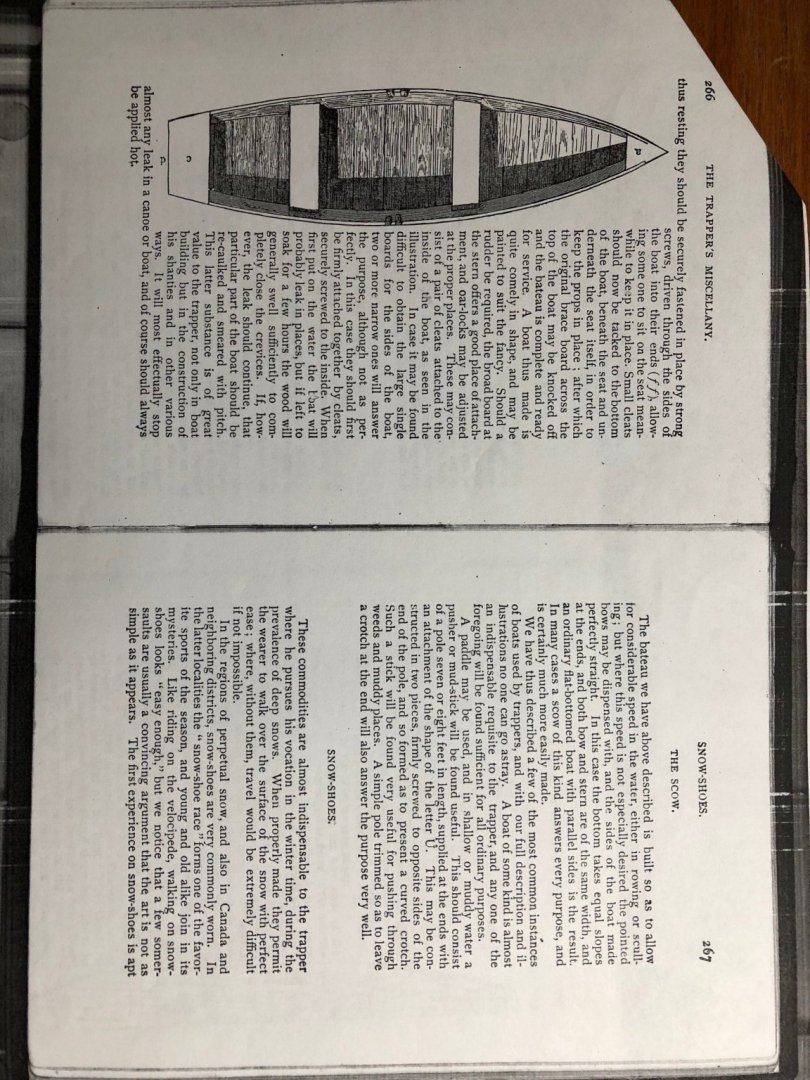

I decided to take a break from a big ship model building project and put together a small, utilitarian boat that would have been common in North American lakes and streams. I have detailed instructions for the building of a "bateau". It is from a book of instructions for how to become a fur trapper. It is called "Camp Life in the Woods" by W. Hamilton Gibson 1881. The author says "...a light, and serviceable bateau, which any boy with moderate ingenuity or skill , could easily construct...". I hope to live up to his expectations. Scale: 1:48 -- One inch to four feet.

-

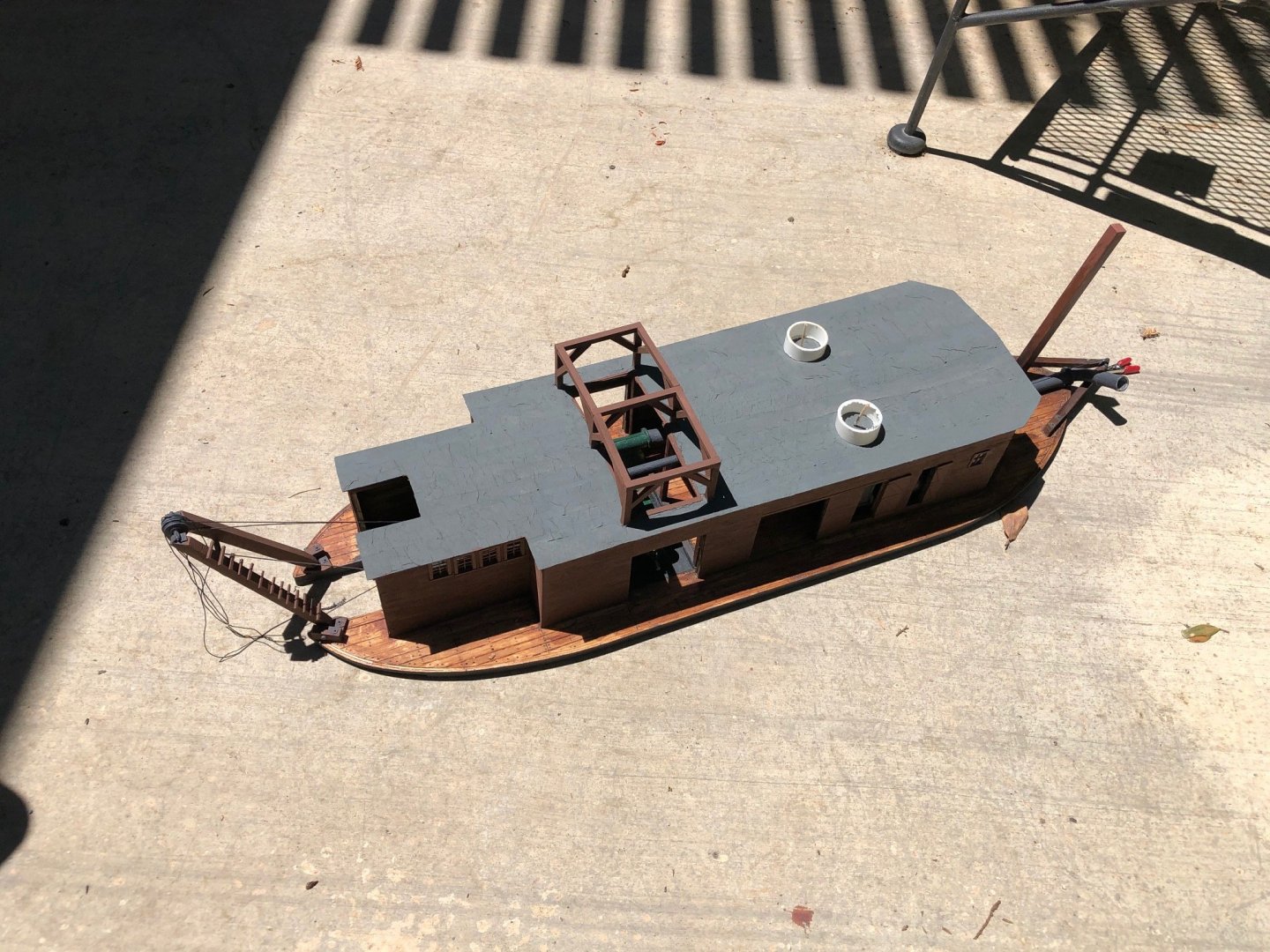

Finished (at least in my mind), I painted the stacks and added two vent pipes aft of the stacks. I think these would have been for the boiler safety valves or blow down. I think I will be weathering it a bit to look like it has been working. This might also bring some of the detail into sharper contrast.

-

I have made up the drip caps for the chimney stack bases. I made them out of a 'beware of the dog" plastic sign. The plastic is thin and takes rivet impressions and paint well. It also bonds well with the solvent. I am sure there is a way to design them with geometry. I just used a hit and miss method for the diameter for the center cut out and the outside edge.

-

I have applied the roofing to the deck house. In keeping with the rough hewn industrial nature of the dredge I simulated rolled roofing with that rare commodity -- toilet paper. I cut it into strips a scale three feet wide and applied it with a gray paint. It came out like it was kind of bubbling up and warping in the heat and humidity. Here re some images with the roof hatches on and off. I also found some plastic tubing that is a good diameter to represent the wider base portion of stacks. There must be a name for these. They insulate the roof from direct contact with the flammable roof.

-

I have finished roofing the deck house and applying trim under the eaves and at right angle corners. I decided to model roof hatches over the pumping equipment bay. I think you can see the edge of a roof hatch in the image of the as-built dredge. My thought has been that the heavy duty scaffolding above the roof was used to service the equipment below with chain lifts. I made the roof hatches removable so it is easier to view the interior. Doing touch up painting as I go.

-

Mississippi stern wheeler by kpnuts

Steve Harvath replied to kpnuts's topic in - Build logs for subjects built 1851 - 1900

Very nice stern wheel project. I have to put twin stacks like that on my hydraulic dredge. How did you build them?

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.thumb.jpg.febc4eca0190657ab59b2cb952af6877.jpg)

.thumb.jpg.9e54a5452ed20b4ca4292ec871c27a3e.jpg)

.thumb.jpg.f3b535b8058e042512f856089cebc5d7.jpg)