woodartist

-

Posts

116 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by woodartist

-

Is that a proxon mill setting on your bench? I have thought about getting one. I really like the Byrnes variable speed sander I got and was hoping to get their table saw. If they stay in business I will get one and get rid of my big one and get more room in the garage. I keep my bandsaw and other major tools in my garage to cut down on the amount of dust in my work area. I roll my bandsand and table saw onto the driveway to do any work and roll them back when I have finished. You have a nice set up!!

-

It is indeed. For me it's indispensable for shaping the planks. One feature I wish the table on the mill had was a feed drive. turning that crank for long planks by hand gets very old very quickly.

I looked at the upscale version, but the table on that didn't seem mechanized either. Note also the use of two vises to hold longer planks. Take a look at Mustafa's build log, he makes great use of the Proxon mill.

One tool I wish I had in a smaller size is a thickness drum sander. I could be making my own stock instead of struggling with the lousy material in that kit. Those 1/8" (3.15 mm) planks vary as much as 10% in width.

When we moved into the house we're in now, my plan was to move my woodworking gear from the basement of the old house to the new one. We opted to take our time with the move, so did not sell the old one immediately. As we were moving things out of the first into the second, I notices sawdust EVERYWHERE - despite having two dust collectors and the basement not being on the house's HV/AC vent system. That led me to the search for a small unit elsewhere, and I am glad I found the place I'm in now. I don't care (that much) about dust there, and if I want ventilation, I open the garage door in back and the man door in the front. Plus it gets me out of the house.

-

-

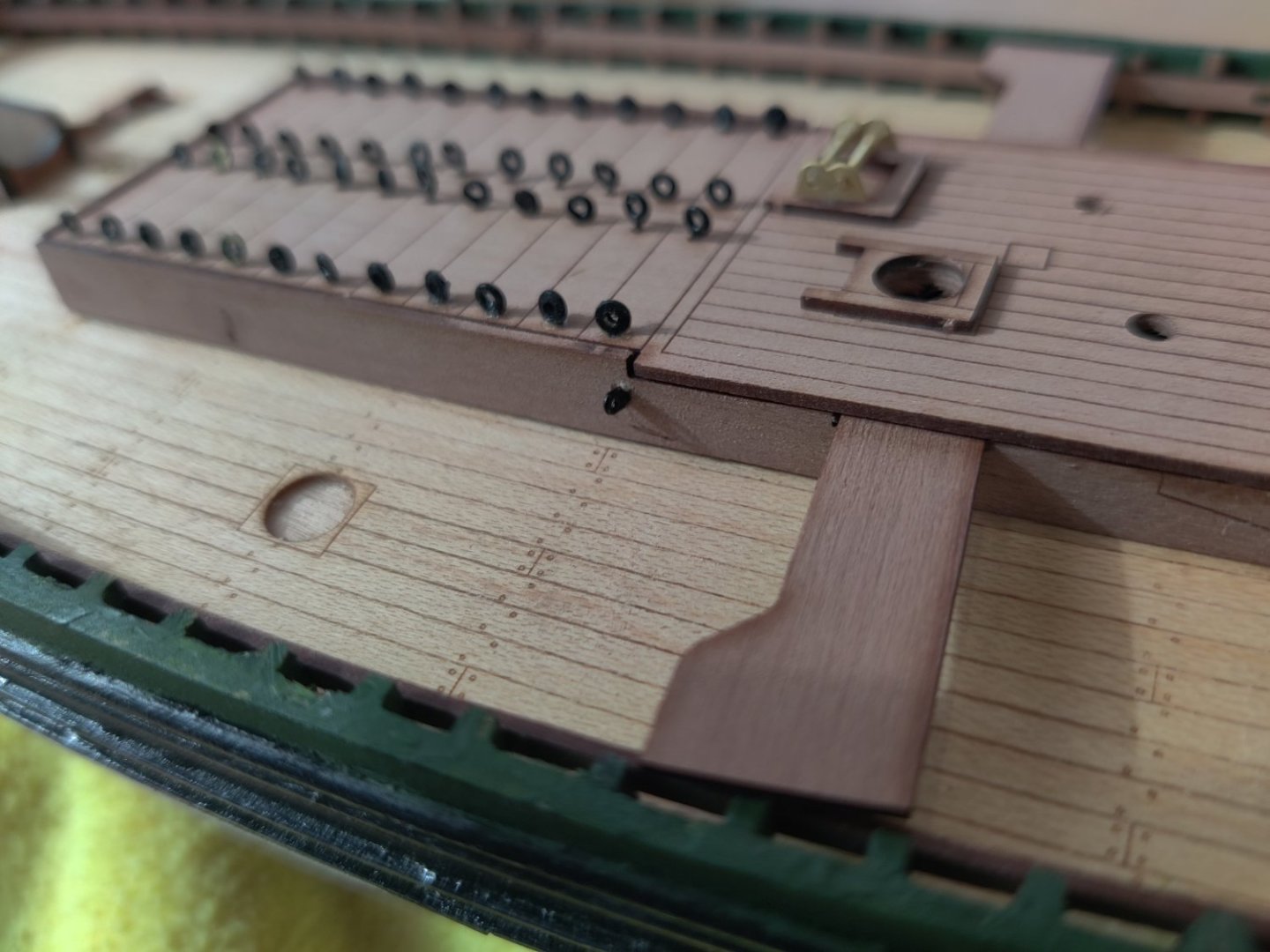

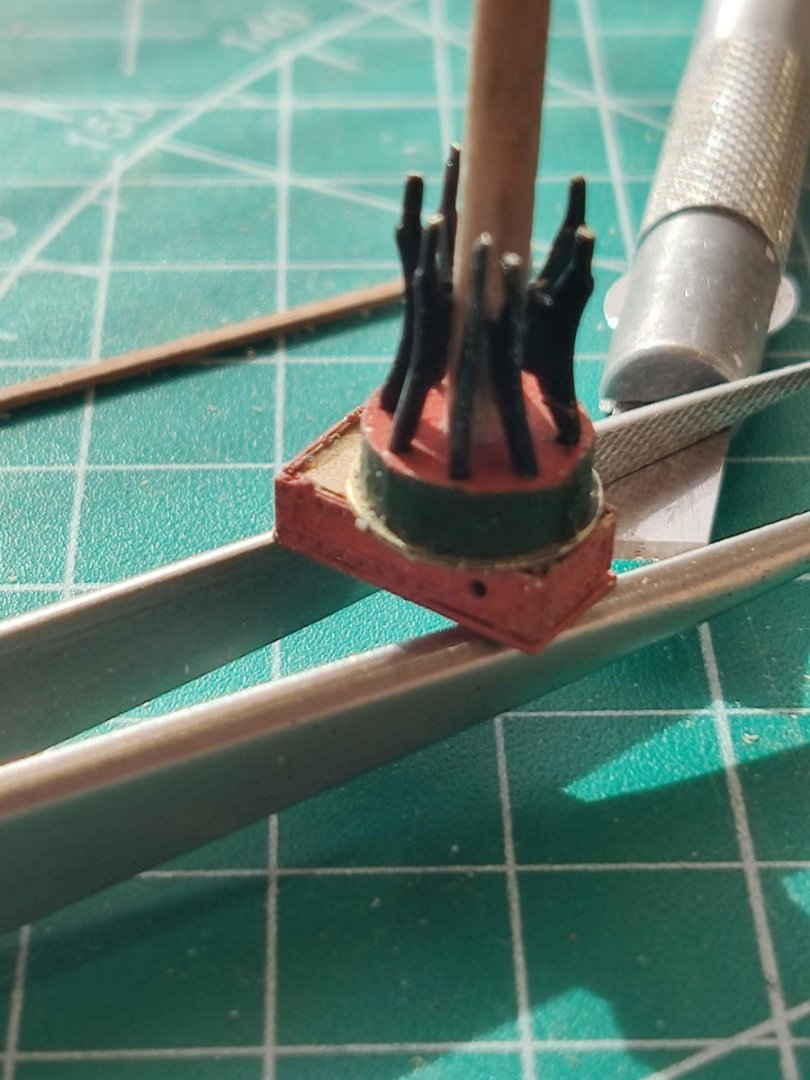

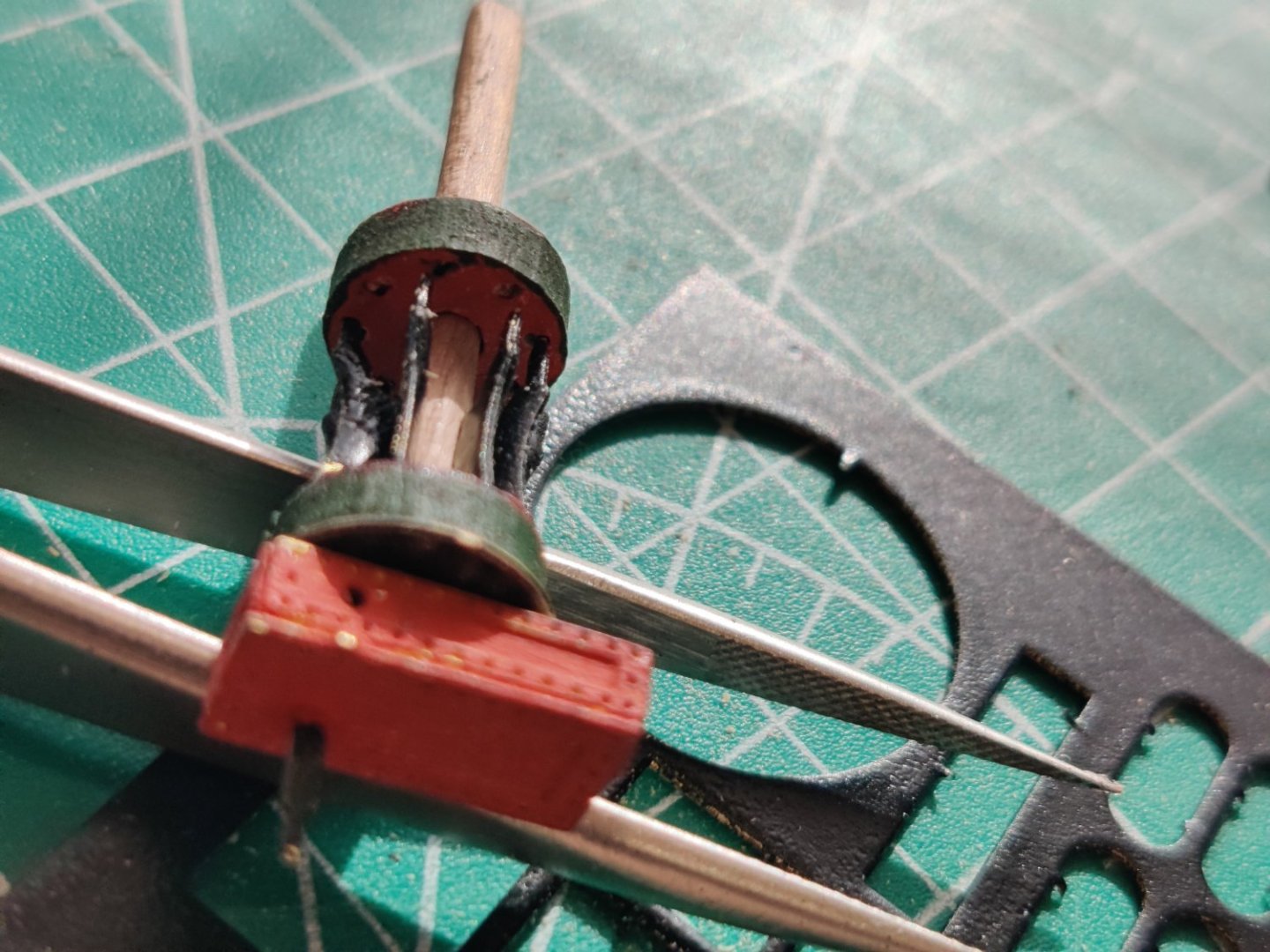

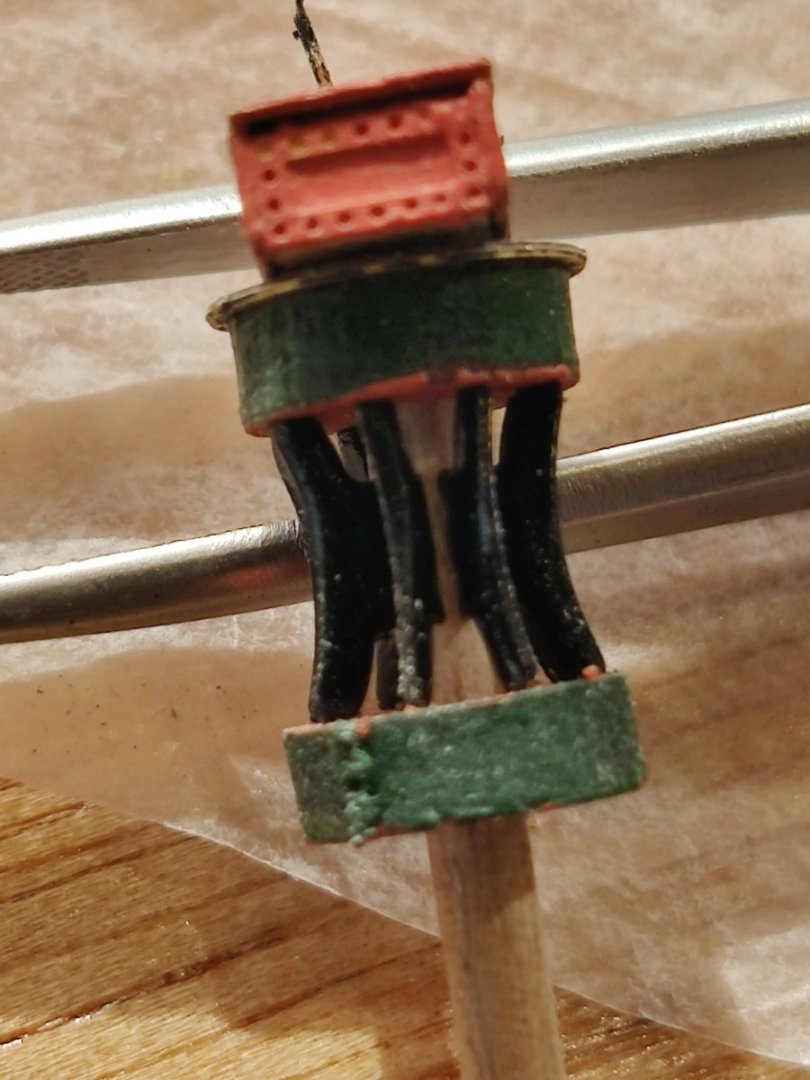

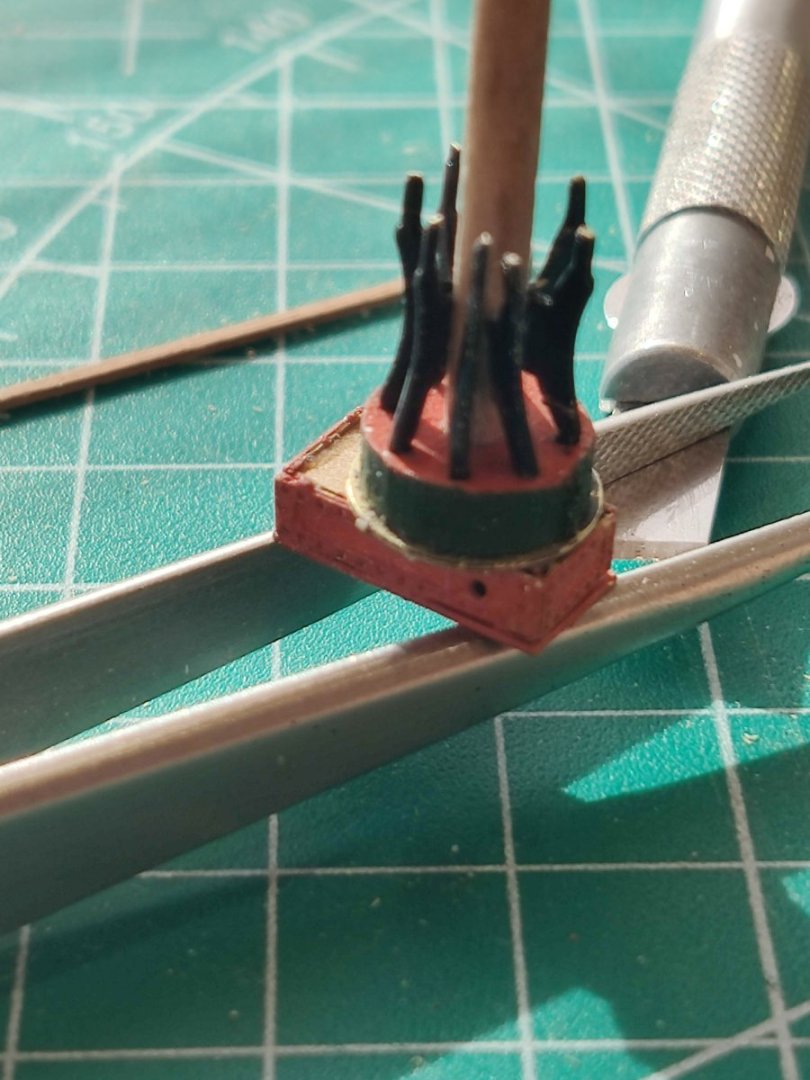

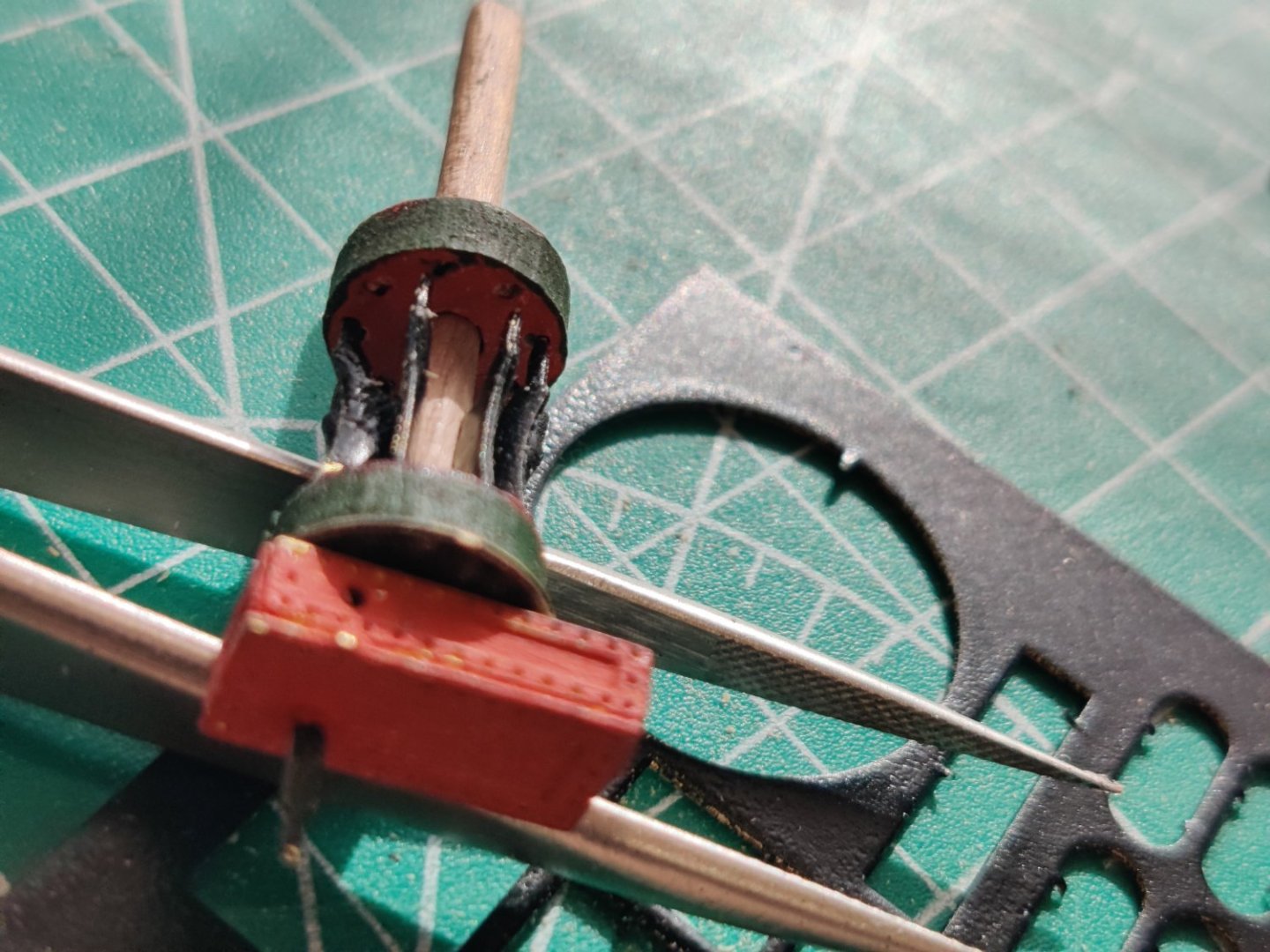

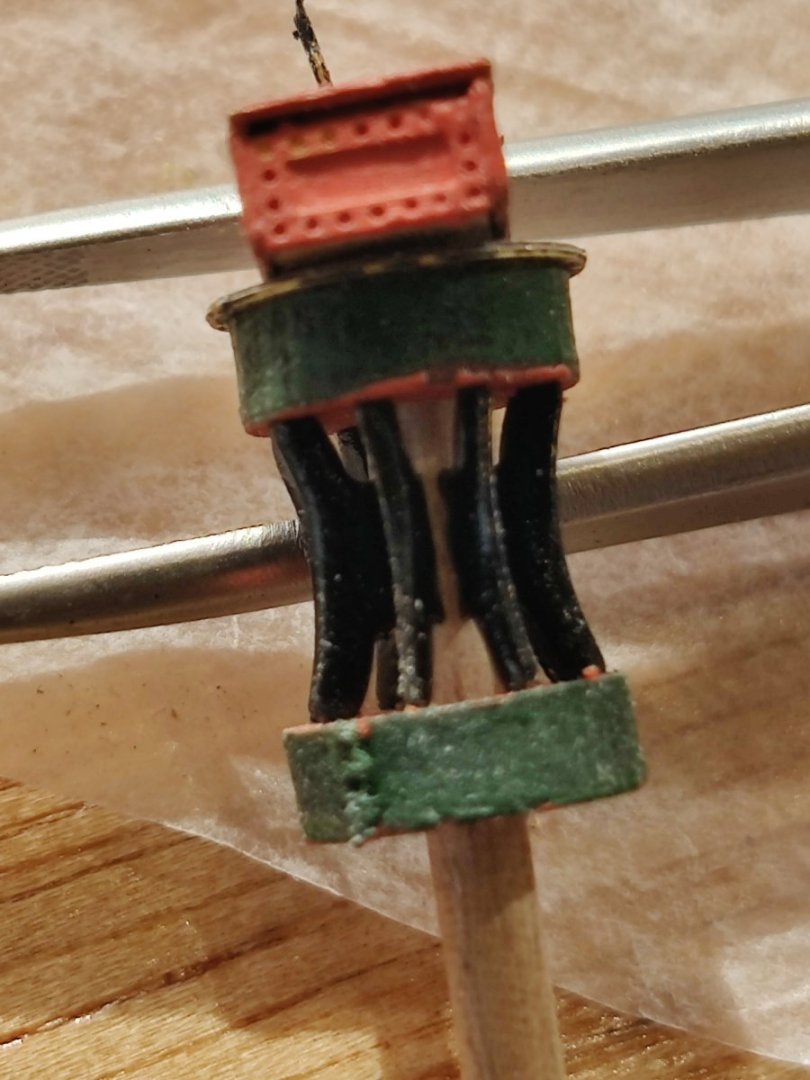

Working on the steam powered winch, it is wise to paint the component pieces before starting assembly, and just do touch up painting after assembly. Be sure to sand the dowel before cutting it to the 40mm length, it is much easier to sand then cut to length. Add the brass components that are not to be painted until after the assembly, including the post which is inserted into the orange top piece. It is helpful to have the winch sit flat when inserting the 8 center pieces that are painted black. You will also likely need to re-drill the eight holes for the center pieces after painting.

-

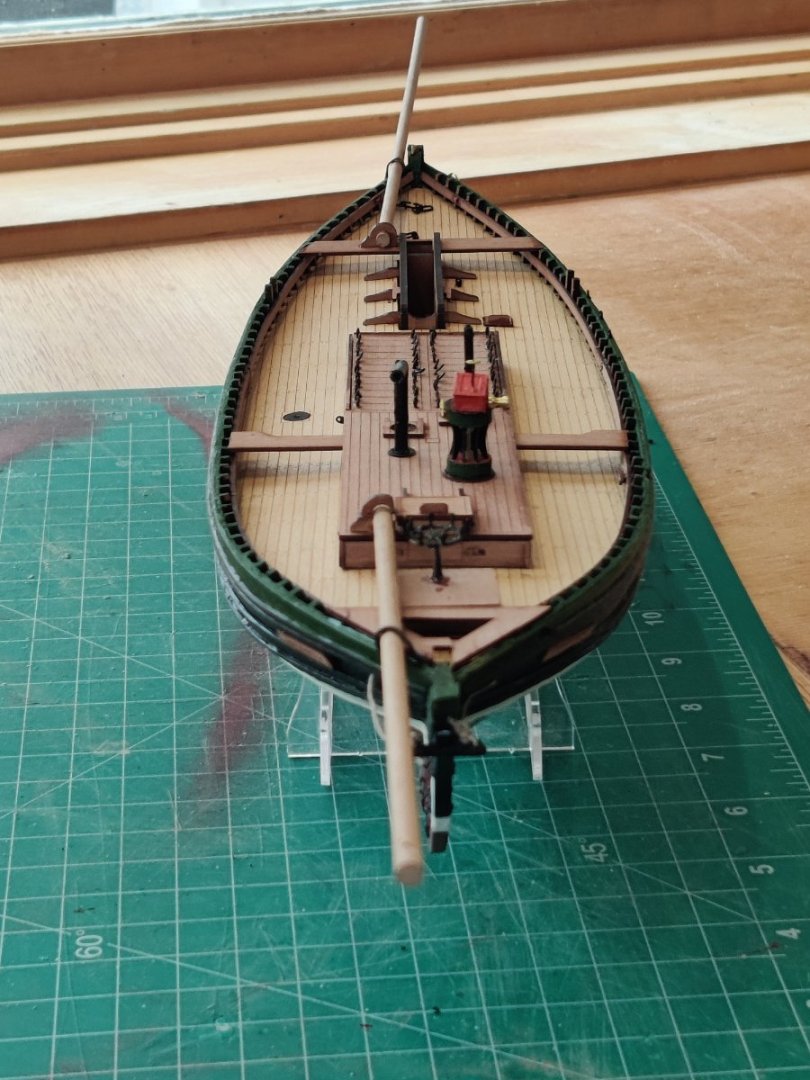

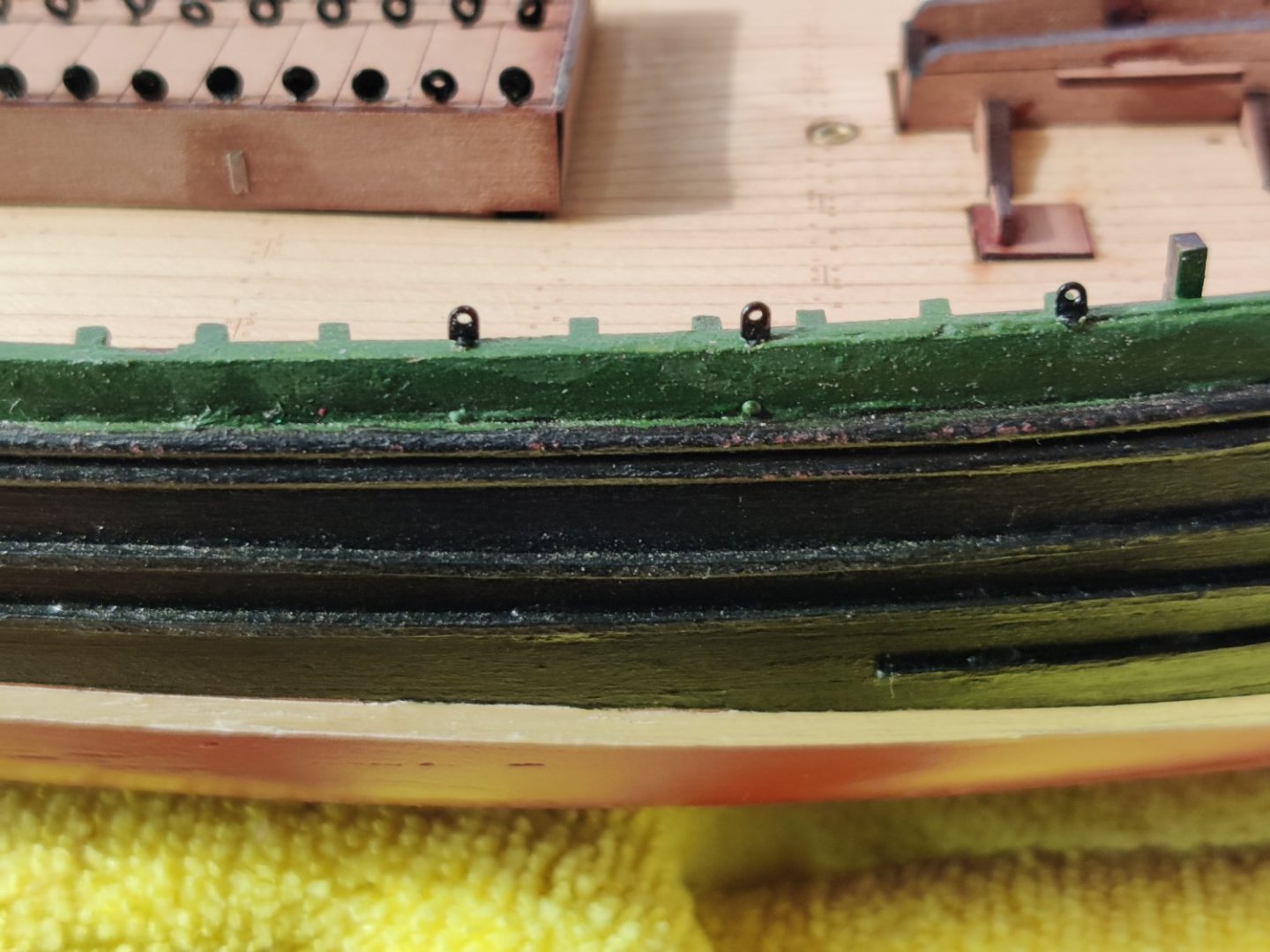

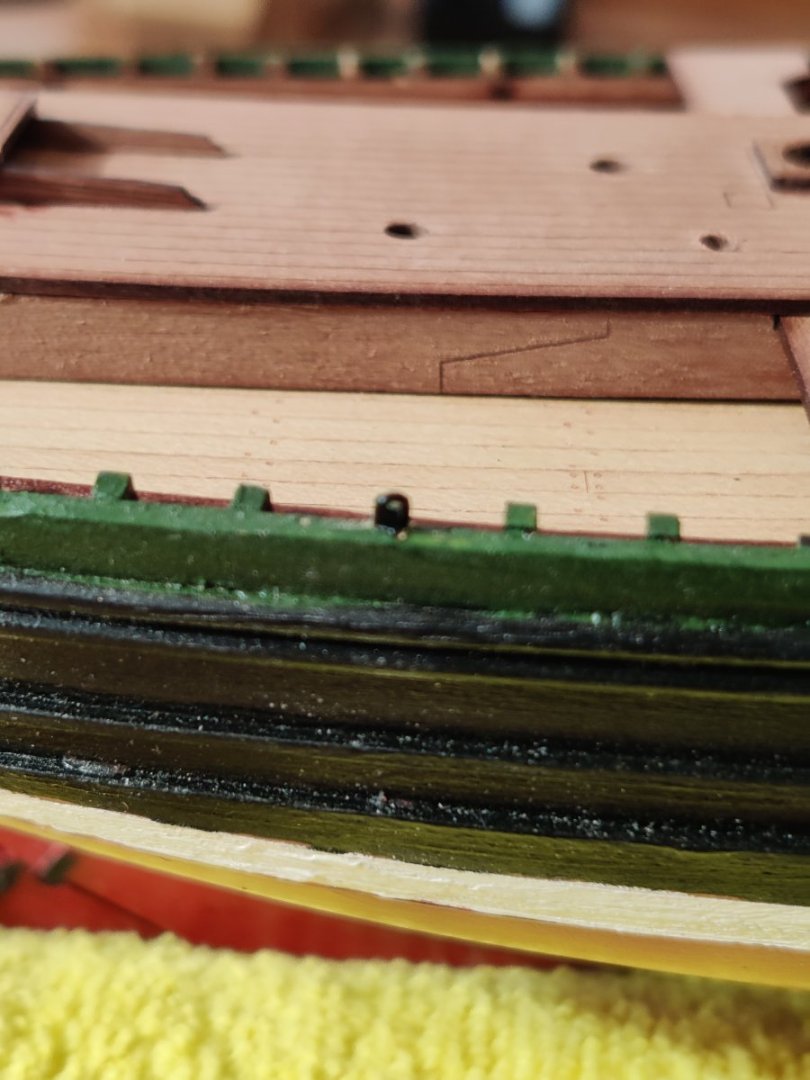

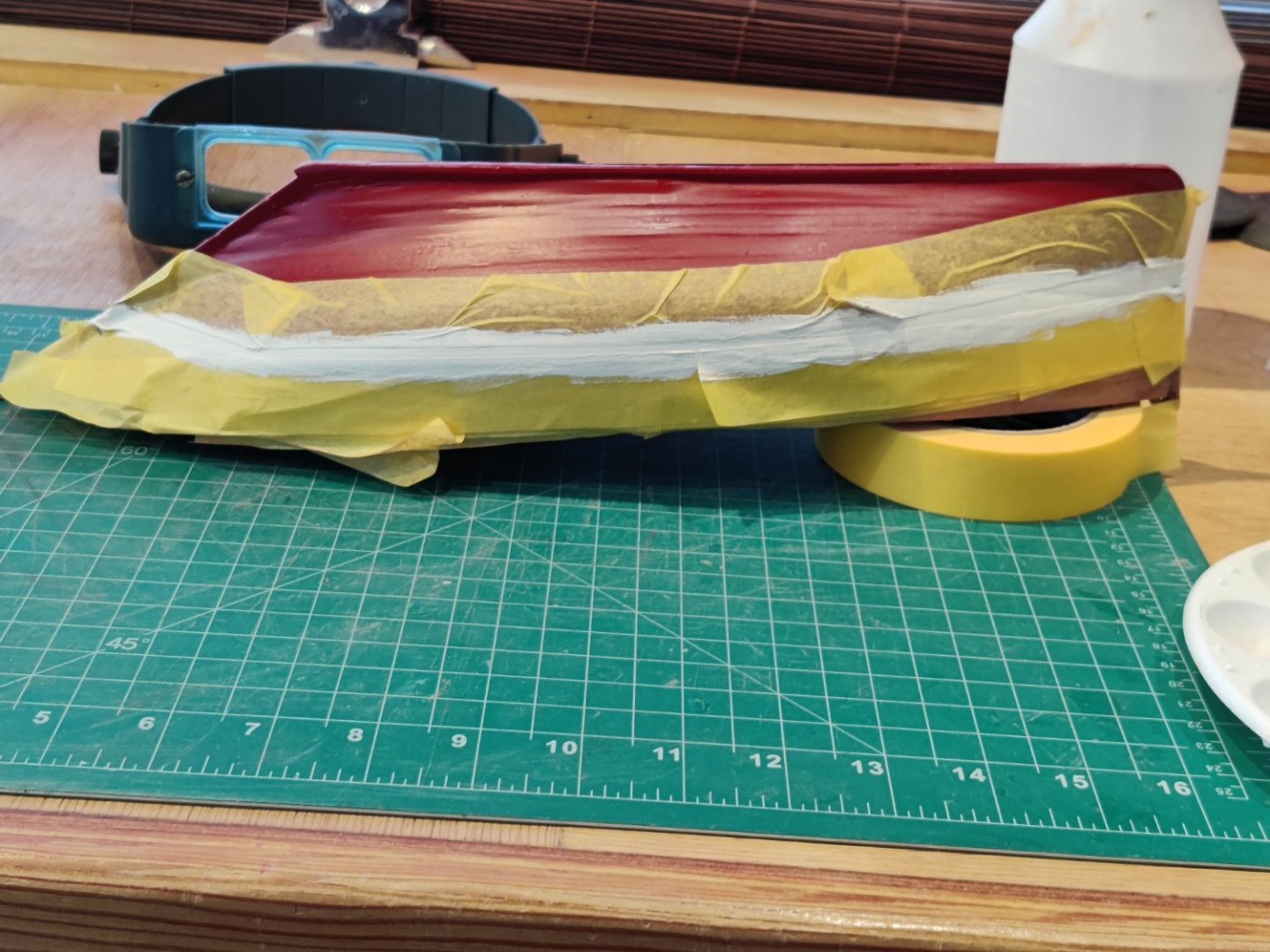

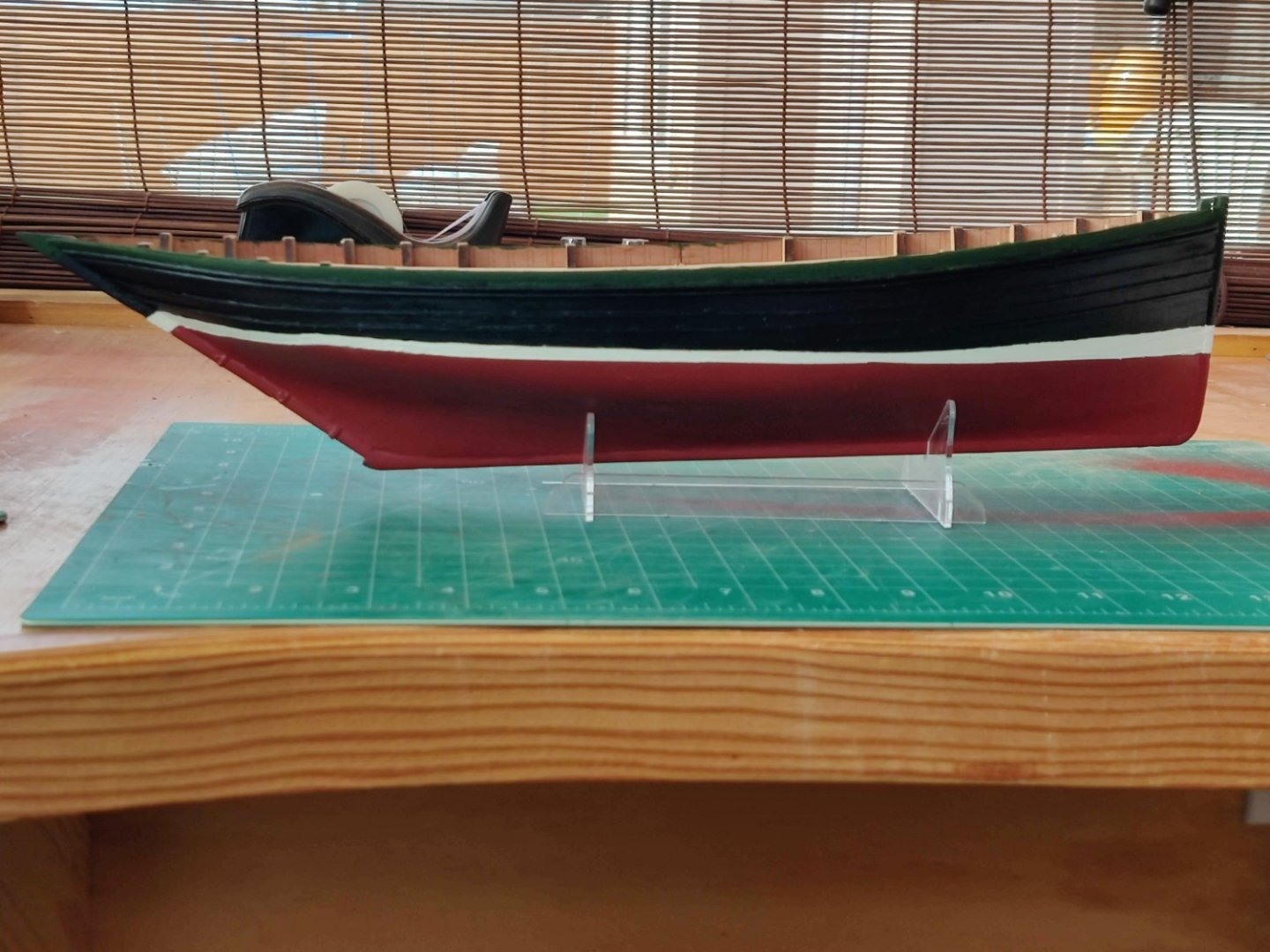

Some tips for novice builders on Lady Isabelle that I learned the hard way: 1.The brass plate that goes on the bow, if you are going to paint it black, wait until it is installed with glue to

paint, drilling the holes for the pins and the hammering of the pins ruins the paint, also the pins are too long at the top of the bow, you need to cut about 1/8" off the pins and it will fine. 2. Go thru all the instructions and identify which brass parts will need to be painted black. It is much easier to spray paint them when they are still connected to the brass plate card. Remove those brass parts that you do not want painted black while they are attached to the brass card before you paint the remainder of the parts. 3.Put the string thru the back of the stern steering box before you assemble the box. 4. Before you paint the bow, put pins in the three holes that will hold the little brass plate. the holes are so small that they disappear when painted. Also if you have sanded the bow the pins may be too long and will stick out the other side and will nee to be trimmed. 5. Before you start putting the 50+ rib pieces on, cover the two large openings on the main deck. I dropped one off the tweezers and it fell into the space and became attached somewhere on the inner hull so I had to make one from the edge of the wood pair card piece. I am sure that there will be more tips I learn the hard way before I am finished.