-

Posts

1,007 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by WalrusGuy

-

-

I applyied two coats of tung oil above the wales, and two coats of WOP below the wales. I only sanded with 600 grit sandpaper between the coats for the WOP. Here are some pics:

IMO, the tung oil darkened the treenails a bit more than I would have liked. There was no way of telling how it would look in a small test section I did beforehand. But lesson learnt! I think next time I'll be using WOP for the entire surface instead of tung oil.

-

Thank you all again for all the likes and the nice comments!

I have glued in the channel wales and black strake, and finished treenailing them. I then chamfered the edges with a sanding stick (220 grit sandpaper stuck on one side of a 1/2in scrap wood). I used a wedge to assist in keeping a constant angle on the sanding stick as I sanded the edges:

I tapered the planks to become thinner from about 2cm from the stem. This is because the wales insert into the stem rabbet in the real ship.

And here are some more photos:

Lastly, I applied wipe-on-poly on the hull. I damped the WOP on a piece of an old t-shirt, applied generously, then used a dry part of the cloth to immediately remove any excess.

I only put one coat for now. Here is a sneak peek:

For my next update I will apply tung oil on the planks above the wales, and finish with one or more coats of WOP on the hull below the wales.

-

-

Very neat and precise! Awesome job copper plating 😁

-

Hi Michael

Can't believe I just found out about this update. I'll be following this thread with a lot of interest.

I'm out of words to see the level of detail work going into this build... The video of the brakes working and seeing all the moving parts is very cool!

The watercolor painting is gorgeous. Perfectly captures the Edmonton winter.

Wishing you and Judy a happy new year!

Harshil

- popeye the sailor, Canute, mtaylor and 1 other

-

4

4

-

-

11 hours ago, Gahm said:

Beautiful planking job!

Thomas

8 hours ago, Brucealanevans said:Looks great! Congratulations.

Thank you, Thomas and Bruce!

Also wanted to take this moment to wish MSW a prosperous new year!!! 🥳

-

Congrats Bruce! She's a beauty 😁

Looking forward to seeing the boats!

-

21 hours ago, No Idea said:

Lovely job I'd be very happy with that result - top job which was worth the effort 👍

20 hours ago, Moonbug said:Beautiful job! Nothing to critique from me.

18 hours ago, Chuck said:Nicely executed

15 hours ago, Nirvana said:Happy to have the same model in my stash! Because this is true inspiration!😀

Thank you so much for the encouraging comments and the likes! 🙂

-

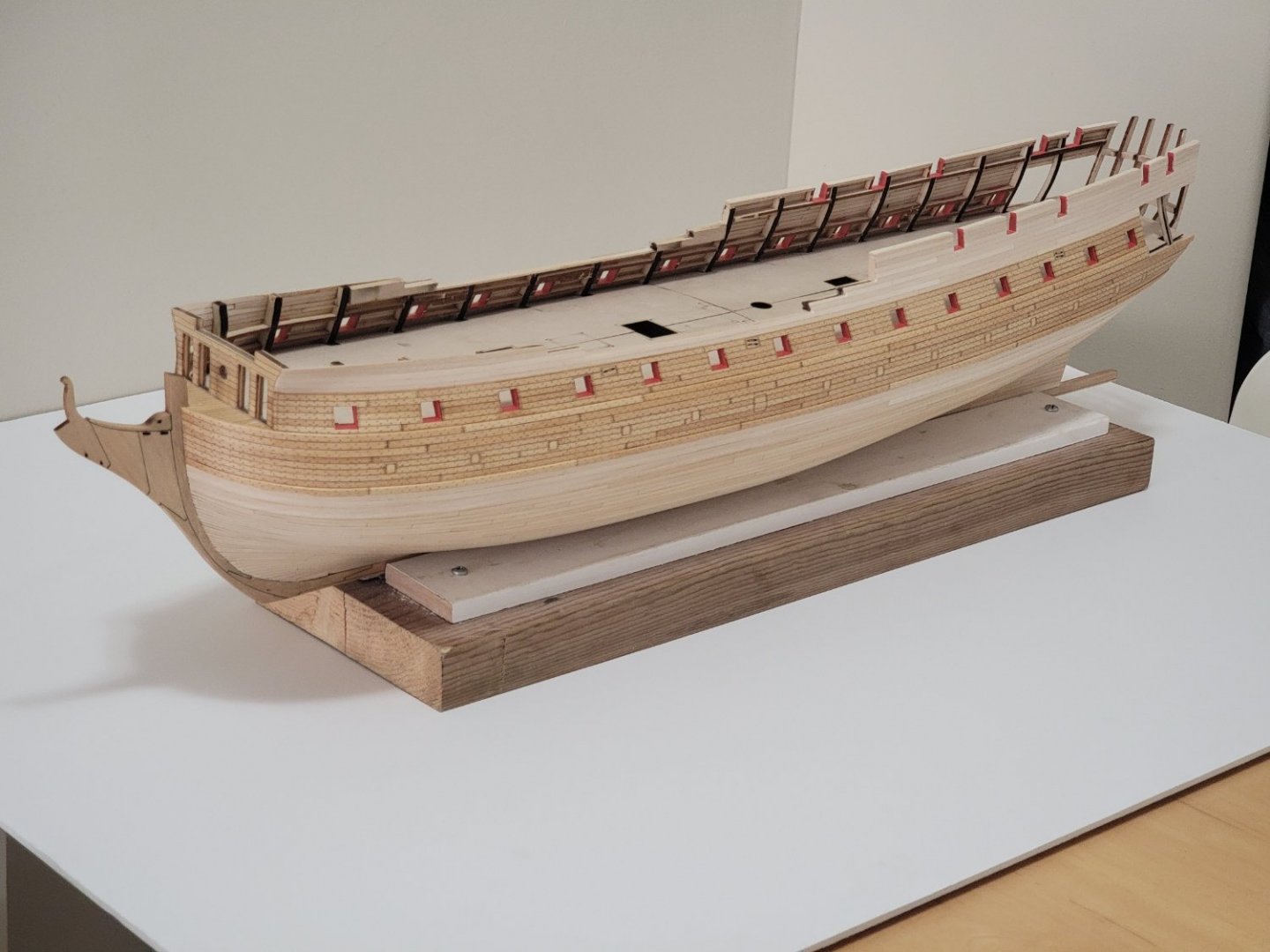

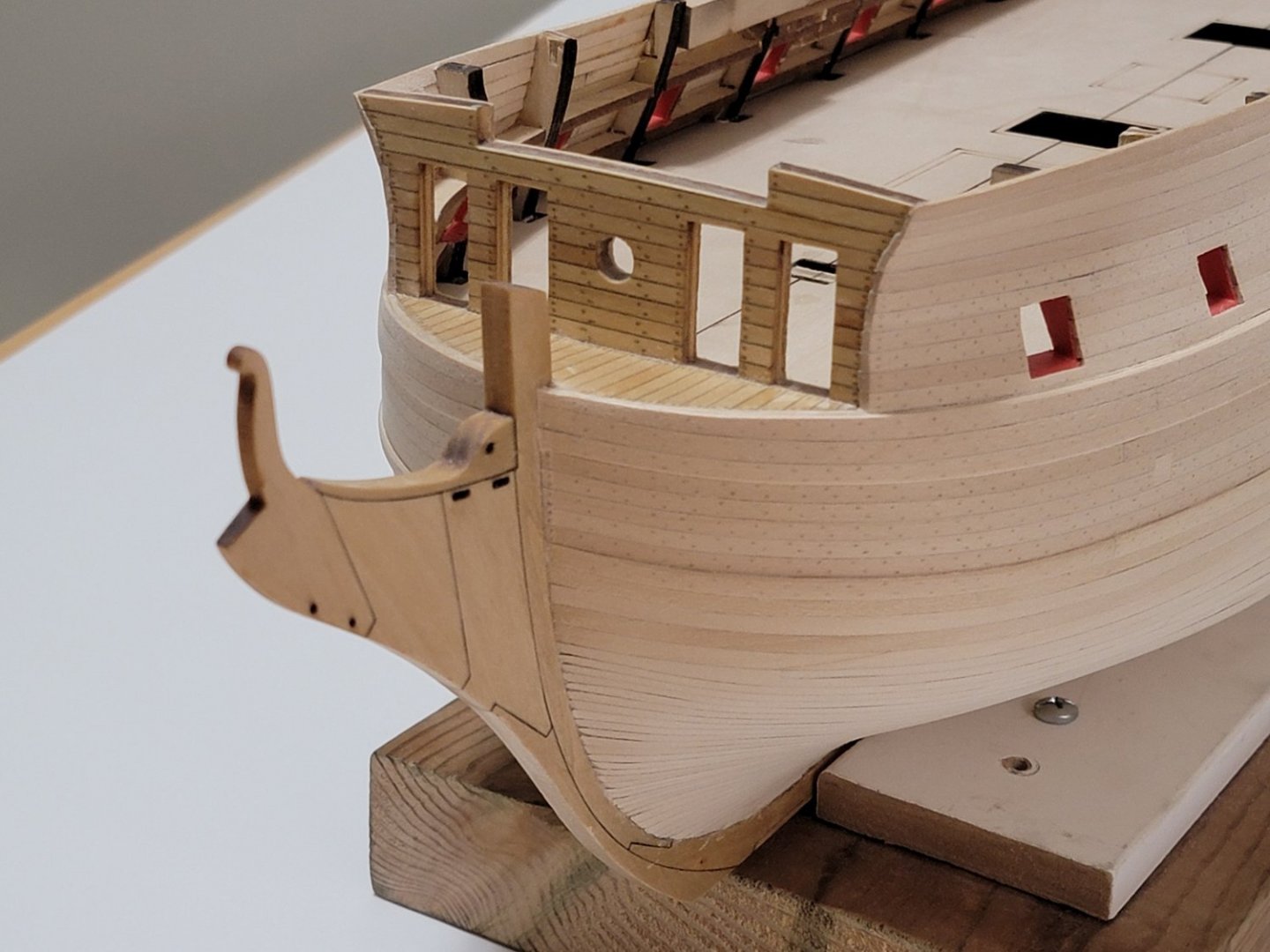

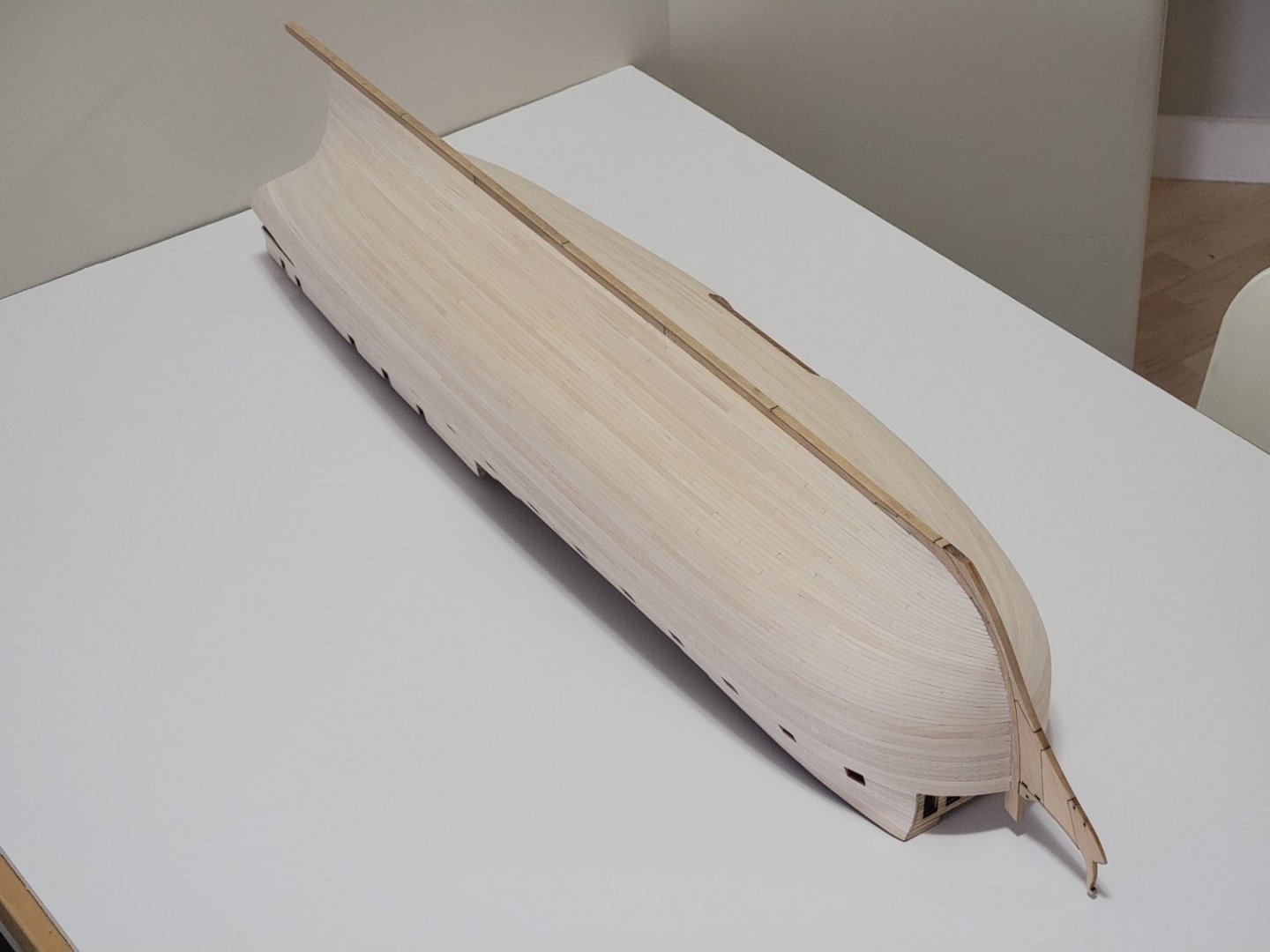

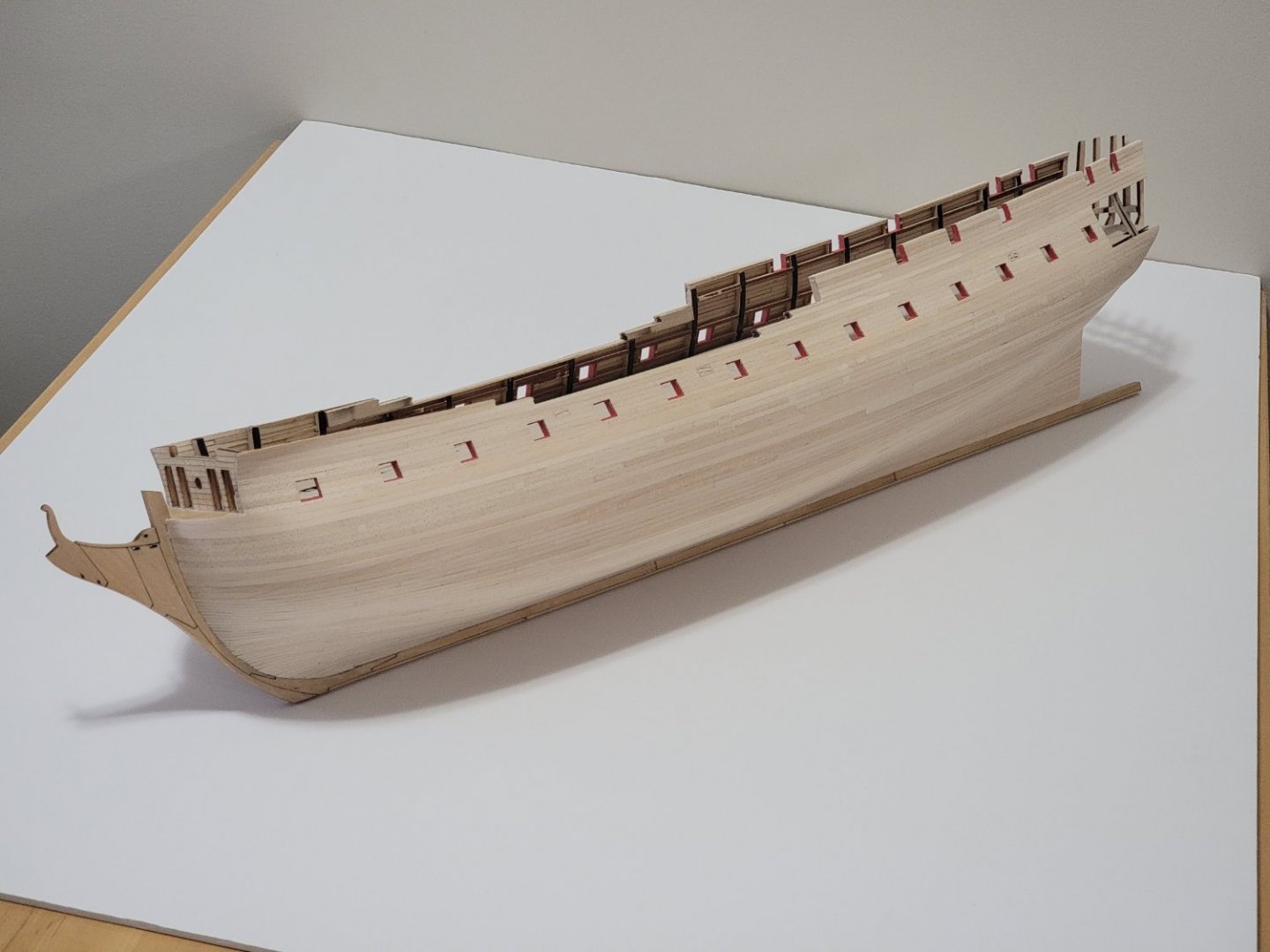

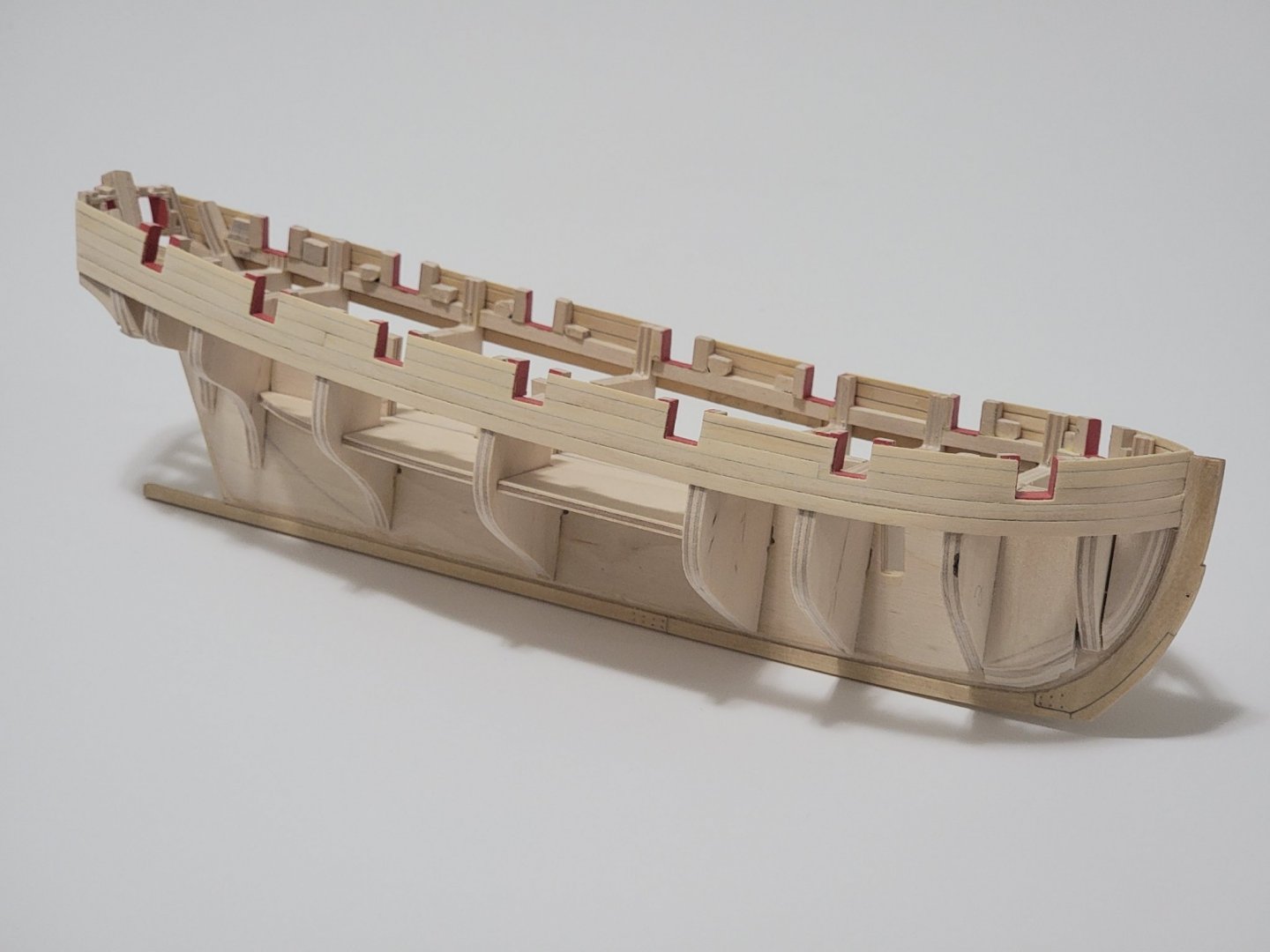

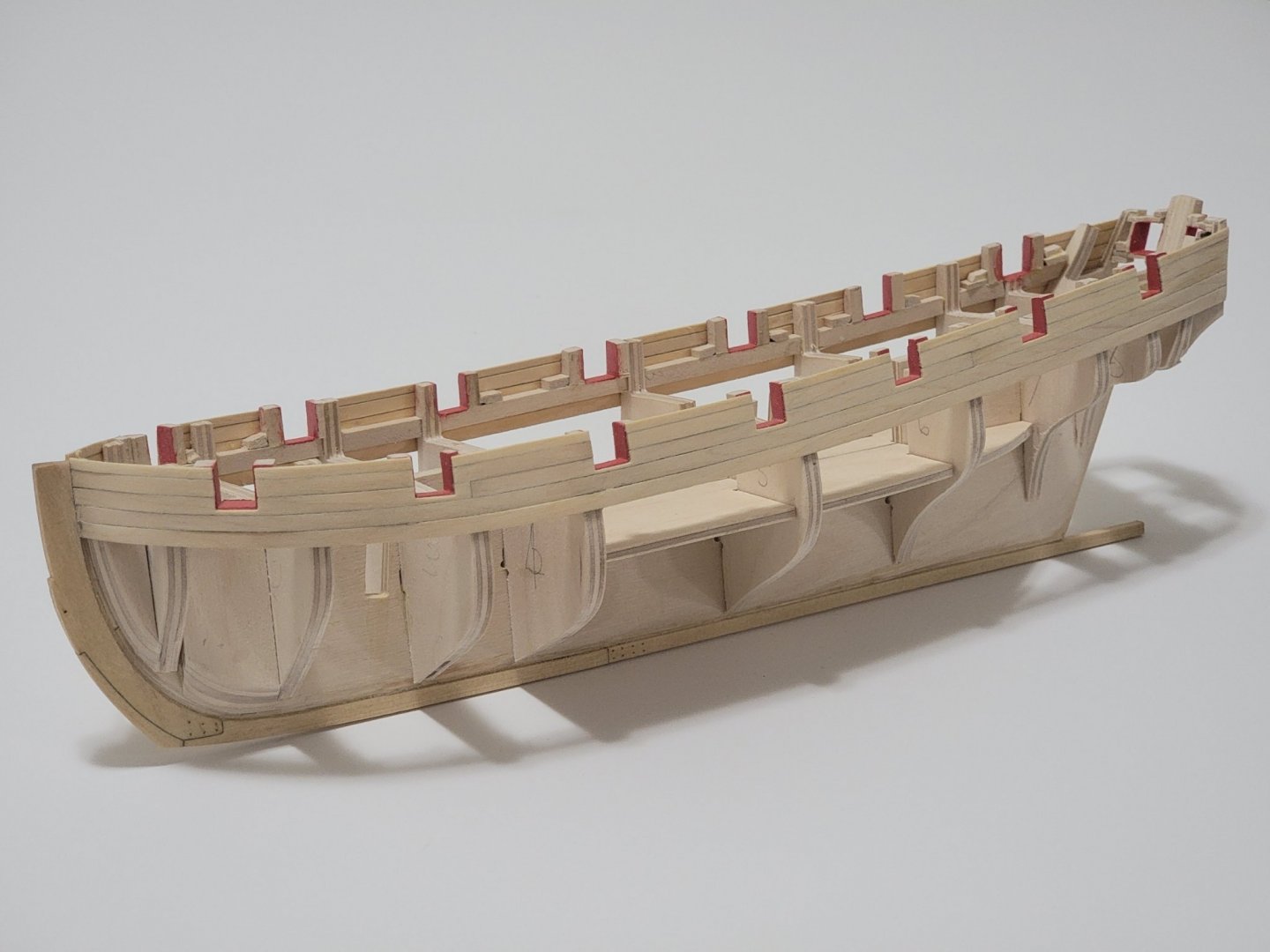

I finally finished planking the hull... and what a ride it was! It was my first time single planking a hull and I am now completely humbled by this task. Other modellers make it look so easy! Cutting each plank got old by the time I was half way 😅.

I've learnt planking is not my favorite part of the build, but closing up the hull with the last 2 strakes were so satisfying!! Also, as @allanyed pointed out, clamps were not needed. I just had to hold the planks at the stern and at the bow for a couple of minutes after microwaving the planks so that they retain the curve.

Once I finished planking, I taped up the keel and exposed frames to protect them from scratches. I then sanded the hull smooth from 100 grit to 600 grit sandpaper.

Here are a bunch of pictures to mark this major milestone of the build:

Also, please do not hesitate to critique my planking. It will help me improve for my next models.

Now, I am thinking of installing the 2nd layer of wales before I apply the finish to the wood.

-

Very beautiful and detailed model! And wishing you a happy birthday! 😄

-

On 12/16/2021 at 12:28 PM, Nirvana said:

Looking good though, just consider each strake as a single project has helped me getting through tricky planking.

14 hours ago, abelson said:Excellent work on planking. Keep it up.

Thank you , Nirvana and Steven. And thanks all for the likes! The encouragement is much appreciated 😁

-

Beautiful work on the figurehead!

-

- KurtH, CiscoH, Paul Le Wol and 7 others

-

10

10

-

-

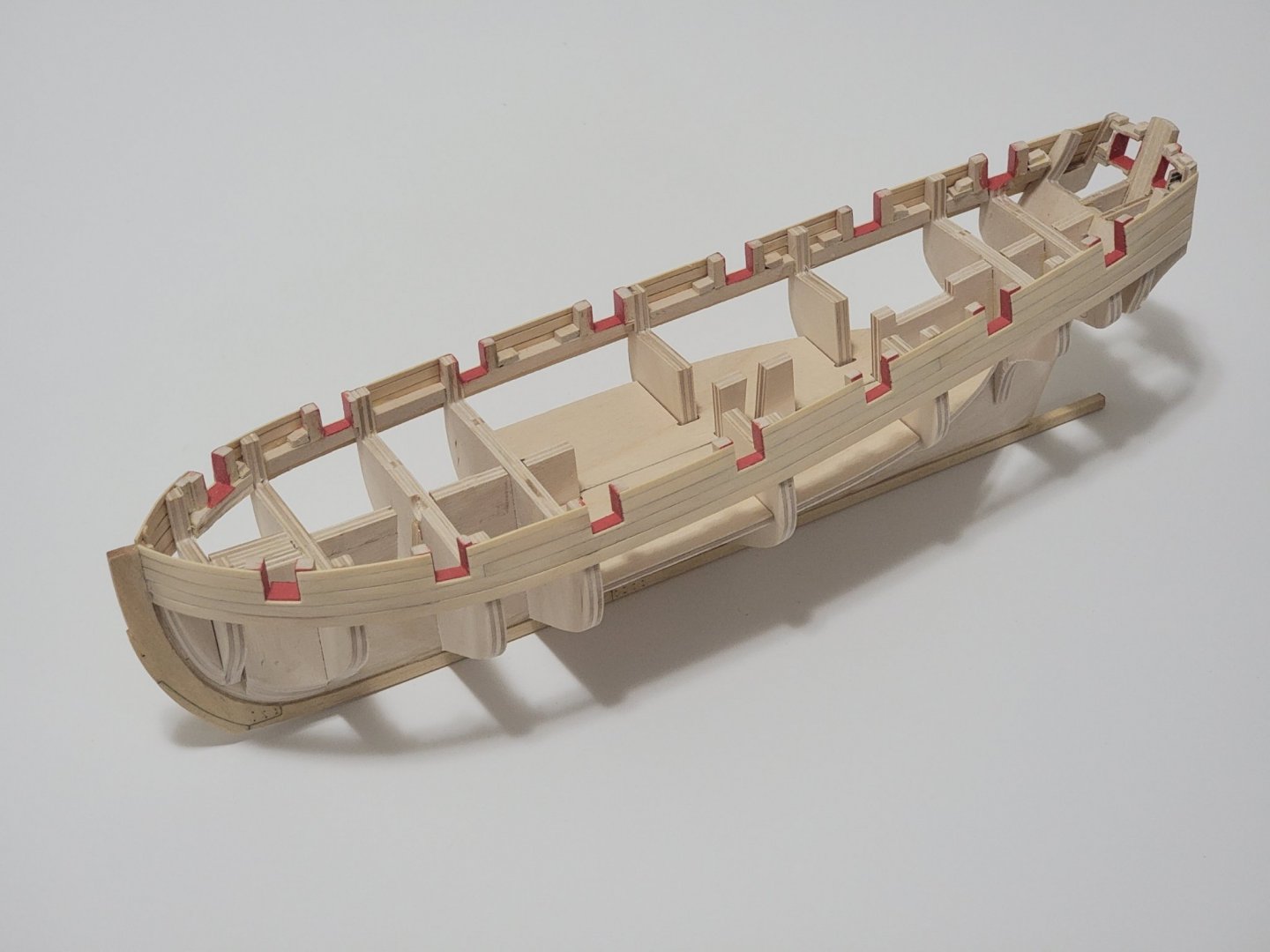

The uppermost band is now planked. I found this part to be much more trickier and challenging than the lower band. I'm not 100% happy with how the planking turned out at the bow where they meet the stem. It's not as smooth or symmetric as I'd like. It looks ok with the ship upside down, but looks a bit weird with it the right way up. No idea why this it is like that 😅. Maybe I just need to sand a bit more (I just roughly sanded it for now).

Also, similar to the bow, all the planks at the stern had to be cut out from a sheet since the planks needed to be curved in shape. So each strake took a couple of days to do.

Here are some photos:

And with the ship the right way up:

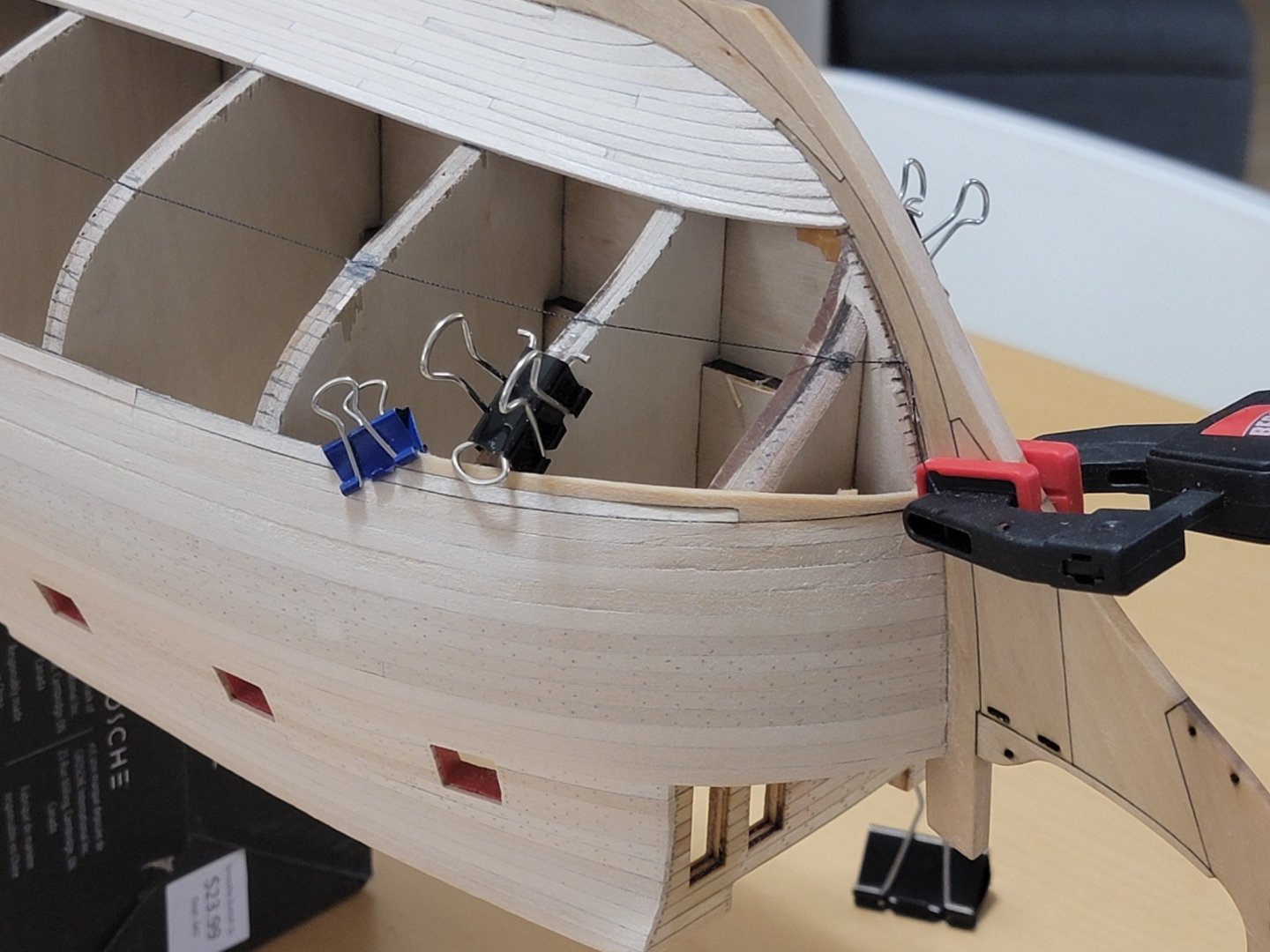

Clamping the wood at the stern was also tricky. I had to think of different ways to do this:

I have a feeling the middle band will be more trickier since I will be slowly running out of space for the clamps.

-

2 hours ago, scrubbyj427 said:

Remember all the laser etched moulding Chuck provided along the rails? They were intended to match the scrolls... there was plenty of extra... I didn’t even think about using them for the columns, clearly nobody else did either except Ben.

I'm still confused 😅, where exactly are they to be used?

-

I'll be following with a lot of interest! I am also building the Confederacy (currently halfway through the planking below the wales).

Your model is looking fantastic! 🙂

-

-

11 hours ago, Gahm said:

Your planking looks really good!

Thomas

Thank you, Thomas 🙂

-

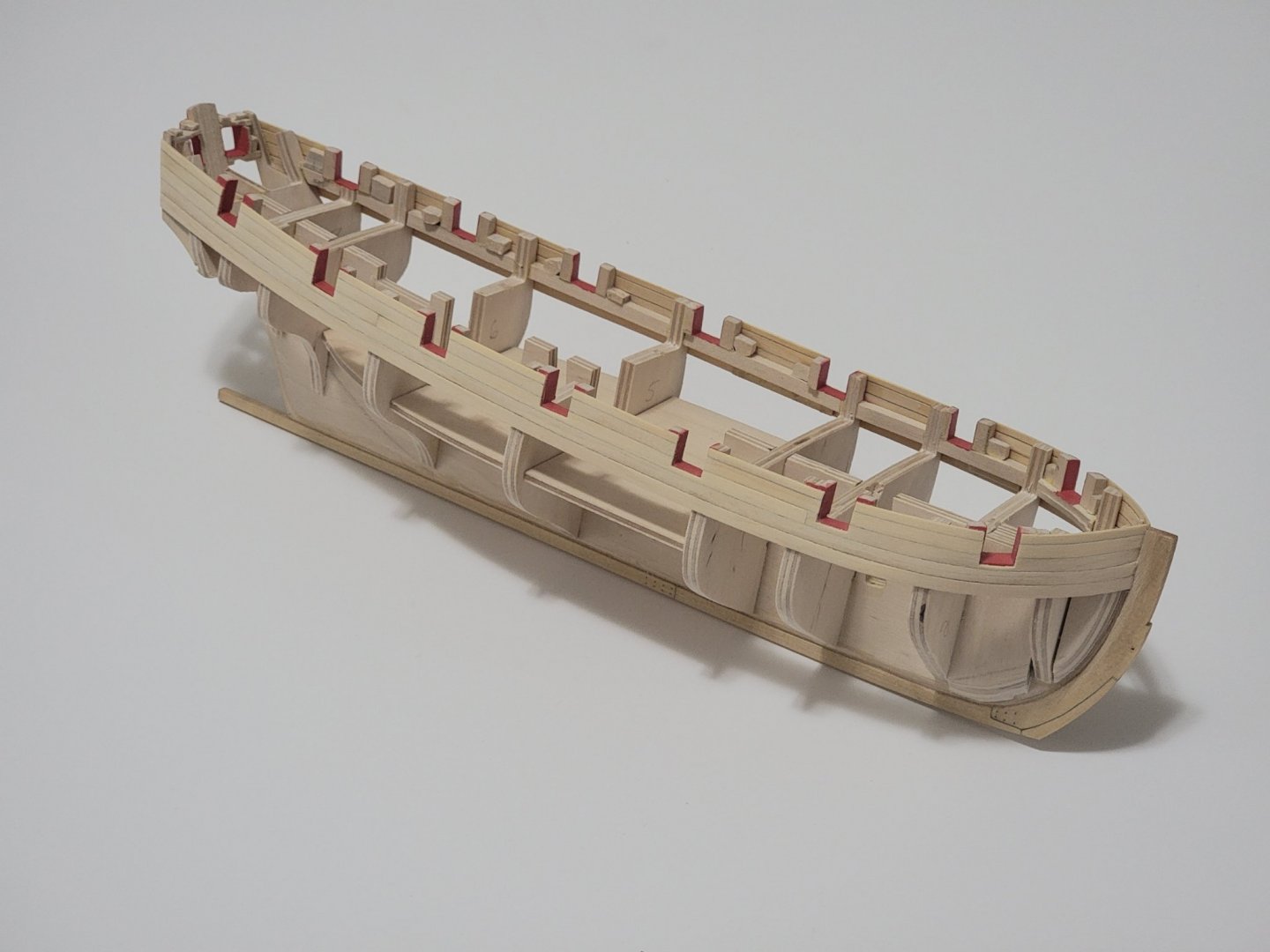

Not much progress since my last update. Took a bit of a break after finishing the lower band.

Here is where I am at right now:

I followed Chuck's Winchelsea where he added a drop plank right below the wales. This will probably be my only drop plank.

For those with a keen eye, you may have realized I replaced the topmost plank. It did not follow the same planking layout as the first lowermost band, so I decided to redo it. That way, I could also work in the drop plank as well.

And I had to mark out the 11 planks on the middle bulkhead for the middle band so that I can see where the butt joints will line up. I hope I calculated where the top plank butt joints are accurately! I did it 5 times to make sure I did not make a mistake! 😅

Guess I will know for sure if I counted them right once I finish up the planking...

- CiscoH, Moonbug, Retired guy and 8 others

-

11

11

-

4 hours ago, abelson said:

Looks like nice symmetry.

Thank you, Steven.

-

Same! I'm very interested in a high quality POF kit 😁

- VTHokiEE and FrankWouts

-

2

2

-

Beautiful work, Mike. Your photos are also amazing and sharp. What camera do you use?

.thumb.jpg.62d1d69fed1f32364417cb1f9cdeb009.jpg)

Confederacy by Realworkingsailor - Model Shipways - 1:64 - Frigate

in - Kit build logs for subjects built from 1751 - 1800

Posted

Beautiful planking, Andy!