mikegr

Members-

Posts

578 -

Joined

-

Last visited

Recent Profile Visitors

-

mikegr reacted to a post in a topic:

HMS Hood 1941 by Johngr - FlyHawk - 1:700 - PLASTIC

mikegr reacted to a post in a topic:

HMS Hood 1941 by Johngr - FlyHawk - 1:700 - PLASTIC

-

mikegr reacted to a post in a topic:

HMS Hood 1941 by Johngr - FlyHawk - 1:700 - PLASTIC

mikegr reacted to a post in a topic:

HMS Hood 1941 by Johngr - FlyHawk - 1:700 - PLASTIC

-

Bill Morrison reacted to a post in a topic:

USS Curtis Wilbur DDG-54 by patrickmil - I Love Kit - 1/200 - PLASTIC

Bill Morrison reacted to a post in a topic:

USS Curtis Wilbur DDG-54 by patrickmil - I Love Kit - 1/200 - PLASTIC

-

Bill Morrison reacted to a post in a topic:

USS Curtis Wilbur DDG-54 by patrickmil - I Love Kit - 1/200 - PLASTIC

Bill Morrison reacted to a post in a topic:

USS Curtis Wilbur DDG-54 by patrickmil - I Love Kit - 1/200 - PLASTIC

-

TurkSailor reacted to a post in a topic:

Rebuilding the fleet by mikegr - 1/700 - restoring old plastic models

TurkSailor reacted to a post in a topic:

Rebuilding the fleet by mikegr - 1/700 - restoring old plastic models

-

mikegr reacted to a post in a topic:

Fifie by TurkSailor - Amati - 1:32

mikegr reacted to a post in a topic:

Fifie by TurkSailor - Amati - 1:32

-

mikegr reacted to a post in a topic:

Type 45 Destroyer by mikegr - 1/700

mikegr reacted to a post in a topic:

Type 45 Destroyer by mikegr - 1/700

-

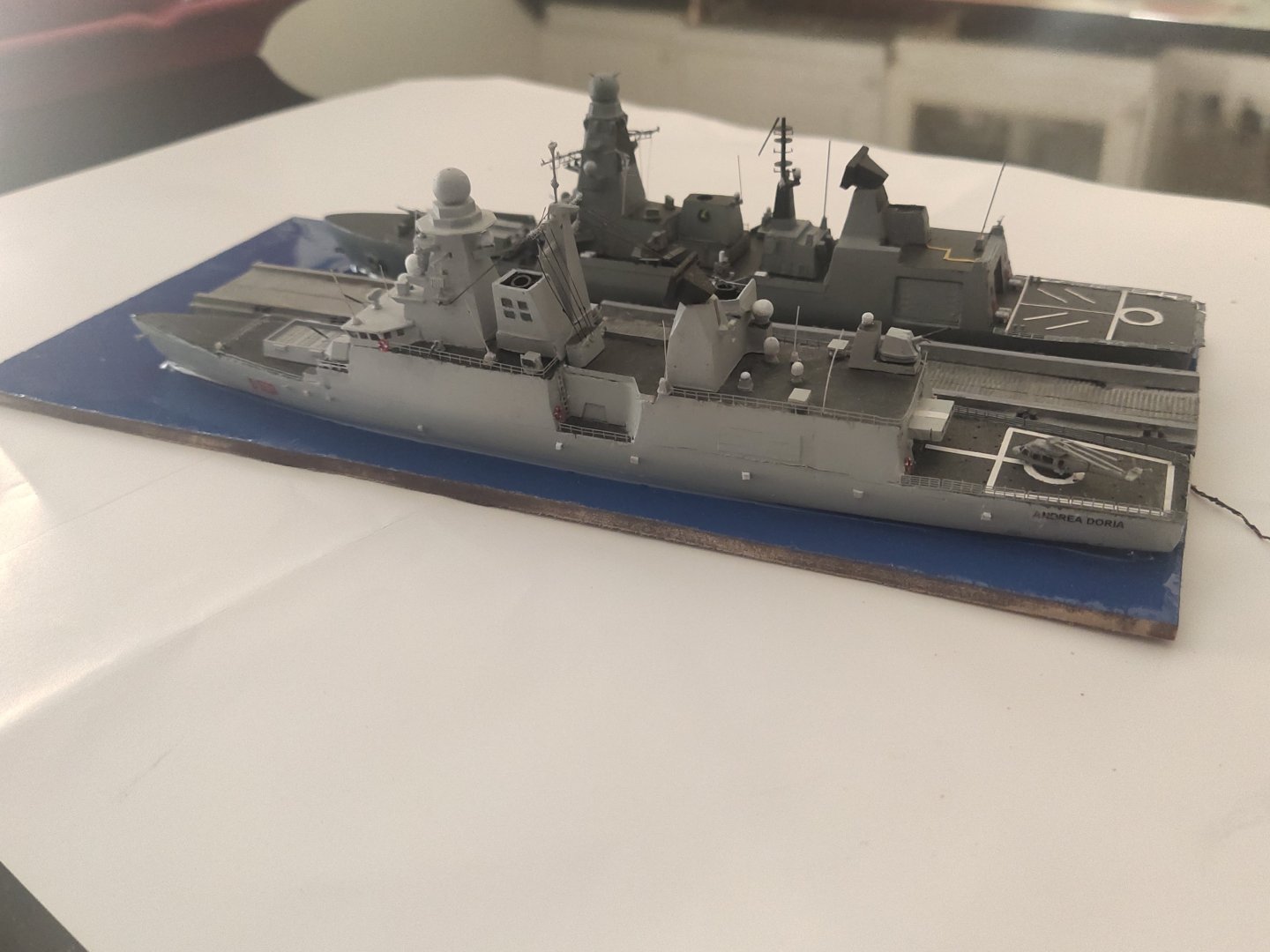

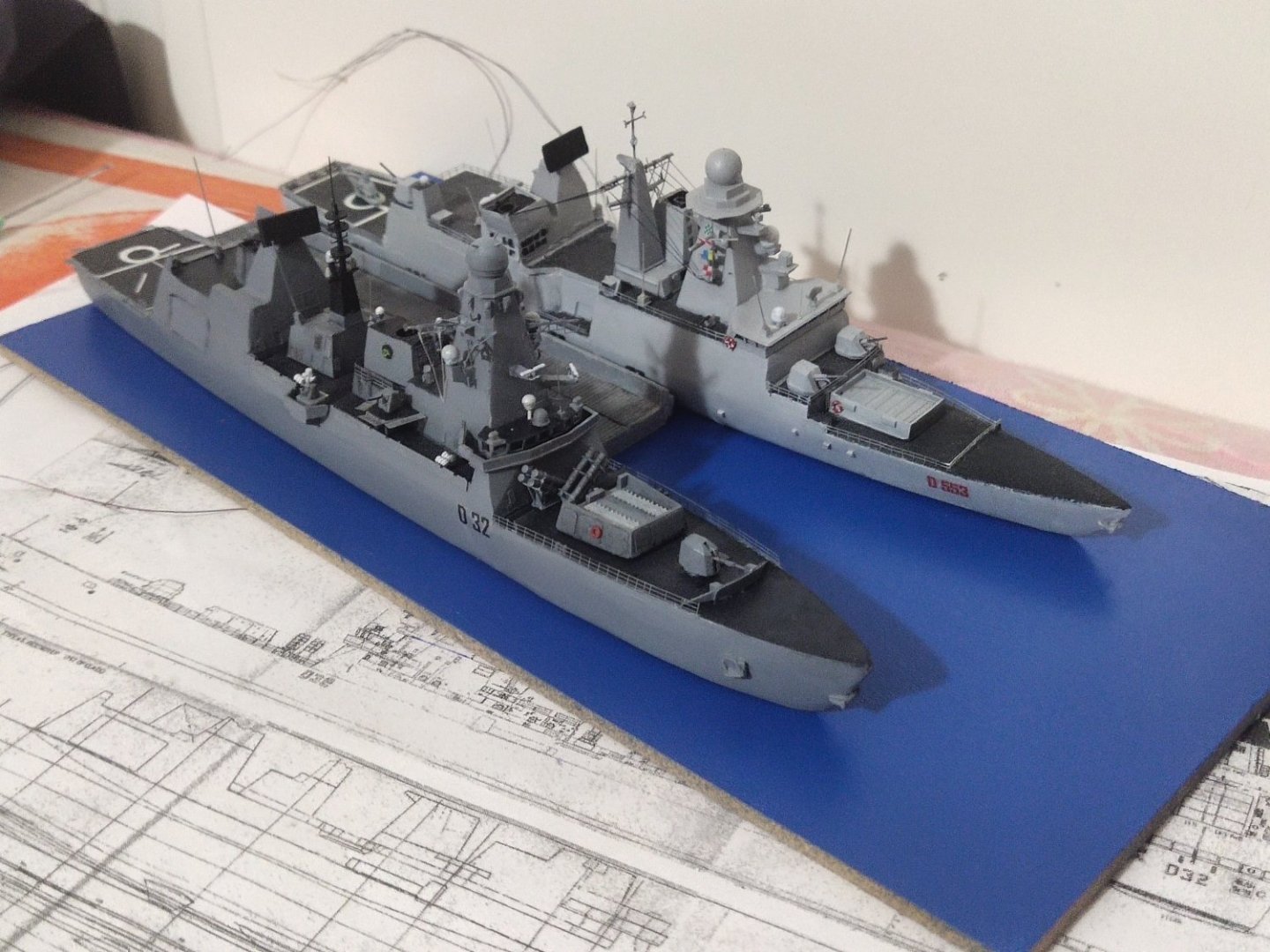

Type 45 Destroyer by mikegr - 1/700

mikegr replied to mikegr's topic in - Build logs for subjects built 1901 - Present Day

I pour the resin and added a second part of dock. In my hurry to finish it yesterday I made a rookie mistake and forgot to check it the surface was flat so the small inclination so the resin was distributed unevenly. Anyway the purpose was just to display the ships together. -

mikegr reacted to a post in a topic:

HMS Spiraea and HMS Zinnia by king derelict - Mirage Hobby - 1/350 - PLASTIC - Flower-Class Corvettes

mikegr reacted to a post in a topic:

HMS Spiraea and HMS Zinnia by king derelict - Mirage Hobby - 1/350 - PLASTIC - Flower-Class Corvettes

-

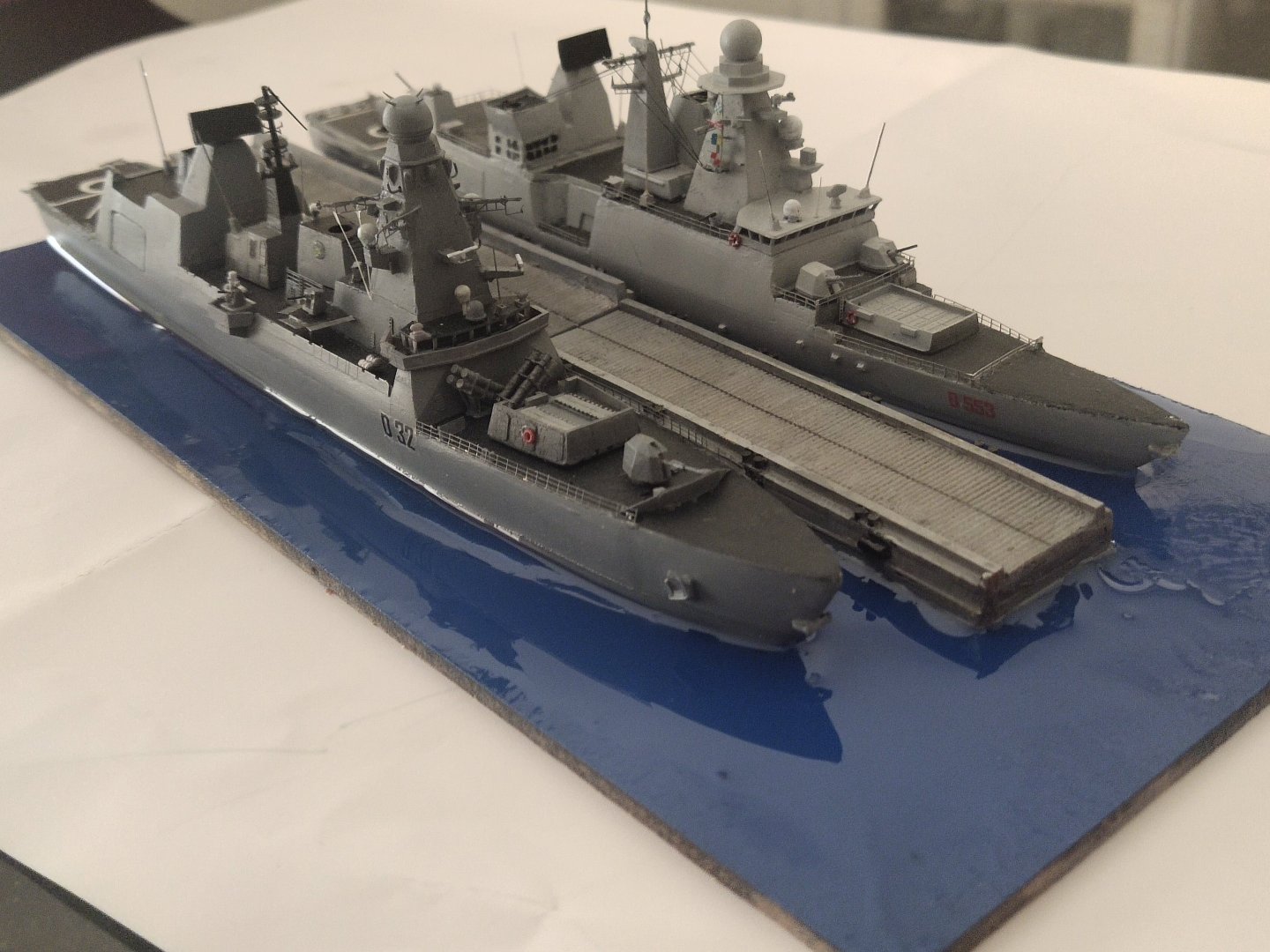

Type 45 Destroyer by mikegr - 1/700

mikegr replied to mikegr's topic in - Build logs for subjects built 1901 - Present Day

So I proceed finishing the model with final details. I put it aside with the Horizon class and add a drydock. Tomorrow I will pour the resin. It will be a simple sea representation -

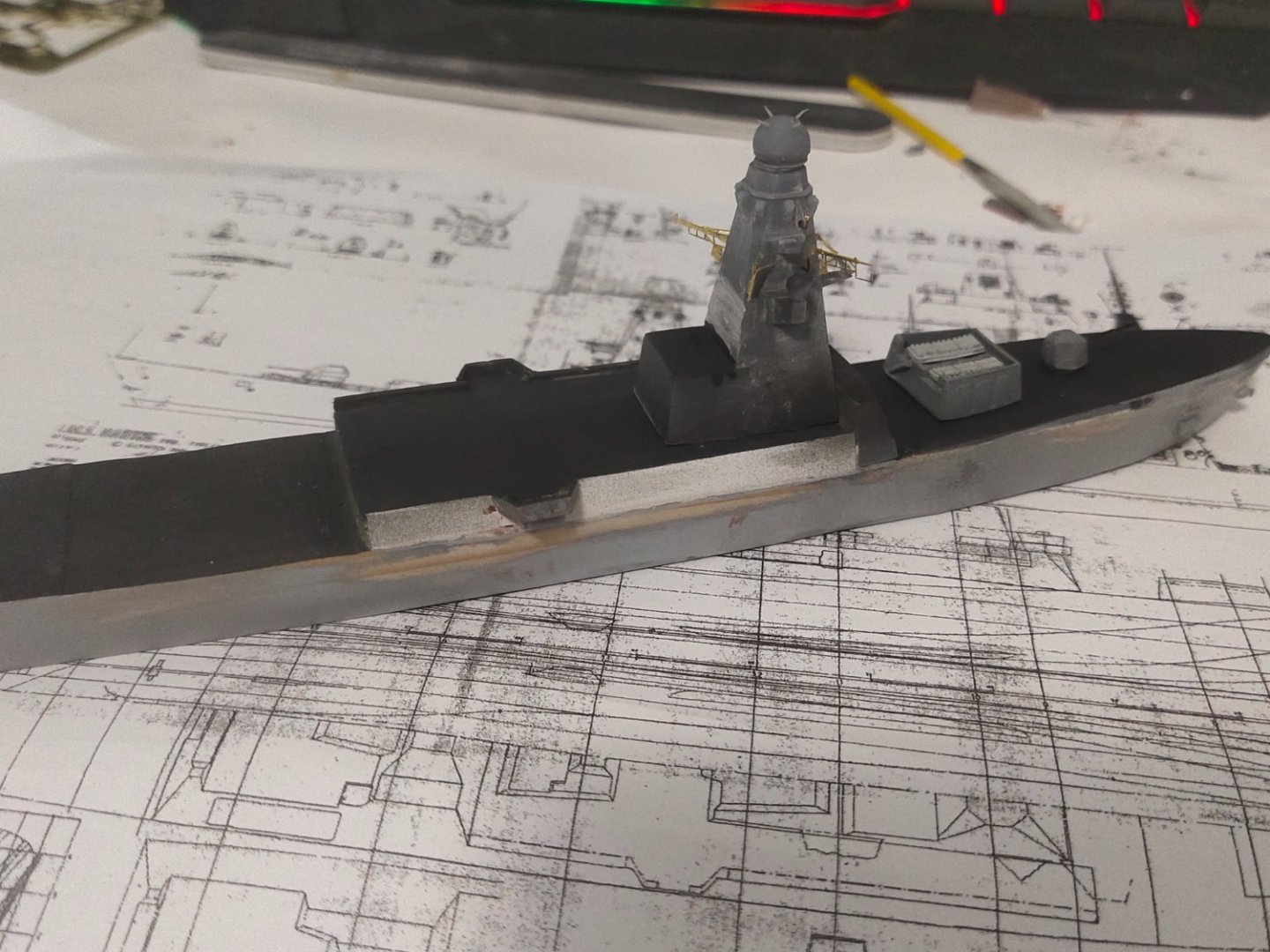

Type 45 Destroyer by mikegr - 1/700

mikegr replied to mikegr's topic in - Build logs for subjects built 1901 - Present Day

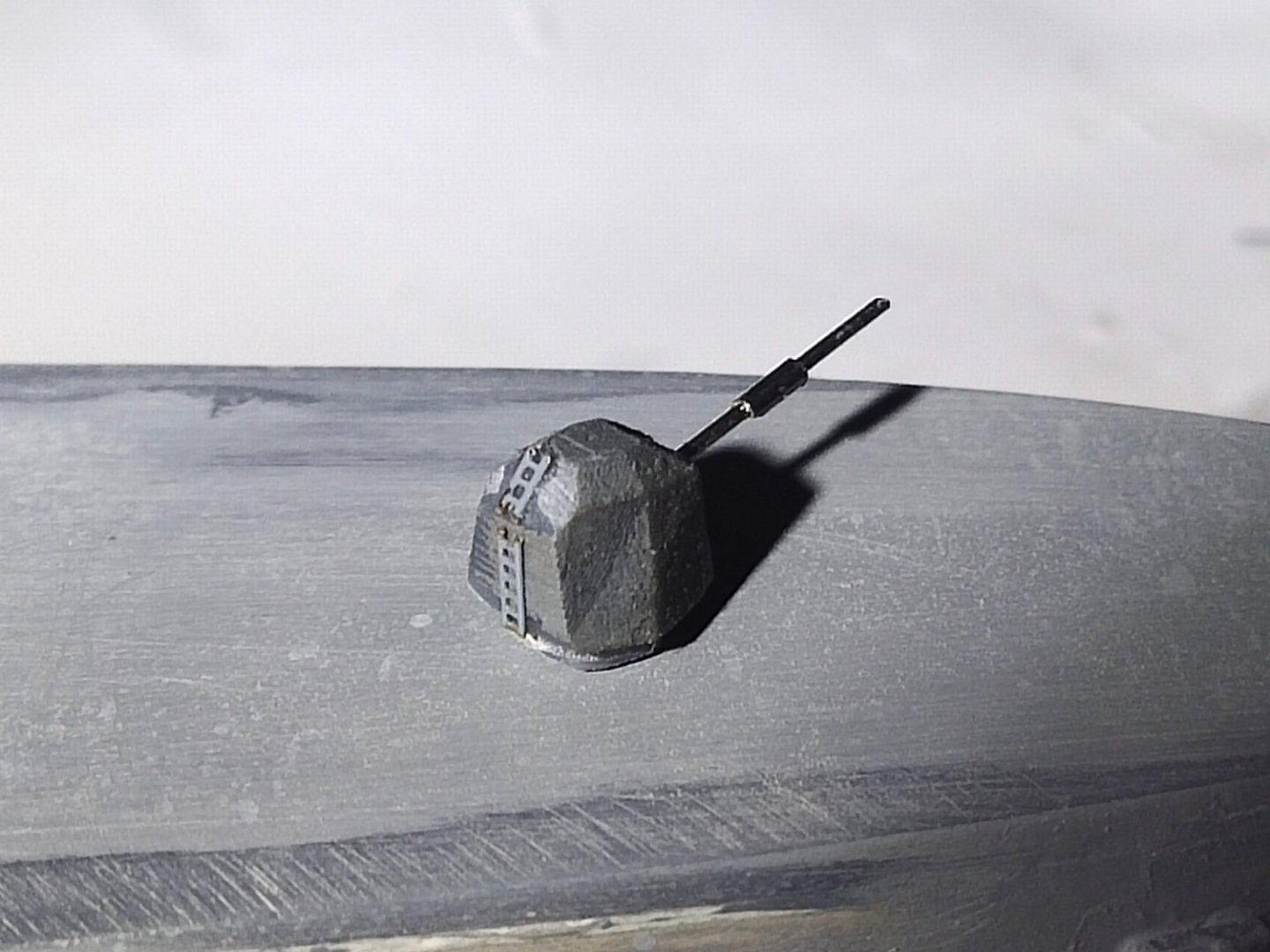

I redesigned the forward launcher in more reasonable dimensions and painted the Phalanx. Other details were added like barrel life raft and rings. -

mikegr reacted to a post in a topic:

Prinz Eugen by CraigVT - OcCre - 1:200

mikegr reacted to a post in a topic:

Prinz Eugen by CraigVT - OcCre - 1:200

-

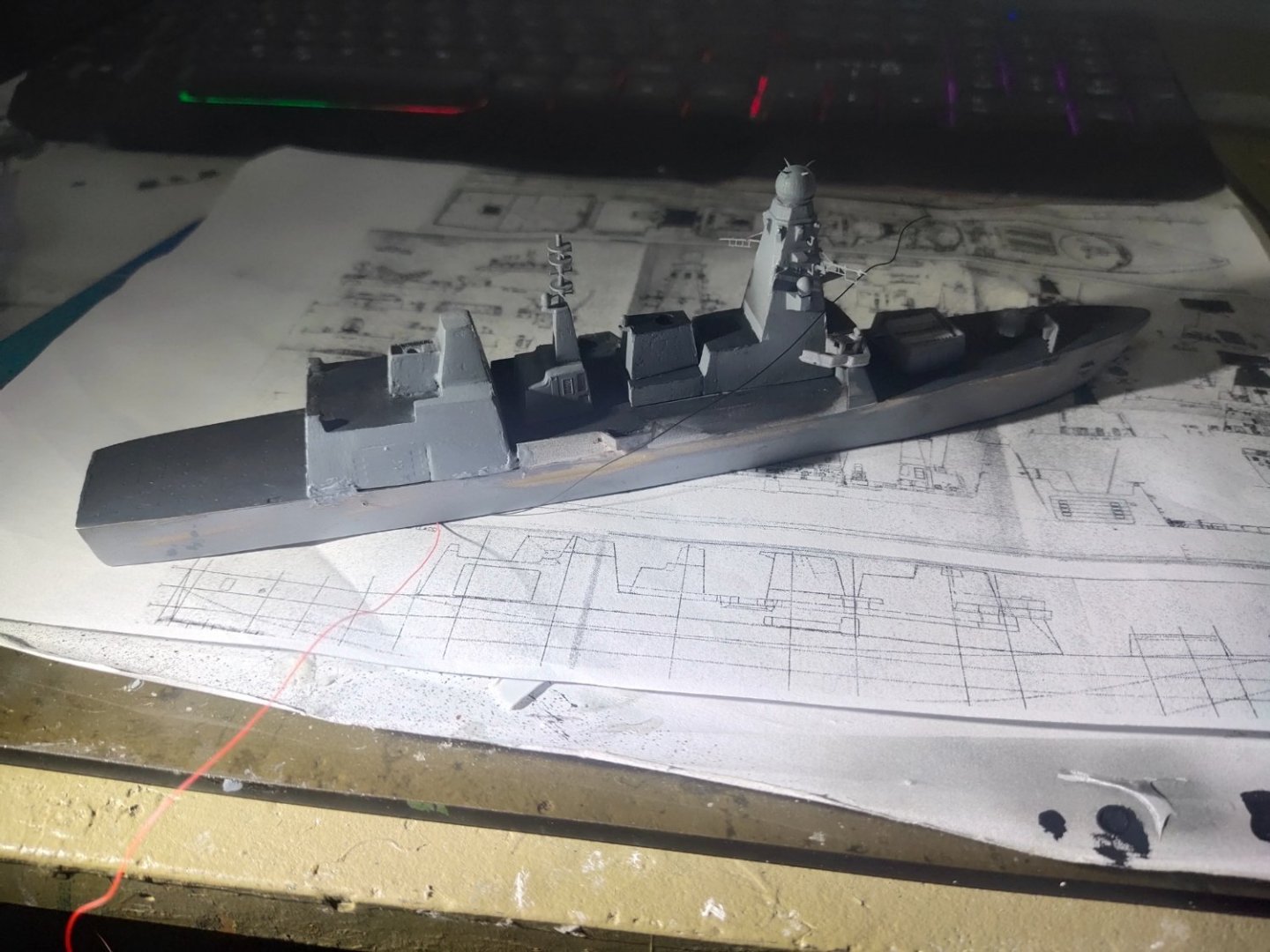

Type 45 Destroyer by mikegr - 1/700

mikegr replied to mikegr's topic in - Build logs for subjects built 1901 - Present Day

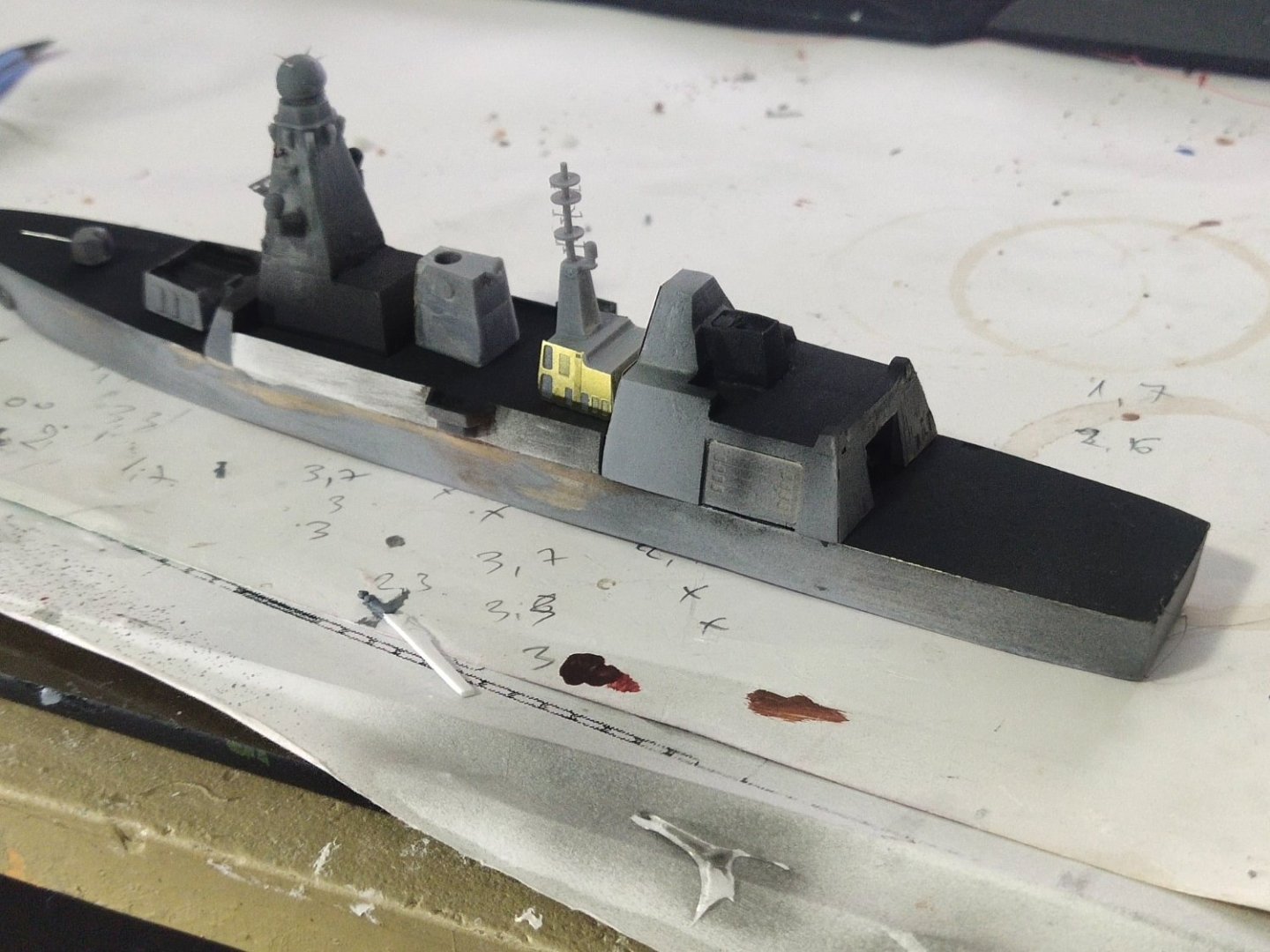

So after painting, repainting, fittings, misfittings, repairs and more I got to the point to glue all main pieces together. Now I need to add details, go for final paint job and rigging -

mikegr reacted to a post in a topic:

HMS Spiraea and HMS Zinnia by king derelict - Mirage Hobby - 1/350 - PLASTIC - Flower-Class Corvettes

mikegr reacted to a post in a topic:

HMS Spiraea and HMS Zinnia by king derelict - Mirage Hobby - 1/350 - PLASTIC - Flower-Class Corvettes

-

Type 45 Destroyer by mikegr - 1/700

mikegr replied to mikegr's topic in - Build logs for subjects built 1901 - Present Day

-

Some modelers report 300$ on upgrade parts for a 50$ kit. Though I do not count my spendings, I cannot cope with that

- 52 replies

-

- Curtis Wilbur

- I Love Kit

-

(and 1 more)

Tagged with:

-

mikegr reacted to a post in a topic:

USS Curtis Wilbur DDG-54 by patrickmil - I Love Kit - 1/200 - PLASTIC

mikegr reacted to a post in a topic:

USS Curtis Wilbur DDG-54 by patrickmil - I Love Kit - 1/200 - PLASTIC

-

mikegr reacted to a post in a topic:

HMS Dreadnought 1907 by RGL - FINISHED - Zvezda - 1/350 - PLASTIC - revisited

mikegr reacted to a post in a topic:

HMS Dreadnought 1907 by RGL - FINISHED - Zvezda - 1/350 - PLASTIC - revisited

-

- 52 replies

-

- Curtis Wilbur

- I Love Kit

-

(and 1 more)

Tagged with:

-

Type 45 Destroyer by mikegr - 1/700

mikegr replied to mikegr's topic in - Build logs for subjects built 1901 - Present Day

-

mikegr reacted to a post in a topic:

HMS Spiraea and HMS Zinnia by king derelict - Mirage Hobby - 1/350 - PLASTIC - Flower-Class Corvettes

mikegr reacted to a post in a topic:

HMS Spiraea and HMS Zinnia by king derelict - Mirage Hobby - 1/350 - PLASTIC - Flower-Class Corvettes

-

There is no cure. Whatever the scale there always will be tiny things that have to be worked with absolute precision. Its just the amount of work that differs like painting hulls in 1/200 instead on 1/700

- 33 replies

-

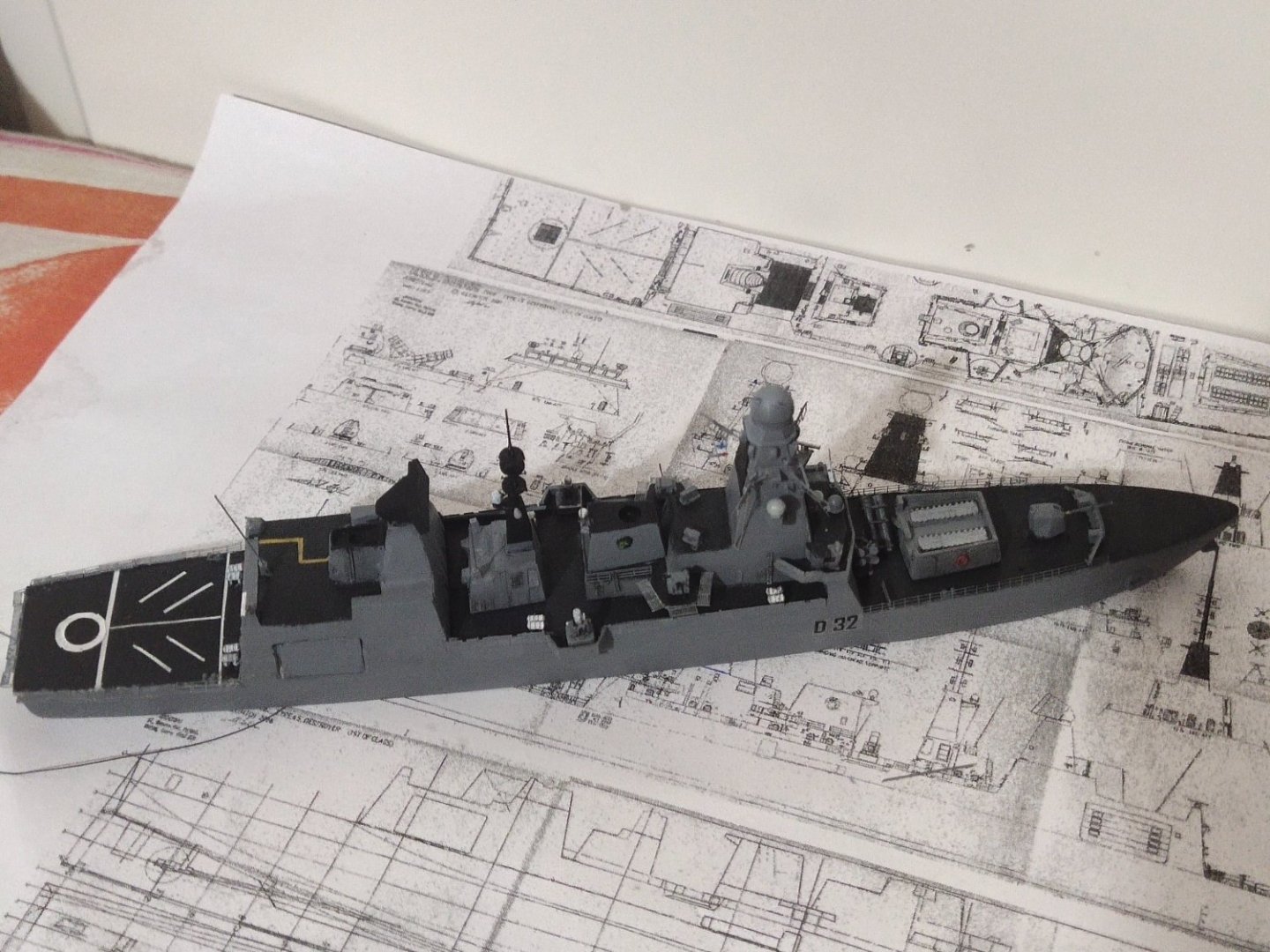

Type 45 Destroyer by mikegr - 1/700

mikegr replied to mikegr's topic in - Build logs for subjects built 1901 - Present Day

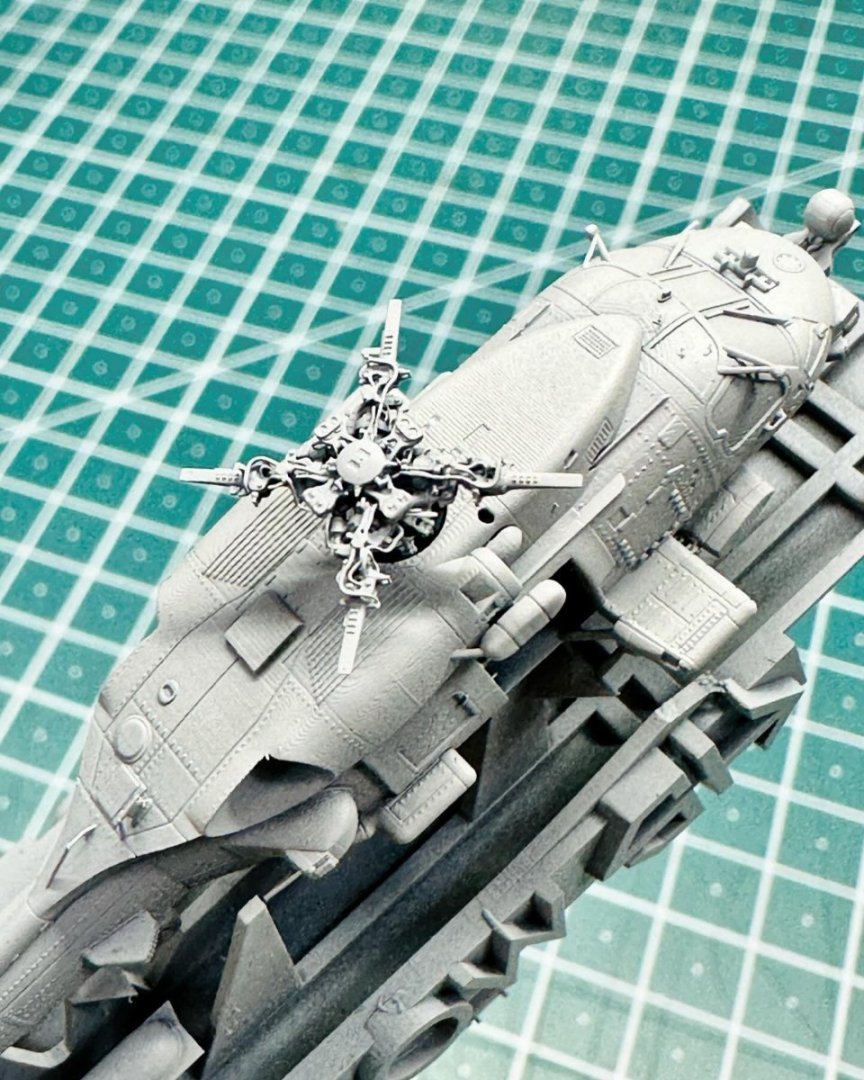

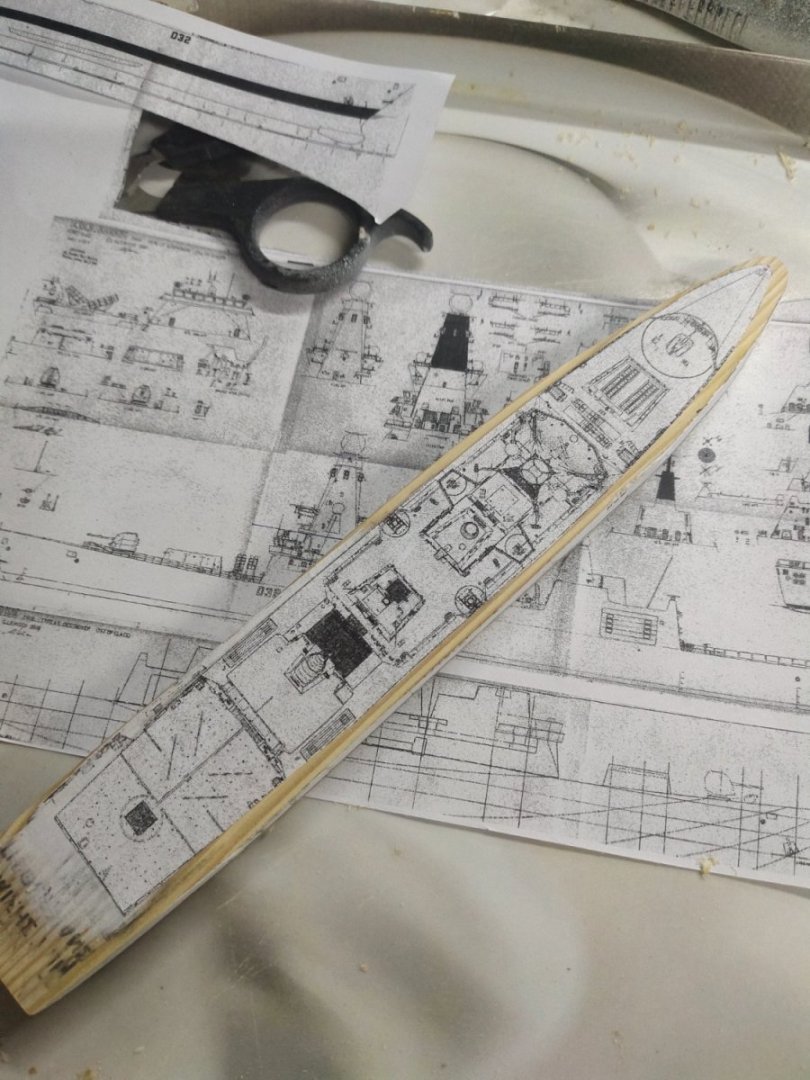

I printed most of the parts.Since I used a plan to calculate the size of the pieces and the PE parts are made to replace standard plastic parts of specific kits some misfitting is expected. Some PEs won't be used as the required details is already designed at the parts I printed. -

Type 45 Destroyer by mikegr - 1/700

mikegr replied to mikegr's topic in - Build logs for subjects built 1901 - Present Day

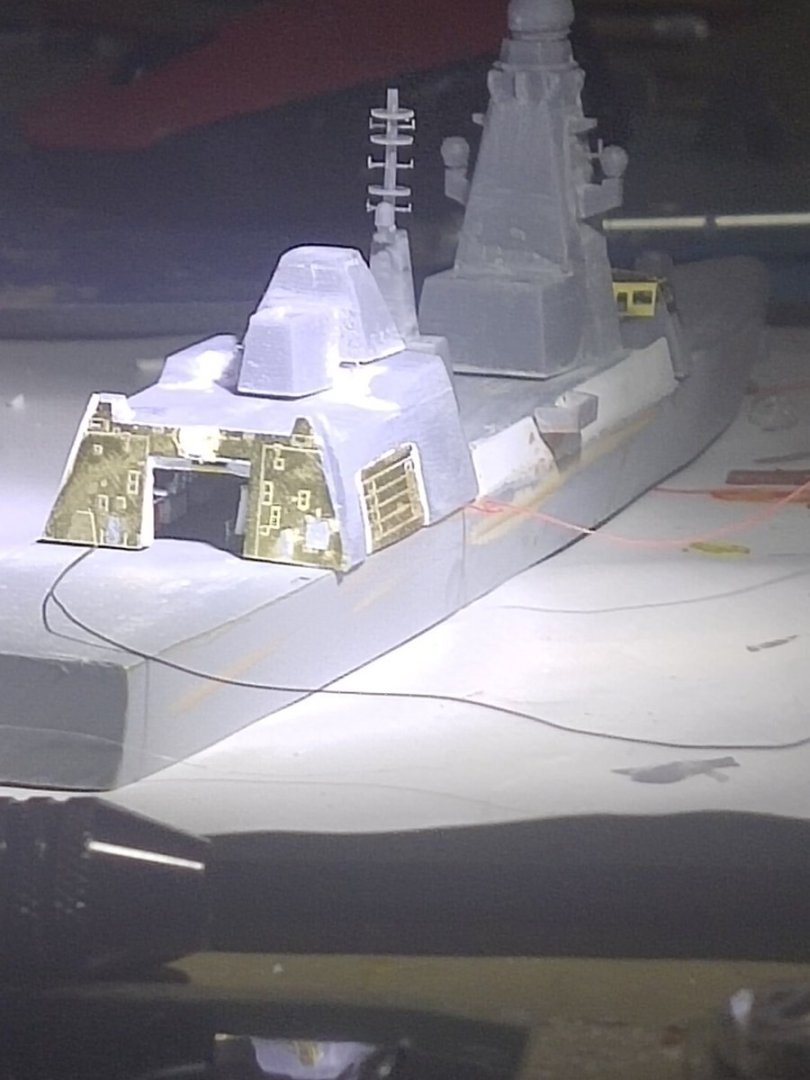

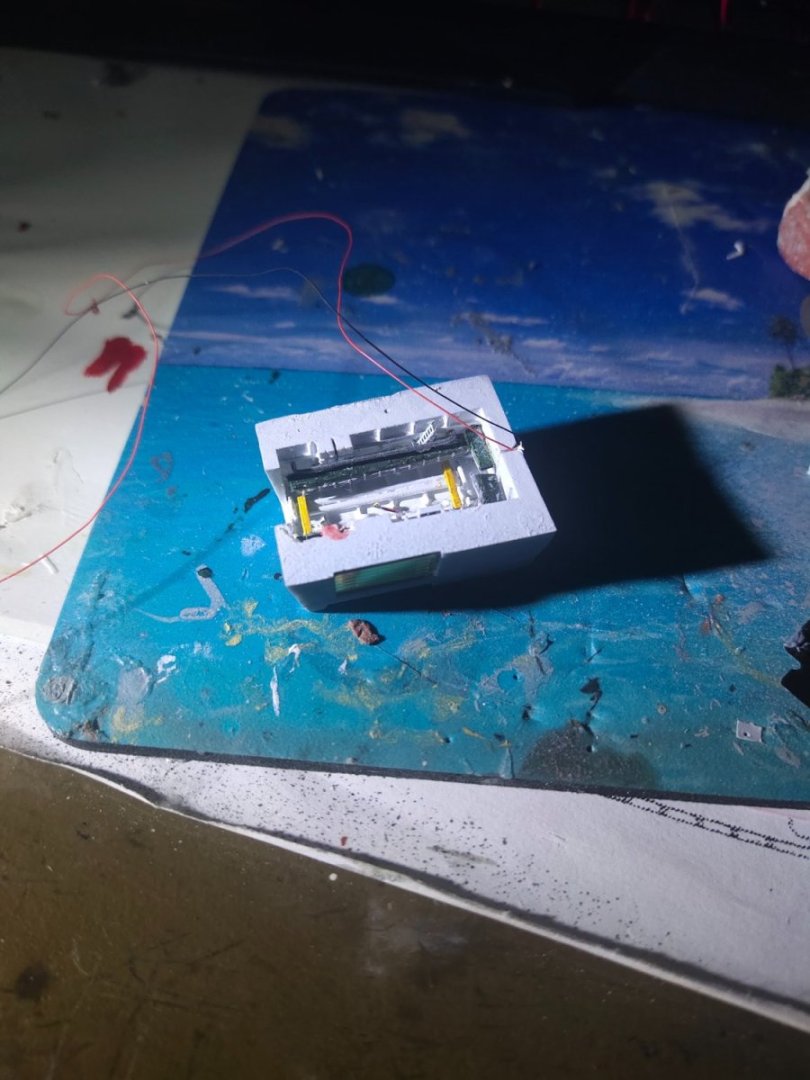

So I made the second part and glued them together. Light was tested. Some misfittings at the end of the hangar won't be visible so I don't bother. -

Type 45 Destroyer by mikegr - 1/700

mikegr replied to mikegr's topic in - Build logs for subjects built 1901 - Present Day

Next was the hangar. I printed the right half and made some adjustment to fit the PE externally. I made them in separate pieces so I can scratch built the interior more easily them glue them together. Like in Horizon class because of the side compartments for inflatable storage, the heli hangar is somewhat narrow. -

Type 45 Destroyer by mikegr - 1/700

mikegr replied to mikegr's topic in - Build logs for subjects built 1901 - Present Day

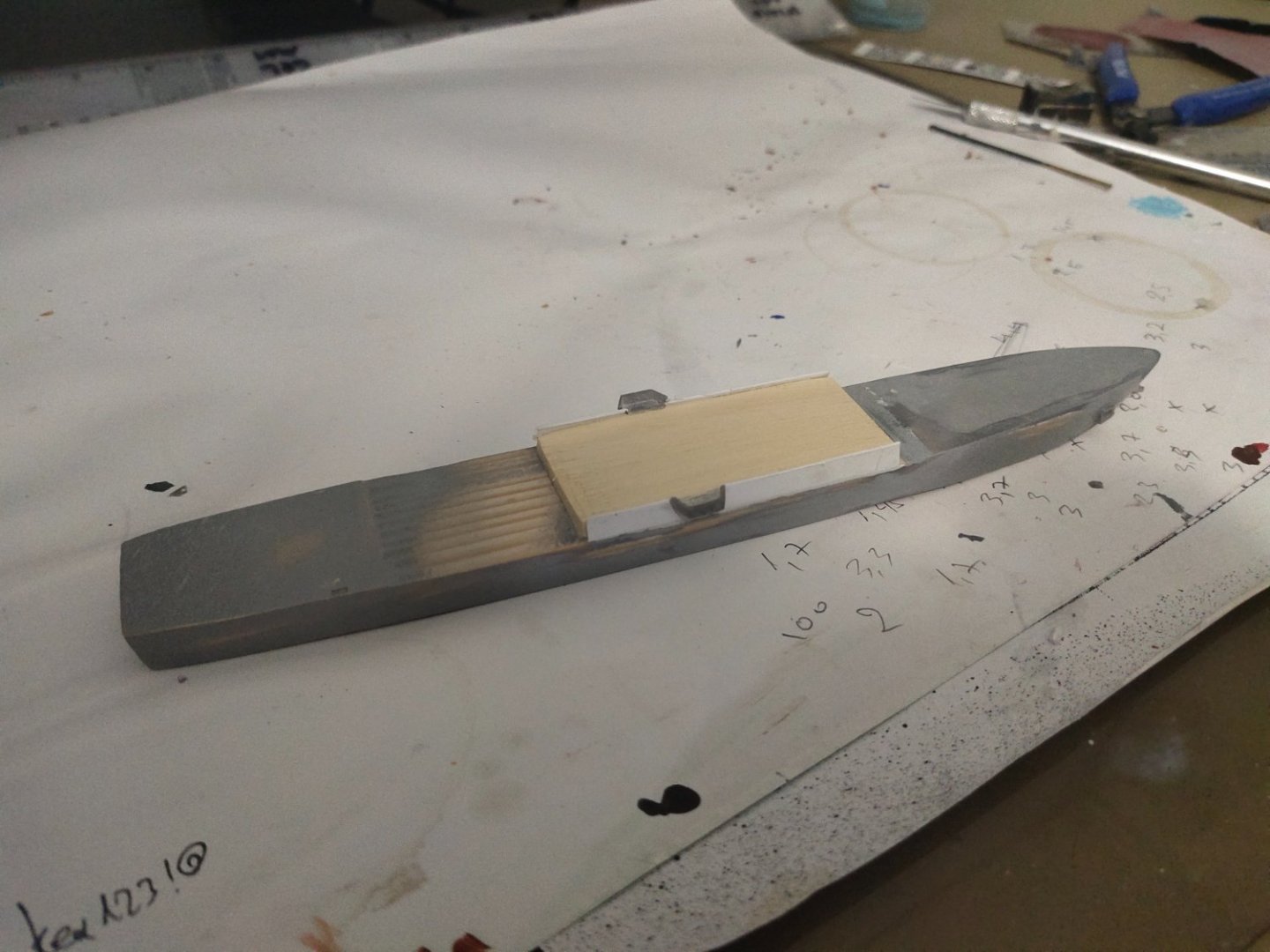

Next was to print the central area between the hangar and the bridge where funnels and towers will placed upon. However because of warping problems that I couldn't solve after many attempts, I removed it and replaced it with plywood wrapped with plastic fillets for a smoother finish. This handwork took me 2 hours instead of 2 wasted evenings, what a bitter lesson. Fortunately the other piece, the main canon printed just fine and a barrel made of needle pieces was added along with hand rails. -

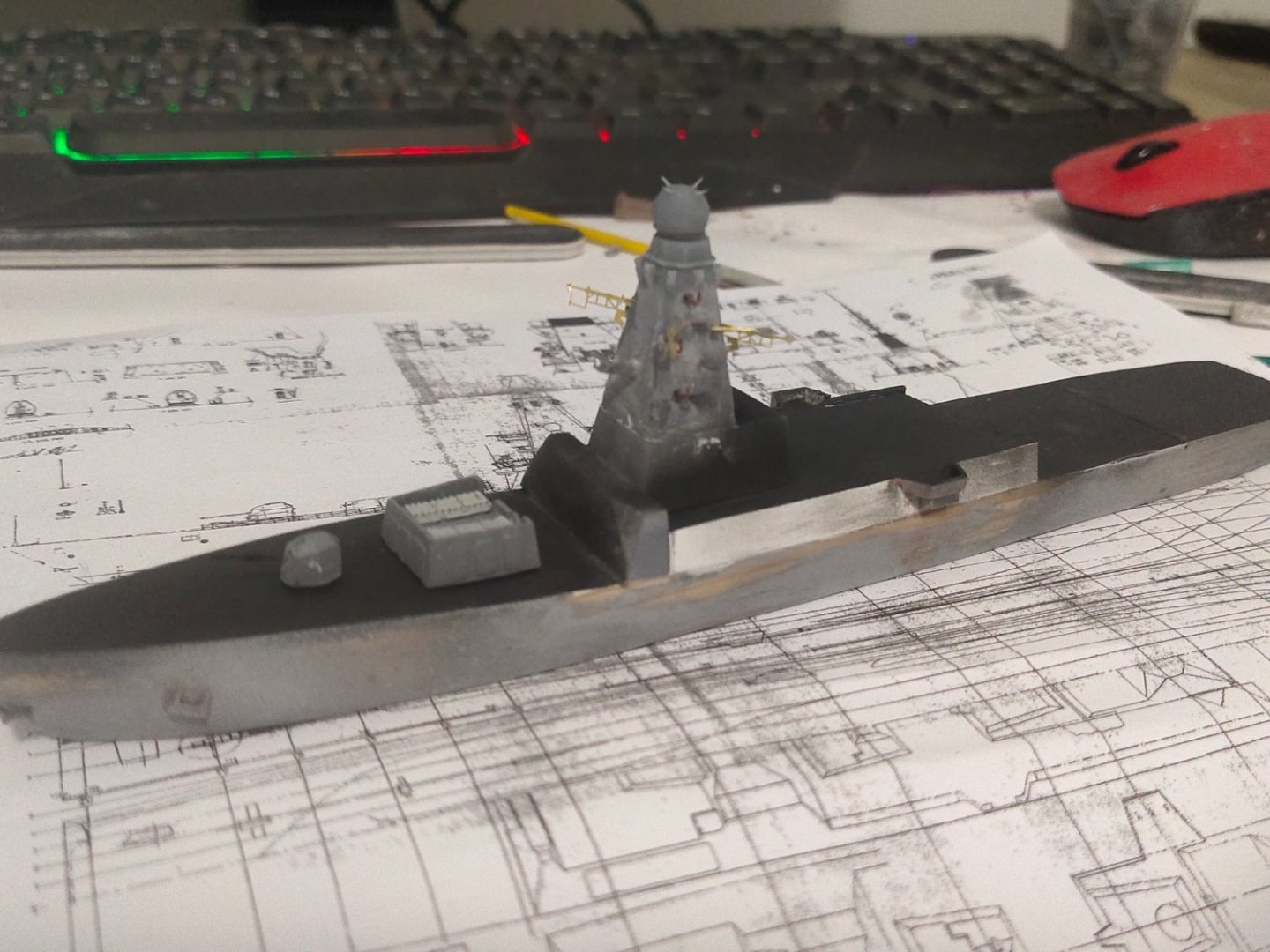

Type 45 Destroyer by mikegr - 1/700

mikegr replied to mikegr's topic in - Build logs for subjects built 1901 - Present Day

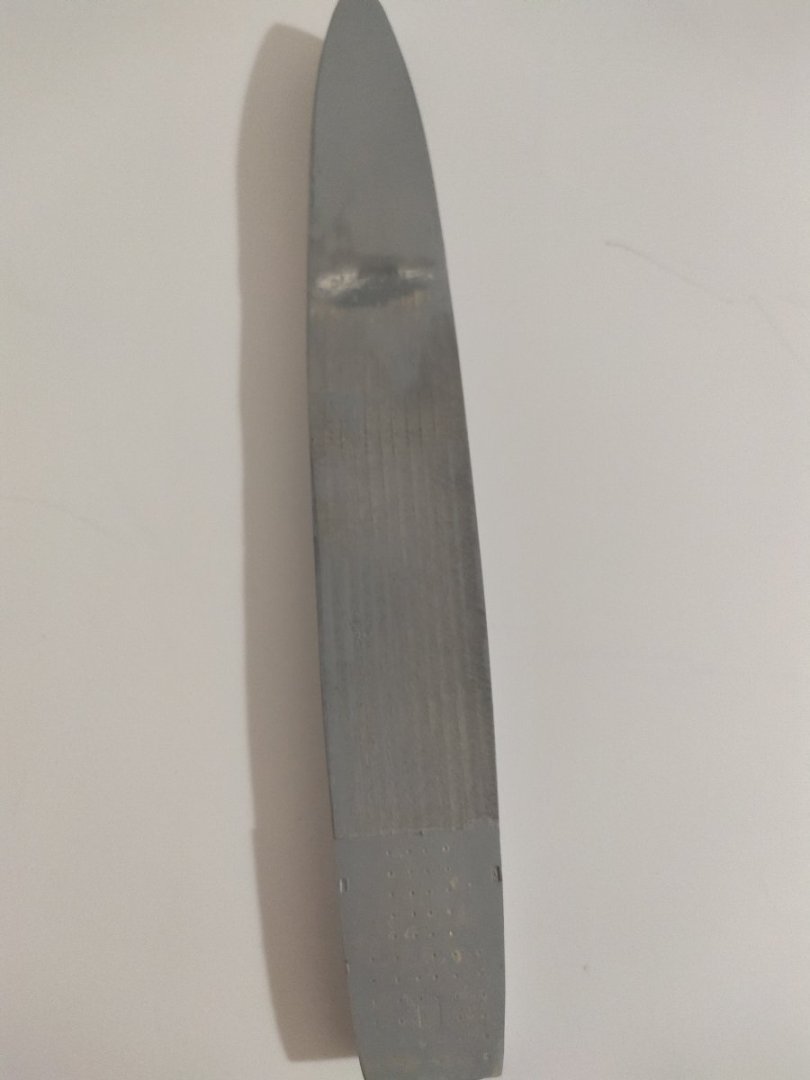

I made the hull. It looked clumsy and wide. I had to remeasure to get the proper dimensions Excess "fat" was trimmed down and it was shortened by 3 cm. After more careful work I shaped the sides and upon finish wood was polished Then, I add the PE heli deck on rear and a 2.5 mm piece of resin on bow to make the right elevation Finally priming and sanding the bow, stern and the sides, several times.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.