-

Posts

241 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Melbourne, Australia

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

ubjs reacted to a post in a topic:

Golden Hind(e) by rkwz - AIRFIX - 1:72

ubjs reacted to a post in a topic:

Golden Hind(e) by rkwz - AIRFIX - 1:72

-

Zocane reacted to a post in a topic:

HMS Victory by rkwz - AIRFIX - Scale 1:180 - First plastic ship build

Zocane reacted to a post in a topic:

HMS Victory by rkwz - AIRFIX - Scale 1:180 - First plastic ship build

-

Zocane reacted to a post in a topic:

HMS Victory by rkwz - AIRFIX - Scale 1:180 - First plastic ship build

Zocane reacted to a post in a topic:

HMS Victory by rkwz - AIRFIX - Scale 1:180 - First plastic ship build

-

Zocane reacted to a post in a topic:

HMS Victory by rkwz - AIRFIX - Scale 1:180 - First plastic ship build

Zocane reacted to a post in a topic:

HMS Victory by rkwz - AIRFIX - Scale 1:180 - First plastic ship build

-

Zocane reacted to a post in a topic:

HMS Victory by rkwz - AIRFIX - Scale 1:180 - First plastic ship build

Zocane reacted to a post in a topic:

HMS Victory by rkwz - AIRFIX - Scale 1:180 - First plastic ship build

-

Zocane reacted to a post in a topic:

HMS Victory by rkwz - AIRFIX - Scale 1:180 - First plastic ship build

Zocane reacted to a post in a topic:

HMS Victory by rkwz - AIRFIX - Scale 1:180 - First plastic ship build

-

Zocane reacted to a post in a topic:

HMS Victory by rkwz - AIRFIX - Scale 1:180 - First plastic ship build

Zocane reacted to a post in a topic:

HMS Victory by rkwz - AIRFIX - Scale 1:180 - First plastic ship build

-

Zocane reacted to a post in a topic:

HMS Victory by rkwz - AIRFIX - Scale 1:180 - First plastic ship build

Zocane reacted to a post in a topic:

HMS Victory by rkwz - AIRFIX - Scale 1:180 - First plastic ship build

-

Old Collingwood reacted to a post in a topic:

Golden Hind(e) by rkwz - AIRFIX - 1:72

Old Collingwood reacted to a post in a topic:

Golden Hind(e) by rkwz - AIRFIX - 1:72

-

Old Collingwood reacted to a post in a topic:

Golden Hind(e) by rkwz - AIRFIX - 1:72

Old Collingwood reacted to a post in a topic:

Golden Hind(e) by rkwz - AIRFIX - 1:72

-

rkwz reacted to a post in a topic:

Golden Hind (ex-Pelican) by Baker - FINISHED - scale 1/45 - Galleon late 16th century

rkwz reacted to a post in a topic:

Golden Hind (ex-Pelican) by Baker - FINISHED - scale 1/45 - Galleon late 16th century

-

Always a pleasure reading your log, Patrick (it has been a while). A man of many talents! Love the work on those sails

- 756 replies

-

- galleon

- golden hind

-

(and 2 more)

Tagged with:

-

rkwz reacted to a post in a topic:

Golden Hind (ex-Pelican) by Baker - FINISHED - scale 1/45 - Galleon late 16th century

rkwz reacted to a post in a topic:

Golden Hind (ex-Pelican) by Baker - FINISHED - scale 1/45 - Galleon late 16th century

-

rkwz reacted to a post in a topic:

Golden Hind(e) by rkwz - AIRFIX - 1:72

rkwz reacted to a post in a topic:

Golden Hind(e) by rkwz - AIRFIX - 1:72

-

rkwz reacted to a post in a topic:

Golden Hind (ex-Pelican) by Baker - FINISHED - scale 1/45 - Galleon late 16th century

rkwz reacted to a post in a topic:

Golden Hind (ex-Pelican) by Baker - FINISHED - scale 1/45 - Galleon late 16th century

-

rkwz reacted to a post in a topic:

Golden Hind (ex-Pelican) by Baker - FINISHED - scale 1/45 - Galleon late 16th century

rkwz reacted to a post in a topic:

Golden Hind (ex-Pelican) by Baker - FINISHED - scale 1/45 - Galleon late 16th century

-

rkwz reacted to a post in a topic:

Golden Hind (ex-Pelican) by Baker - FINISHED - scale 1/45 - Galleon late 16th century

rkwz reacted to a post in a topic:

Golden Hind (ex-Pelican) by Baker - FINISHED - scale 1/45 - Galleon late 16th century

-

rkwz reacted to a post in a topic:

Golden Hind (ex-Pelican) by Baker - FINISHED - scale 1/45 - Galleon late 16th century

rkwz reacted to a post in a topic:

Golden Hind (ex-Pelican) by Baker - FINISHED - scale 1/45 - Galleon late 16th century

-

rkwz reacted to a post in a topic:

Golden Hind (ex-Pelican) by Baker - FINISHED - scale 1/45 - Galleon late 16th century

rkwz reacted to a post in a topic:

Golden Hind (ex-Pelican) by Baker - FINISHED - scale 1/45 - Galleon late 16th century

-

rkwz reacted to a post in a topic:

Golden Hind (ex-Pelican) by Baker - FINISHED - scale 1/45 - Galleon late 16th century

rkwz reacted to a post in a topic:

Golden Hind (ex-Pelican) by Baker - FINISHED - scale 1/45 - Galleon late 16th century

-

.thumb.jpeg.d239701c2f7247a100a3f432822c4eda.jpeg)

Golden Hind(e) by rkwz - AIRFIX - 1:72

rkwz replied to rkwz's topic in - Kit build logs for subjects built from 1501 - 1750

Hello Kirill, it has been a while. I have been busy with life and work unfortunately so I haven't had the time to work on the model! It will come... -

rkwz reacted to a post in a topic:

Quanzhou Ship by Schrader - 1:54 - Chinese Junk

rkwz reacted to a post in a topic:

Quanzhou Ship by Schrader - 1:54 - Chinese Junk

-

Great discussion guys and loving the extra effort put into the rigging, Bill. You're in good hands with Kirill4 and Patrick guiding you

-

Superb! My favourite is the 1780 with it's friezes and deck scrubbers. But they're all excellent in any case Happy New Year to you Daniel!

-

Neat paintwork, you must have buckets of patience and a steady hand Bill! Merry Christmas!

-

Excellent advice as always, @kirill4. I went ahead and got those 2 books to finish my Xmas shopping although they won't arrive till after haha. I suppose the publishers will be pleased with that and won't be too offended with the pdf link posted earlier? 😉 @bosco72, keep up the good work and remember, build what makes you happy as it's your model... Although I agree with kirill4 that having a crack at learning some new rigging techniques is very rewarding although a further investment in time and effort

- 265 replies

-

- Golden Hind

- Airfix

-

(and 1 more)

Tagged with:

-

.thumb.jpeg.d239701c2f7247a100a3f432822c4eda.jpeg)

Golden Hind(e) by rkwz - AIRFIX - 1:72

rkwz replied to rkwz's topic in - Kit build logs for subjects built from 1501 - 1750

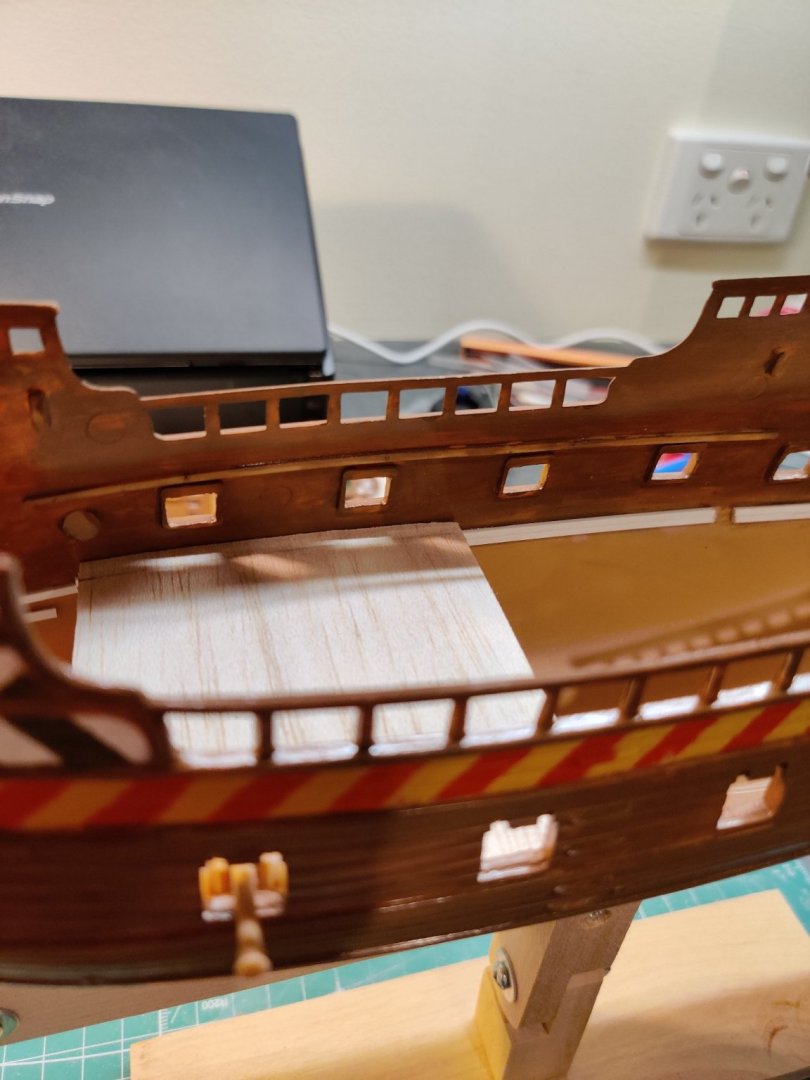

Sorry, I meant the spritsail yard which was bent upwards, haha. My Victory rig was pretty basic, no time spent making actual rope so I must have saved a year's worth of effort! Not sure I can get away with the Golden Hind at 1:72 scale though... Just read your amazing spanish galleon build log, kirill4... I will be re-reading it again and again, taking notes. You humble me with your kind comments, but I'm really just a two bit hack at this 😅 Meanwhile at the dockyard... Started test fitting some false decking. Styrene strips cemented below the gunports, realised later the level was too low and added an extra 1.5mm strip above to compensate. Calipers used to mark out where the strips were to be laid... Initially planned to use balsawood, then realised my planks weren't wide enough so I flipped it and recut the deck , hence the incorrect direction of the wood grain. I wonder if it is even visible through the gunports? But it'll always be nagging me in the back of my mind so I'll just have to be patient and source some wider planks and use what I've made today as a template/jig. Also, I've marked out the waterline using a simple jig (helping hands clamped onto a pencil 😅), but holding off the paint job until I have the time to pop into my local to grab some white acrylic paint... Birch wood veneer deck applied with CA and first coat of wipe on poly applied. Hopefully it'll protect it from the inevitable paint and glue splatter later on. -

.thumb.jpeg.d239701c2f7247a100a3f432822c4eda.jpeg)

Golden Hind(e) by rkwz - AIRFIX - 1:72

rkwz replied to rkwz's topic in - Kit build logs for subjects built from 1501 - 1750

Thanks Krill, I agree with you. The plastic molded yardarms look good with the detail already molded in but may not hold up well later due to rigging later. I haven't worked with wood much and honestly am a bit worried I'll mess it up, so will be experimenting with bbq skewers or toothpicks and a mini hand plane, watch this space. Funny you mentioned the bowspirit issues, here is a pic of my Victory build for a laugh showing a severe upward bend because there wasn't a counterbalancing stay, whereas the rest of the spars actually turned out ok provided I adjusted the tension in the rigging carefully on either end. I must find your spanish galleon log for more inspo! Cheers -

.thumb.jpeg.d239701c2f7247a100a3f432822c4eda.jpeg)

Golden Hind(e) by rkwz - AIRFIX - 1:72

rkwz replied to rkwz's topic in - Kit build logs for subjects built from 1501 - 1750

Thank you, Kirill. I've had fun with this so far, the parts are nicely molded and easy to work with at this scale, I'm sure you will too when you get to kit bashing the Hind. Why don't you post a log too? Still battling on with a false deck for the lower deck cannons and making sure everything aligns nicely before glueing the parts together, not to mention waiting for paint to dry between coats... Lots of learning for this newbie still -

It's great the kit doesn't have too much excess flashing...looks like a fun kit to work with and I especially like the window and door details. Good luck with your build, looking forward to more progress pics! Cheers

-

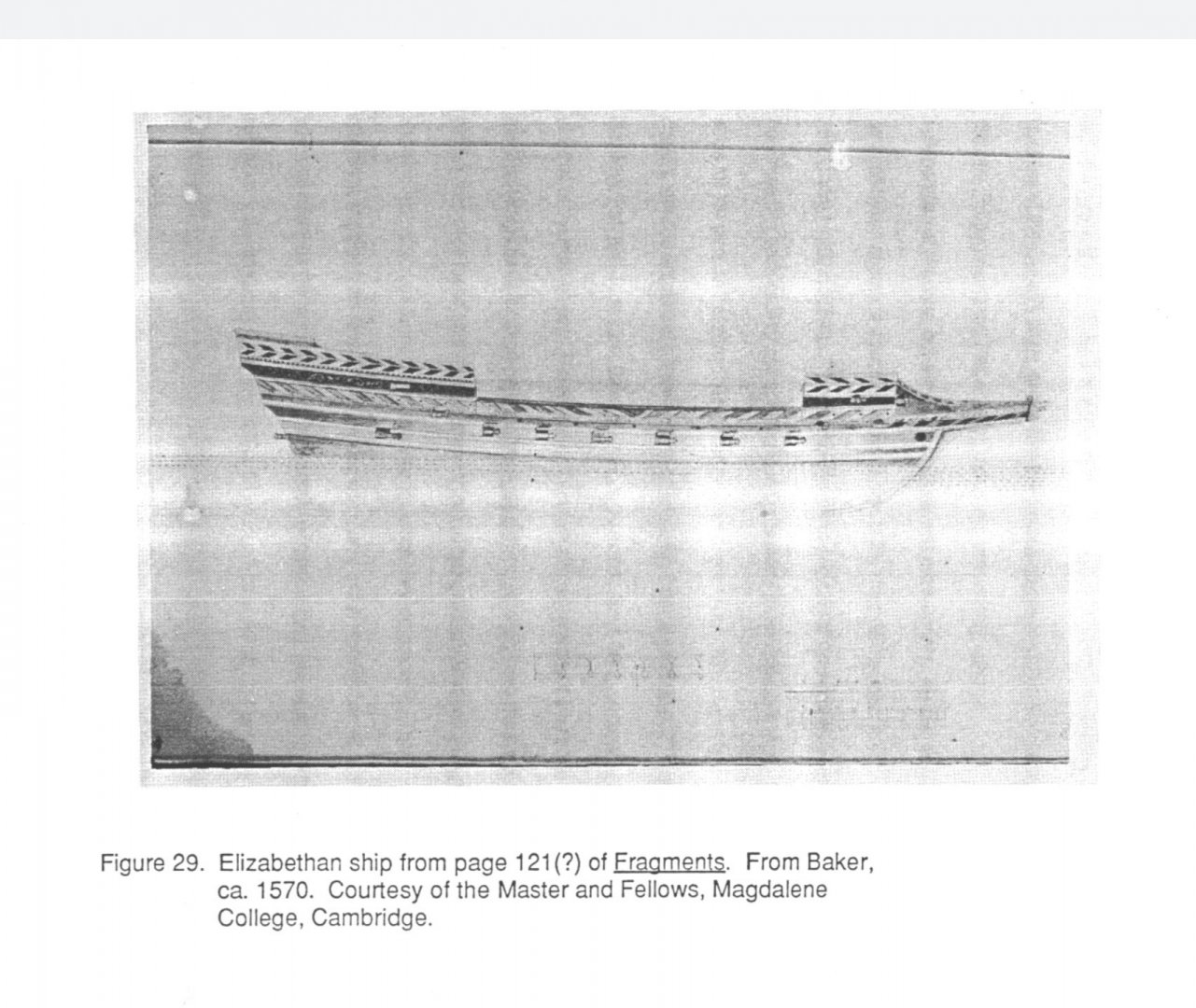

Oh yes, and I forgot to mention a few coats of thinned paint works better... As for the chevron design, I based my paint scheme on this image from a resource shared by Backer ... a concept sketch by Matthew Baker (Fragments of Ancient English shipwrightry) And a supposedly 16th century unattributed painting of the Armada in action vs English ships. It seems spanish ships had chevron patterns pointing towards the stern, while the English, towards the bow. I also felt the Pelican was probably less elaborately decorated compared to the "Queen's ships" and more of an "armed merchantman". Of course the beauty of the Golden Hind is you could always let your imagination run riot and claim artistic license

-

.thumb.jpeg.d239701c2f7247a100a3f432822c4eda.jpeg)

Arado 196B by Danstream - Revell 1:32 - FINISHED

rkwz replied to Danstream's topic in Non-ship/categorised builds

I thought I was looking at the real thing for a moment! I admittedly don't know much about planes, but is that a BMW engine I see? 😄

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.