-

Posts

1,238 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by John Ruy

-

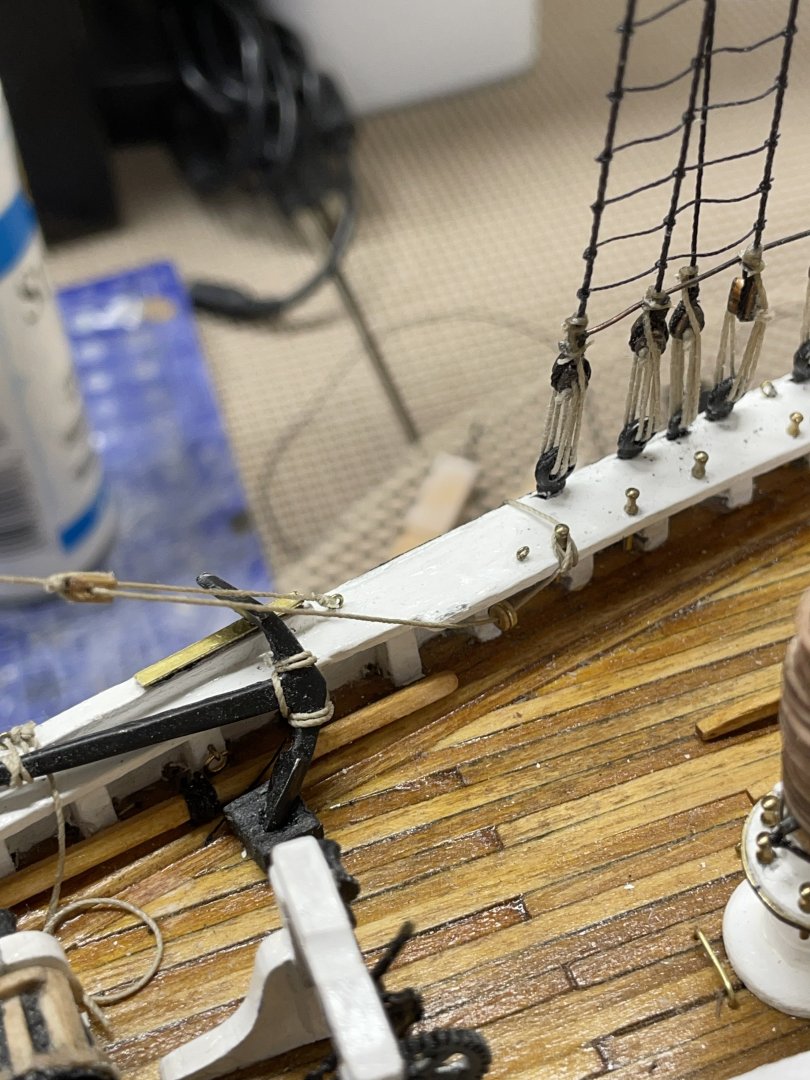

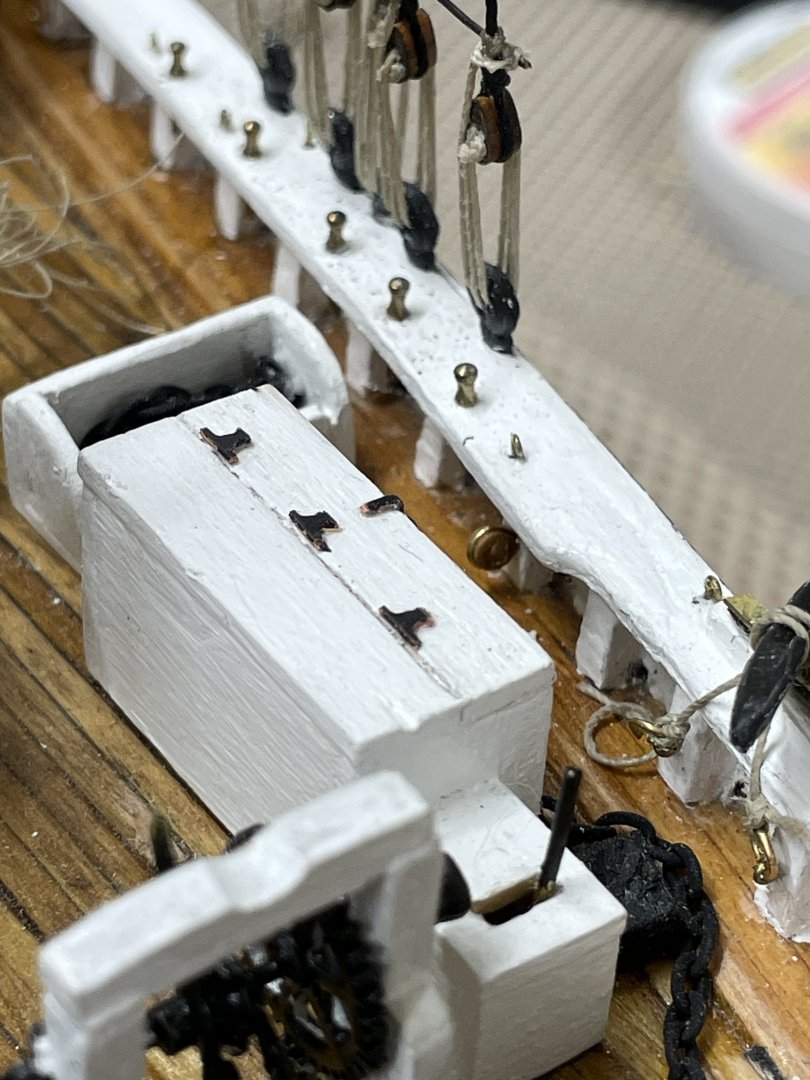

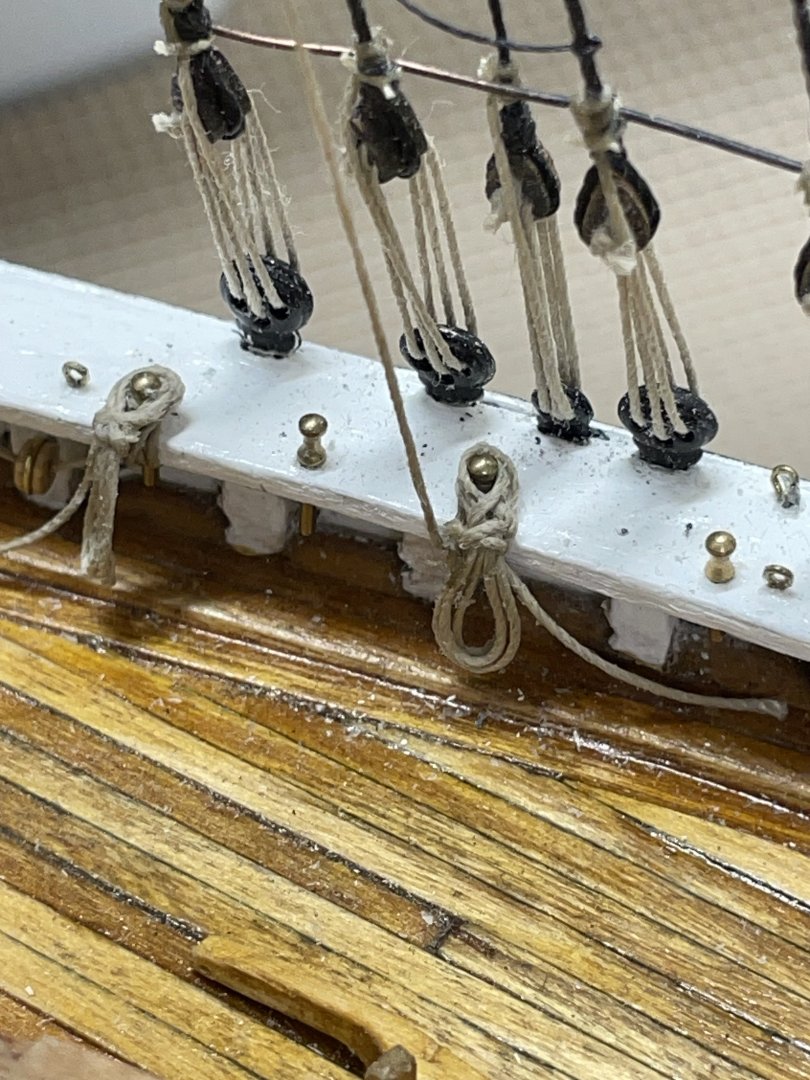

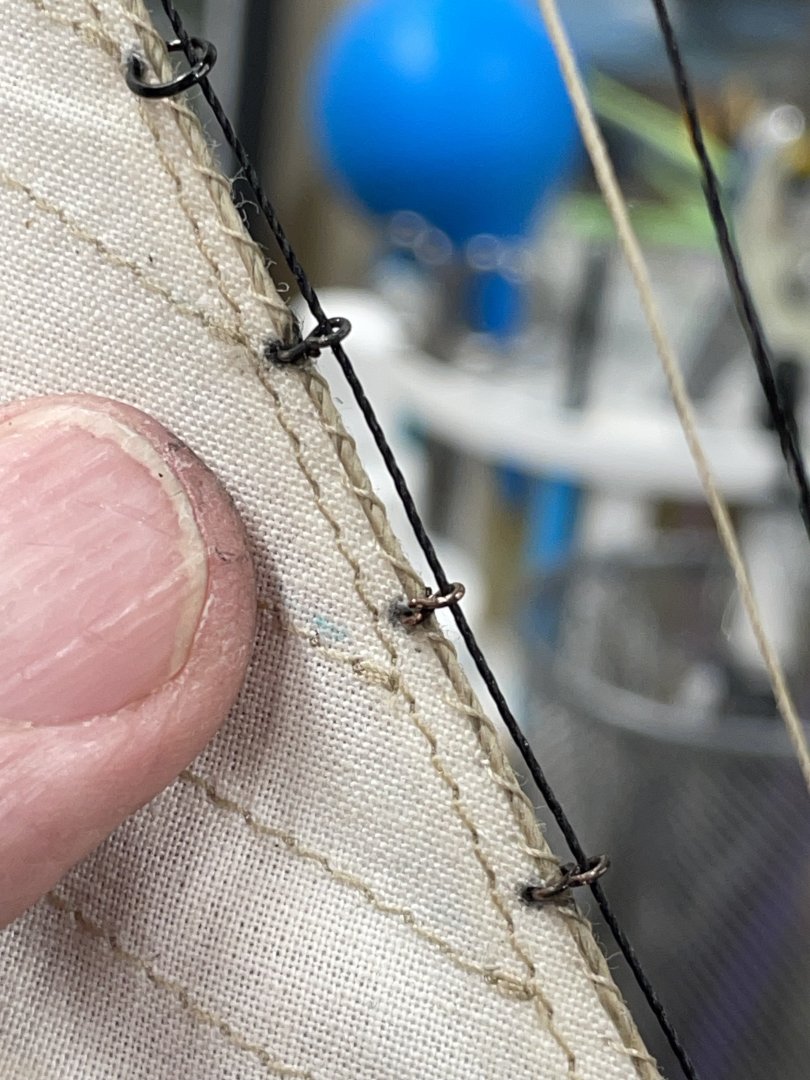

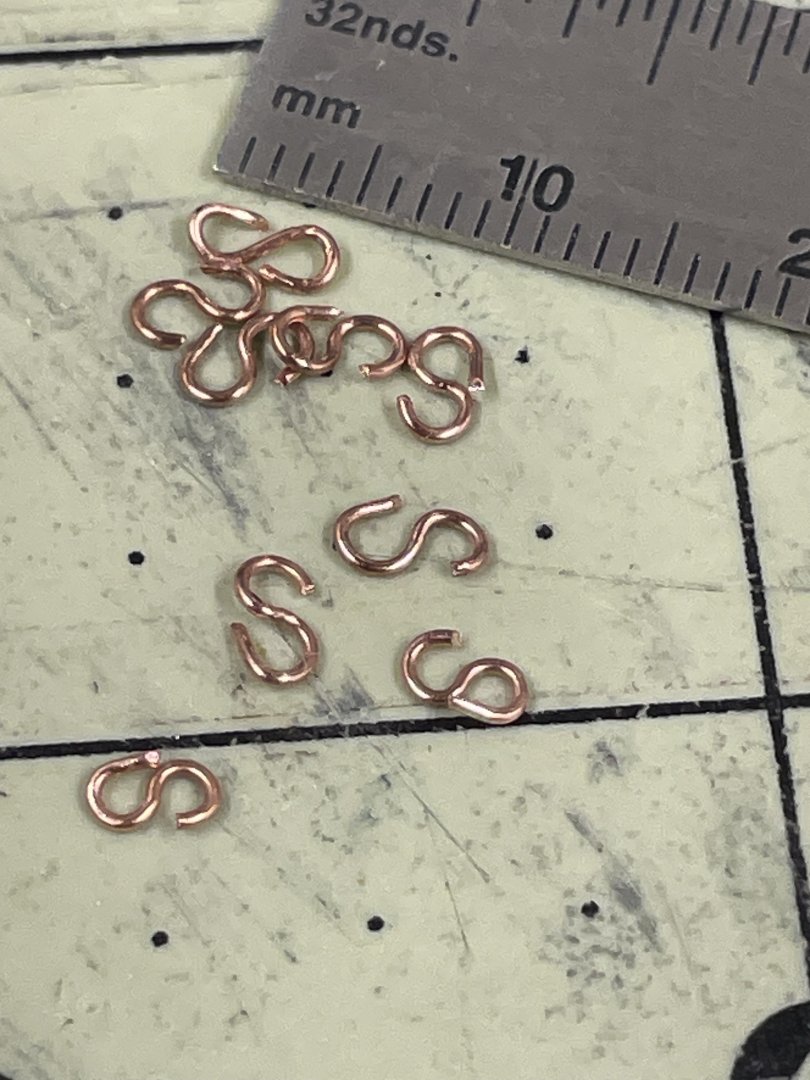

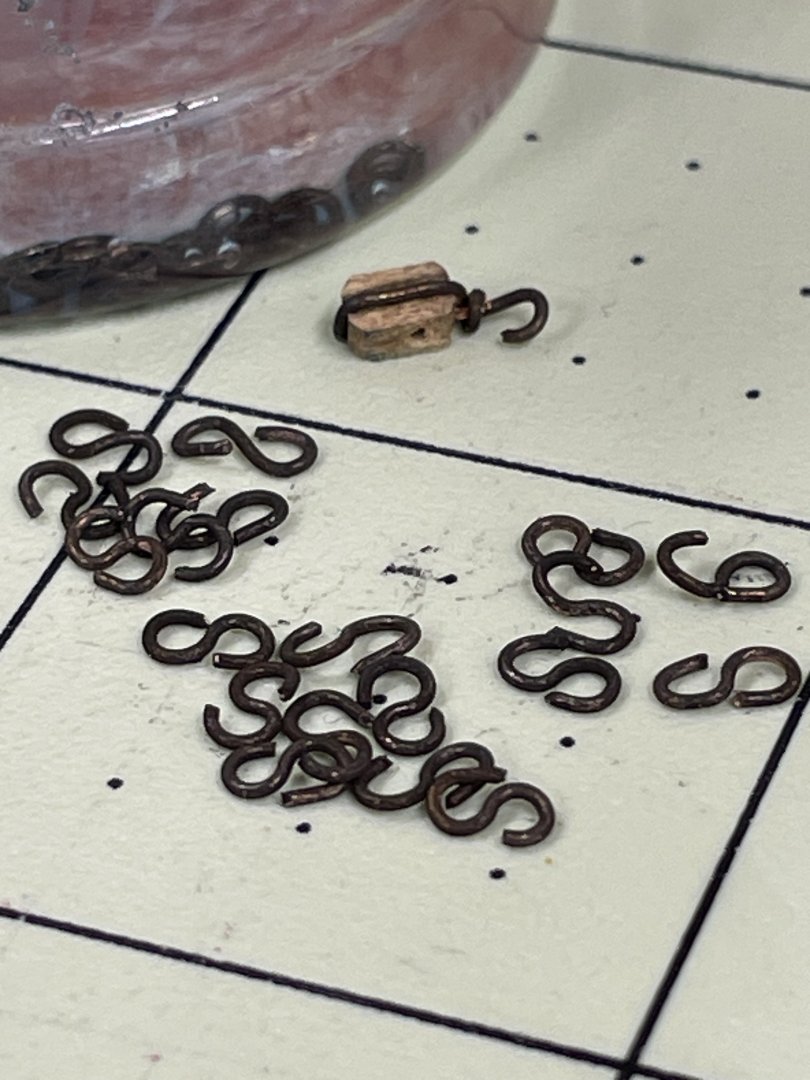

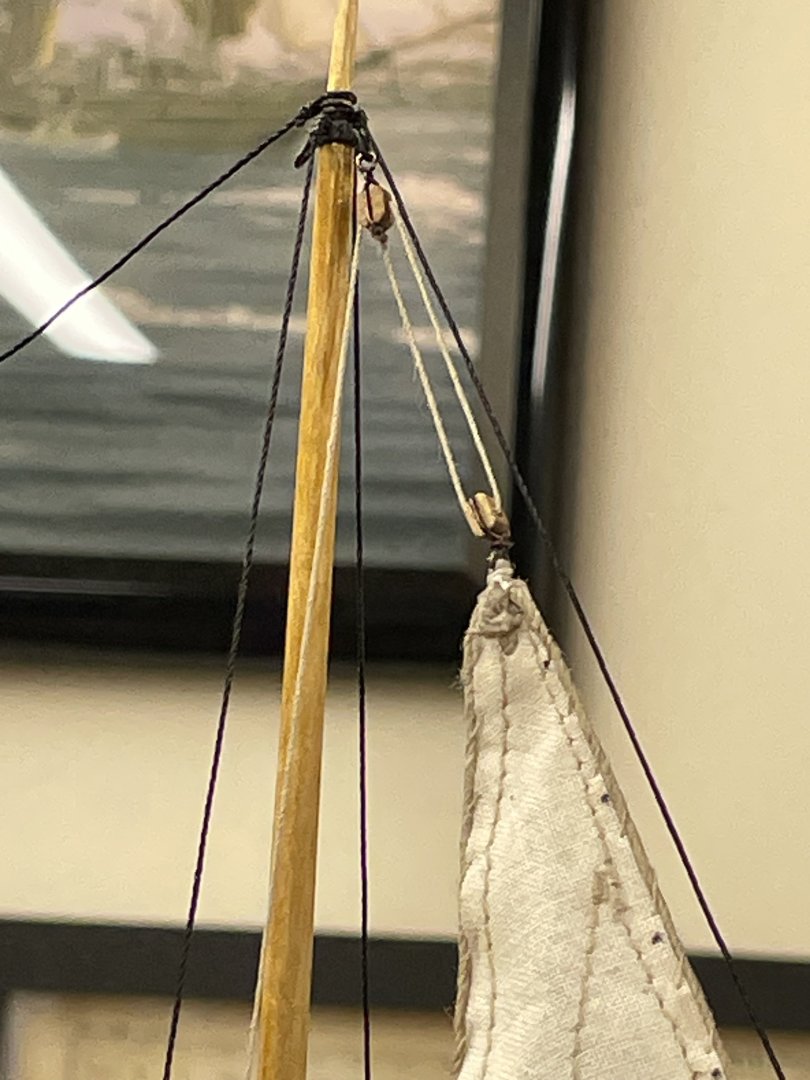

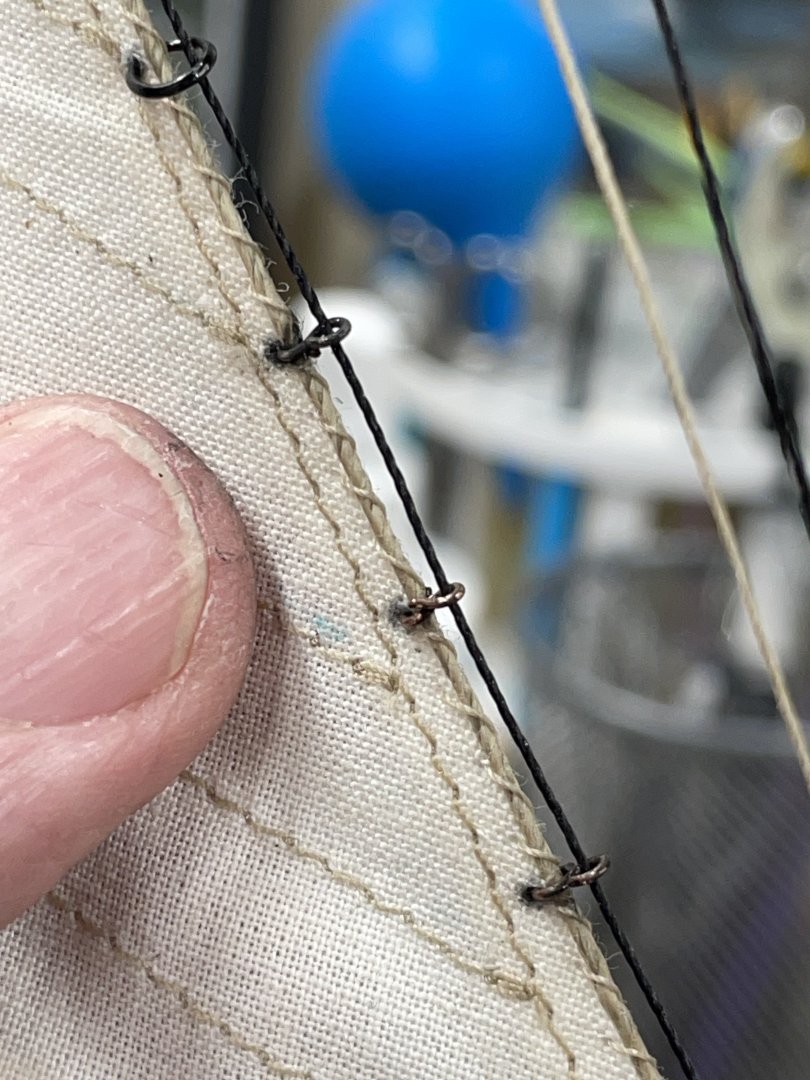

Jib Sails… Sewing on the Bolt Rope… Attaching the Jib Tack… Halyard Jib Head… Sheet Lines Jib Clew… Hanks made from .5mm Copper… Blackened Copper Hanks… Jib and Balloon Jib mounted… Installing Hanks… Curling Jibs with Fabric Stiffener… Jumbo Jib with Bolt Rope… 50 more Hanks… Jumbo Jib Mounted and lashed to the Boom. Jumbo Jib Halyard… Jibs mounted, I will finish the jib running rigging before moving on to the Fore Sails. Cheers 🍻

-

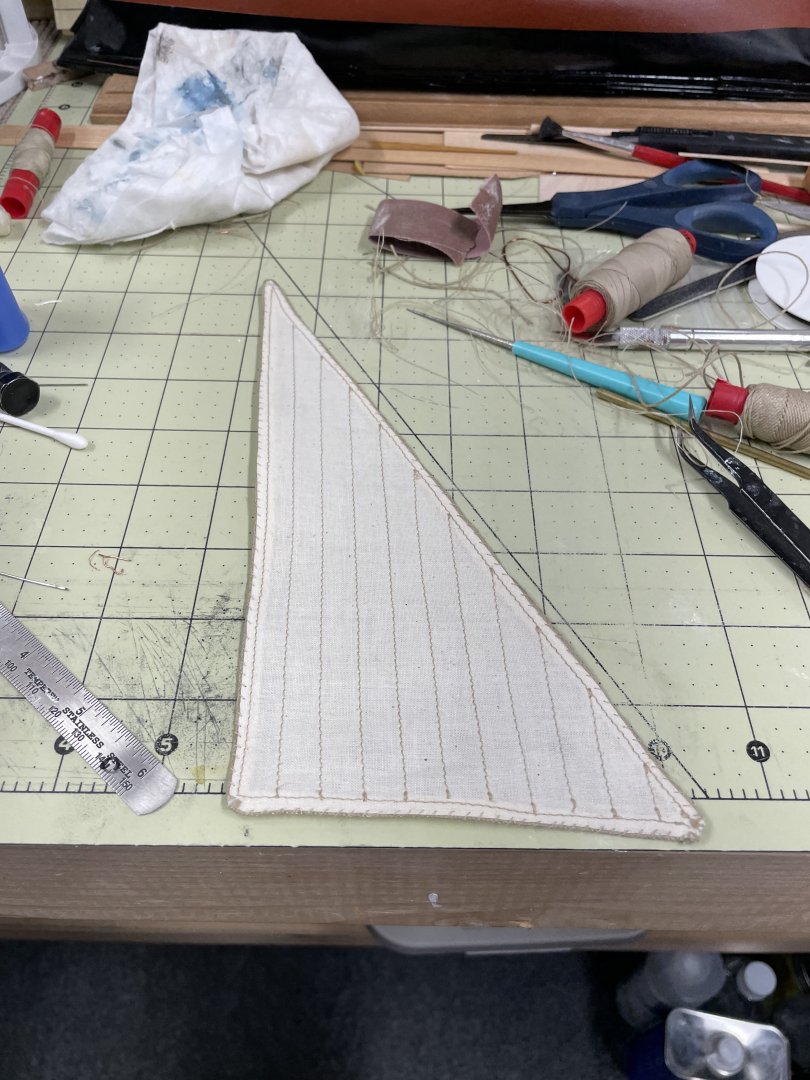

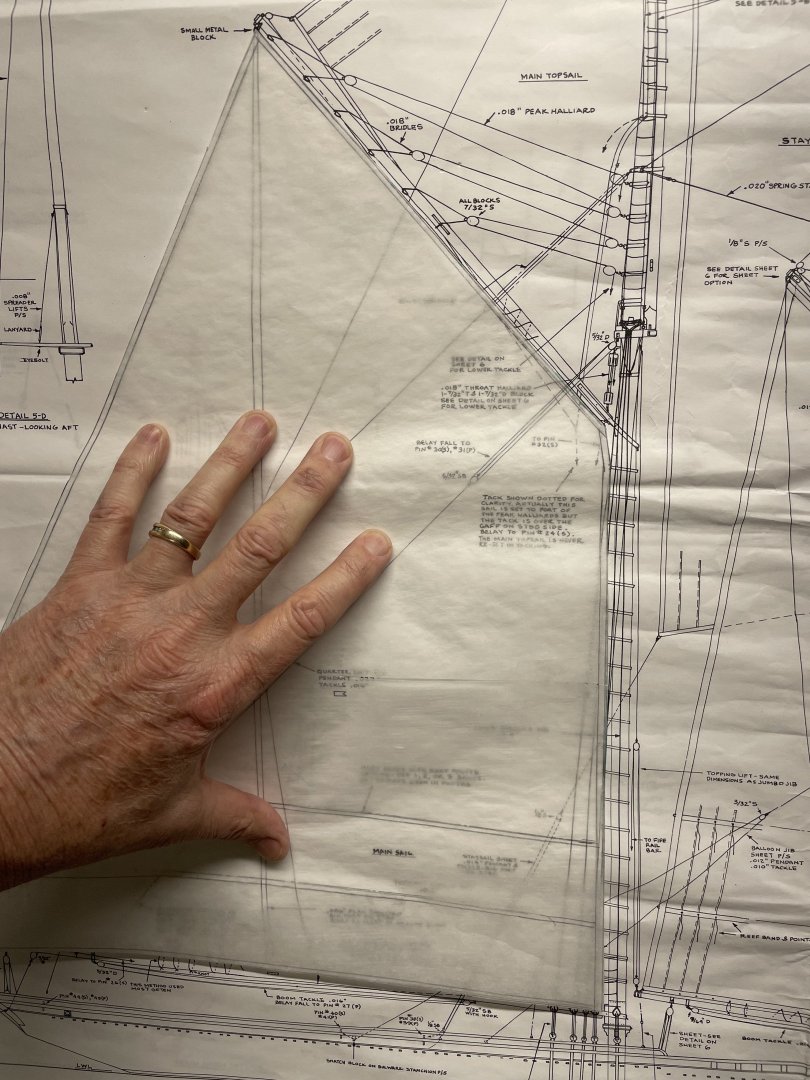

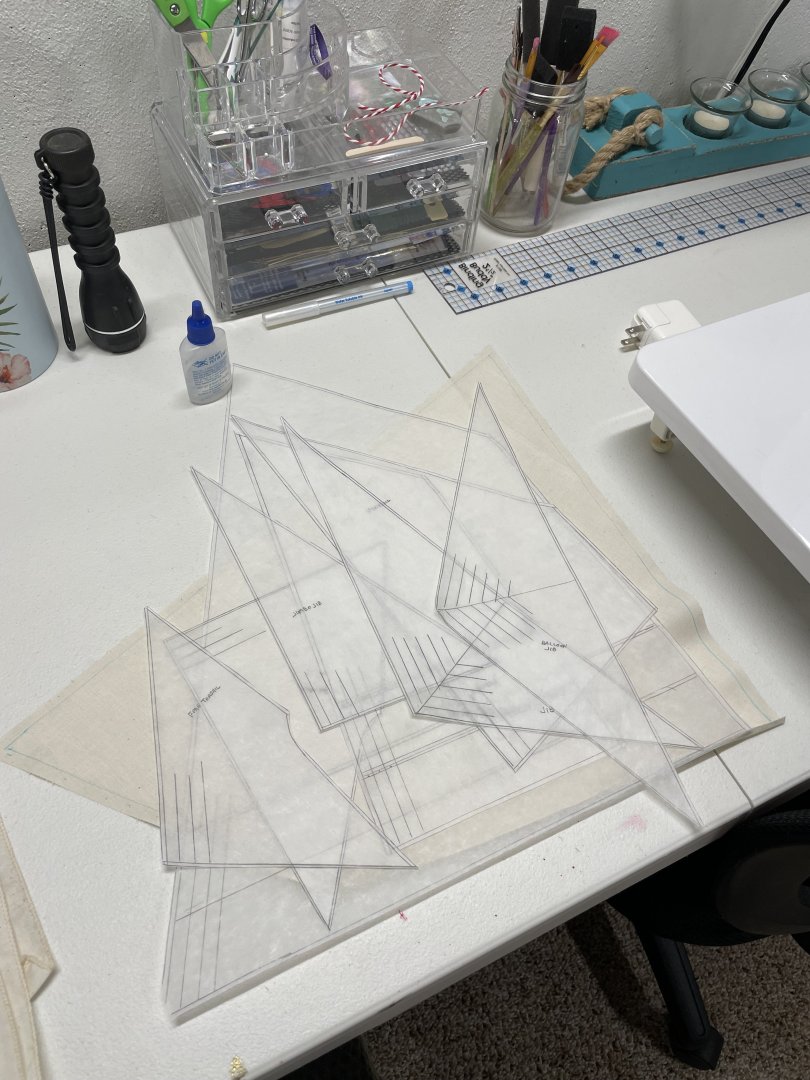

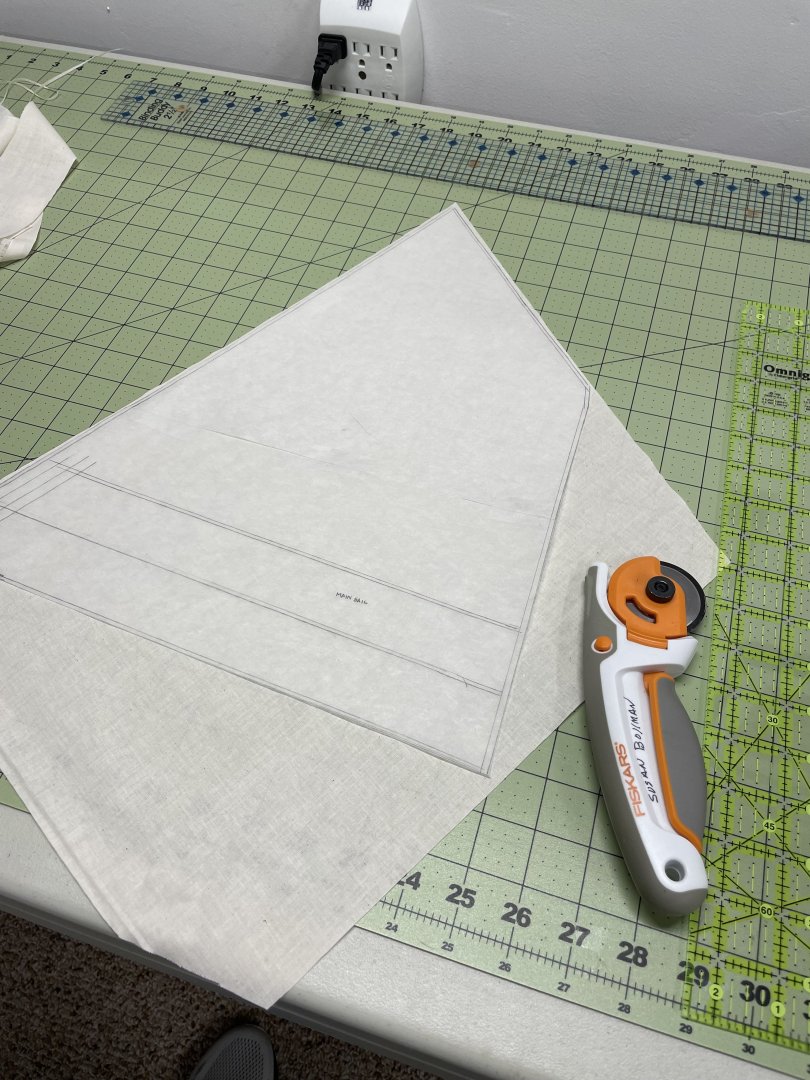

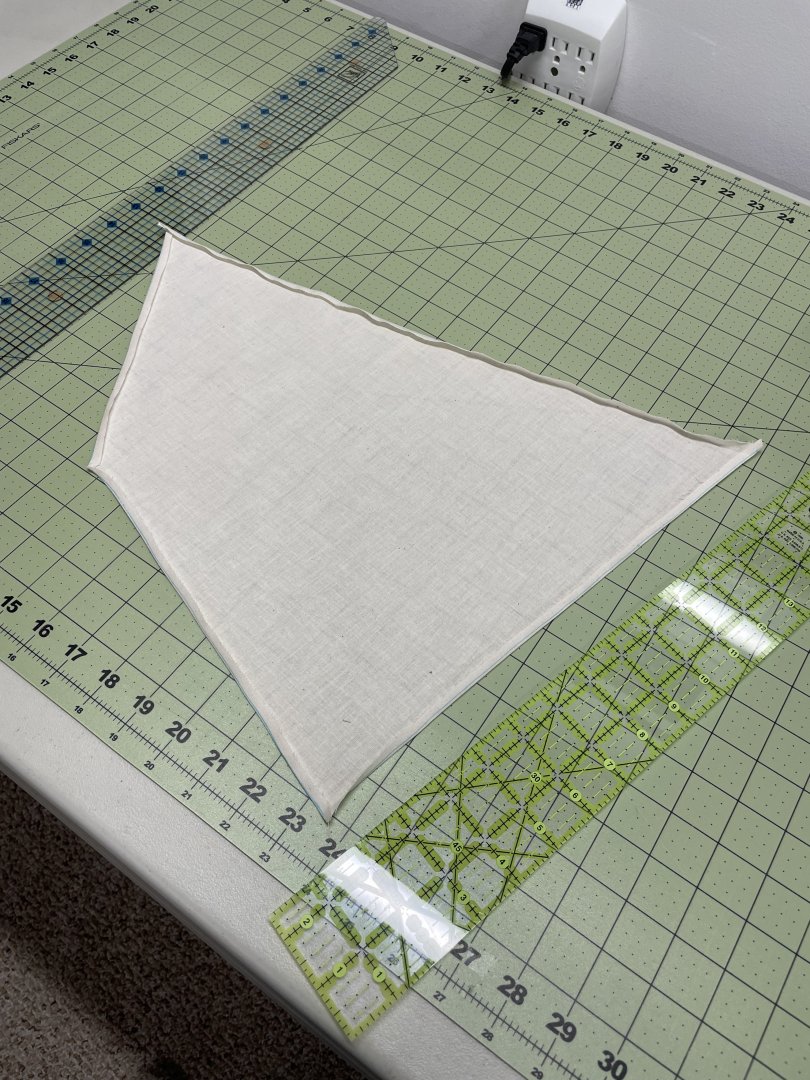

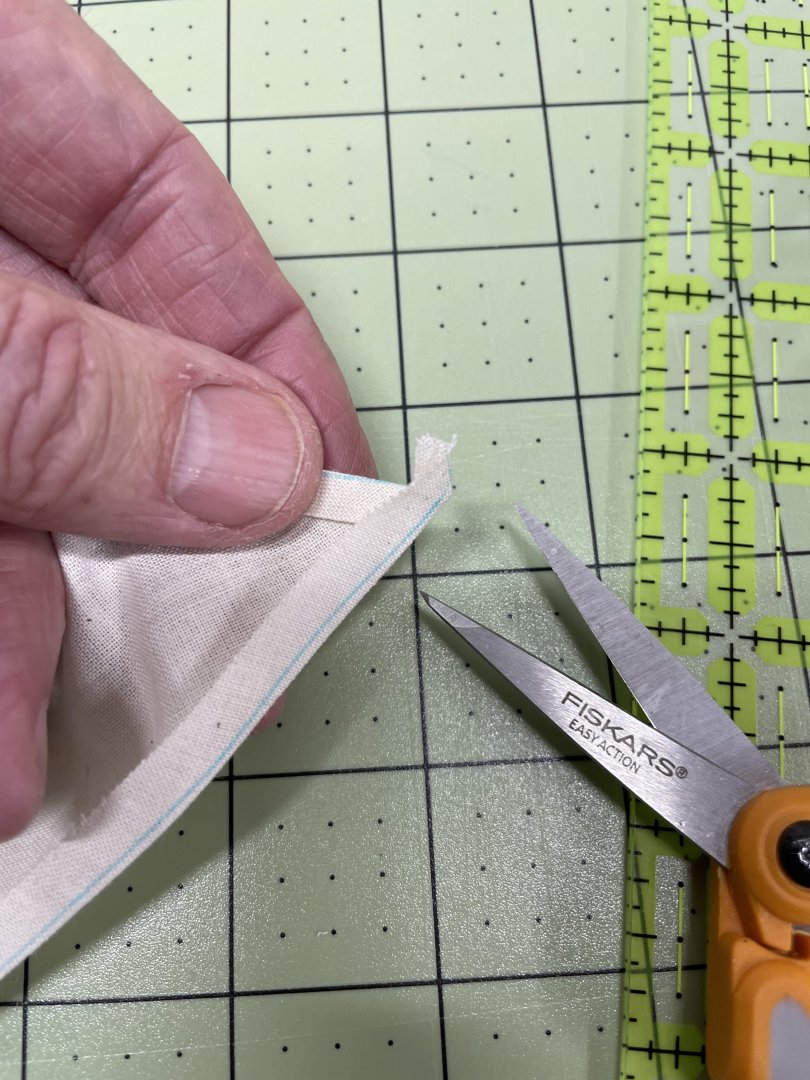

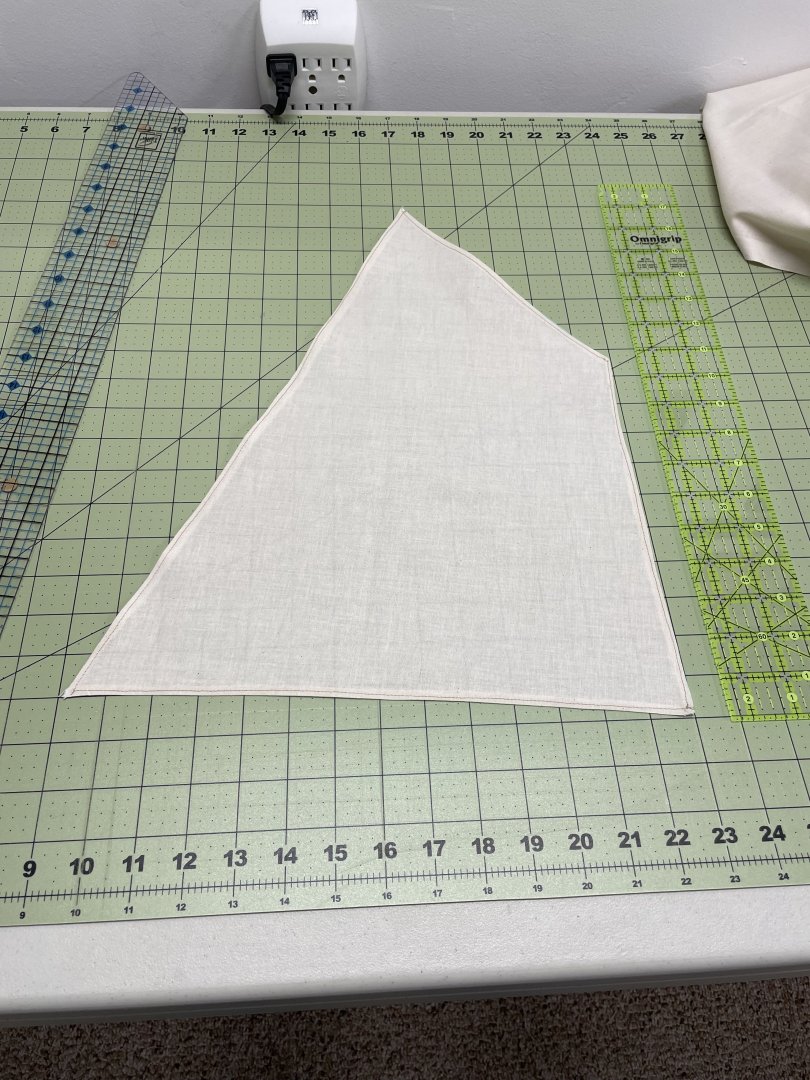

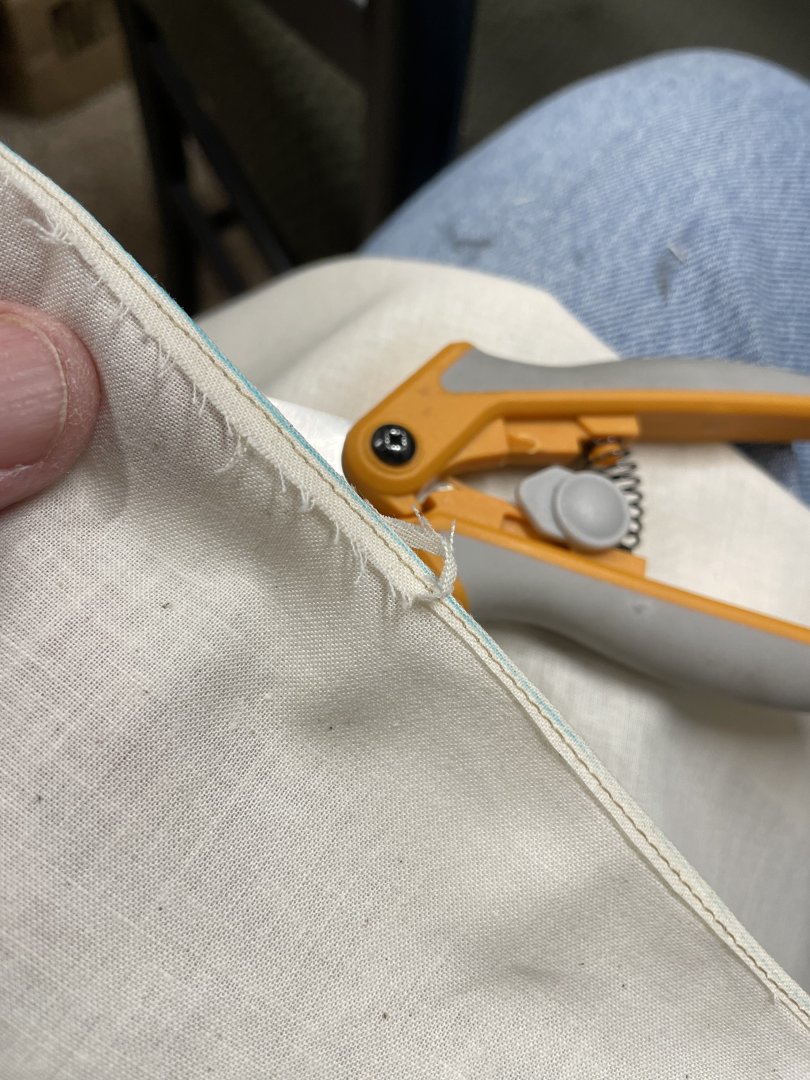

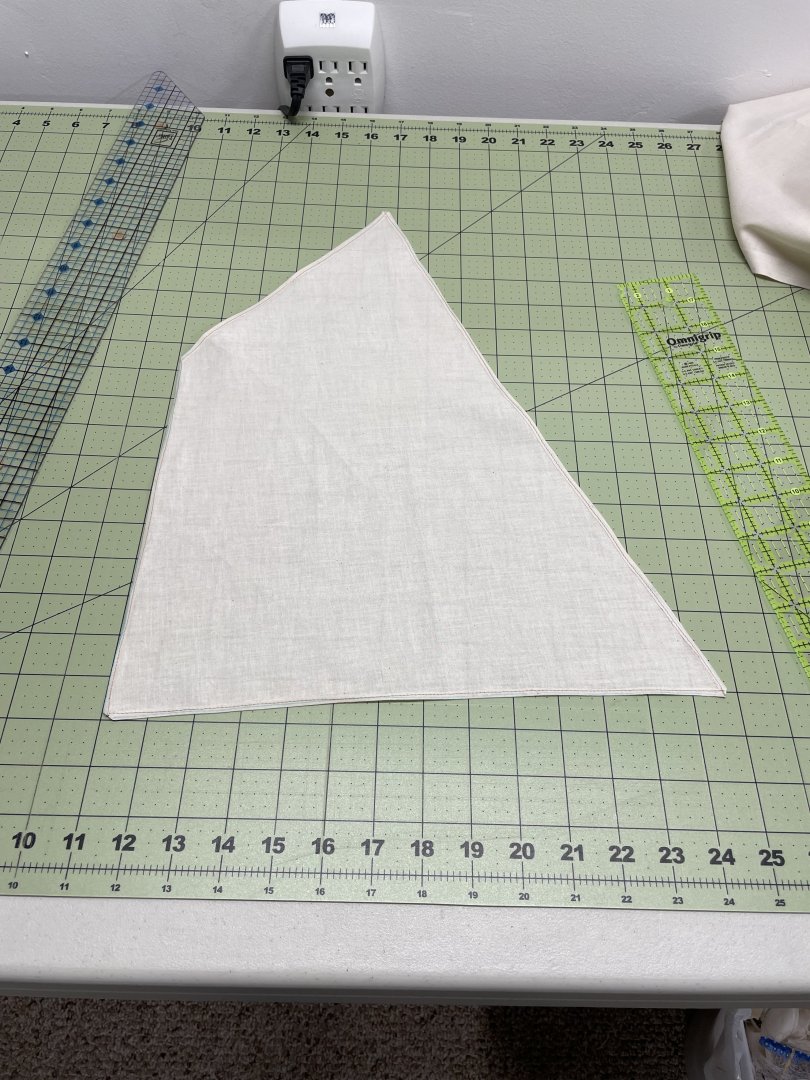

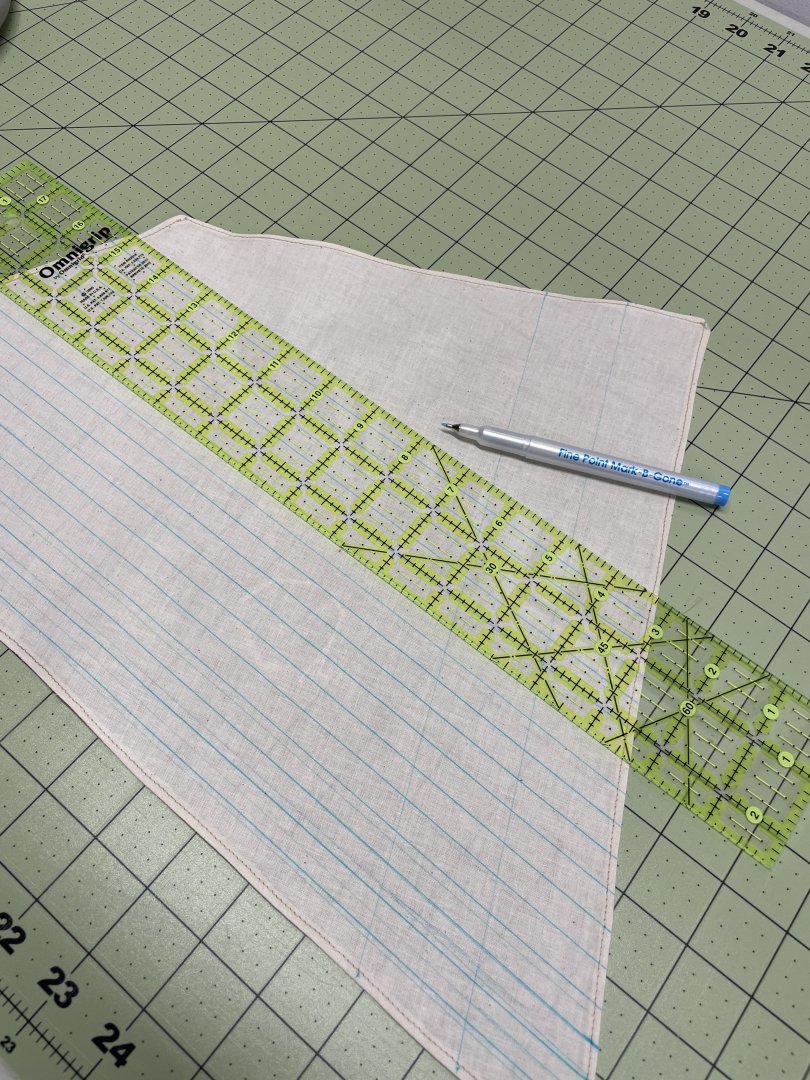

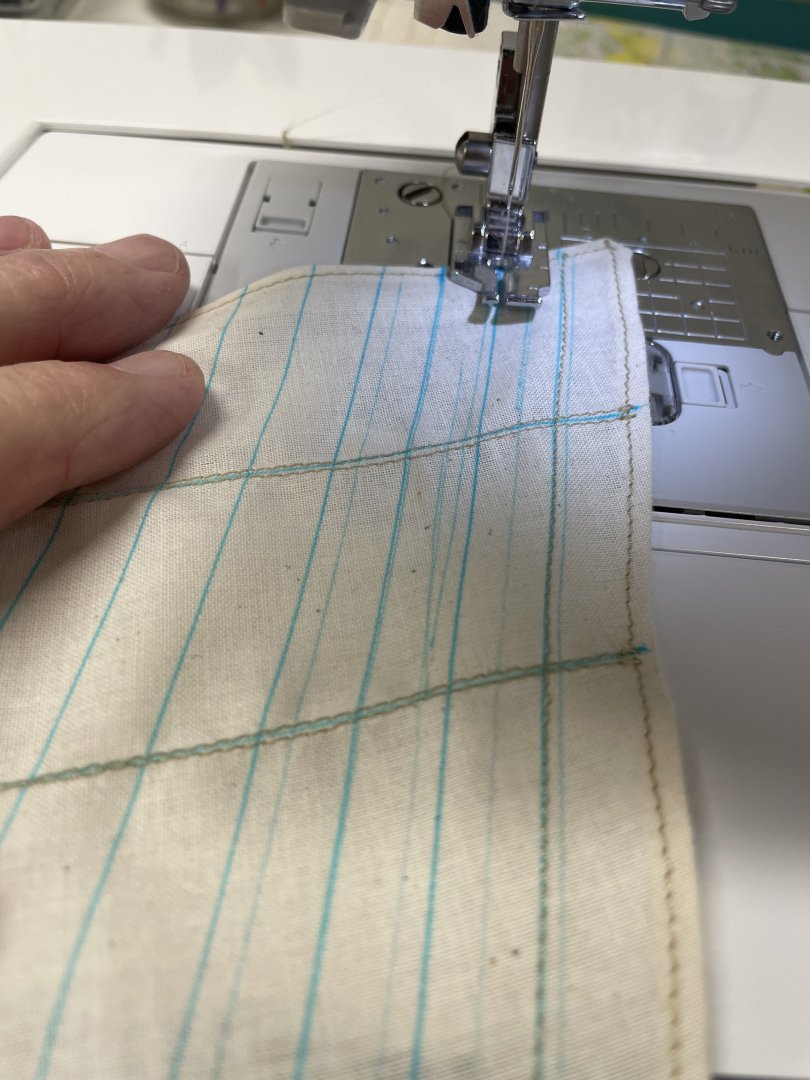

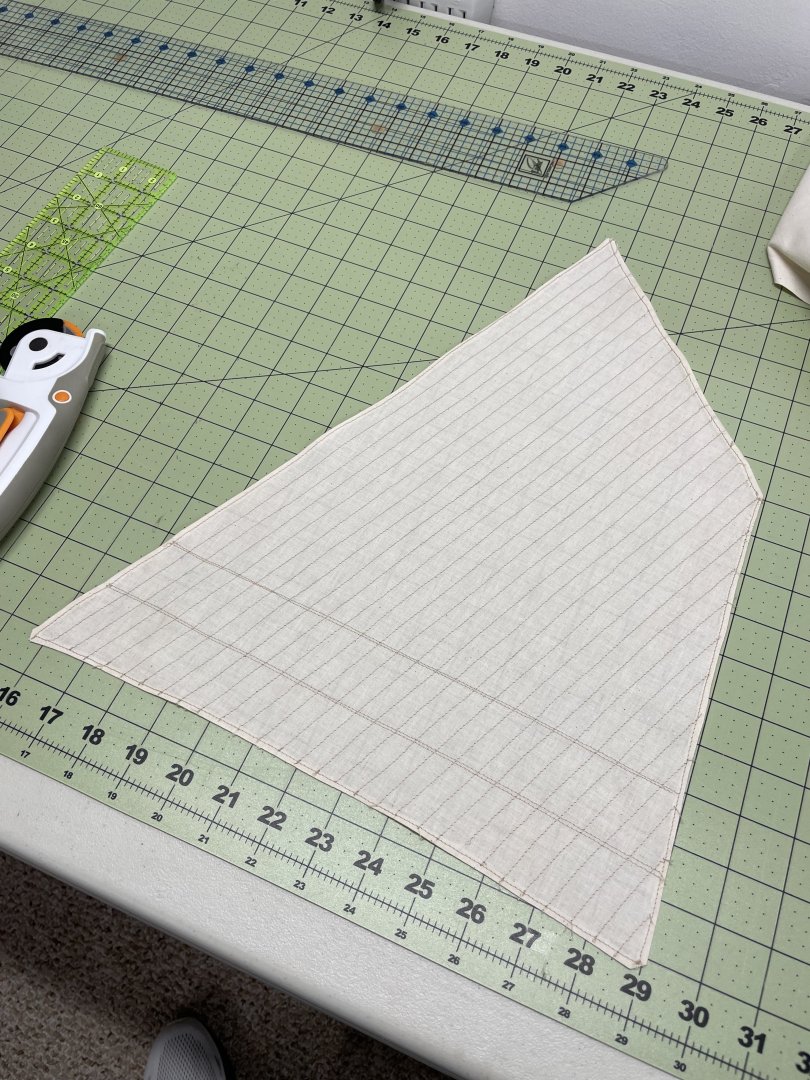

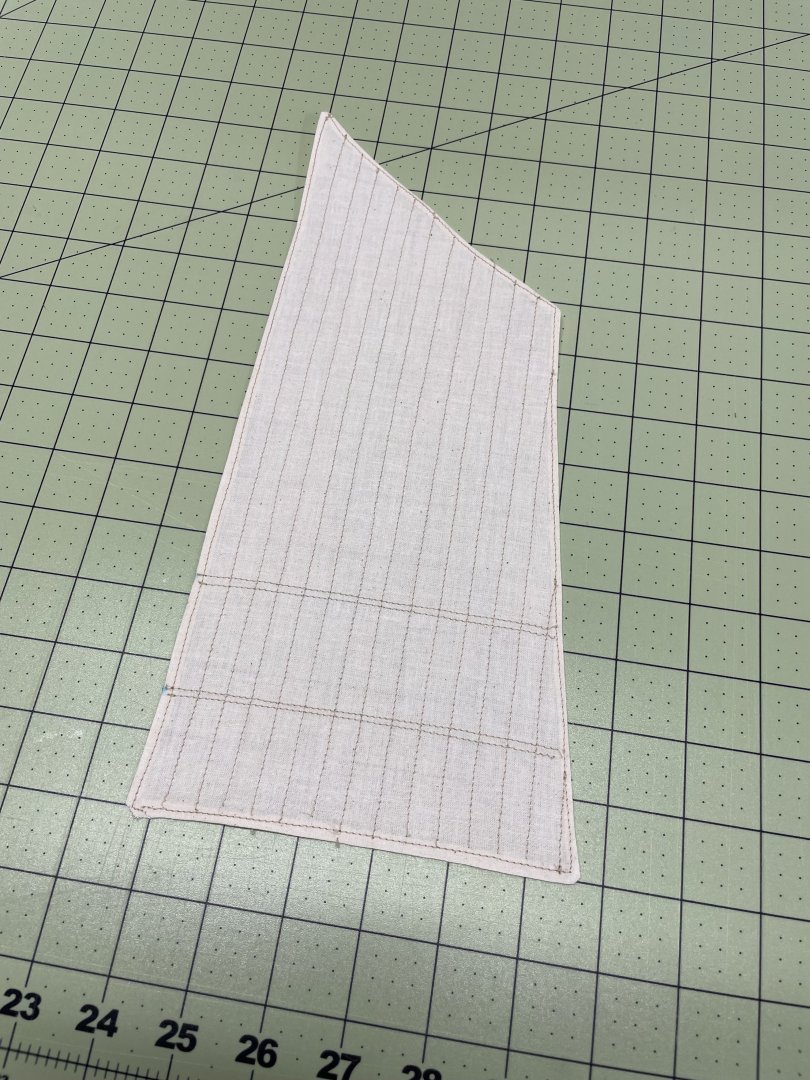

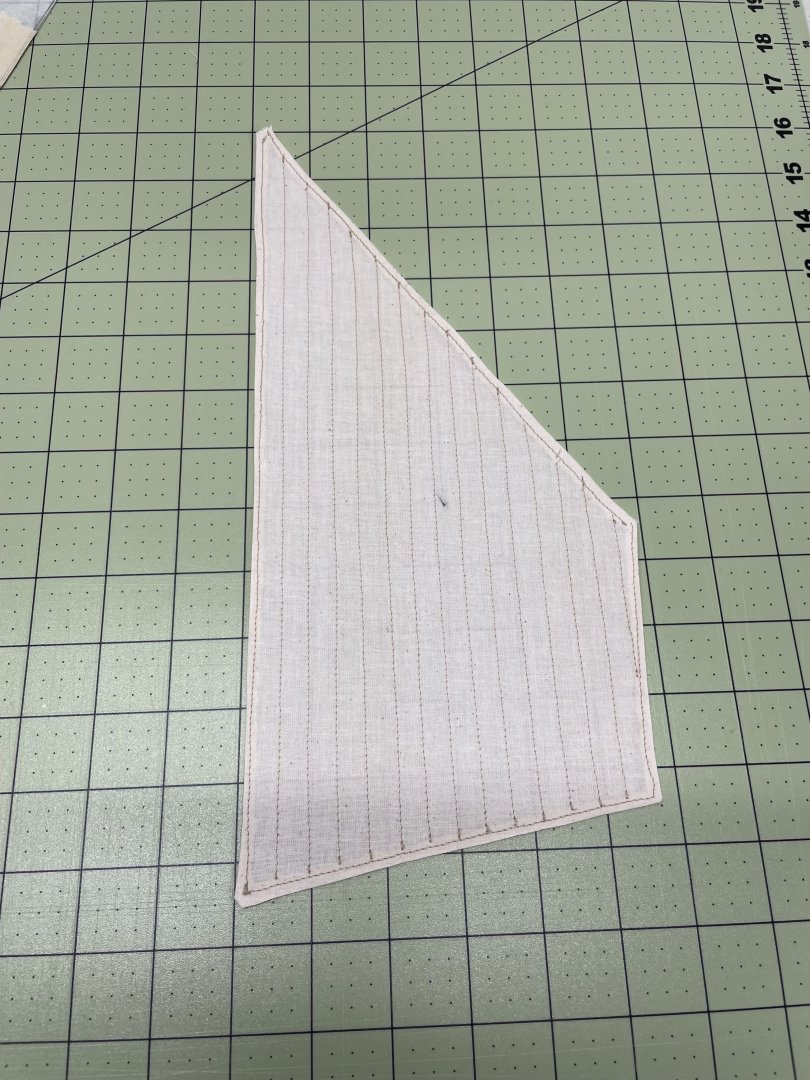

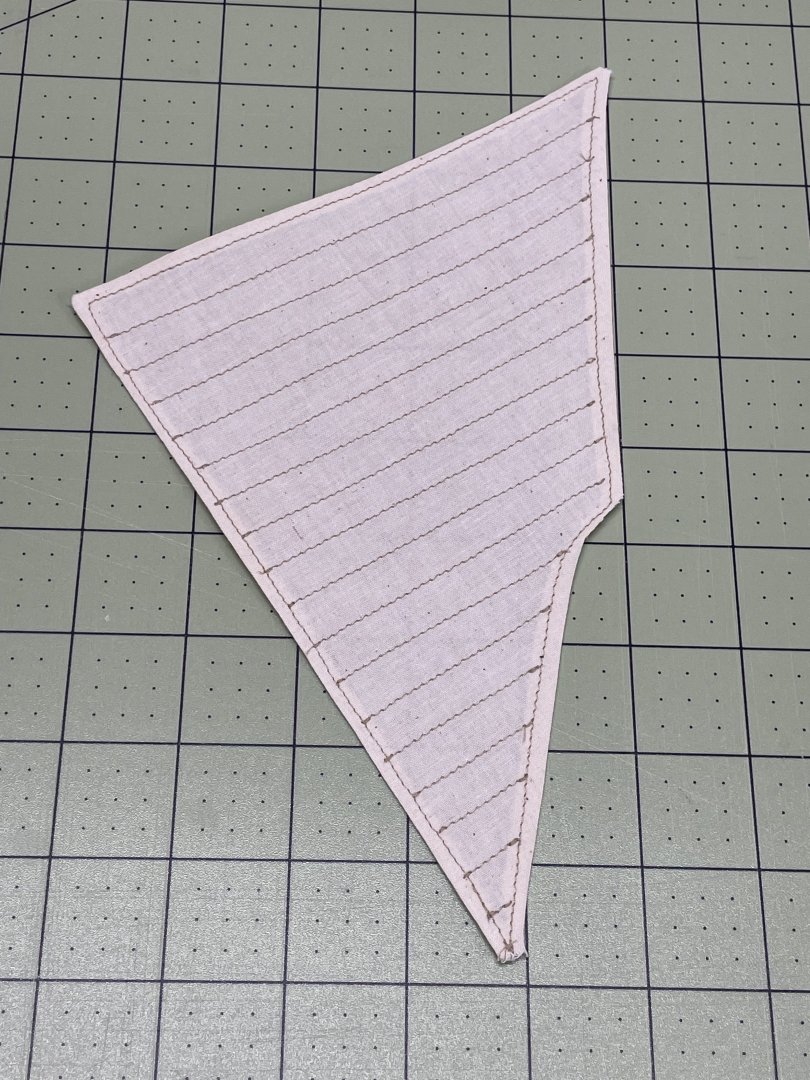

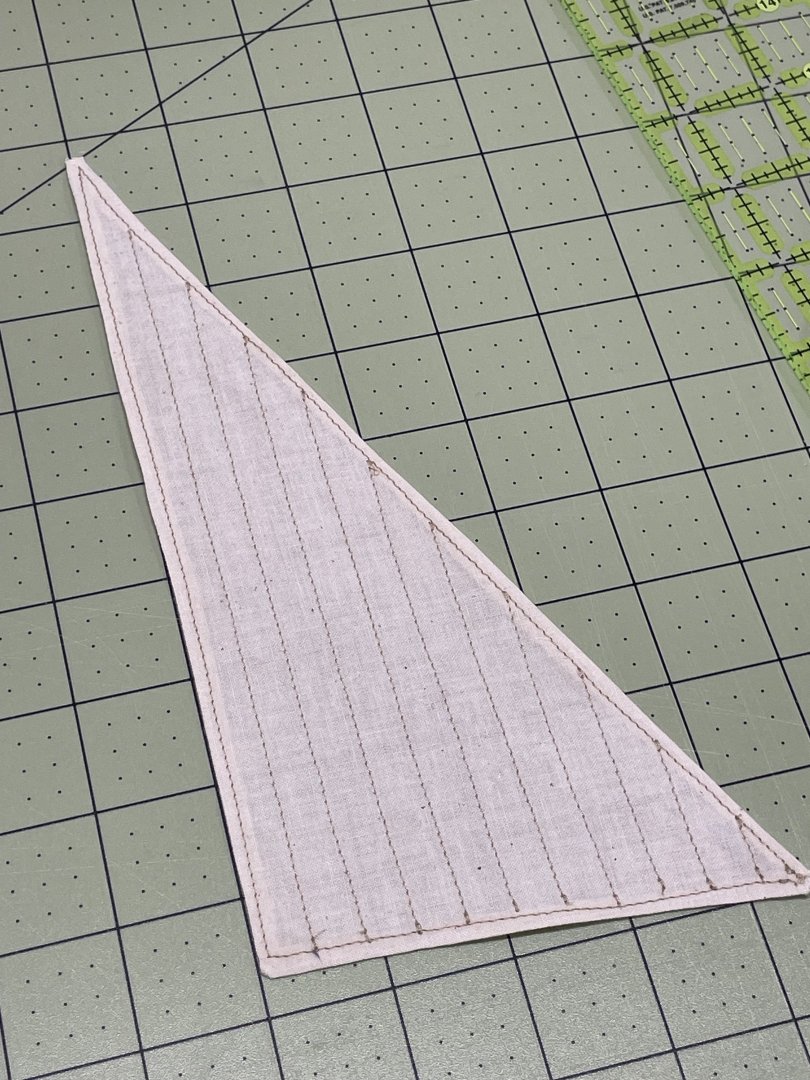

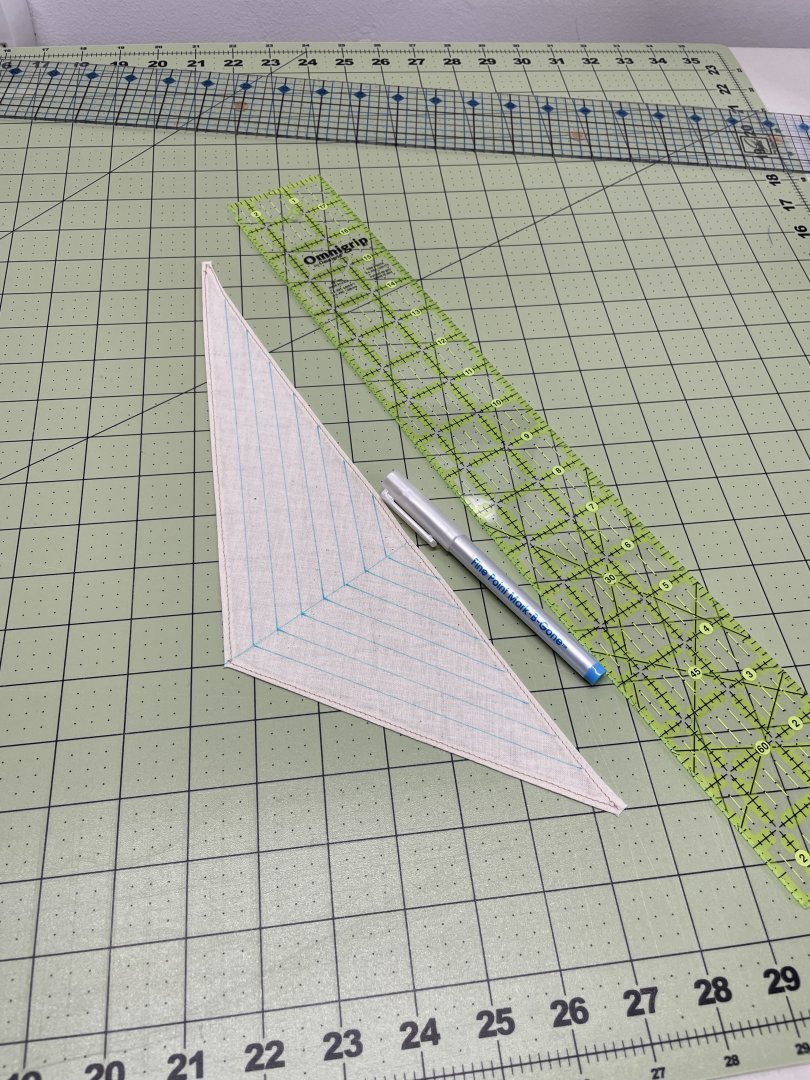

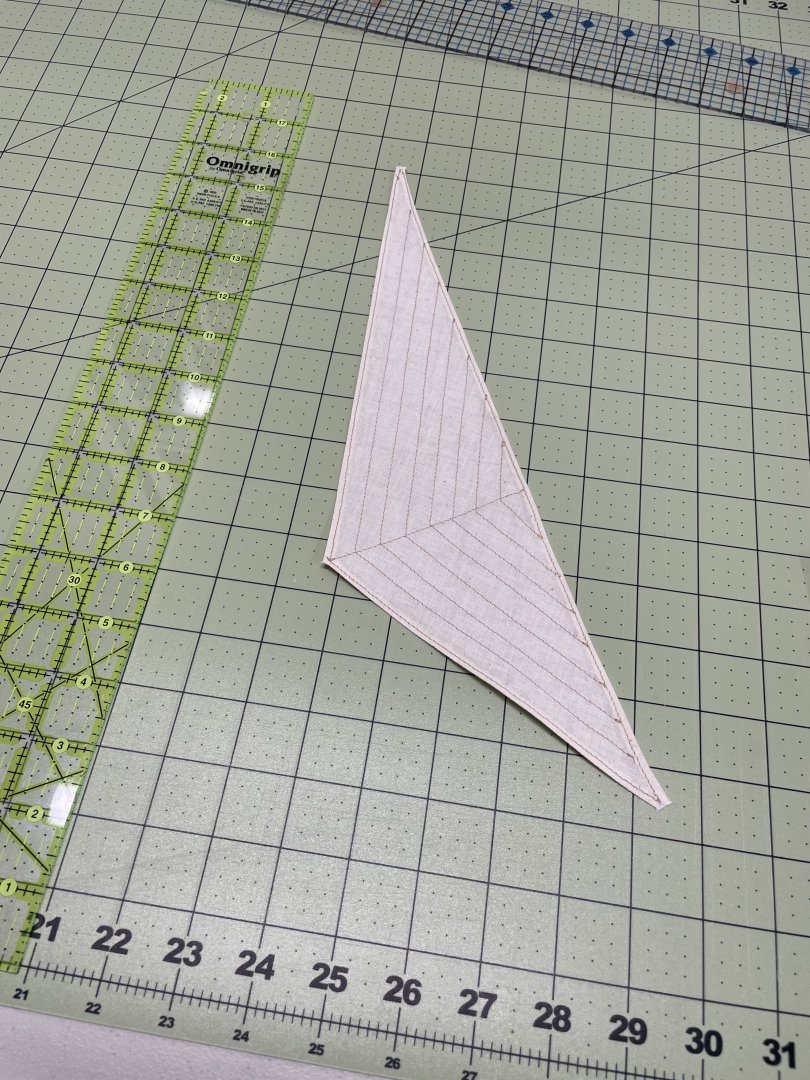

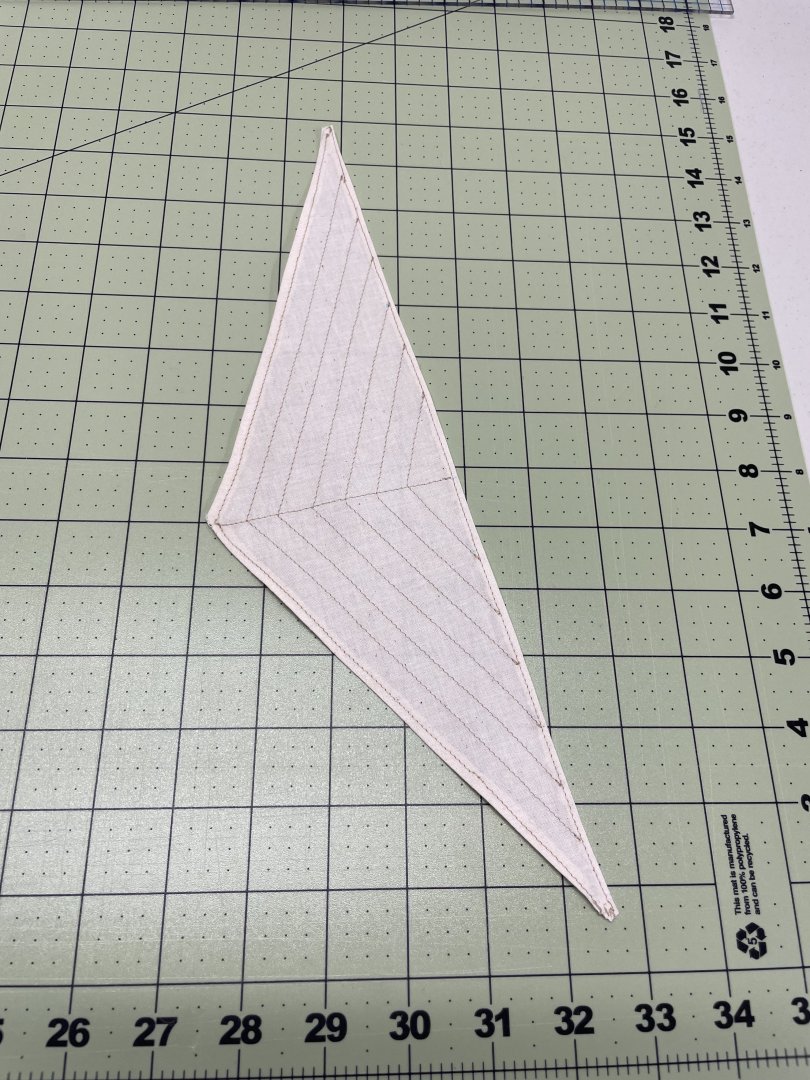

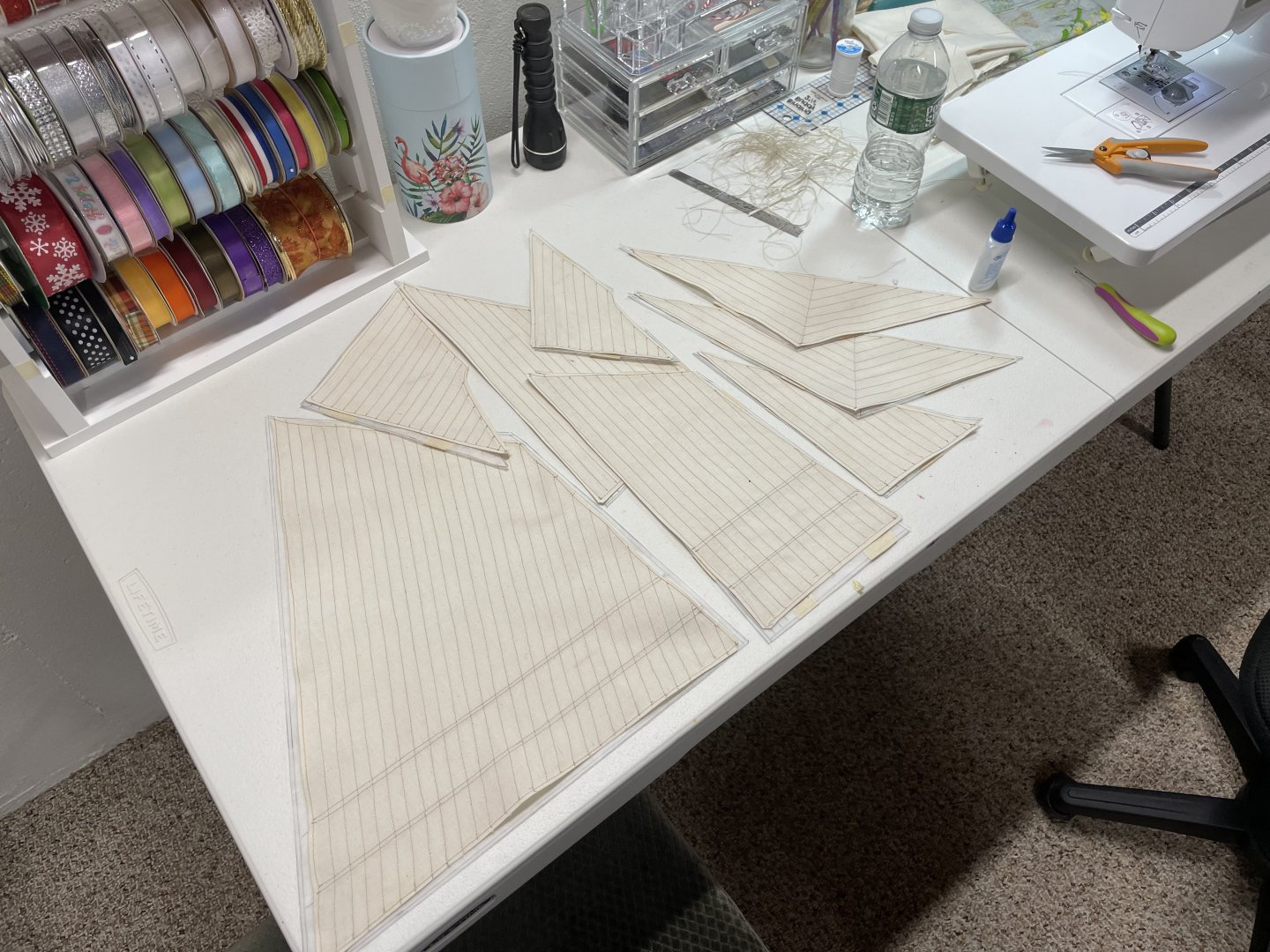

Sails… Carefully trace all sails from drawings. Cut out sail leaving 1/4” to fold over the edge. I use a muslin material purchased at a fabric store. The Kit supplied sail cloth is usually too heavy. Fold the 1/4” edge seam and iron it flat for sewing. Trim corner to lay flat before sewing. Edge seams sewn 1/8” from the edge. Trim the under side, fray check the fabric edges and iron out flat. Mark up seams with water soluble ink pen. (fine point) Sew seams including those for reef points. Main Sail sewn and ready for additional details. Bolt rope, reef point ropes and corner rings. Remaining sails cut out ready for sewing. Fore Sail Stay Sail Main Top Sail Fore Top Sail Jumbo Jib Jib Sail Balloon Jib All Sails sewn and ready for details to be added. Cheers 🍻

-

Eric, I like the canvas decking made with masking tape. Looks great. 👍

- 254 replies

-

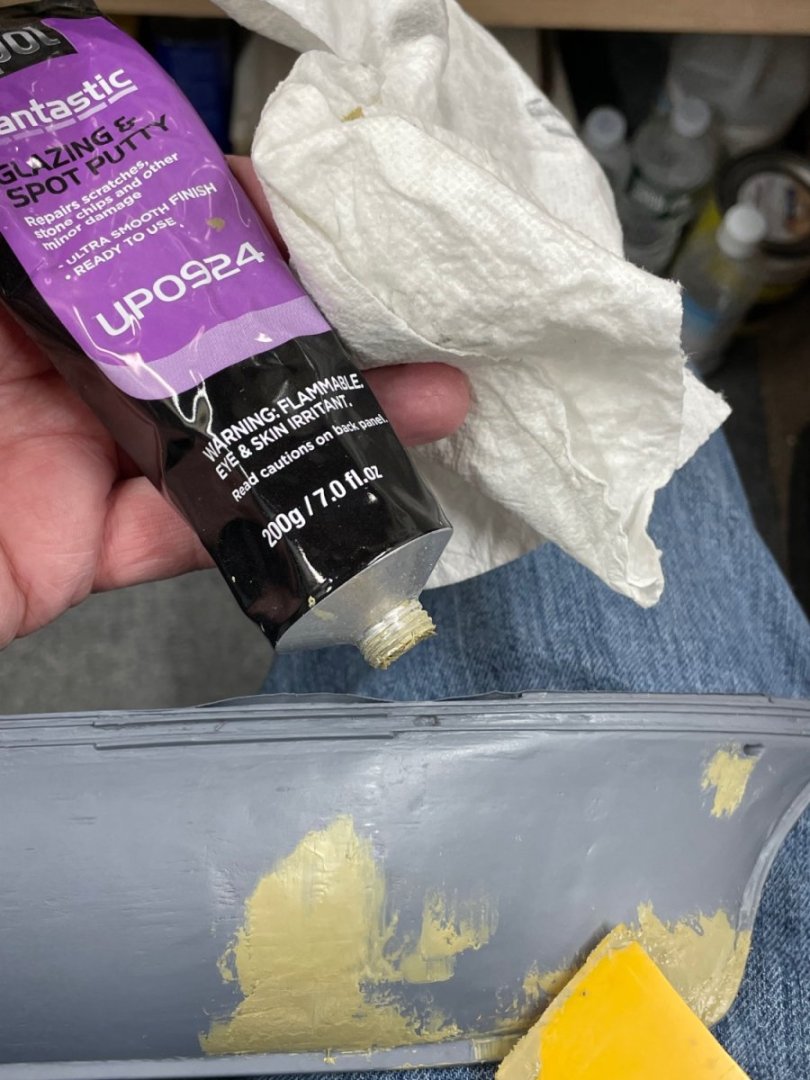

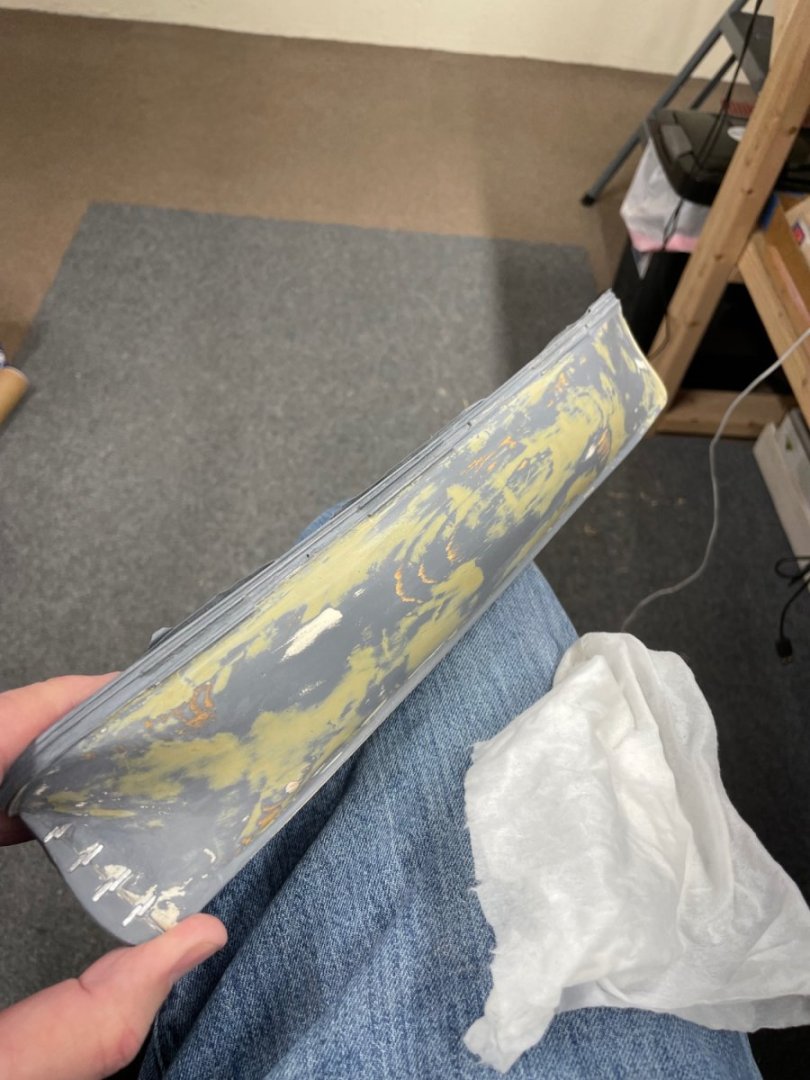

Agreed… POF is the way to go, I still have some spot filling and sanding to do here. Many more coats of paint. 😜

- 44 replies

-

- Red Jacket

- Marine Model Company

-

(and 2 more)

Tagged with:

-

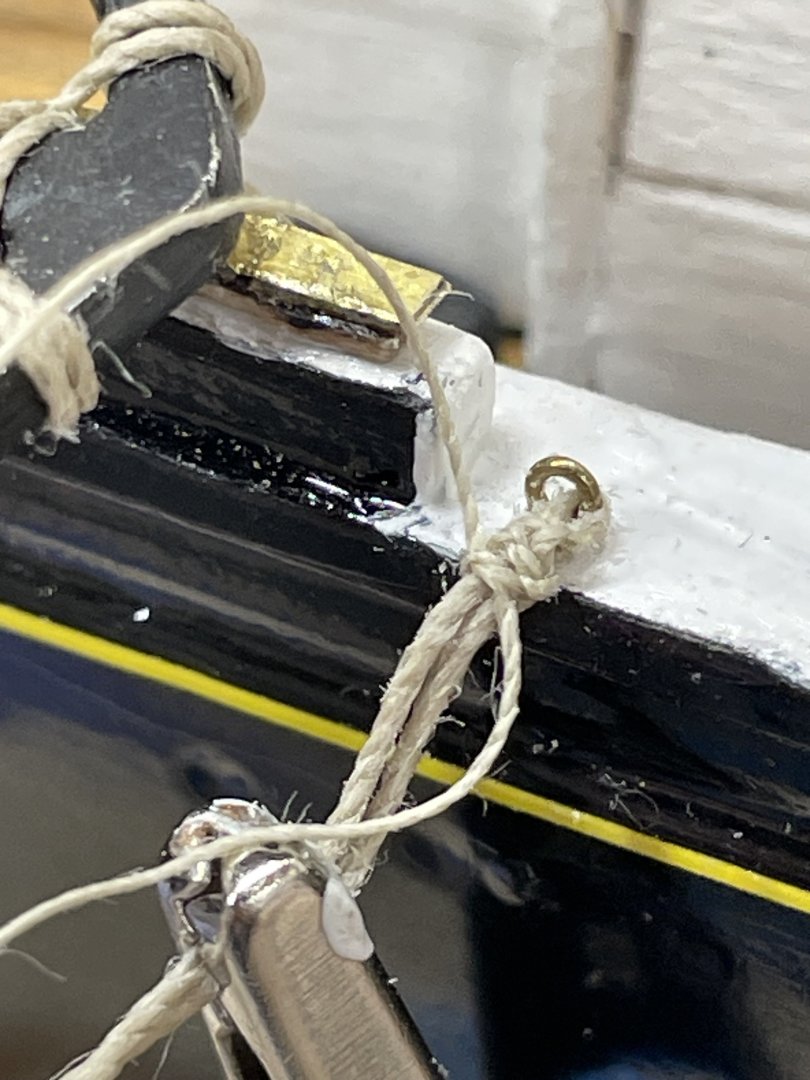

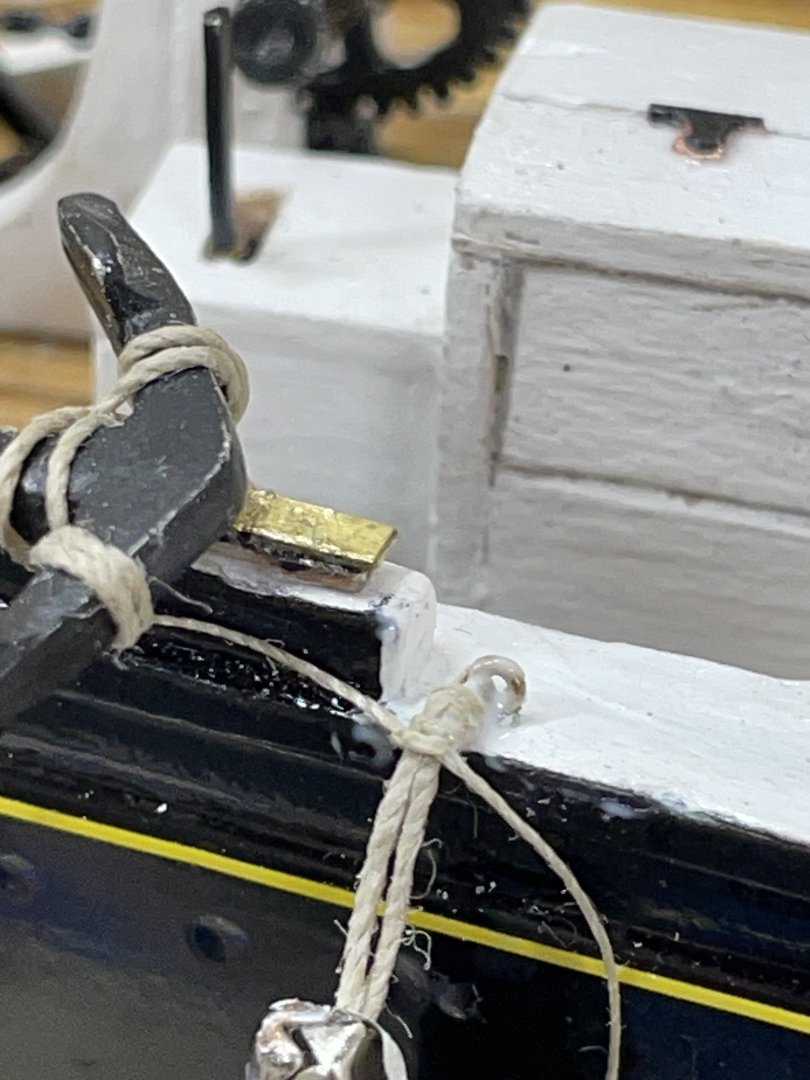

Painting the hull continues… Spot putty and sanding prior to color coats… Painted hull semi gloss black and masked off water line in preparation for Hull Copper Red below the Water line. Air Brushed the Hull Copper Red… Color coats complete, still needs some touch up prior to finishing with Semi Gloss Clear Coat. Cheers 🍻

- 44 replies

-

- Red Jacket

- Marine Model Company

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.