-

Posts

1,507 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Vladimir_Wairoa

-

Hello, its lovely work indeed, very enjoyable and beautiful colorless rendering of ship.

-

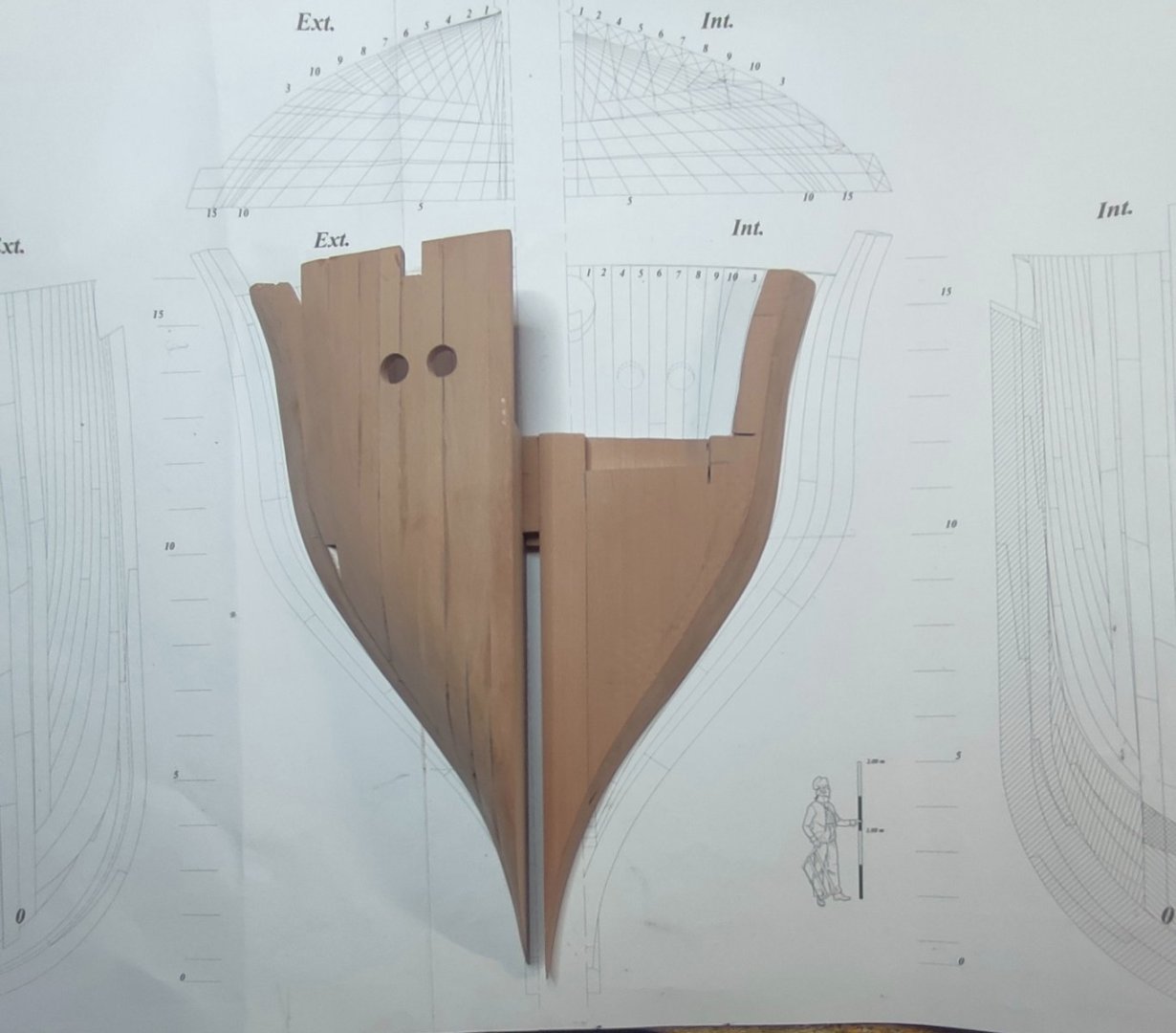

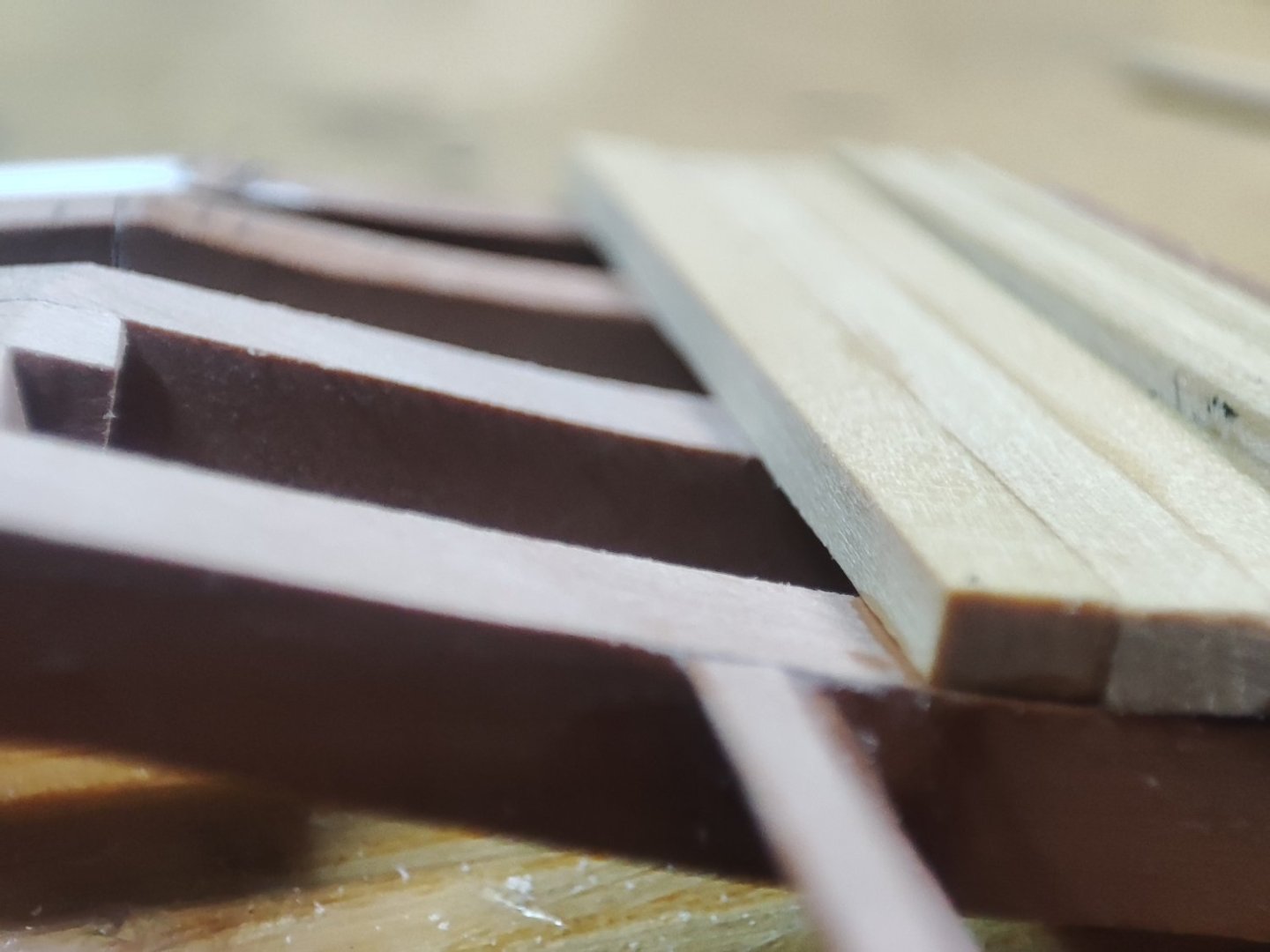

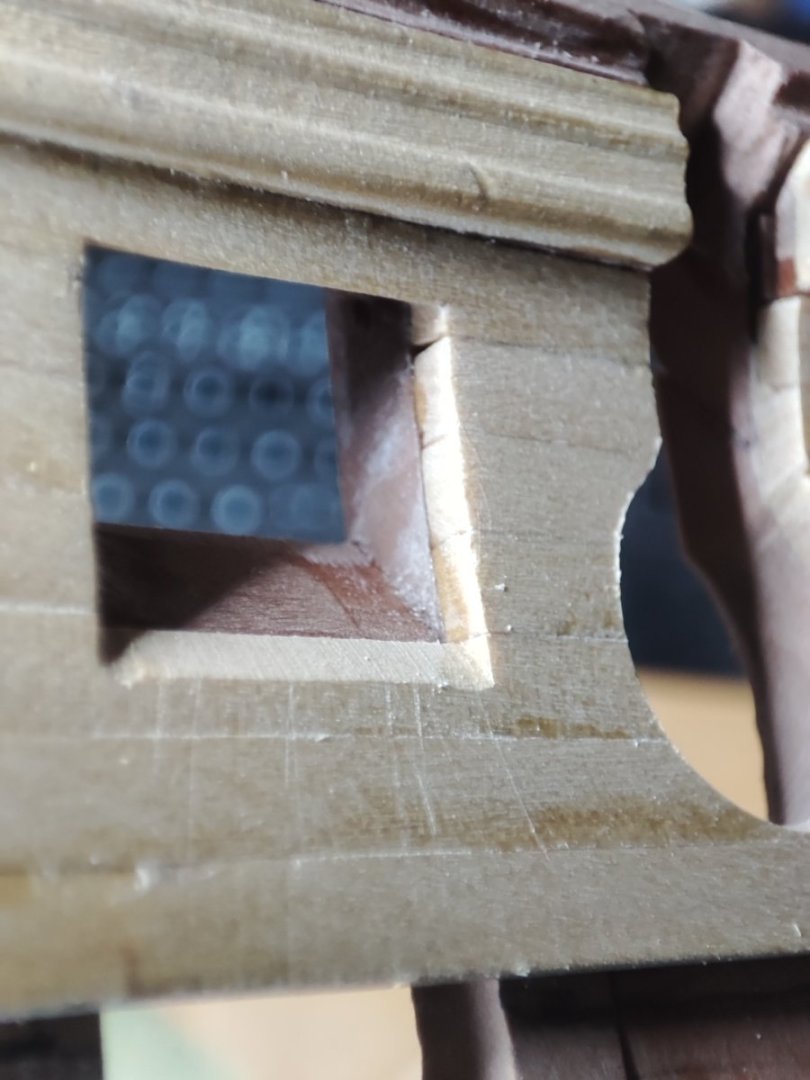

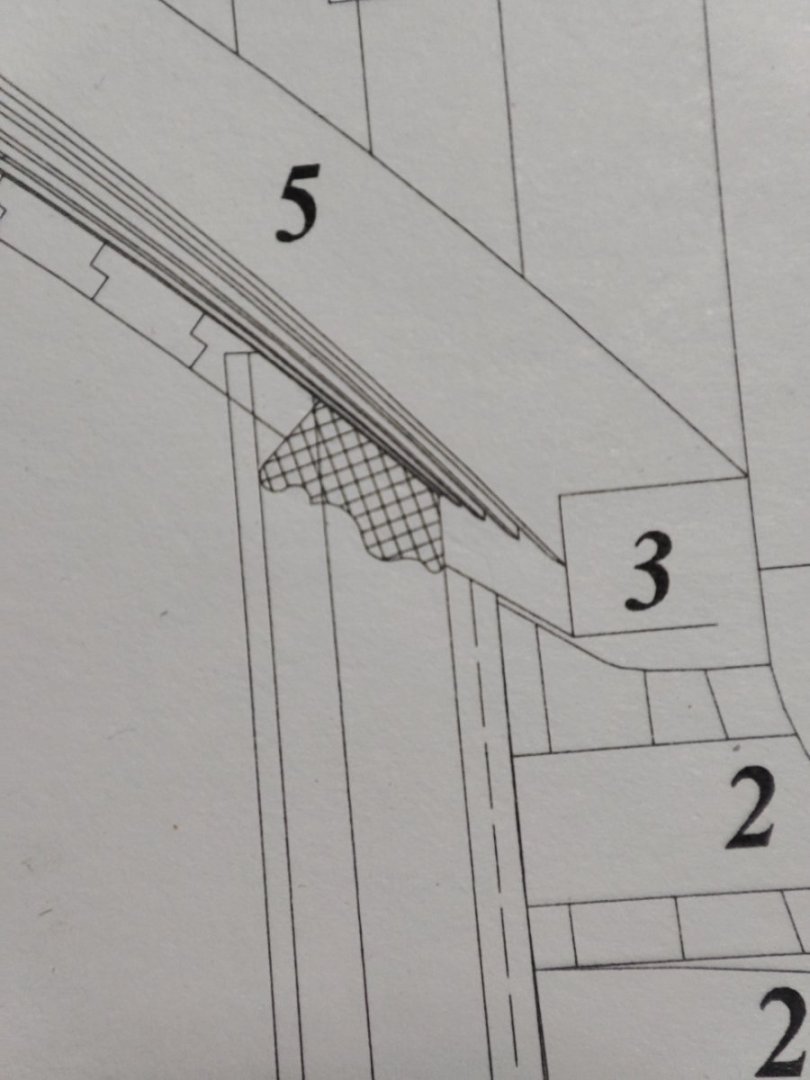

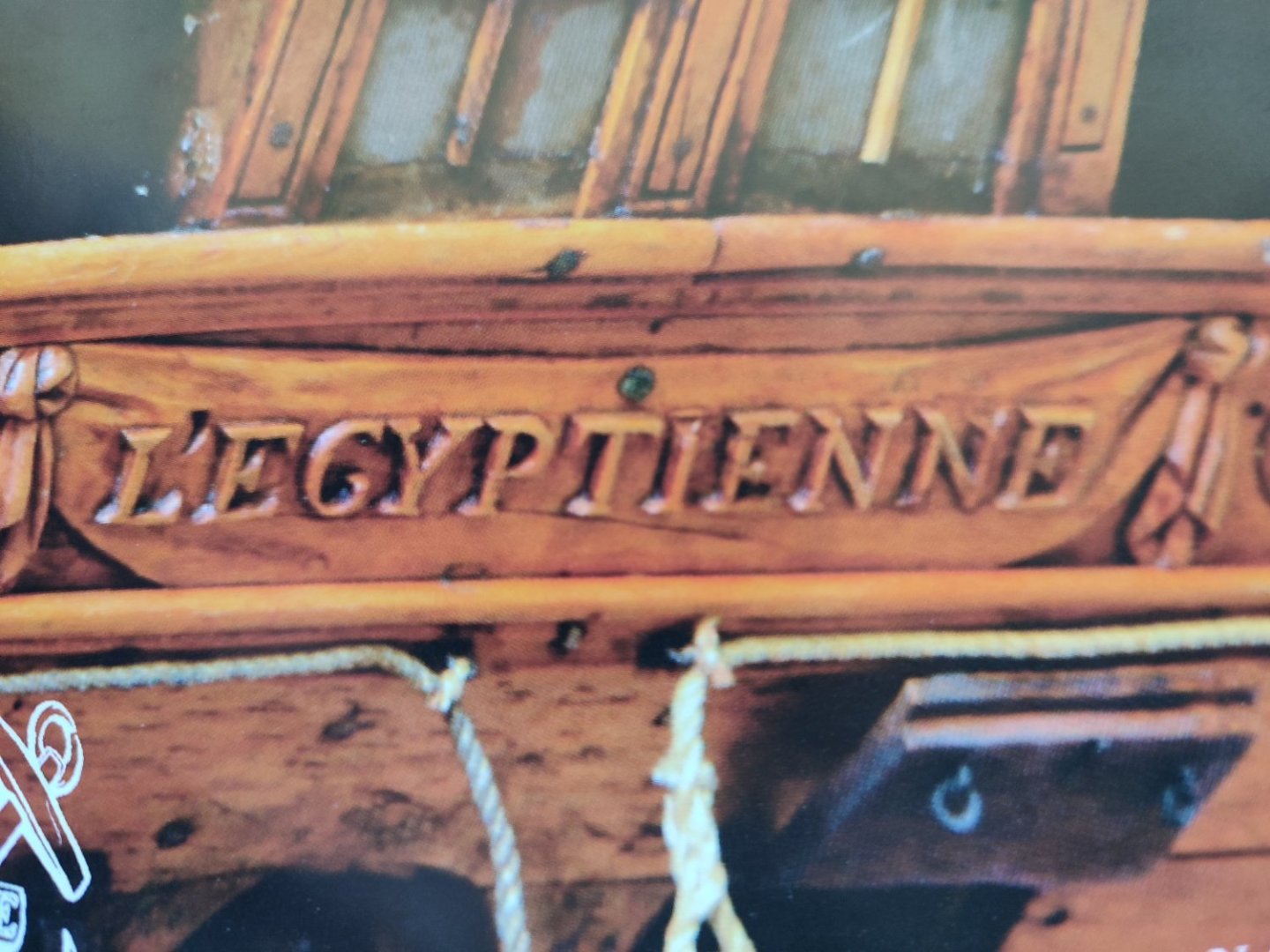

phoenix raises from the ash This is first time i have priviledge to build from boxwood at will and Im quite perplexed how beautiful this wood is not for carving only but for bending as well. its pure joy to work with and I am delighted how helpful this is. So I finished starboard side from wells up. Sharp eye wipll spot my usual sinful things as unnecessary repairs. It was constant pressure on me whether planks would meet upper end correctly, so there it is. After brute thorough sanding boxwood colors out almost white. im not sure what final treatment to use for it. tung oil? one can spot not advanced fancy modeling here as cutouts around gunports... its quite obvious how this shape differ from english tradition shapes, being fattest at the prow thinning slender aft. and how shallow is foreship curvature. I like most enter of forecaatle opening up outwards of deck providing splash protection. its really modern cathedral of ships. as far as moldings, according compendium, streak between double molding between gunwales and channel strip can be black or yellowˇ I tried to leave it natural not sure if permanently. maybe later on i will paint it black so it will provide one color up down molding shape. so far i like it this way too. well there will be longer because as I have worked franatically in this and my fingers need rest. thank you for looking in and any comment etcetera.... I dont like looking at bare skeleton, finally this long passage is behind me and part of boat is coming up. there is now other side to be done. same work same challenge. and now million dollar question. treenail or not :))) ://// hm hm. i guess i will do. i never tried it before. outward strake shape is my favorite one. better view.... damn there she goes... upper deck gunwales closer. most important curvature of entire ship. 2 mm thick strakes ...and holes before fairing. . I like idea bowsprit hole is just underneath front small deck...so so but 4 mm molding just fitted. barely but...will work on it later. on the aft side its "just there". curvatures... overall... bowsprit support simple doors opening with one ugly seam moldings are quite substantial gunport sill detail

-

thank you. Will see after fairing though, how those turns out. There will be some sanding off I presume. My plan is to reinforce skeleton a bit more with balsa wood and treenail planks with brass but im not there yet. these preparations are crucial. tokorrow i d like to continue assemblinh all bulkheads and start fairing. cheers.

-

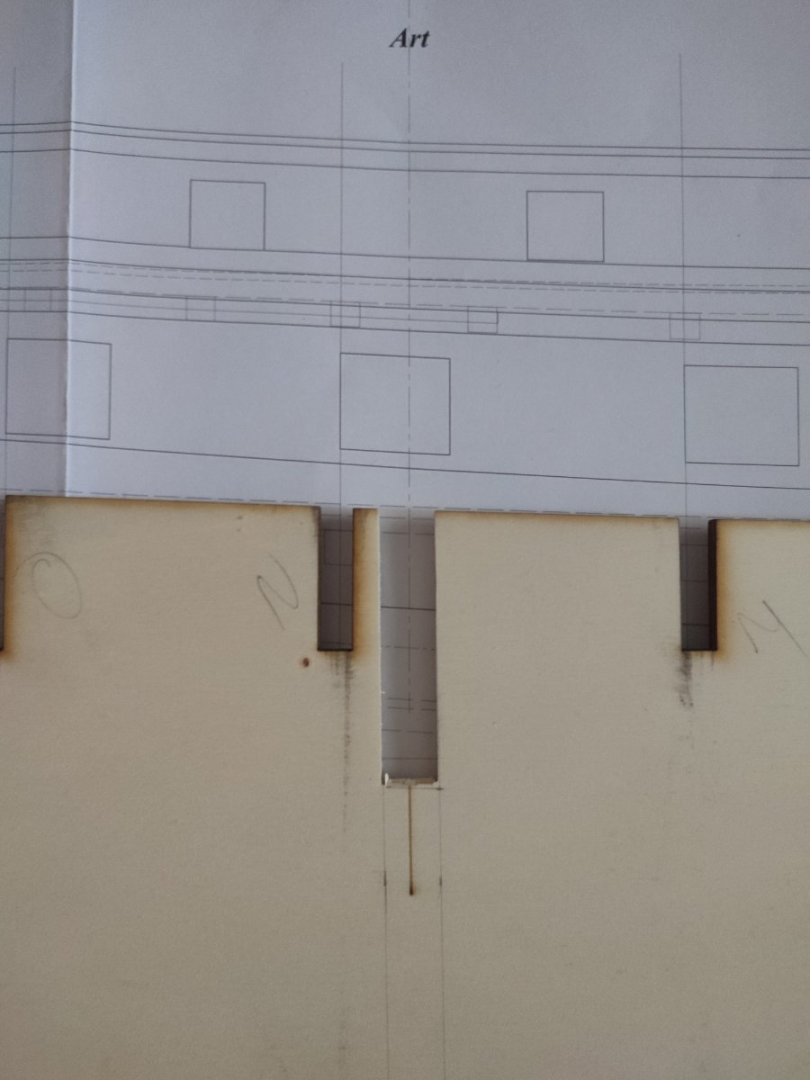

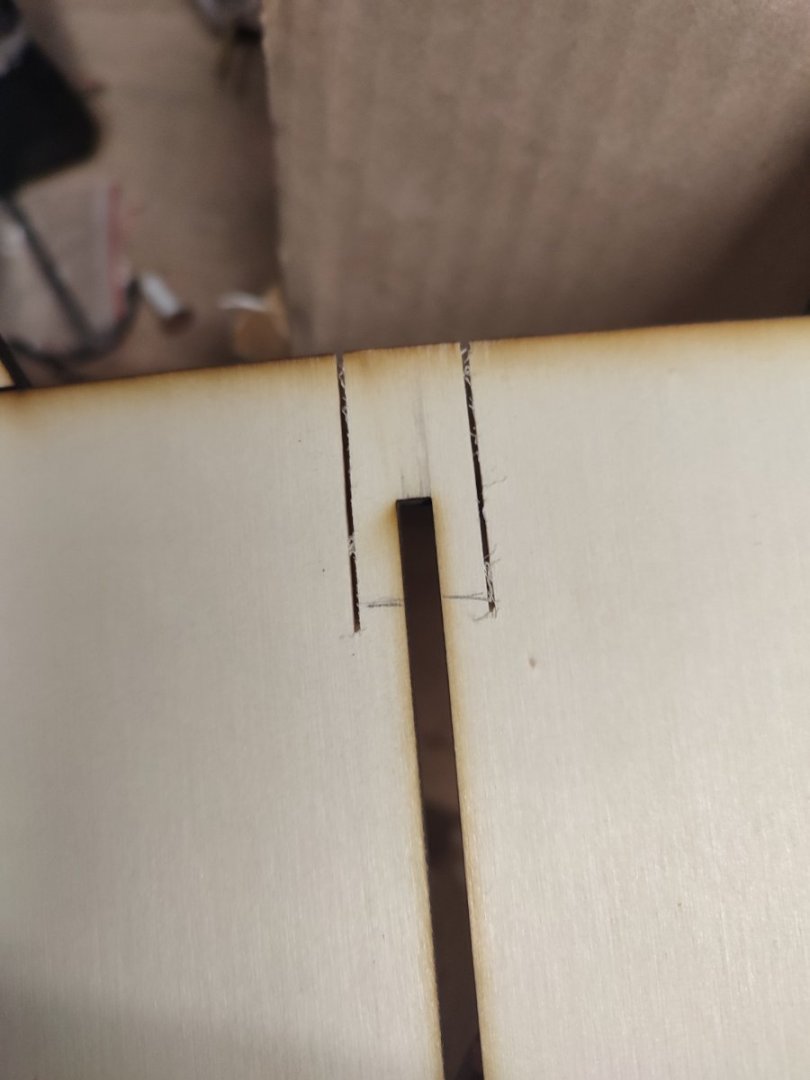

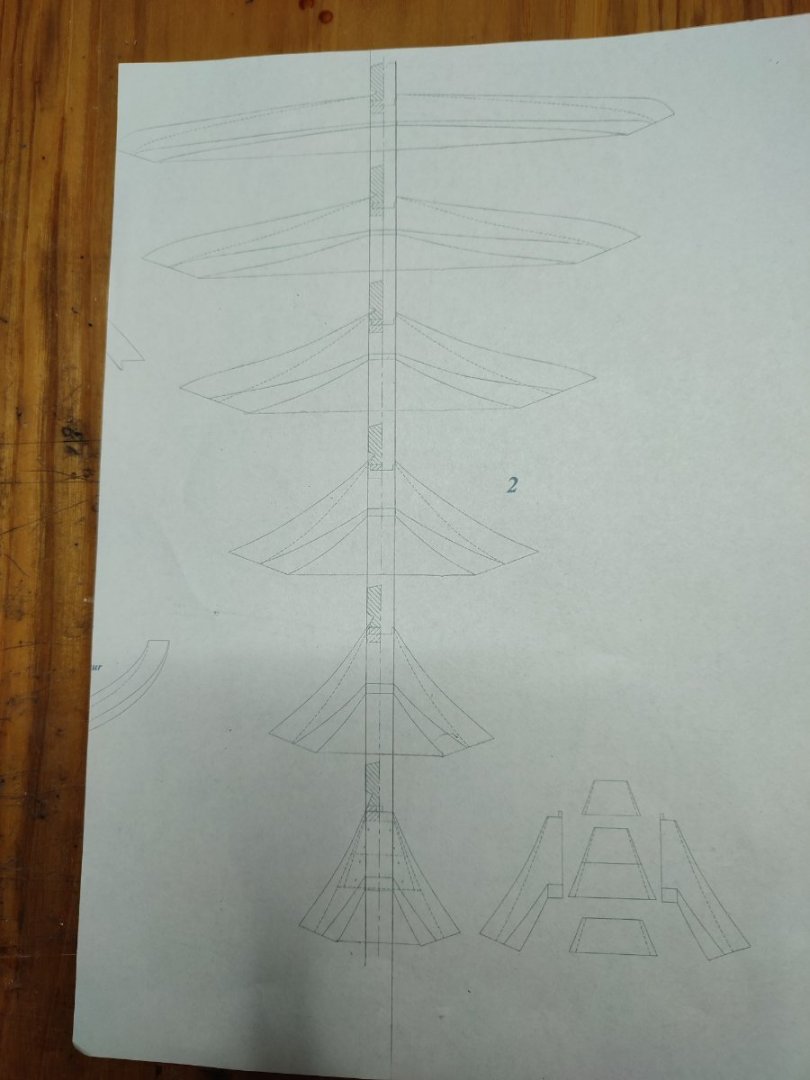

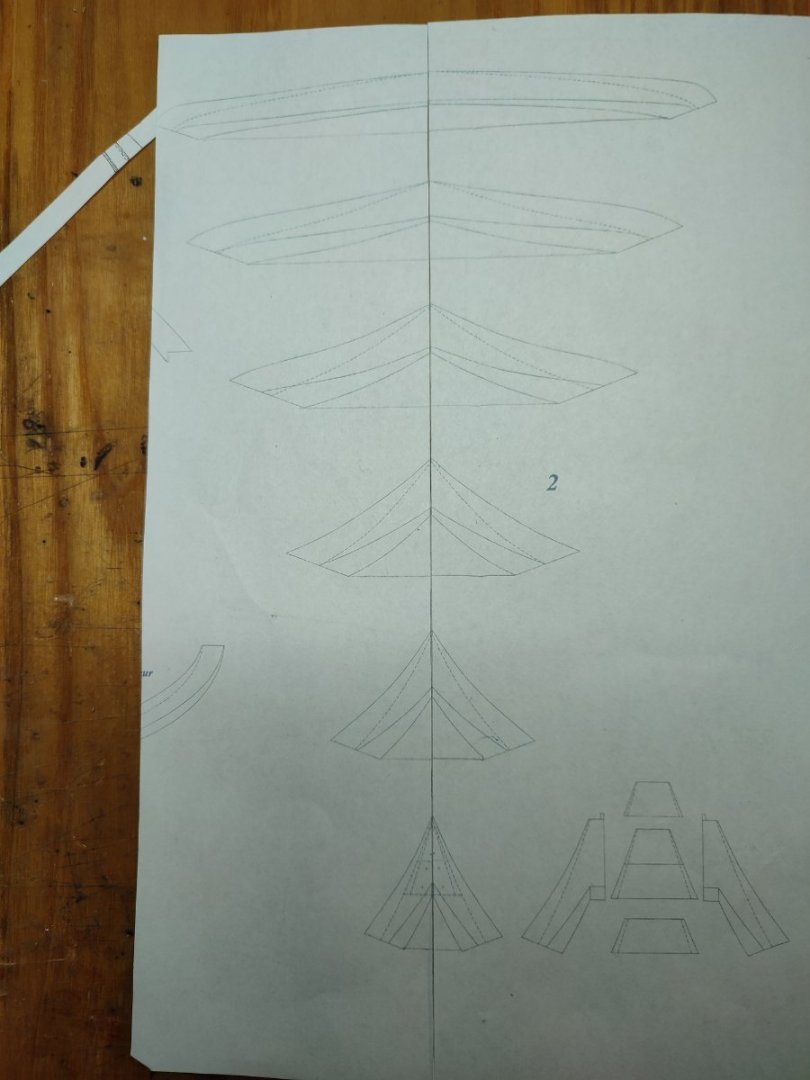

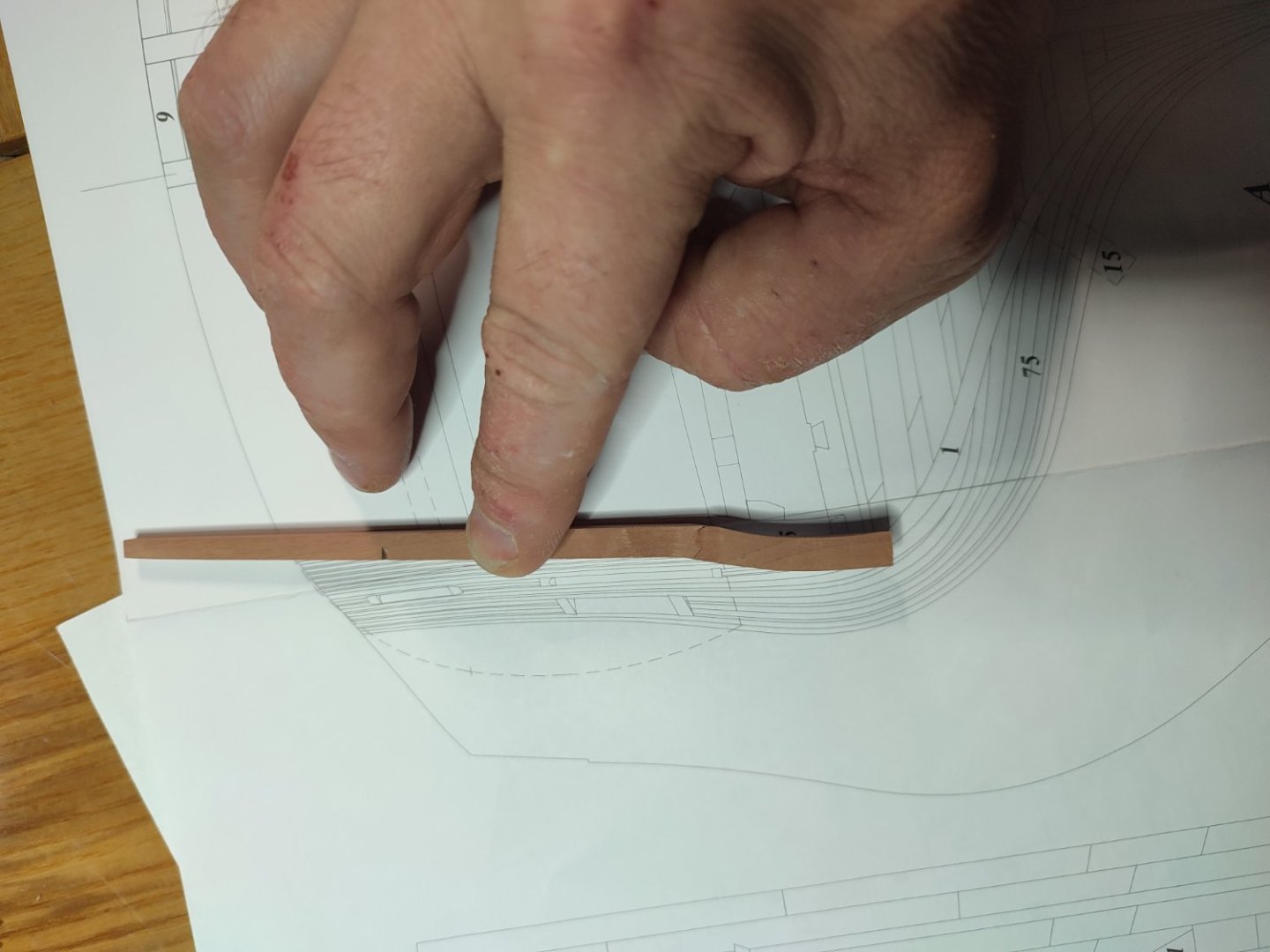

some continuation... started from opposite sides...bowsprit hole 28degrees, and masts resting holes..main mast is going right thru bulkhead so i had to think a bit... thanks for stopping by. till next time ...i hope bulkheads will be faired. so far so good though i guess i lowered stern profile 5 mm down though I will see how many problems arises when fairing hull...i intend to measure curvatures with blank plank...

-

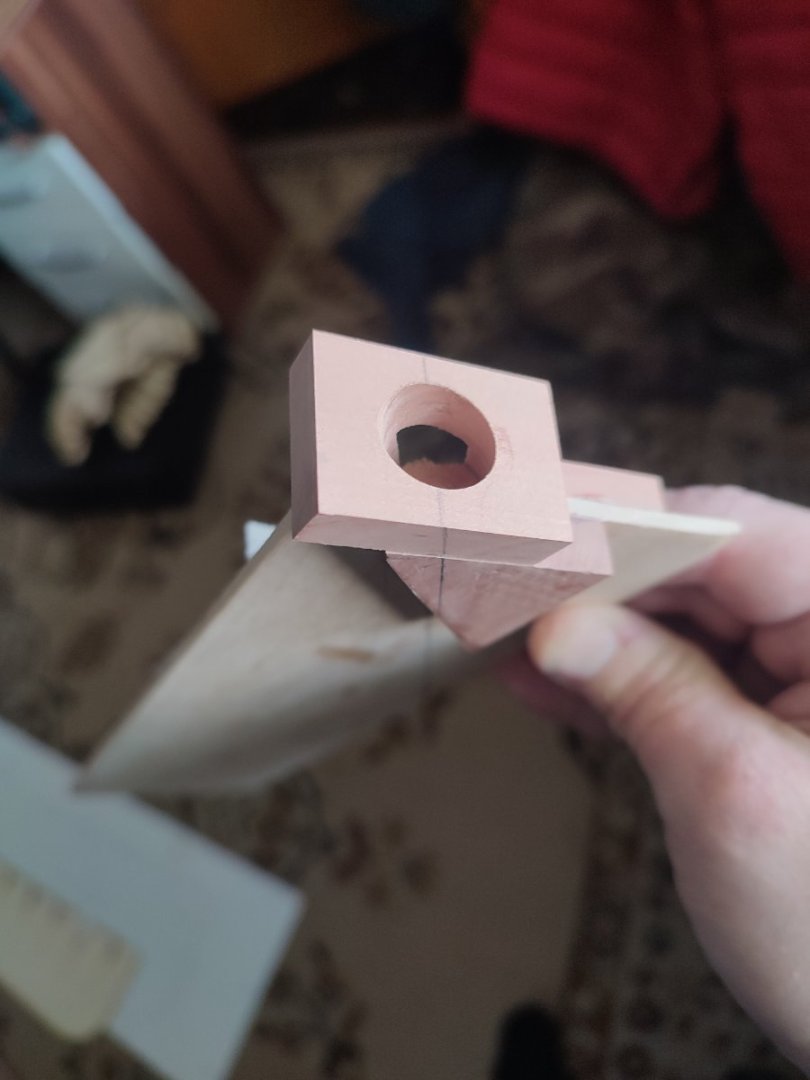

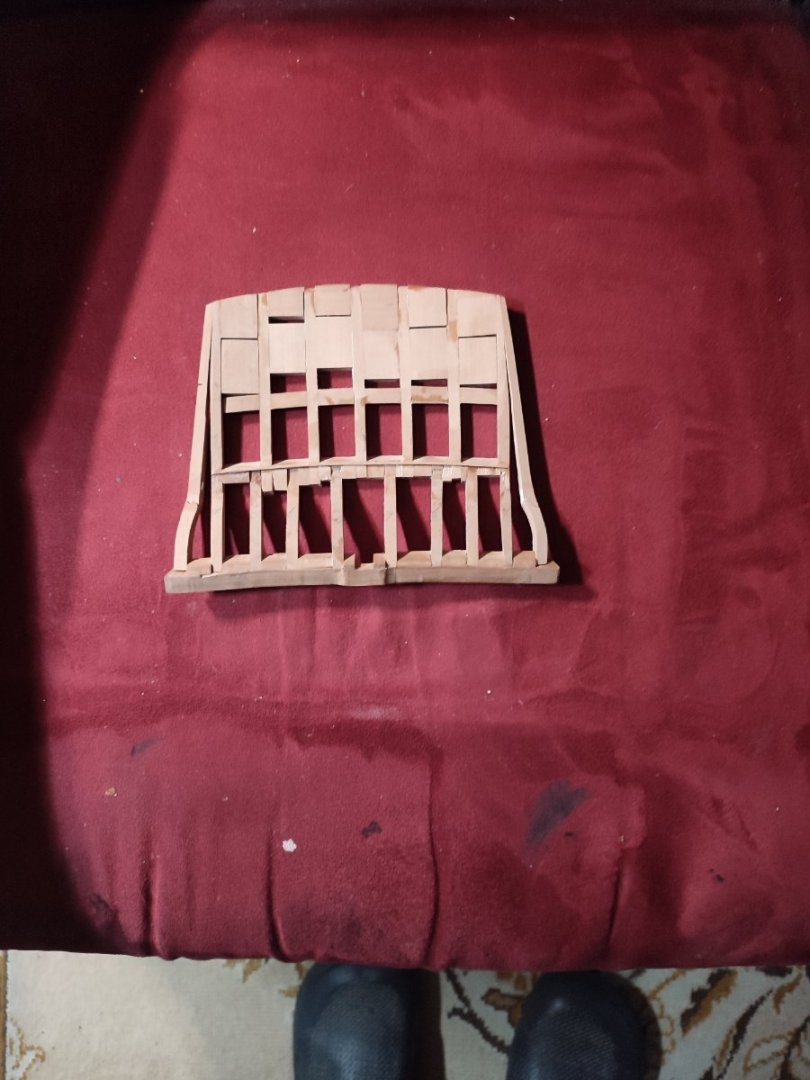

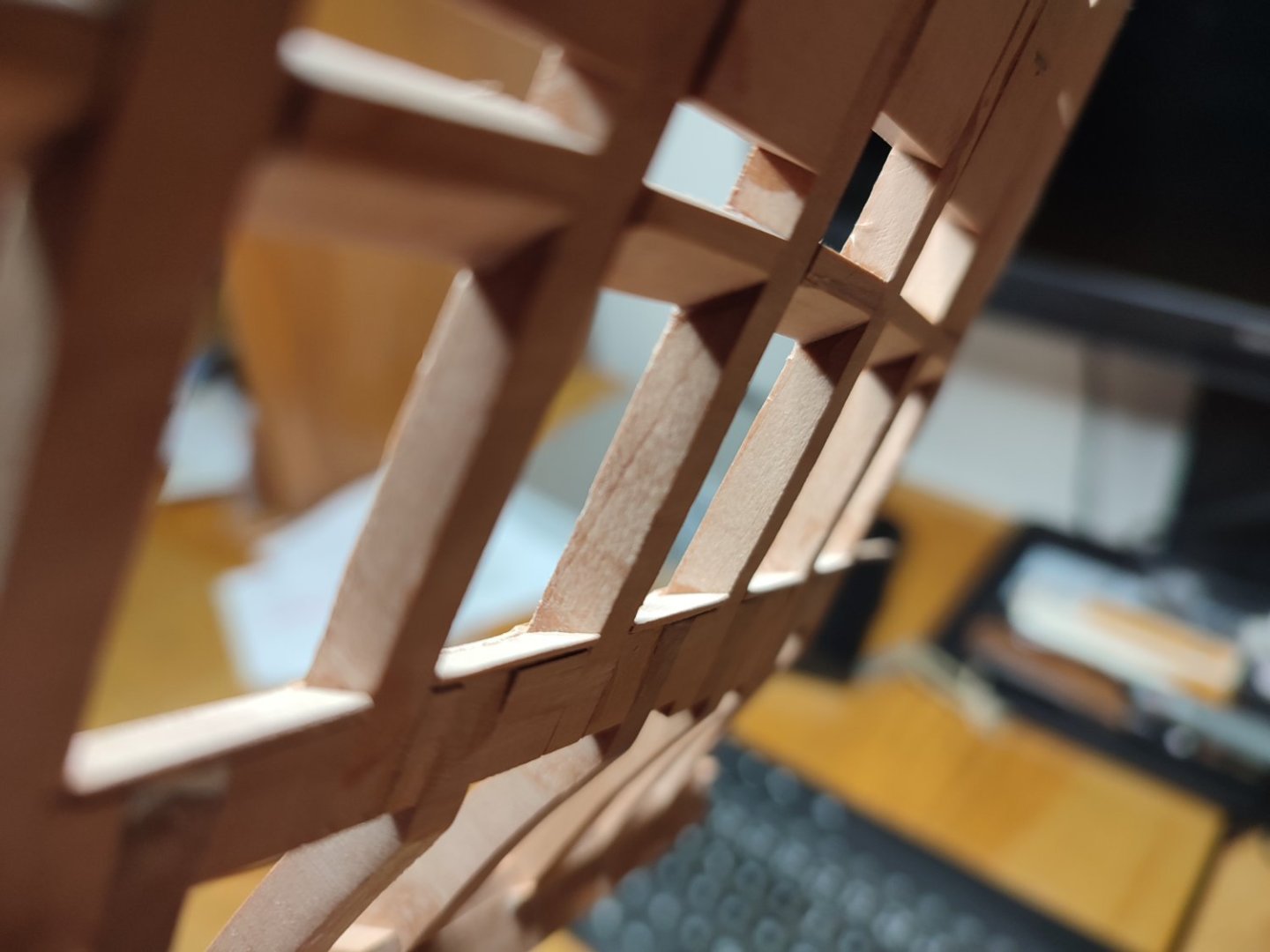

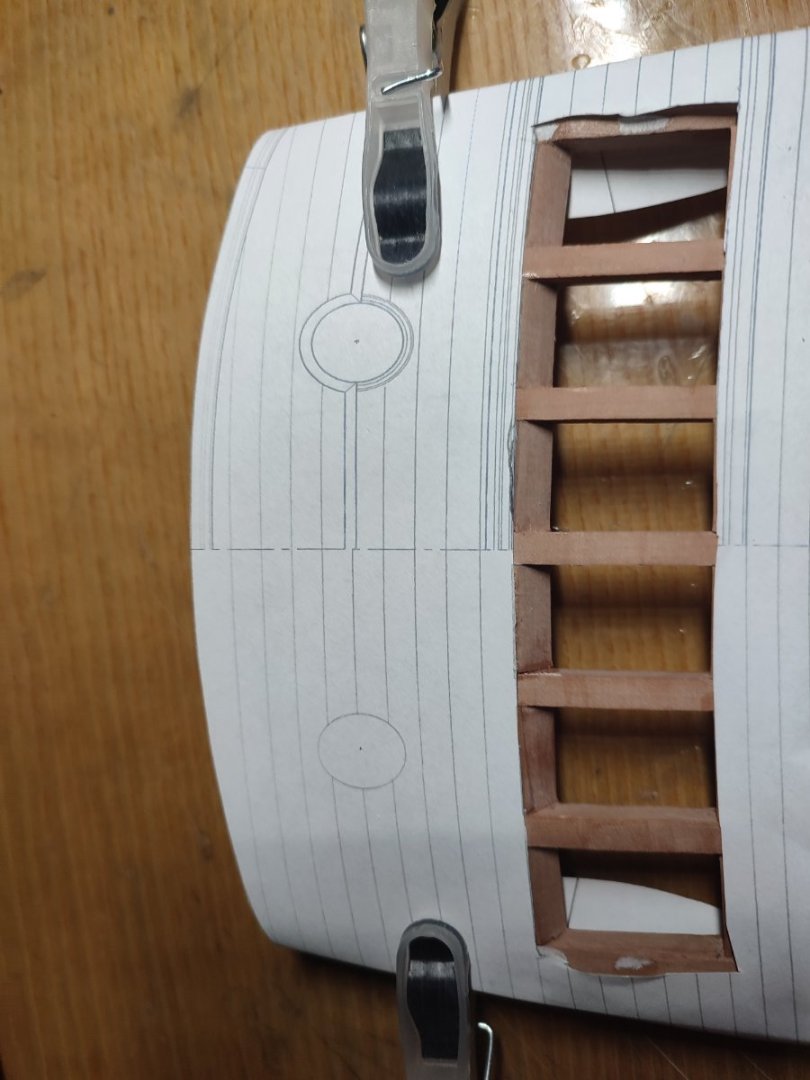

Hello, I finished half of hawse timbers kind of ..."mimic'. its probably overkill for pob, but im satisfied with outcome enough. I cant imagine comfy planking wirhout this structural part. only half yet though , im quite done. firstly I made bulkheads no0 and from there jig for it. I made bulkheads removable from one another, so when finished i will glue those together. and hole for bowsprit of fourse. thank you for watching etc. it will take some time to finish second one so i will post afterwards. what do you think? )

-

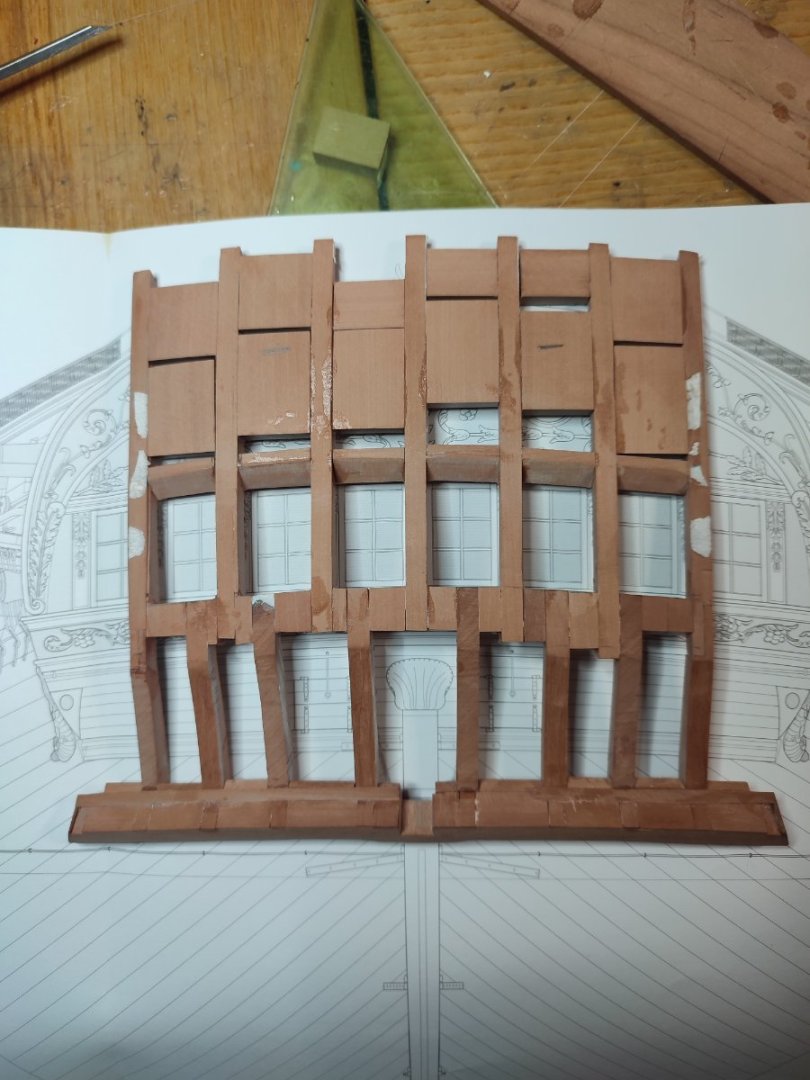

It should take no more than week or two until I get bulkheads. Im thrilled waiting. I little continued on stern...first making planking grove and transom planks.. next massive ornamental piece that attaches to the skeleton. im not good at scraping but i tried to make- modify pattern out of comercial one to mimic prototype....photos to say more. transom will be black but i intend to leave ornamentals natural boxwood so far. I should cover it at this stage not to smudge it much. thanks.

-

my goodness, its real nice. stove is incredible.

- 793 replies

-

- speedwell

- syren speedwell

-

(and 1 more)

Tagged with:

-

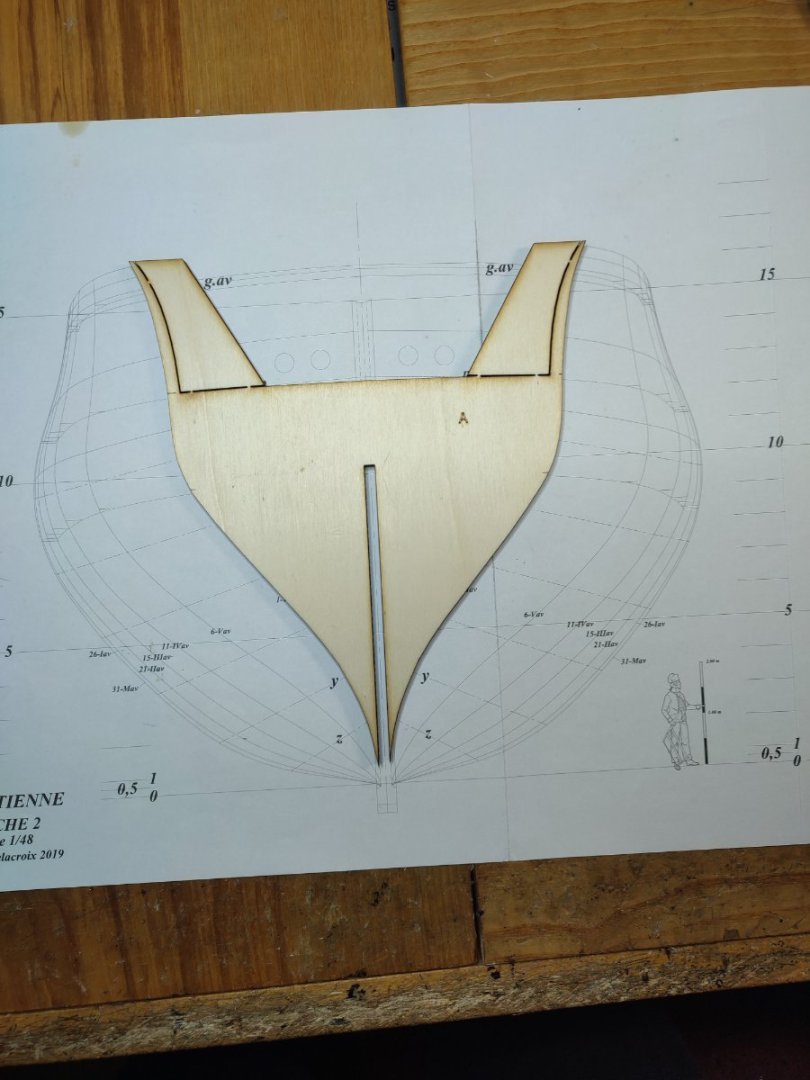

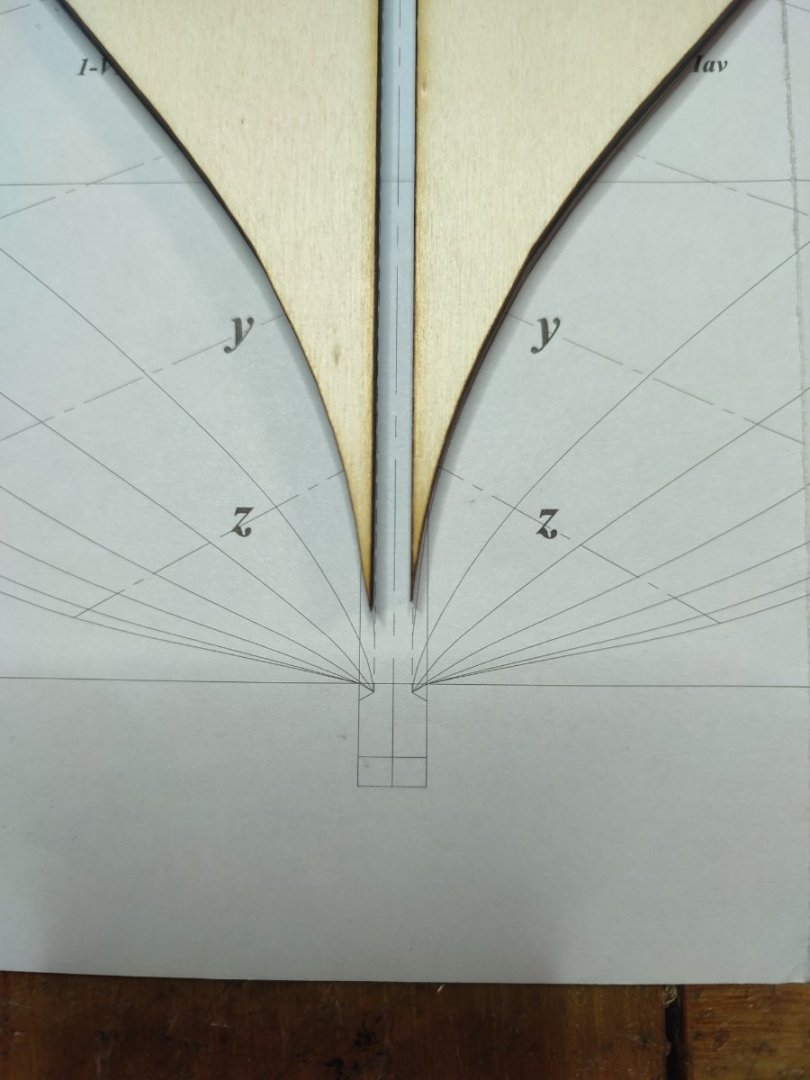

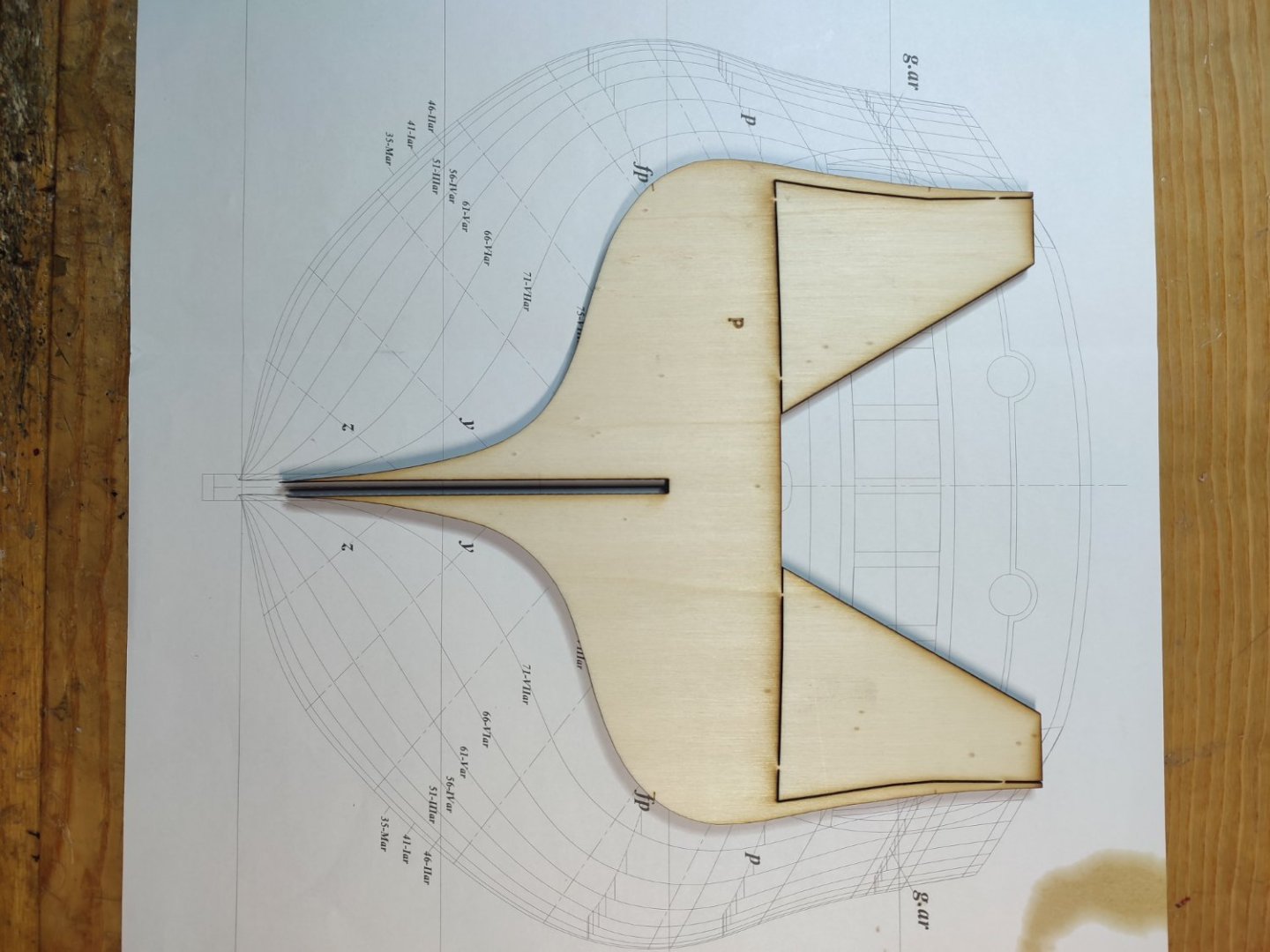

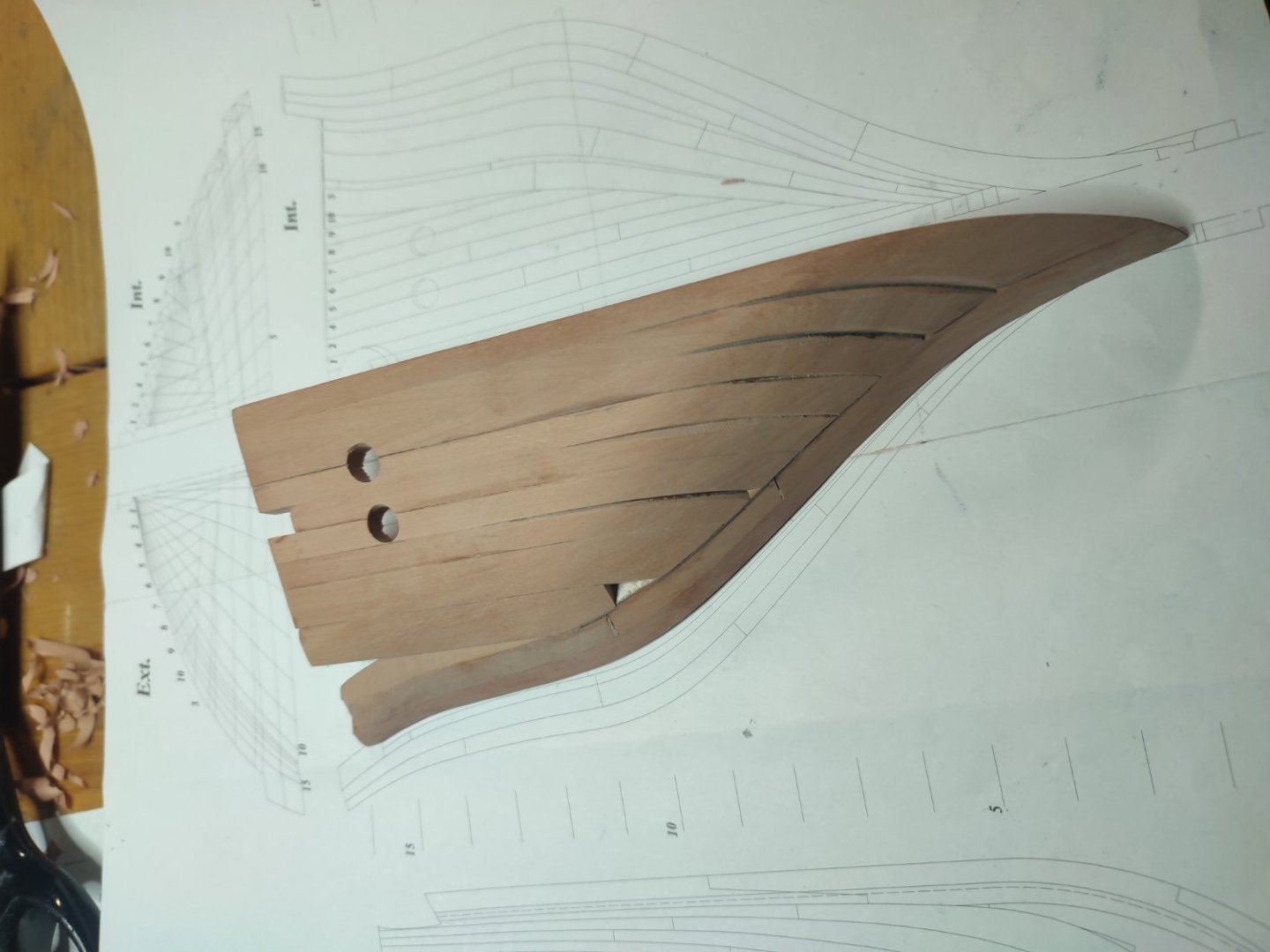

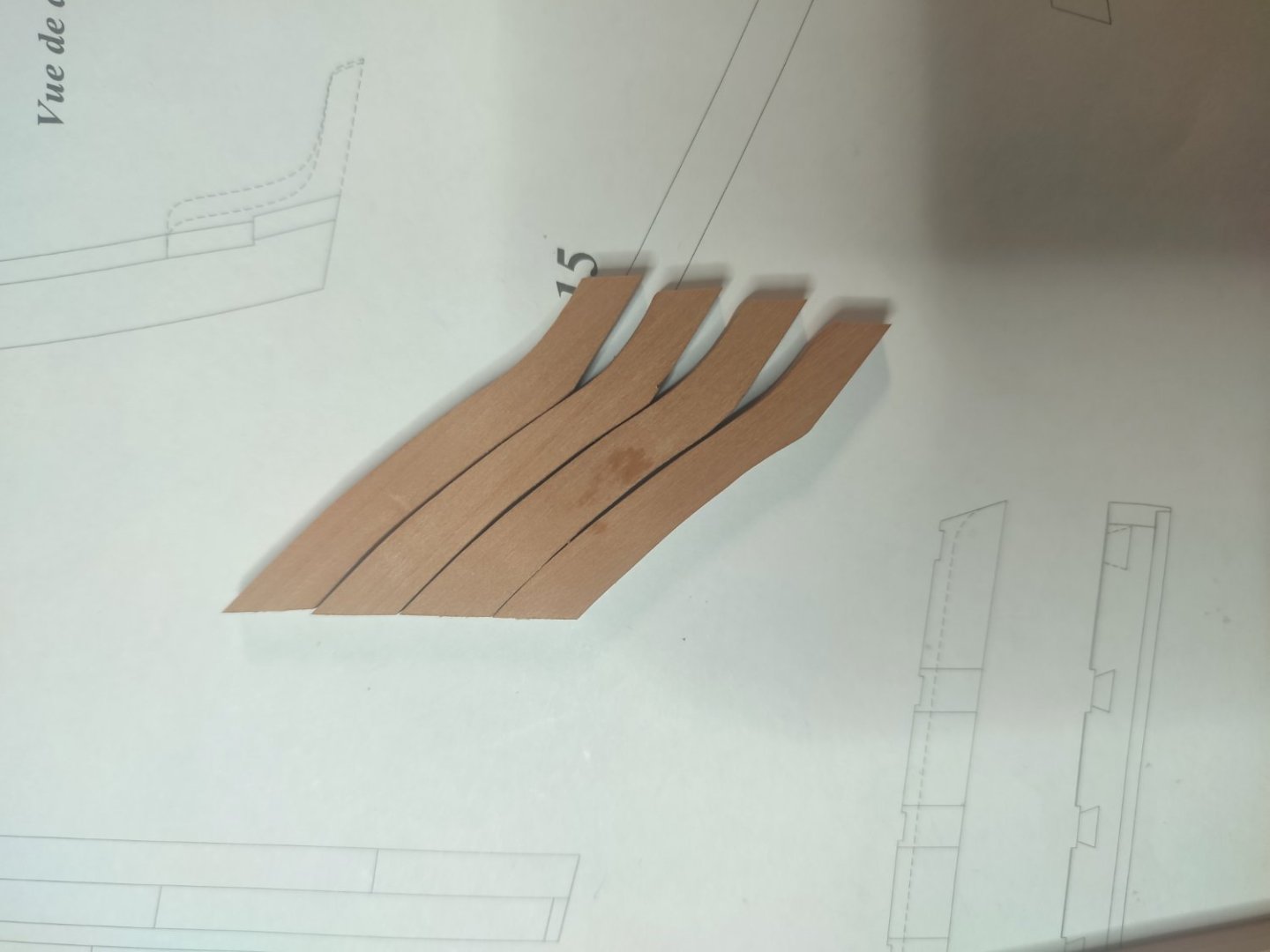

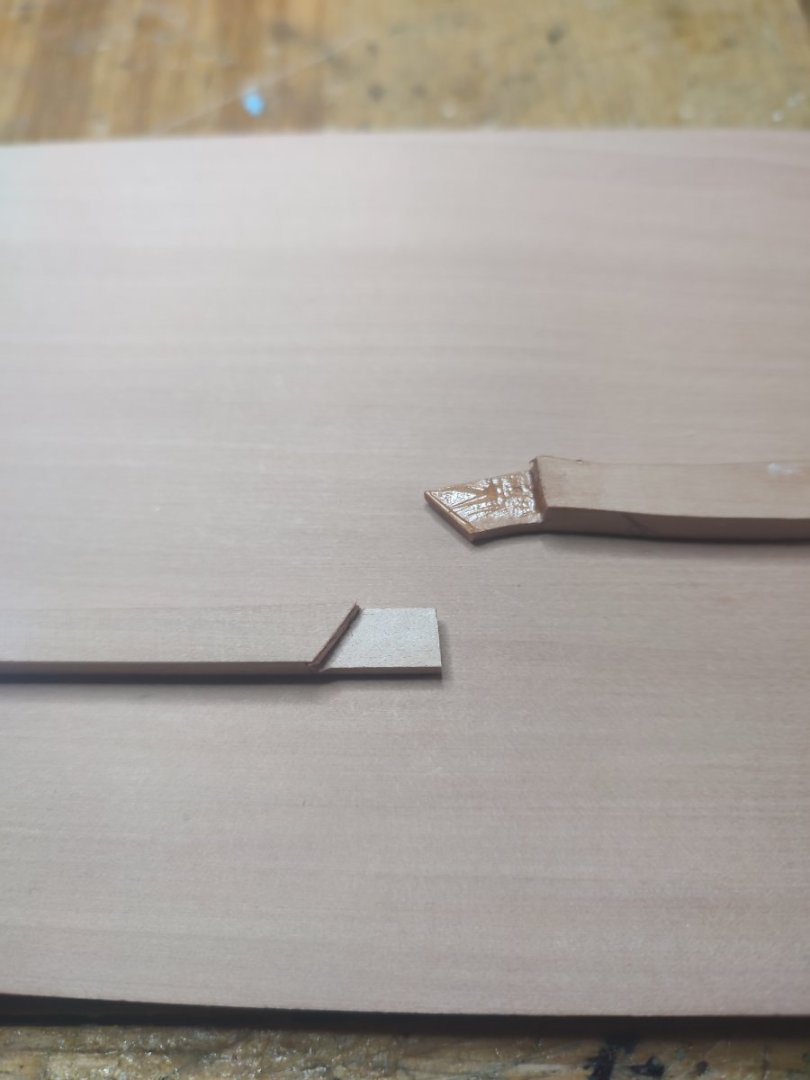

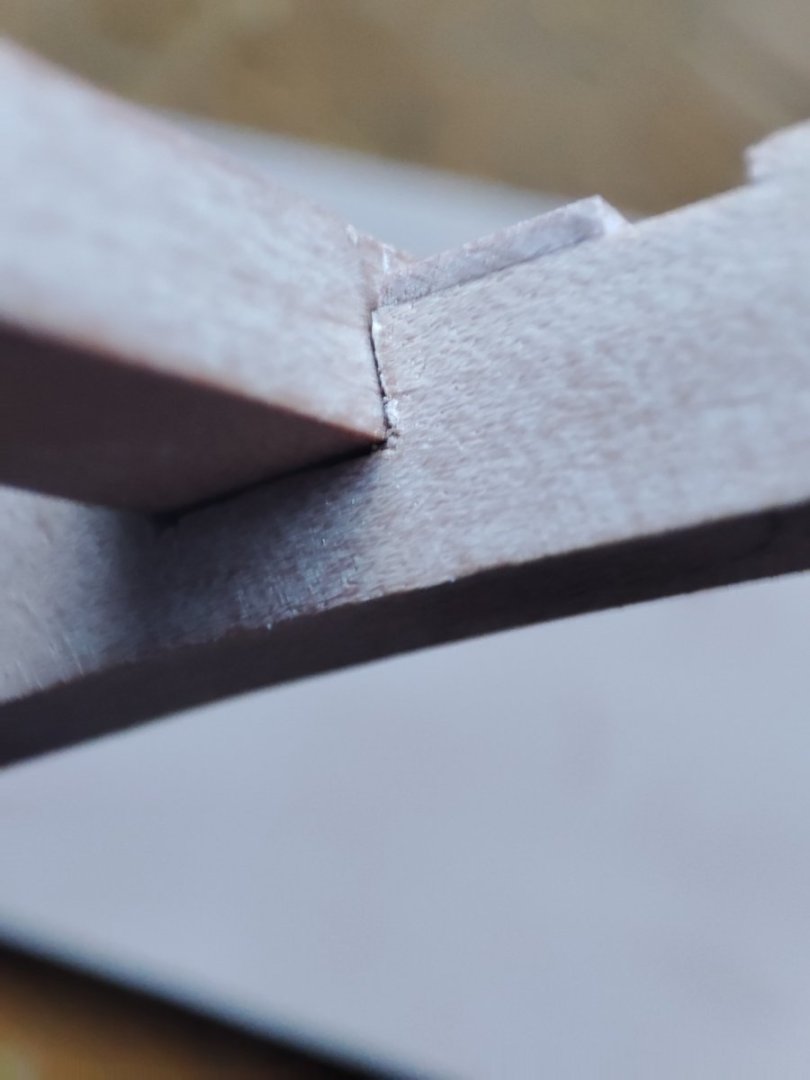

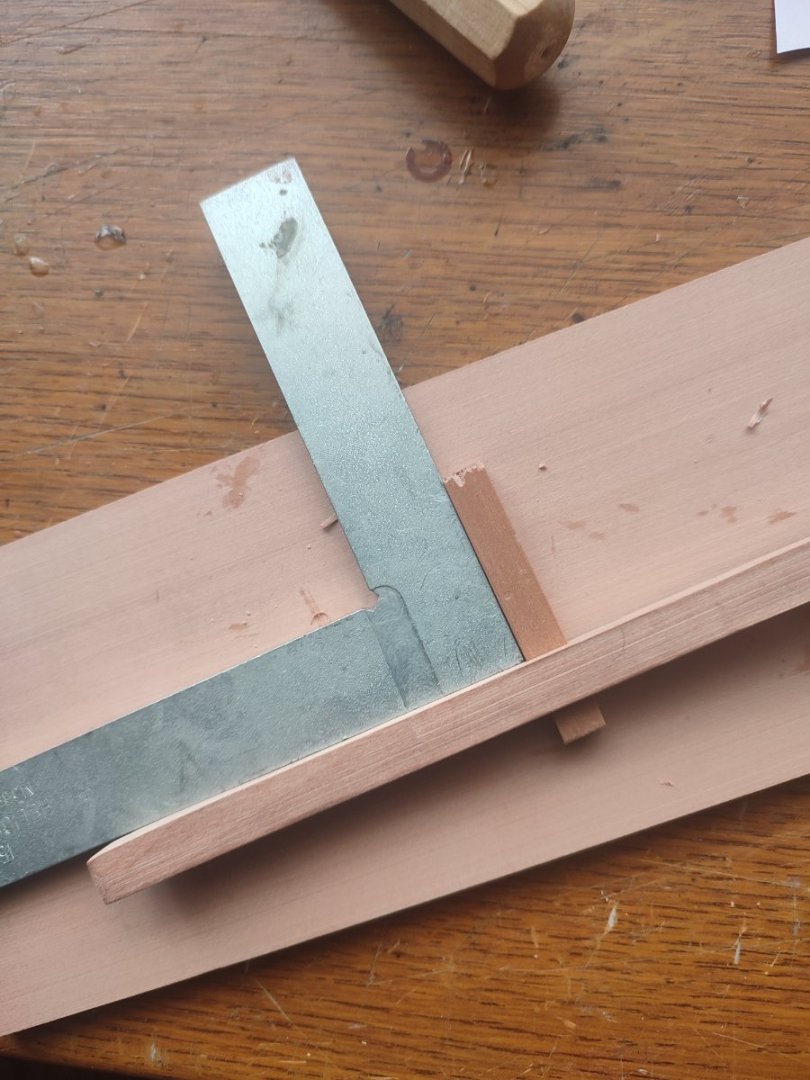

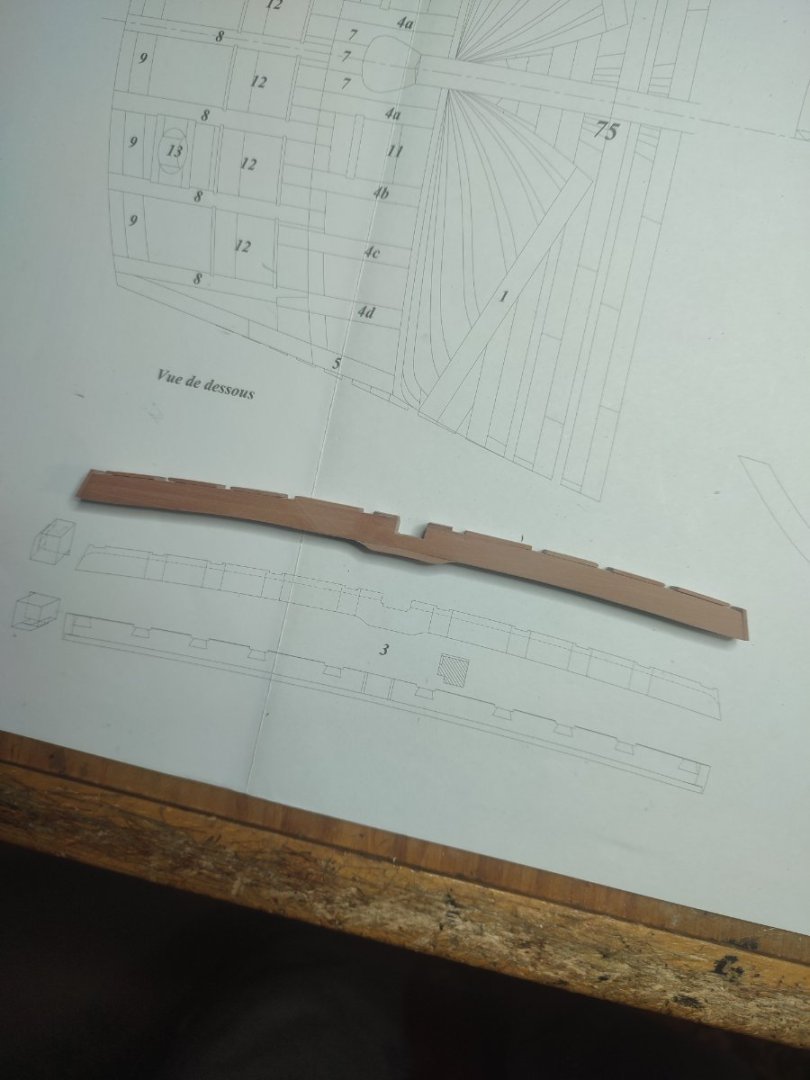

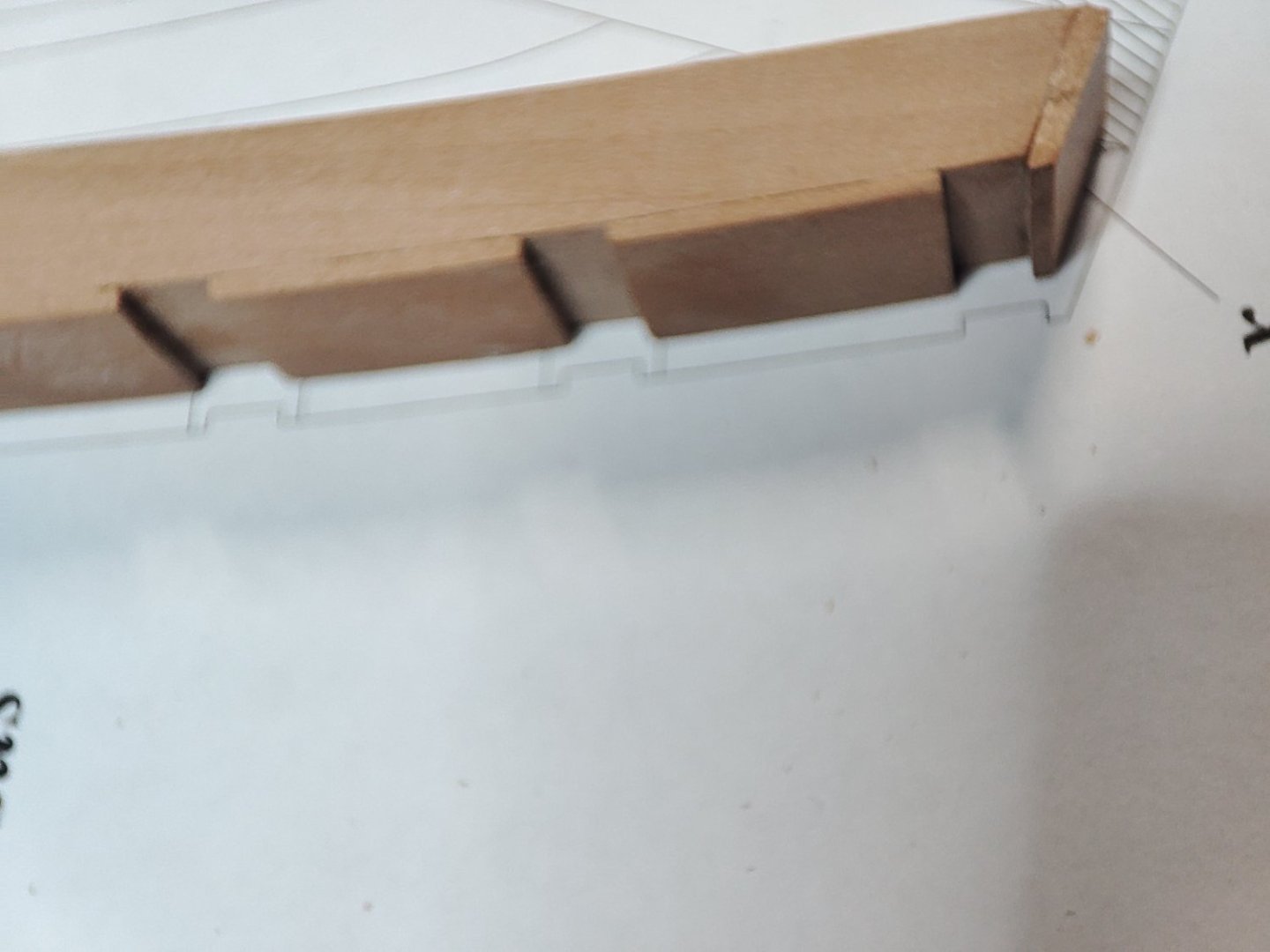

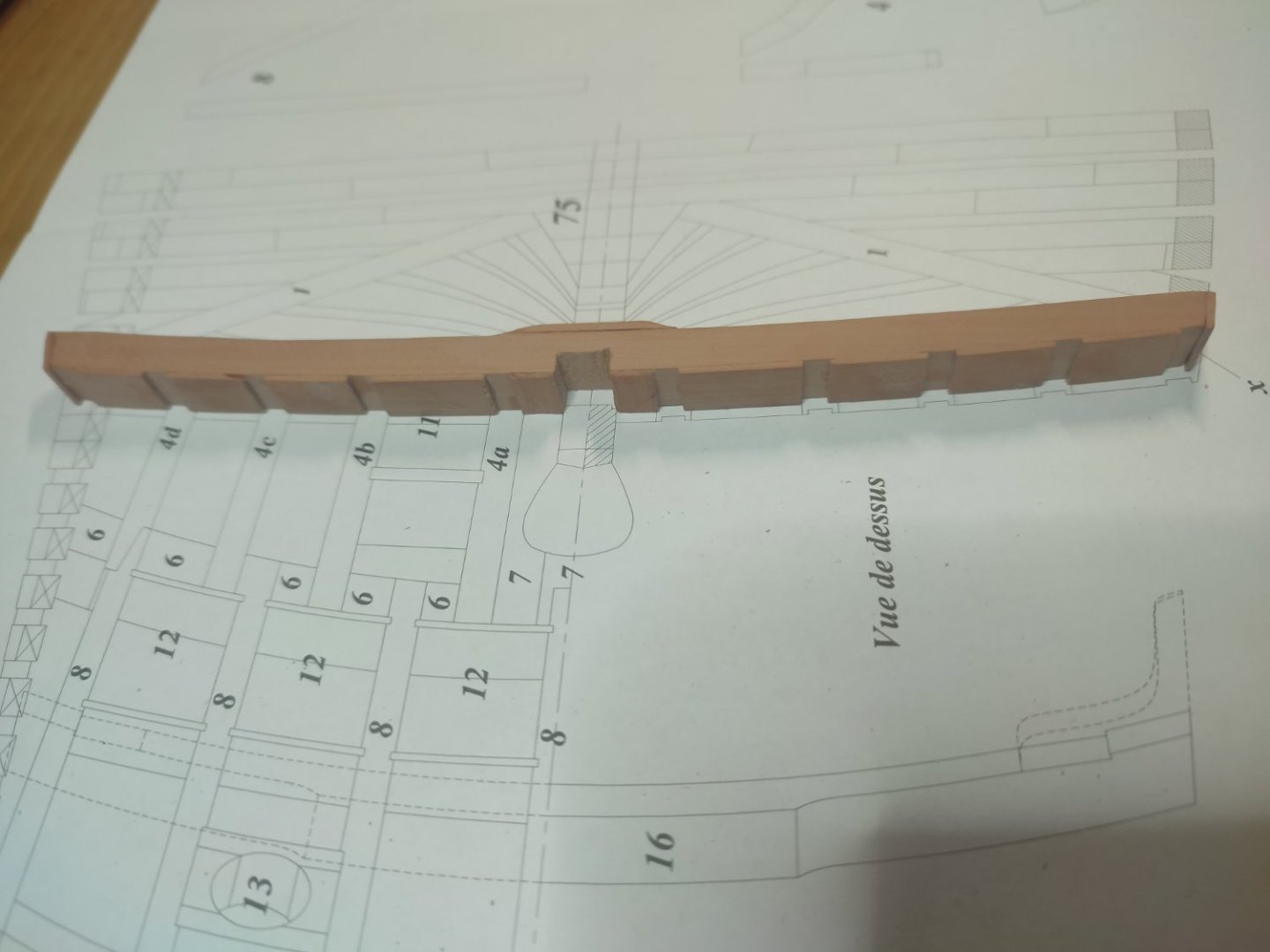

Transom wings? or whatever those are called. well, finally little weekend time. I was thinking what sort of filler to apply ..but, i realised i wouldnt be able to guess curvature without making proper pieces. Im making these, but had to though out how. Surely its quite easier than pof builders have to endure, but i dont have any sort of mill anyway...after checking against plan its not quite there yet but tweaking along. Thankfully i had to sand off only backside of them. I made jig mimicking center piece where they will be. offset by 2.5 mm according to plan right next to vertical post fastened to center line. they will be secured nicely along centerline as sticking surfqce is quite long. im still working on them. two in middle are shorter i have to adjust that.. thank you for looking in, comments , likes, advices etc...

-

congratulations for lovely ship and presentation as well.

- 302 replies

-

- Diana

- Caldercraft

-

(and 1 more)

Tagged with:

-

Thank you. Yes I found it difficult as well. there is probably far more ways to make it more simply or easier it one is building counter jig with curvature bed so legs could be under control, and making it from pear wood without laset cut precision requires utmost effort to maintain accuracy otherwise it gets soon cramped. but it is main structural part so it requires attention. I was finally happy I strenghtened it as much as possible as it required fair amount of sanding for final correction so it needed to be stiff...but lots lots of work there for me.

-

Many thanks Rob. Tell the truth, I was just plain beginner when building cutty sark not capable of making glory at all around that time so it was good decision to wait a bit. sure this build was not piece of cake due to fact that we hurried up building after having sortrd out hull structurd as well as part of excitement and curiosity. and we discussed along ...yes we came into funny part when both had to lift forecastle, but it all was just hell of a journey. I would say we know her from bottom up at this point. Cheers to Mckay !

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.