Unegawahya

Members-

Posts

58 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Unegawahya

-

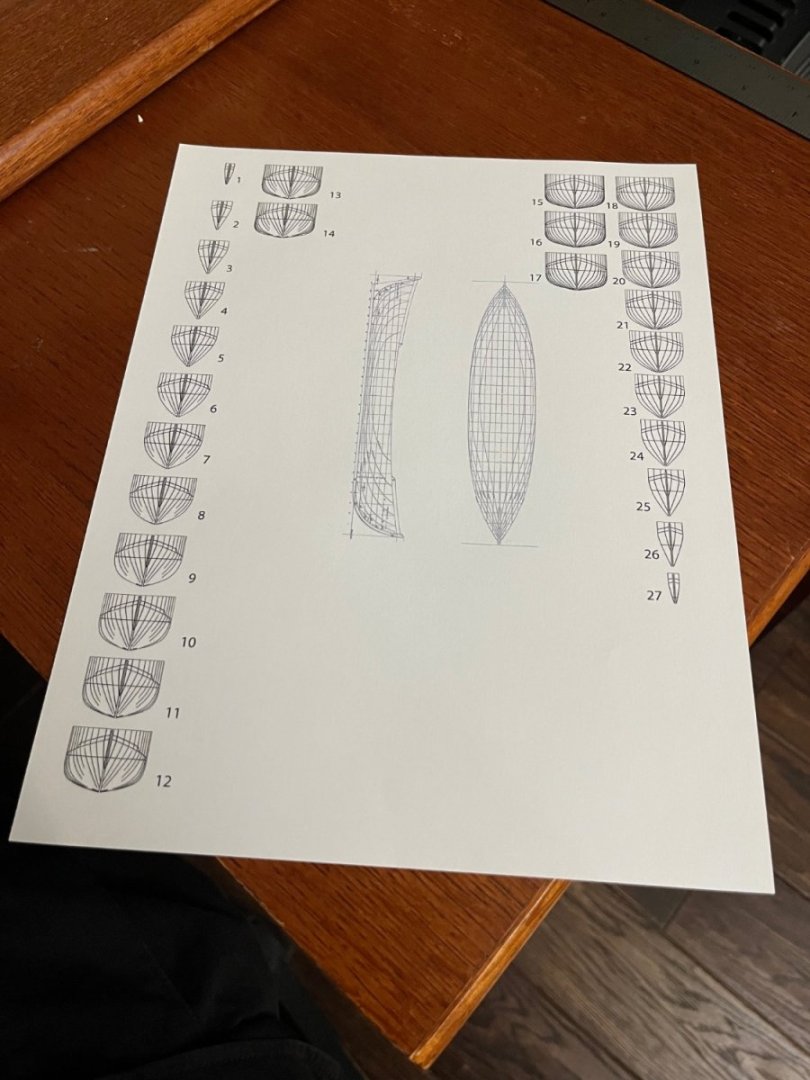

Thank you so much for all the help! I thought I was going crazy. I looked every where for these. I'm starting to think that they where removed for some reason, because the museum didn't have them and I didn't get them with the download the I got from the Navy Museum. After I get the 28' Whaleboat done I'm going to get started making a Jig file for this one too! 28' GIg Whaleboat.pdf

-

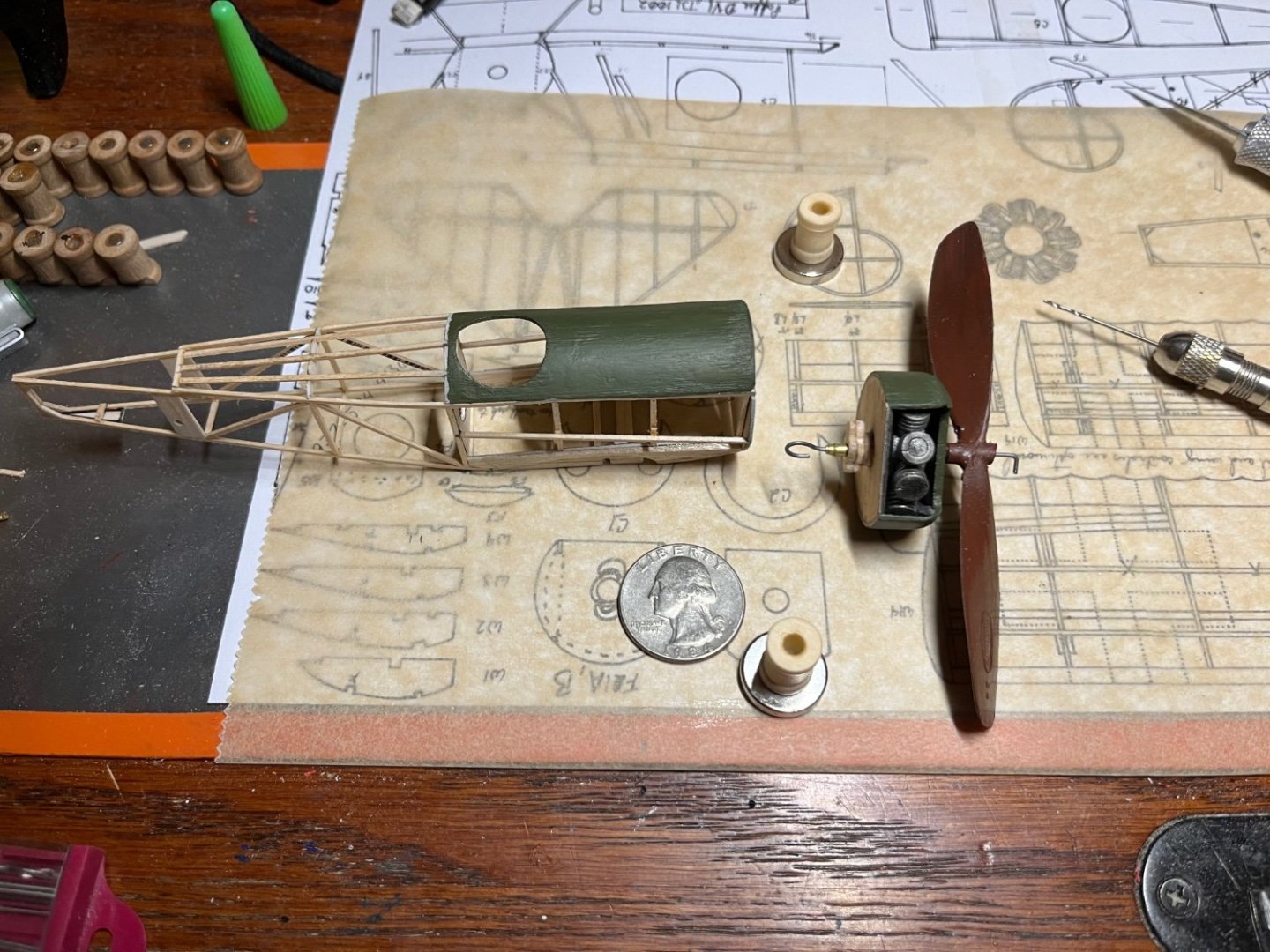

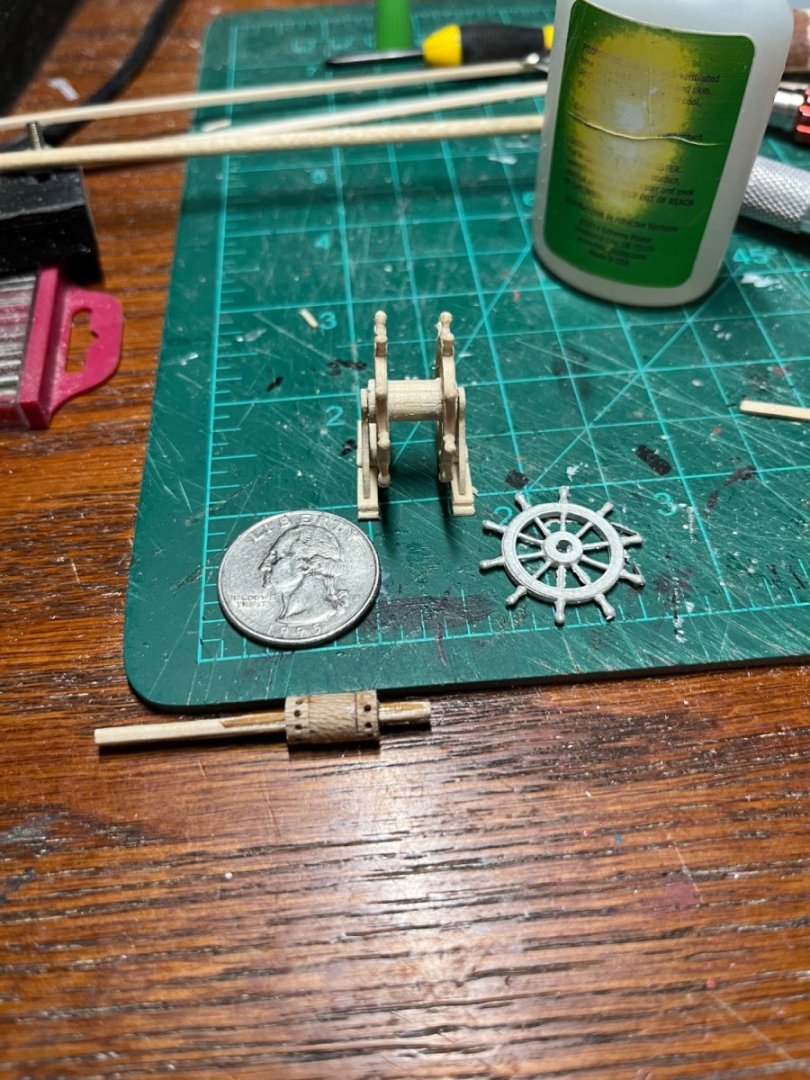

To start thins off, after sleeping on it I was not a fan of the way the barrel of my wheel looked for my USS Constitution. So today I backtracked and rebuilt the barrel today. I started with a 1/8” dowel and used 1/16” sticks to cover the dowel. (This took me two try’s) Luckily my new barrel turned out to be exactly 20mm in circumference which made it easy to mark the 10 holes. I used modeling tape with the marking to line up and poked small pilot holes to use my hand drill on. I got the stands finished tonight and now I just need to stain everything.

-

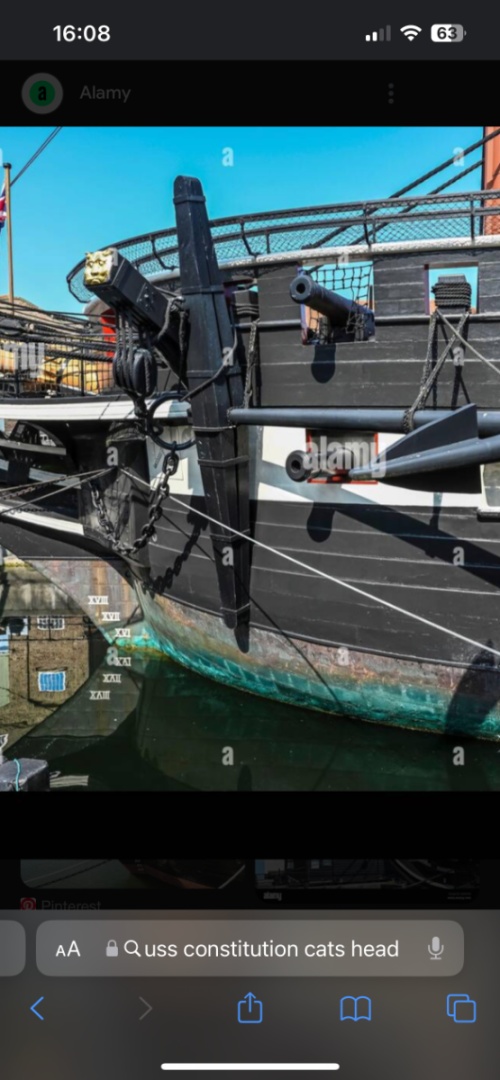

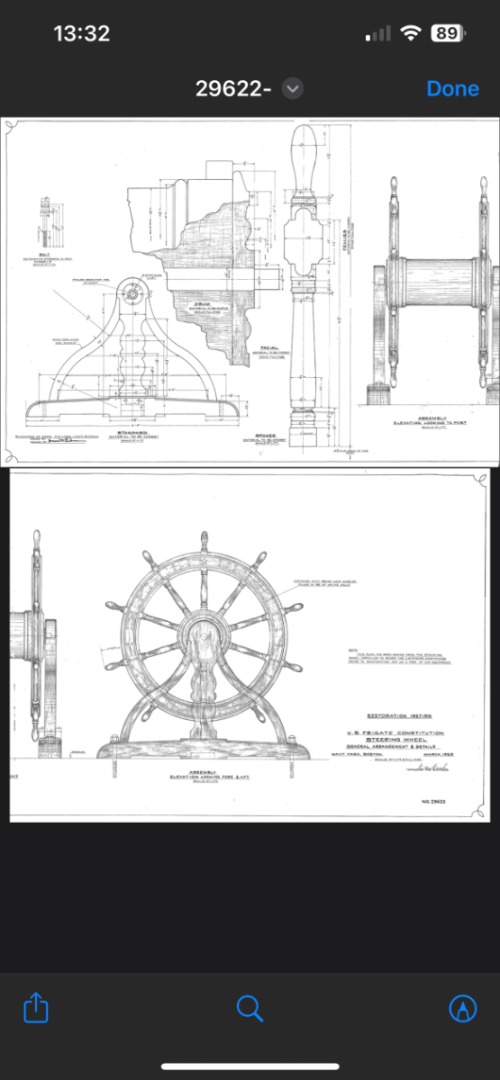

On my wheel I had a hard time drilling out the two wheel hubs for the wheels, I had just decided to to make them completely separate. In the end this turned out to maybe not be such a good idea because now I had to make everything close to square and I used a toothpick as a center shaft to keep everything together. The toothpick allowed me to glue the ends of the wheel to keep everything together. I was worried about that because I wanted everything to accept stain somewhat evenly. To that end all of my spindles and hubs have a small interference fit. The only part of the wheels that are glued are the rims and the small spots on the very ends that will be covered by the stands. Once I stain the wheel I was thinking of using a test peace of wood and drilling all the small wholes and inserting small brass wires. If this doesn’t work on the test peace I may just try to paint them on. I referenced all of my sizes and shapes from the Model Shipways plans and unfortunately I still can’t find the wheel in the instructions accept for a picture on page 33 of the actual wheel. I also referenced the Navy plans. Unfortunately, after looking I have been unable to find Bobs Practicum.

-

Thank you! I really appreciate your kind words! This is technically my third all wood kit but I’ve been building plastic models and stick and tissue planes for about 28 years! I made three attempts to make my wheels. The first two I used too thick wood and I could not get the tight bend. I finally decided to use use 1/32 mx1/16” basswood. From here I boiled one stick that was about 24” for about 15-20 minutes. Then I curled the wood around a small spray can. Once the wood dried for about 6 hours I boiled it again. After I boiled the second time I taped about an inch of the wood to the socket and the rolled to wood to the socket on the counter. Doing this I still had one split in the wood, but it gave me enough material to have a little extra leftover. After I got it secured to my socket I let it dry completely overnight. To form the wheel I layered two more layers on the first. Each layer was offset by one third of the wheel. To make the holes for the spokes I used the cast wheel from the kit to get a good even positioning around the wheel. The I used a needle awl to make a small pilot hole and started with a three sizes smaller drill bit. Each time I drilled the holes I checked for center and took my time. I went up each size to make sure that I didn’t get to close to the sides. The spindles I had to use my fingers and different files to lethe them. Making the spindles has so far taken the longest of everything.

-

The way I drilled the holes as close to the center is, I made all my marks first. Then I uses a needle awl to make a pilot hole to start. Then I started with three sizes smaller than I needed the hole. Once the first holes were done I went up in each size drill bit. Each time I drilled the holes I also made shire that the drill wasn’t walking to one side or the other. to make all the spindles I made a master spindle to model all of the next ones off. Unfortunately I don’t have a actual lathe so I had to use my fingers to turn the spindles using different files to shape.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.