Riotvan88

Members-

Posts

108 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Riotvan88

-

Hi guys Building a scratch Zwarte Zee and now approaching the time to fiberglass the Hull. Previously built a smit rotterdam and used west systems Gflex epoxy only but this time I want to use cloth aswell. What is the best weight of cloth to use and what epoxy resin to use? The Gflex used previously was thick and probably not suitable for wetting out cloth. Just looking for suggestions and tips as to what everyone else uses. Cheers

-

Thanks for all the info guys. Regarding the instructions apparently both kits come with a detailed booklet and online reviews rate both instructions as good. I think I'll buy those books so I can build a more accurate model either way.

-

So I'm currently building a Caldercraft Sherborne, so far the Hull is coming together and I'm fairly happy with the result. This is my first period ship model although I have now built three wooden hulls previously. I'm looking to start the next model at some point in the new year. I'm keen on building the gallion Revenge. It appears there's two kits available the occre revenge kit and the Amati/victory models kit. Has anyone got any experience with either kit? The occre is much cheaper and looks to be a more decorative model whereas the Amati looks to be a more realistic representation of the real ship. The Occre kit also comes with sails and although less realistic I very much like its appearance. That said I also like to more scale realistic look of the Amati model too. I just wondered what people's opinions are on the two options. Additionally I think the occre kit is aimed more at beginners like myself so thats also a plus for that one. Would the planking be harder for these kits than the Sherbourne? Interesting to hear people's thoughts Cheers

-

Hello Is there a way to sand or remove a raise edge in paint where masking tape has been? For example along a Waterline? Without effecting the paint shine or matte level of the finish? Would rottenstone archive this? I've built a boat and there is an edge that can be felt where the red paint meets the black. The paint has the finish I want so I don't want to do any polish or sanding that will alter the finish.

-

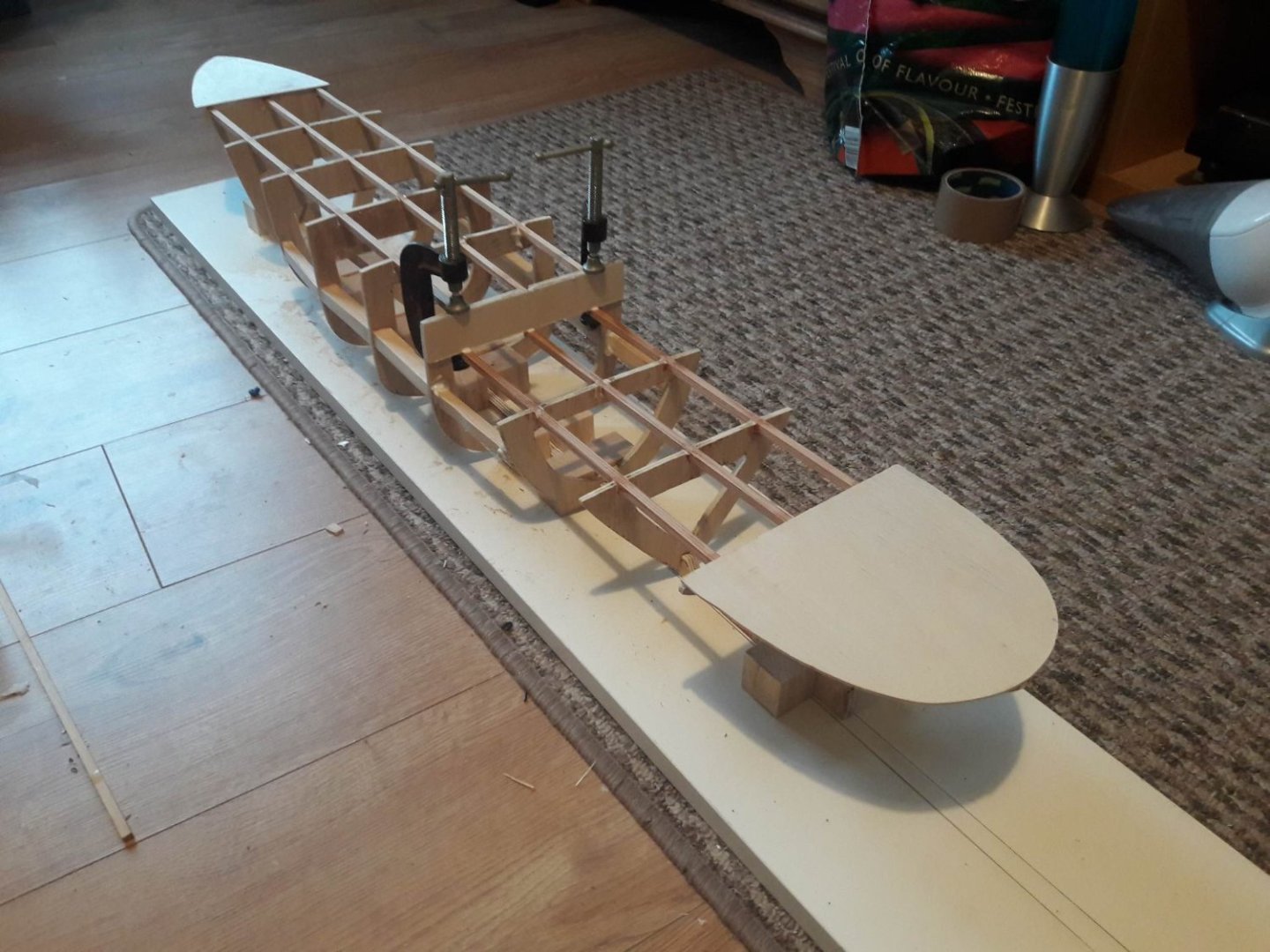

Thanks for all the advice and suggestions. In the end I built it using cheap ply using the method I've used previously in kits. Progress as of one week. However my next build is already planned (schooner Argus from Sarik hobbies) for that I'll use bread and butter method since as many of have noted Wickes appears to have reasonably priced pine.

-

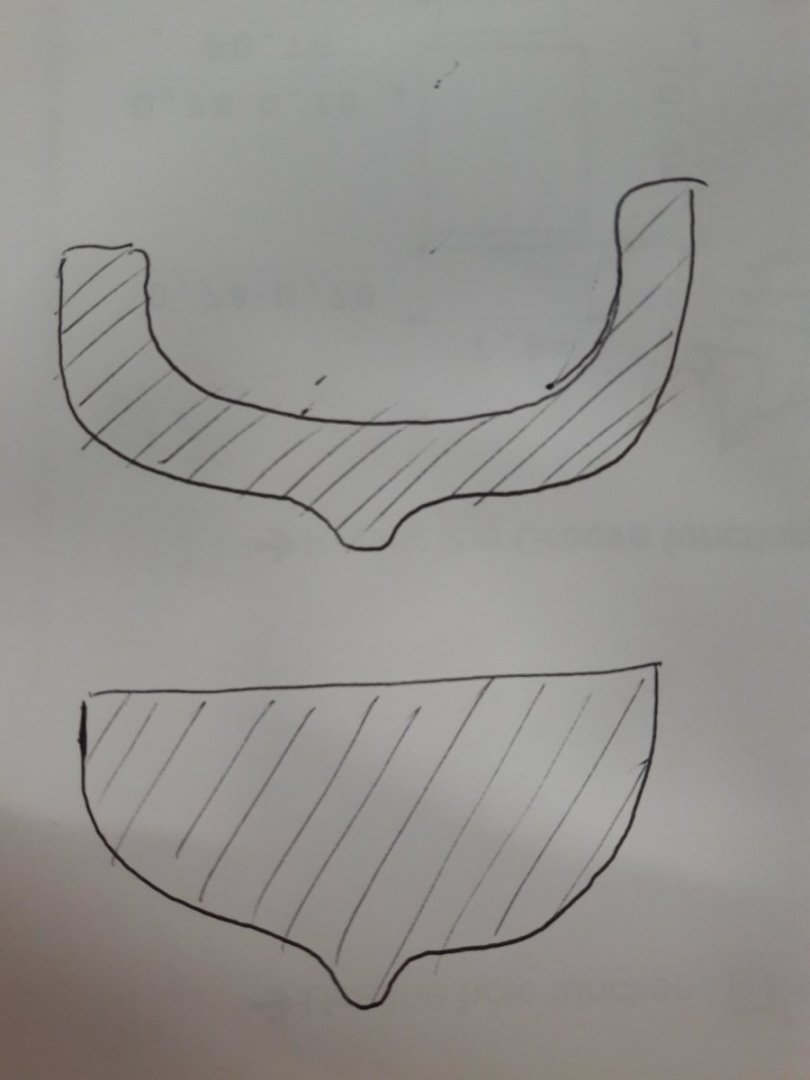

I think wood must be more expensive in the UK. This model is about 1 meter long. Even at £30 a sheet your likely to only get one WL out of each sheet and need about 5 to 10 WLs depending on hull. Stil very expensive. I'm going to search for a local yard and ask around. As a bread and butter looks less tedious than building a structure and planking it.

-

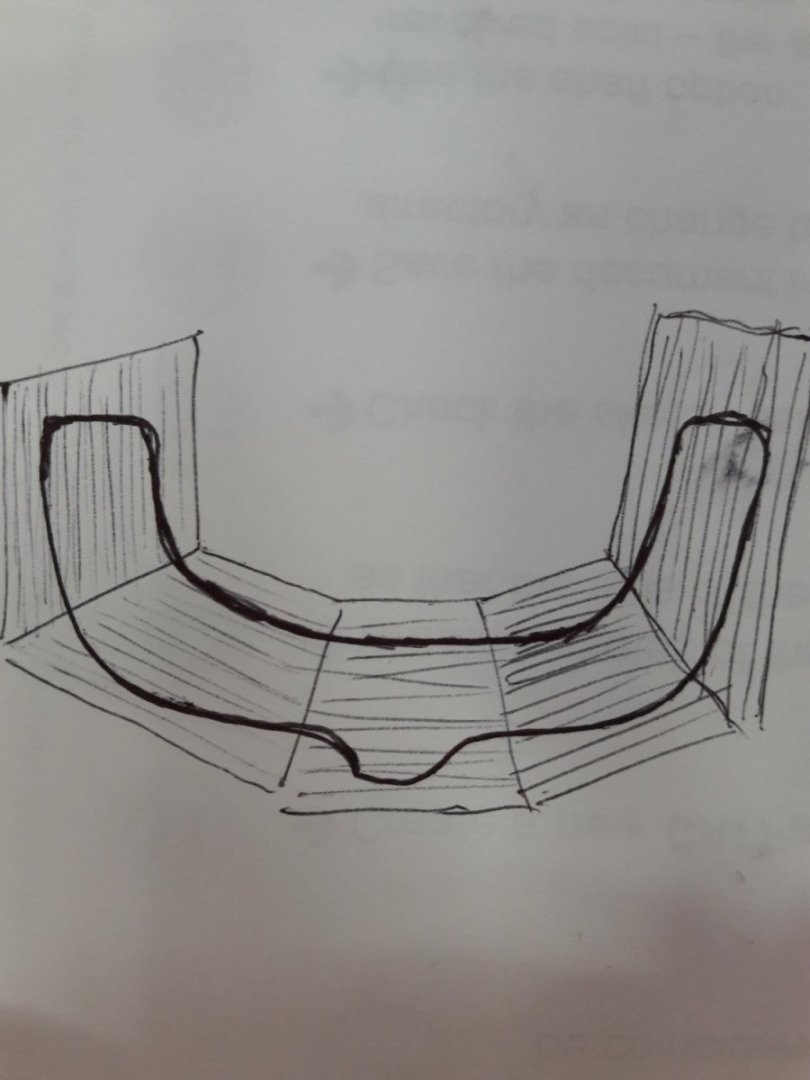

After some consideration I'm going to attempt a bread and butter build. I'm going to create the WLs using tracing paper and Mark them off over the original plans. I plan to use 1inch thick basswood. I'll see how it goes. Whilst not in a rush it looks to be a quicker build method than planking an internal support structure.

-

Thanks for the advice. I do have some experience and not a total beginner. I've built a Billings smit Rotterdam. Along with a couple of caldercaft models and a scratch built albeit basic model I built some years ago. For the Rotterdam I replaced most of the fittings with ones I made. So creating the detail parts is no problem. What I'm mostly asking here is what wood is best for the moulds/bulkhead. I've no idea what is used in kits but they didn't involve doubles with joints. Which is why I'm asking simply because whatever wood the kits use seemingly allows one to eliminate that process. I don't want to incur unessesary expense on fine decorative wood and don't want something that isn't up to the task. So hopfully that explains why I'm asking these questions. I've not been very clear but the plans I have are complete, what I meant by more work was that to do a bread and butter method I'd have to measure each cross section at various heights and record that data to create the waterlines either in drawing form or a list of points to work from. Otherwise I can just cut directly from my plans as is. The reason I don't want to buy the kit is because it is 1/100 and I want this to be 1/75 and I want to scratch build it.

-

Would Birch modelling ply be any good? Is that the high quality type ply? https://www.hobbies.co.uk/quality-birch-plywood Otherwise it'll be 3mm mahogany sheets from the model shop and done Hahn style. I'm just cautious of buying expensive finishing/decorative wood unnecessarily for something that's going to be used for hidden internal structure

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.