-

Posts

144 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by ortho85

-

Wow! That's a brave option he's taking. Thanks, Grant.

-

Hi All, I'm in the market for my next build, and top of my list is the Amati version of the Titanic. However, there is not much on this forum about her - nor anywhere else, really. Is there anyone out there with positive or negative views? Thanks, Brett

-

Thanks, hamilton. Dave, I use 'Satin' Poly. I have sanding sealer, but, when I tested that on this timber, I decided I preferred the deeper colour that straight Poly gives. Also the Poly seems to hide the blemishes a bit better, where I have filled with strips of timber or wood filler. Cheers, Brett

-

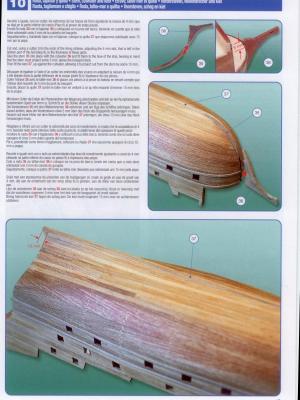

Dave's progress on his build prompted me to show a bit more of mine. After failing to find a definitive guide (I think that's the only purpose of these logs - to help those who follow), I decided to use a garboard plank that tapered towards the bow. I planned to leave the 4mm gap at the stern, and trim out the rest of the space for the keel later: In that photo you see that I was gluing a break towards the bow. I prefer to use PVA for my models (where possible), so at this stage the stern is glued, and I added glue further forward later. I tried to shape the planks in 3 dimensions as much as I could, but soon found I was useless at it. Here we are after 4 planks each side: It all gets a bit boring after that. I just wanted to get the planking finished ASAP. So we'll cut to the chase. Here are a few photos after the planking has been mostly sanded, and given its first coat of poly: If anybody wants more gruesome detail please PM me. Cheers, Brett

-

Wow! You're racing along. I took sort of the same approach - a few up the top, then a few by the keel, then fill in the middle. That's about all those useless instructions suggest. I will have to update my log sometime. You'll be surprised and pleased when you sand and seal the whole hull. Looking good!

- 114 replies

-

- san francisco ii

- artesania latina

-

(and 1 more)

Tagged with:

-

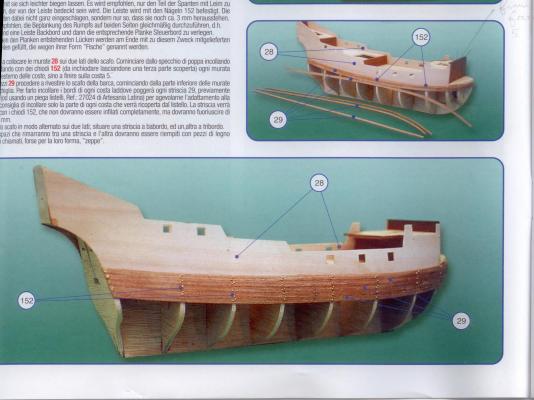

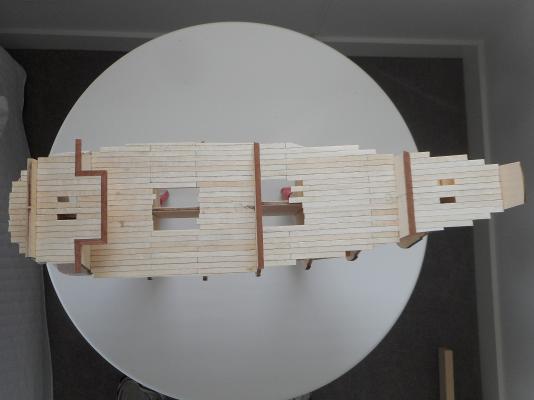

Ah well, I had sort of decided to stop my log here, but am now encouraged to continue. Hamilton - on we go! Sephirem - I know EXACTLY what you mean about planking nightmares. More later. LMDAVE - yes, I would use 2.5 or 3mm wide deck planks if I could get them. So, planking began. I asked around, and the response from another forum was that it works/looks better using full length planks, so that is what I decided to do. In retrospect I think it looks pretty, but incorrect, with full length planks. It is also proving $%@*ing impossible to bend them accurately, so I am currently experimenting with fillers to compensate for the clinker built effect on the hull. To be continued! I found most started with a plank below the pre-formed bulkhead, so, after much experimentation and agonising, that's what I did. Clamping it was a bitch, and is getting harder with each plank: The planks are 5mm wide, 2mm thick, brittle as hell, and need to be bent in all three planes. I tried various methods of soaking/heating/bending, and ended up going with an hour of soaking, then clamping around a curved former. This has to be repeated with gradually smaller curves, necessitating about 2 days to get enough bend! After all the breakages, I think I may be short of timber later. To get the edge bend, I used a router to cut out a curve in some MDF. I soon found that the curve needed to be exaggerated, but this is the first attempt: I had previously obtained the (relatively) simple curved end, but, of course, when you resoak the plank the first bend wants to straighten out. Hence the plastic tubing to hold/increase the curve there: BTW, if you use this tubing idea, remember that the enclosed plank won't dry out as fast as the exposed timber. I was doing one plank per side, for symmetry. Here we are with 3 planks each side: It soon transpired that there were differences in my bending, which did not equalise when the planks were glued on. So I experimented with some wood filler: After sanding and sealing, that looked stupid, so I am now looking for a better match. I may use strips of thin timber and extreme sanding. Next is the dreaded garboard plank (I had to look up the term!). Cheers, Brett

-

Hi all. I'm building the San Francisco II and need some planking advice. This is my first time with single planking. The planks are mahogany, 2mm by 5mm. The instructions show the planks as being laid in one length. This seems wrong to me, both because I don't believe the ship would have been built like that, and also because it will be extremely hard to do with 2mm thick planks. Here is a section of the plans: So, my question is which way do you think will be better, sections or full planks? All opinions and advice welcomed! Thanks, Brett

-

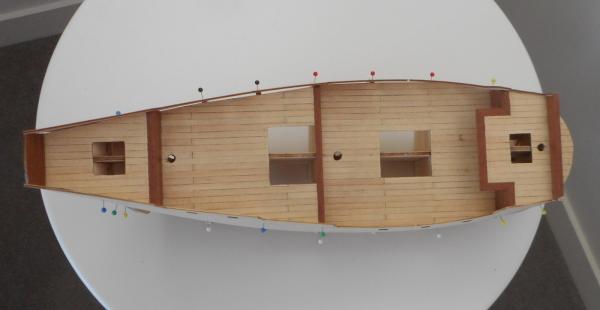

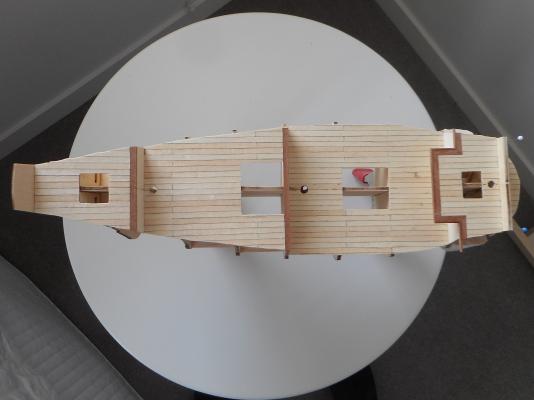

Bit of a progress report. I completed the deck planking, using 10cm max length planks. Scaled up, this makes 9m long, by 45cm wide. Not sure what the real size would have been. Here they are before edge trimming: After some trimming: And after some of the vertical walls were planked: These walls are planked in a clinker pattern, which may show up in future photos. This view from the stern shows a variety of patterns. The top 1/3rd is thin planks, butted together vertically; the next little bit is the same planks run horizontally; then there are six 2mm thick planks horizontally; finally the same 2mm ones in a 45 degree pattern: And after a bit of fairing, starting to place the nails: Currently I am waiting for the glue to dry on the bulwarks. Photos of that and more detail to follow. Cheers, Brett

-

Hi Hamilton, Yes, the stem etc are added after the planking, into a slot cut to receive it, like so in the plans: Here are two better views of the way the frames sit on the false keel at present: My concern is that this is single planked, and the planks are 2mm thick! It may all work out simply by pre-bending the planks, but I just want to make sure I'm not missing something here. I think the one you did was double planked? Ah, the fun that poor plans/instructions cause! I can see why the experts build from scratch. Cheers Brett

-

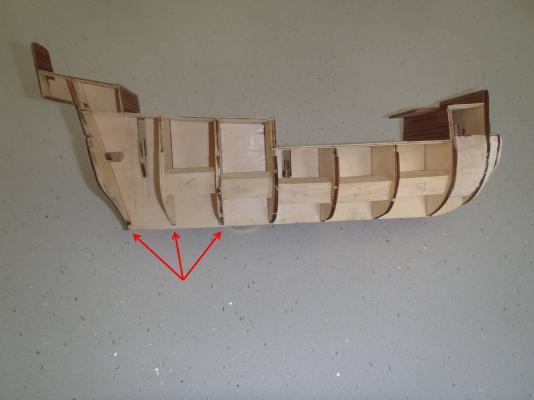

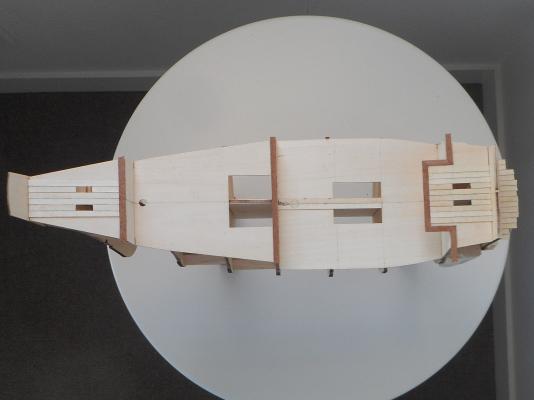

Before I post my progress photos, I have a question that I hope someone who has made this will answer. I have not been able to find out from reading logs. The frames do not all finish at the same level on the false keel. The sternmost 3 are short as shown by the red arrows, below. This seems intentional, but odd: I am ready to get stuck into the fairing, then I will be planking. Should I do anything in this area to simplify the planking? Thanks, Brett

-

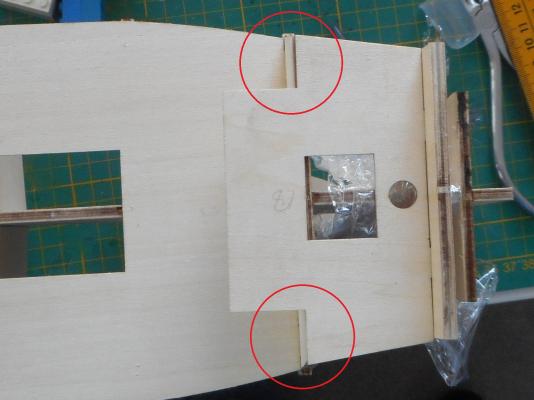

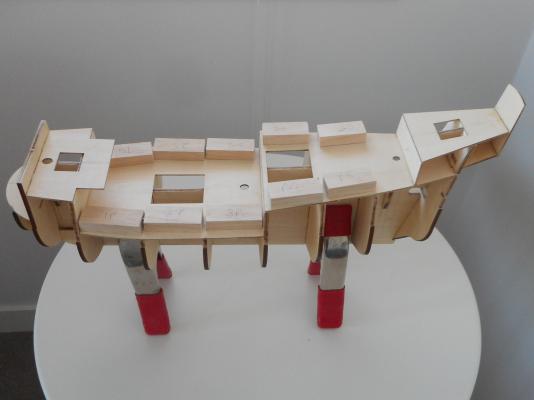

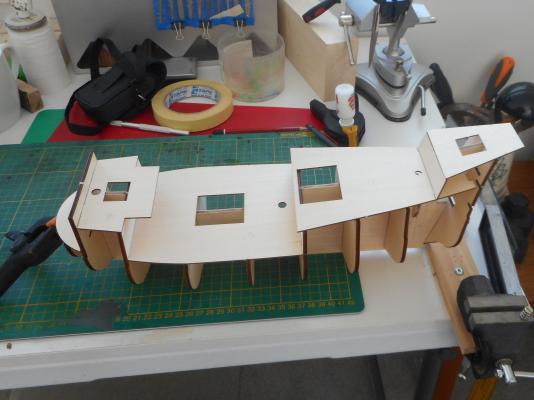

I plodded on fitting the remaining frames, trying to be as accurate as possible, then added the remaining decks. However, when I got to what I normally think of as "the sharp end" (this ship has a very blunt bow), I noticed an error of a mm or so: You can see in the red circles how the deck and frame are a bit out. So I put my ungluing skills to work: Fortunately I didn't have to remove the frame, just twist it a little. Decks all fitted, I cut some blocks to strengthen the assembly: I also added some roughly cut balsa at the bow, to aid with planking later: I'm thinking of adding some balsa at the stern, too. Any comments on the necessity of that? Now I'm on to the deck planking. The supplied planks are 5mm, which is obviously oversized for the scale. Unfortunately I could not source thinner planks locally, so I've decided to run with what I have: All comments and suggestions will be gratefully received. Cheers, Brett

-

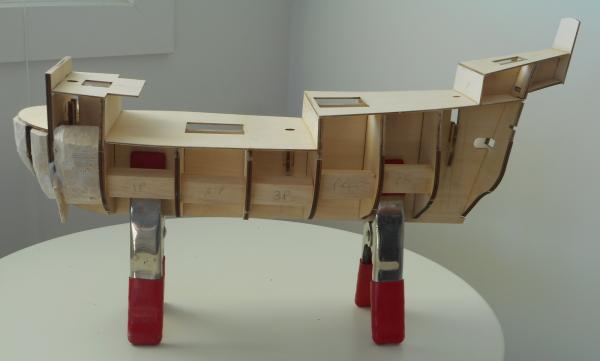

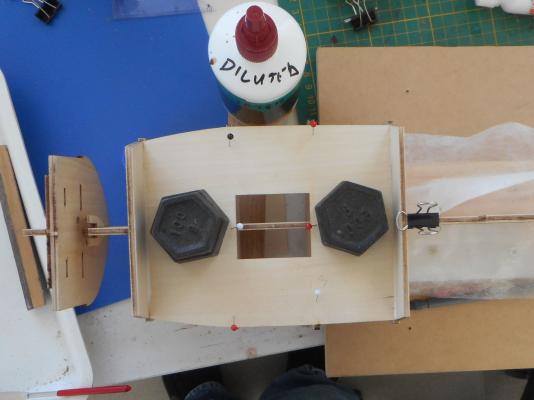

I was given this as a birthday present by one of my sons. So, despite intending to select a model with excellent instructions, I'm stuck with A-L. It will be my first attempt at single planking. I've seen a couple of brave souls attempting this as their first build - no way would I recommend that! There are surprisingly few surviving full logs on MSW, but I have found others on another forum that have more detail. After reading and asking for hints, it was time to get under way. The plans say to test all the frames and decks, so off we go (no glue yet): They then tell you to pin everything, then glue by running diluted PVA glue into the joints with a brush. I couldn't see this being successful, as the assembly would be too flimsy and flexible, and likely to distort during the glue application. So I opted to fit some of the frames before the decks. Here are frames 5 & 6 squared and glued, also you can see the mast supports glued in: Next came frames 7 & 8, then frame 9 complete with the waist deck: So, I'm off and running, and hoping for hints and comments from anyone. Cheers, Brett

-

Hi Brian, Firstly congratulations on the whole build. I especially like the index you've put at the beginning of the log. Very helpful to others. For the mount, I initially preferred the square one, but on review I think the U shape would look better if made the same height as you've done the square shaped one. Cheers, Brett

- 831 replies

-

- Armed Virginia Sloop

- Model Shipways

-

(and 1 more)

Tagged with:

-

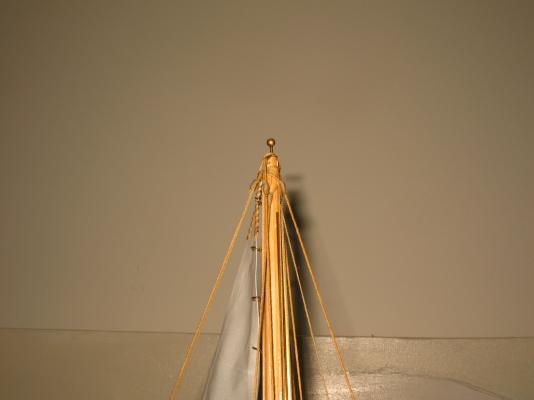

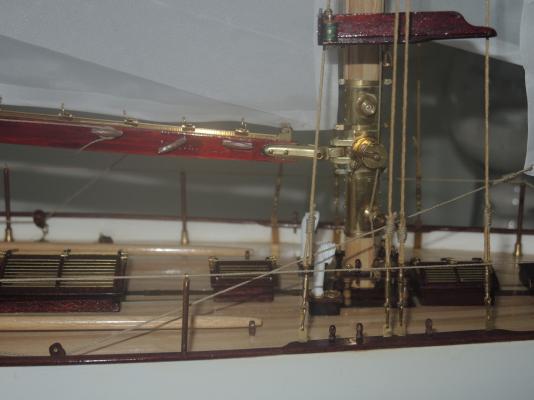

Posting some photos, to show a bit more detail. First, the rigging. The top of the masts became a jumble. I would have done better if I had been able to go back in time. I did not realise how many ropes were at the pointy end! Other views, to show the rigging: Finally, a bunch of views from various viewpoints: The End! Now, normally at this point the search for the next model would begin. However, that has been decided - one of my sons bought me the San Francisco II. Not sure when I'll start it, but I can feel the pull already. And, to finish, here's a couple of photos from last week's holiday: Cheers, Brett

-

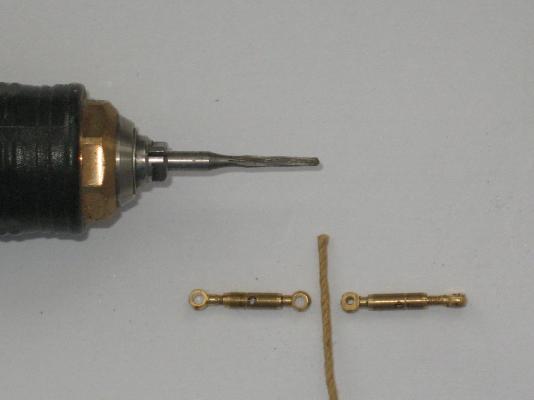

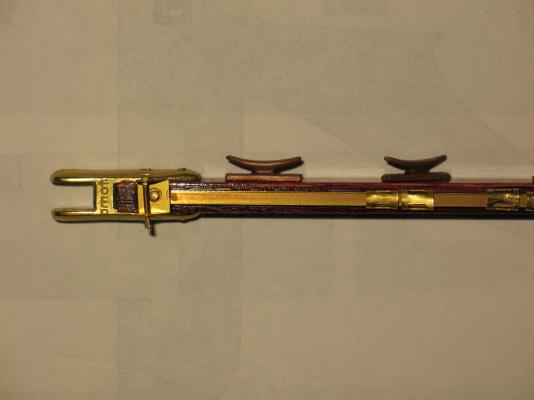

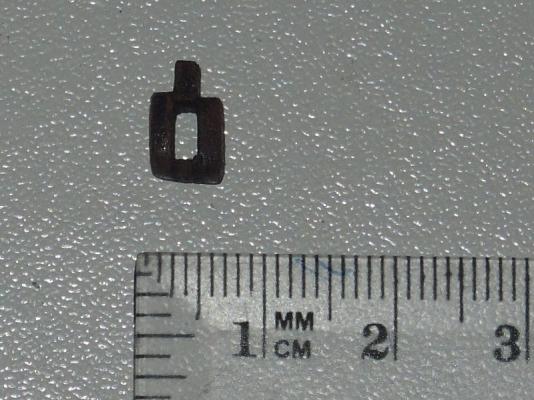

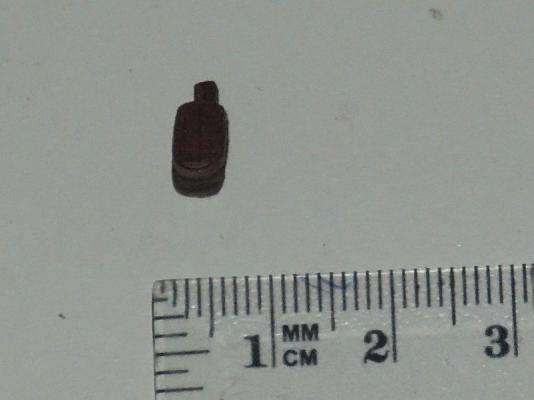

Well, the break's over, and this model is finished. I've been hiding while I fitted the rigging and sails. There were the usual FUBARs, but I promised myself I would stop whining about Amati. Still, it was fun when my wife "volunteered" to make the sails. Her comments made mine seem restrained by comparison! One thing to comment on. The rigging was nice to work with, as the "rope" was 1-2mm thick. This made seizing easier, but created difficulties threading through relatively small holes. Some surgery was required, as seen here, where I had to bore out the windlasses from the size on the right to the end result on the left. You can see the dental drill I used, and the size of the rigging rope: As before, this is not a model that likes to be photographed, so apologies for what follows. Here she is in her intended position in our lounge room: I planned to display her from the port, but the sails are rigged such that you see all of them from the starboard. I may change that later. And a few other full views: Soon, I will post some other views, but that may have to wait a while. We are off for a week on a catamaran in the Whitsundays - this one http://www.whitsundayescape.com/product/seawind-1250/ Tough, huh? Cheers, Brett

-

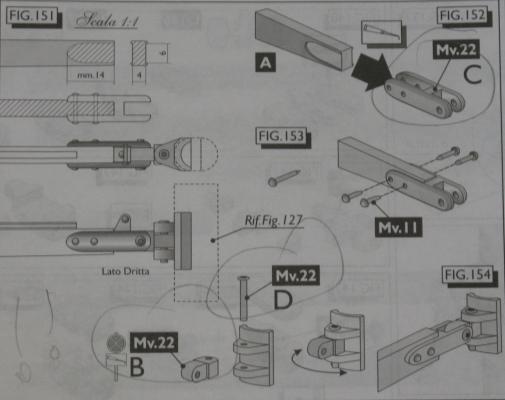

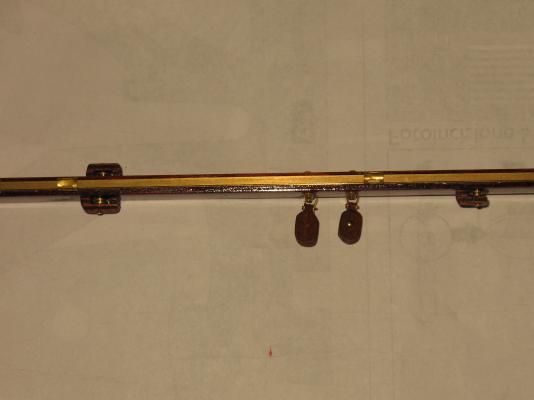

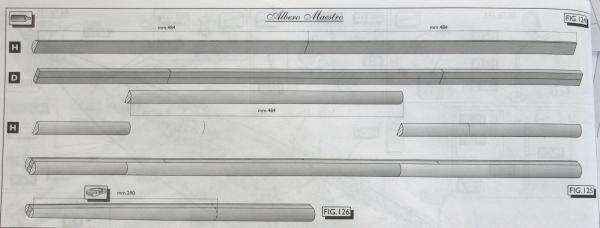

We're about to head off on a month's holiday, so there will be no work done on the boat for a while. Here's the current state: As you can see, I've fixed the masts (main and mizzen) - not without difficulties and extreme stress. I'm not exactly happy with the 3D positioning, but I hope it will look OK when the sails are on. You can also see the two booms are in place. This is despite the "wonderful" Amati instructions. Note how three different items are all shown on the plan as the same!!! Here is the mizzen mast boom: And, finally, some other views: And now to lock the room she's in, while we're away! Cheers, Brett

-

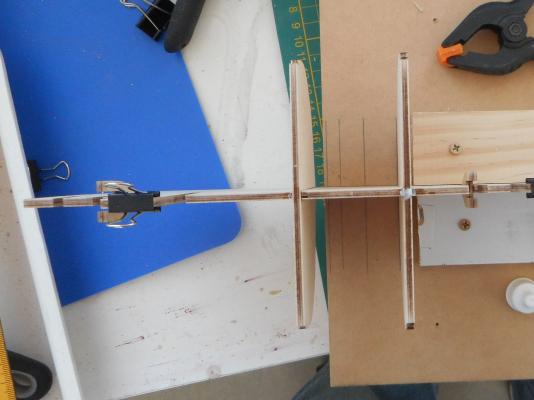

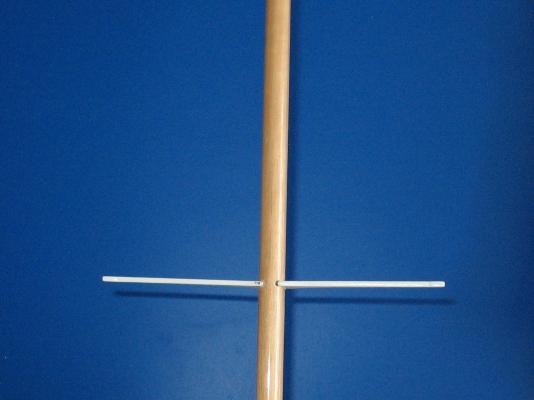

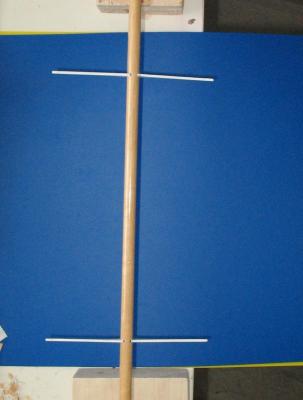

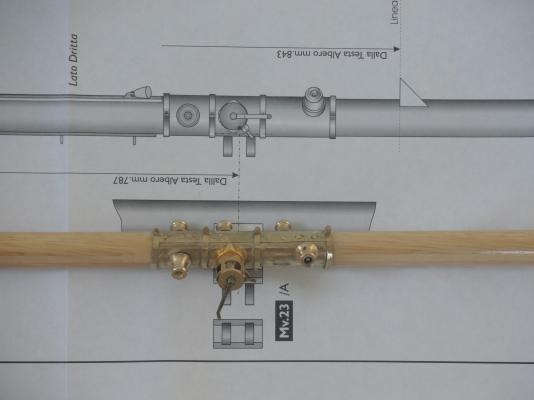

Thanks for the support, everyone. The last few weeks have been spent on the mast and boom. I decided to keep the mast natural timber colour. When I woke early this morning, I thought "what have I done?". Oh, no! I had (again) blindly followed the plan, and stained the boom mahogany. Only now did I think it might have looked better in a natural finish. Too late, now - there's too much on the boom to backtrack. And The Boss likes it, anyway, so I'm safe. First the mast received its 'crosstrees'. These are fitted into cuts in the mast: Then finished with brass strips: In the photo above you can also see the timber strip and eyebolts that run most of the length of the mast. On the other side (facing the bow) are fitted two brass channels. These caused a lot of trouble and stress in their cutting, fitting, and gluing! At the tip of the mast goes a recessed pulley, requiring a cut through: And with the brass fittings in place: The ball on the top is a wooden bead, with the simple direction to paint it brass coloured. I've been unable to find this locally, so am trying gold spray paint. Now to the boom. It's a miserable day here, so there's lousy light. Some are with the flash, some without - apologies. Here's a fair colour match: And the other side with bad colour: And, finally, some detail views: And the storm's about to hit, here in Brisbane, so it's time to close down. Cheers, Brett

-

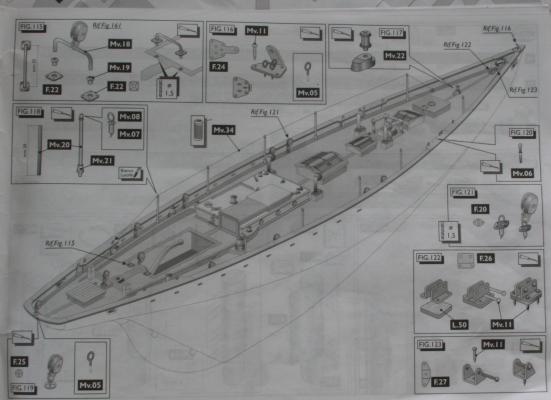

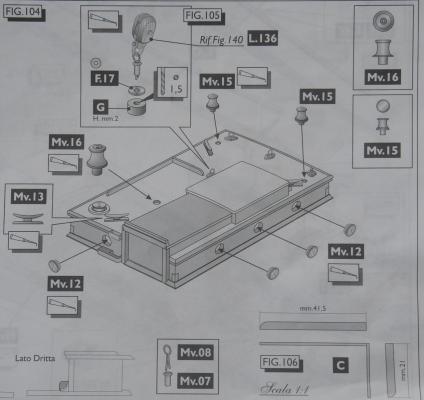

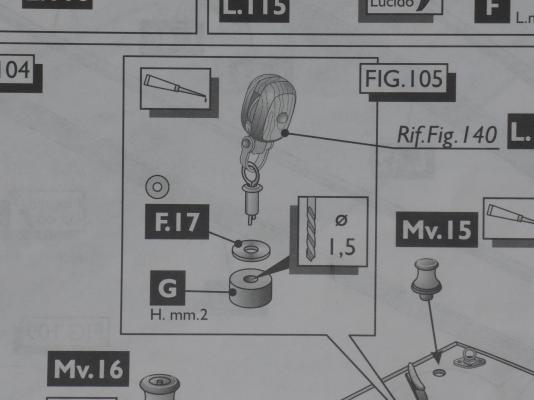

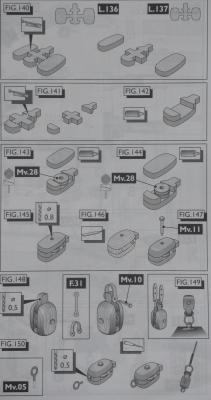

So, here's the boat a few days ago, with the side ropes etc in place: Earlier I mentioned the pulleys. Here is the plan of how they are constructed: And here are some photos of the fiddly construction: And some details of the finished products in situ: Next step is the main mast. Again the instructions basically say "find wood, make mast": It's made from half-round and rectangular cross-section timber, tapered at the top 290mm, and overall length of 960mm! Not easy to photograph, but here are a couple of views during assembly: I forgot to photograph the whole thing, but here it is with some of the brassware attachments: And a close up of those bits: Next I have to cut into my beautiful mast and add some brass channels that run the whole length. To make it more interesting at this point the instructions get things out of order, and the plans are wrong. So I'm spending a couple of days poring over everything to try to avoid another 'oh, fork' moment. Cheers, Brett

-

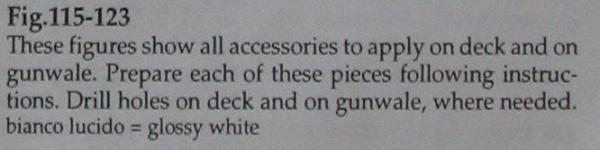

Still not sure what they are called, but here's the Deckhouse and "curly bits" in situ: I glued the deck furniture on, and added a few winches etc.: In these detail photos you can see the start of the posts and ropes at the sides of the deck, and a few other fiddly bits. As usual the instructions are ********ed - And here is the plan: And here's my interpretation of some of this: It's starting to look pretty! More soon, Brett

-

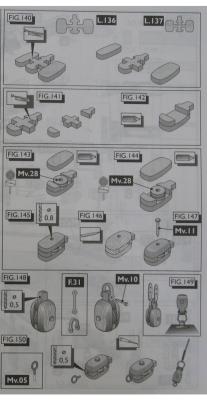

For a change I'm not going to whinge about Amati! Just present info on the fiddly bits I've been creating. It's one of those stages where nothing seems to happen - then you look at all the stuff you've made. Here are some hatches and skylights, resting on the deck: Then it was the deckhouse. Here's part of the plan for that complicated structure: Early stages of construction: I forgot to seal around the masking tape before applying the mahogany stain - so I got some bleeding. I plan to touch up the gloss white paint later. Progressing (not sure what the curly things are called!): And nearly finished: I still have to fit the skirting boards, and the pulley seen in this part of the plans: Silly me! I assumed this was a pre-fabricated item. Oh no! Each pulley is constructed according to this plan: That's gunna take a fair time for the first one! However, I suddenly realised I'm actually enjoying all these little fiddly bits! So, on we plod. Cheers, Brett

-

I think these settings might work. Changed the colour and light profiles. The colours look more realistic, now? Cheers, Brett

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.