-

Posts

18 -

Joined

-

Last visited

About agamemnon9

- Birthday 07/02/1964

Profile Information

-

Gender

Male

-

Location

Québec,Canada

Contact Methods

-

Yahoo

pierrebonenfant@yahoo.com

Recent Profile Visitors

-

thibaultron reacted to a post in a topic:

Byrne's Saw Reference (also good for other desktop hobby saws)

thibaultron reacted to a post in a topic:

Byrne's Saw Reference (also good for other desktop hobby saws)

-

rvchima reacted to a post in a topic:

Cathedral Notre-Dame de paris and a stained glass windows Notre Dame de la belle verrière

rvchima reacted to a post in a topic:

Cathedral Notre-Dame de paris and a stained glass windows Notre Dame de la belle verrière

-

rvchima reacted to a post in a topic:

Cathedral Notre-Dame de paris and a stained glass windows Notre Dame de la belle verrière

rvchima reacted to a post in a topic:

Cathedral Notre-Dame de paris and a stained glass windows Notre Dame de la belle verrière

-

Jorge Hedges reacted to a post in a topic:

Show me yours tools !

Jorge Hedges reacted to a post in a topic:

Show me yours tools !

-

reklein reacted to a post in a topic:

Show me yours tools !

reklein reacted to a post in a topic:

Show me yours tools !

-

FriedClams reacted to a post in a topic:

Medieval Fortified Village by Ekis - 1/87 scratch base kit Aedes Ars

FriedClams reacted to a post in a topic:

Medieval Fortified Village by Ekis - 1/87 scratch base kit Aedes Ars

-

Egilman reacted to a post in a topic:

Medieval Fortified Village by Ekis - 1/87 scratch base kit Aedes Ars

Egilman reacted to a post in a topic:

Medieval Fortified Village by Ekis - 1/87 scratch base kit Aedes Ars

-

Egilman reacted to a post in a topic:

Medieval Fortified Village by Ekis - 1/87 scratch base kit Aedes Ars

Egilman reacted to a post in a topic:

Medieval Fortified Village by Ekis - 1/87 scratch base kit Aedes Ars

-

popeye the sailor reacted to a post in a topic:

Medieval Fortified Village by Ekis - 1/87 scratch base kit Aedes Ars

popeye the sailor reacted to a post in a topic:

Medieval Fortified Village by Ekis - 1/87 scratch base kit Aedes Ars

-

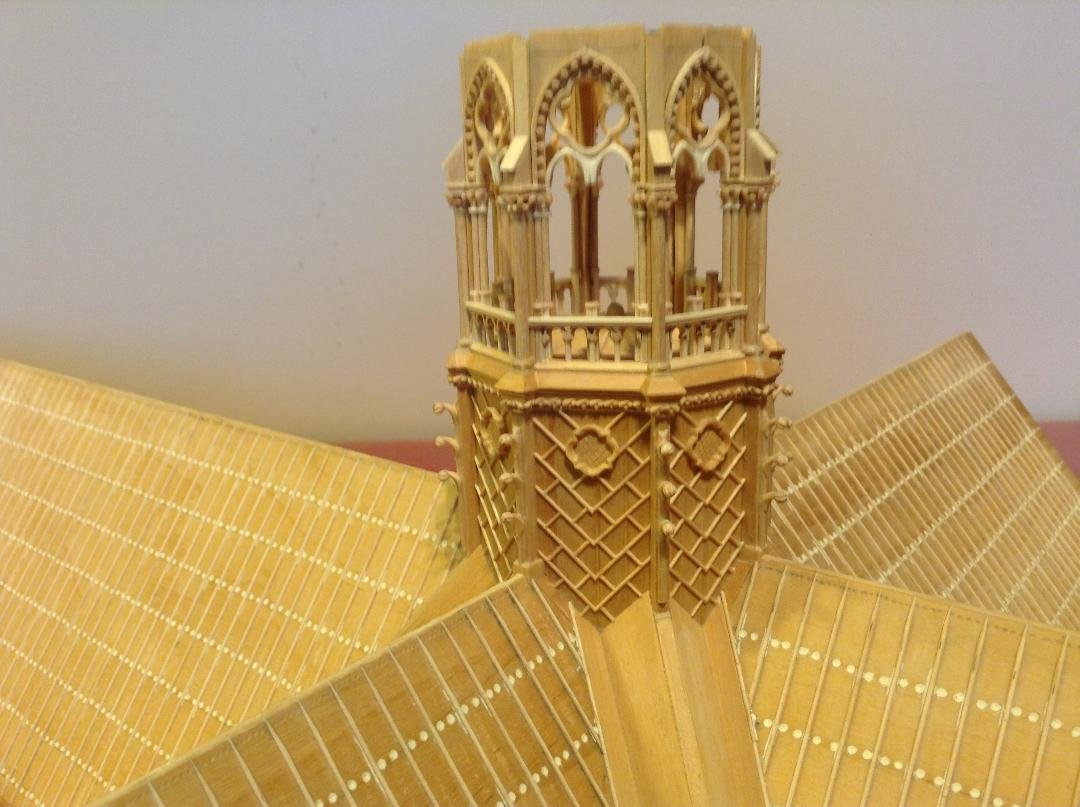

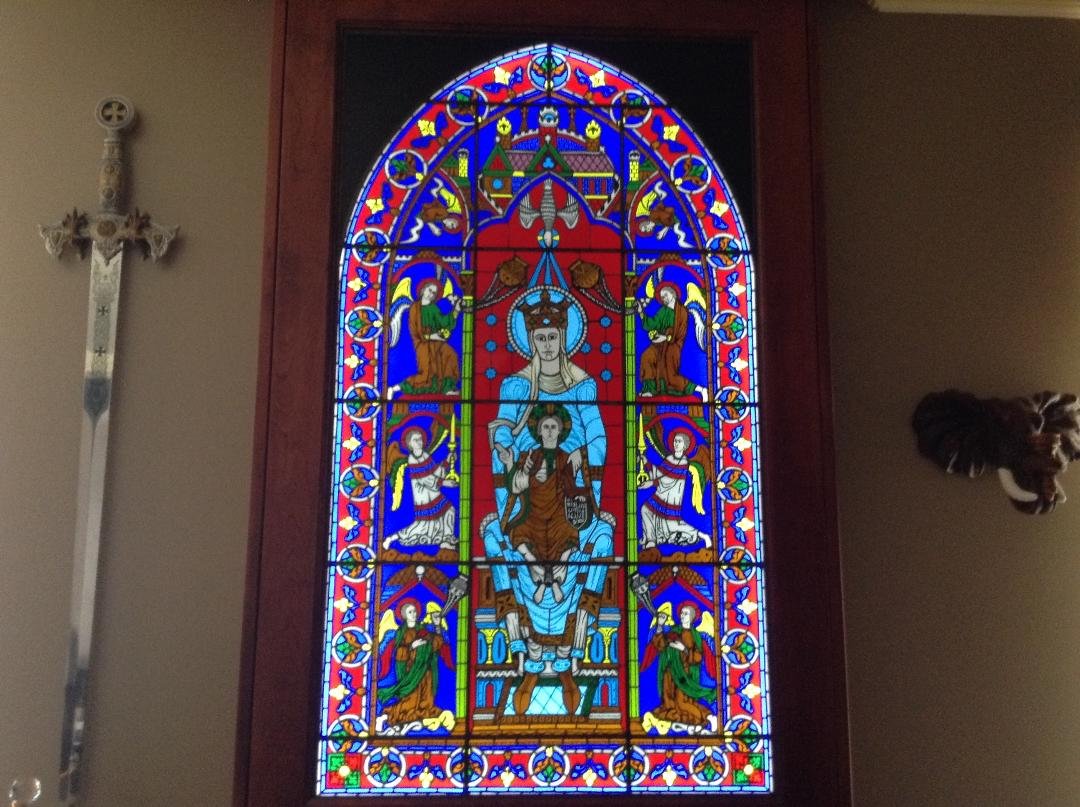

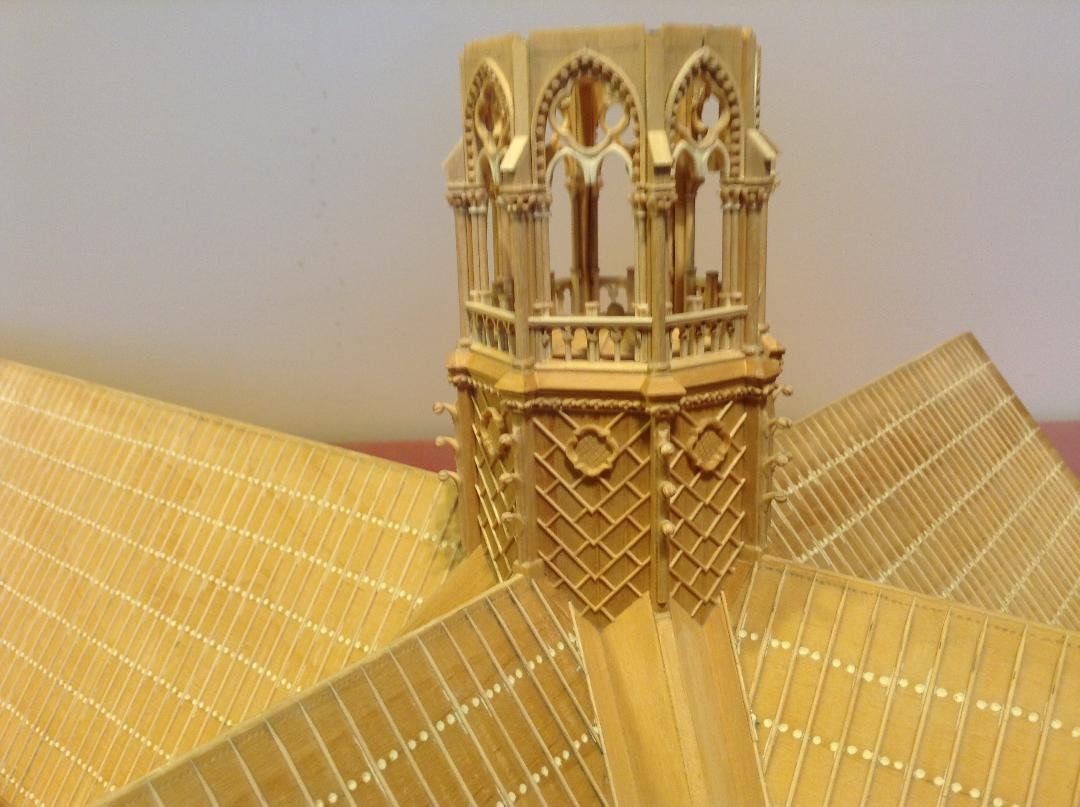

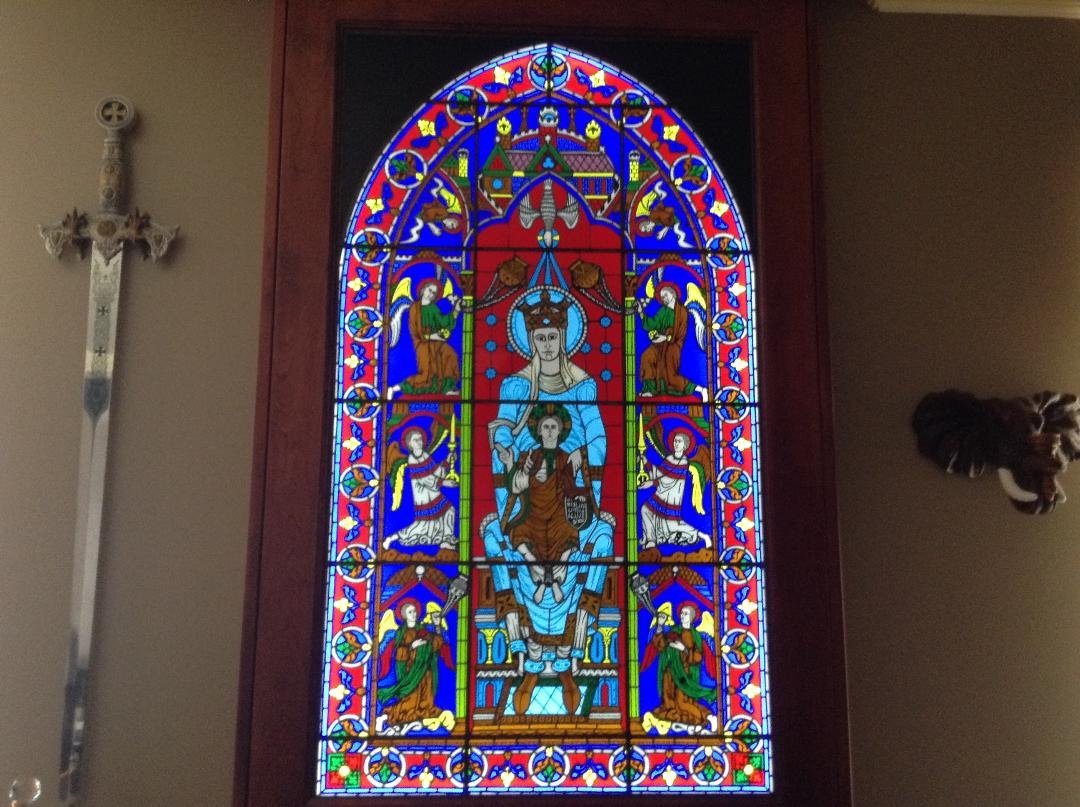

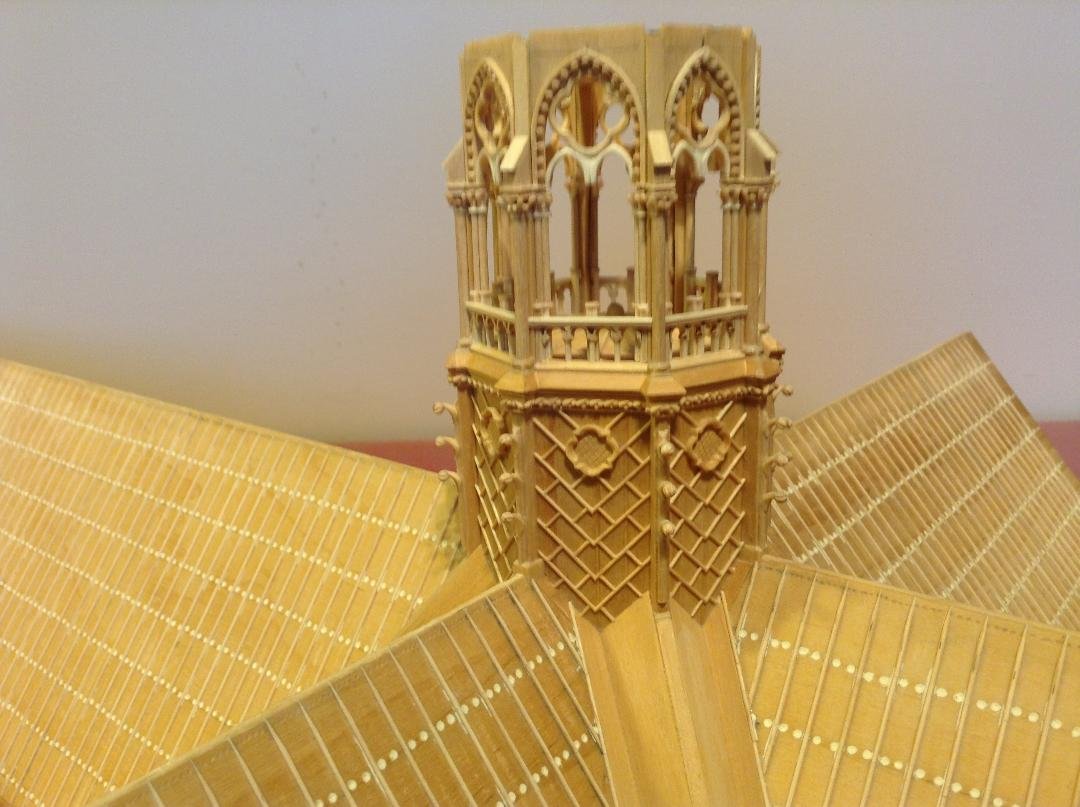

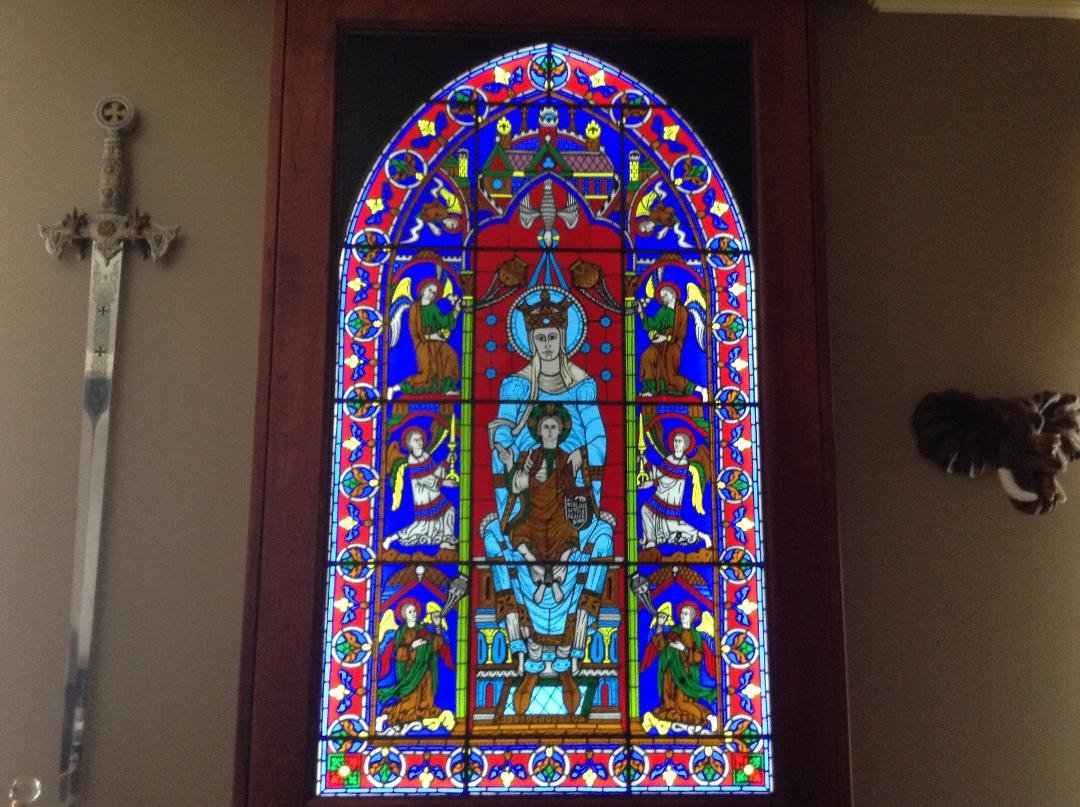

Félicitation Ekis ! Ah ...enfin quelqu'un qui aime le moyen-age 🙂 j'adore le cloitre et le fait d'utiliser la pierre donne tant de réalisme...Moi-meme je suis sur un projet du moyen-age ..la cathédrale Notre-Dame de Paris..j'ai fait aussi un vitrail..Notre-Dame de la belle verrière...dont voici quelques photos en bas...si je ferais comme toi mon projet en pierre,cela me prendrait au moins 20 ans...c'est pourquoi je la fait en bois...Ce que je trouve merveilleux aujourd'hui c'est le fait d'avoir accès a plusieurs matériaux différents , des outils aussi comme proxxon , dremel sans oublier le banc de scie de jim byrnes qui est d'une remarquable qualité.Tout le monde ont leurs projet....avions,navire etc...mais quelqu'un qui fait un projet comme le tient ,c'est rare et c'a prend beaucoup de temps et de patience...Ce que j'aime de ce site a part you tube,c'est d'avoir acces a beaucoup d'informations sur des techniques différentes ...c'est très rare sur internet. Les gens sur ce site s'entraide beaucoup et sont très respectueux.......................J'espère voir d'autres projet de ta part et bonne continuation...........Pierre ton petit cousin du Québec😁. English Translation: Congratulations Ekis! Ah ... well someone who loves the Middle Ages 🙂 I love the cloister and the fact of using the stone gives so much realism ... Myself I am on a project of the Middle Ages .. the Notre-Dame de Paris cathedral ... I also made a stained glass window ... Our Lady of the beautiful glass roof ... here are some pictures below ... if I would do my stone project like you, it would take me less 20 years ... that's why I made it out of wood ... What I find wonderful today is the fact of having access to several different materials, tools also like proxxon, dremel without forgetting the bench saw by jim byrnes which is of a remarkable quality. Everyone has their project .... planes, ship etc ... but someone who does a project as he wants, it is rare and it it takes a lot of time and patience ... What I like about this site apart from you tube, is having access to a lot of information on different techniques ... it's very rare on the internet . The people on this site help each other a lot and are very respectful ....................... I hope to see other projects from you and good luck ........... Pierre your little cousin from Quebec😁.

-

B-25 Mitchell "Meet Miss Runyon" by Javlin-HK-1/32

agamemnon9 replied to Javlin's topic in Non-ship/categorised builds

Hi Javlin...it's fantastic, I never see that in my life ... congratulations ....Now I want to know something...Do you use a paintbrush and if you use it , what kind of paint...ie tamya or createx for example..... tanks.😁 -

Hi Kurt ... I've been working on it for a few months, it's hard to answer ... maybe 2 months of continuous time. I work outside during the week and I can only work on this project only The weekend. What you see is only the beginning ... I have already done a roof before but I had to start again because the proportions were not good ... that's why you see a gable, balcony and clock next to the roof ... it was on my last roof. I've heard that some ship project takes up to ten years, it's probably a big ship ... ... my project will take a few years, I am 55 years old and when I retire at 65 I will finally be able to work on it every day .... PS my stained glass window took me a month. .... . when you have a passion, time does not count. Tanks a lot.

-

agamemnon9 reacted to a post in a topic:

Cathedral Notre-Dame de paris and a stained glass windows Notre Dame de la belle verrière

agamemnon9 reacted to a post in a topic:

Cathedral Notre-Dame de paris and a stained glass windows Notre Dame de la belle verrière

-

Show me yours tools !

agamemnon9 replied to agamemnon9's topic in Modeling tools and Workshop Equipment

Hi Y.T. I want to know something about your mini disc sander... what is the RPM and what kind of sand paper you use i.e. 120 grain,220 etc... and what is this tool with the orange color handle,is it for curving wood while heating it ? This mini disc sander is a very good idea for my project...Tanks a lot🙂 -

agamemnon9 changed their profile photo

-

Show me yours tools !

agamemnon9 replied to agamemnon9's topic in Modeling tools and Workshop Equipment

Hi Y.T. This pieces are made by sections , each section are made individualy...To make this I take a plain piece of wood of aproximatively 10 mm x 10 mm...after that I drill two holes and I put 3 leaves in each holes,,,now for carving the leaves in '' Y '' shape above ,I use dremel cutting disk...If you watch carefully no one are identical to other ...Oh I forgot to tell you that each piece was drawn on top. tank , I hope that this answered your question. -

agamemnon9 reacted to a post in a topic:

Show me yours tools !

agamemnon9 reacted to a post in a topic:

Show me yours tools !

-

Show me yours tools !

agamemnon9 replied to agamemnon9's topic in Modeling tools and Workshop Equipment

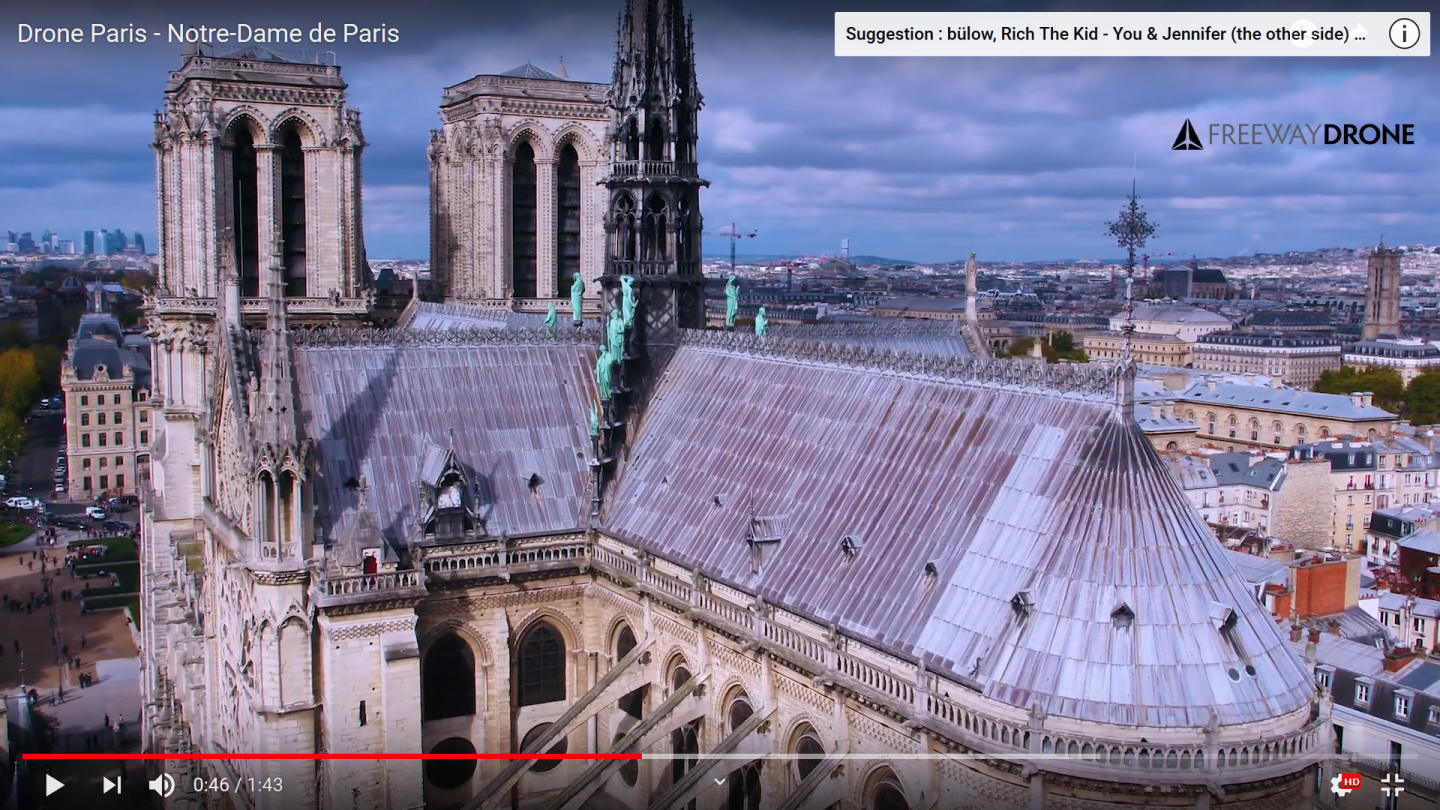

Hello Moxis .... Firstly I don't like 3D very much, I like to draw my plans by myself, I have a better connection, it's also emotional ... The only time I used a big printer in a specialized printing house it is for my ground level plan, for the rest I use photos in books or on the internet and also videos ..... For the carvings I use Dremel a lot .. To make columns I use my proxxon leathe ... Sometimes I make my own tools, for example when I want to sand the inside of my four leaf clover, I take a round wooden stick and I glue my paper sand on it . After having drawn a piece I always wonder how to do it, I look for a way, sometimes it work sometimes not but I always find a solution. Thank you Moxis ..have a nice day -

Hi Druxey......First of all I made enlarge a ground plan of my cathedral , and with the drawing of Eugene Viollet Leduc (the man who renovate this cathedral from 1844 to 1864) plus a hundreds of photos in books plus pictures on the internet and finally the drawing at the University Laval in the archives department I have everything I need. This cathedral will be made entirely of pine wood,,,,What you see in pictures is only the beginning,,,First I start with the roof,,,now I built the spire of the cathedral...........My techniques is easy...Once I know the width and the height of my spire,I go by section...Each section is drawn by myself..each piece is measured and noted....after and that's where the fun begins,I try to do the piece in different ways...sometimes it's work sometimes not...it's by trial and error...For example..... if you take the fifth picture..I show you what is called a Balustrade,this balustrade are made of two section...the above section you have the nnnnnnnnnn and the under section you have the posts IIIIIIIIIII.To built the posts it's easy but not for the nnnn above.To built the nnnnnnn,I take a piece of plain wood approximately of 4 mm high by 30 mm long and if I make 12 nnnnnnnnnnnn I drill 12 holes with my dremel in the plain wood , after that I use the saw blade to round off the top,,, ET... VOILA....I used and abused Dremel a lot. Tanks Druxey I hope it answers your question.

-

Hi, I show you my pictures of Notre-Dame under construction and my stained glass window,,,,,Notre-Dame is not an assemble kit ...I made my own pieces with the help from pictures in books and from the internet. The scale will be 1/100. I made some stained glass windows and this is my first one.....Tanks a lot.

-

Show me yours tools !

agamemnon9 replied to agamemnon9's topic in Modeling tools and Workshop Equipment

Hi everybody ,,,,,I want some new ideas for other tools (see my pictures above) I send you photos from other project Notre Dame of Paris and a stained glass window Notre Dame de la belle verrièere. Tanks -

-

hi ,, I know that most people on this site use woods of medium to hard density and also wood of several species for color and grain ... but I have never heard of anyone which used white pine .... it has a low density but is comparable to basswood, it has great stability and is very inexpensive and very easy to find .... If it is not a good wood, ,,Why ? I would also like to know the characteristics of basswood. please I would like to have your comments ... thank you

-

angle of attack of my blade

agamemnon9 replied to agamemnon9's topic in Modeling tools and Workshop Equipment

1mm It's the thickness of the wood and for the width sometimes I go to 0.7 milimeters maximum...I read the topic about how to choose the right blade for very fine cut (220 teeth 0.23 kerf 3 inches blade) for wood of 1mm but it don't work.....Tanks -

angle of attack of my blade

agamemnon9 replied to agamemnon9's topic in Modeling tools and Workshop Equipment

Firstly tank you for answering me, it's my first visit to this site 🙂I'm not good enough on the net to take pictures at the moment but the wood I use almost exclusively is white pine no 1 and as far as the blade is concerned is a Malco slitting blade 220 teeth 0.23 kerf 3 inches...I wrote to Jim Byrnes and he gave me the answer today , he said he used a 3 inch blade with a thickness of 0.30 and 90 teeth for a thickness of wood of 1/4 inch or less, if I understood corectly what he wanted to explain to me..he told me that a blade with too many teeth tends to heat up because wood that does not drain enough between the teeth...I also observed that the lower height of the blade change the angle of attack.....the teeth don't point downward enough..but maybe I was wrong,,,so I ordered other blades with fewer teeth,,,Oh I almost forget,,I feed very slowly and nothing change...so I want to ask you a question....what do you use as a blade to cut very fine piece,that would help me a lot,,,,,,TANKS AGAIN.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.