Kranck

Members-

Posts

69 -

Joined

-

Last visited

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

KentM reacted to a post in a topic:

La Belle by Kranck - as per the monography of Jean Baudriot

KentM reacted to a post in a topic:

La Belle by Kranck - as per the monography of Jean Baudriot

-

KentM reacted to a post in a topic:

La Belle by Kranck - as per the monography of Jean Baudriot

KentM reacted to a post in a topic:

La Belle by Kranck - as per the monography of Jean Baudriot

-

KentM reacted to a post in a topic:

La Belle by Kranck - as per the monography of Jean Baudriot

KentM reacted to a post in a topic:

La Belle by Kranck - as per the monography of Jean Baudriot

-

KentM reacted to a post in a topic:

La Belle by Kranck - as per the monography of Jean Baudriot

KentM reacted to a post in a topic:

La Belle by Kranck - as per the monography of Jean Baudriot

-

KentM reacted to a post in a topic:

La Belle by Kranck - as per the monography of Jean Baudriot

KentM reacted to a post in a topic:

La Belle by Kranck - as per the monography of Jean Baudriot

-

KentM reacted to a post in a topic:

La Belle by Kranck - as per the monography of Jean Baudriot

KentM reacted to a post in a topic:

La Belle by Kranck - as per the monography of Jean Baudriot

-

KentM reacted to a post in a topic:

La Belle by Kranck - as per the monography of Jean Baudriot

KentM reacted to a post in a topic:

La Belle by Kranck - as per the monography of Jean Baudriot

-

KentM reacted to a post in a topic:

La Belle by Kranck - as per the monography of Jean Baudriot

KentM reacted to a post in a topic:

La Belle by Kranck - as per the monography of Jean Baudriot

-

KentM reacted to a post in a topic:

La Belle by Kranck - as per the monography of Jean Baudriot

KentM reacted to a post in a topic:

La Belle by Kranck - as per the monography of Jean Baudriot

-

KentM reacted to a post in a topic:

La Belle by Kranck - as per the monography of Jean Baudriot

KentM reacted to a post in a topic:

La Belle by Kranck - as per the monography of Jean Baudriot

-

Thank you for your answer ! Yes , his Le Gros Ventre is a fantastic build. i am also amazed by what Oliver manages to do with a manual milling machine on his La Belle and Le Redoutable. thanks for the tips. I will give La Belle some rest now and think some more. Meanwhile, i came back to my former build, the smaller Le Cerf. No CNC there, and no admiralty build... much easier ans satisfying !

-

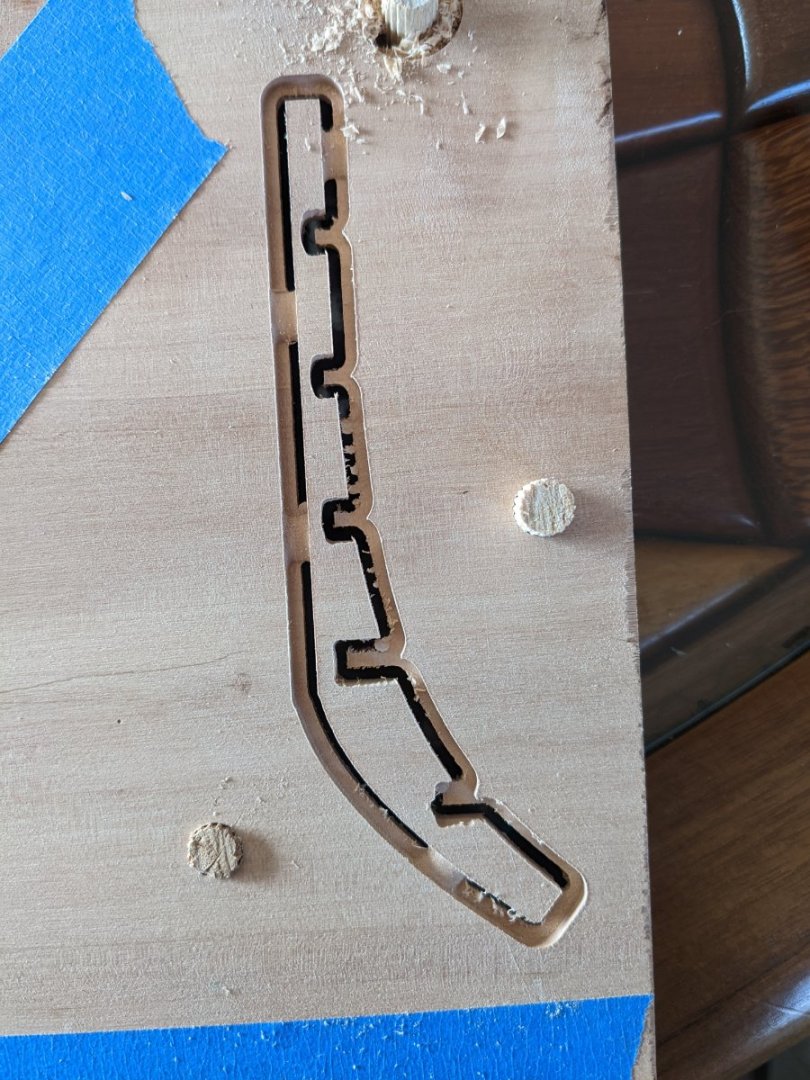

So, after a few months on and off the hobby, I just wantd to update on the project. * CAD drawing was satisfyingly accurate. I stopped at some point to start getting some real parts for this ship. * Getting accurate 2D or 2.5 parts is rather easy with one sided machining on the shapeoko 4. It took just a few days to get a .2 mm accuracy, which is sufficient for our purpose. * Getting 3D parts with two sided machining is an entirely different matter: Consider for instance a frame or a part of a queel with a rabbet on each side. The two main issues with two sided machining are getting an accurate thickness when turning the part, and be able to accurately zero X and Y. But the nightmare starts way before that: first, you have to choose a CAM soft to be able to transfer your part into a series of G-code instruction. To whom it may concern: most pieces of software available for hobby are NOT accurate enough. Only engineering-grade soft are good enough. For instance, Aspire, from VECTRIC, does not handle properly 3D parts (an issue with voxel size). Other just can't handle 2 sided machining properly. I ended up using fusion 360. But first, it is therefore necessary to transform the rhino files into fusion 360 readable files. You don't want to know, but it is not an easy tasks (many restriction for the free version of fusion 360). Since even in fusion 360 there is not 'intuitive' way to prepare your files for 2 sided machining, It does take a lot of time foreach file to do so. And an error in one single step will wreck your piece on the machining table. Then you have to deal with all the diffficulties of preparing appropriate dowels, double sided tape, and be extra careful for each manipulation of the part while machining. Of Note: the more you machine your stock, the less wood is left for rigidity. It WILL start to bend. Well, as you can infer, I finf this step extra difficult. I increased my knowledge of the process and I got better and faster. I do enjoy the accuracy of the curves, but with such tools, it is wrong to think that all parts will magically fit perfectly. Sanding is indeed required. I just wanted to show the queel and the first half-frame. I do wonder how people can get parts to so nicely and tightly fit. Is it necessary to finish machining with a manual milling machine? I also wondered how do hobbyists highlight the edge of the parts with a black line? I think caulking shouldn't be visible at this scale, but the effect is nice. Anyway, my main difficulty is that I have no bakcgroung in manual machining of wood. I hoped to compensate with CAD and CAM but it's hard. Any good books on the woodworking tehcninque itself as requied by the hobby? Best regards, Nicolas

-

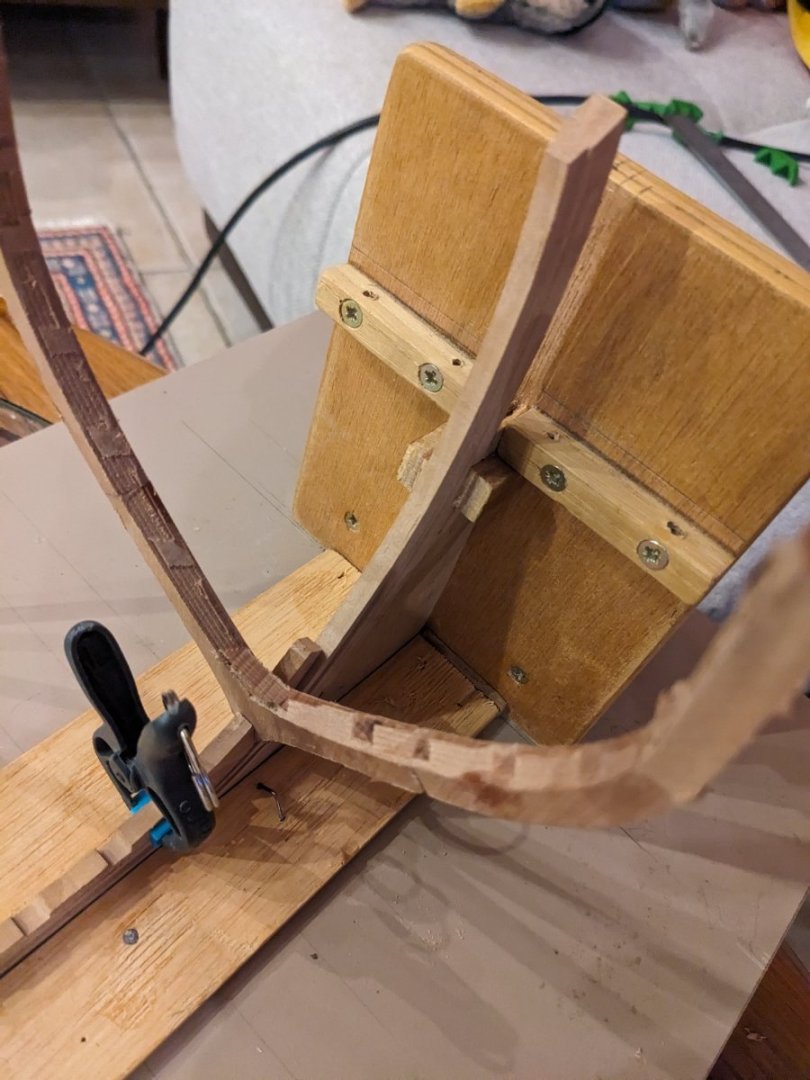

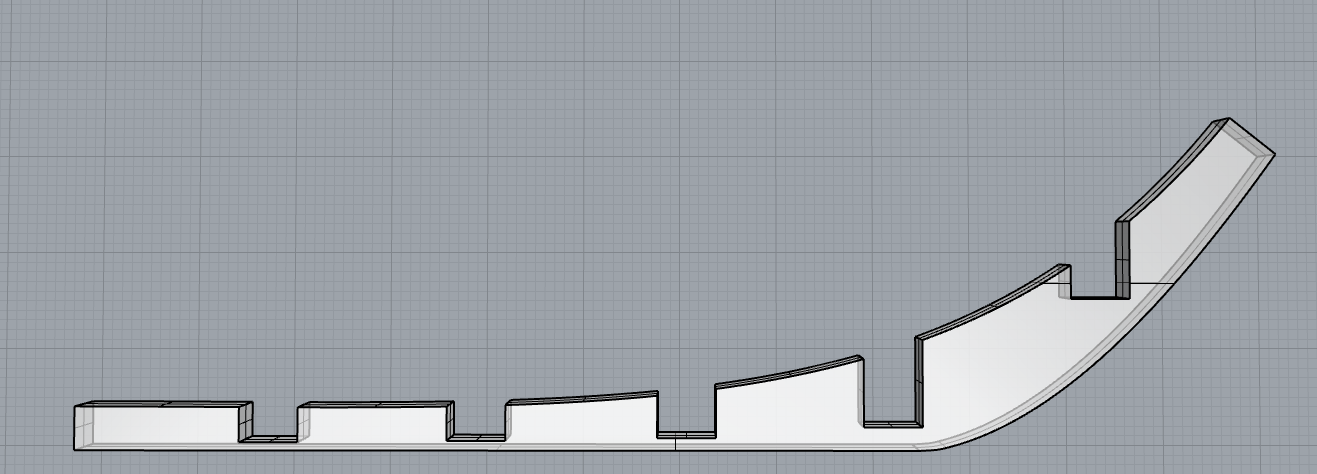

Finally the main structure of the ship is finished. There are several defects, especially in the aft area as depicted in the monography. But those are acceptable. I planked the deck. I will try to plank the hull later and perhaps deveelop the planks for CNC cutting. Speaking of CNC, I decided to cut the first parts, starting with the keel. I wanted to start designing a process and see wether it had any chance at all to be successful. Results are mediocre so far but I should improve. the process is the following: - Designing the part with Rhino - RhinoCam is too expensive (but new licensing option are available for 2023 that may be interesting). So I export the part as a stl file - Importing the file in Vectric Aspire. It is a nice piece of software available at my club. 2-sided machining seemed quite straightforward. - Preparing 2-sided machining on Vectric. Ok, it was not so straighforward. Tip: using 3 asymetric dowels to reposition the stock when machining the other side. Use tabs to avoid motion of the part. - I bought nice planks of wild cherry. But they are too thick: 25 mm, wich is too much for 1mm bits. 1 mm bits are sufficiently precise to capture details and approximate rectangular pockets for instance with the corners looking too 'round-shaped'. The issue is that 1 mm bits are not that long, otherwise they would be too fragile. So a first step roughing the stock with a 1/4'' endmill is necessary. Roughing area should include lateral margins around 1 cm to account for the width of the router collet when the 1mm finishing bit plunges far below the surface of the stock. - Cut and hope for the best. I will not summarize here the pain of this trial and error endeavour. It was fun in the end though. The first part is not that nice. Many errors. But the next will be better. I shall use the mill to improve the accuracy of some corners but the surface is real smooth .

-

ancre La Belle 1684 by Oliver1973 - 1/36

Kranck replied to Oliver1973's topic in - Build logs for subjects built 1501 - 1750

I find your skills in milling remarkable. Do you use the Proxon Mf70 or do you have more 'professional' tools? Keep up the great work ! -

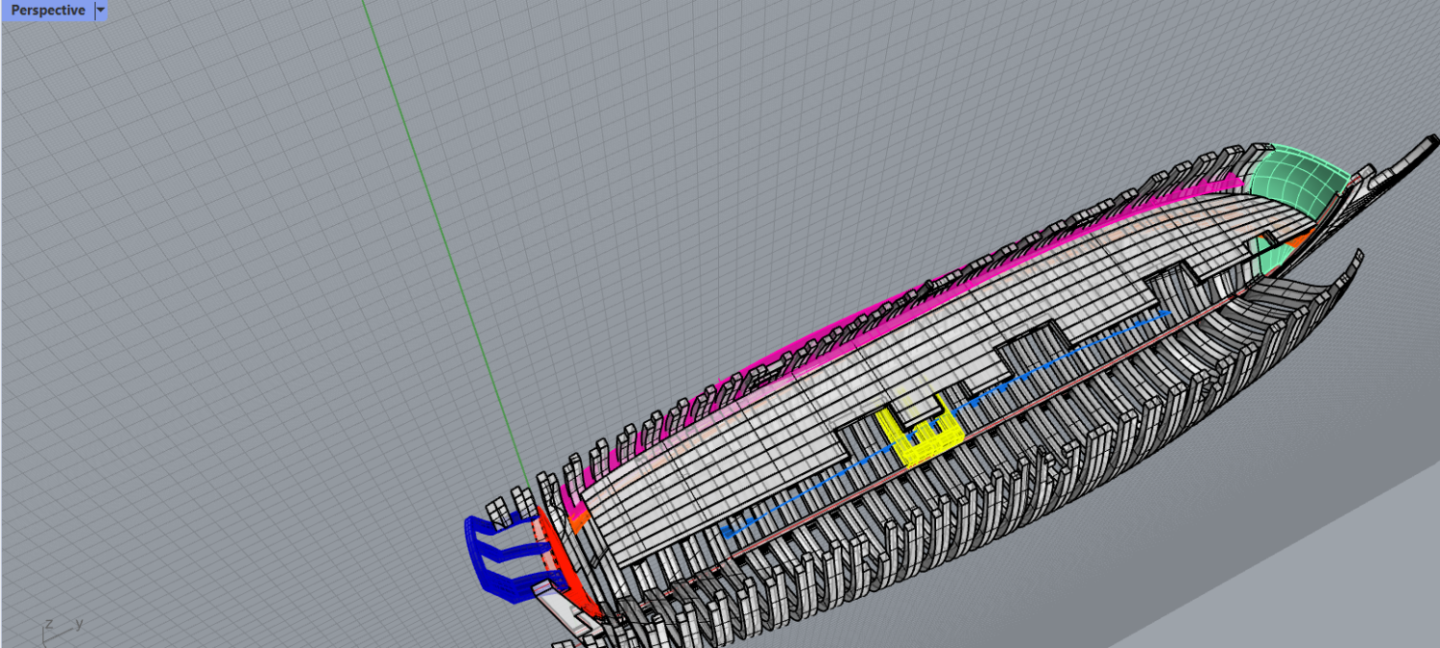

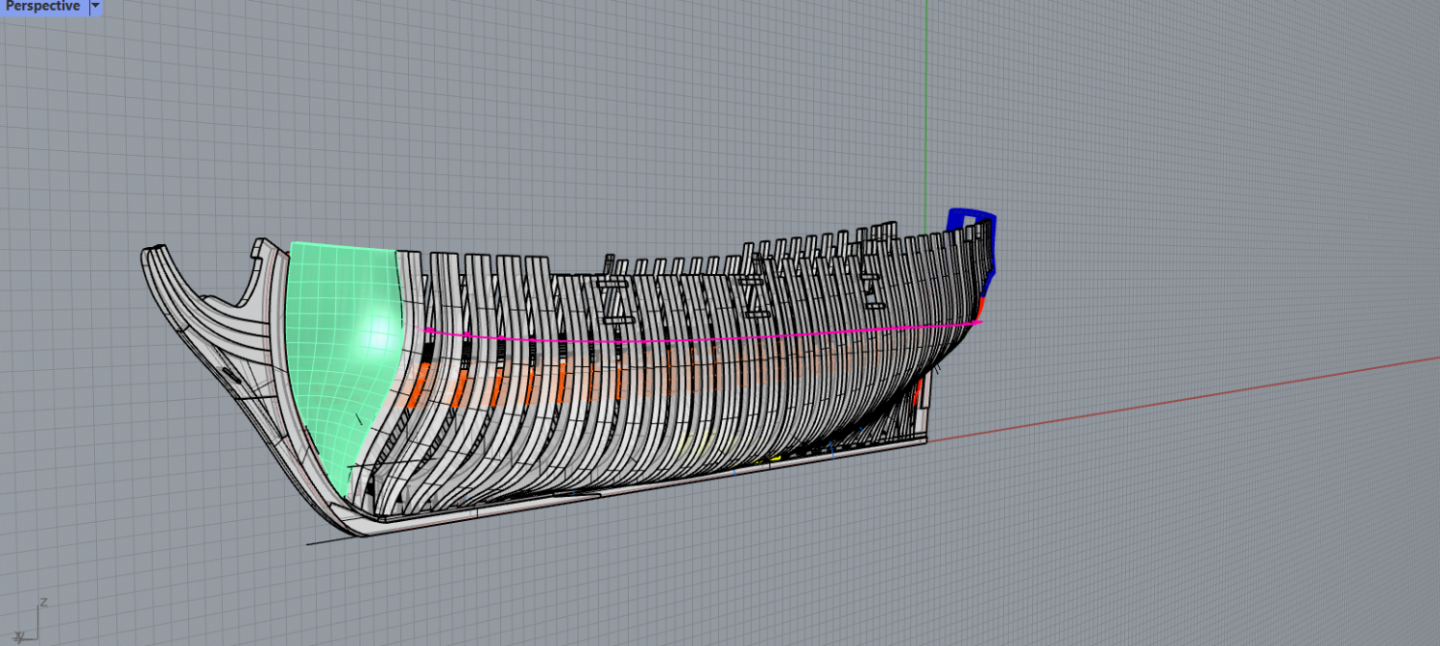

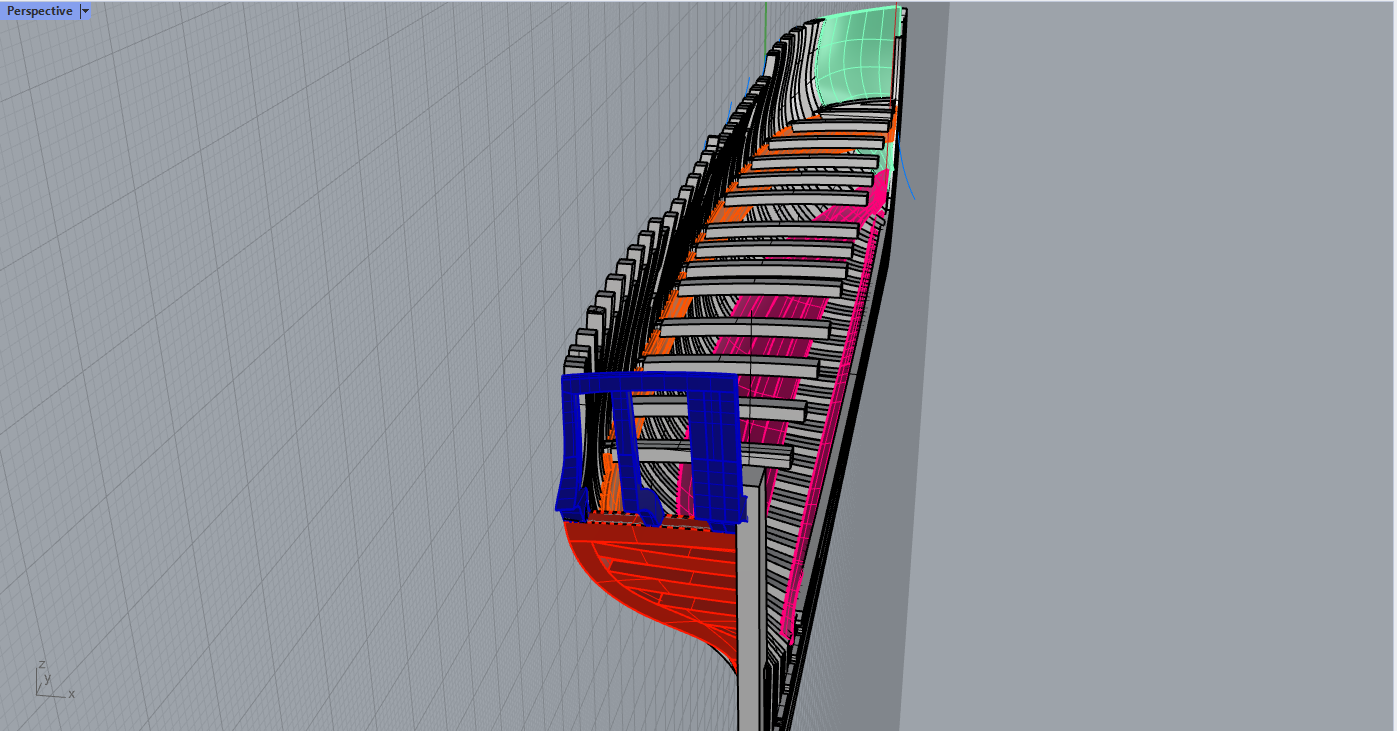

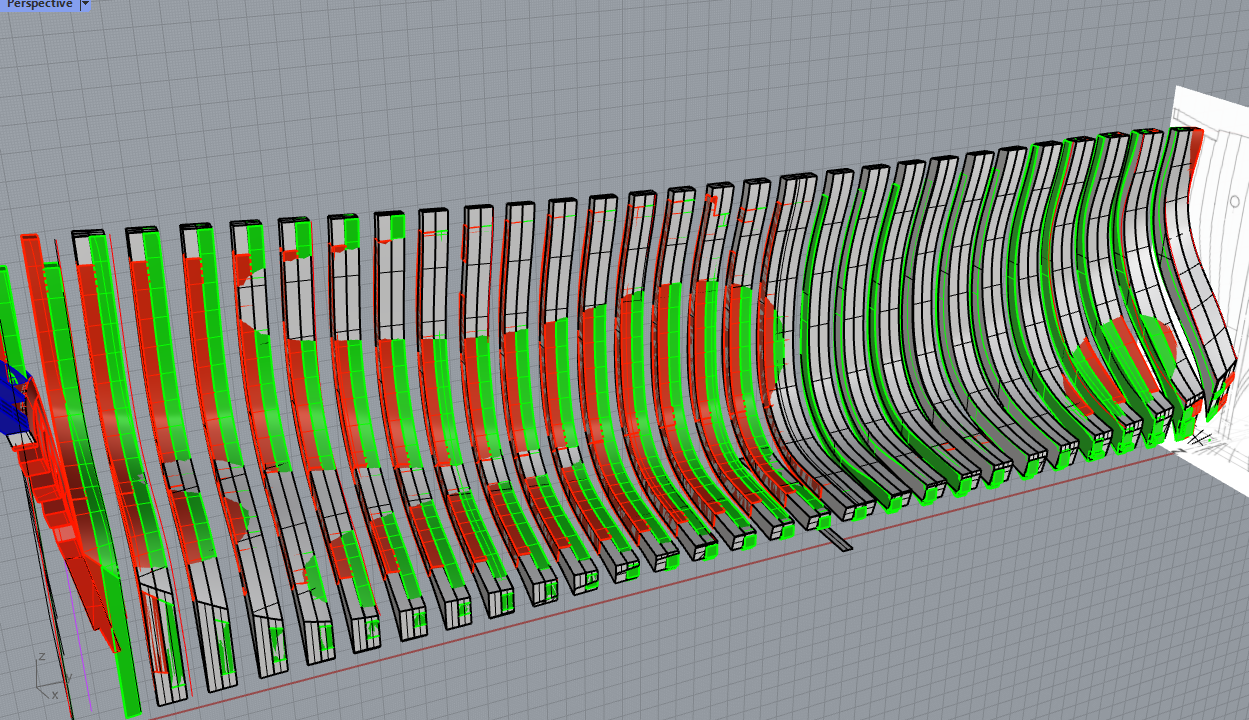

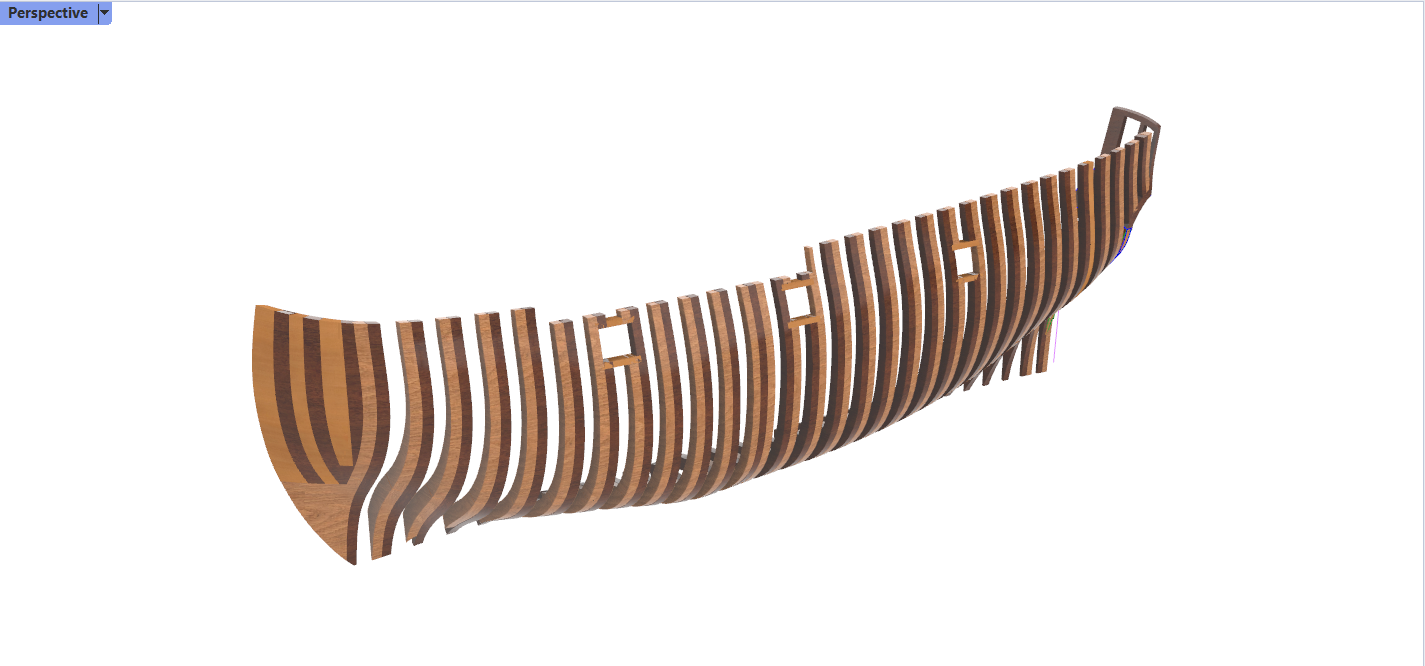

Reworked the inner surface once again The outer one is fair. In color, the old frames. In grey, the new ones. Much fairer. I managed to get something much smoother and removed the bumps here and there. Still a bot of work at the stern, where I will keep the sternpost (the design is fine, no need to do that again). I'll have to deal with the bow too. But how? Many possibilities. Sorry for the lack of consistency in this log. Ideas come and go, and I write what I think is right at the time...

-

Hi, I did try to just offset the hull surface. There are two issues: - If the surface is offset to a defined thickness, the top of the frames is too thick and the lower part is too thin. - I the offset is variable, it is very difficult to get something nice in the stern area with the tools I found in rhino. It gets very bumpy and not accurate since the offset variation is linear. I will think about your method, I'm not sure I understan. Best regards, Nicolas

-

The link to the rdm files follows, if the rules of the board allow it. https://drive.google.com/file/d/11s1BxOKmqo73I2yY2q8fYigun9q_qBle/view?usp=sharing I removed everything that was not necessary. I kept some image files within. The external surf is not linked to the curves because I tweaked the UVN motion, which breack history. However, for the internal surf, you can still use curve motion to control the loft. This is the best I could do so far. The frames I get are not that bad. I chose not to draw the bow this time (which might be mistake).

-

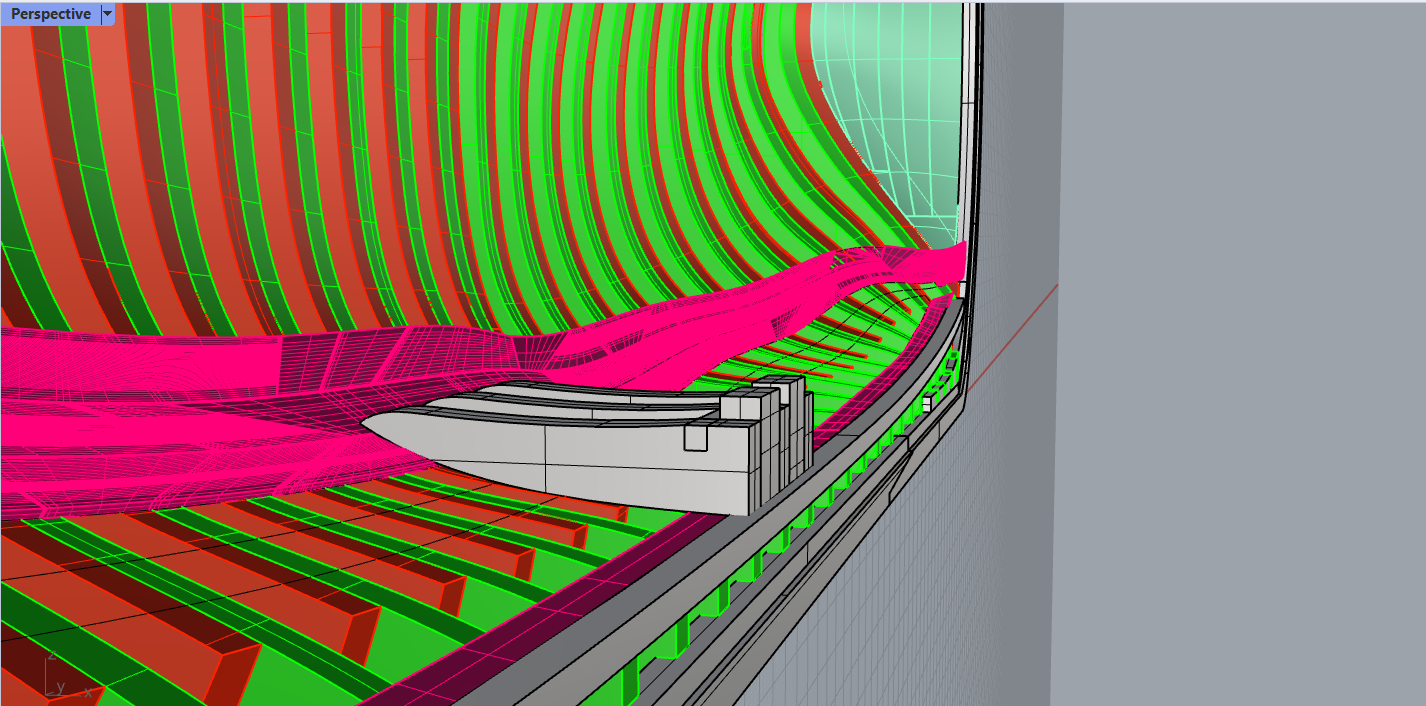

Thank you so much for your interest in thiws work. This is really important work for me as I intend to do this properly for each ship I build. I think that this is not bad for a piece of software I didn't know just 2 months ago but still... I fully agree with your statement: It is worth getting a correct loft before proceeding with the rest. I started lofting again with without using 'normal', it is much better. But the accuracy cannot be as great as intended and I get some curves quite far from the monography. I lofted from the stations drawings. The issue I run into when using your method is that when I extrude from the futtocks joints with the thickness at that point, the resulting frame (whose section I could use to loft the inner surface) is too thick close to the deck and too thin close to the keelson. Unlesse I misunderstood our method ! but I agree it should force the loft too behave in the same way as the outer surface, which is what we want. The pink surface is obtained according to the following: - Draw the contours of the hold planking in the XY plane (monography) - Project those contours on the inner surface - Create a surface joining 4 sides of each plank - Solid Offset this surface to get the plank. This is too complicated, I should use your method to cut the inner surface. In your second post, you mention a picture of my first loft. I discarded it for those same reasons: isoparms were too nasty I will prepare today a file with my new loft. I tried a new method to get the bow in a separate way. Many thanks PS : Just bought some wild cherrytree planks. Eager to machine !!

-

Kranck reacted to a post in a topic:

La Belle 1684 by Oliver1973 - 1/36

Kranck reacted to a post in a topic:

La Belle 1684 by Oliver1973 - 1/36

-

Dire times. I designed some more elements in the hold and at the bow. I tried to project the contour of the inner planking of the hold, but the results is not satifying. Obviously, it is wobbly and irregular because of some bumps on the frames due to an inner surface that is not fair. The outer surface if much better. Projecting the planks and adding thickness on those frames highlights the defects of the surface. It should be better with actual wood, since there will be some rigidity with the material and some sanding that will allow for a compensation of the irregularity. But up to what point? I'm not sure it will be sufficient to smoothen the biggest bumps. I don't know what to do. I'm not sure I can get a fairer hold. Any slight offset or UVN change in the lower part of the hull surface results in big changes in the actual XY position of the projected contours of the planks, which is quite natural since the surface is almost flat at that location. Is there another way to model those planks? Should I loft again the surfaces? Should I stop designing here and get to woodworking with the hope of compensating the defects?

-

ancre La Belle 1684 by Oliver1973 - 1/36

Kranck replied to Oliver1973's topic in - Build logs for subjects built 1501 - 1750

Do you feel that this Paulimot is better than the Unimat ? Easier to maintain maybe? Wondering about buying one... -

Some update: - I redrew and lofted again the outer and inner surfaces. Much better. Some futtocks are still a little too thick, especially towards the bow, but this can be dealt with later with smaller cuts with an uptdated version of the inner surface loft if needed. - The stern is quite satisfying. Lots of projection of curves on surfaces etc, and a final touch directly dealing with solid edition but it is quite accurate. - Currently cutting the futtocks in smaller parts as shown on the blueprints. Next step will be setting the decks.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.