Richard Feliciano

Members-

Posts

48 -

Joined

-

Last visited

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

thibaultron reacted to a post in a topic:

Chuck's carving attempts - #11 blades and micro chisels

thibaultron reacted to a post in a topic:

Chuck's carving attempts - #11 blades and micro chisels

-

EricWilliamMarshall reacted to a post in a topic:

Chuck's carving attempts - #11 blades and micro chisels

EricWilliamMarshall reacted to a post in a topic:

Chuck's carving attempts - #11 blades and micro chisels

-

Jack H reacted to a post in a topic:

HMS Fly - Richard- 1:48 scale

Jack H reacted to a post in a topic:

HMS Fly - Richard- 1:48 scale

-

GrandpaPhil reacted to a post in a topic:

HMS Fly - Richard- 1:48 scale

GrandpaPhil reacted to a post in a topic:

HMS Fly - Richard- 1:48 scale

-

druxey reacted to a post in a topic:

HMS Fly - Richard- 1:48 scale

druxey reacted to a post in a topic:

HMS Fly - Richard- 1:48 scale

-

mtaylor reacted to a post in a topic:

HMS Fly - Richard- 1:48 scale

mtaylor reacted to a post in a topic:

HMS Fly - Richard- 1:48 scale

-

dvm27 reacted to a post in a topic:

HMS Fly - Richard- 1:48 scale

dvm27 reacted to a post in a topic:

HMS Fly - Richard- 1:48 scale

-

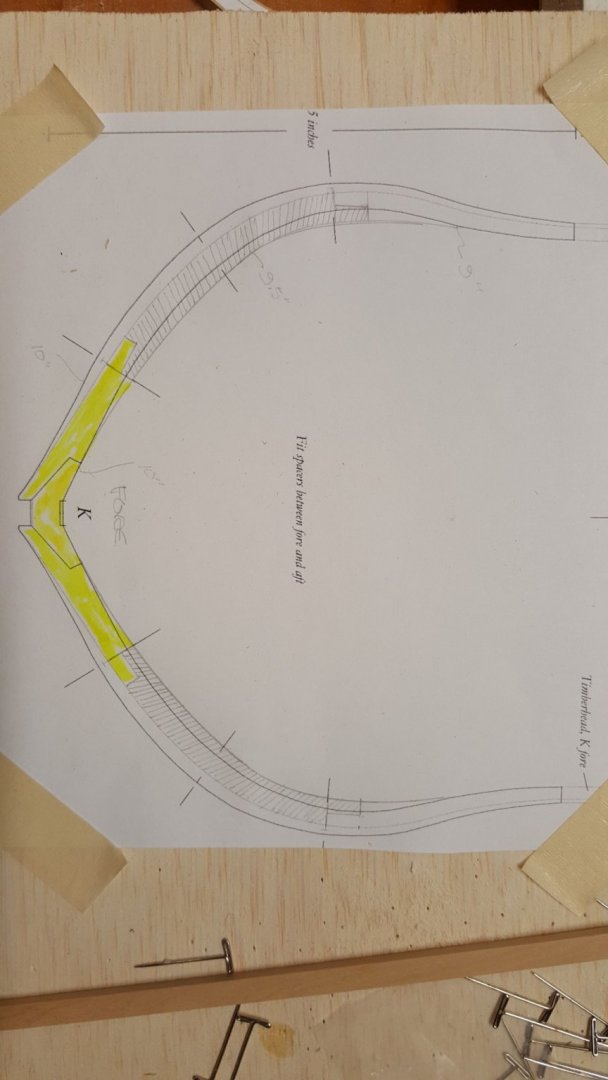

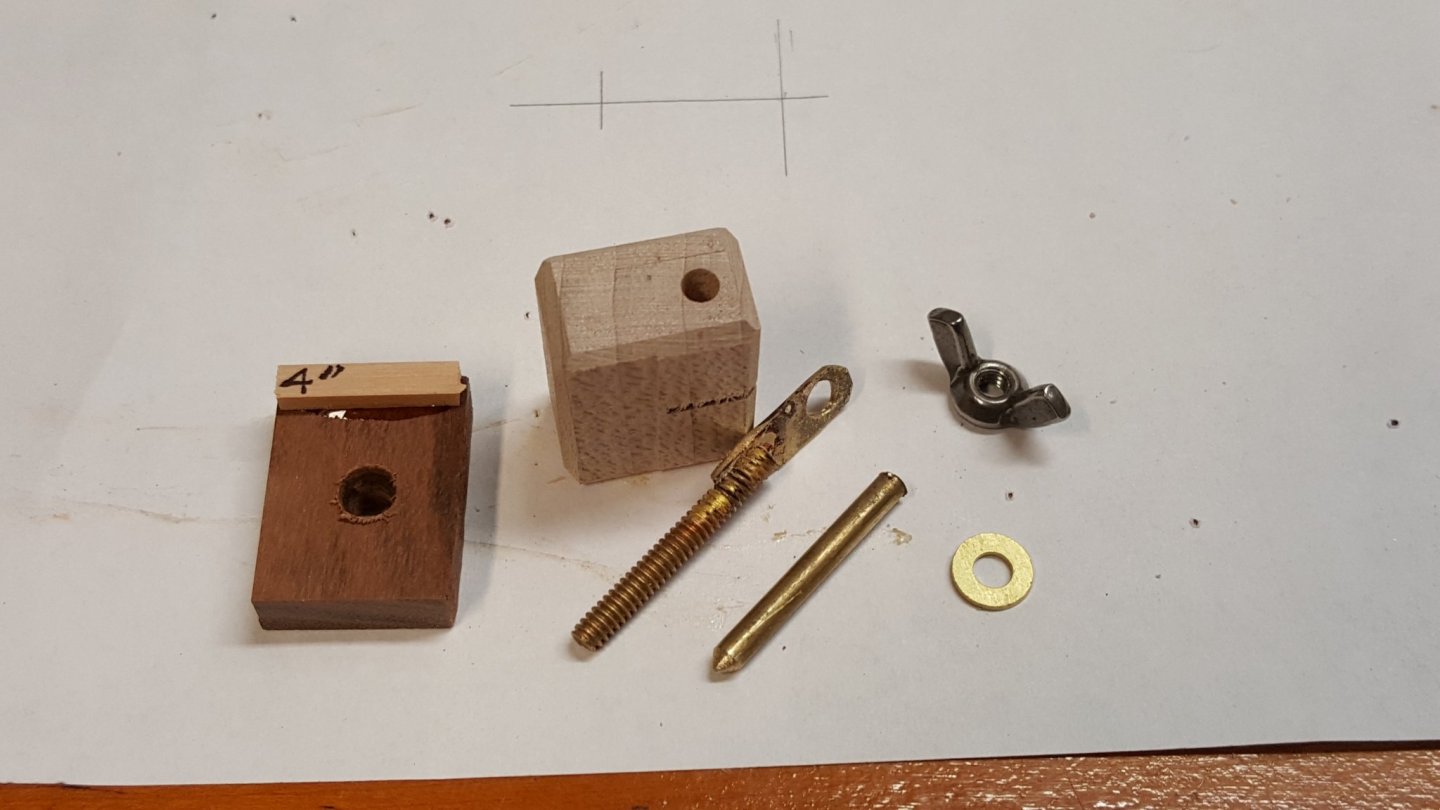

I've taken a one month hiatus from my model to work on my spring gardening and couple of Chopin's Preludes. I did take time to fabricate some "Spreader Clamps" based on my favorite modeler the late Dan Vadas. I changed his approach slightly by grinding the screw to half its cross section rather than trying to file a slot. I did not anneal the brass strap after silver soldering to keep it flexible. I used various offsets from zero to six inches to allow for various hall curvature which the clamps will be attached. I made 8 clamps in all. Attached is a photo off the pieces and one showing how the clamp would be used for exterior planking. I intend to fabricate Dan's other tools in the near future.

-

KARAVOKIRIS reacted to a post in a topic:

HMS Fly by Richard Feliciano - 1:48 Scale - POF

KARAVOKIRIS reacted to a post in a topic:

HMS Fly by Richard Feliciano - 1:48 Scale - POF

-

KARAVOKIRIS reacted to a post in a topic:

HMS Fly by Richard Feliciano - 1:48 Scale - POF

KARAVOKIRIS reacted to a post in a topic:

HMS Fly by Richard Feliciano - 1:48 Scale - POF

-

KARAVOKIRIS reacted to a post in a topic:

HMS Fly by Richard Feliciano - 1:48 Scale - POF

KARAVOKIRIS reacted to a post in a topic:

HMS Fly by Richard Feliciano - 1:48 Scale - POF

-

Thanks for your advice. I'm sure most follow your procedure of using a chisel with great results. I'm against your method primarily as a result of my background. My objection response would be too lengthy and wouldn't change anyone else's mind on the procedure to follow. The slotting file enables me to make a cross grain cut where I want (assuming my measurements are accurate which is a leap of faith).

-

Struggling with the square frames and port hole construction. Not very satisfied with the results. The following shows steps taken to create port holes. I find try as I might, I need to resort to miniscule shims to get any sense of proper proportions. My notching skills require 45 degree notches to get any sense of looking right. The 60/120 degree notching too difficult for me.

-

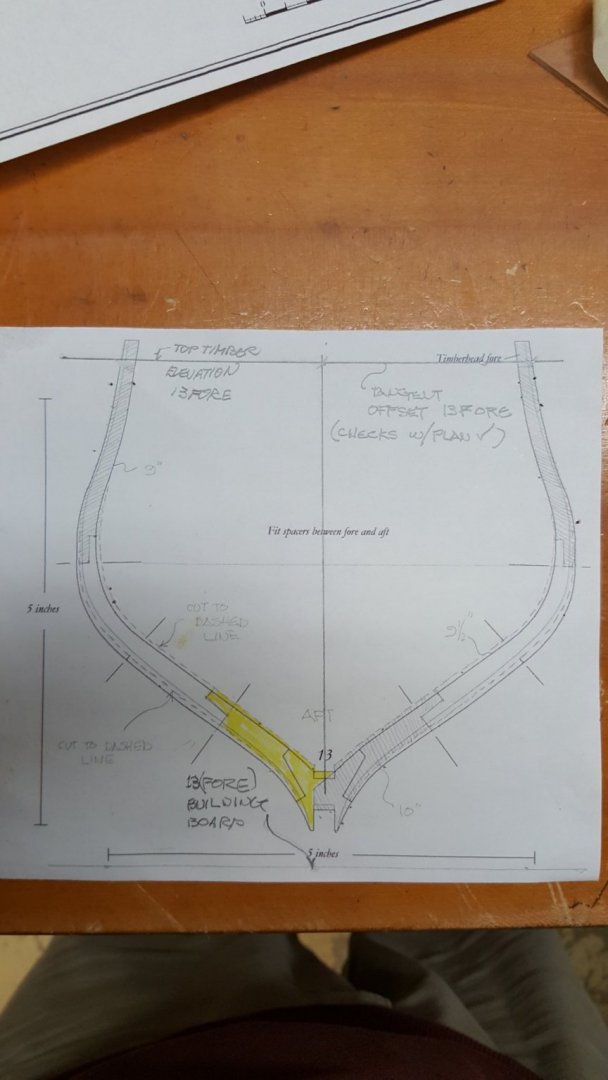

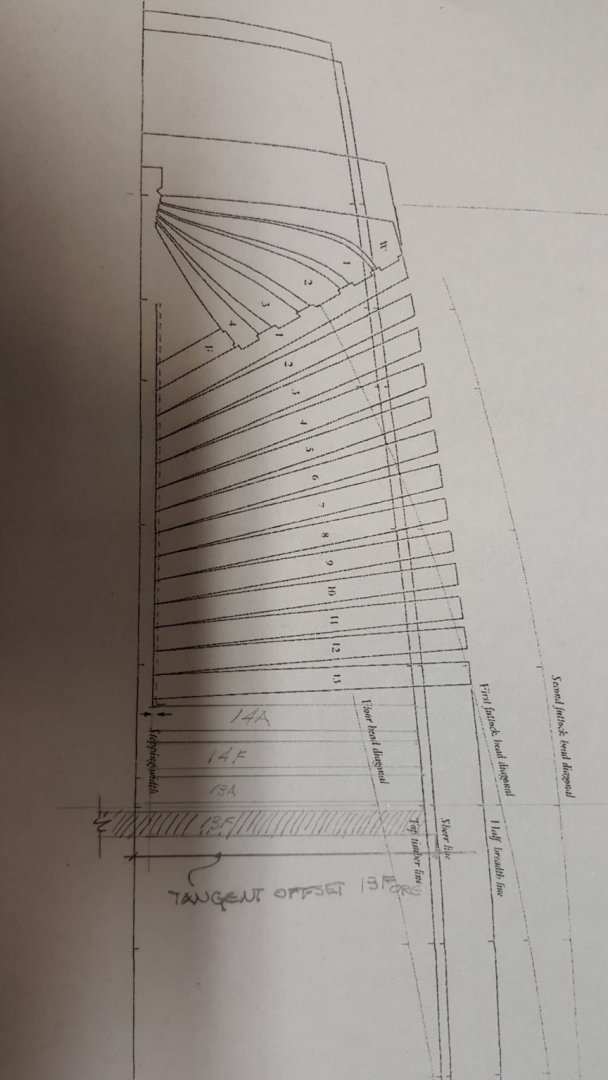

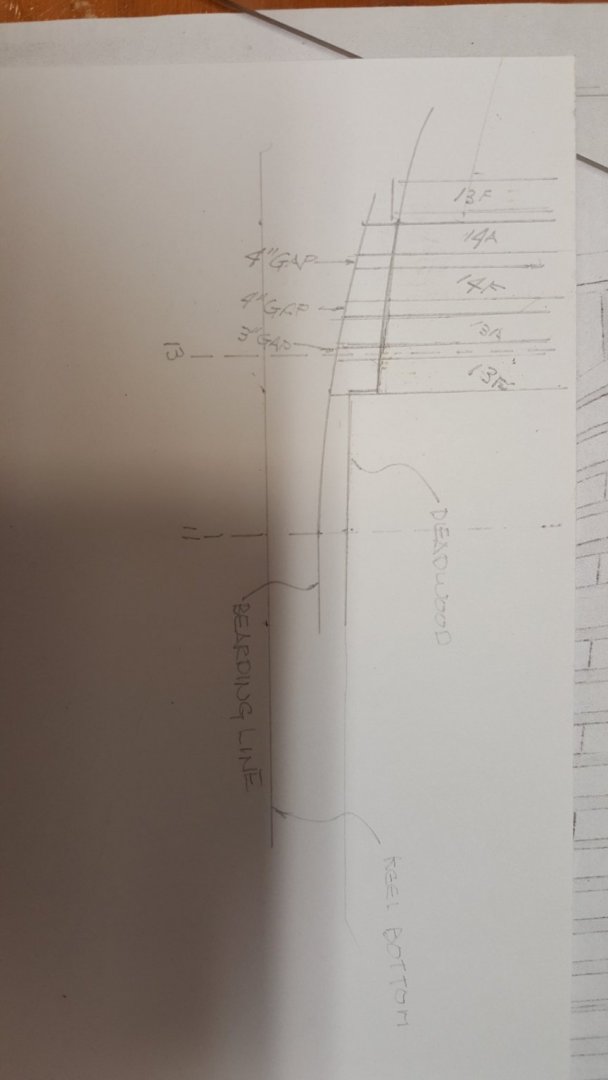

The Square Frame patterns for 13 & 14 Patterns do not take into account the rising slope of the deadwood for the tops of the frames (see photo below). The frames are higher moving from 13 F to 14A. I wanted to check spread of the frames at the top of the patterns for the temporary cross spall. Using the information that I had previously drawn and the Plan Section for HMS Fly, I plotted the Tangent Offset for the frames in question. I then plotted the design heights for the top of timbers on the pattern drawings. Fortunately the Tangent Offset on the pattern drawings checked exactly with the Tangent Offset. The main point is Frames 13 thru 14 need to be cut down to design height. (As previously stated, the 36 timberheads will be fabricated separately and attached to the frames later.

-

As previously stated, I believe that the 14 Aft pattern is too narrow due to the significant slope of the deadwood at it's location. The pattern is satisfactory on the forward face but the back face is much higher thus requiring a wider overall cut out to achieve the interior and exterior surface. I made adjustments on 13 Aft by cutting the pattern fuller (~2" S) on the inside and outside. You can see the interior of the stern has been faired. I agree that there may be some alignment issues on the last cant frame, but looking down keel axis the alignment of the frames looks good to me. After I raise the 12 & 11 frames, I will post a photo.

-

After fabricating frame 14 Aft, the resulting frame was too narrow to conform to the existing inside framing. To correct the problem a thin (2" S) strip was laminated to the interior of the frame with satisfactory results. The inside of the frame will never be seen. A bending heating iron created the needed curvature. The ends were tapered to zero thickness.

-

It's been a challenge to get started on the square frames. One of the issues one needs to consider is the layout of frames 14 Aft and Forward. The patterns given by Admiralty Group are for the forward faces of the frames. The rear faces are entirely different because of the slope of the deadwood. In addition, the actual disposition of your deadwood slope is not the same as mine due to construction variations of each modeler. I mentioned this to Greg Herbert who stated he had a similar problem. After constructing 14 Aft, the resulting frame was to narrow in width. My approach to resolving this issue: 1. Make a fairly accurate drawing of my deadwood using a carpenter's moulding template. 2. Draw building board line on this drawing using drafting dividers. I find my old K & E dividers to be more accurate than calipers for this purpose since they can fit into tight spaces. 3. Lay out the proposed frames (14 down to 12) on this drawing. Use this drawing to determine the bevels needed on the base of the frames.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.