-

Posts

104 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by LucienL

-

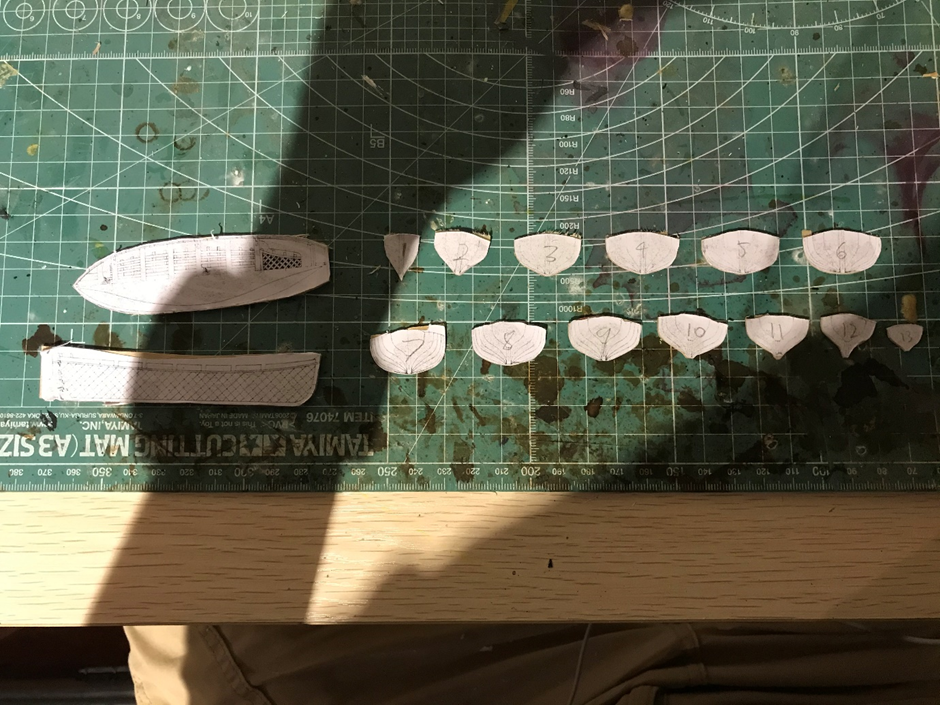

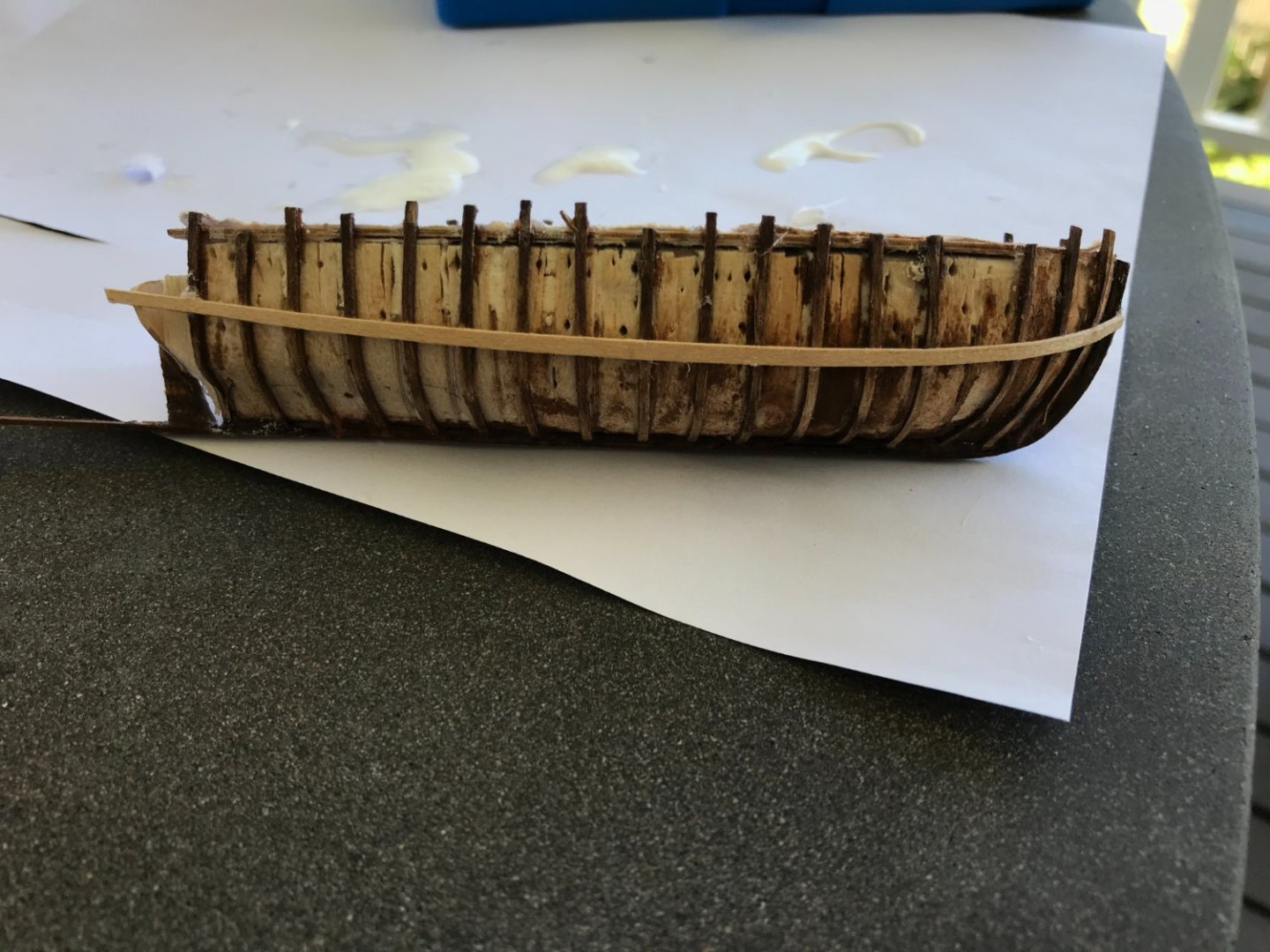

Okay, so it’s been a while, but I haven’t exactly been idle. Over the past year and a bit I’ve been continuing to work on the Beagle’s boats. In my last post, which was January of last year, I had finished up the yawl. The next steps were to make the chocks for it on the ship. I next started on building the cutter that would have nested inside the yawl. This would have followed a similar construction plan, so it made sense to do it next. Similar to the yawl, I printed out the plans and used these to cut the pieces of jig I glued these into a frame and filled the gaps with balsa Then I sanded it back to the frames. I also thought it might be a good idea to add some glad wrap this time as I had such a problem getting the hull off the jig last time Then came lots of bending and staining frames to create a platform to lay the planks on Then planking Unfortunately, it was only at this point I decided to size the boat up next the yawl I had already made. I’m not sure how it happened, but the plans I printed out were too small, which resulted in the ship having significantly reduced dimensions compared to the yawl. I spent plenty of time trying to determine whether I could live with this. Ultimately, I figured that the scale problem would likely only become worse as I proceeded and make it more difficult to fit all the deck planks and thwarts into the boat at the dimensions I wanted. I decided to bite the bullet and start over. This caused a big break in progress, so when I eventually came back to the ship, I decided to try to make all 6 remaining boats in parallel to move the project along a bit faster.

-

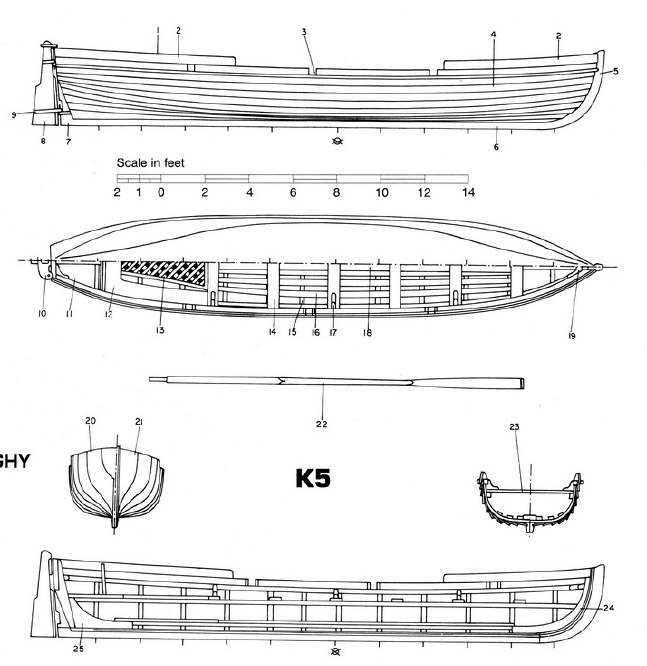

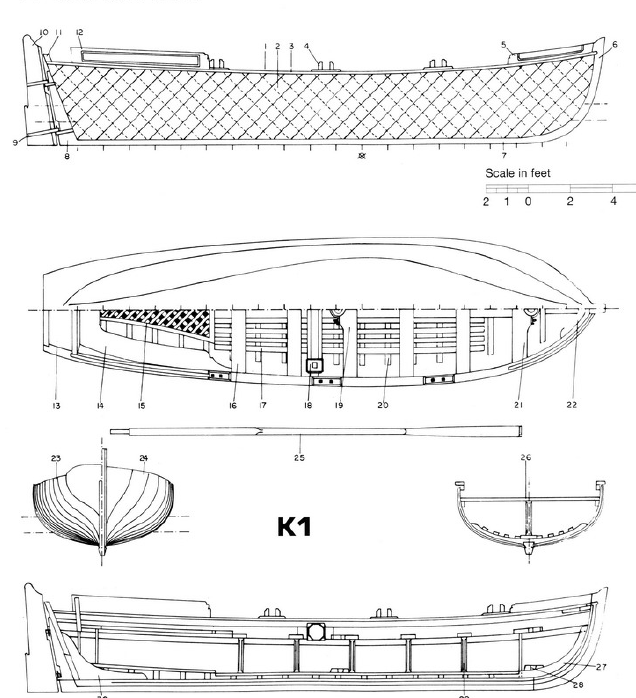

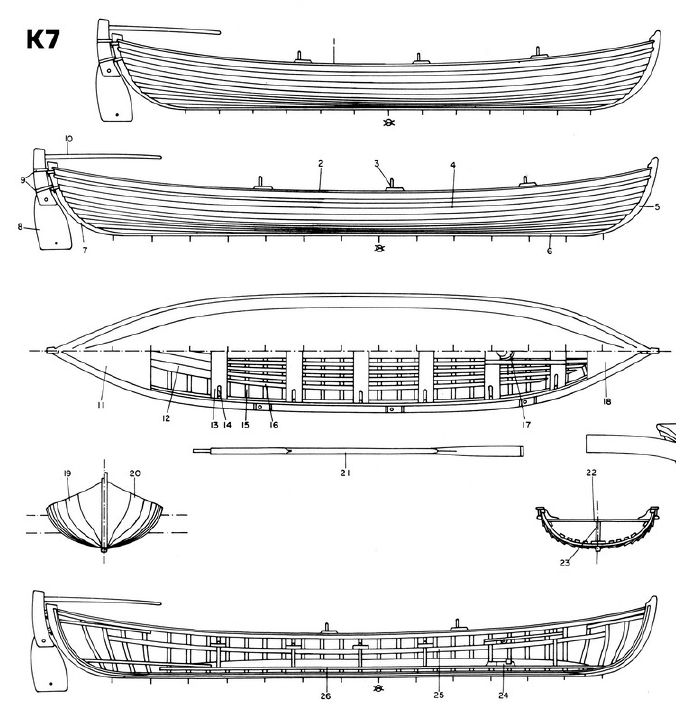

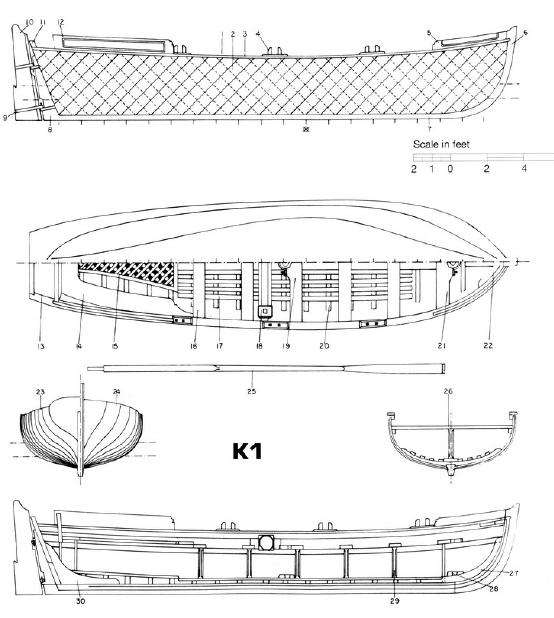

Hi Allen the plans outline 2 different types of whaleboats (25 ft and 28 ft), both of which have only 5 tholes. The whaleboats made up 3-4 of the Beagle's boats. There are two other single banked boats in the plans, the yawl (the Beagle's largest boat) and a gig that was built/purchased as a replacement for one of the lost 25 ft whaleboats at some point around the ship's second voyage. The plans for both these boats have 6 tholes (or rowlocks in the case of the gig). I've included the plans for these two boats. The two other boats, the dinghy and the cutter are both double banked.

-

I see, that would make sense, although this part is much higher up than the thwarts. I wonder why they haven't drawn that on the plans though. I'm not a fan of the asymmetry so I think I will add an extra thole for the last thwart. Thank you. Progress has been a bit inconsistent on the beagle, but the boats are coming along pretty well. I've been meaning to post an update for a while and probably will soon now.

-

Hi there. I am currently building the boats for the HMS Beagle and have been following the anatomy of the ship as a guide. This is the whaleboat There are six thwarts total and 5 tholes, presumably the aft-most thwart was for someone to control the rudder. As far as I can tell, this is what the plans suggest I'm just not sure if this is right as this would result in an odd number of rowers that would make the boat difficult to keep straight. If anyone knows whether this is something that may have been done, please let me know.

-

Thank you for the kind words everyone. @allanyed I think the trouble came when I tried to glue the spacer pieces that sit between the frames. I think some of the glue stuck to the jig, which meant that it would be impossible to remove in one piece. I think that next time I will wrap the jig in some cling wrap and that should allow the boat to lift off the jig easily if I do it the same way. Thank you for the link, I actually did come across your log towards the end of this process. The Bounty's launch from the Model Shipways kit was my first build, so I'm interested to see you tackle it. @Capella The darker bits were stained using an oak stain. This is much darker than other oak stains I have seen and I think that this stain is meant to be diluted before use with a colour reducer that is sold separately. I liked the colour that came from the undiluted stain, so that's what I have been working with. I also rub in a small amount of walnut filler into the grain before staining to give a more even colour and hide some of the grain. I have used some paulownia wood for some pieces, which doesn't stain the same way as the limewood and has a very large grain. Adding the filling putty is necessary to get all the bits the same colour. The pale bits are just the raw limewood sealed with a matt varnish.

-

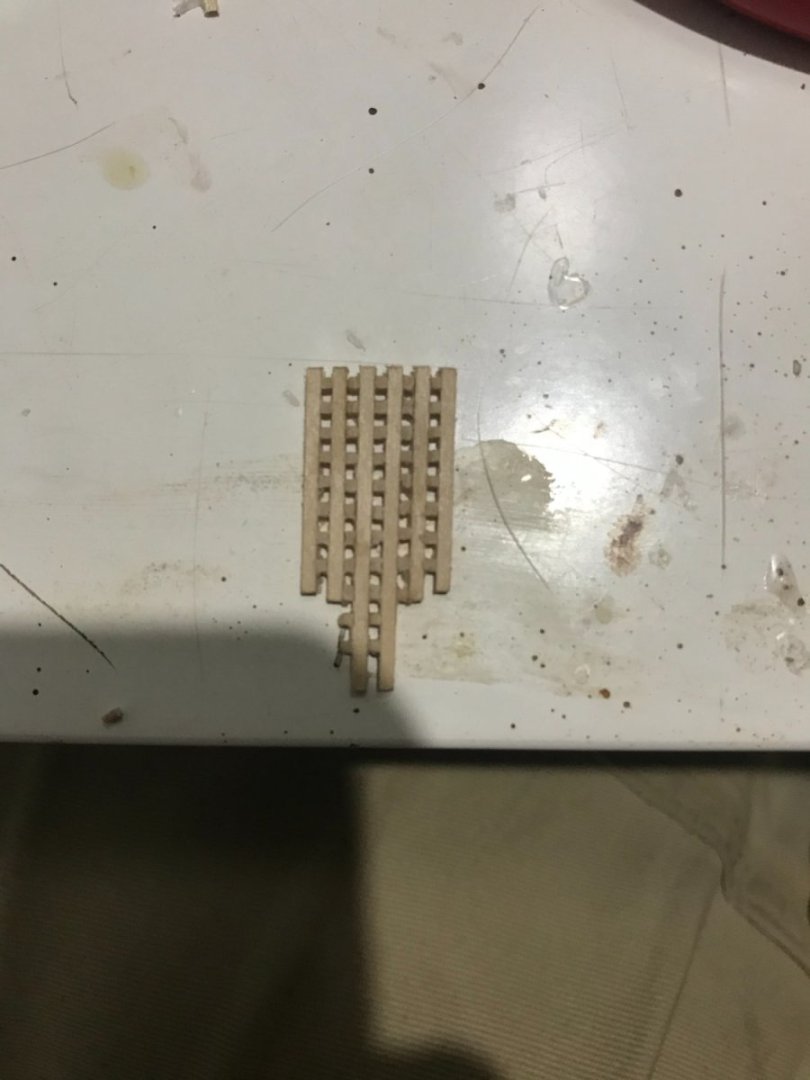

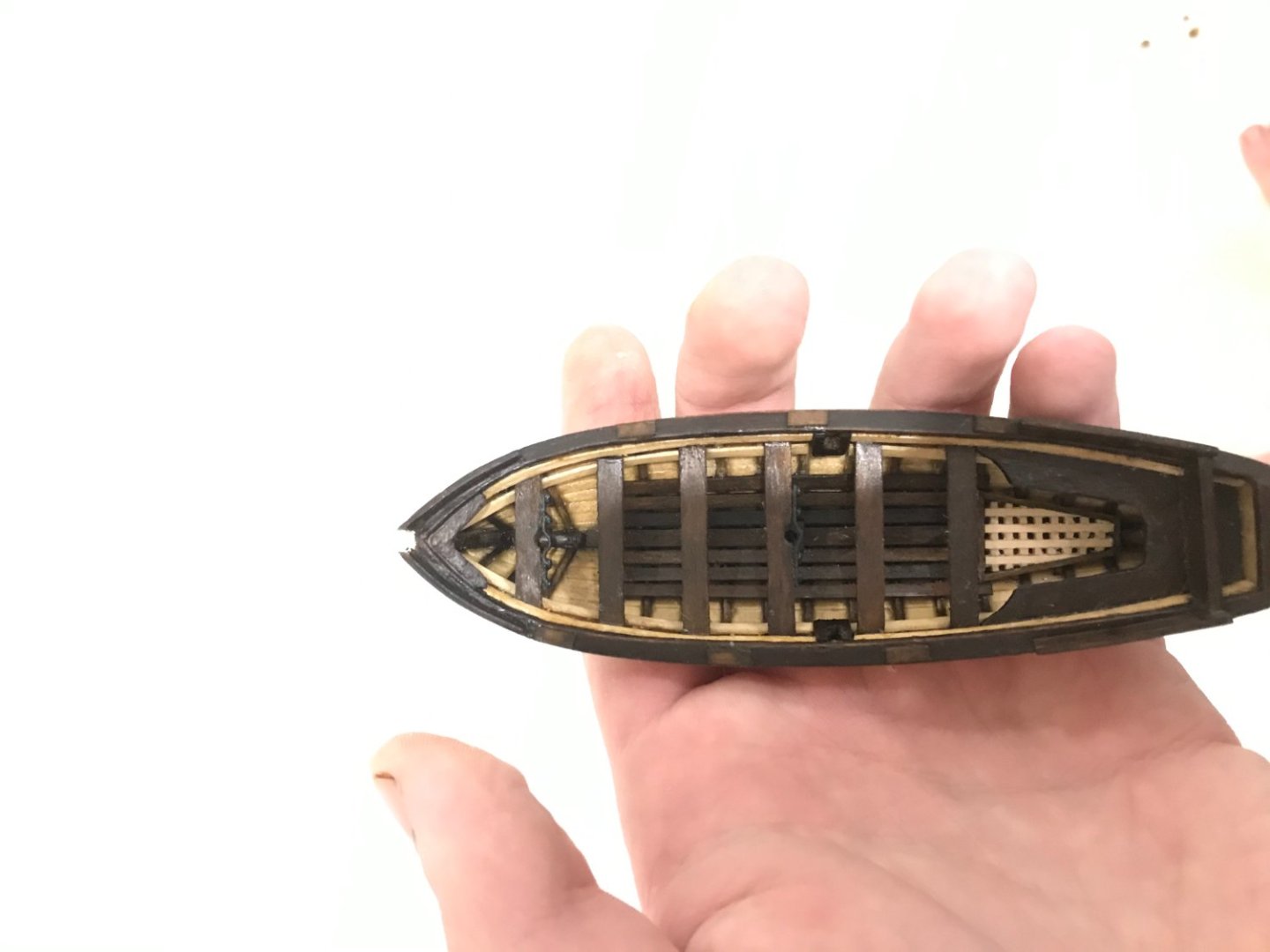

Been finishing up some of the last details on the yawl. The big one was the grating that makes up the quarter deck. I glued some 1 x 1 mm sticks to a 3 x 1 mm stick using some 1 mm spacers. Then I cut them in half to double the amount of grating made, which could then be glued together. In only had a small amount to make, so this relatively inefficient process was still effective. I’ve also done the thwart stanchions, mast steps and the tholes, which means that this one is basically done aside from boat gear, which I might combine with some of the other boats a bit later.

-

I'm currently working on building the Beagle's boats, starting with the 26 ft yawl. I'm drawing from the anatomy of the ship, which outlines the plans here. My question is regarding the aftmost tholes, i.e. the ones that appear to be positioned for a rower seated on the stern-sheet bench. This seems as though it would present a very awkward rowing position and this individual would be forced to place their back to the thole and move the oar to their side. Is this something that is seen on other boats? How realistic is it that a rower would be able to use an oar positioned as such?

-

Hey capella, this is probably too late, but I found that shading the edges of the planks before fitting them helped. Alternatively, you could go as you have and outline the planks. Then run over it with a razor blade (or even a broken piece of glass) to clean the planks and hopefully keep the grooves

-

Another smallish update but has taken some time. I fitted the stern-sheet bench and back, which took ages to make from scratch and sand to fit properly. I also added a few thwarts, the third one is the mast thwart and is only dry fit. The mast helpers are made from 1 mm wide brass strips and painted back. I’ve used the kit nails to fit them in, they’re probably a bit too big but add some nice detail. Also made the windlass holders. I think I will make up a full windlass and strap that to the deck as part of the boat kit. I’ll probably also make up some oars, a grapnel, the rudder, masts and sails and chuck in a barrel. I’m drawing a lot from my experience on my first build: The Bounty’s Launch to make these little boats. I think my sheer clamp and thwart raisers are too wide, but I can live with them. And finally, with all the thwarts in. No pennies in Australia, but our 2-dollar coin is around the same size (I think) Next steps are to make the grating for the quarter deck, do the mast steps, tholes and the thwart stanchions. Then I should be able to move on to fitting it into the main boat and building the 23 ft cutter. Feeling motivated and keen at the moment, so should be able to keep making progress (unless the gratings kill me).

-

Hi Capella, great build so far, looking forward to seeing your progress. The planks you describe definitely seem like the ones that should be A20 (even just going by quantity) it's interesting that the dimensions are off though. Although, the 5 mm planks are probably too wide for scale so that might actually be a bonus (or they've improved the kit).

-

Hey Rob That's an impressive list of stuff you're thinking about! You've definitely found a lot of limitations with this kit. I will follow along with interest. One of my biggest frustrations is also the cannons and boats (as well as the belaying pins). I've also been working on this kit and trying to incorporate as many improvements from AOTS as I can. My biggest bottlenecks so far in terms of motivation, time and learning have been coppering the hull, making cloth hammocks and scratch-building the small boats (I also probably want to make my own sails).

-

Hey everyone, I’ve been working on fitting out the hull of the yawl and making it look nice. I painted it and fit the sheer clamps to give it some more rigidity. I was a bit worried about it spilling out at the sides, as this happened on my first build the Bounty’s launch After fitting the gunwales it was much more sturdy. I cut these from a piece of ply after tracing the outline from the remnants of the jig. I cut them wider than they should be to start (around 4-5 mm width), and then sanded them down to fit the hull as best as possible to around 2-3 mm. They should be mirror images, but I did have to bend them a bit while gluing. Then some other bits and the deck planks (varnish is not quite dry yet. It was a bit fiddly to get the bow looking right I think the sheer clamp got a bit grubby by this stage, will try to clean it a bit. Really enjoying making this little guy and getting into it. I think I’ve gotten over the main barriers which were bending frames, planking and fitting the gunwales. Should be much easier to do boat number 2 (and 3-7) now.

-

Just a quick update here, I fitted the final layer of the keel over the planked hull and started painting it. I got a little excited and tried to get the hull off the jig. I still have painting to do, but I was a little worried and wanted to see how it would go. It did not come out of the jig easily, definitely glad wrap it next time, I’m amazed nothing broke. The remnants of the jig are also attached.

-

Hey everyone, so I have finally gotten around to planking the first boat, which is the 26 ft Yawl that sits in the centre of the main deck. I’ve used the anatomy of the ship to construct the jig. This involved printing out the body lines and using these as template to cut each piece of the jig out of 1.5 mm plywood. These were all fitted into a false keel and the space between them filled with balsa. I sanded them down to give a jig that closely approximates the body lines in anatomy of the ship. Then I used the jig to bend 1 mm sticks to shape to form the frames, I stained each of these with a dark oak stain. I glued each of these at the top with a spacer piece (I think it was 5 mm length and 0.5 mm thick). I hoped that this would prevent them from sticking to the jig, but in hindsight, I should have covered the jig in plastic to really prevent this. After fitting all the frames, I added another layer of the keel to hold them all in place, the planks would then meet the keel at this height. I also fitted the transom and sternpost and then did some fairing I figured I would lay the sheer plank first to get an idea of how much space I was working with. It was very difficult to measure these things accurately as the boat is so small and my equipment is not really precise enough. I ended up eyeballing a lot of it and hoping things were the correct length. I think I am extremely lucky that it worked out as well as it did. I did my planking from the garboard up. The logic was that if there were problems at the top, I could simply re-adjust the sheer plank to make it all nice. Fortunately, this was not necessary (it is such a little thing!) Then filling and sanding to give a nice finish (this will be painted white). This hull would have been double diagonal planked on the real ship. I was tempted to give this a try, however I figured that it would be a good idea to get practice planking on this one as I would want to hide much of the planks in the finish anyway (because it is inaccurate already). This would help me later when I try and do the remaining 6 boats, 5 of which are clinker planked. I guess we’ll see whether it comes off the jig...

-

Hey everyone, so long time since my last post. I haven’t had a lot of time this year to work on the boat much, but I’ve been slowly working away at a few things. Part of it is time, but I also haven’t been able to give the proper head-space to the boat all that much. I've been very busy with my final year of uni, which is a research project that has been occupying a similar place in my brain that was previously occupied by the boat. Last post was about the cannons, they were tied down using some tiny blocks, but that I think look okay. I also painted the figurehead and did the prow details with some blackened chain Then it was finally time to actually do the hammocks. It took some trouble shooting, but eventually I did end up with a method that worked. Then it was just a slow process of repeating it 100 times. They are a bit random and rough, but I don’t mind that, as my key frustrations with the kit hammocks were the regularity, the missing fold lines and the fact that they were completely the wrong material. This was one of the three biggest changes I had been planning from the start of the build and been most apprehensive about so I’m really glad that this is done. Coppering was the first. The third big change is what has been causing considerably more difficulty, which is to scratch build all seven of the survey boats. At the moment, I am working on a jig for the frames and planking. I think I will post when that is done even if it is not very exciting

-

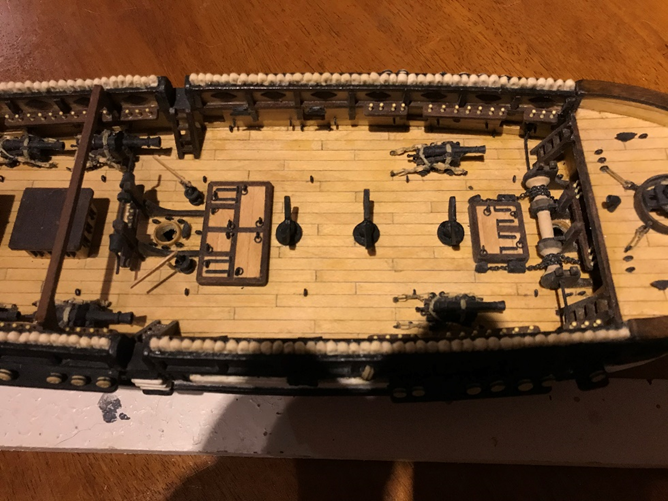

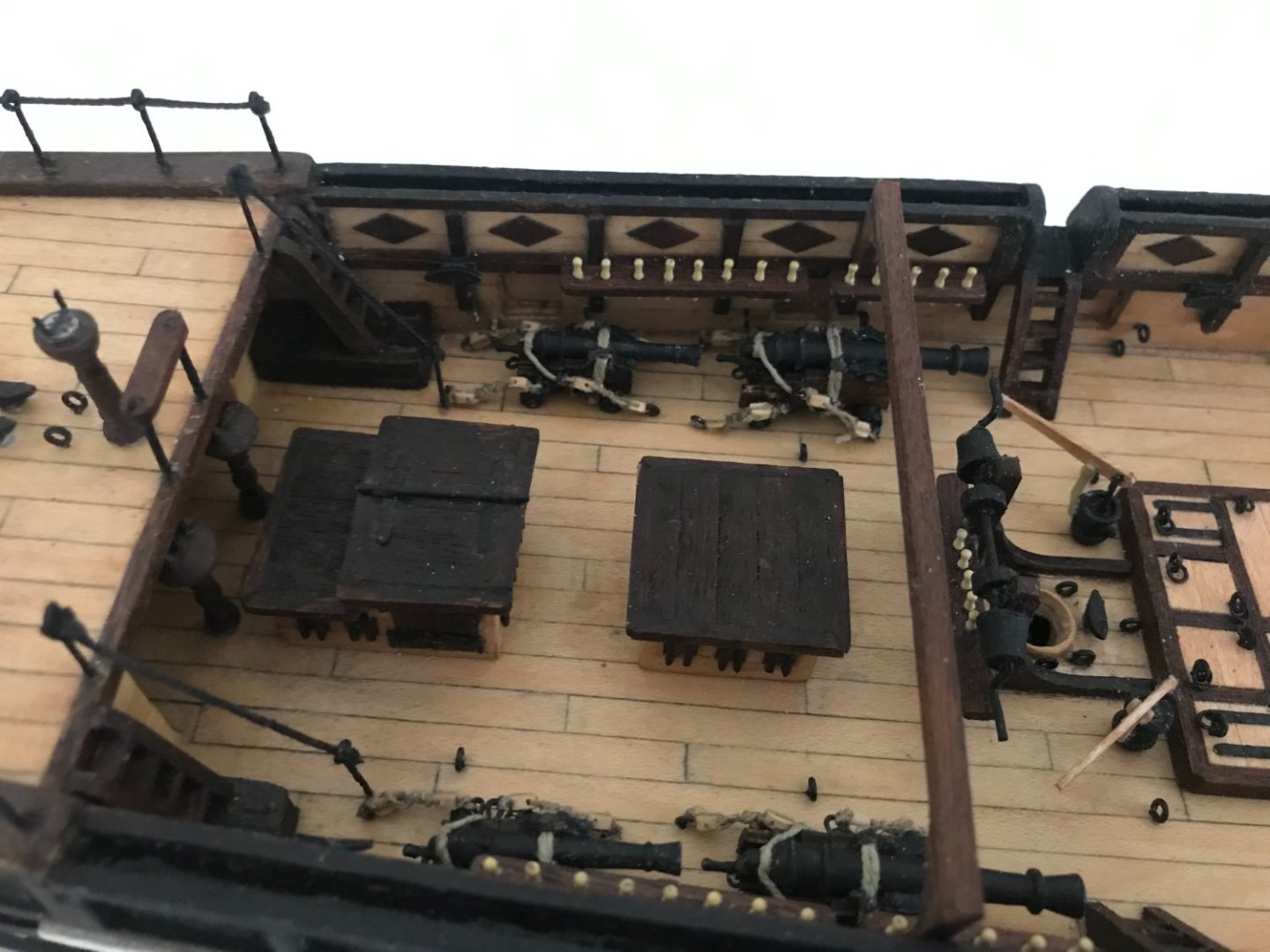

Cannons were also a fairly significant deviation from the kit instructions. Instead of using the laser cut parts which did not look right to me, I only cut off the top ridged bit of the side pieces and used that. The bottom section of the side piece was then glued to that to give a groove. I made up the quoin using the previously purchased brass belaying pins Then I could add the actual cannon barrel (yay) The main body of the cannon was finished off with wheels, eyebolts (from 0.5 mm wire) and cannon hinges. This all had multiple steps that took quite a while with 6 cannons. I can’t even imagine doing 100 for something like the Victory, but I would definitely want to do a big battle ship like that eventually. I also rigged them with some 0.5 mm thread. I now need to add the blocks and tie them down to the deck. I think I will also add eyebolts to each of the gunports where the cannons are supposed to go. Anyway, here are some more pictures.

-

Similar to how I did the cabin windows, I wanted to cut holes in the wood and place a mirror behind it to give the illusion of depth. This proved quite difficult with the pre-cut parts as cutting out the holes was extremely painful and they ended up being too small. So instead, I decided to scratch build them using some of the limewood pieces. This gave some ugly little skeletons here (I think the main one is wrong here, I fixed it later but the slope on the roof should go the other way) They looked a bit better with the sycamore lining and the roofs I had to also make the bars from scratch, which was a long night cutting 1mm brass rods (I ended up buying some spare stuff in the end) I really did not feel like priming all of these and then painting them multiple times, so I decided to blacken them instead, which turned out okay Then I glued in the mirrors to give this effect, which is quite difficult to take photos of Then I fixed them to the boat, and the deck was starting to come together There was a bit of trouble on the poop deck as the sounding winch did clash a little with the larger sky light and I had to rebuild it with shorter wire and shift it a bit so that there was enough clearance (I think this piece is a little too large for scale, but I still like it) Anyway, cannons next.

-

Hey everyone, I’ve been quiet for a while but have a couple of posts that have been ready for a while now. It’s been slow going for the past couple of months, but significant progress has been made since the last update and I have a few posts I can do now. First up is all the details around the main mast. The hatchway was mostly straightforward to make. I had a bit of trouble with the number of eyebolts around the main mast. I settled on 6 around the mast and one in front (changed after this photo). I did also need to order some more cleats as I think the rigging in the OcCre guide is not quite accurate. I’ve forgotten the specificities of what each of the eyebolts are for, but I’ll get into that later. The winch was a little tricky. I added some gears by cutting a thin wheel off of a dowel and cutting in some grooves to mimic the effect, which I think works. I also had to make the posts a little longer as it clashed with the belaying pins Bilge pumps were fiddly, but mostly straightforward, getting them to align symmetrically took a bit of trial and error but turned out okay. The sounding winch was also fun. For ages I could not figure out what this thing was for. This was apparently used to lower ropes to the sea surface in order to gauge the depth of the sea floor, which is pretty cool. Then it was either cannons or skylights. I had planned some pretty major deviations for both of these and both seemed a bit daunting. In the end, I decided to do sky lights first to get all the stuff that is actually fixed to the deck done first.

-

Understanding Truss Pendants and other rigging things

LucienL replied to LucienL's topic in Masting, rigging and sails

Hey Henry, I was hoping that would be the case, but wasn't sure if there was something I was missing. Looking at it again, it does seem like they've only included some of the rigging for one side, so you're probably right. That does put me more at ease, thank you. -

I don't know what the normal distance is, but AOTS has the same number as the OcCre plans, which would come out to 24 cm in real life and 4 mm on the model. This man is about as tall as 8 ratlines, but it's difficult to tell with the angles and the way he is holding on, but that would be equivalent to 7 x 24 or 168 cm, which is possibly accurate, but there might be more spacing here. If you went with 5 mm, he'd be 210 cm tall, so somewhere in the range of 4-5 mm is probably right. I'd say 4 mm would be decent spacing, but you might want to measure yourself and see how many ratlines you can fit given the length of your shrouds. Also, from when I did ratlines on my last ship, it might help to do the top one and the bottom one first so they end up being the same height on both sides of the mast. I ended up messing up the spacing a bit and one side was slightly higher even though they had the same number of ratlines.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.