marsalv

-

Posts

528 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by marsalv

-

-

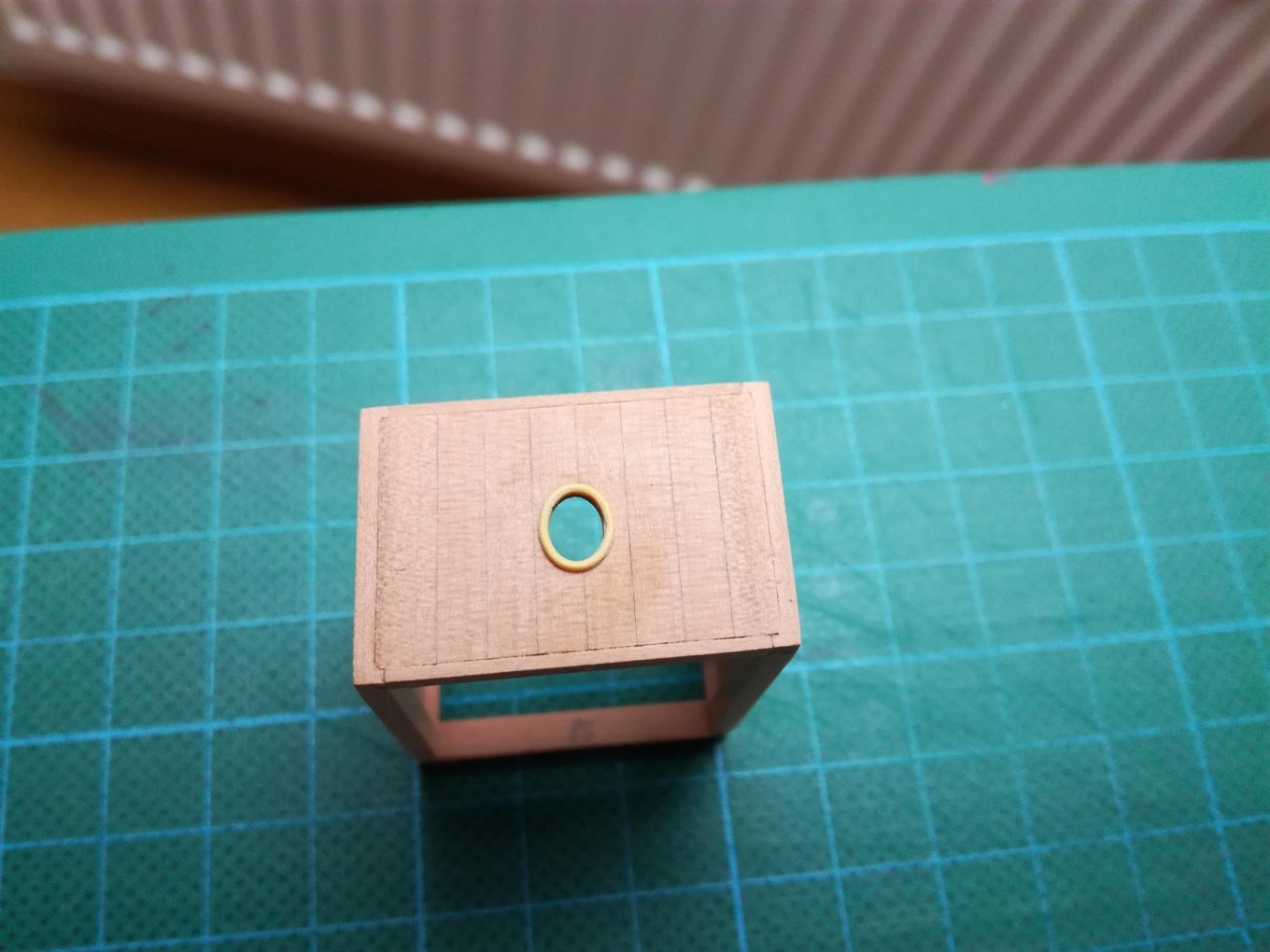

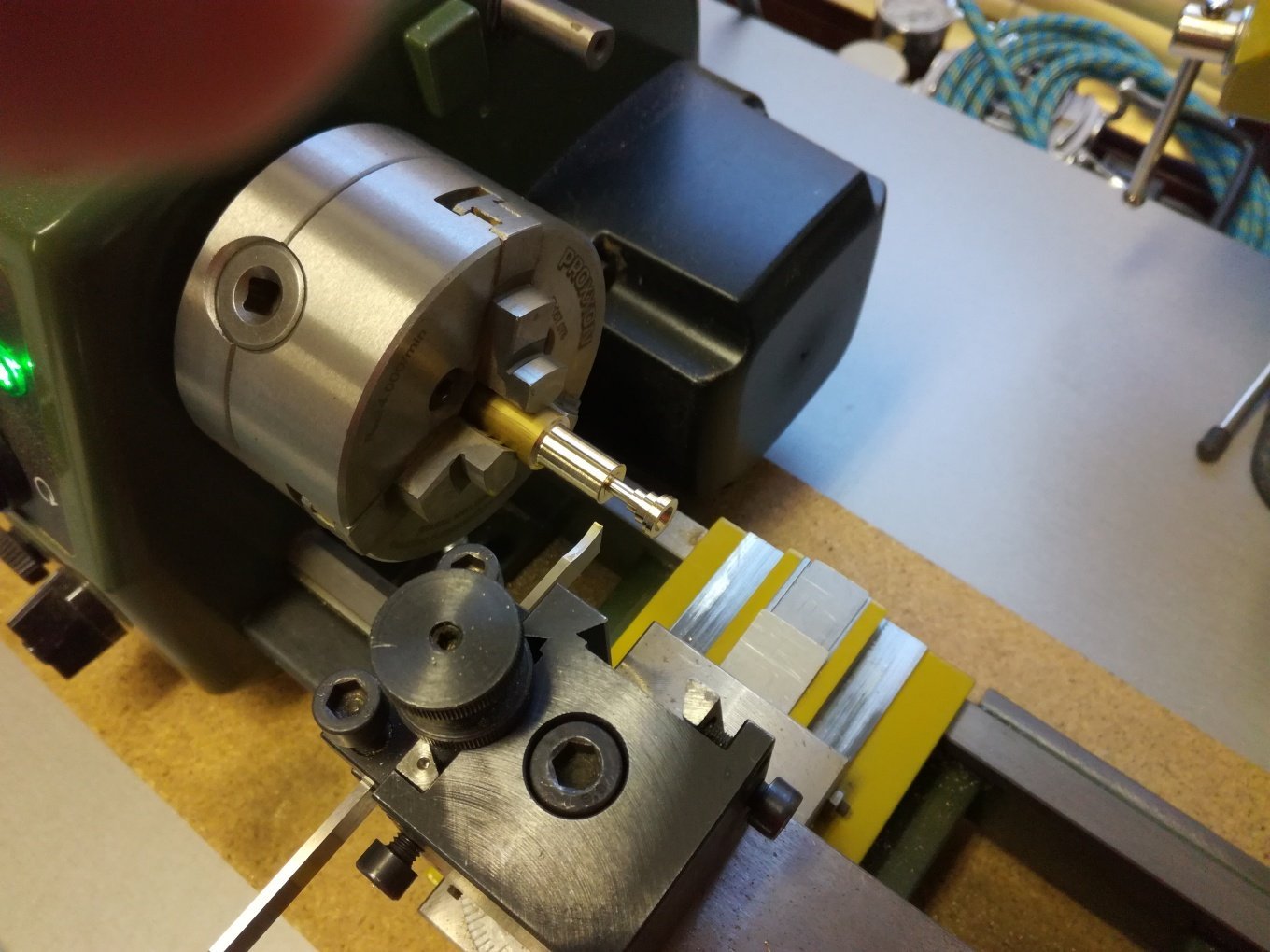

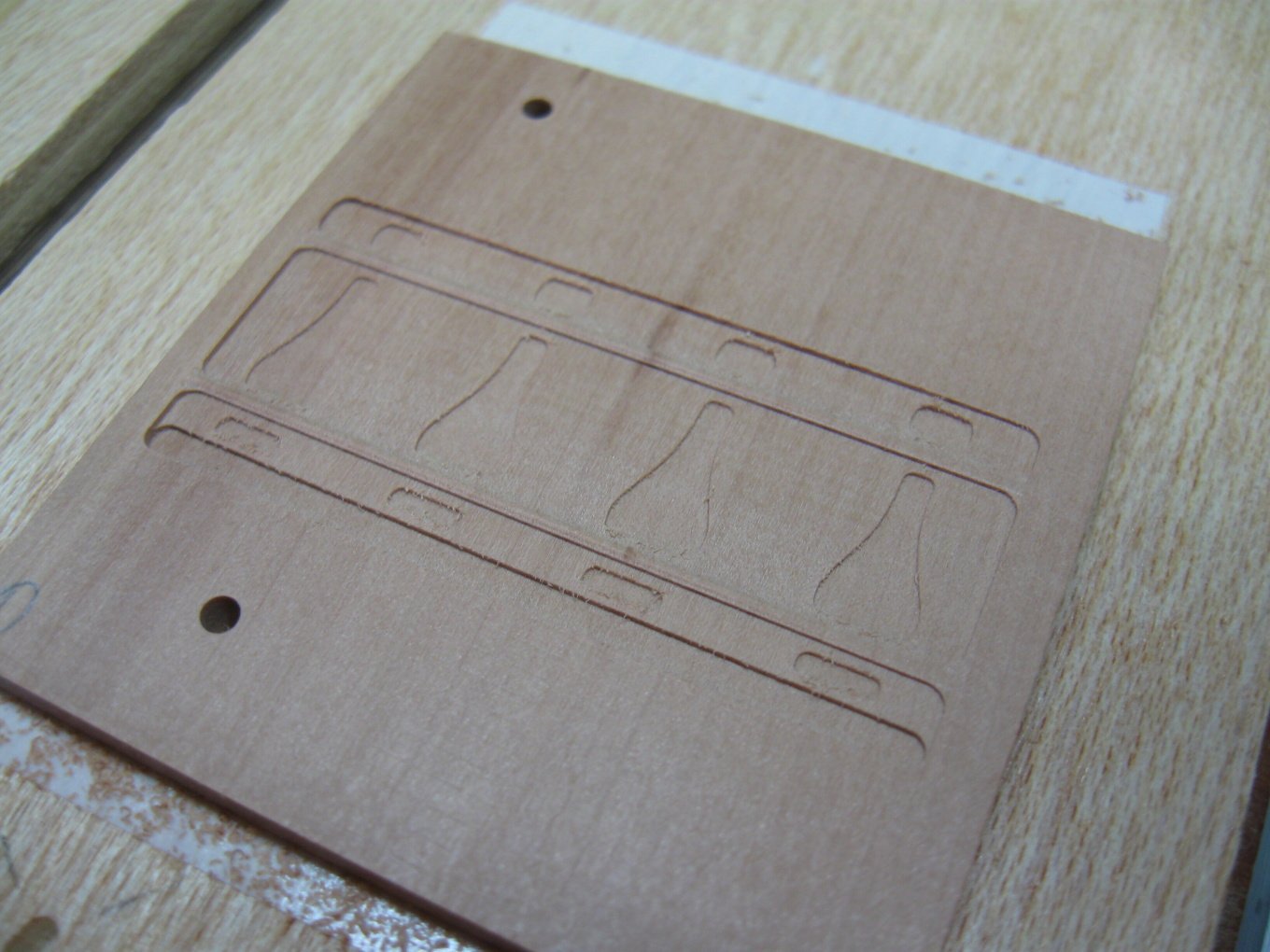

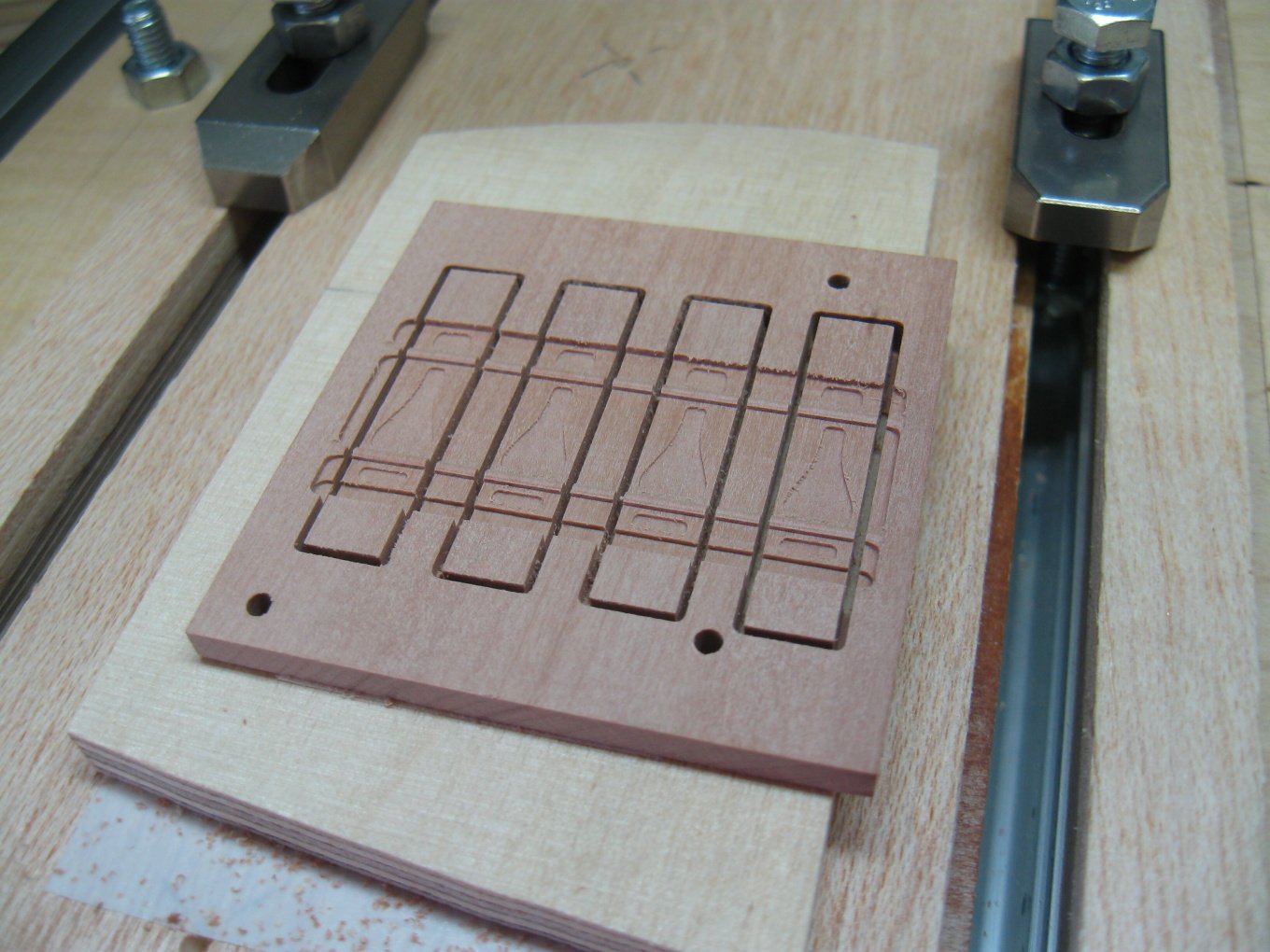

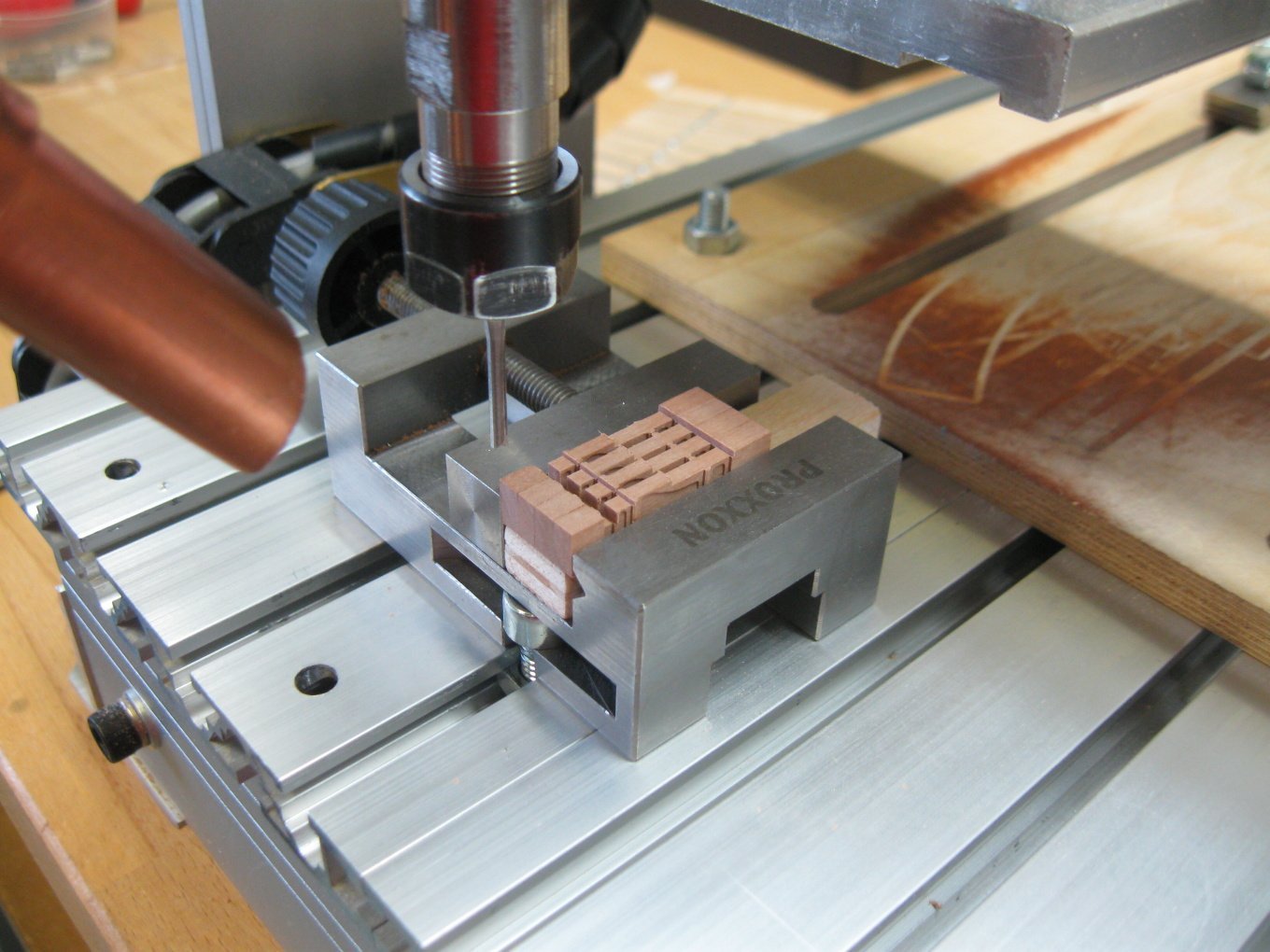

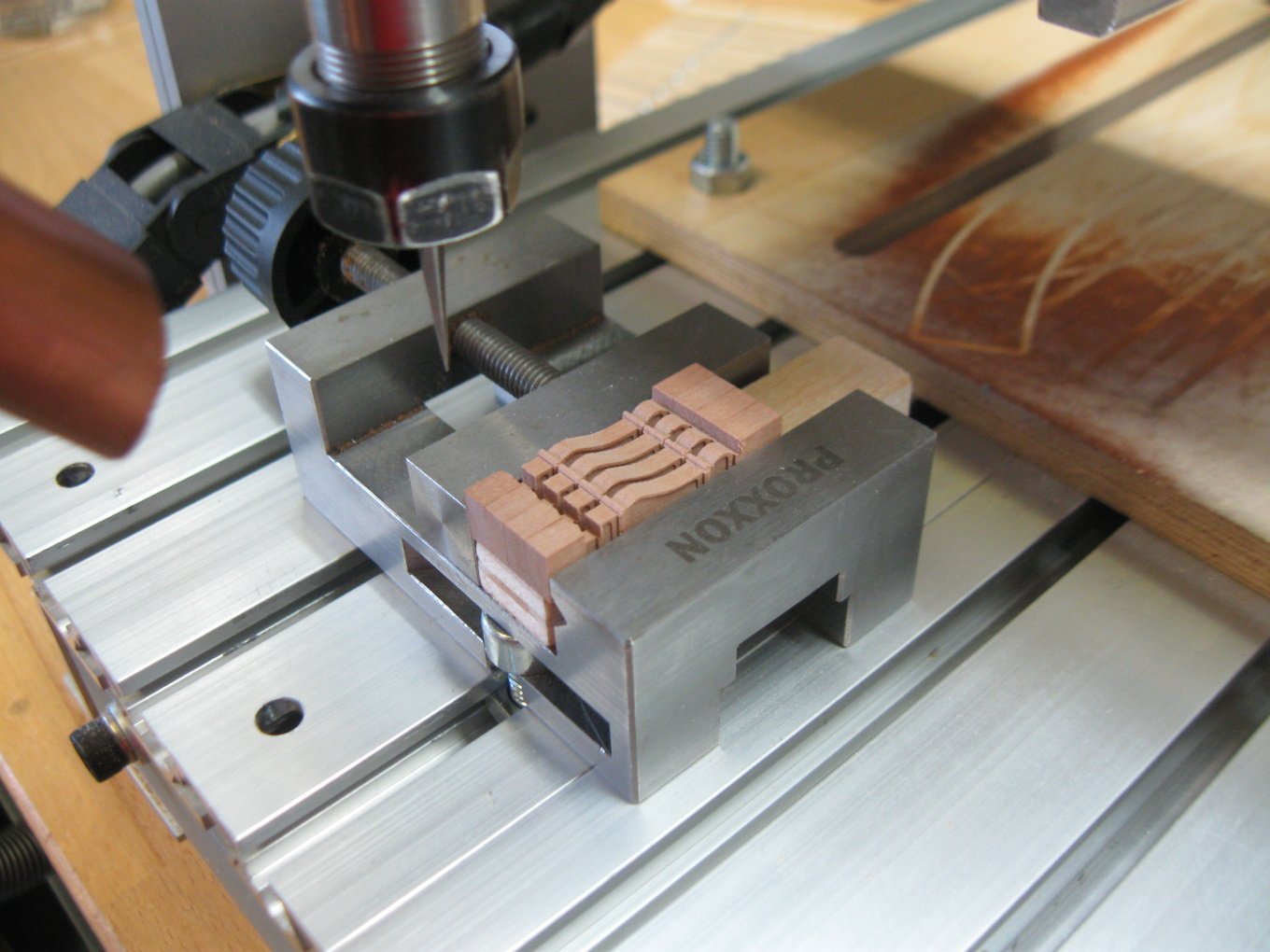

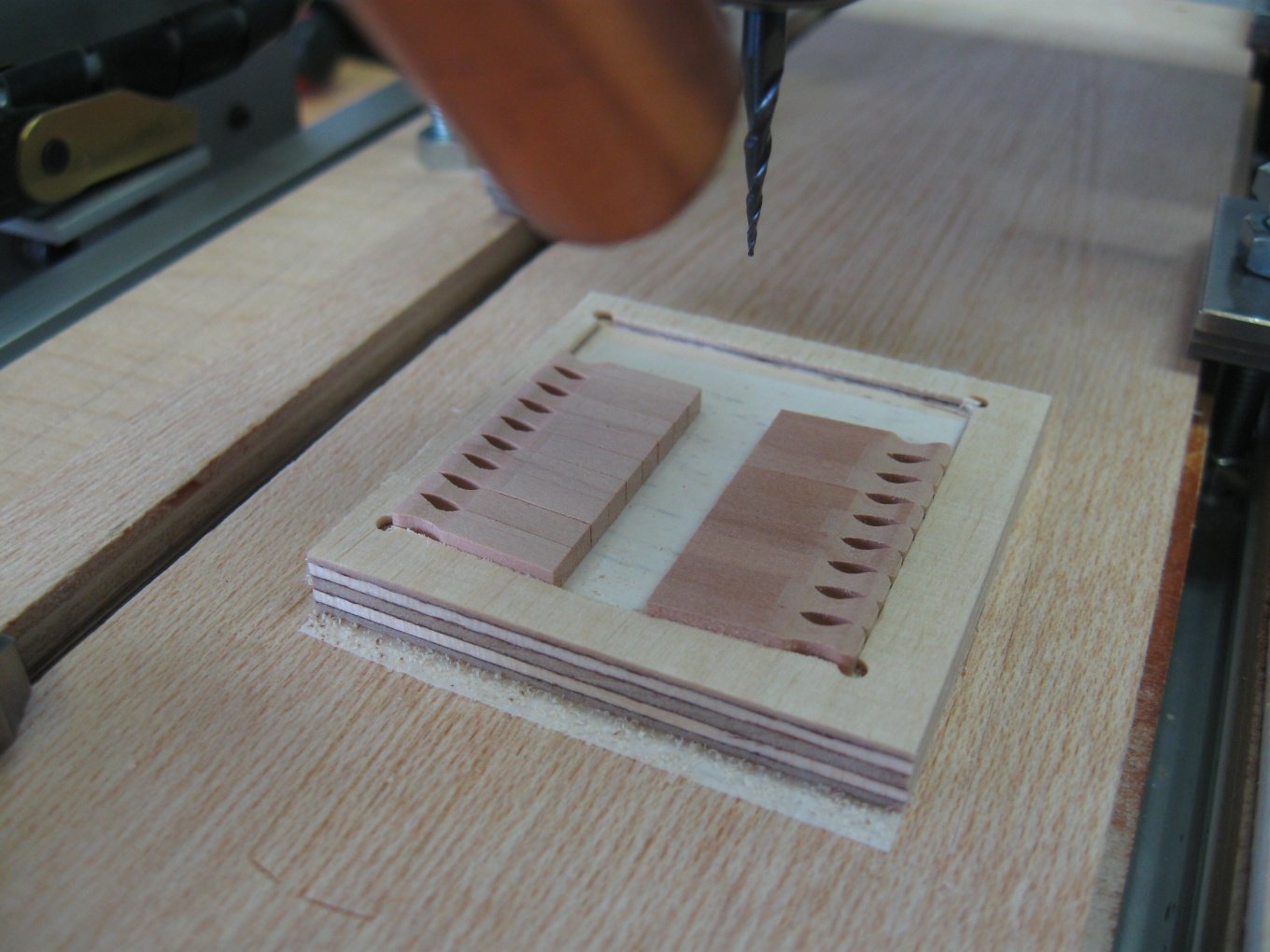

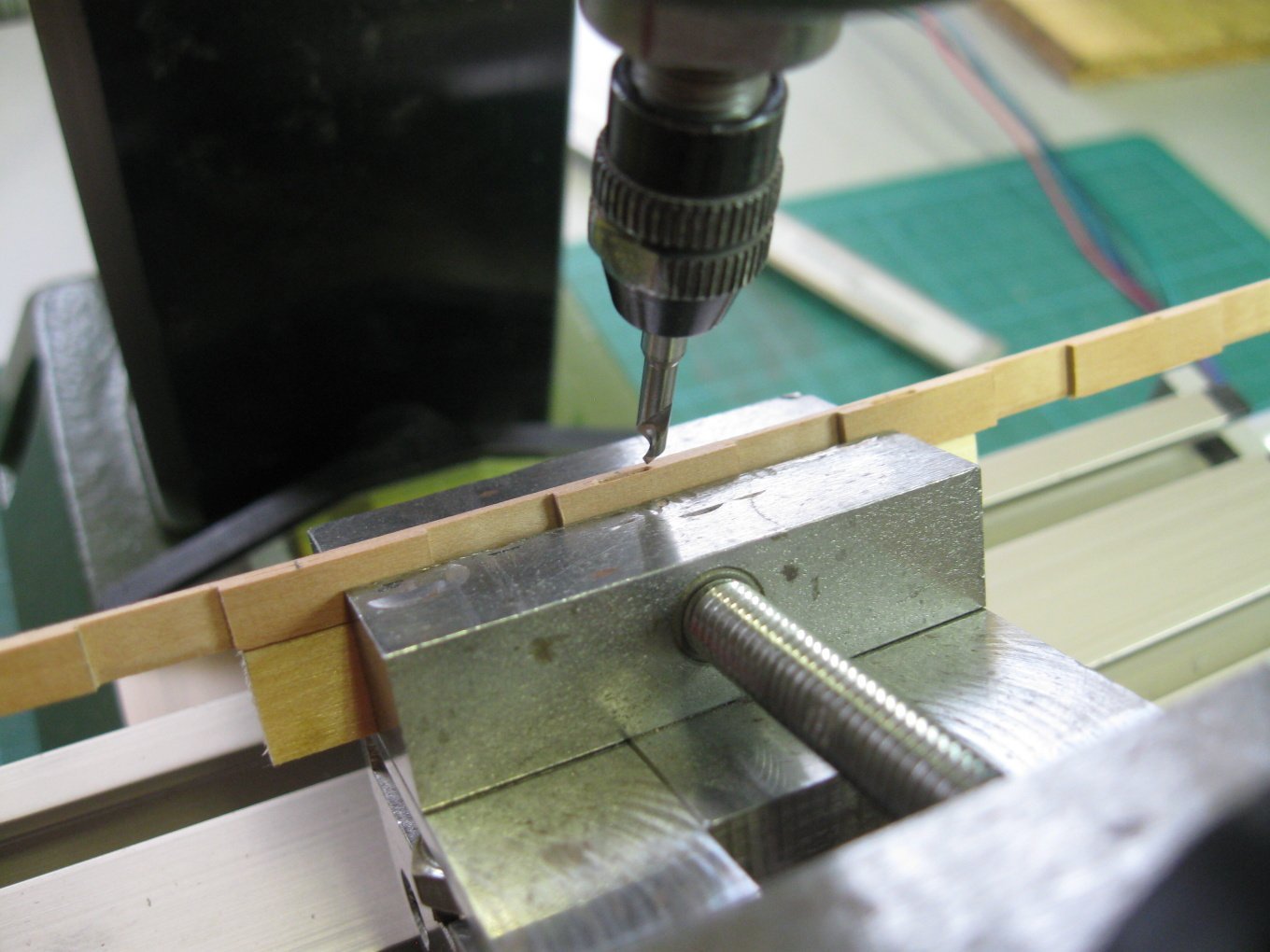

To druxey: I'm almost ashamed to say this, but the elliptical frame is made with a CNC milling machine.

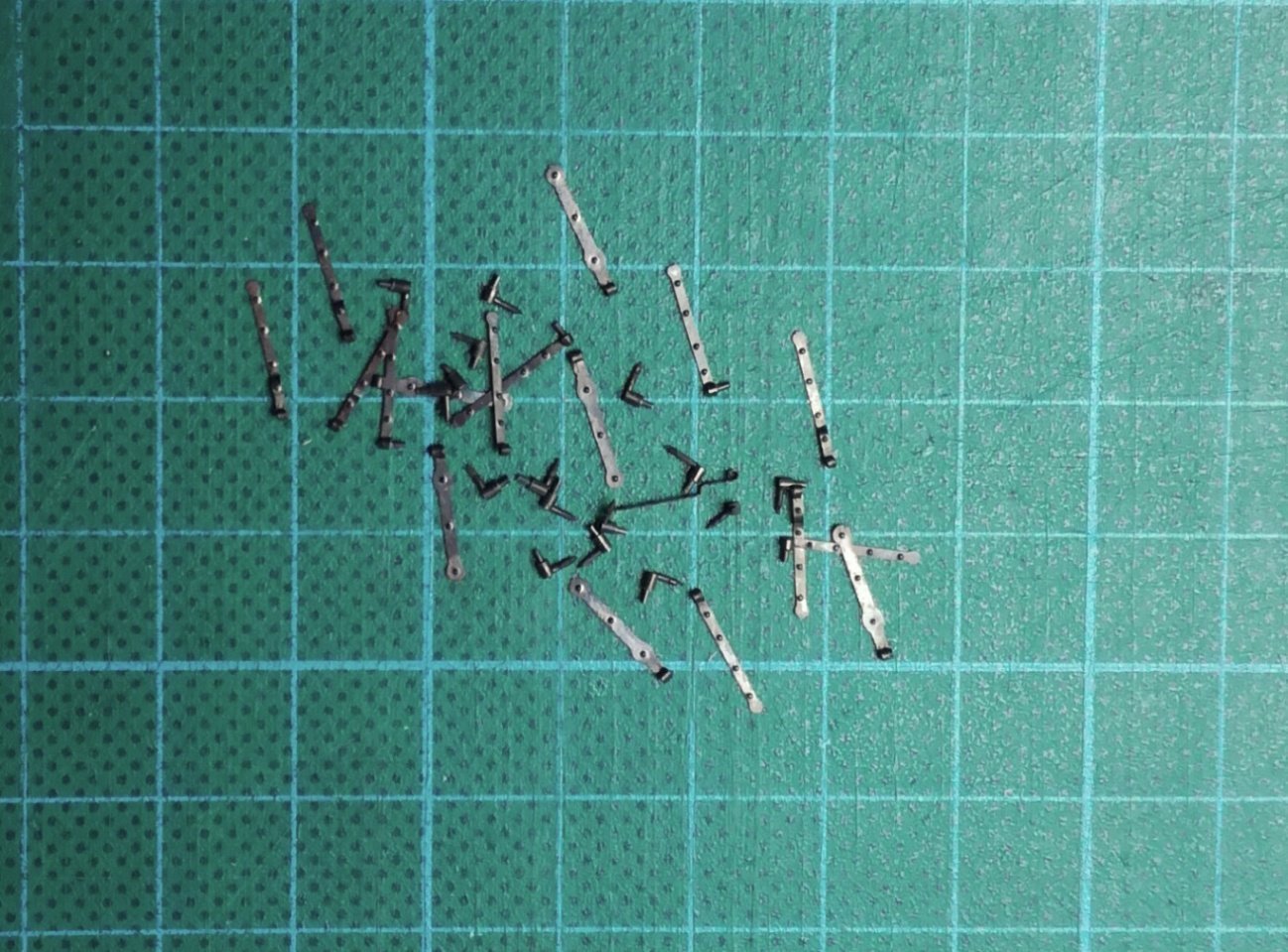

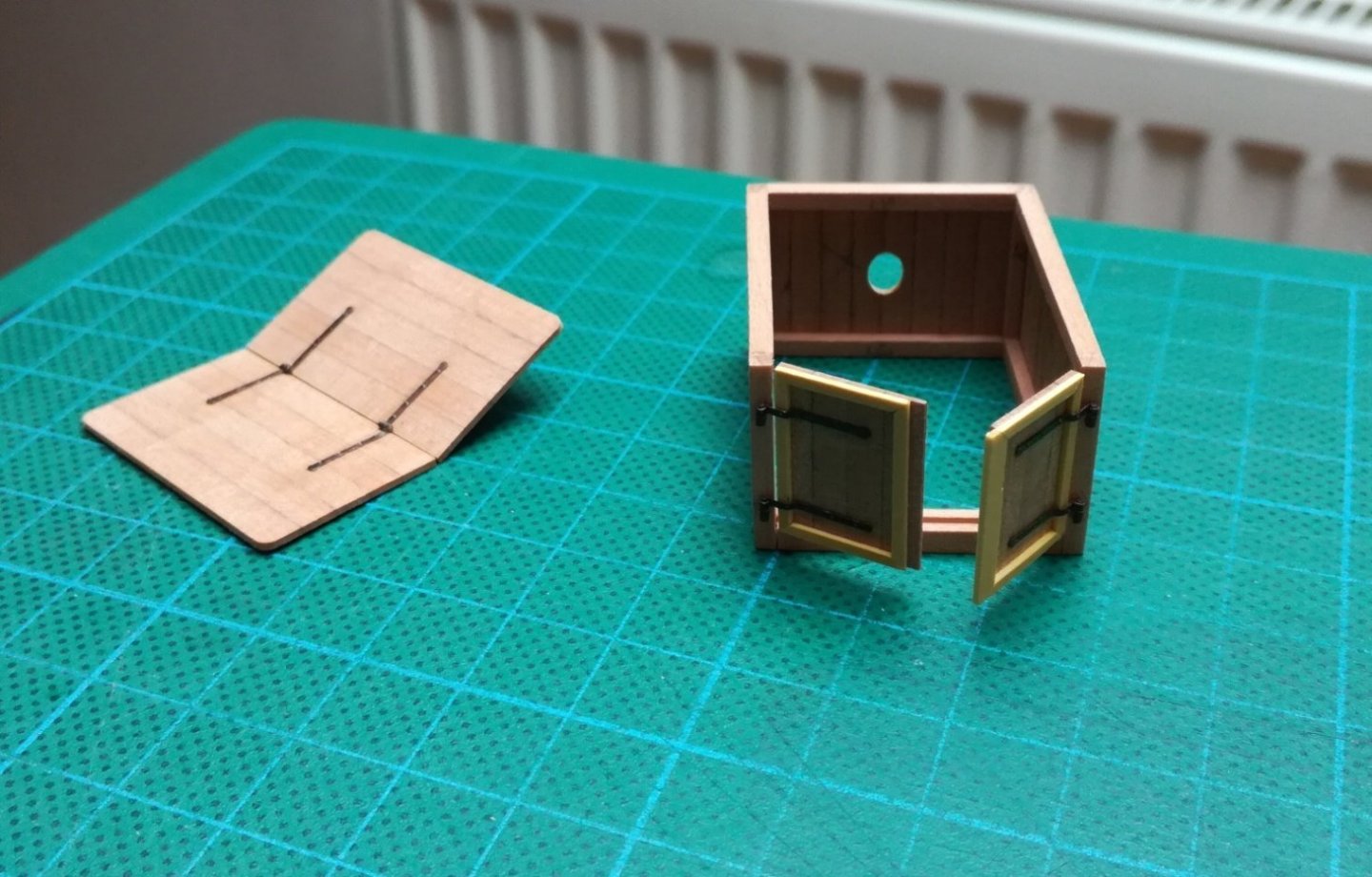

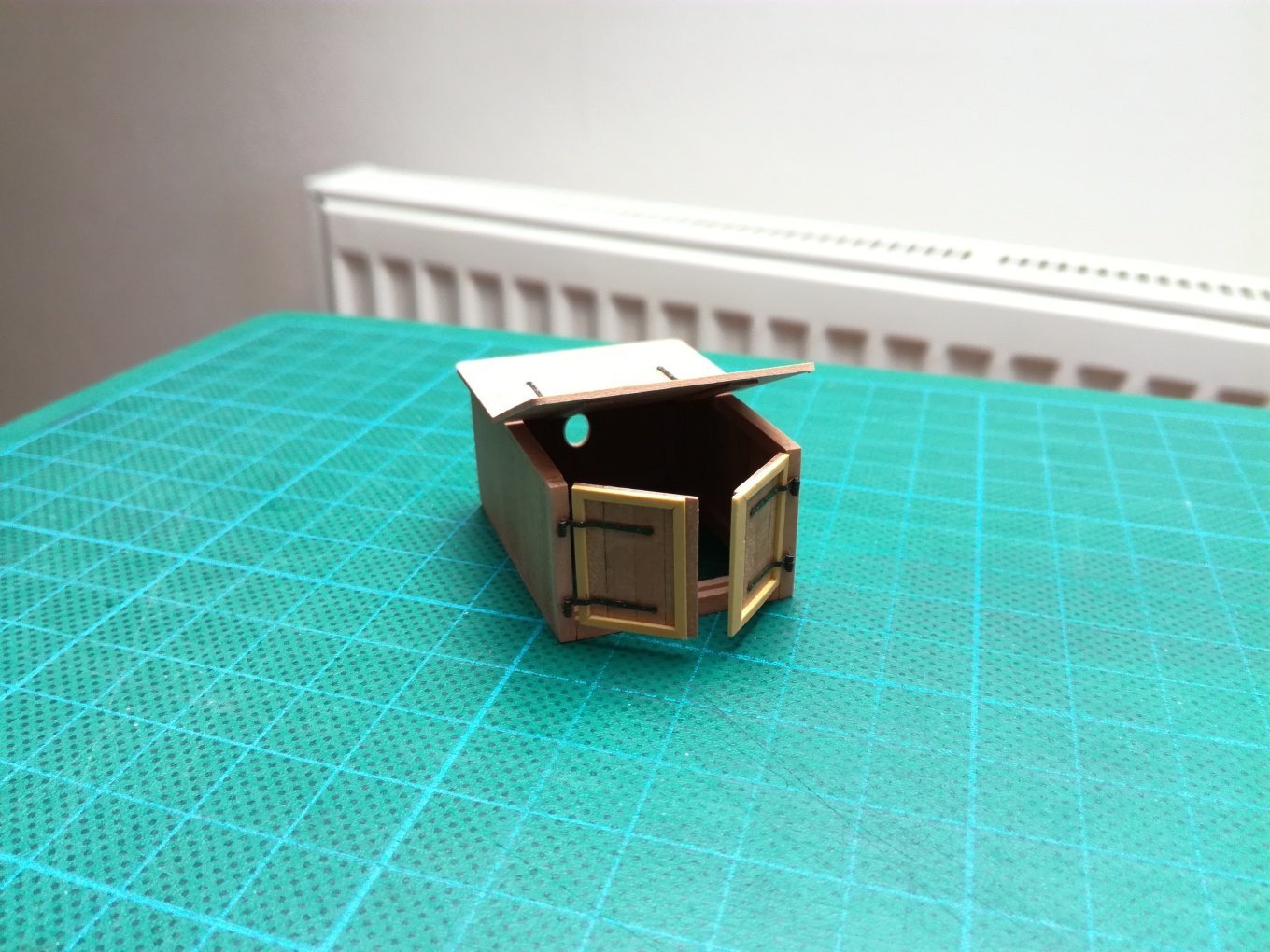

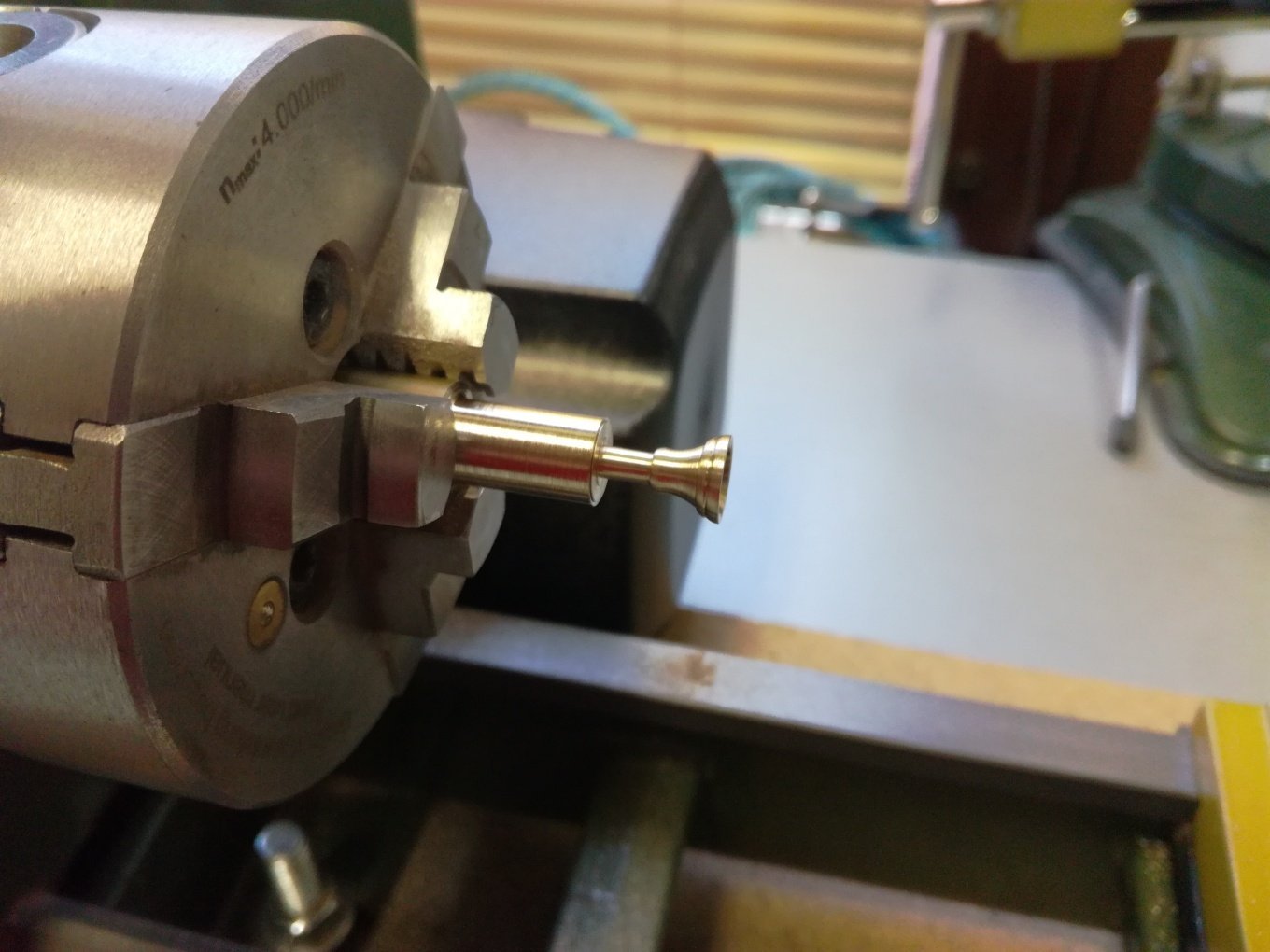

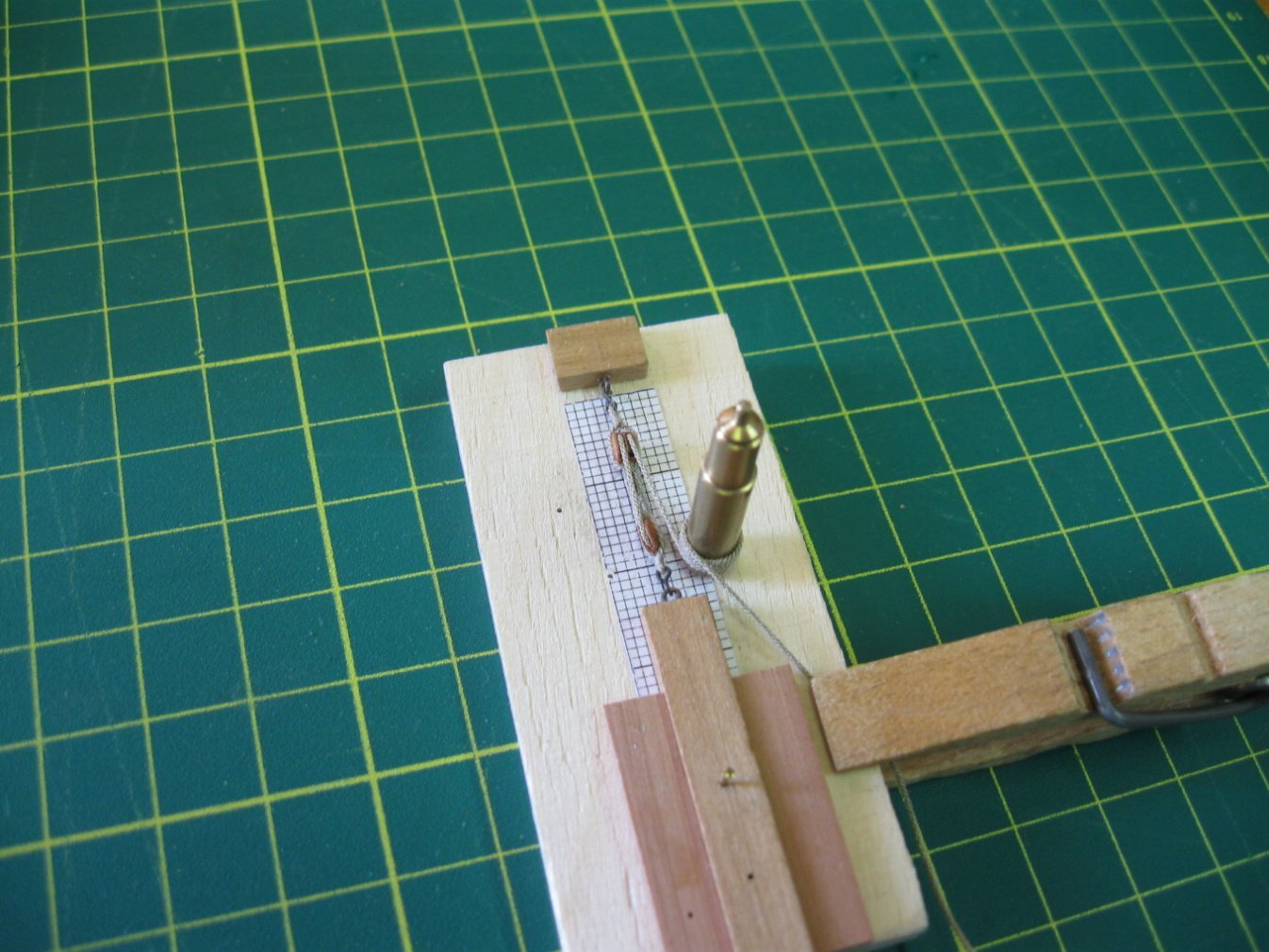

To Dowmer: Hinges are made of a brass tube 1.0 / 0.2 (ie. the inner diameter is 0.6 mm). A groove with a length of approx. 0.6 mm is milled into this tube with a 0.5 mm milling cutter, the tube is then cut to a length of approx. 1.2 mm. The 0.5 mm brass nail (0.5 mm brass wire can also be used) is bent at a right angle and the nail is inserted into the tube so that it fits into the notch. This assembly is soldered with silver solder.

-

-

-

-

-

-

-

- Peta_V, oneslim, FriedClams and 23 others

-

26

26

-

-

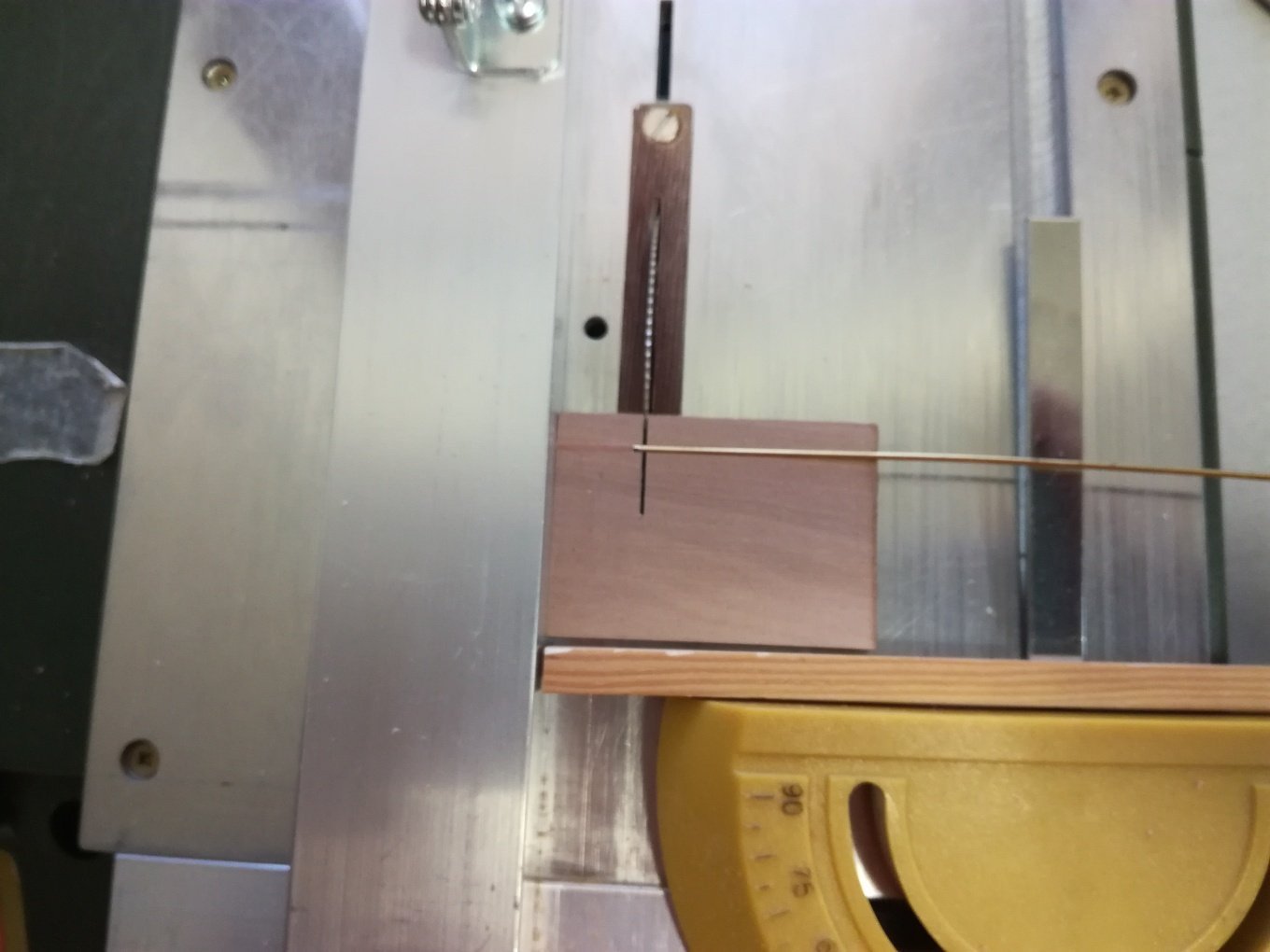

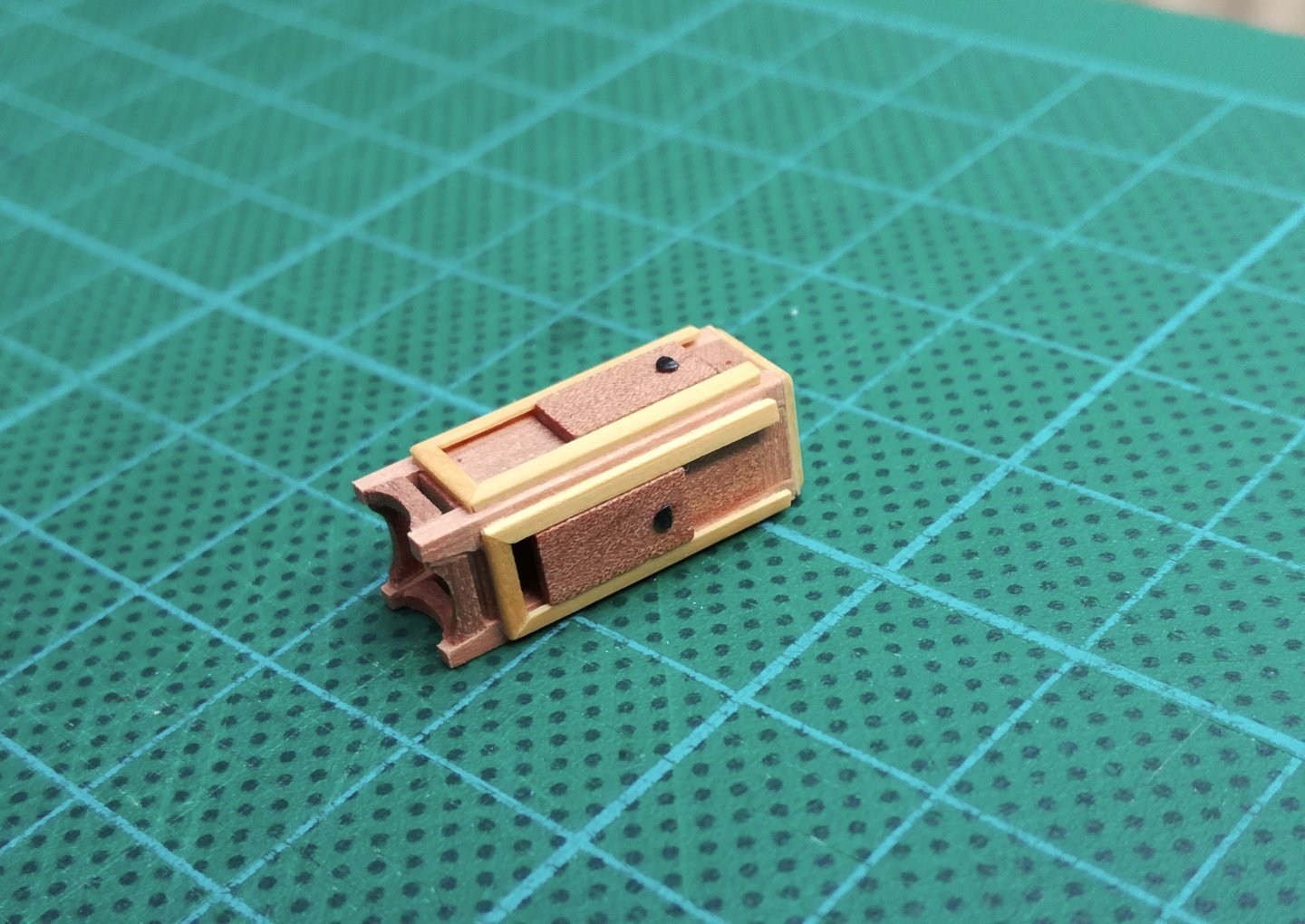

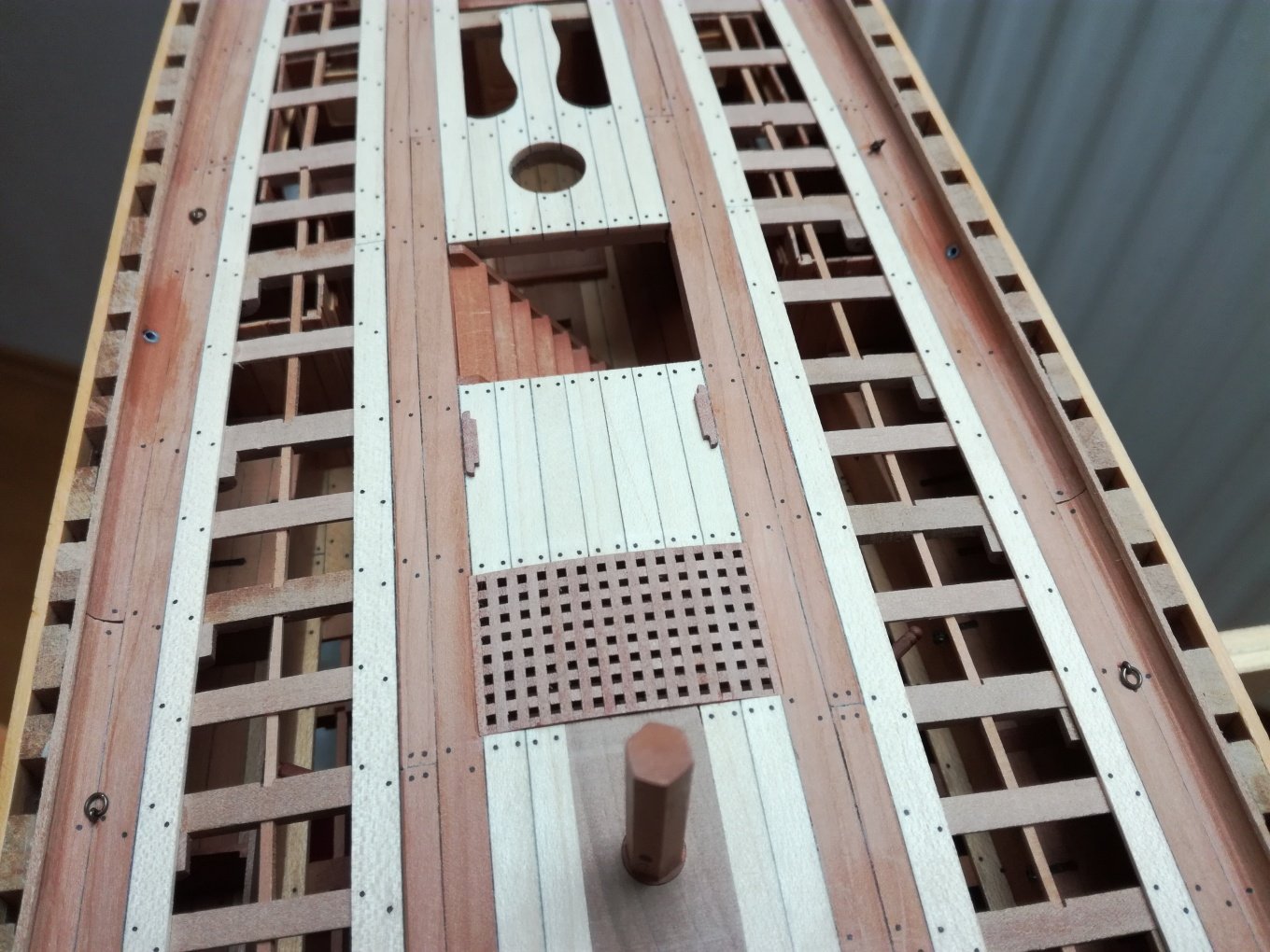

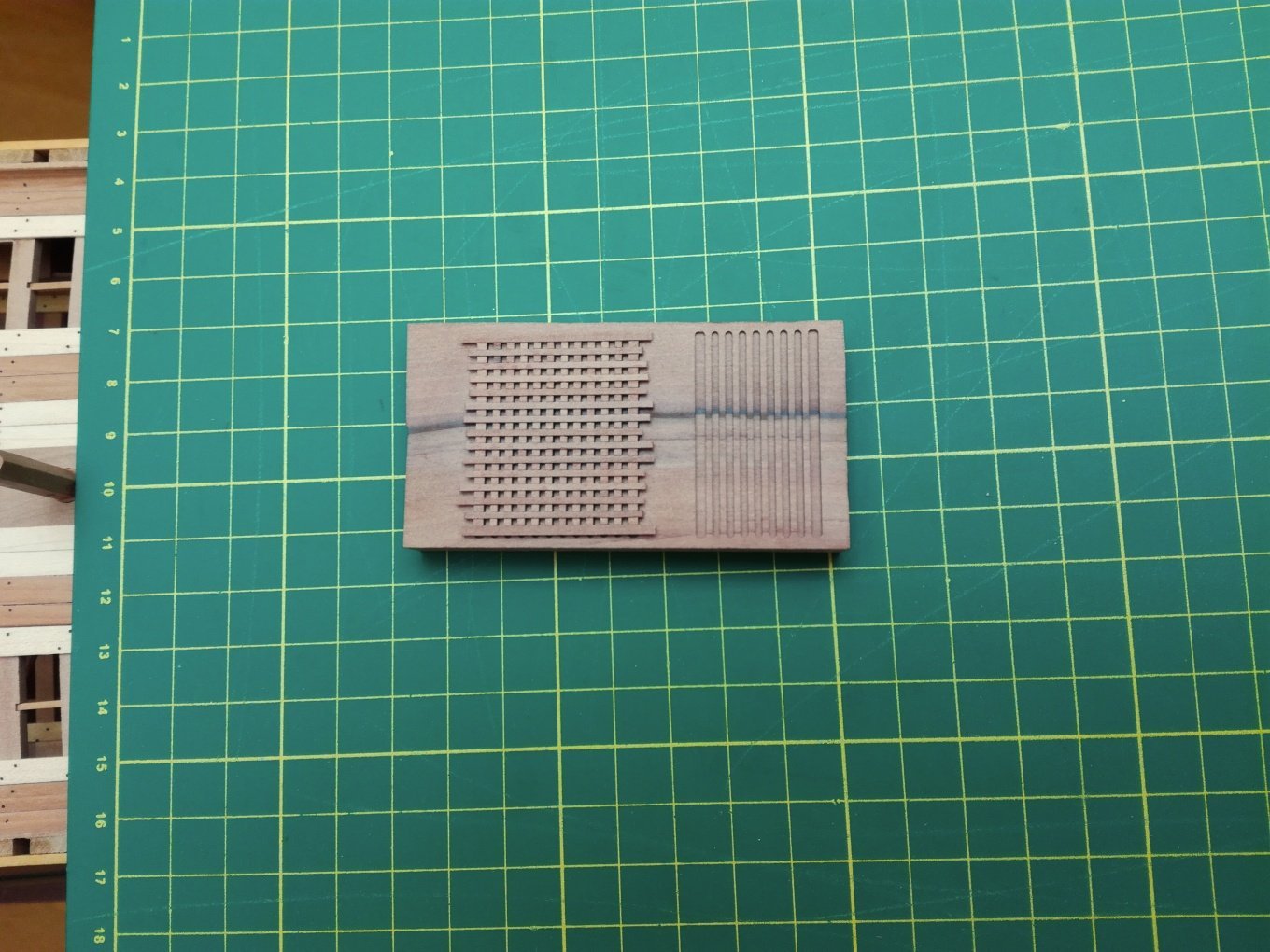

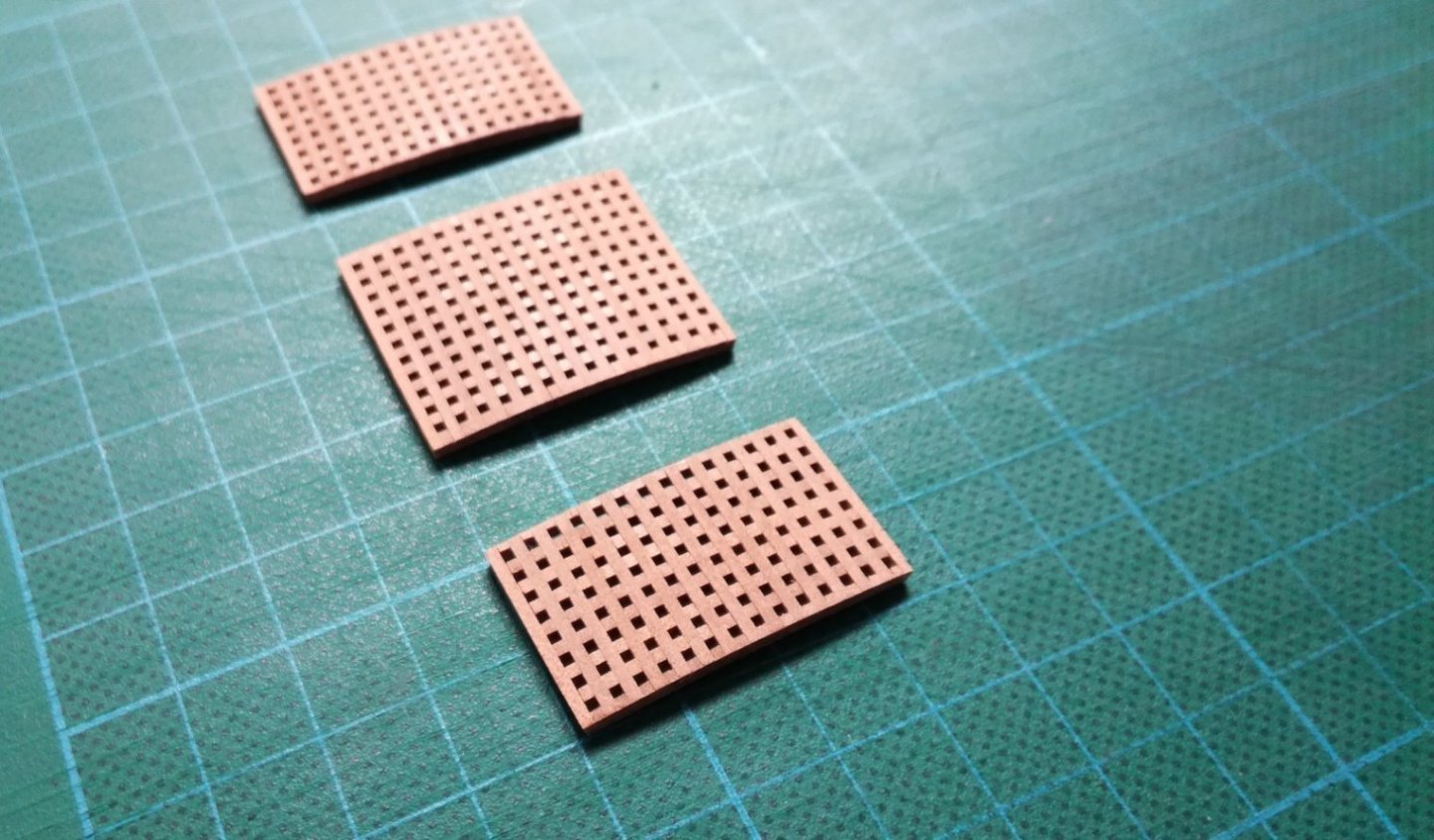

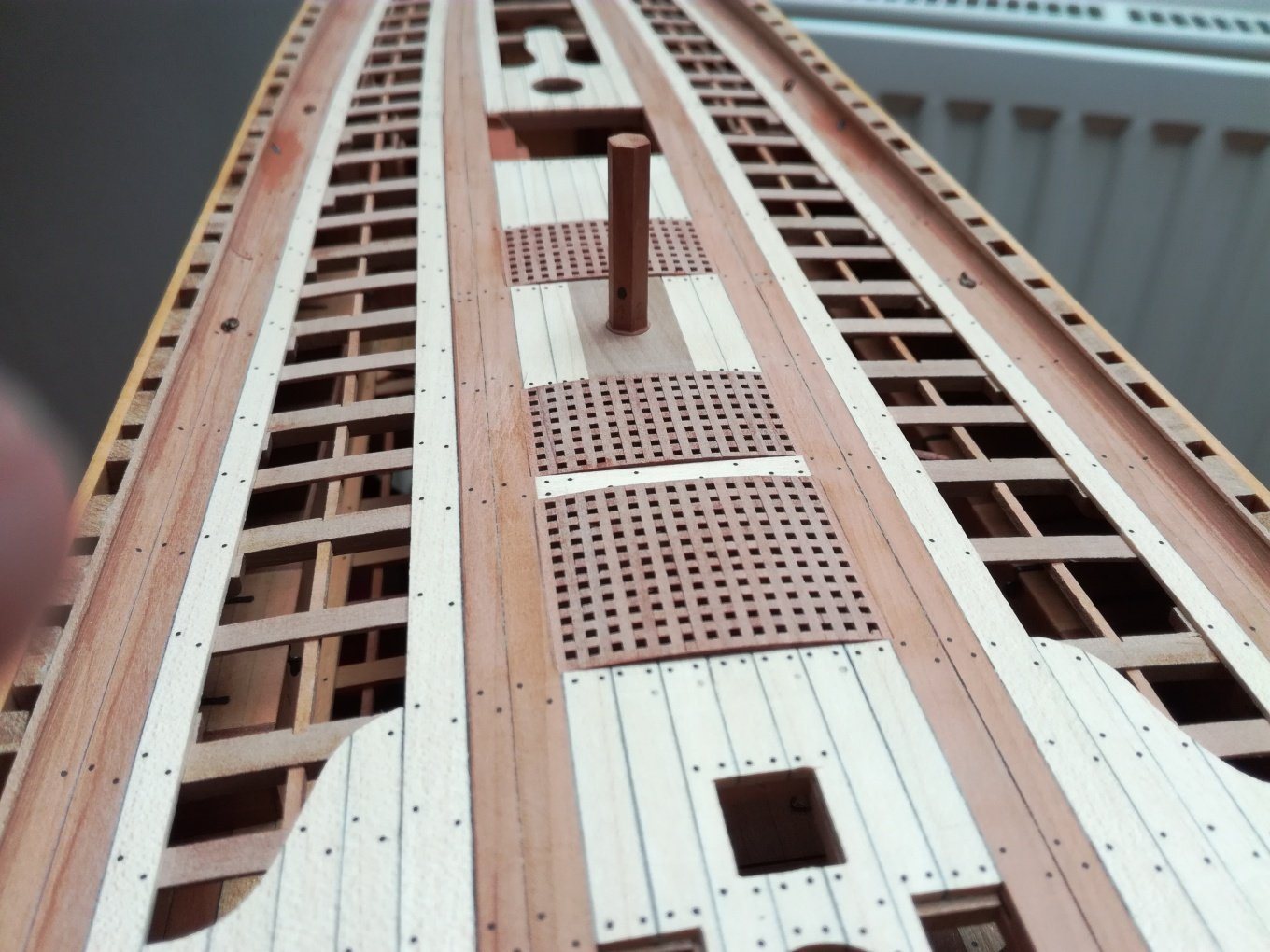

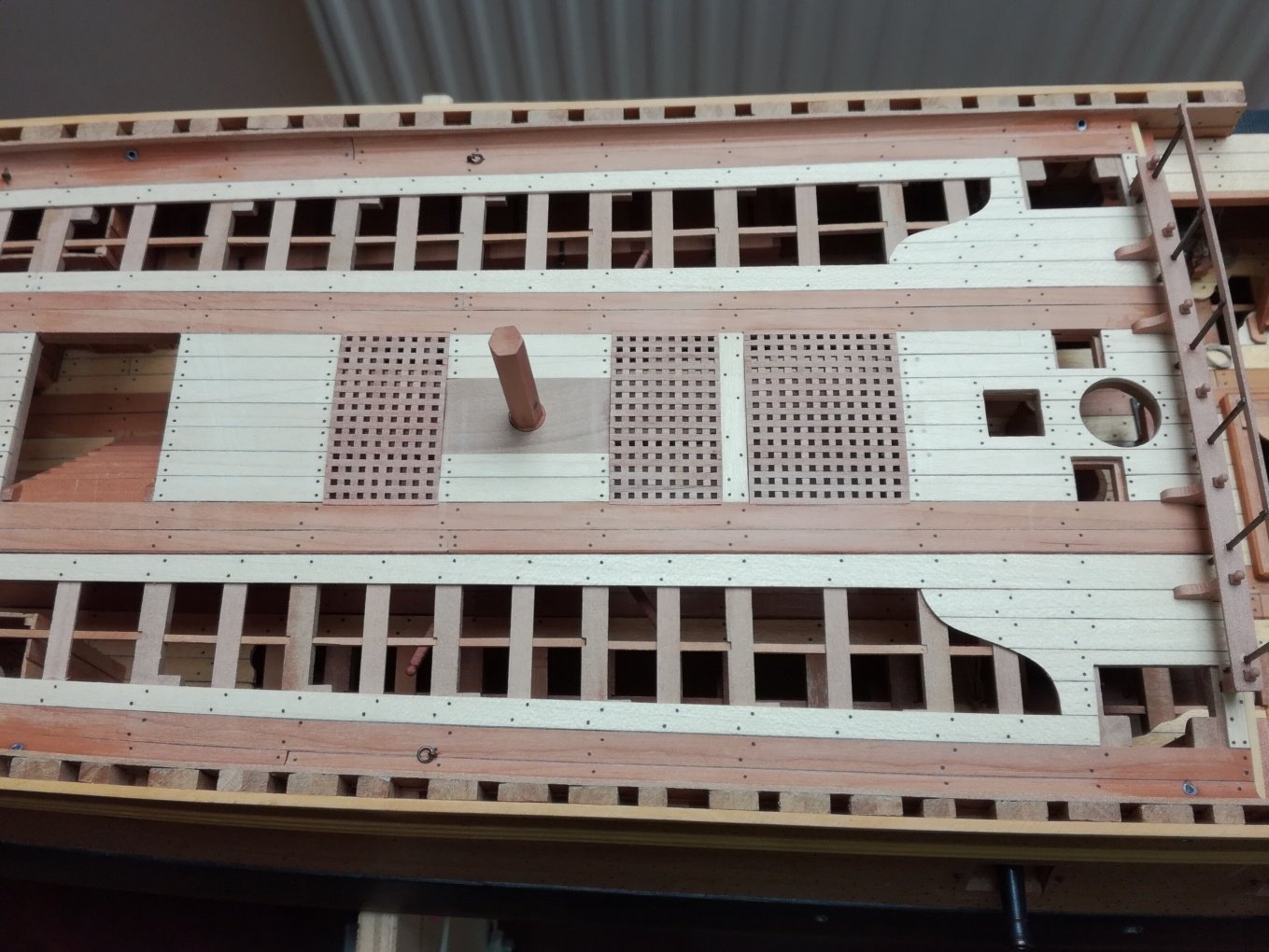

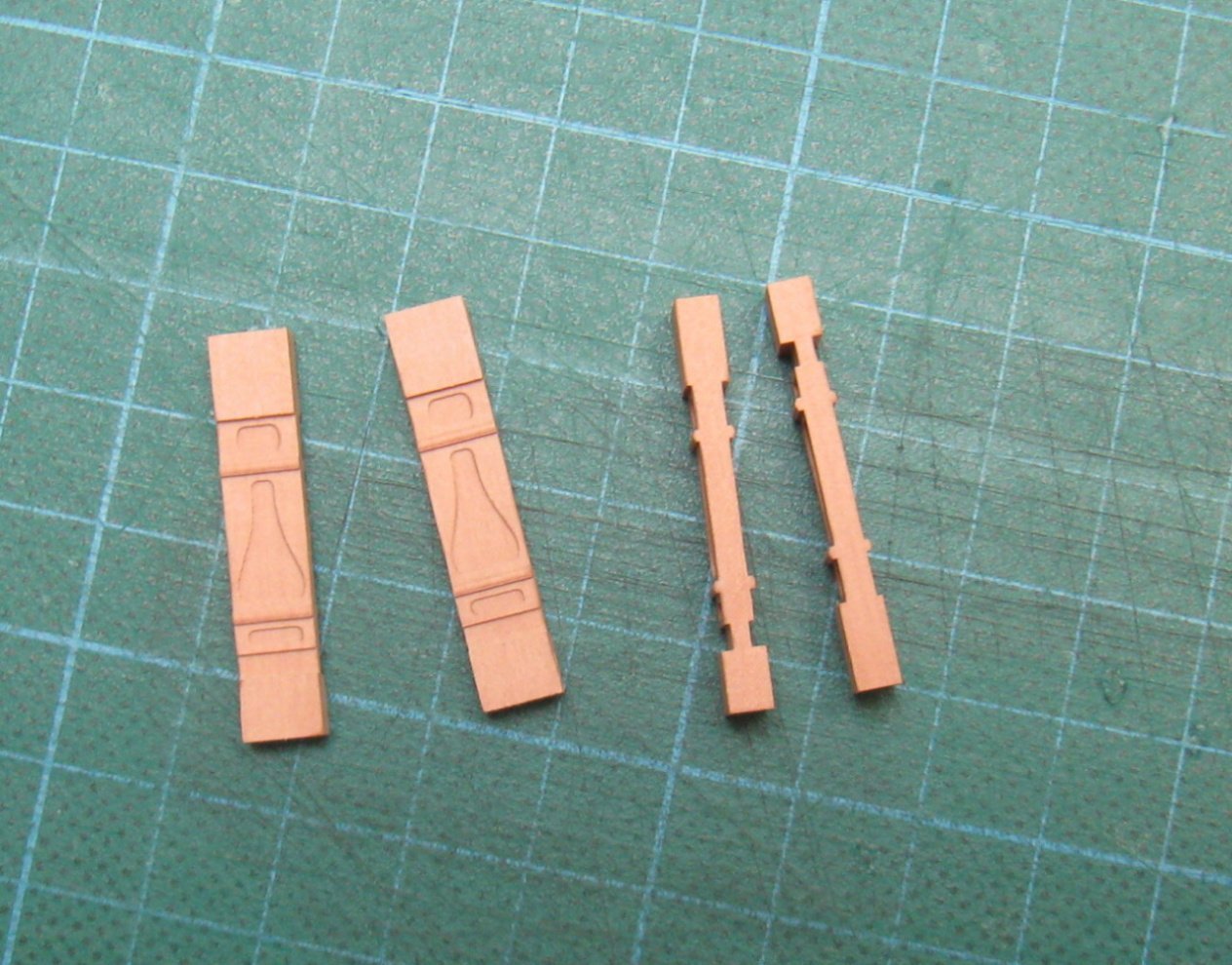

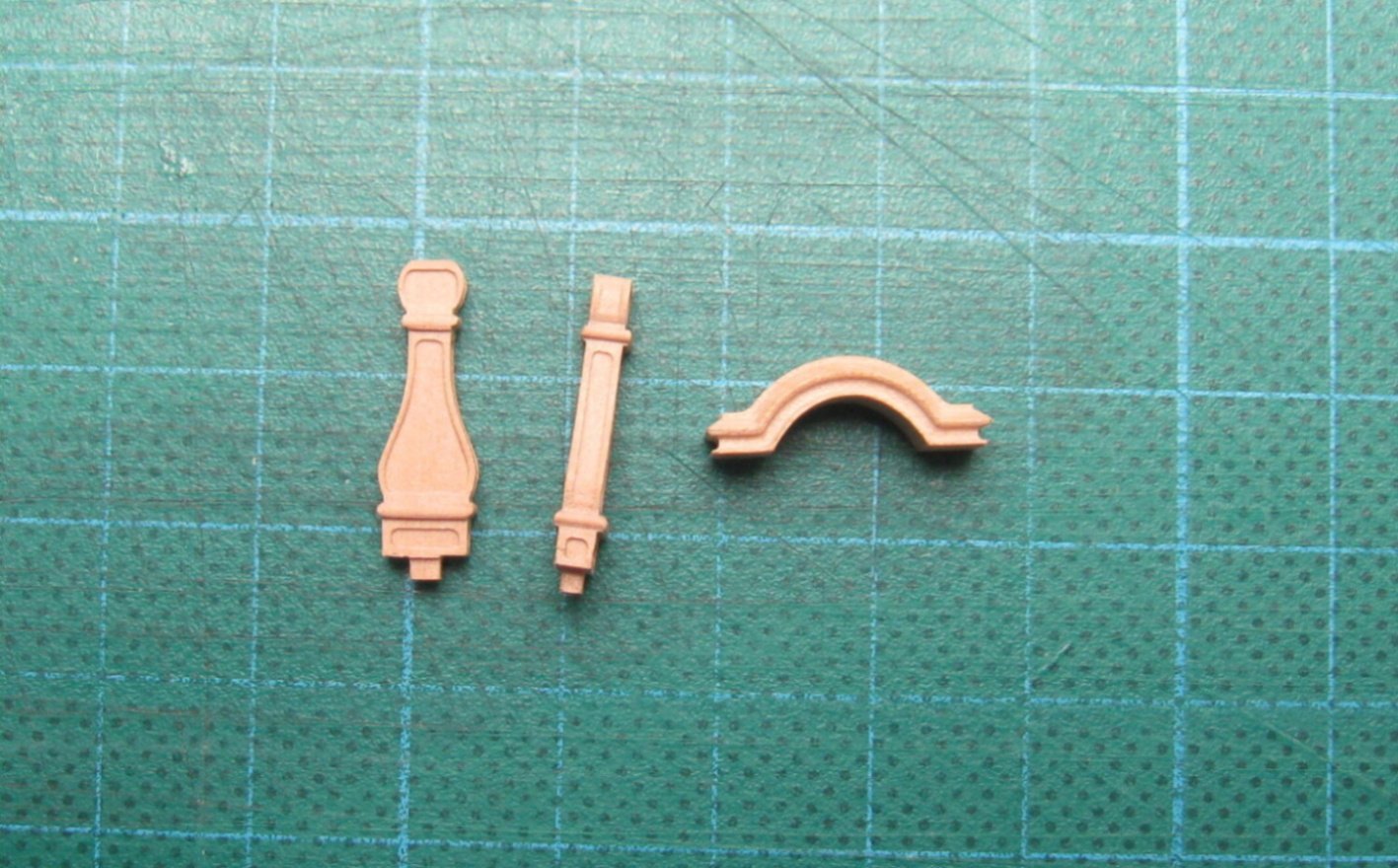

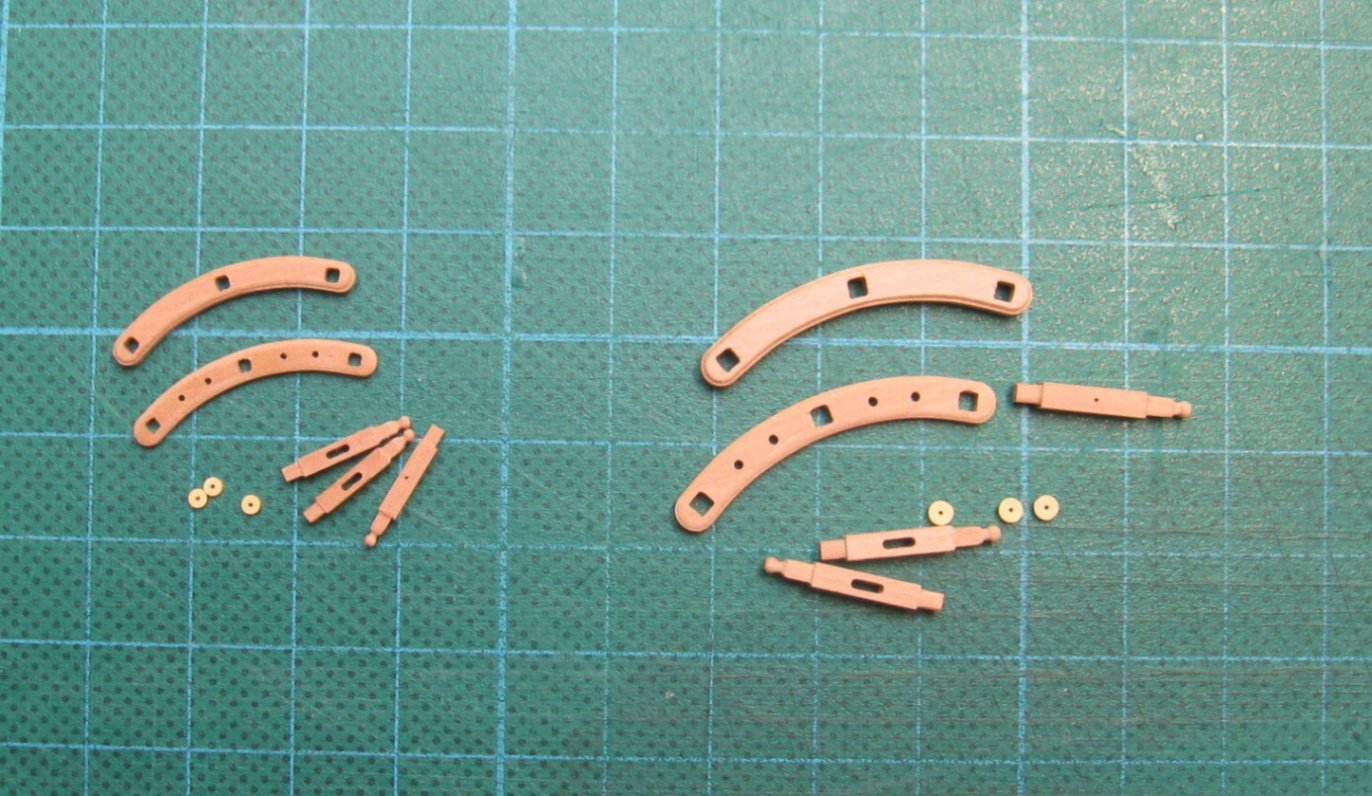

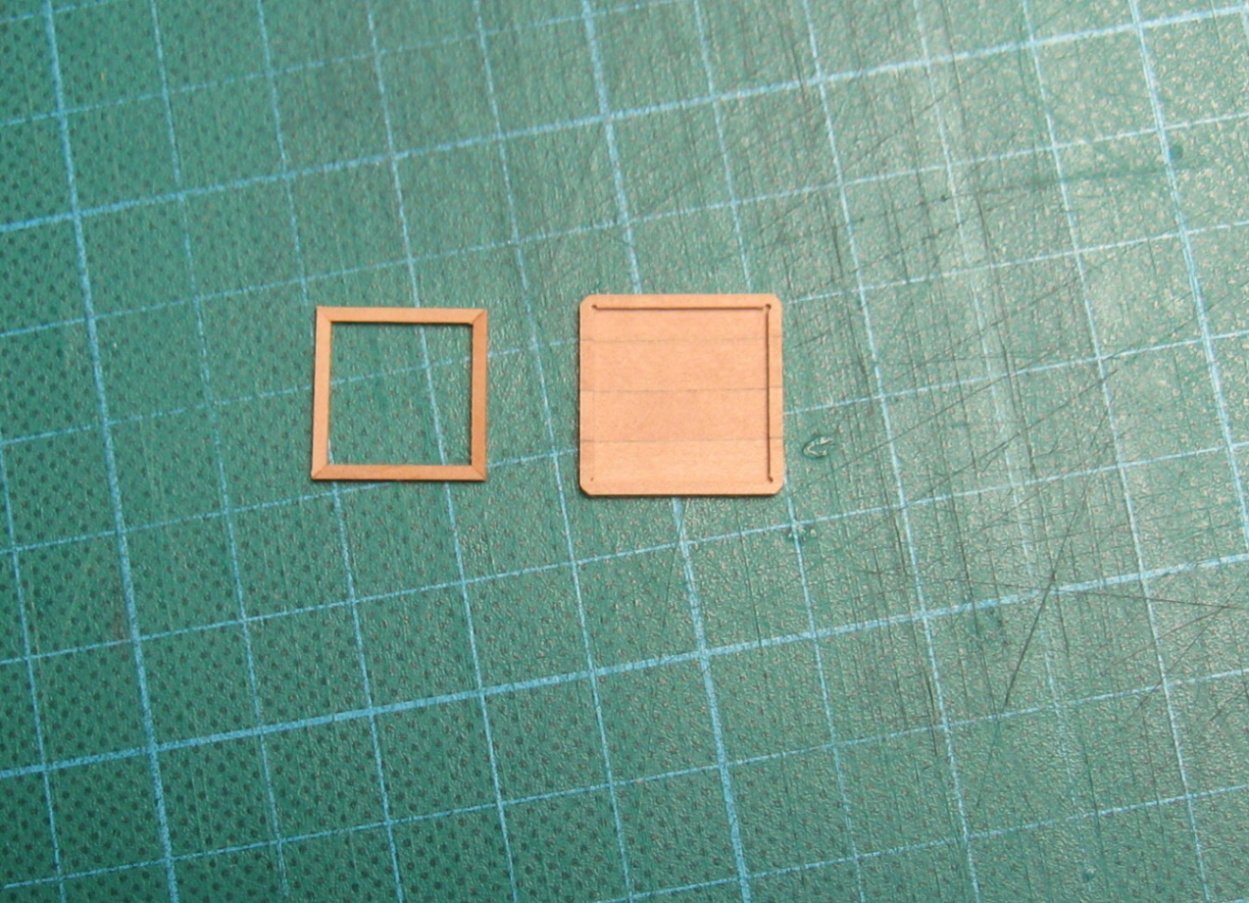

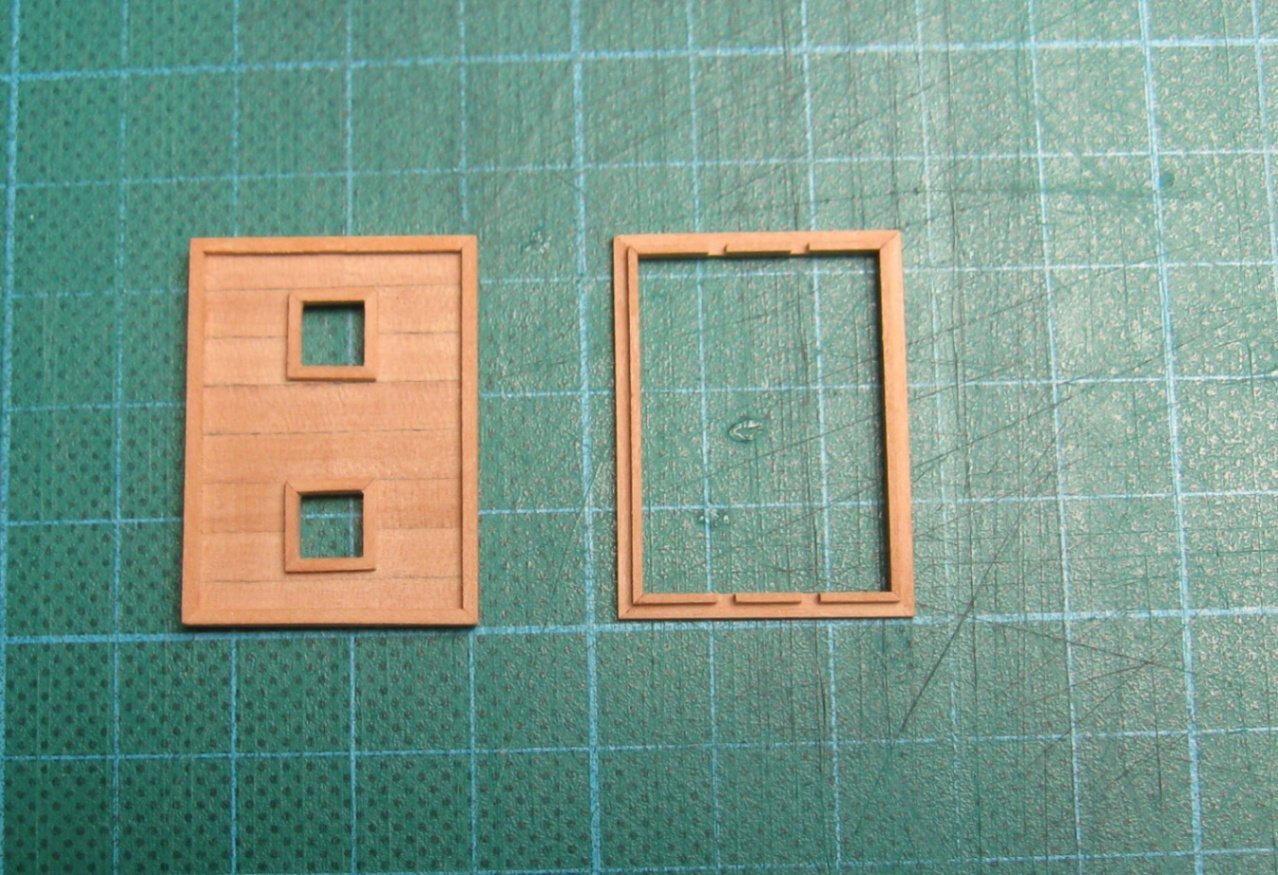

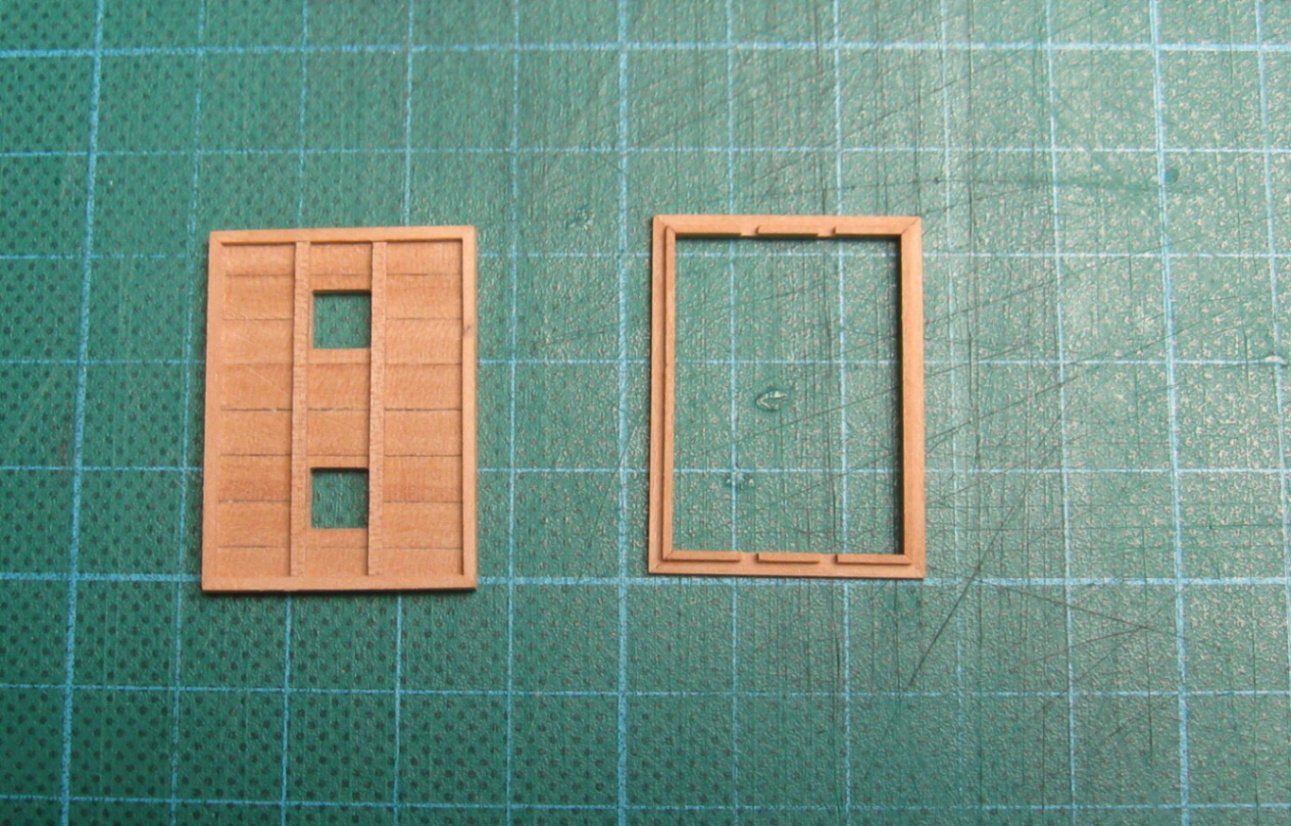

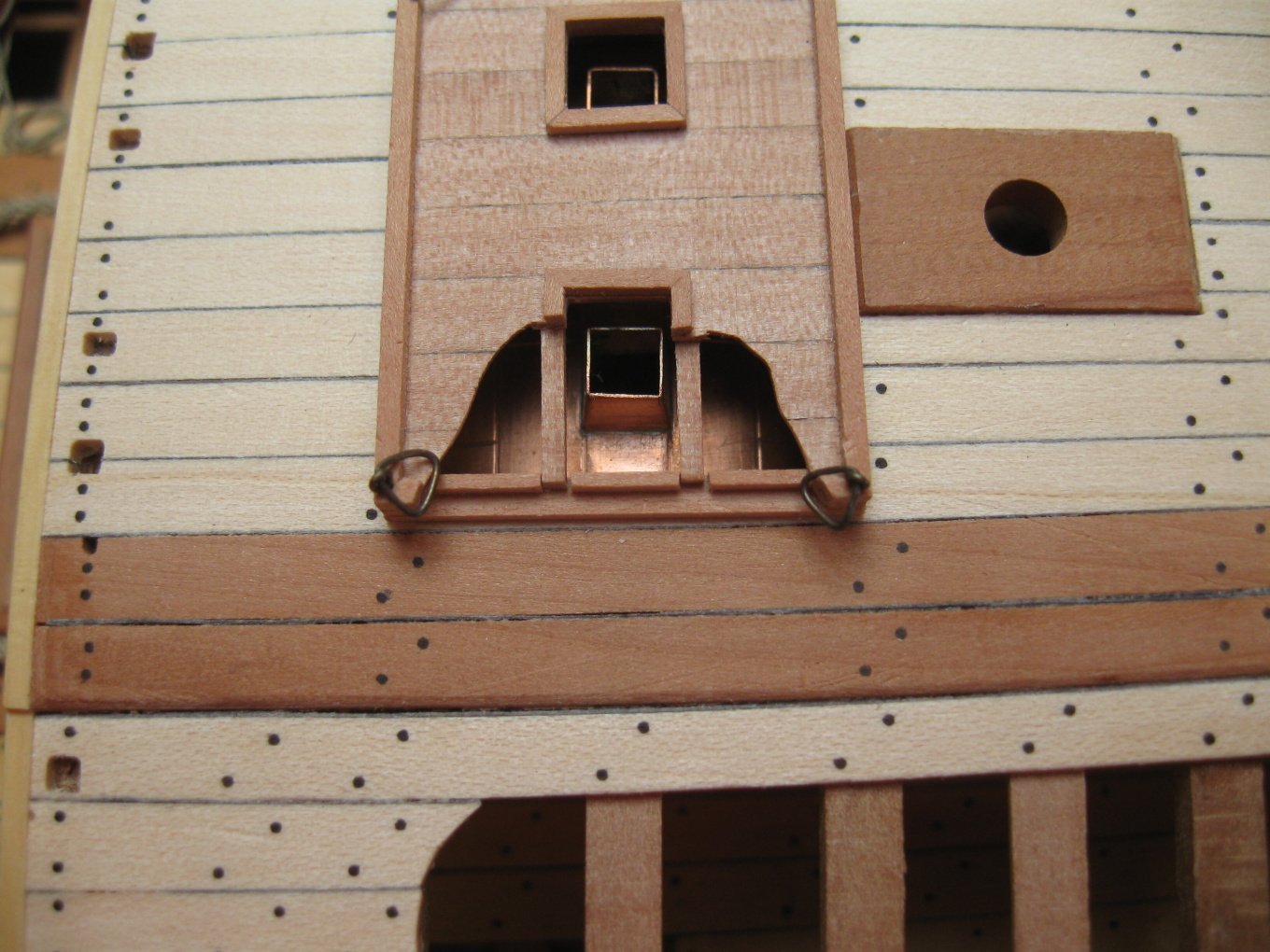

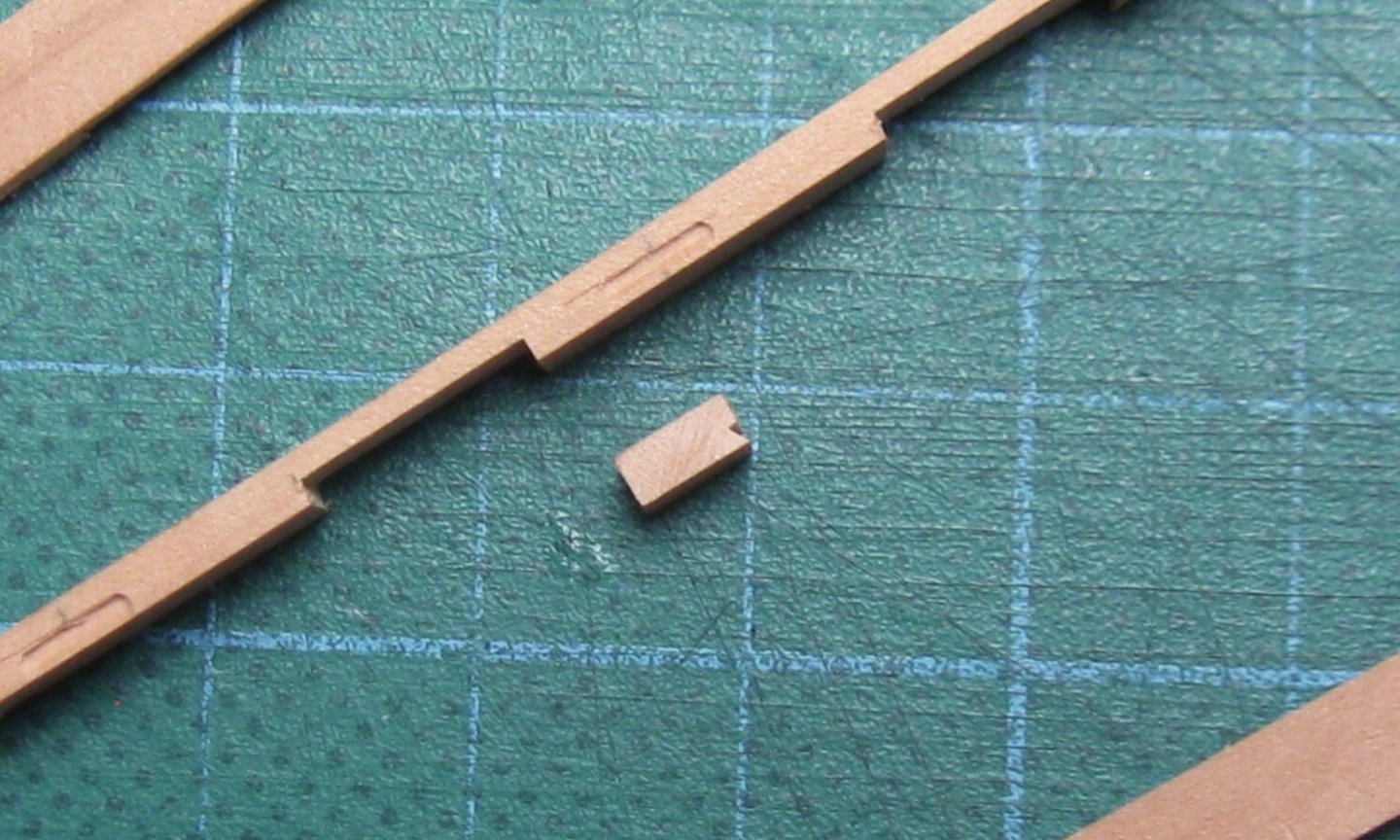

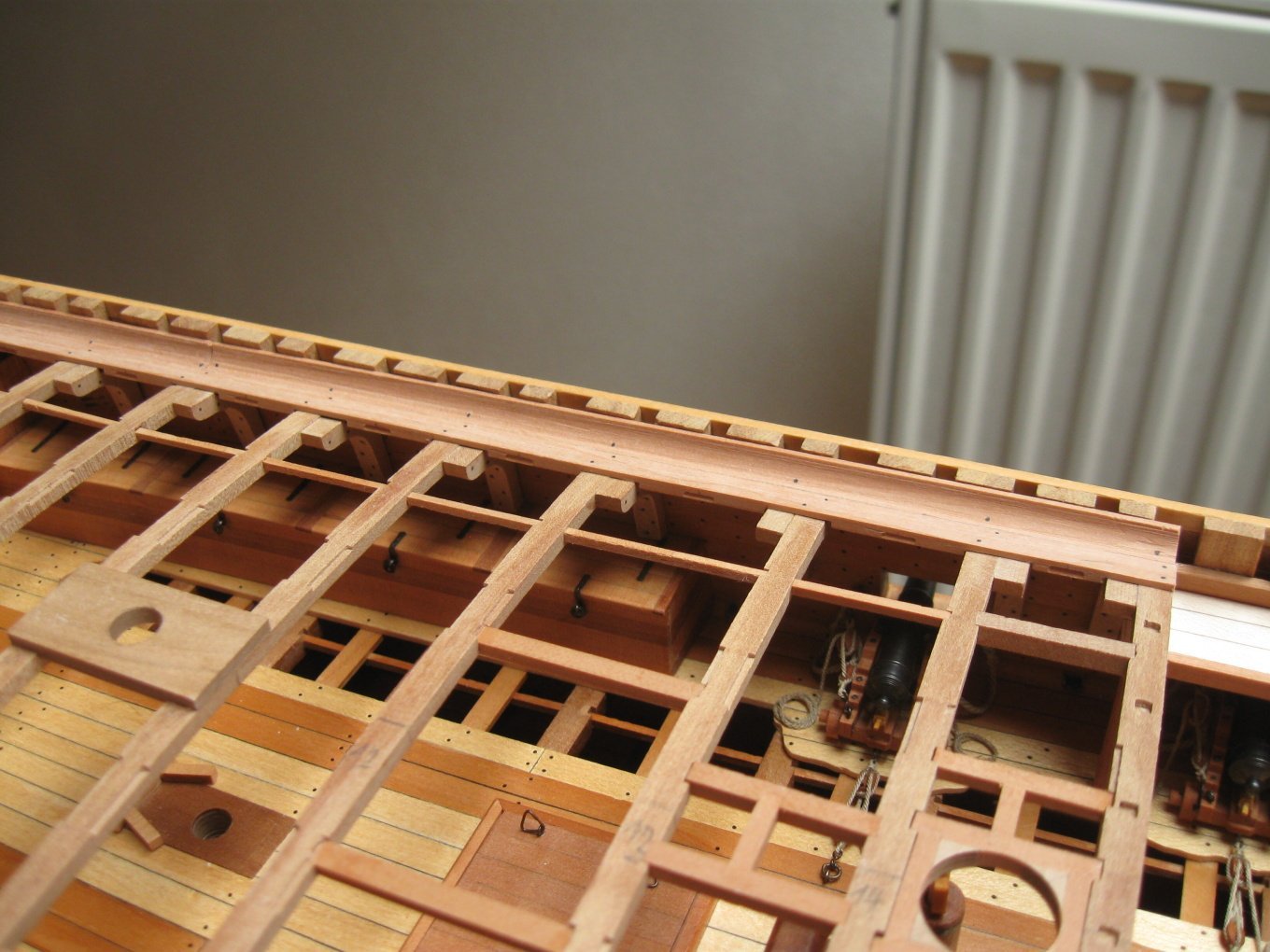

To Hsae: The square holes are made with small diameter milling bit (0,5 mm) and the rest with file.

To popash42: I am using VCarve Desktop software for CNC milling. As regards Laser Engraver, I´m not sure, but the VCarve Desktop is propably not primarily intended for laser. You can find information on the optional laser add-on module on the Vectric website (https://www.vectric.com/products/laser-module).

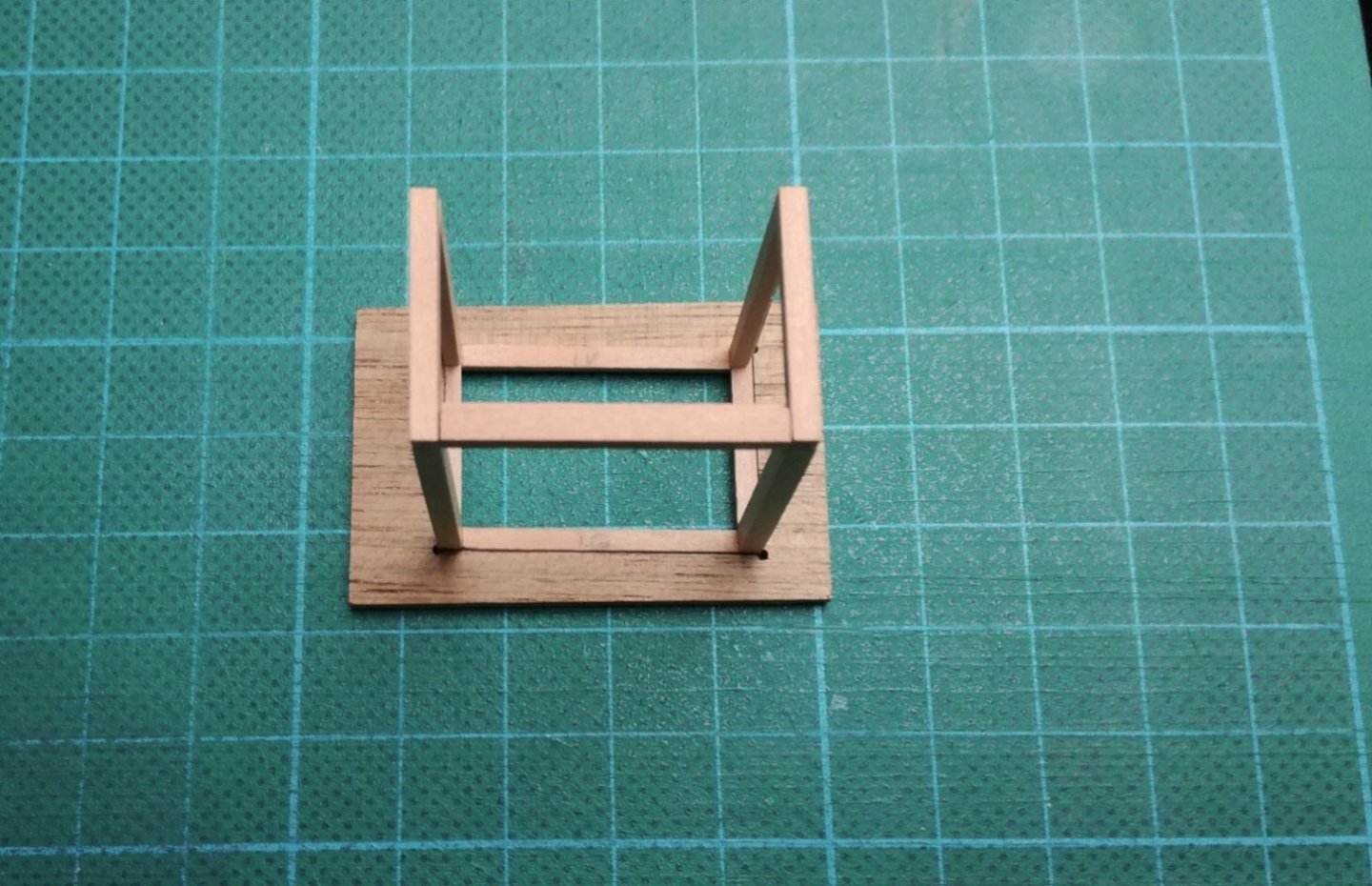

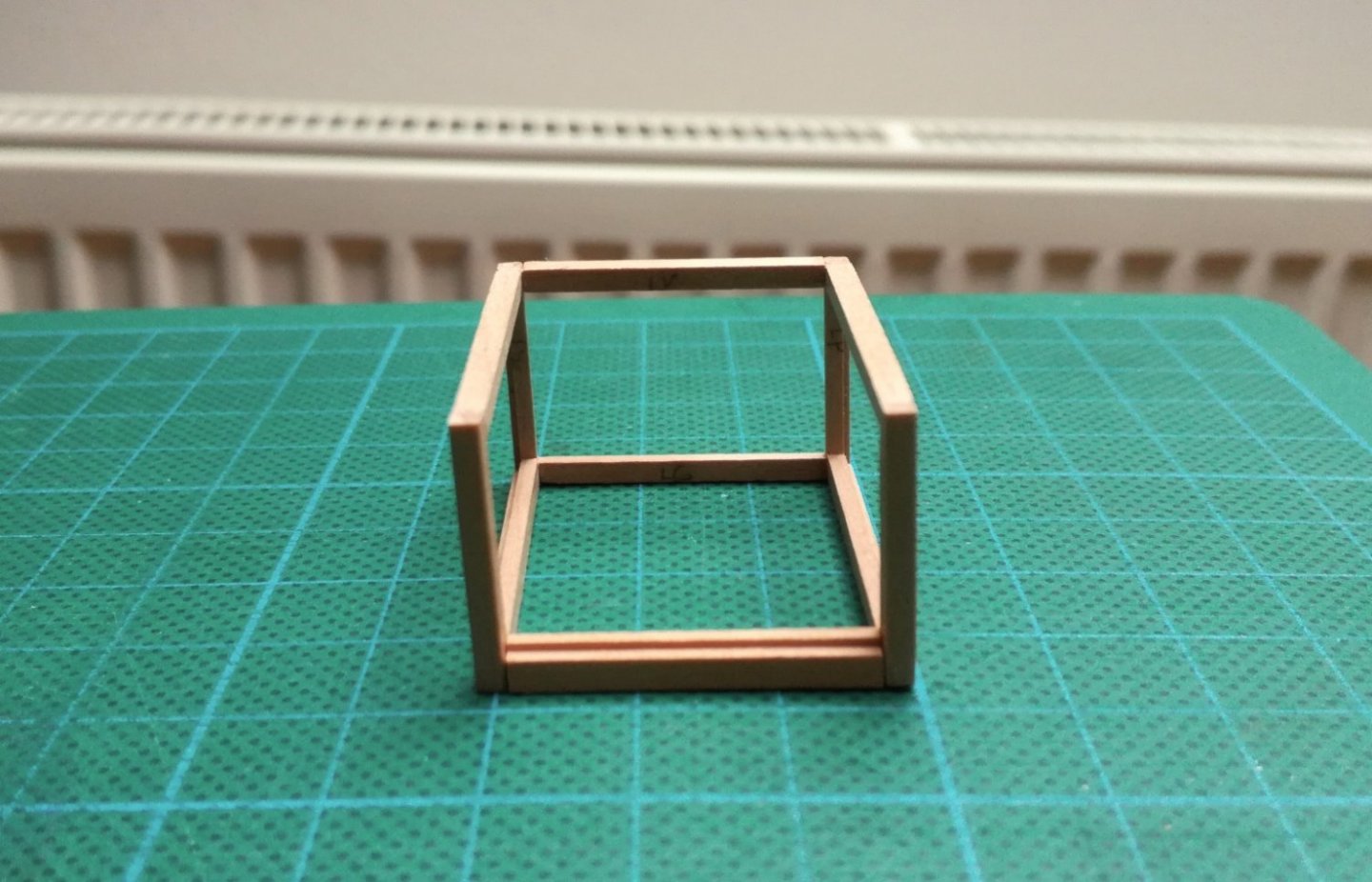

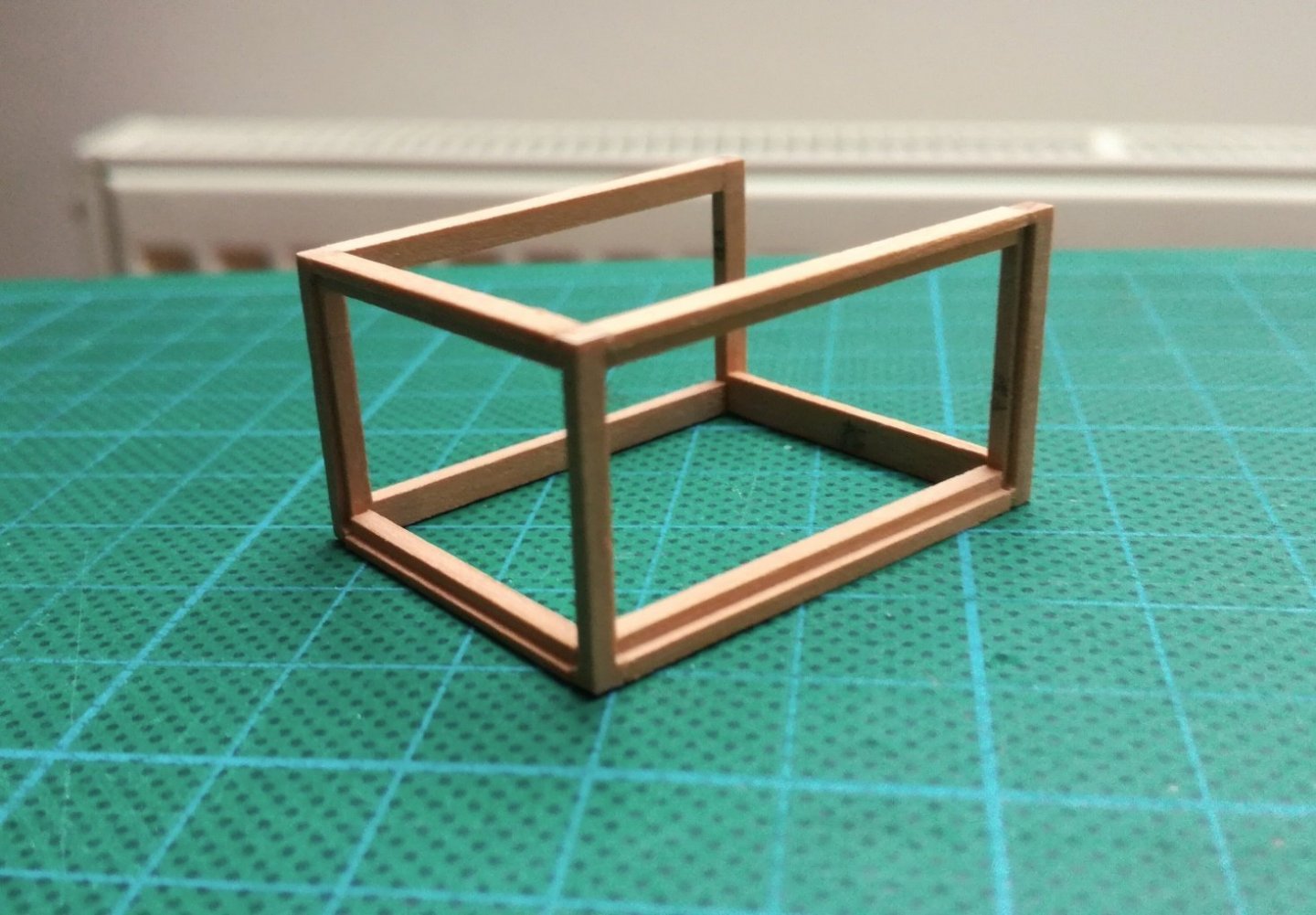

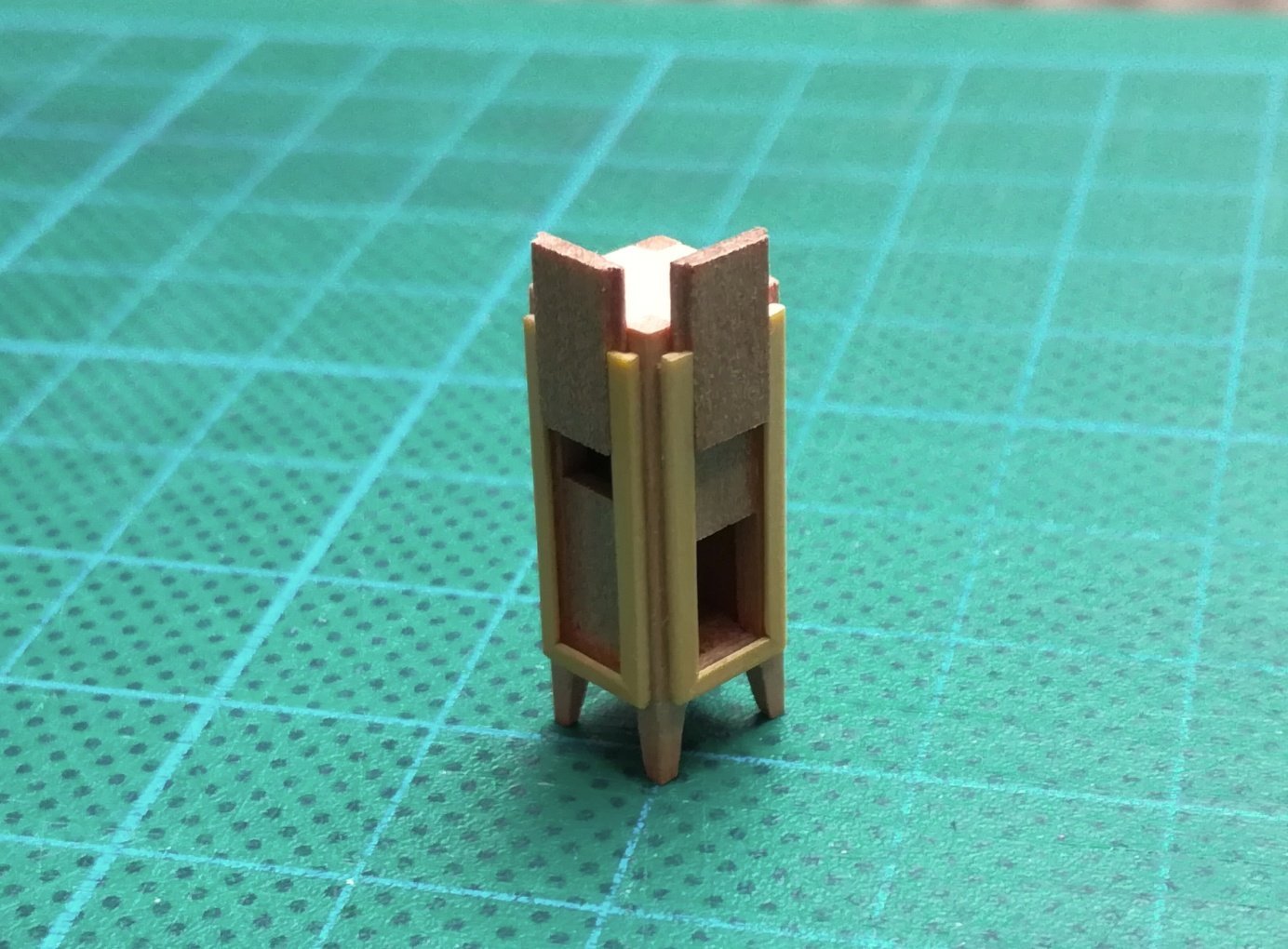

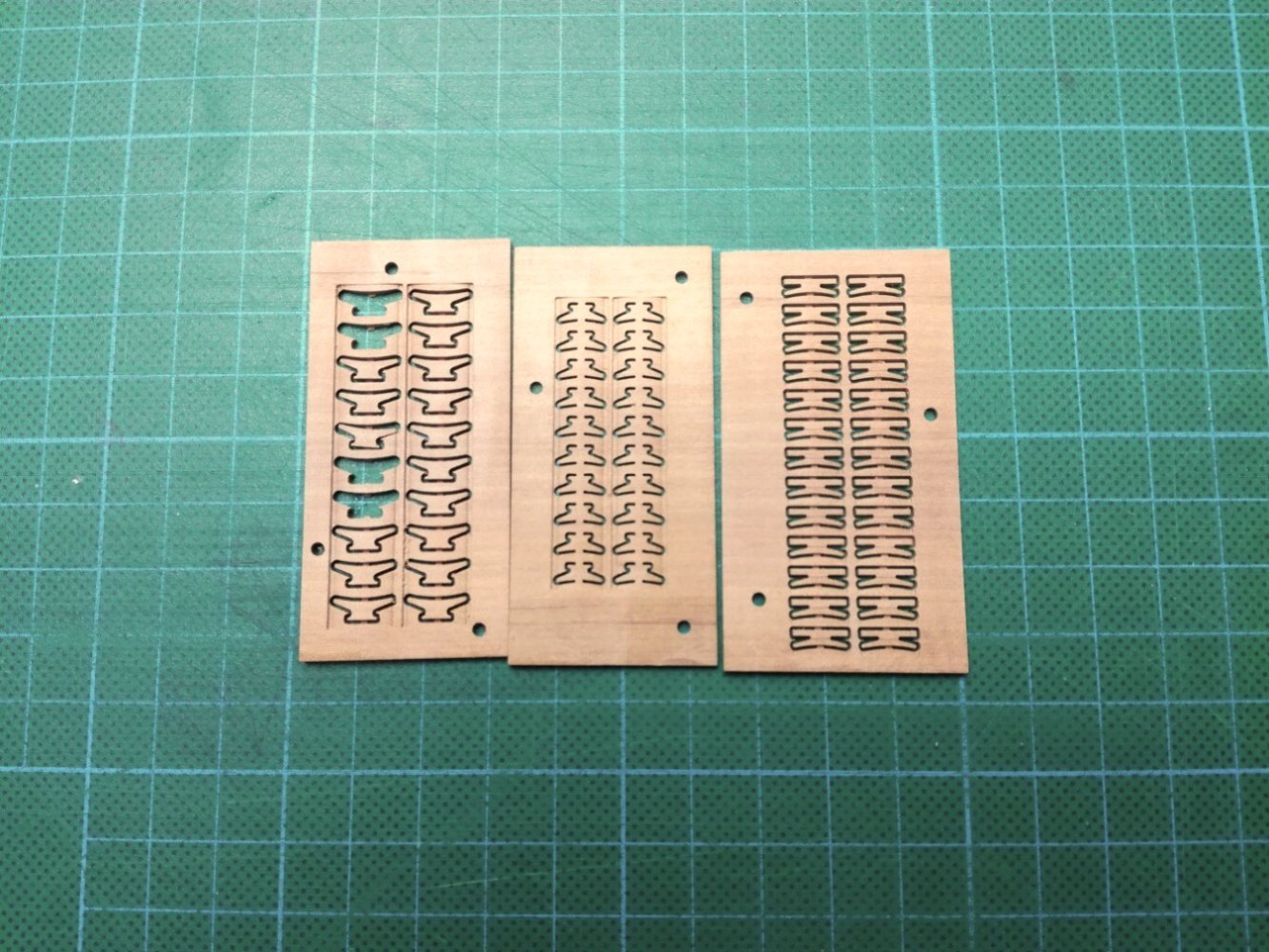

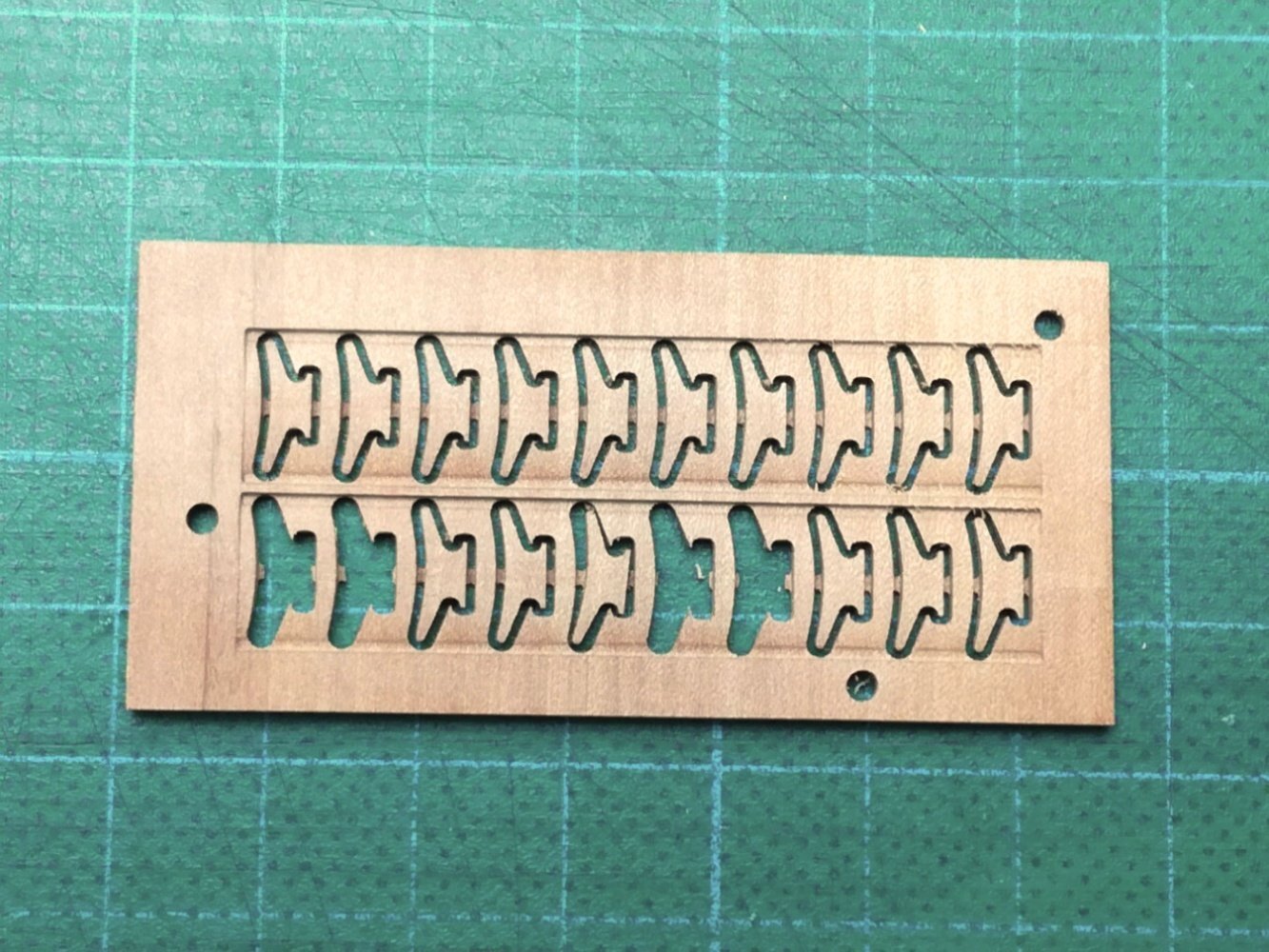

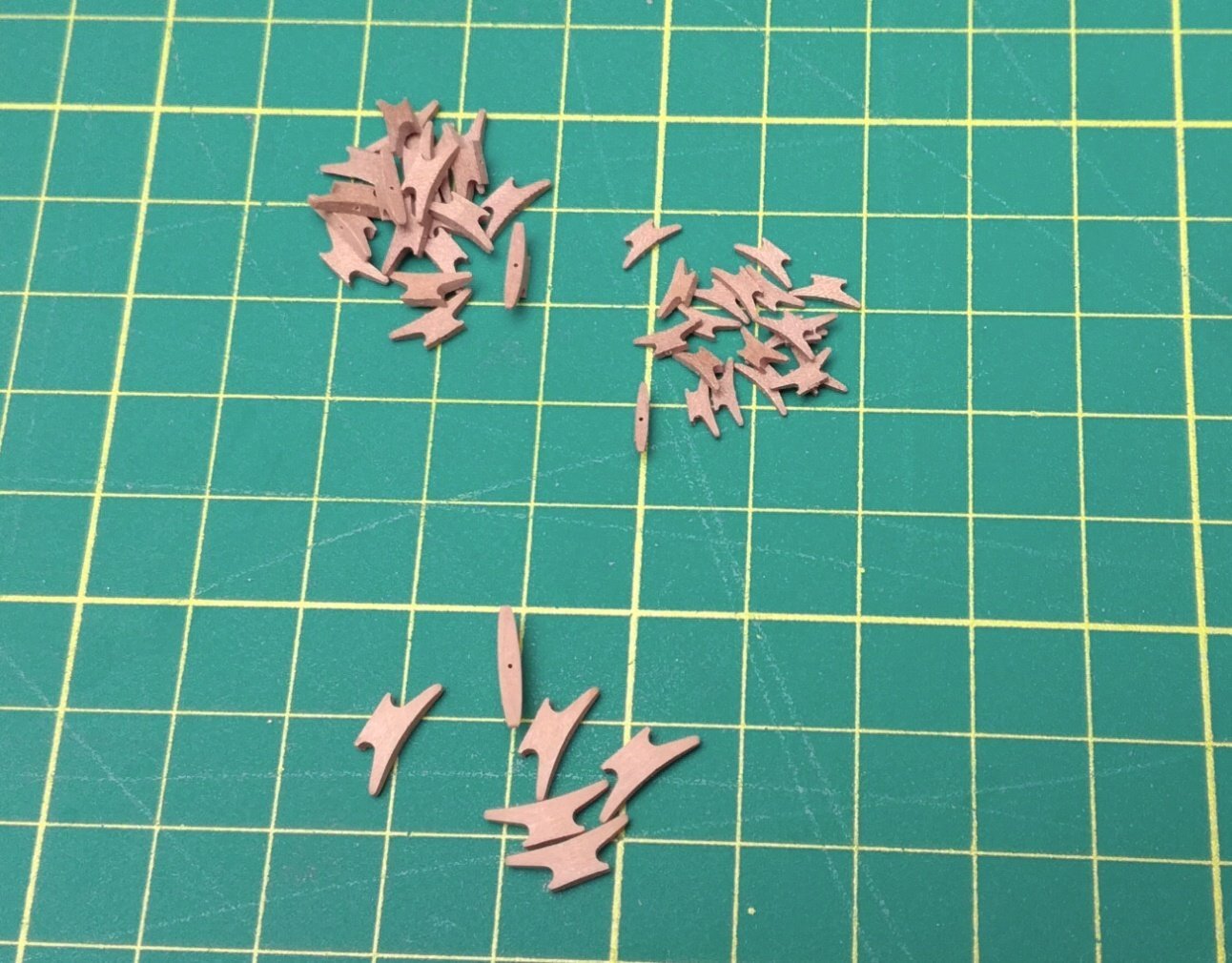

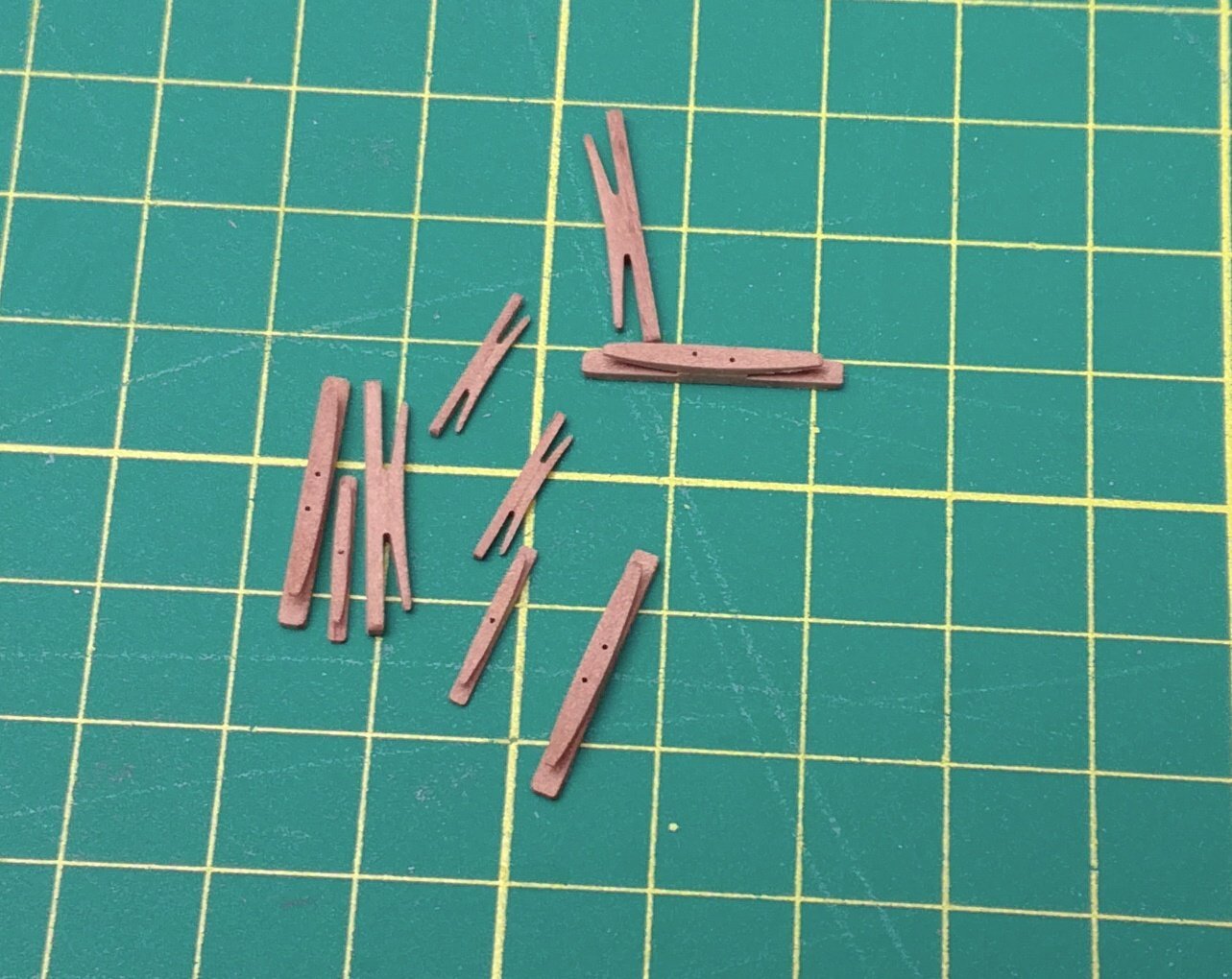

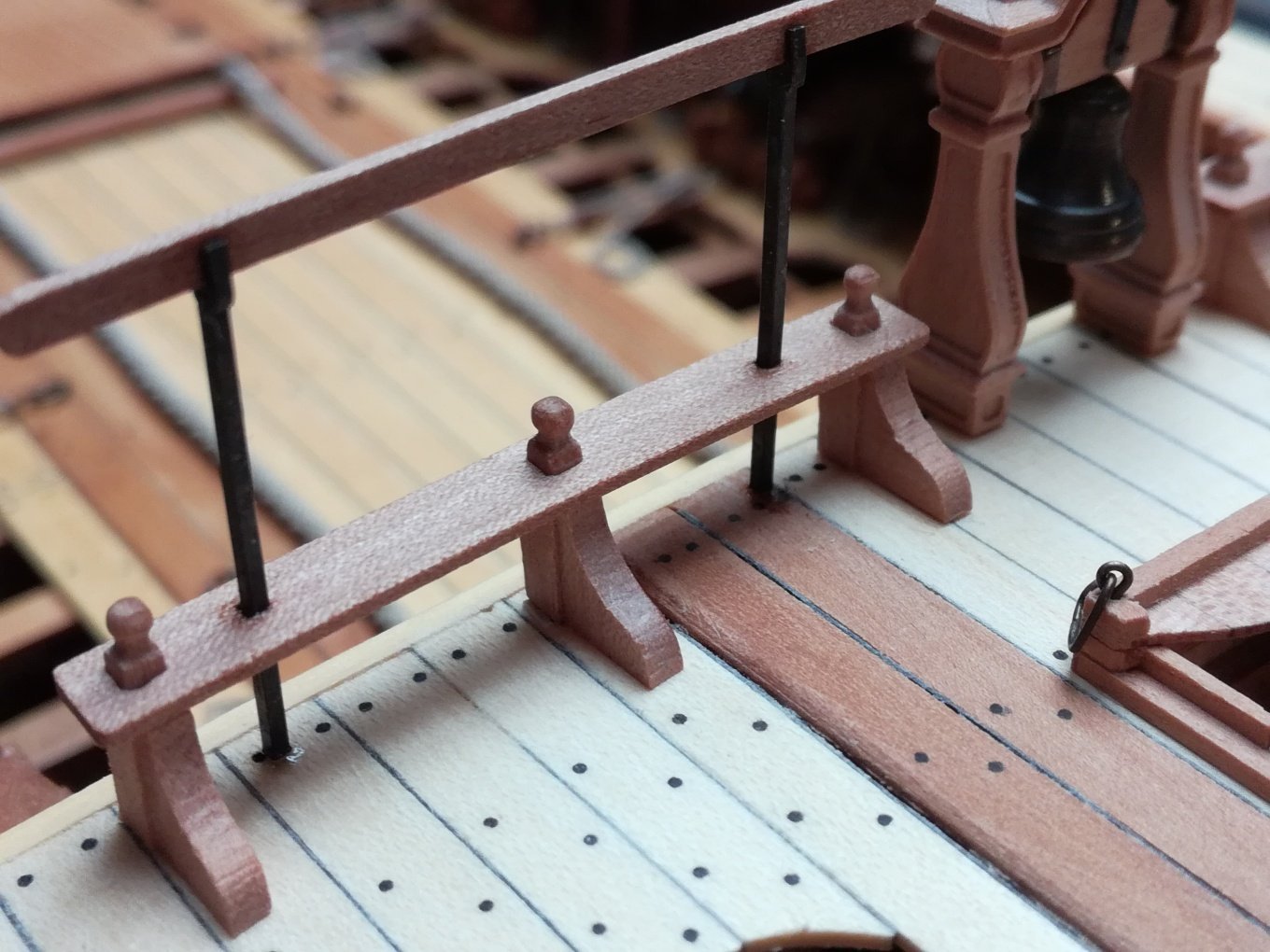

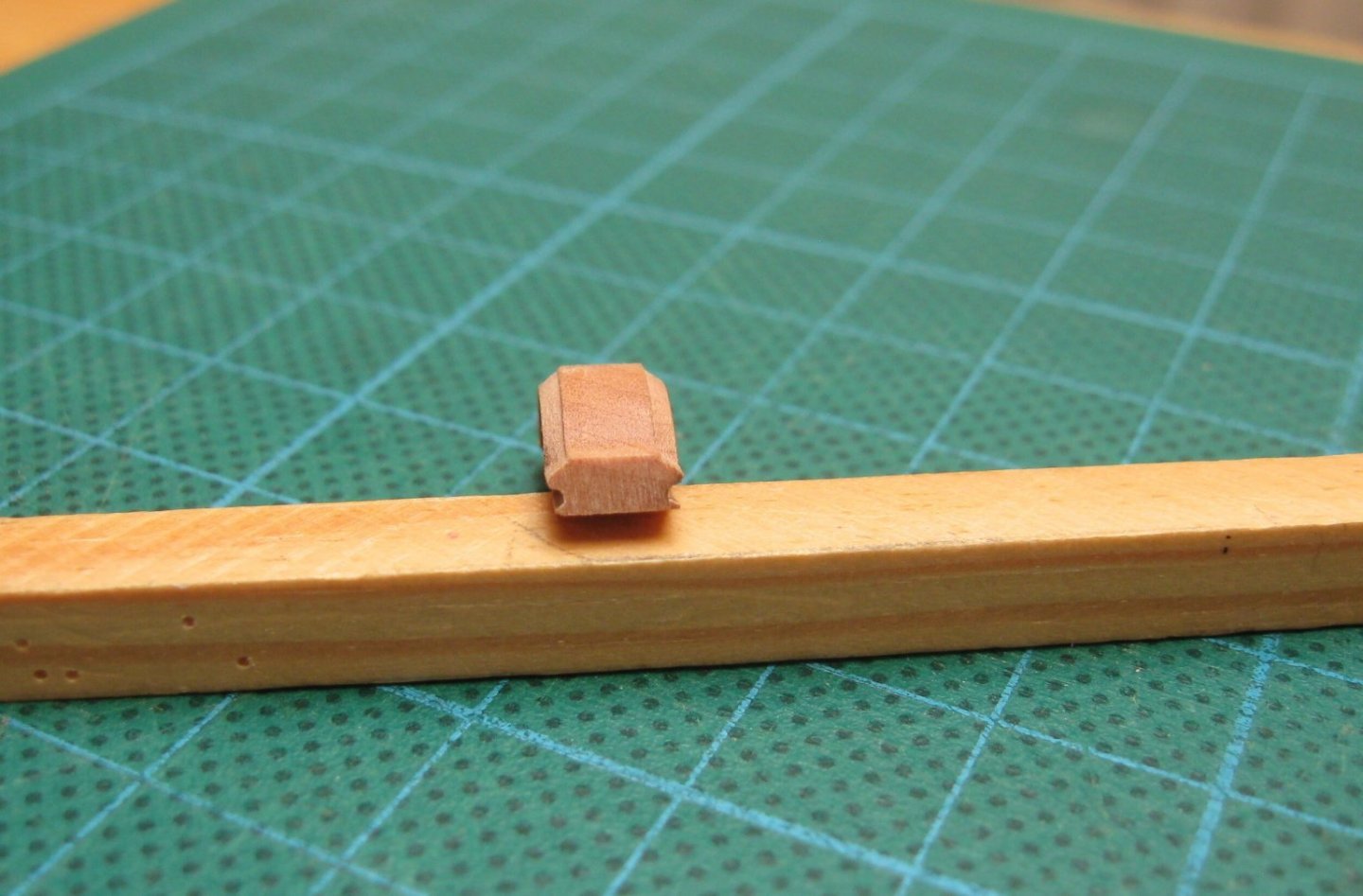

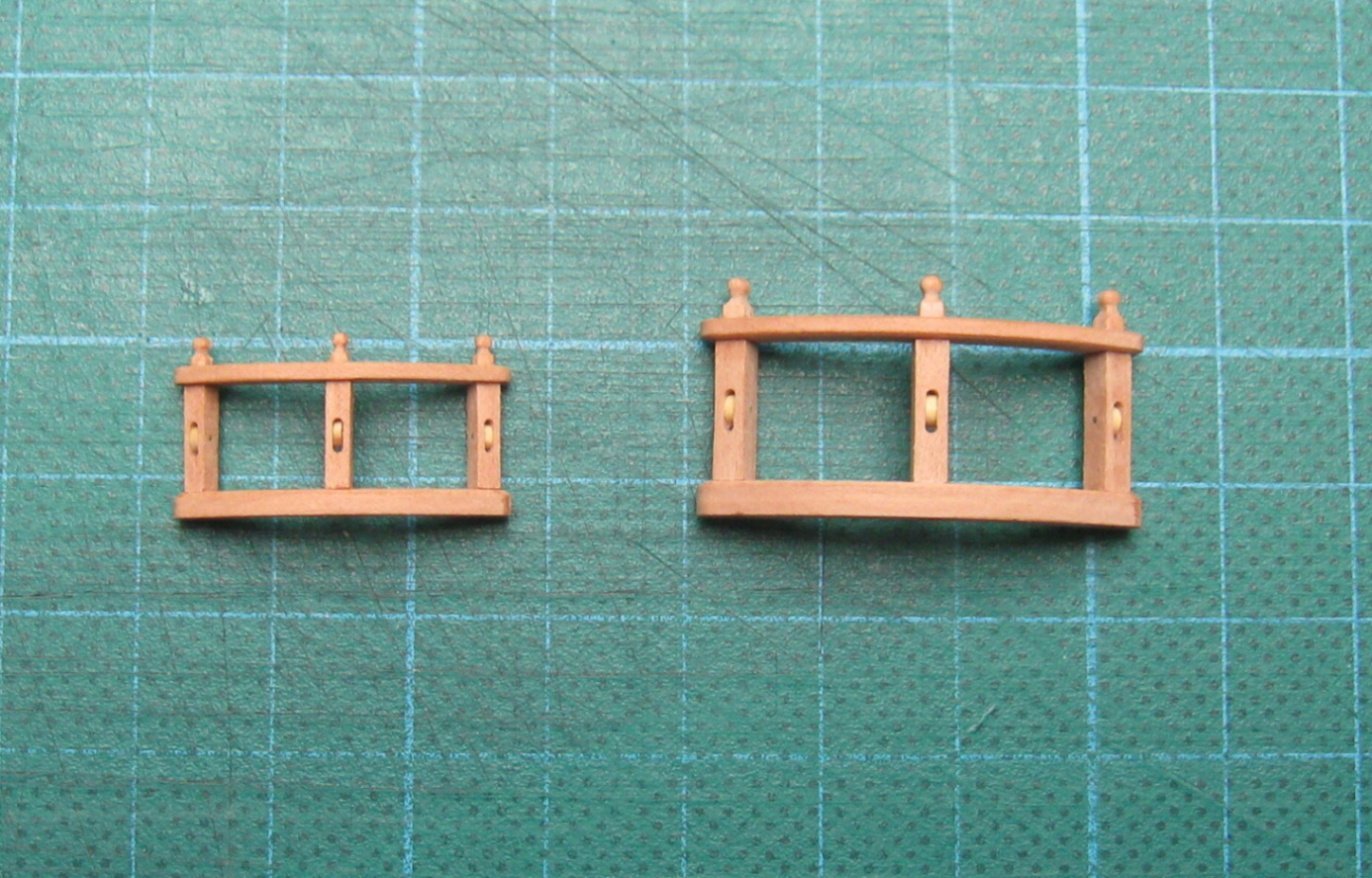

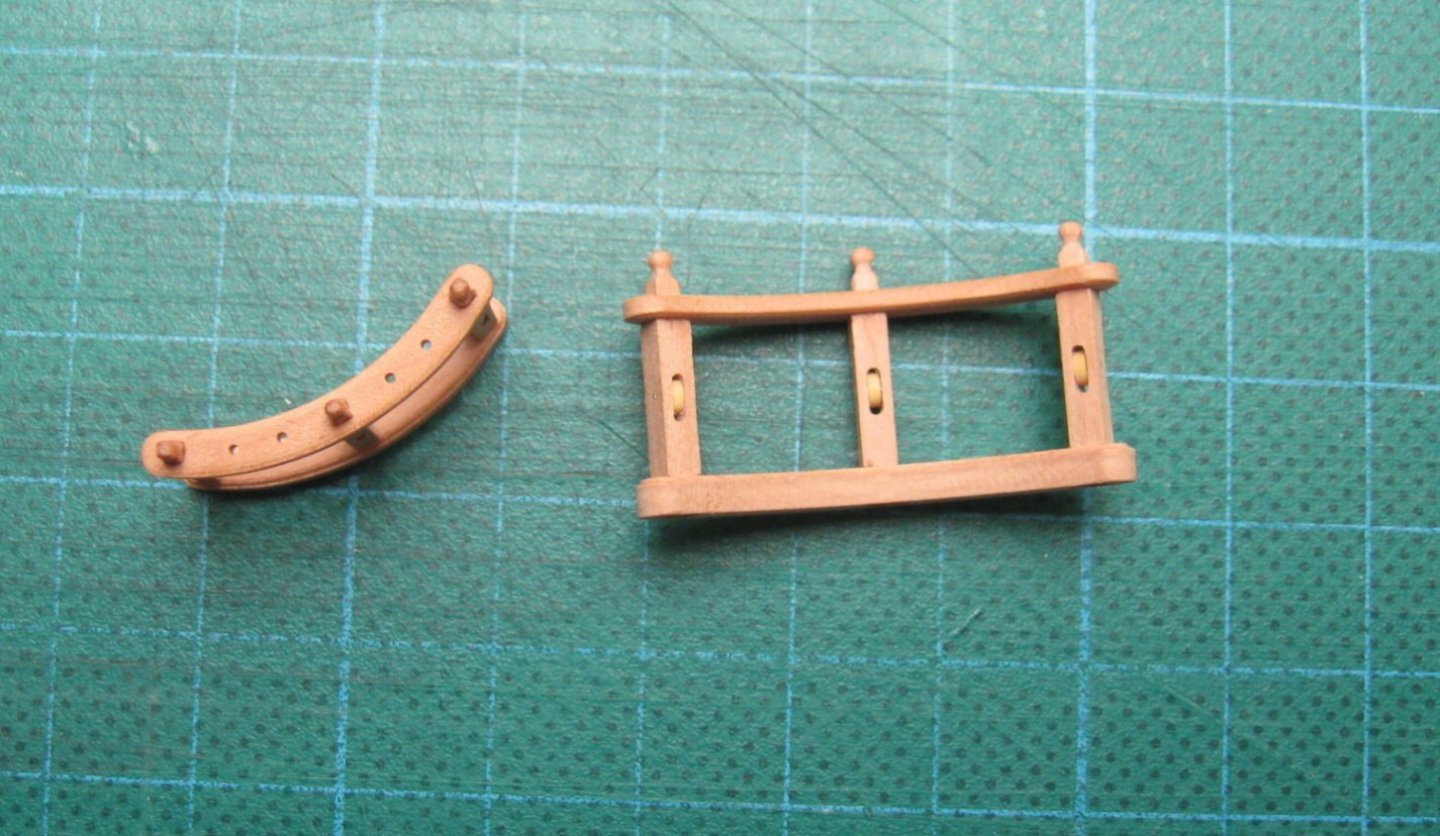

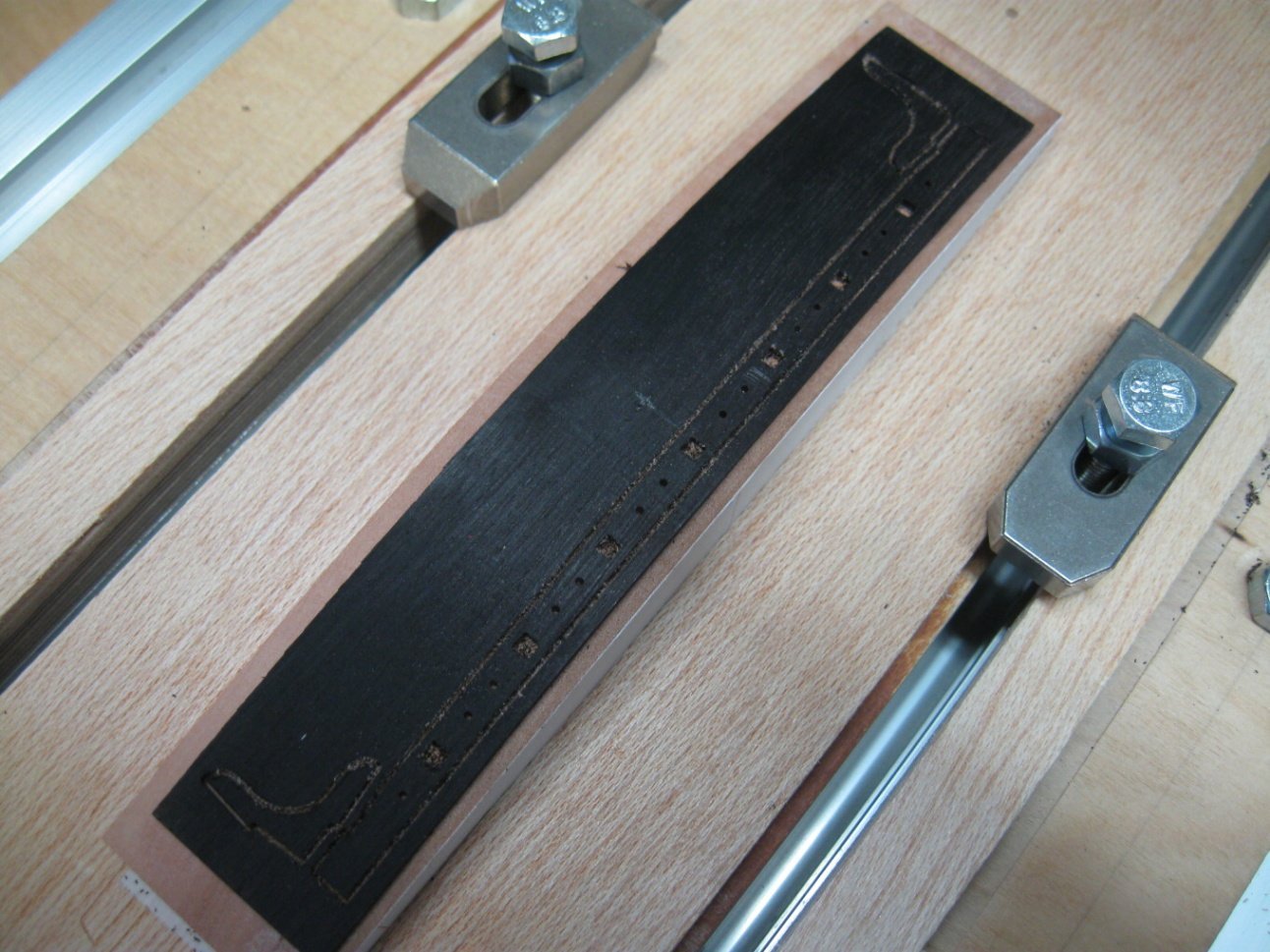

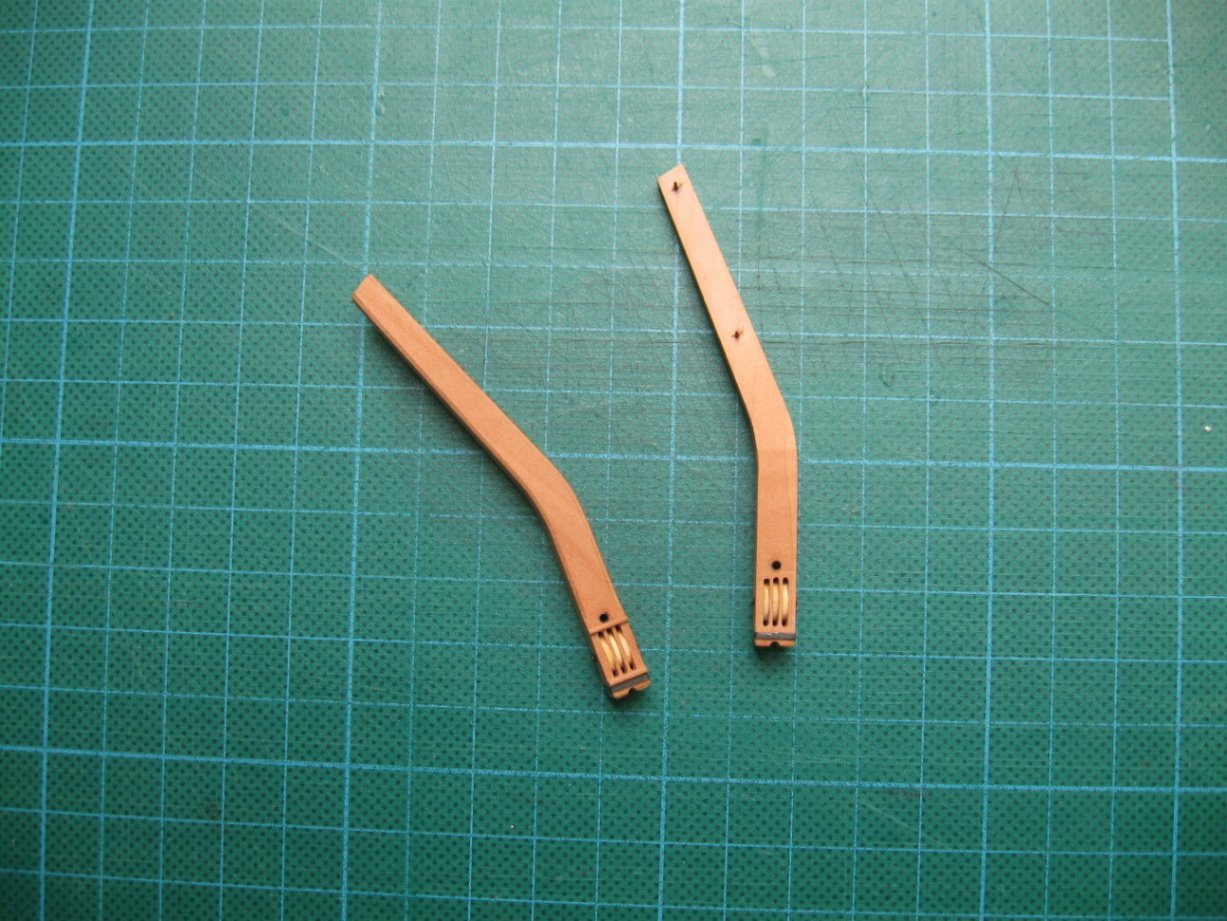

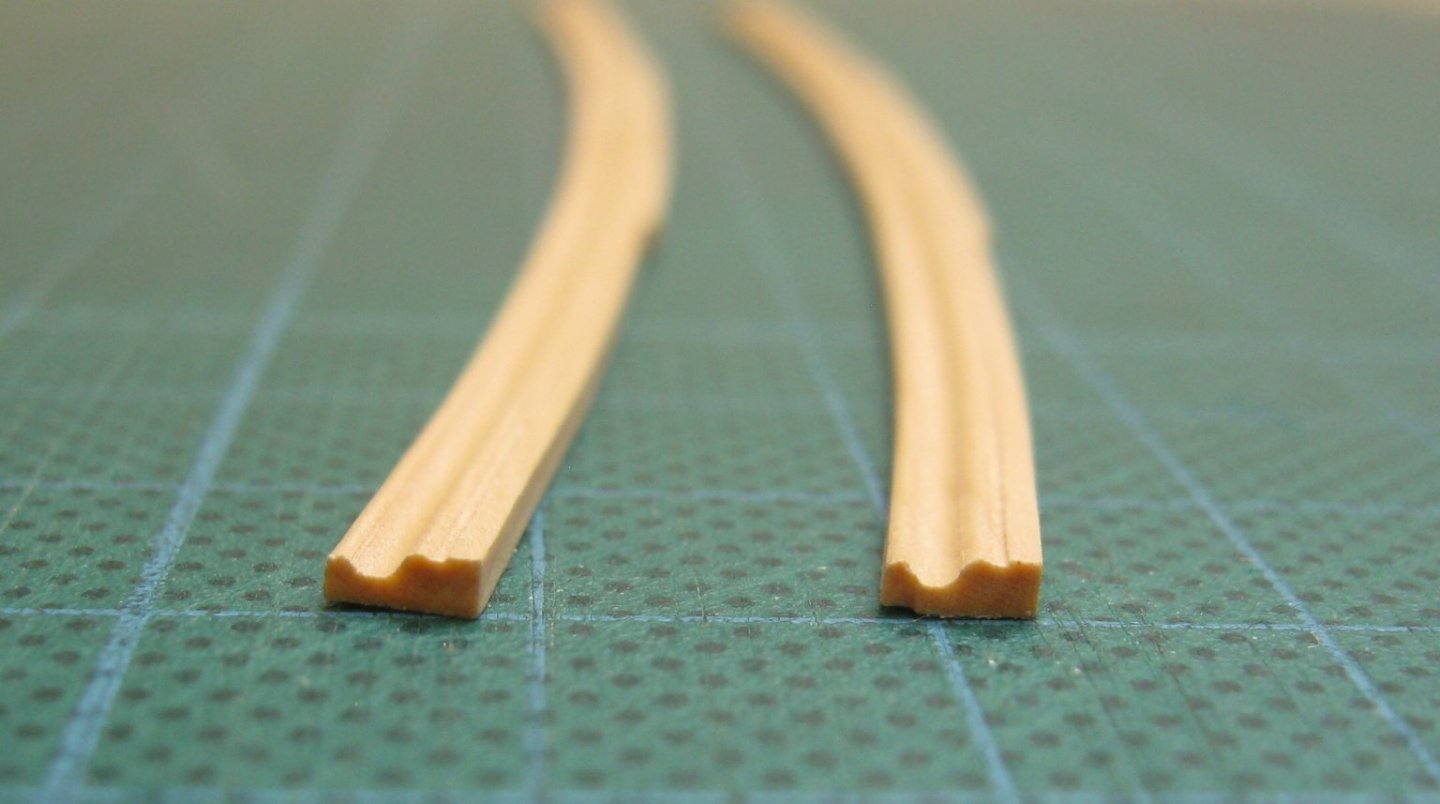

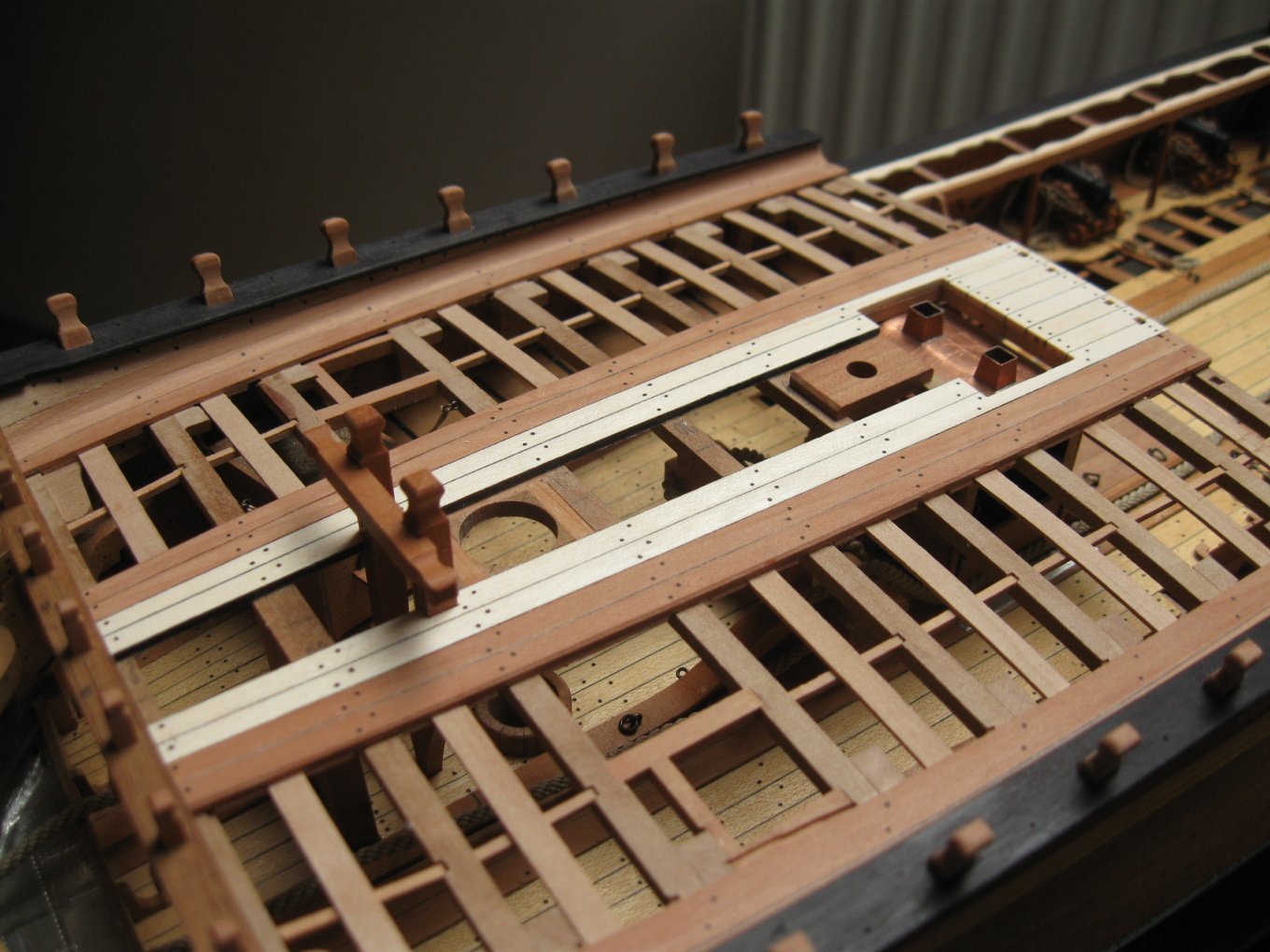

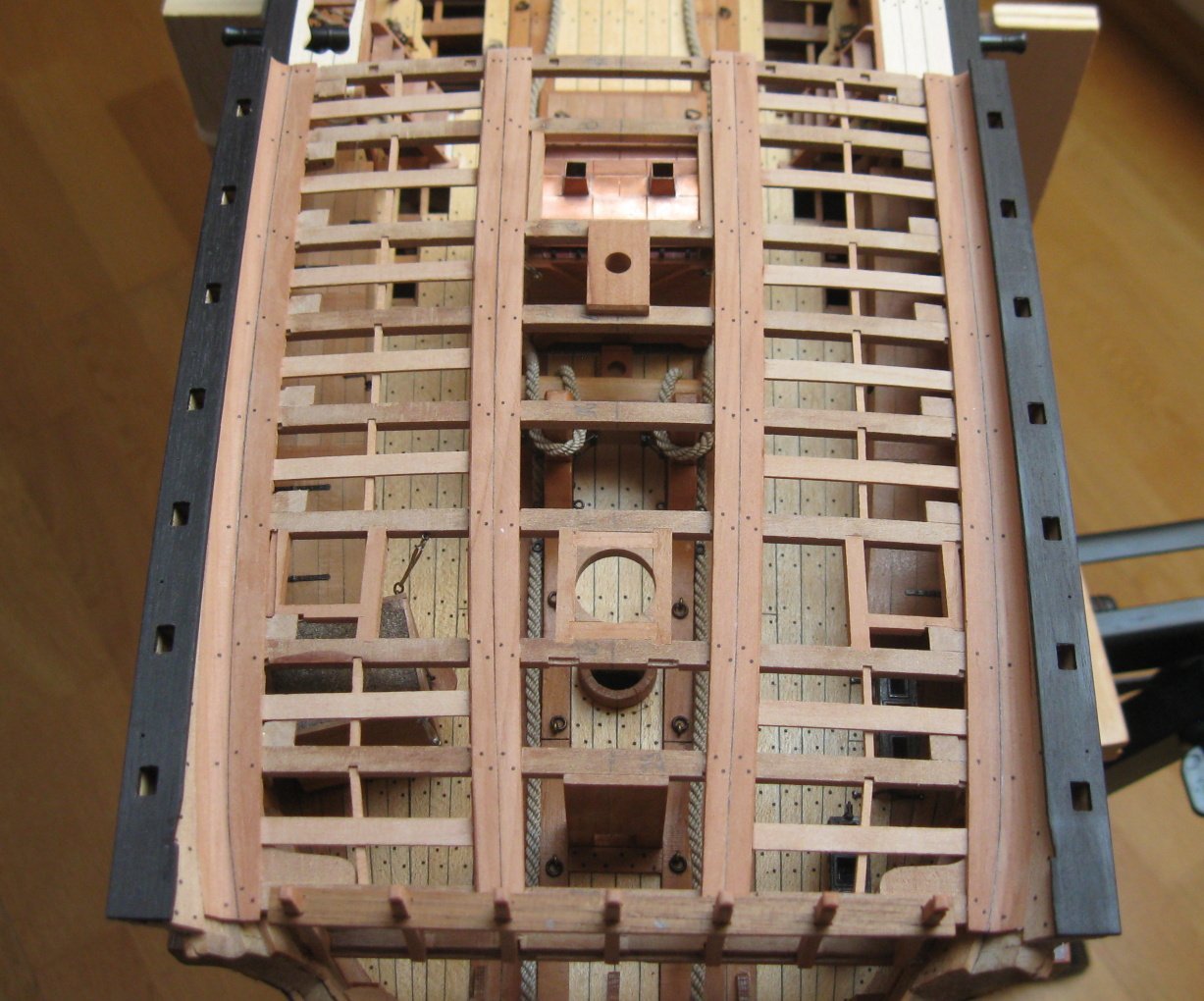

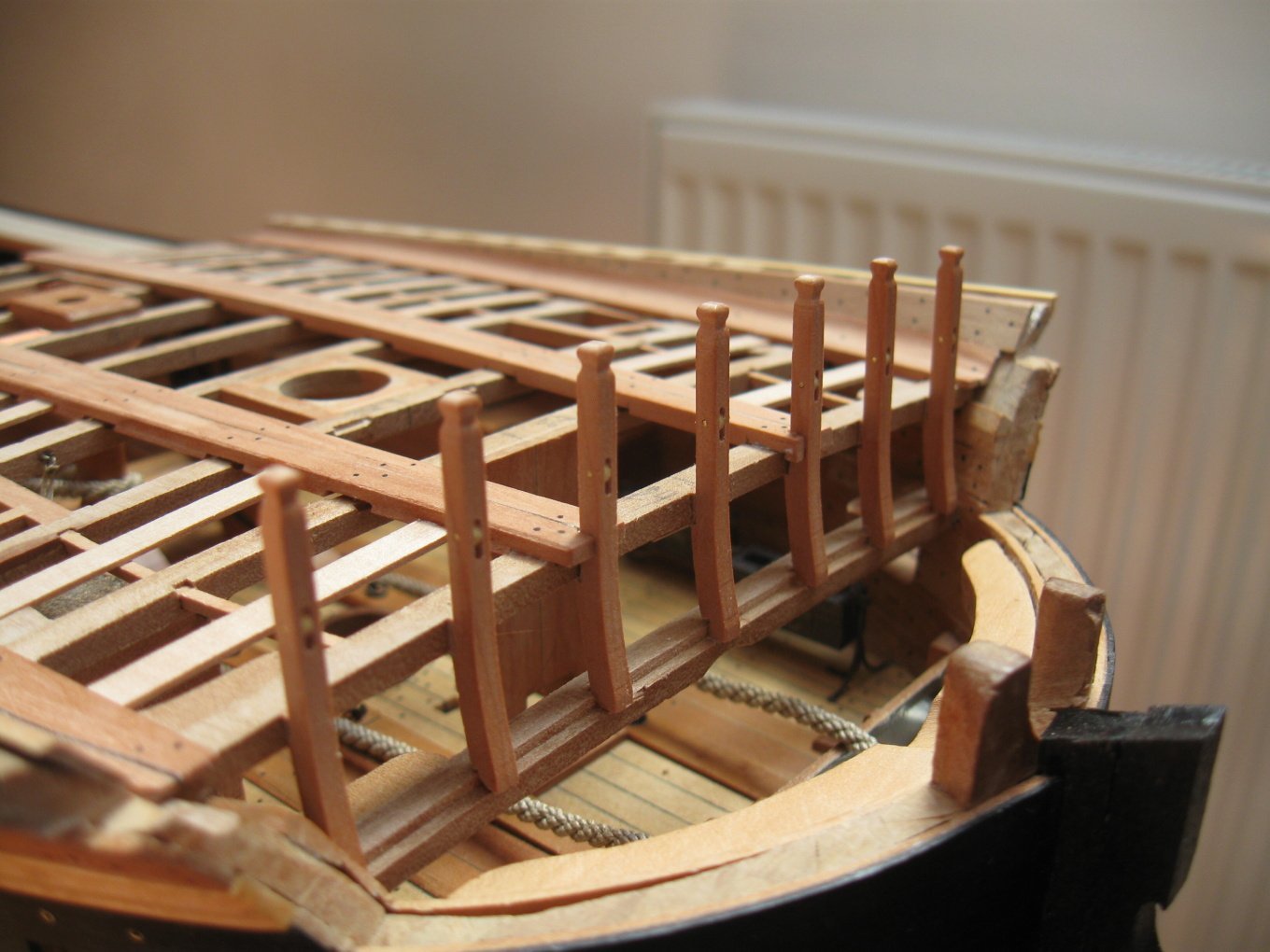

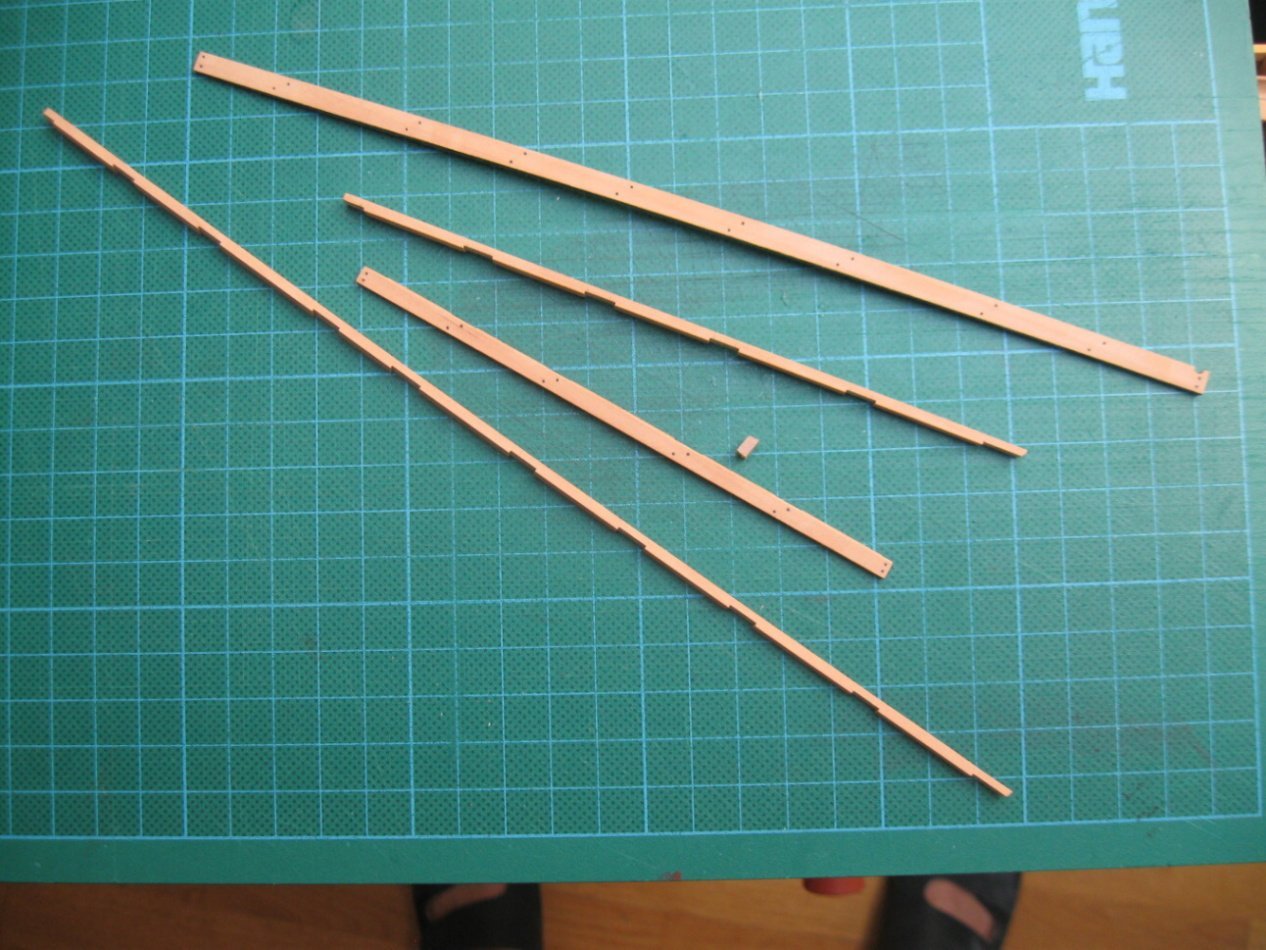

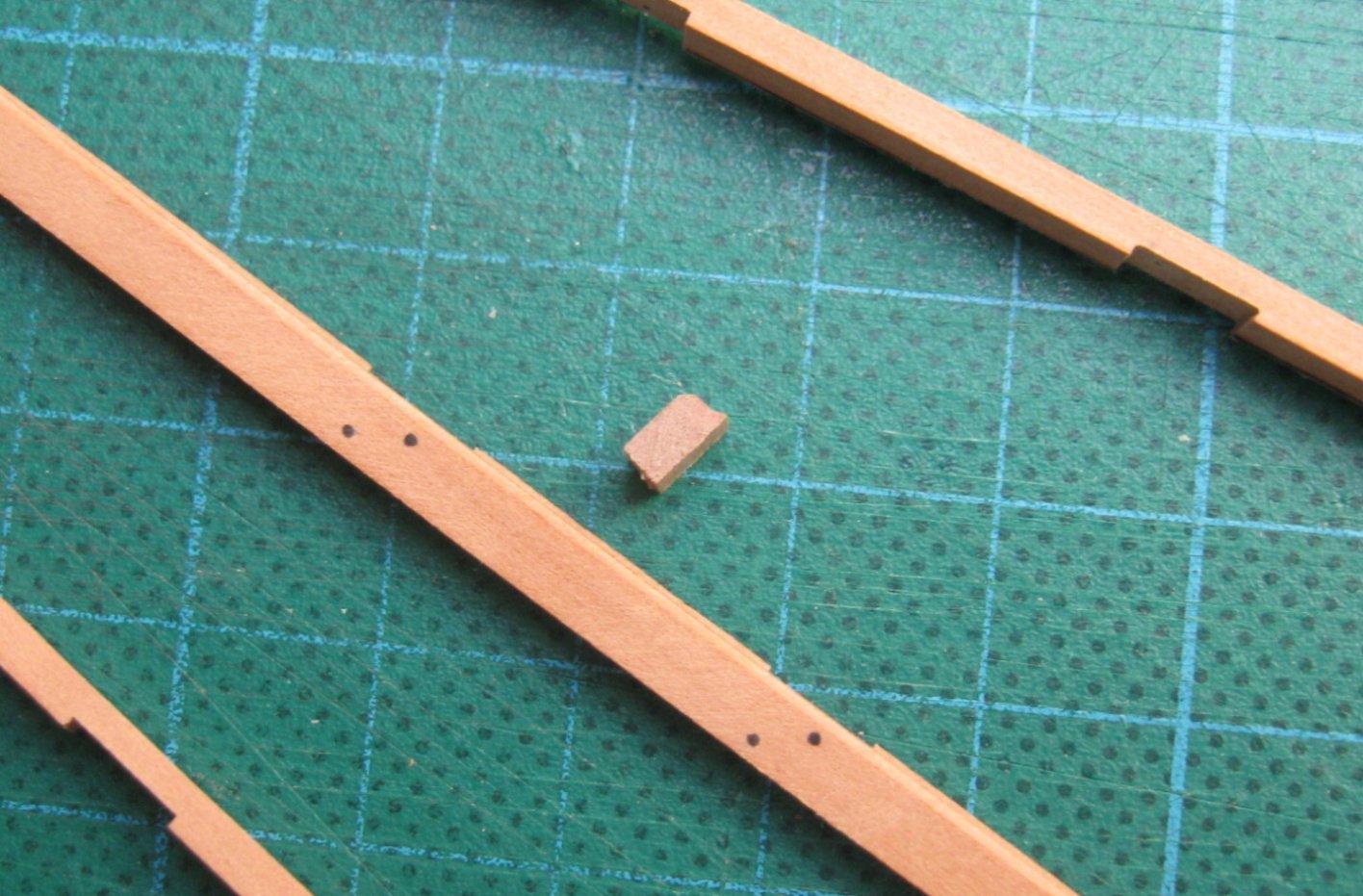

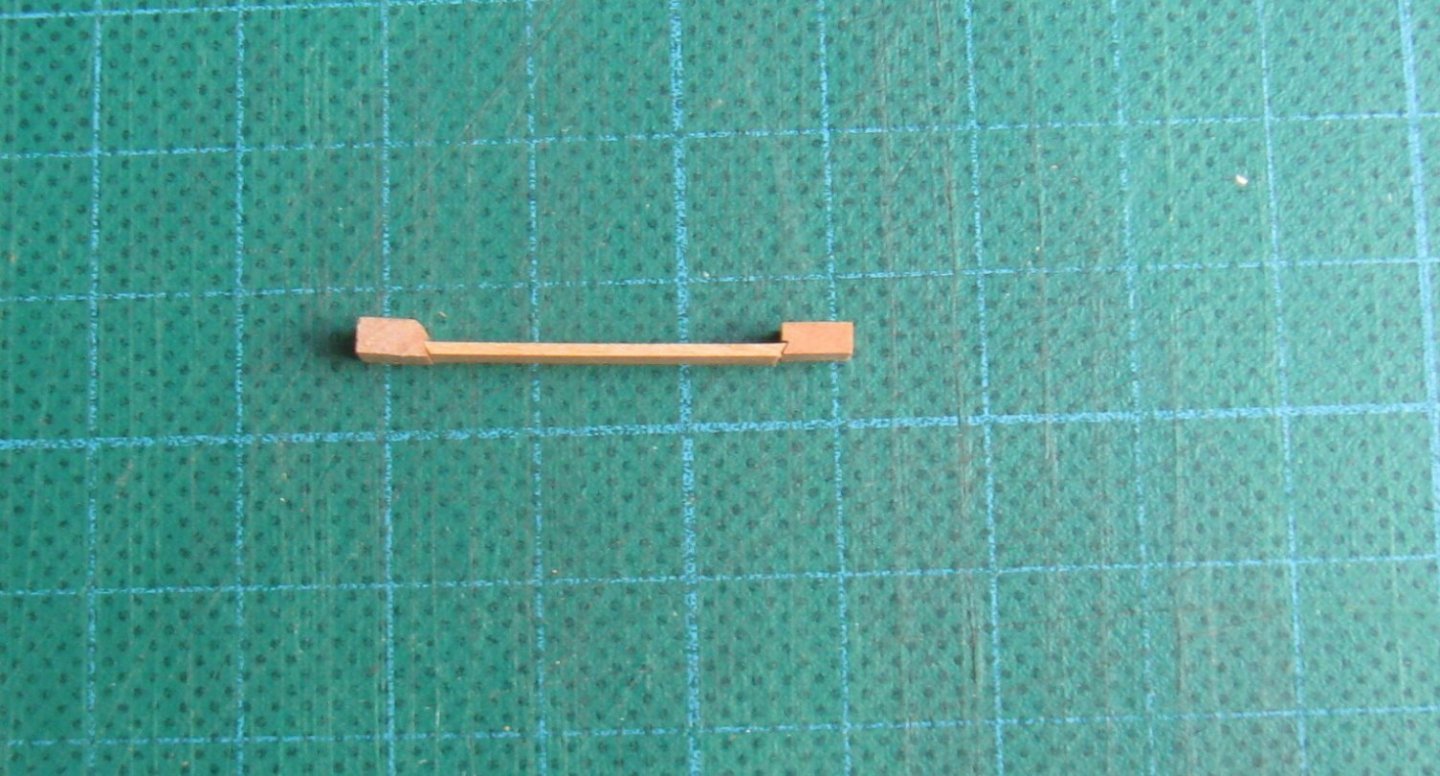

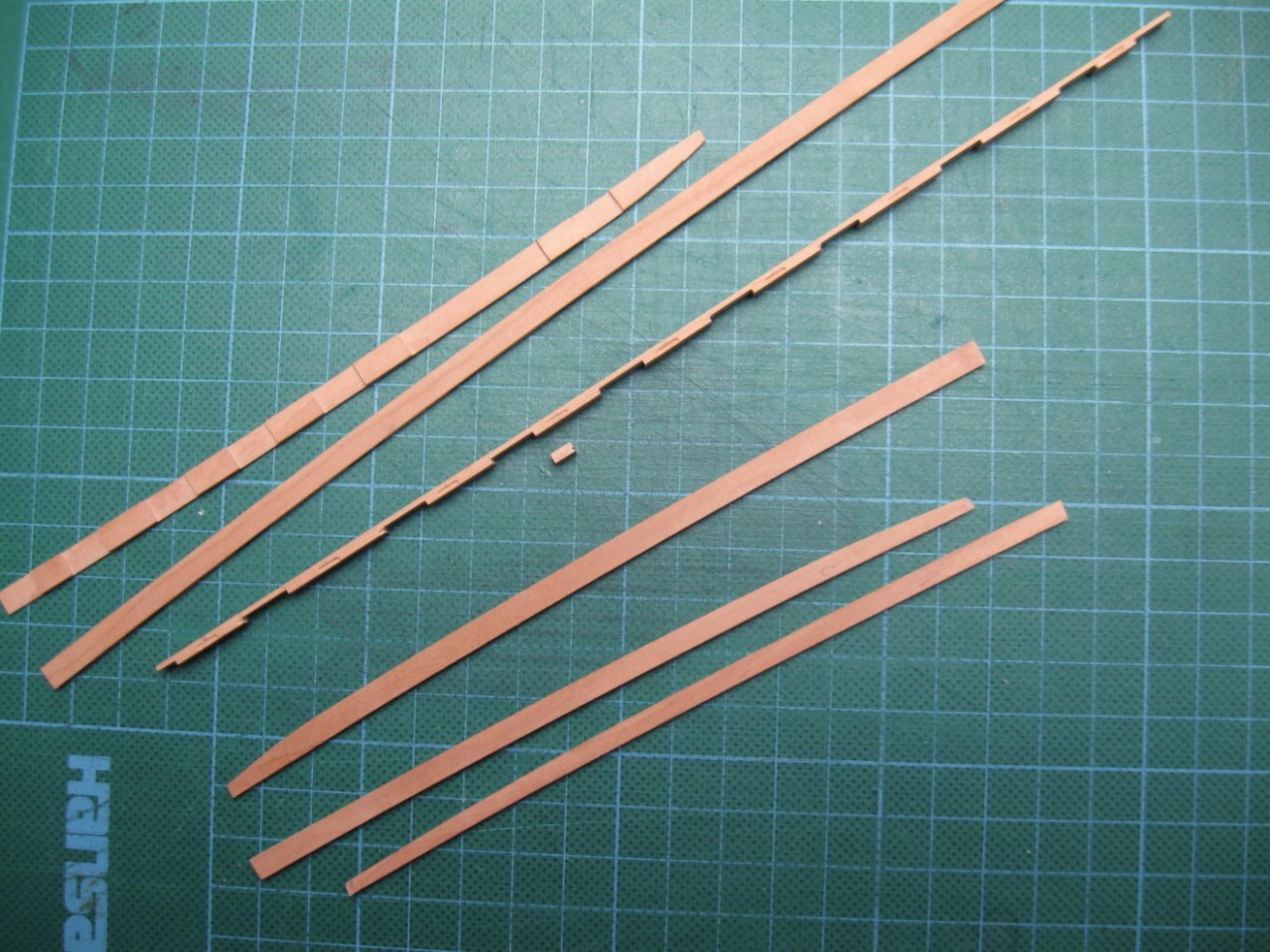

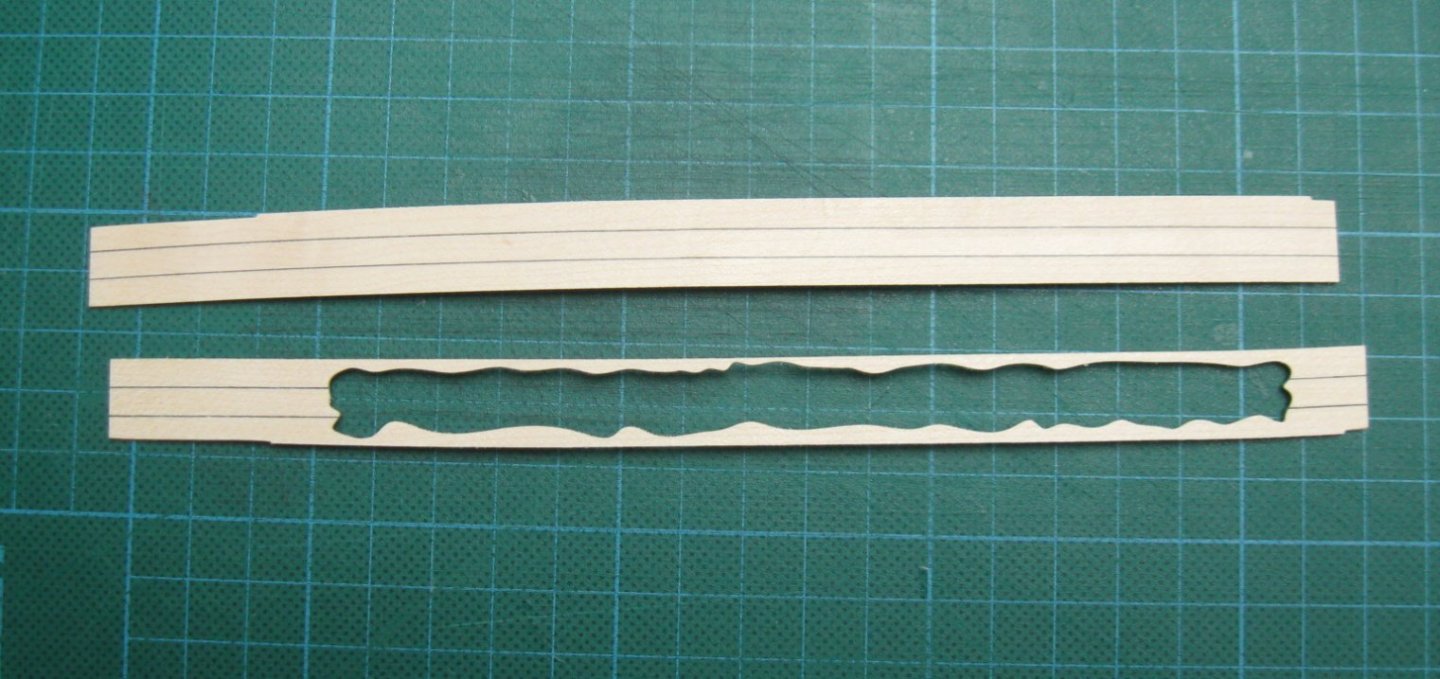

Pinrails.

-

- sferoida, Jorge Diaz O, FriedClams and 26 others

-

25

25

-

4

4

-

- shipcarpenter, sferoida, Rik Thistle and 24 others

-

21

21

-

1

1

-

5

5

-

-

- mugje, FriedClams, CaptMorgan and 19 others

-

20

20

-

2

2

-

-

-

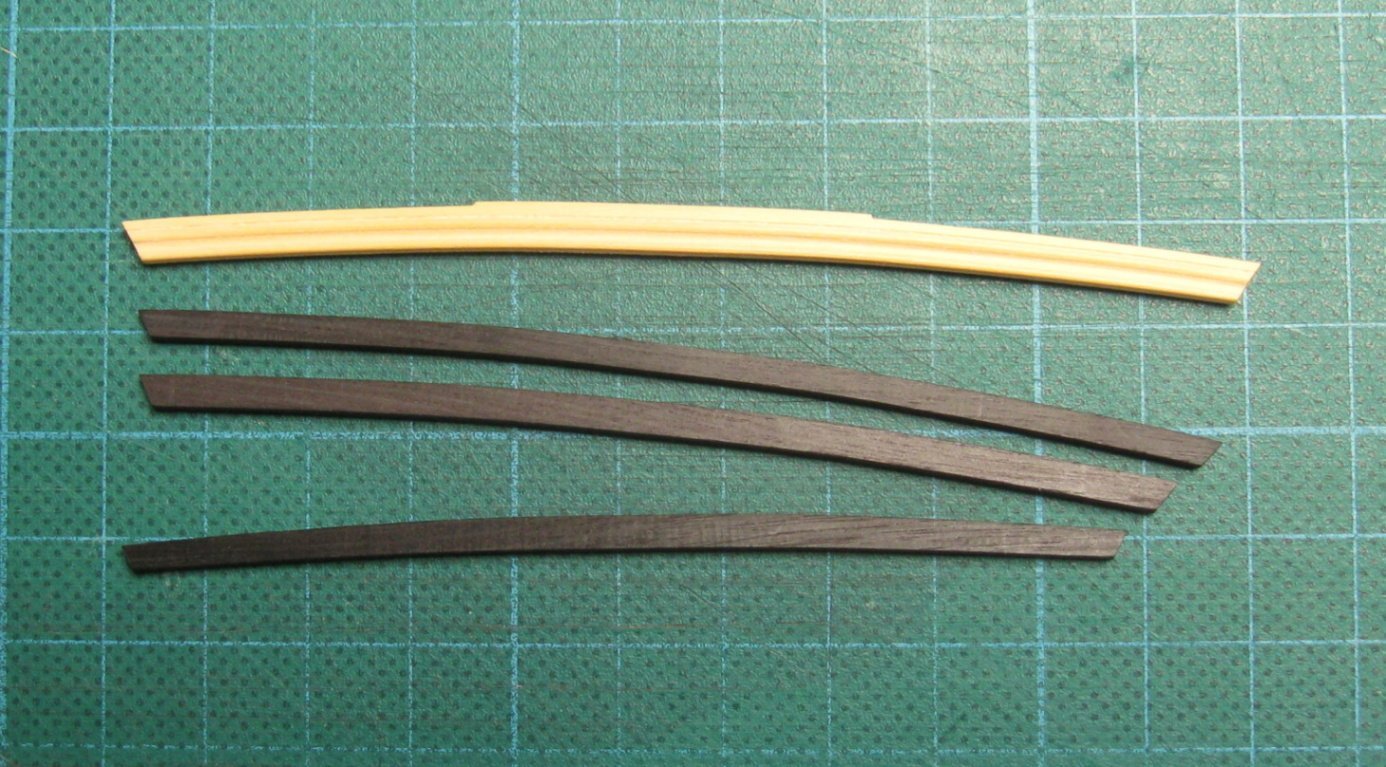

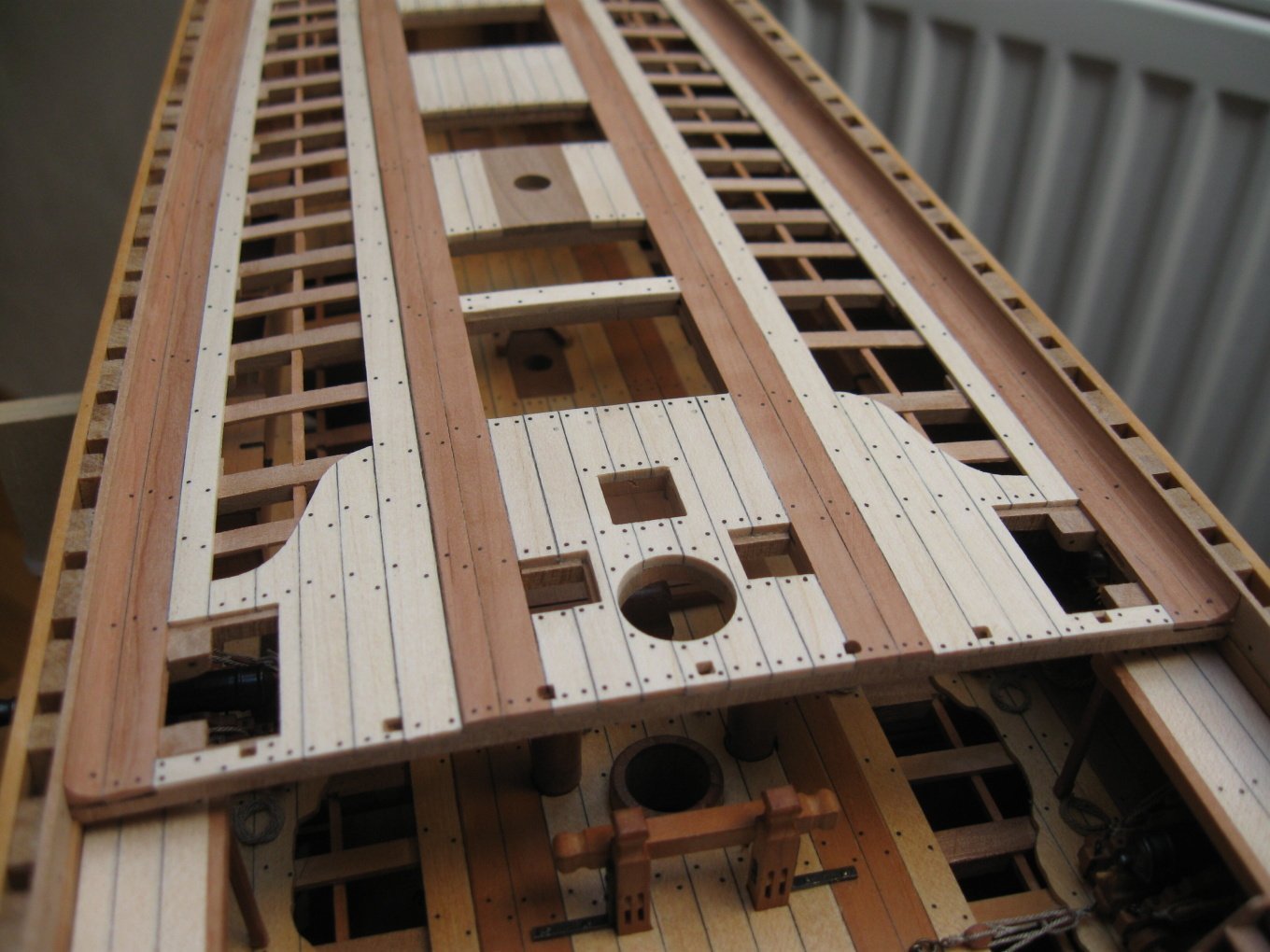

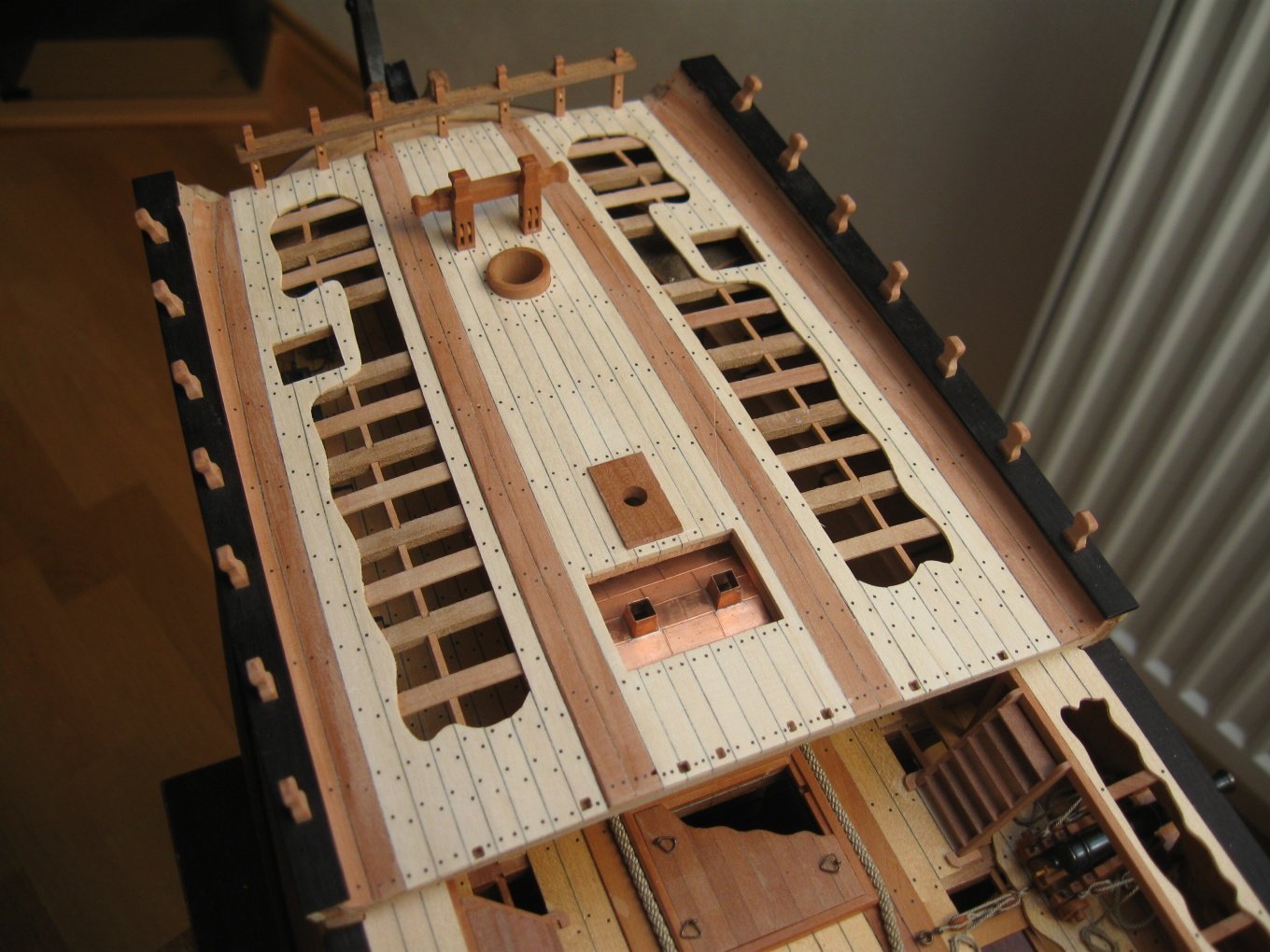

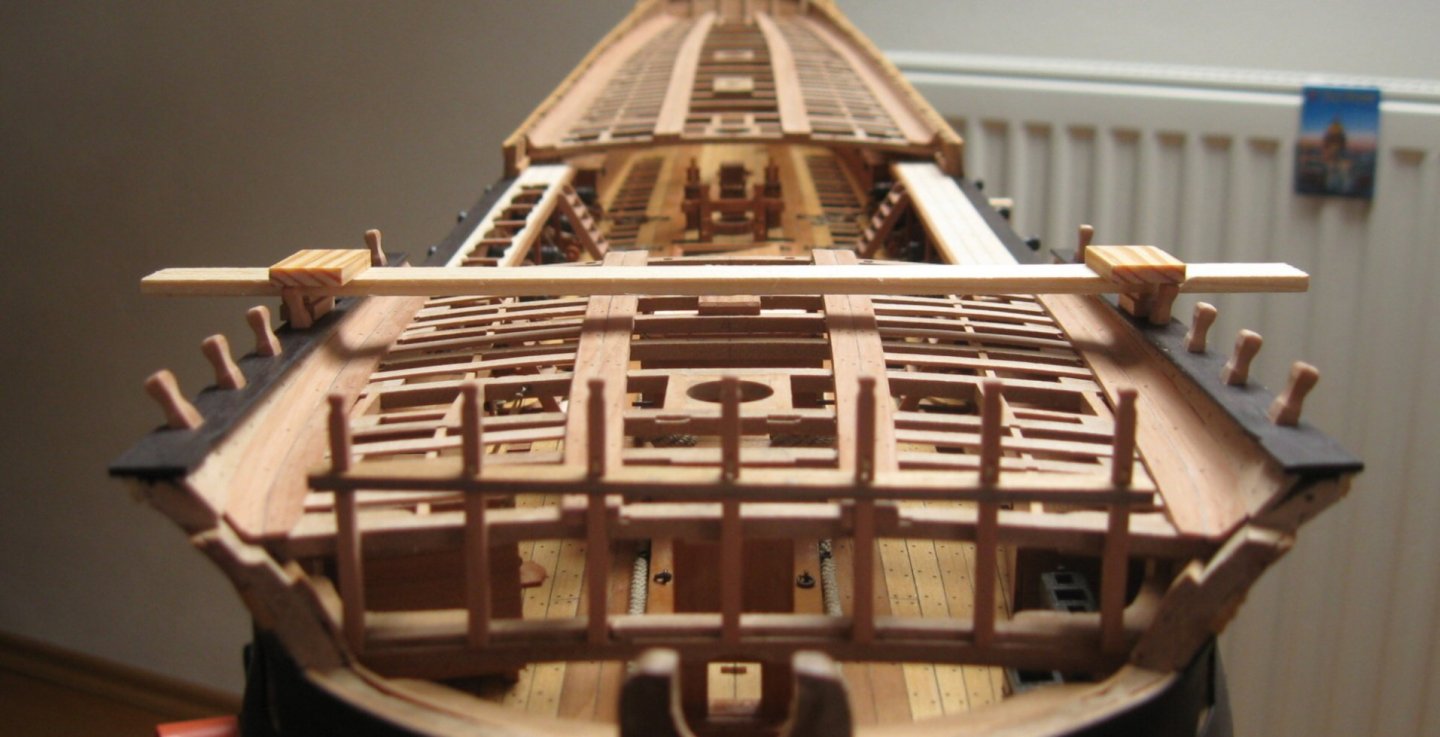

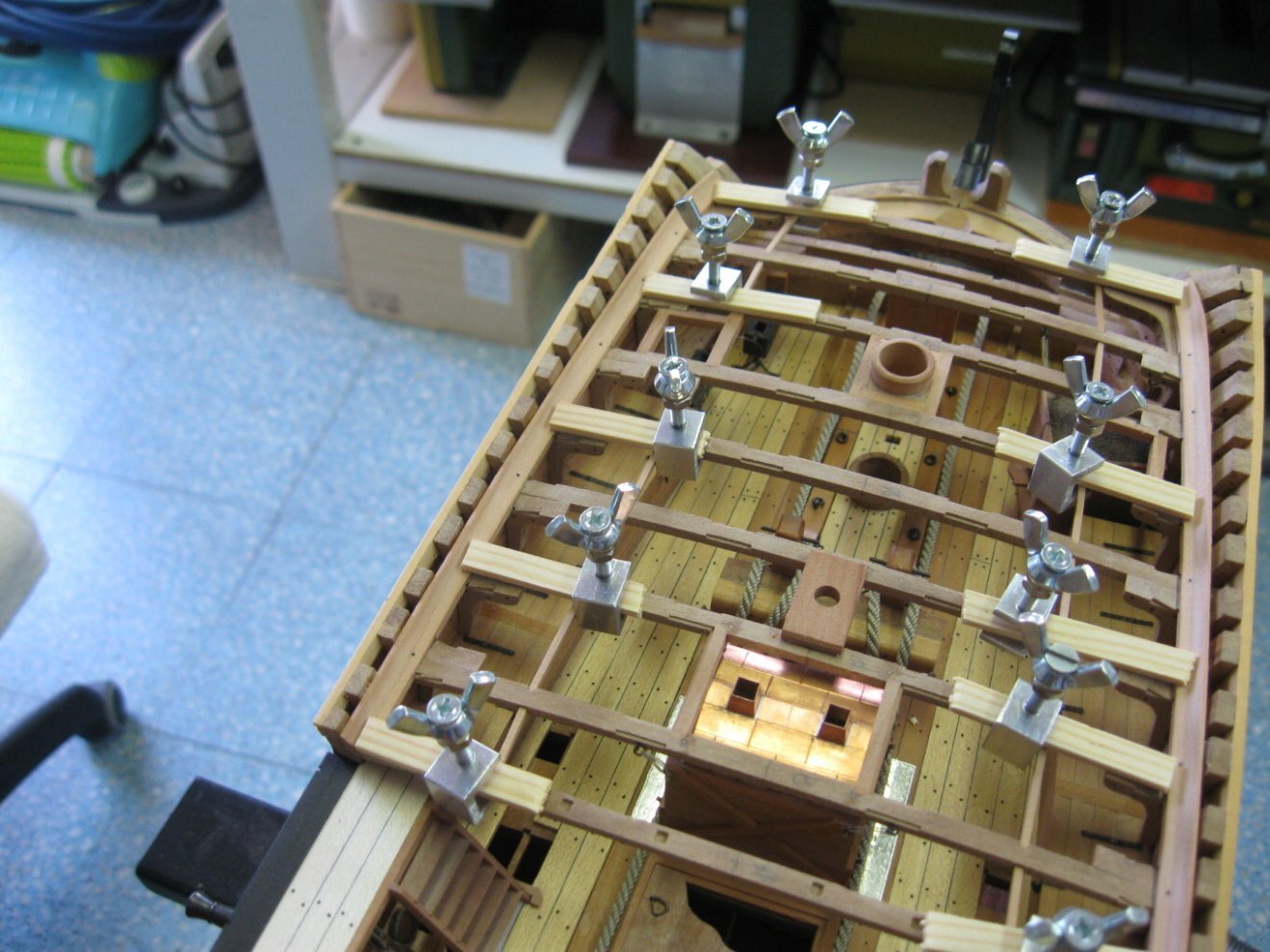

Thank you guys for answering daniel.b question and for the compliment my work too. Forecastle deck planking on the pictures is before waxing. After waxing get the wood little bit yellowish color so the contrast between maple and pear is not so big. On the other hand, I must say that on uncolored models, the color contrast of different types of wood is very important. Otherwise, the model is too dull from my point of view.

-

-

-

-

-

-

- Jorge Diaz O, Tigersteve, mtaylor and 22 others

-

23

23

-

1

1

-

1

1

-

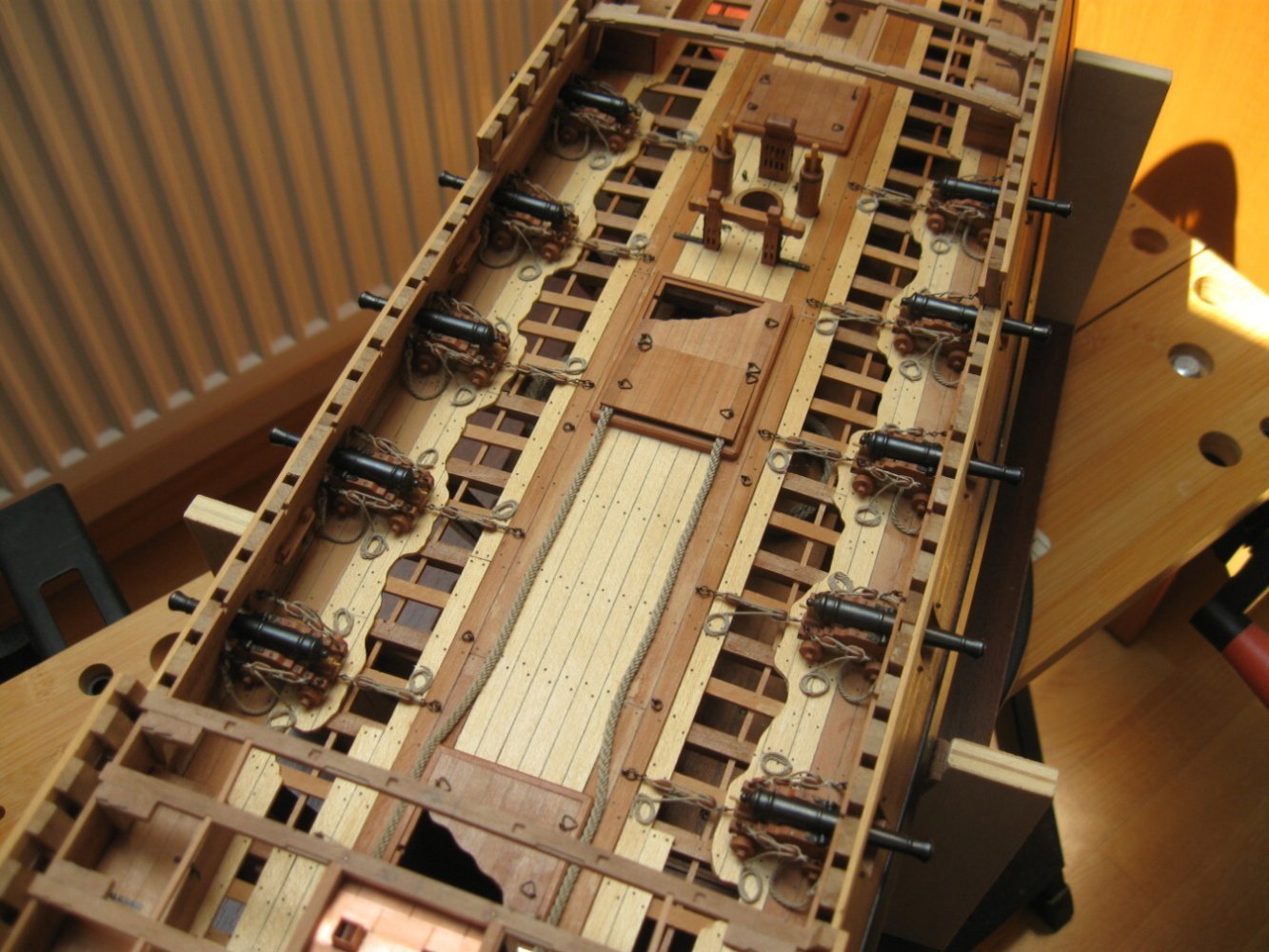

Le Gros Ventre by marsalv - FINISHED - 1:48 - POF

in - Build logs for subjects built 1751 - 1800

Posted

Thank you giampieroricci. I had the opportunity to see your L´Amarante model in Rijeka last year. Great model. L´Amarante will probably be my next model, so I will study your L´Amarante log afterwards.

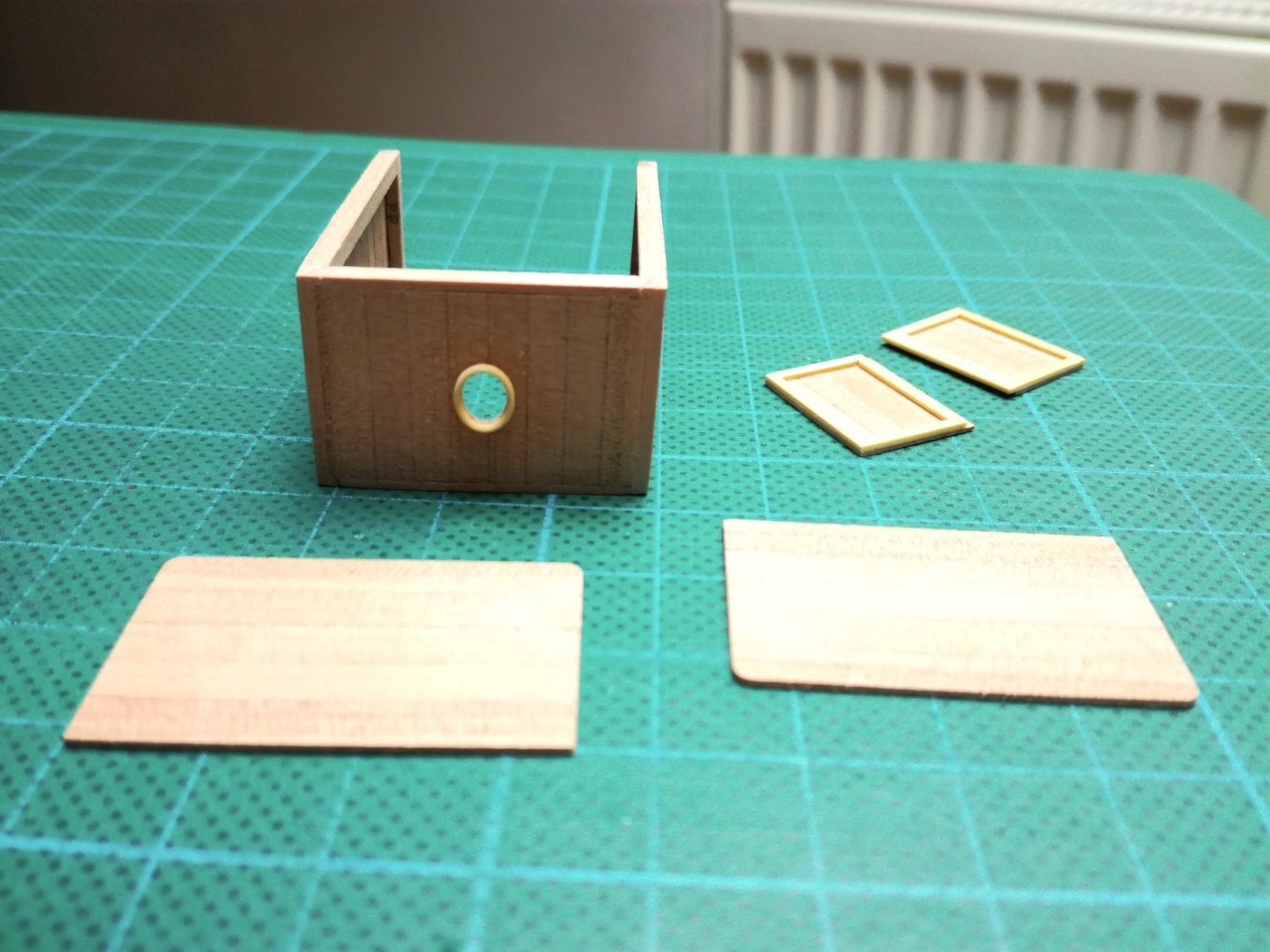

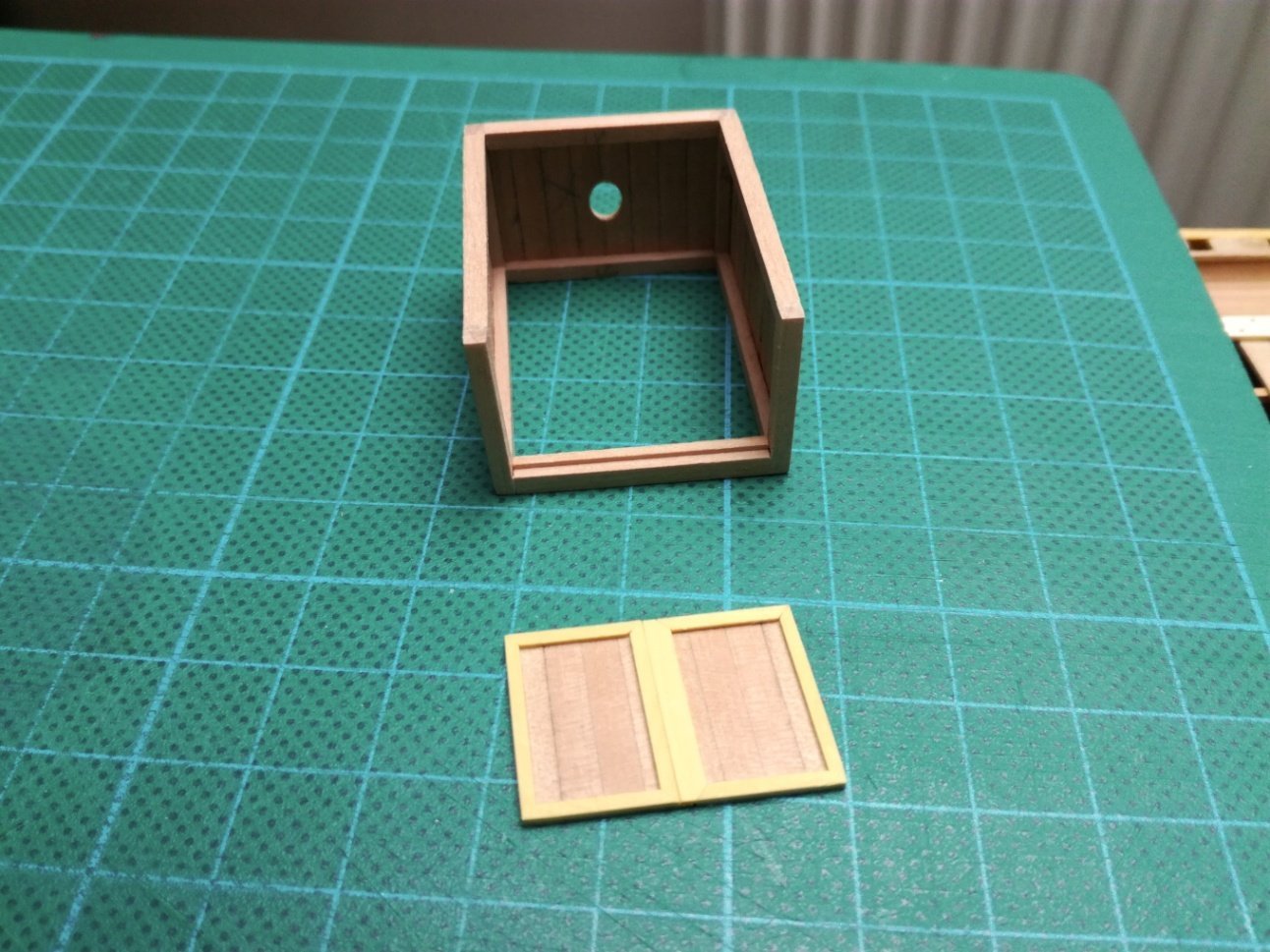

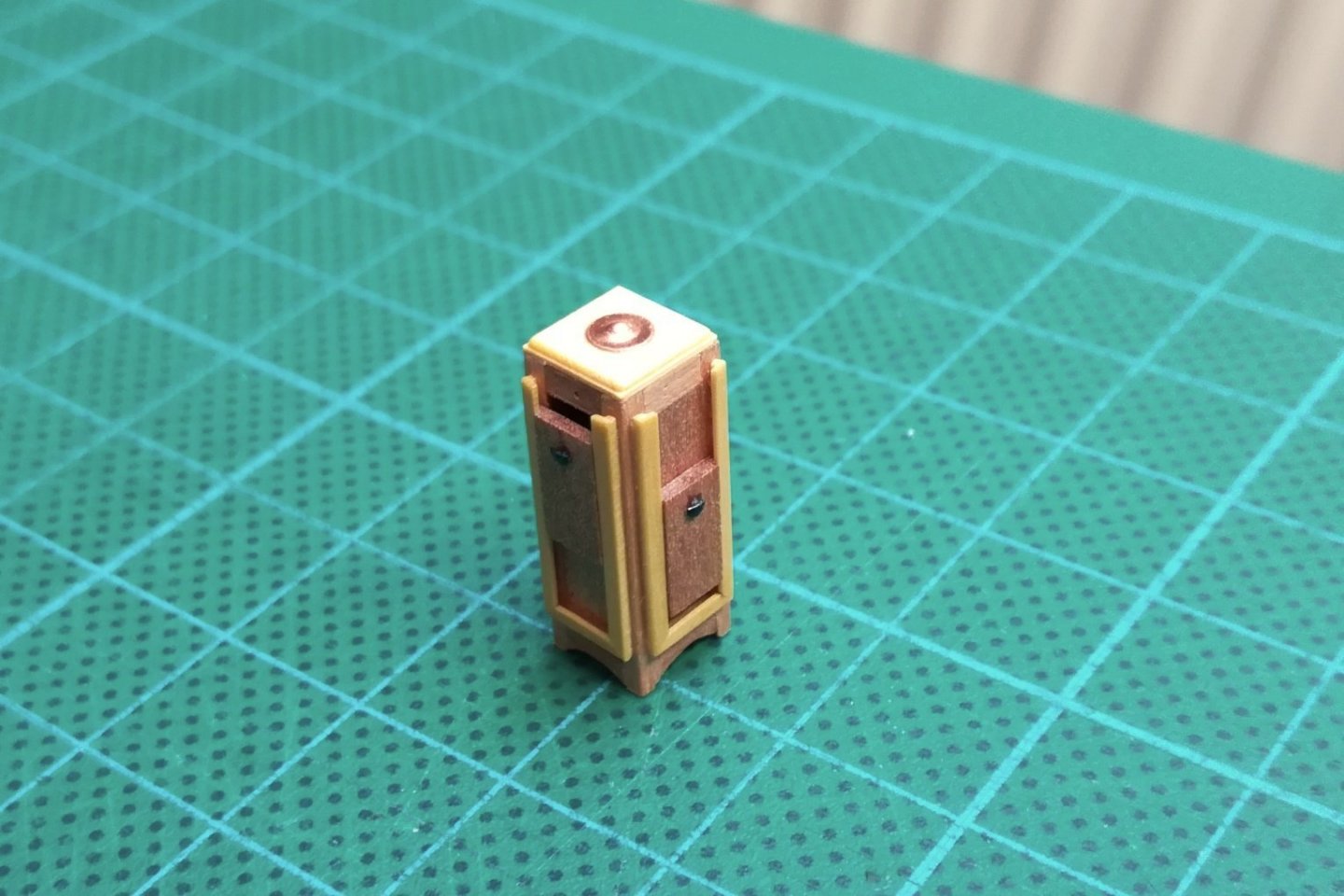

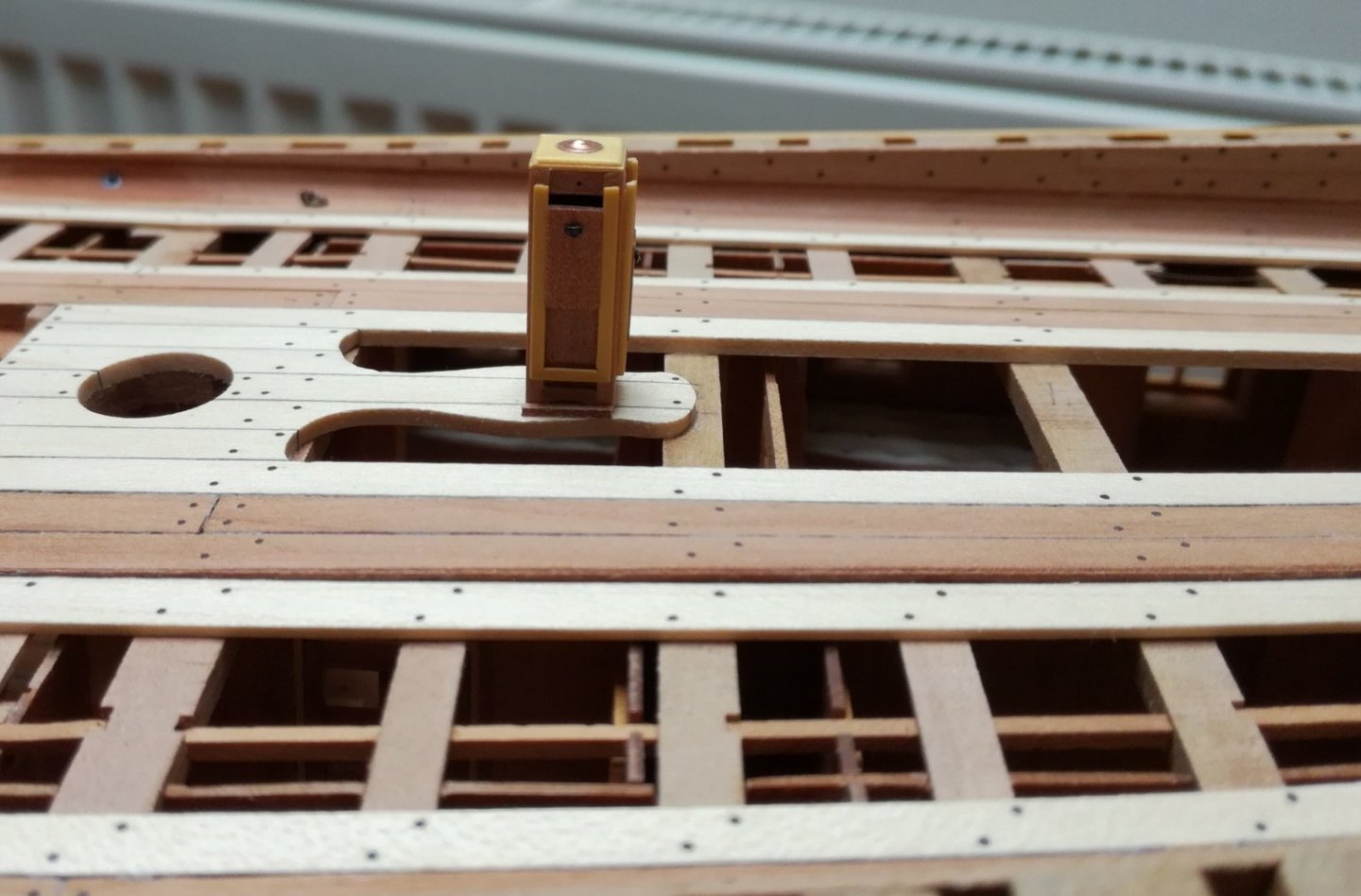

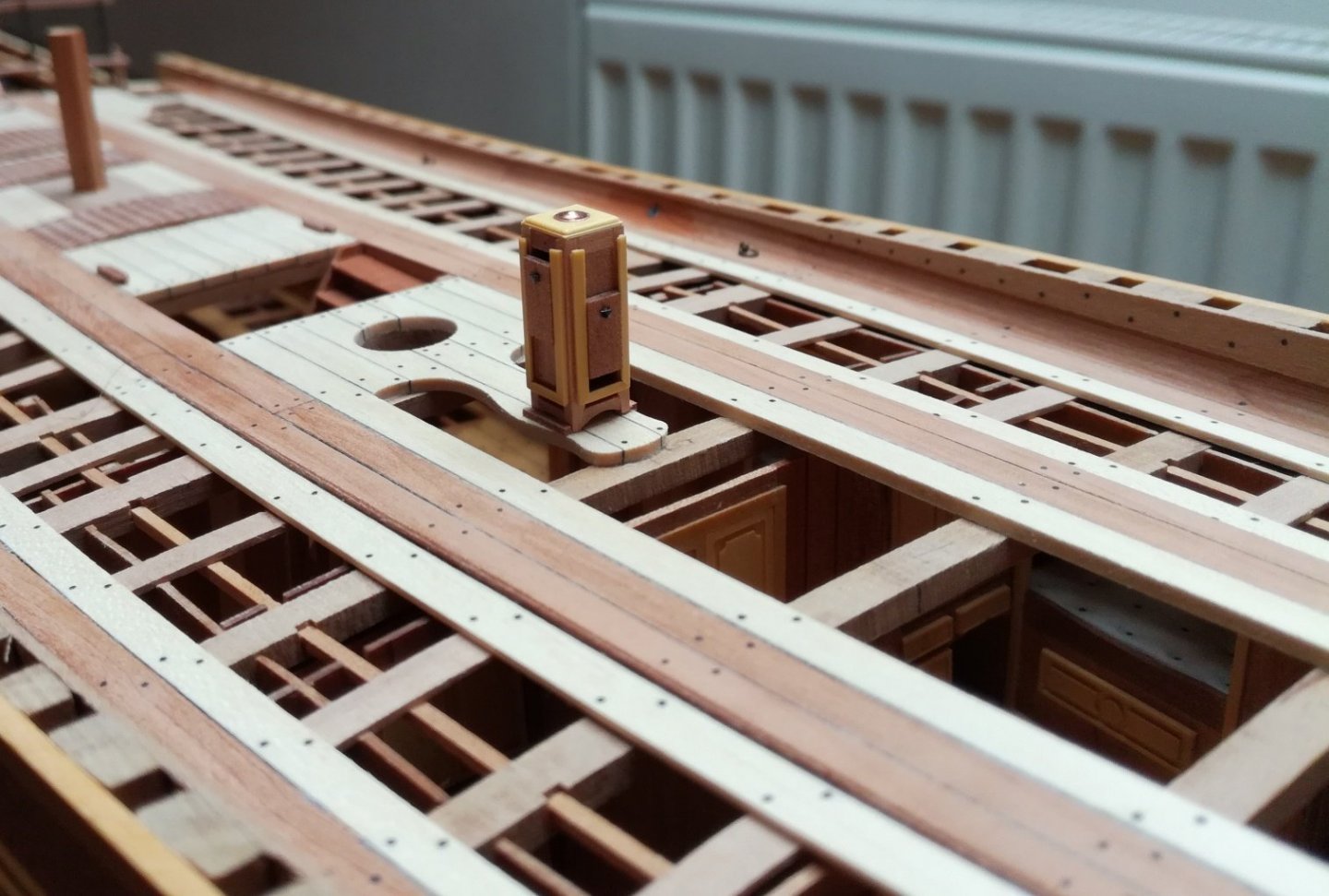

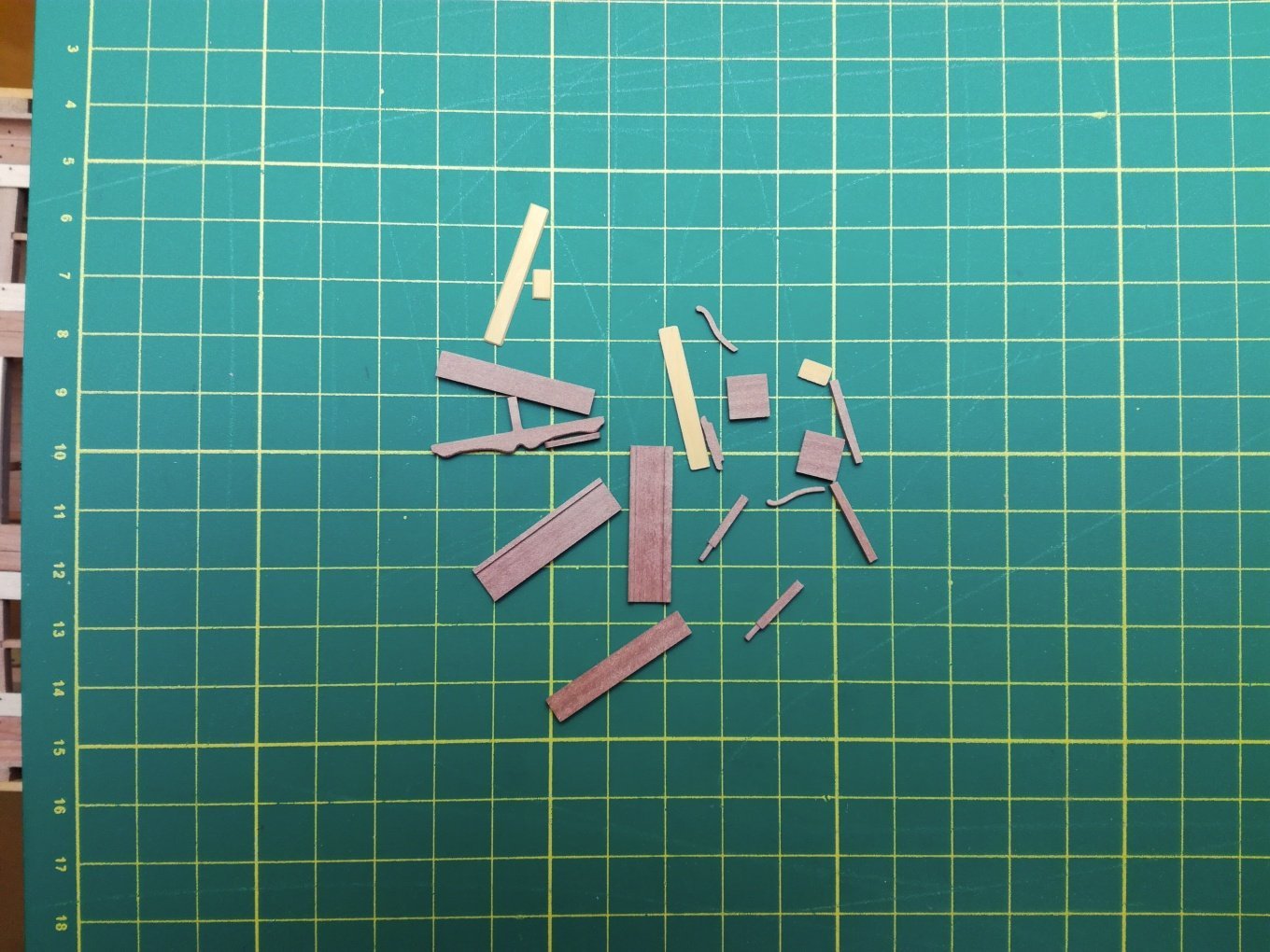

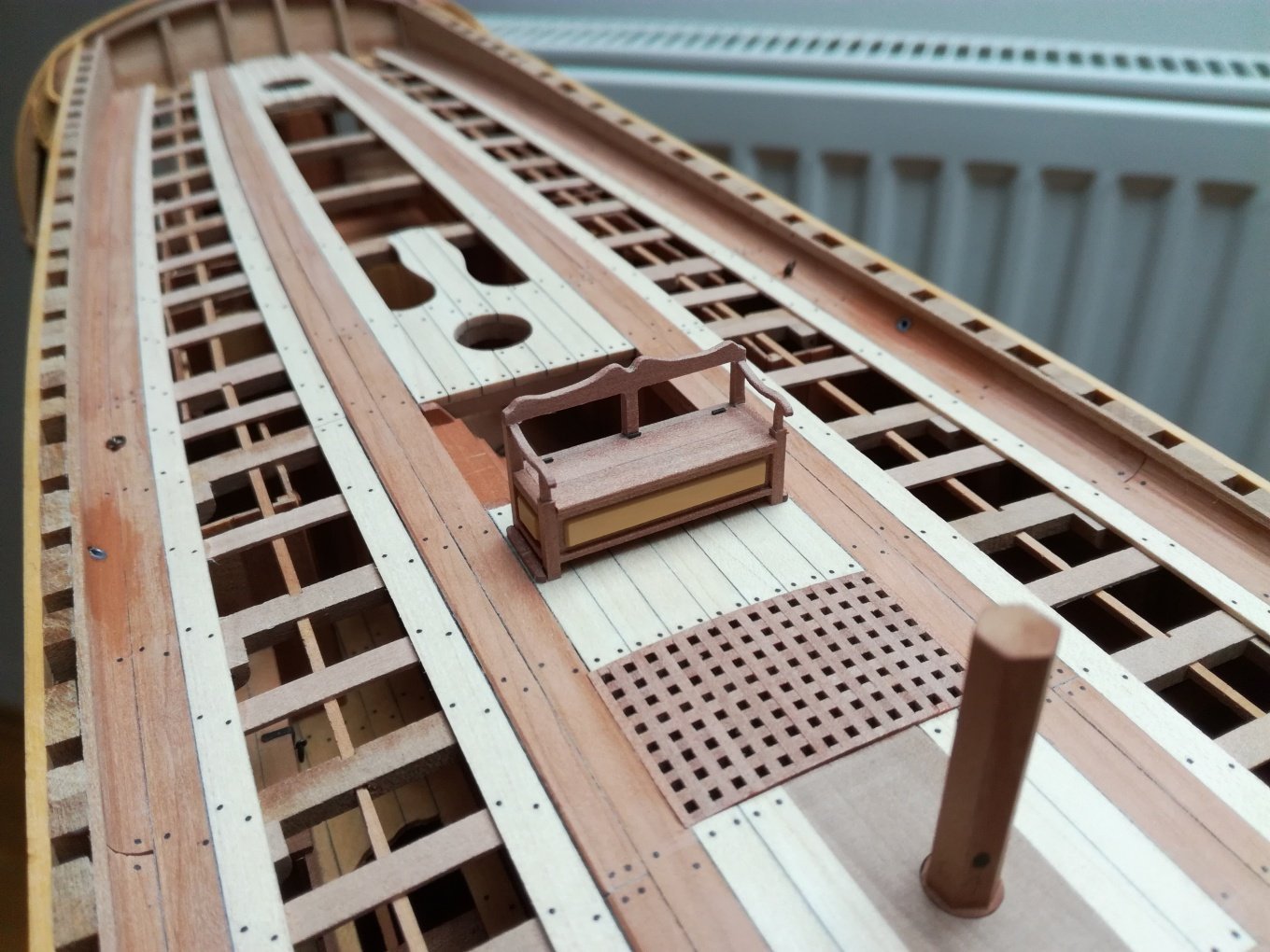

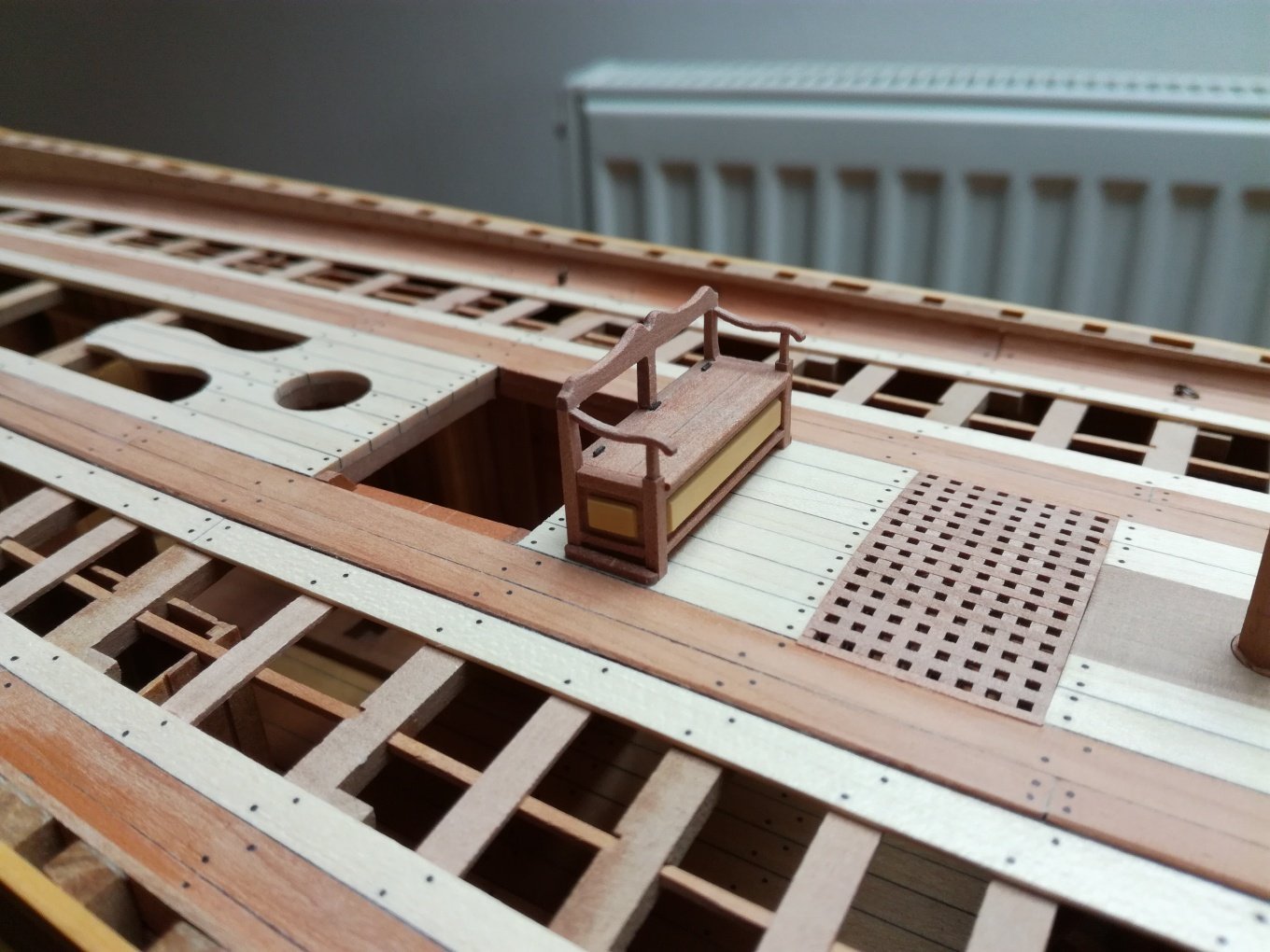

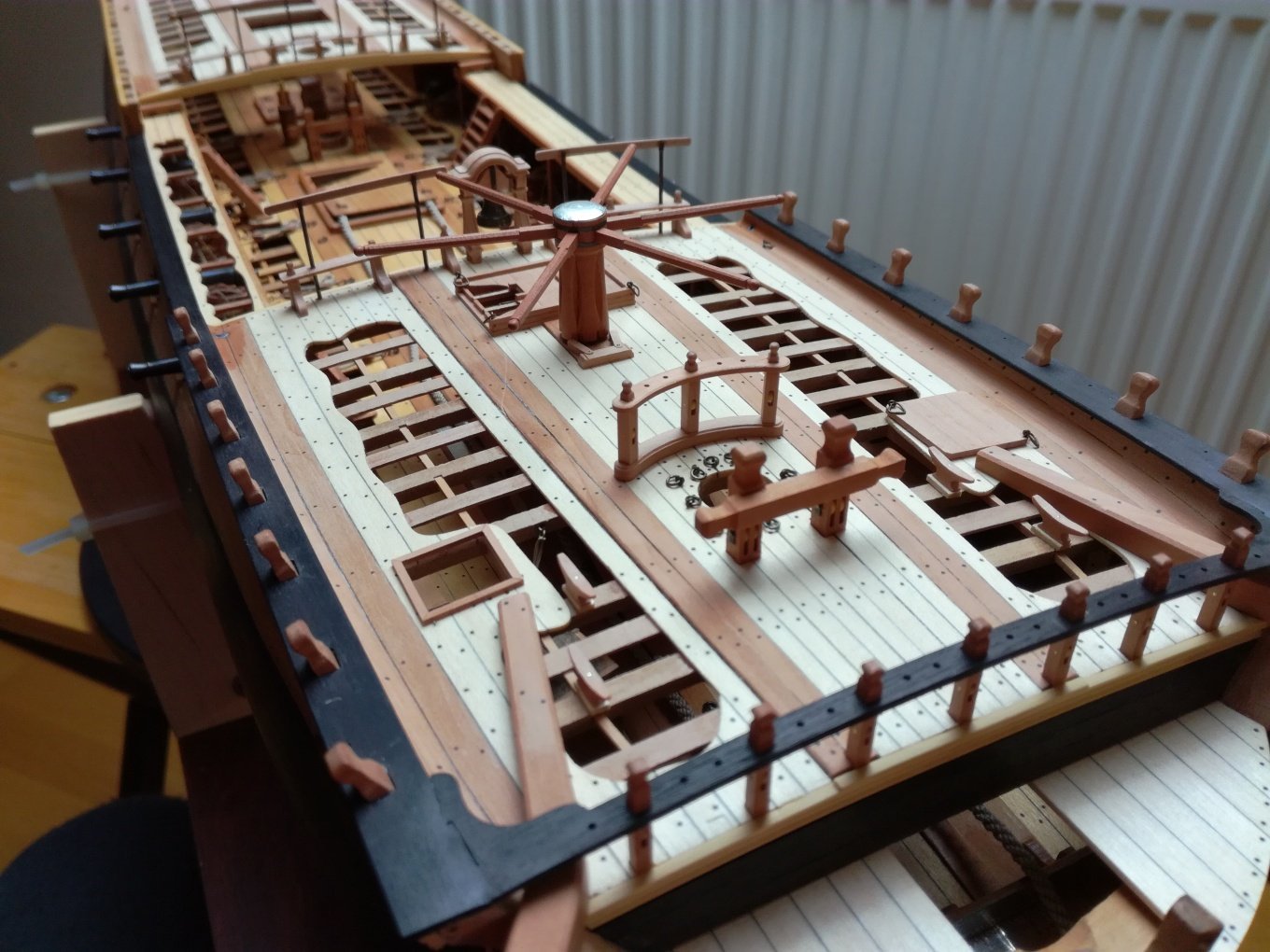

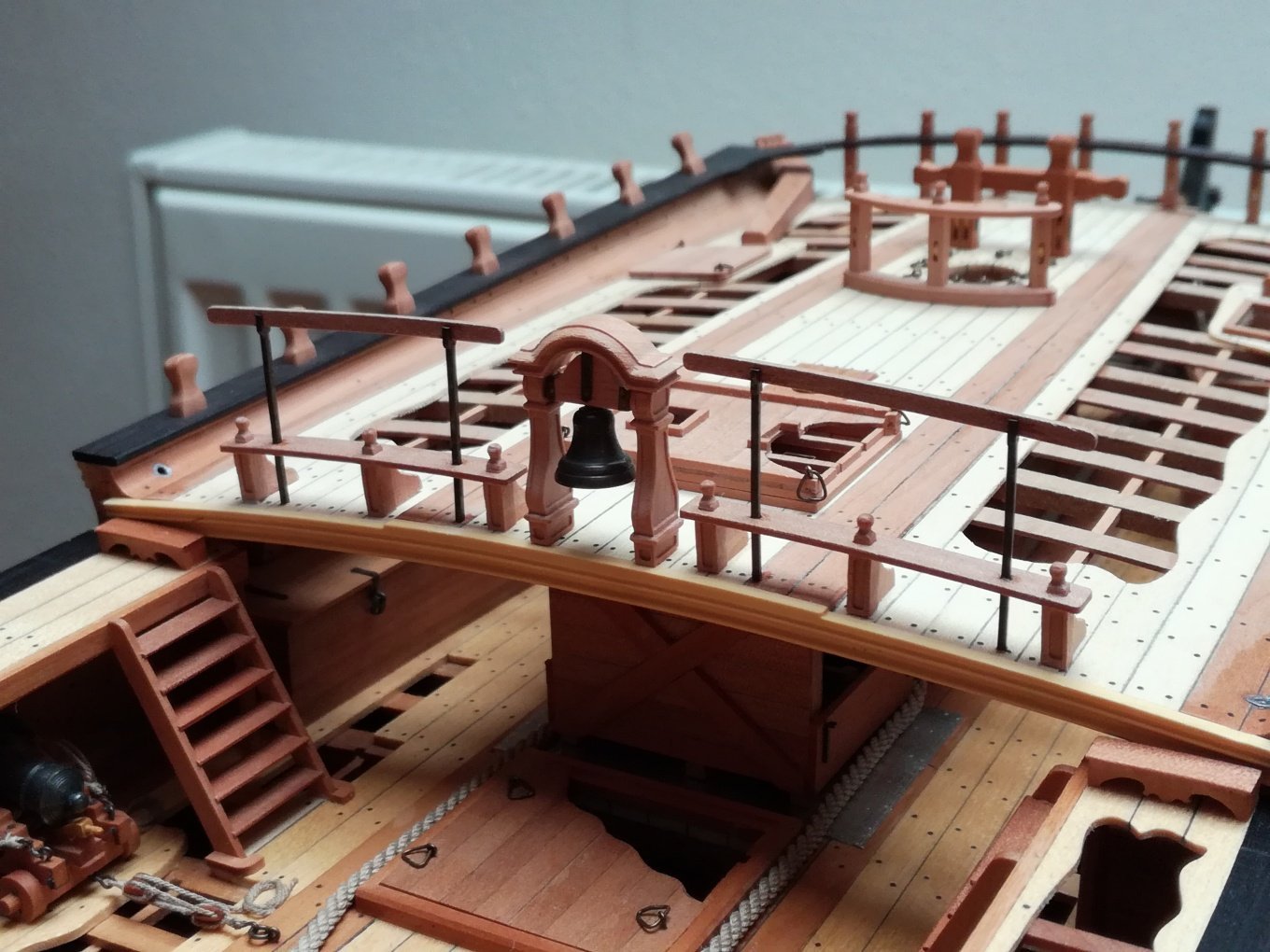

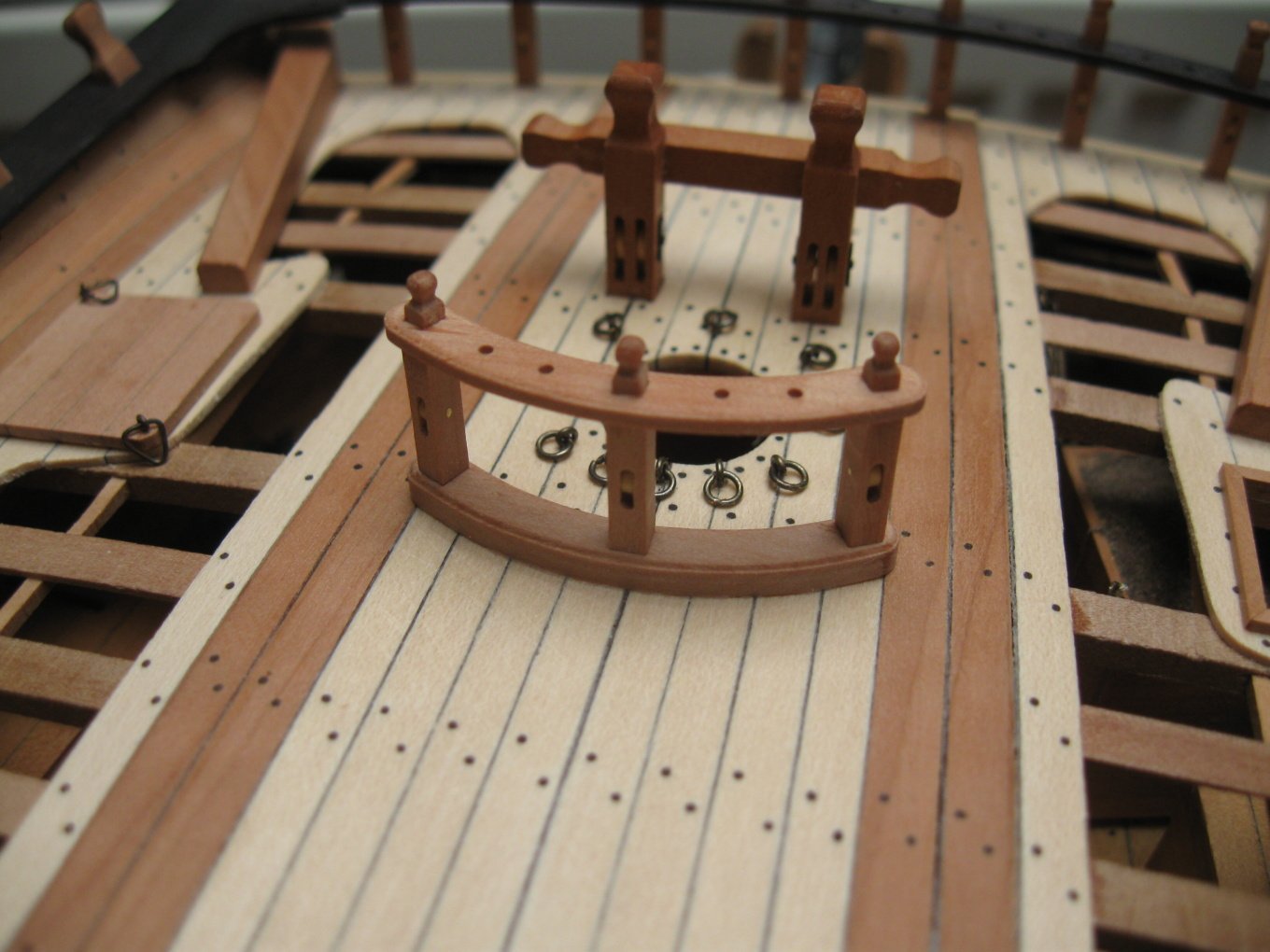

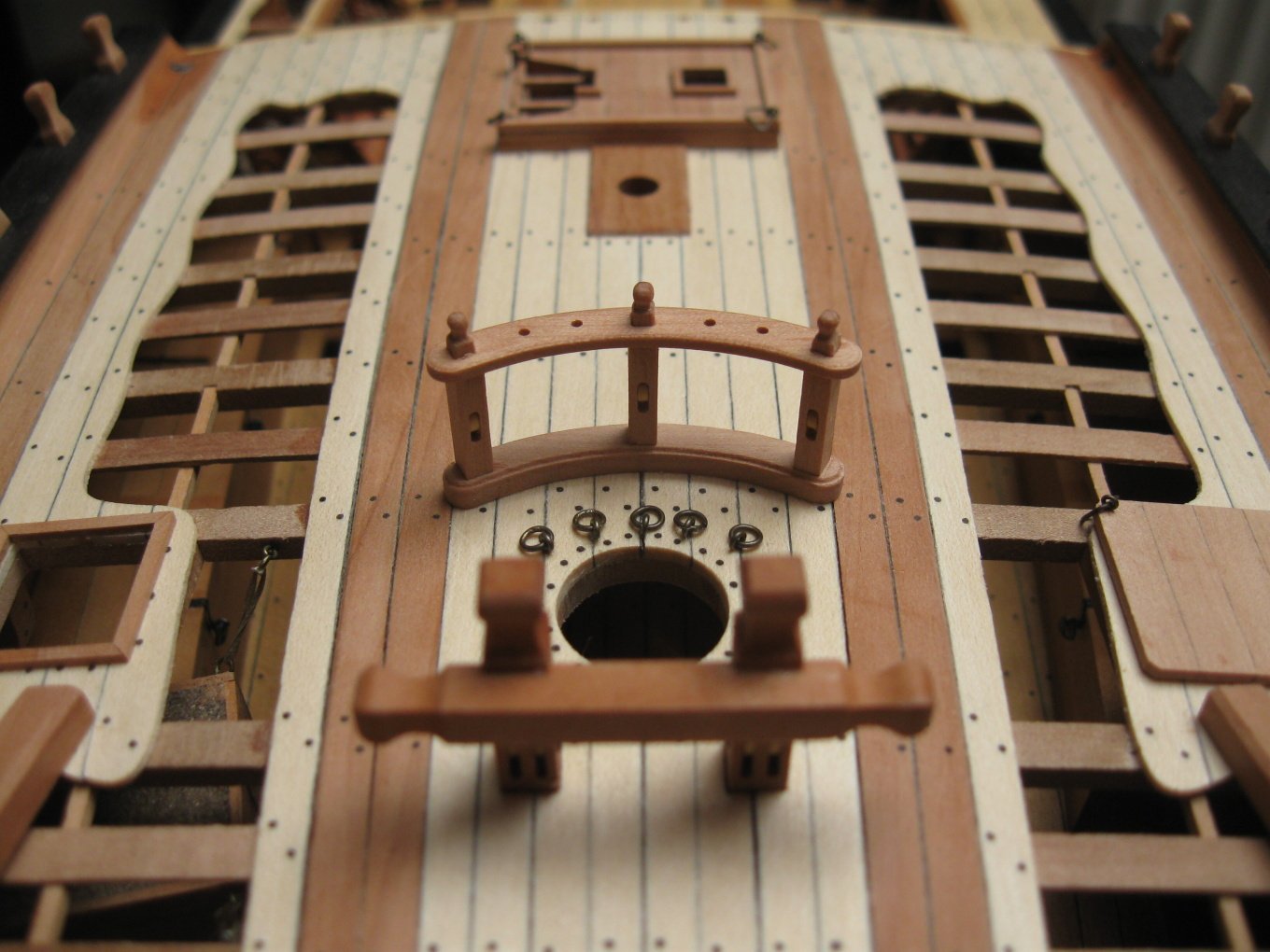

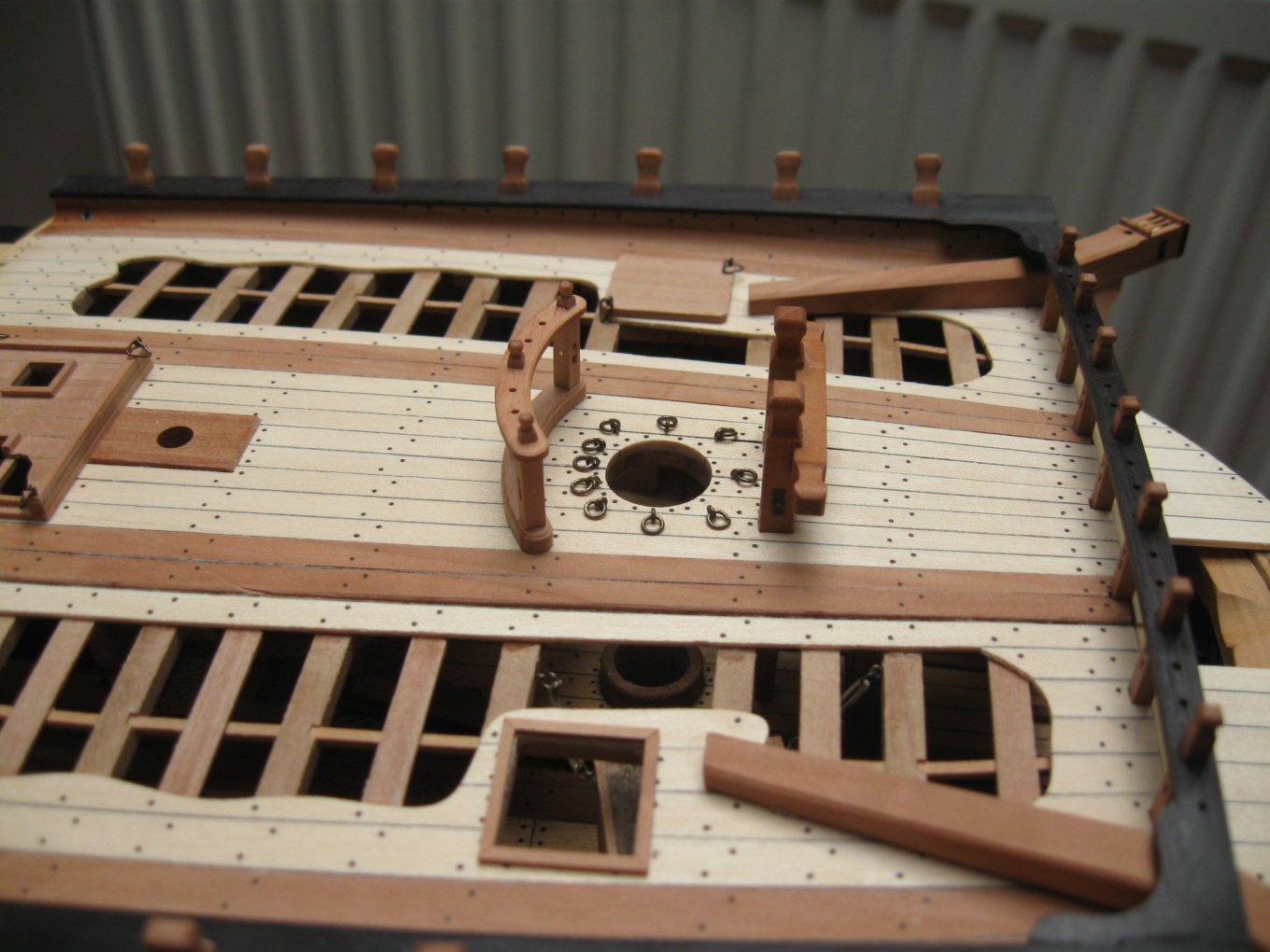

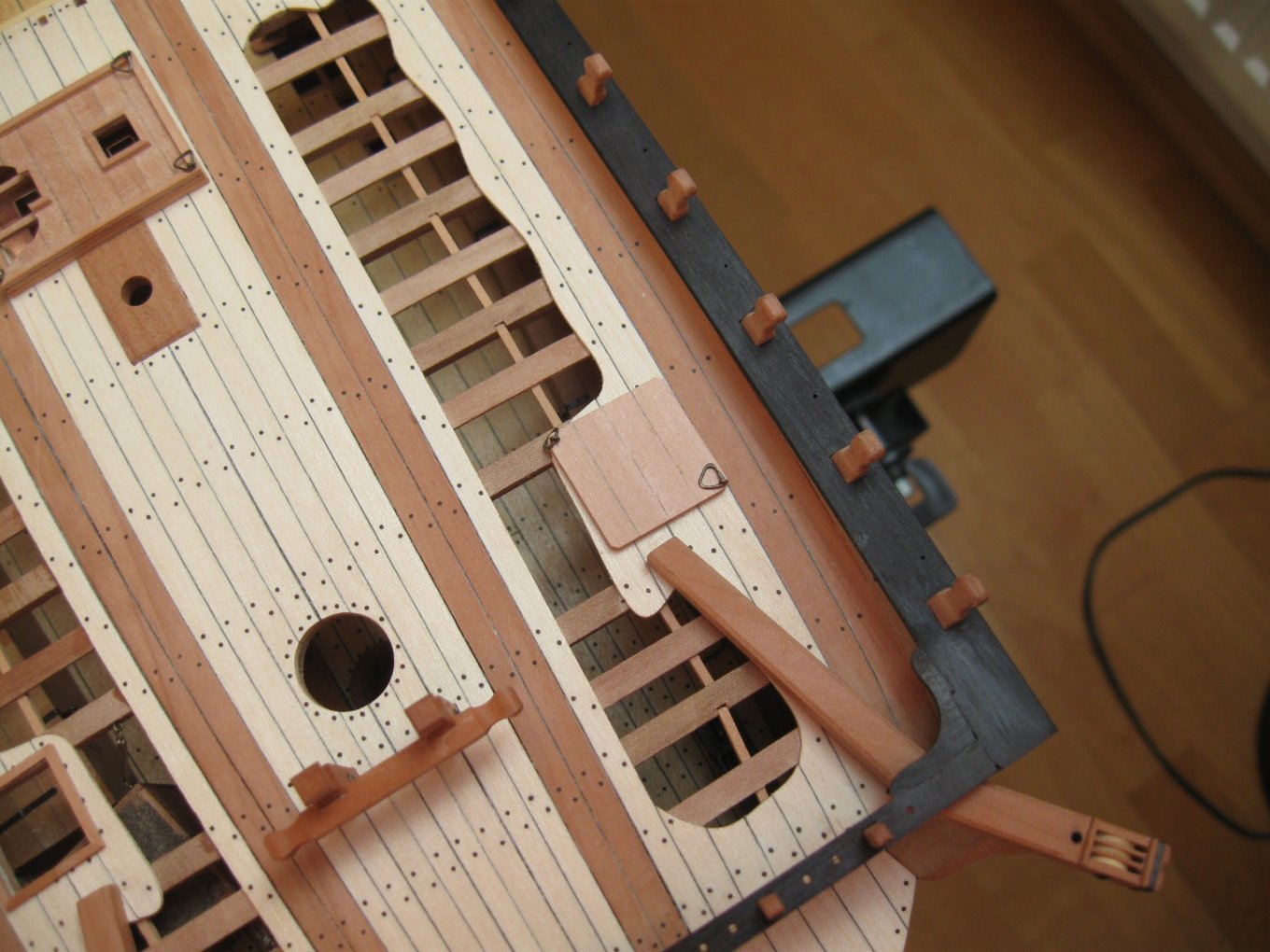

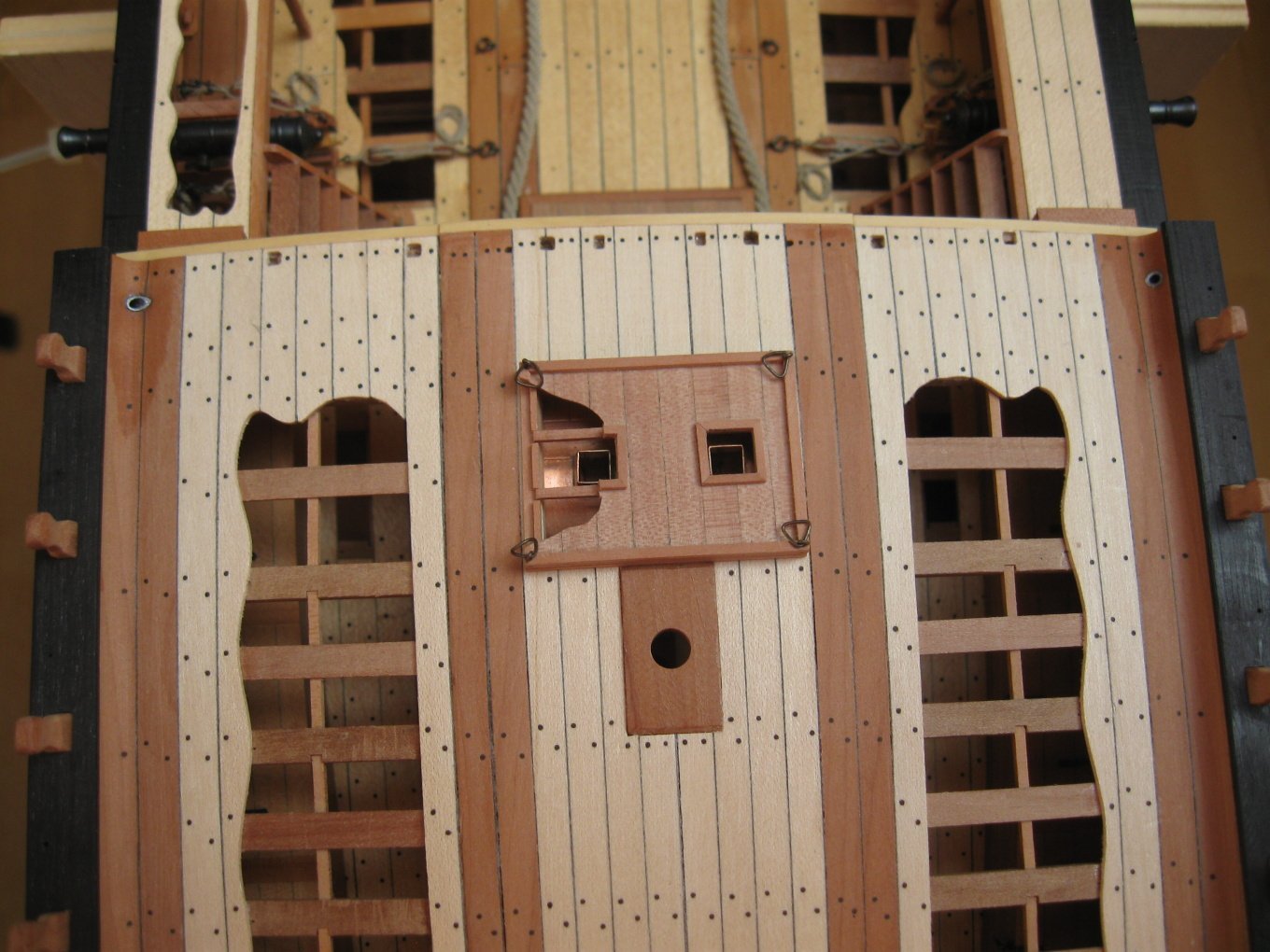

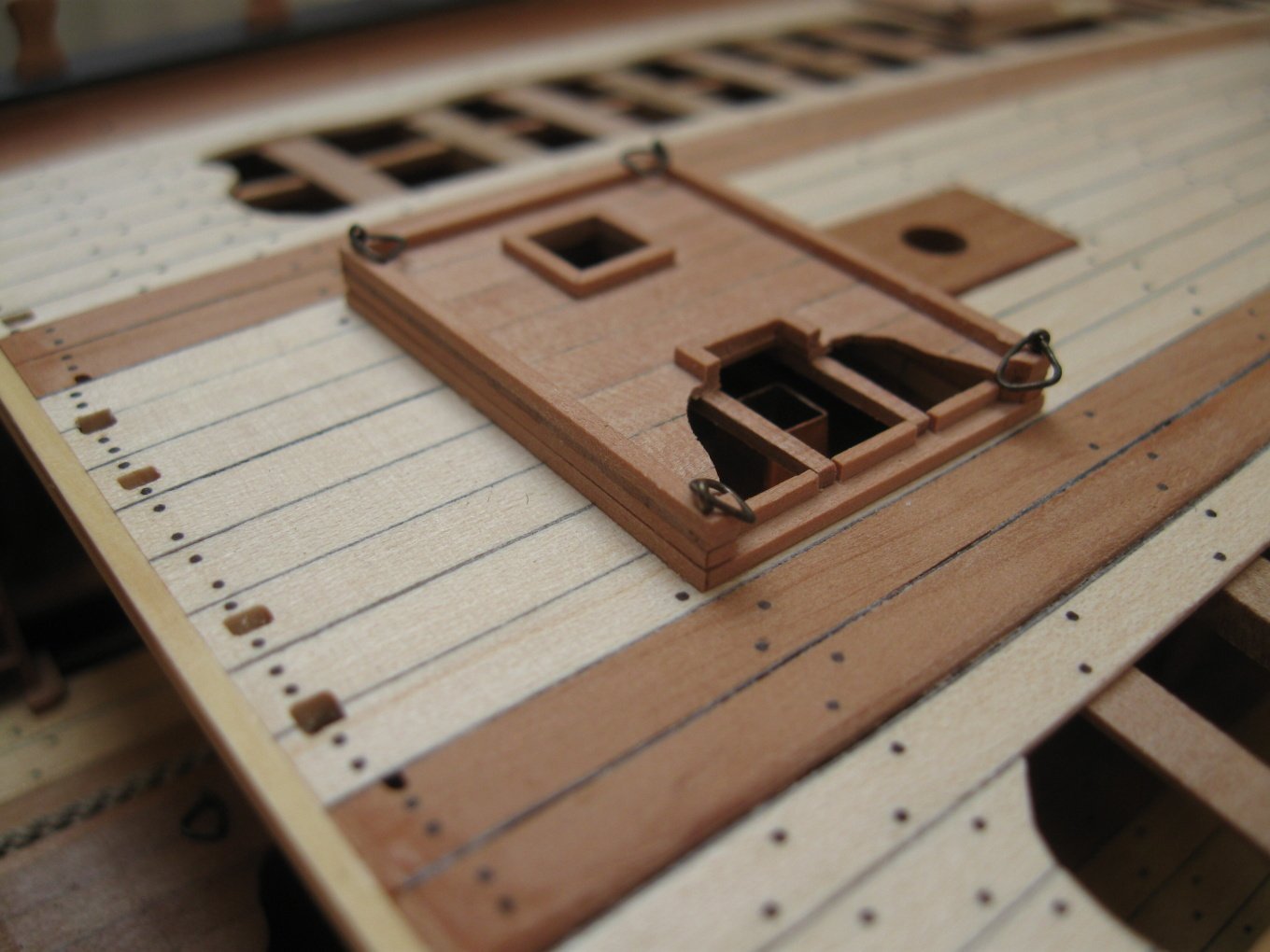

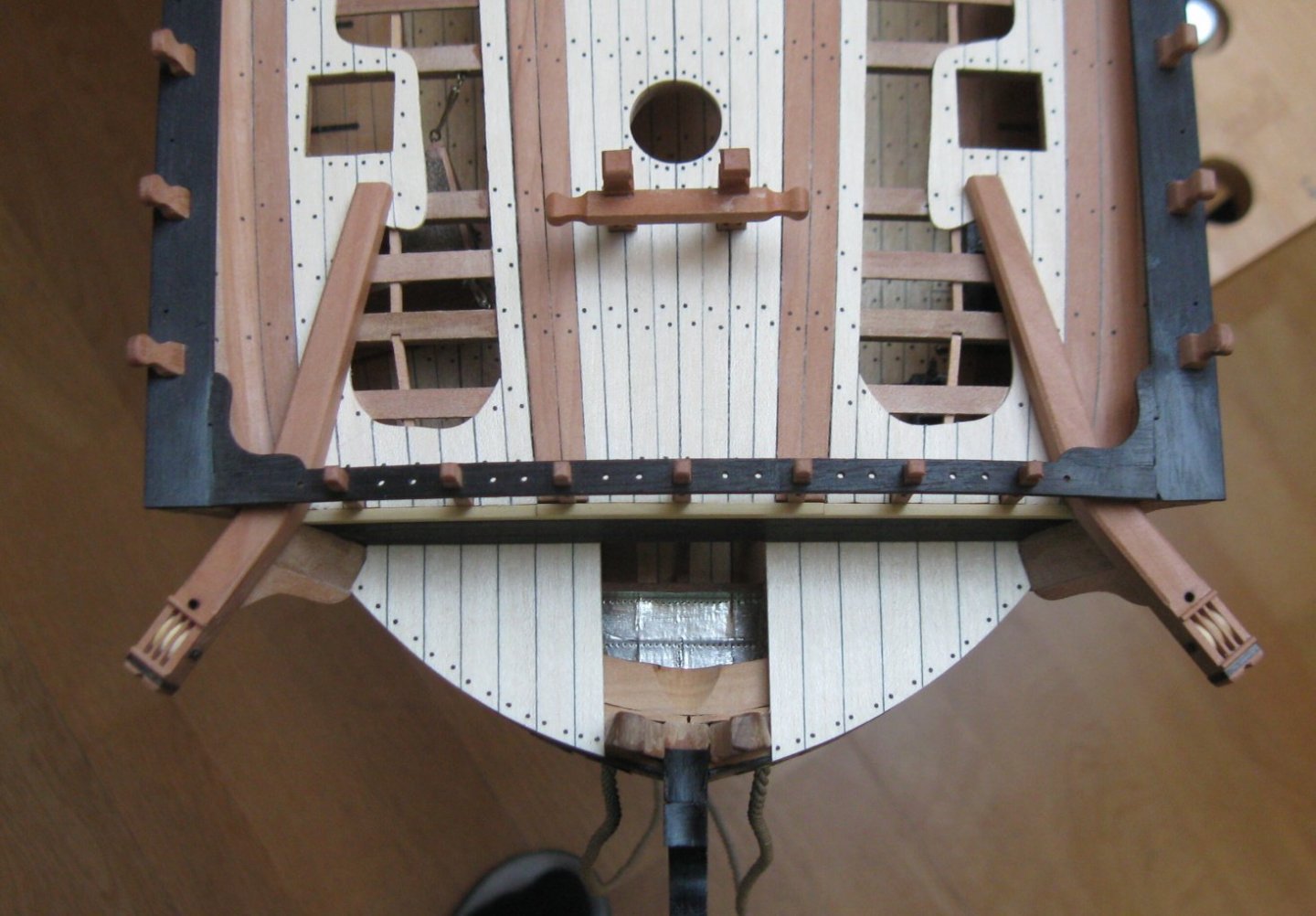

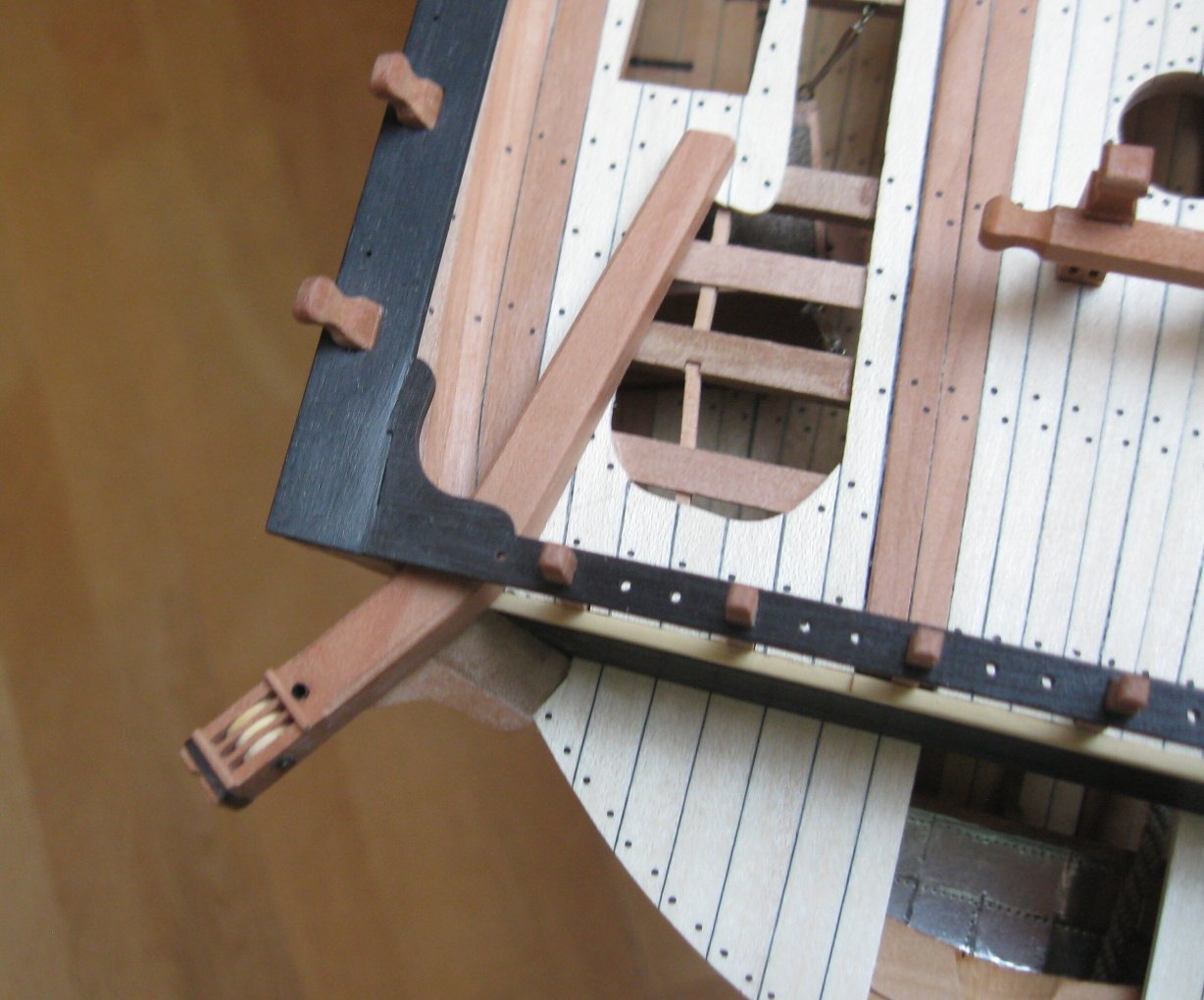

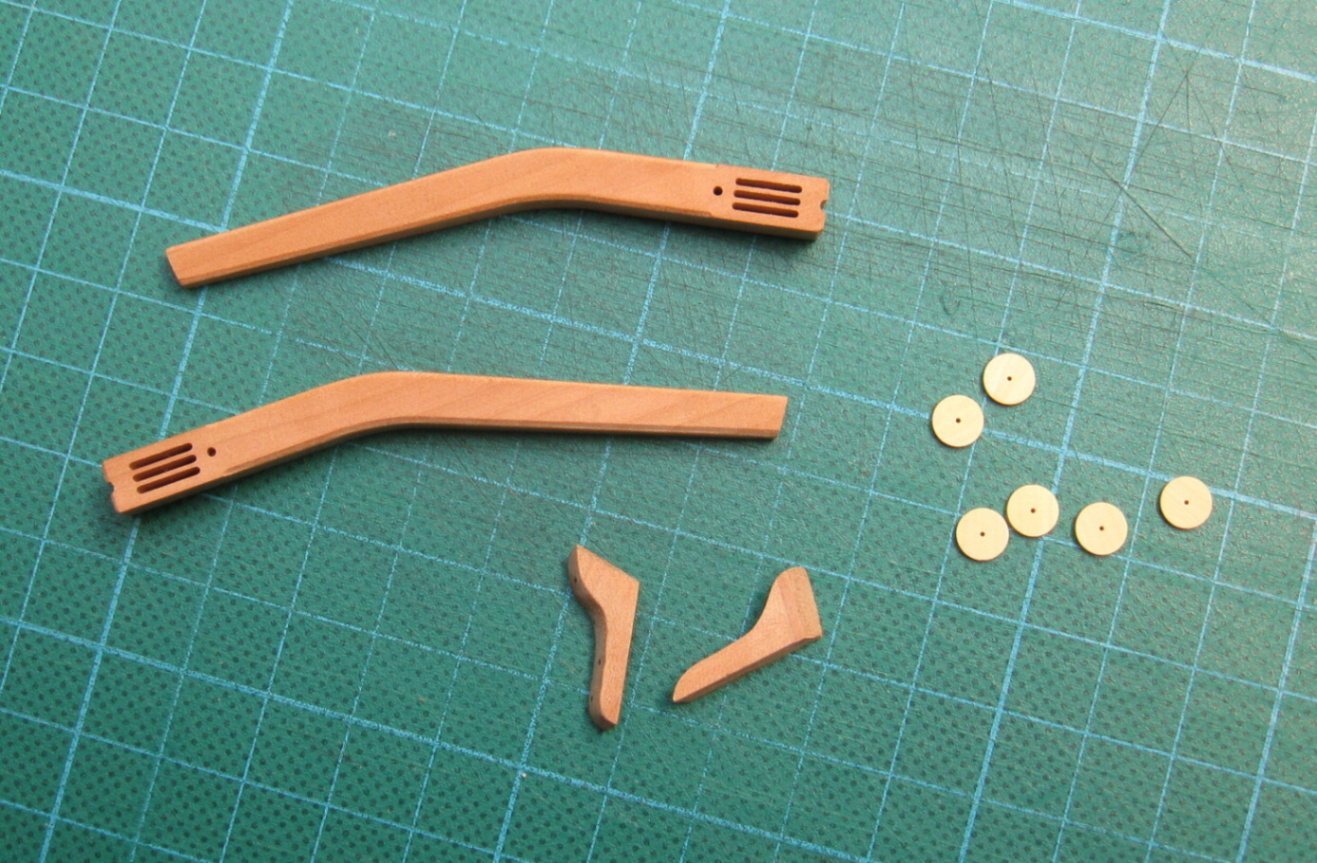

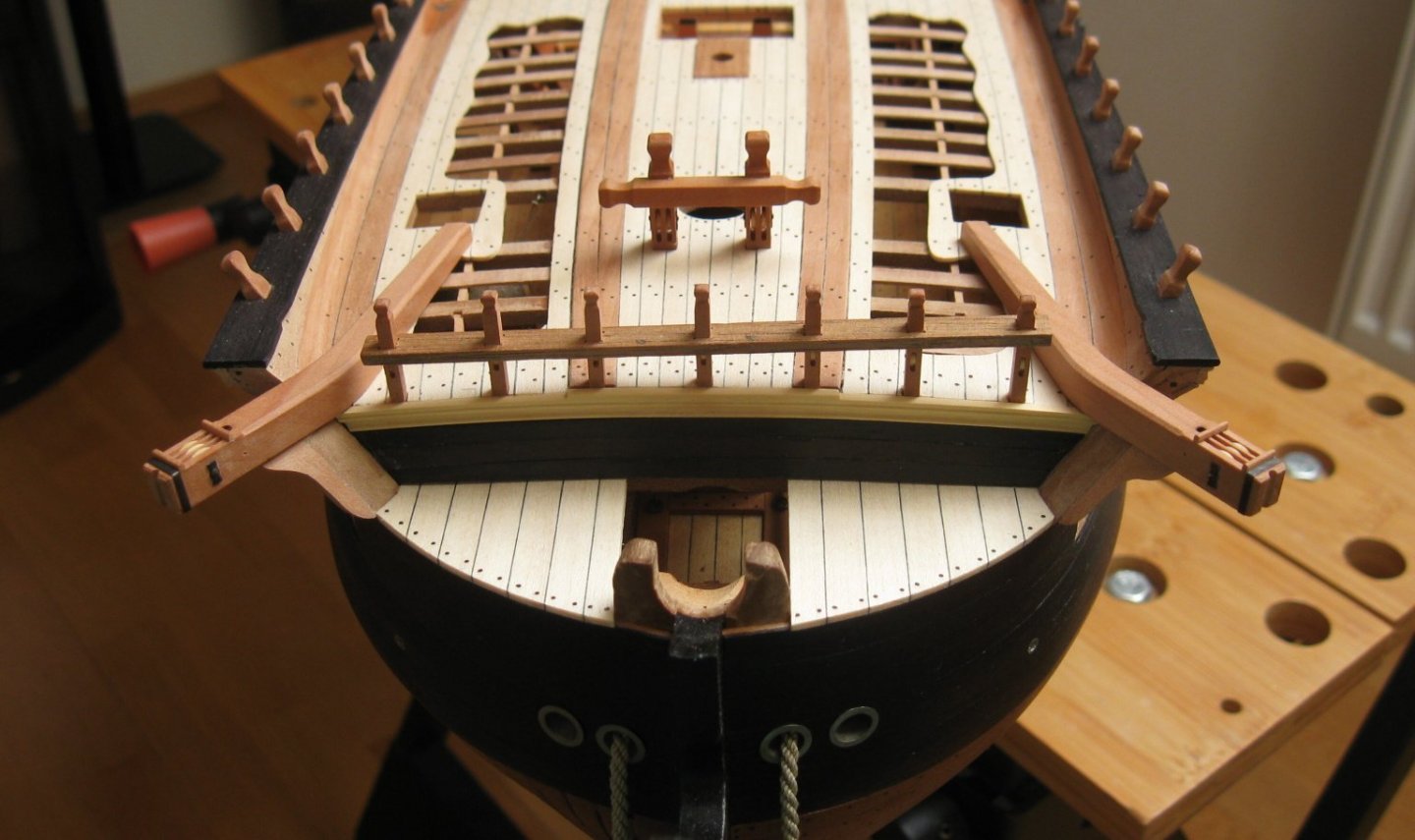

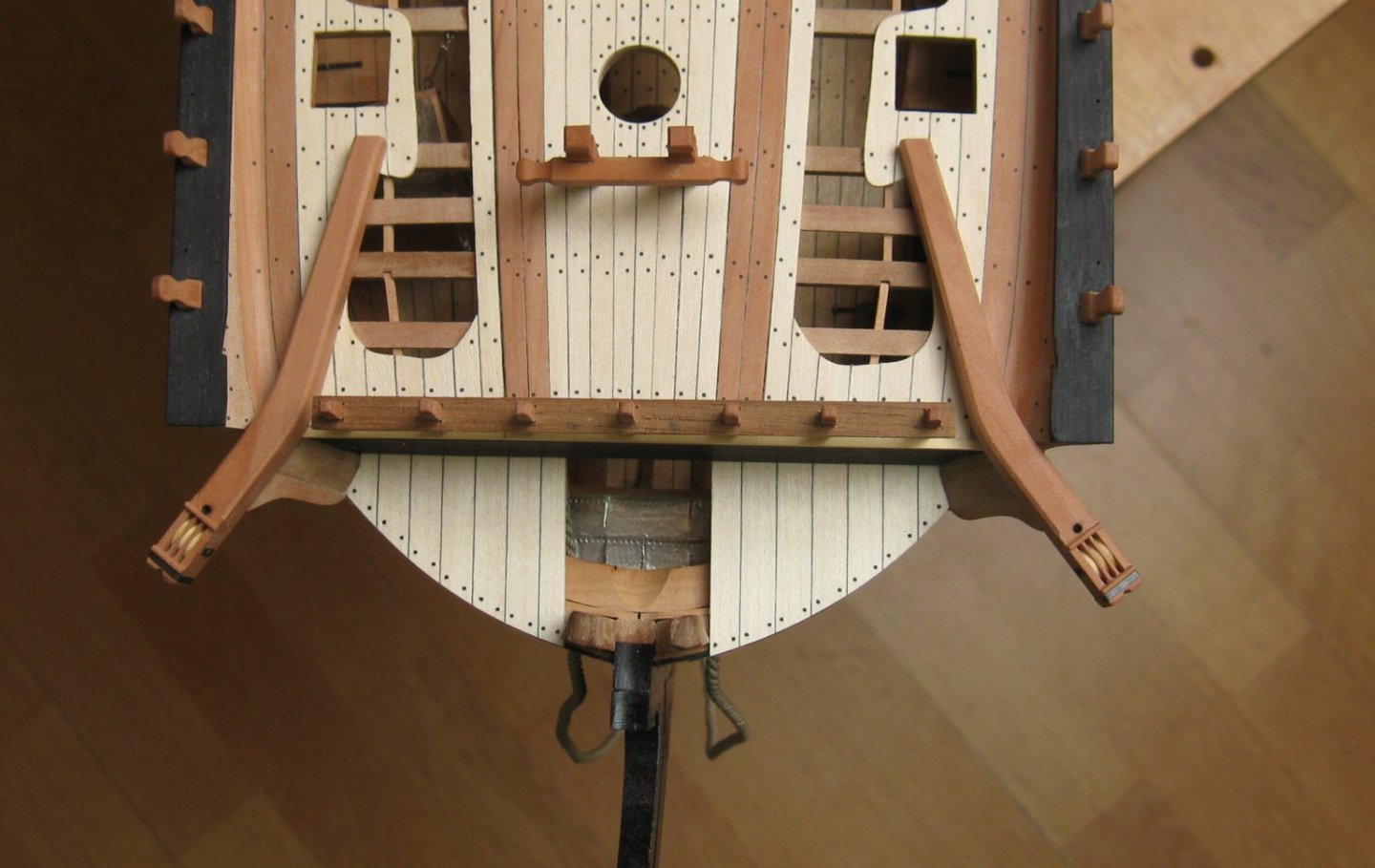

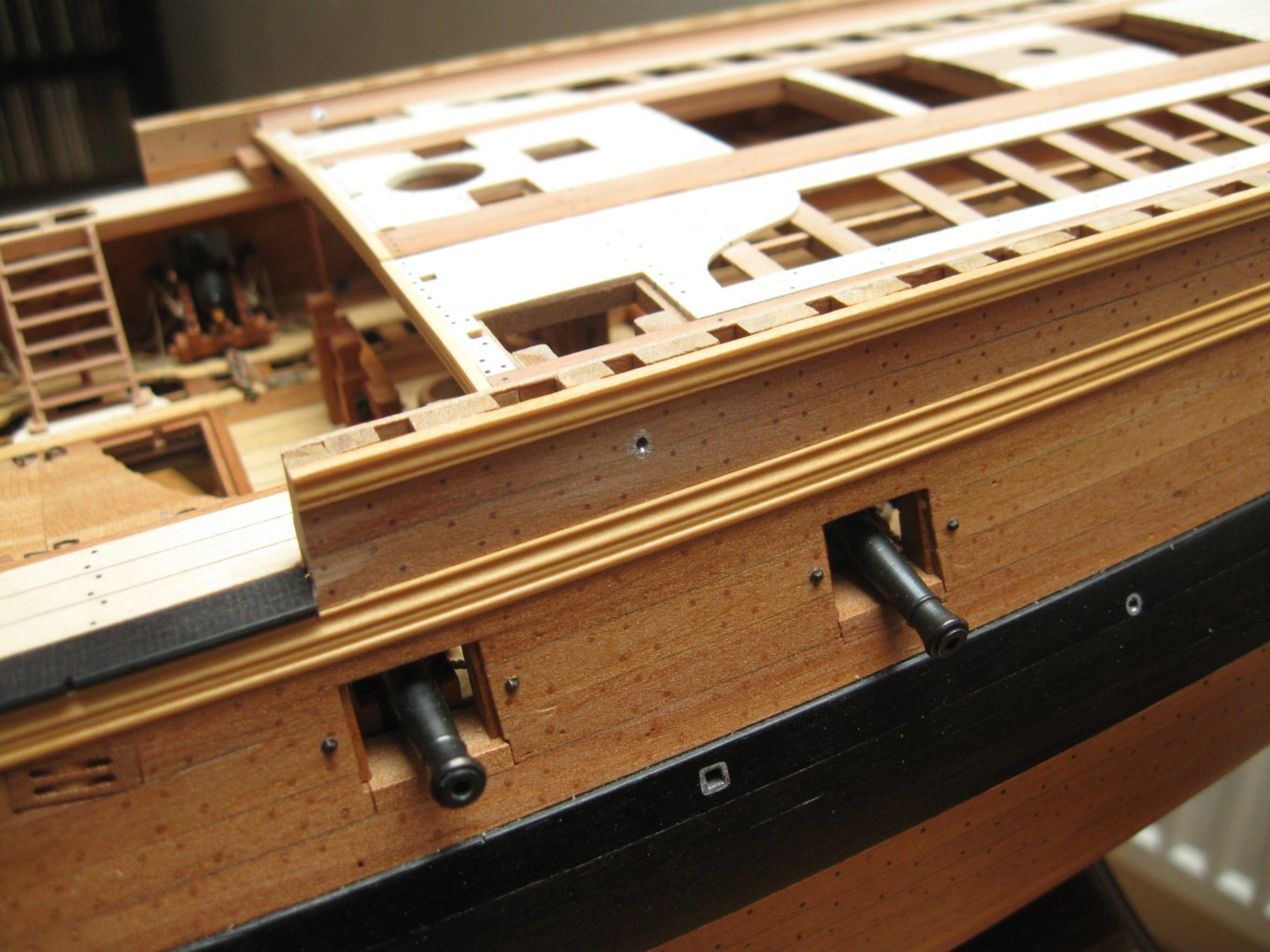

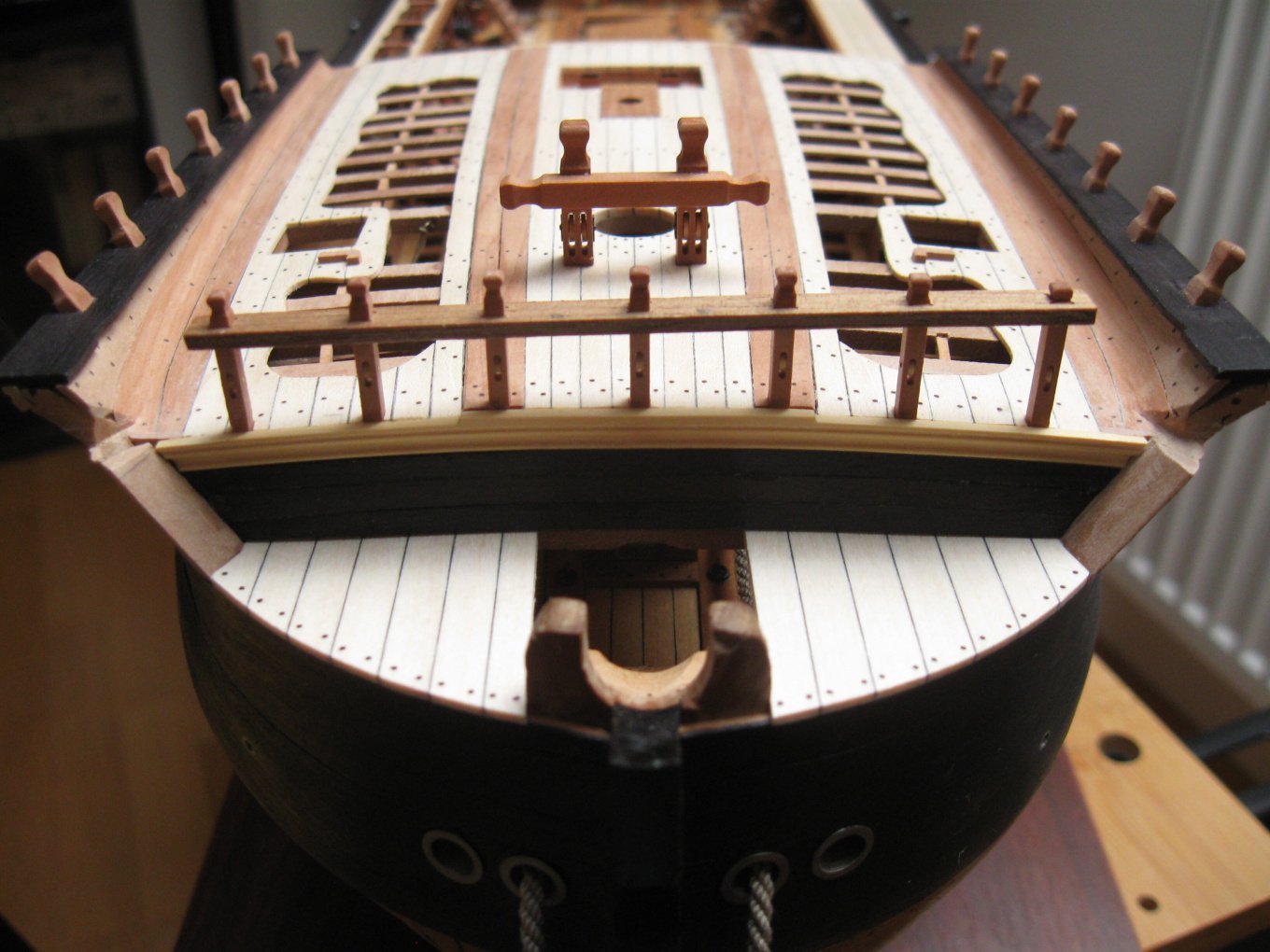

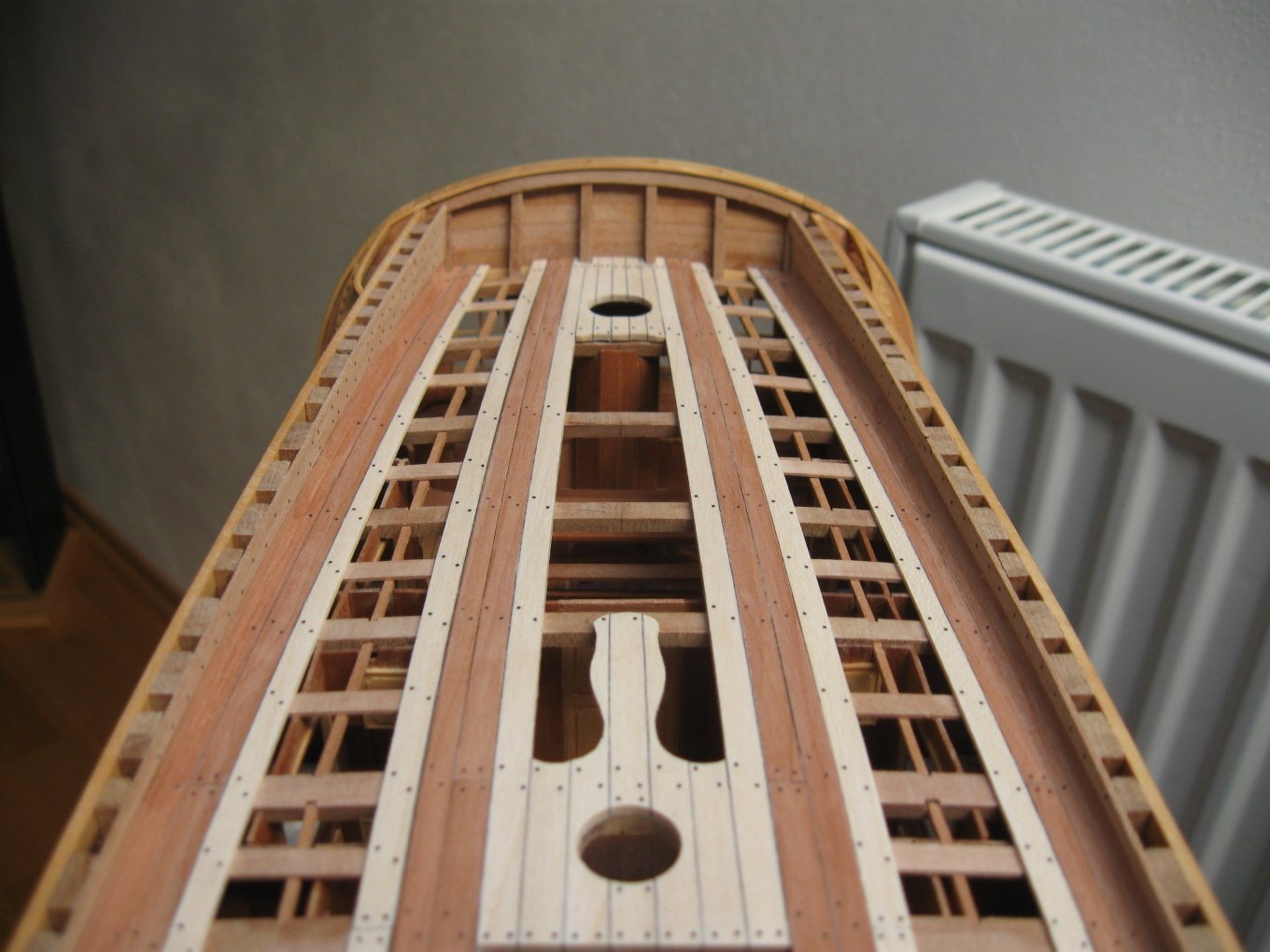

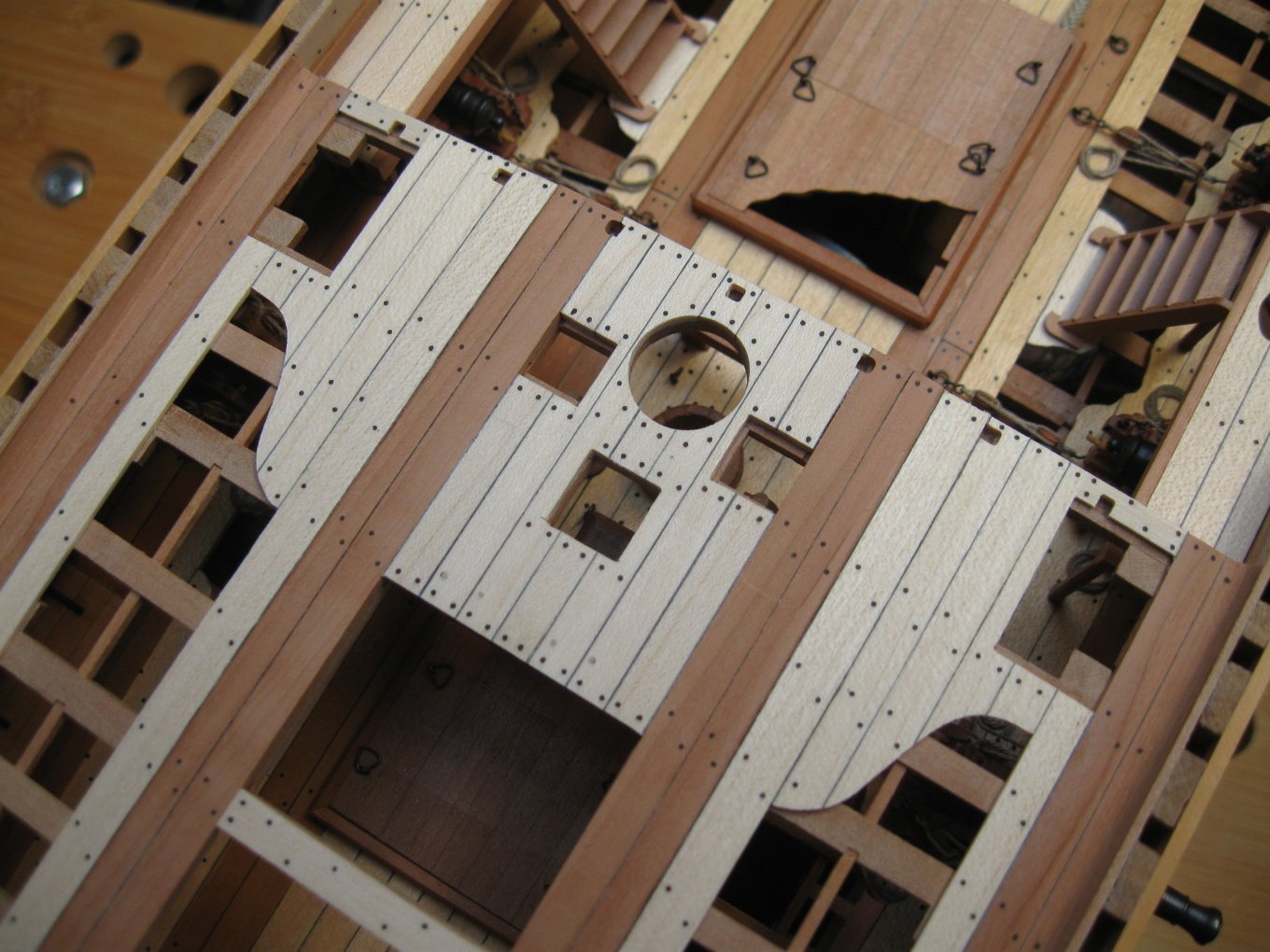

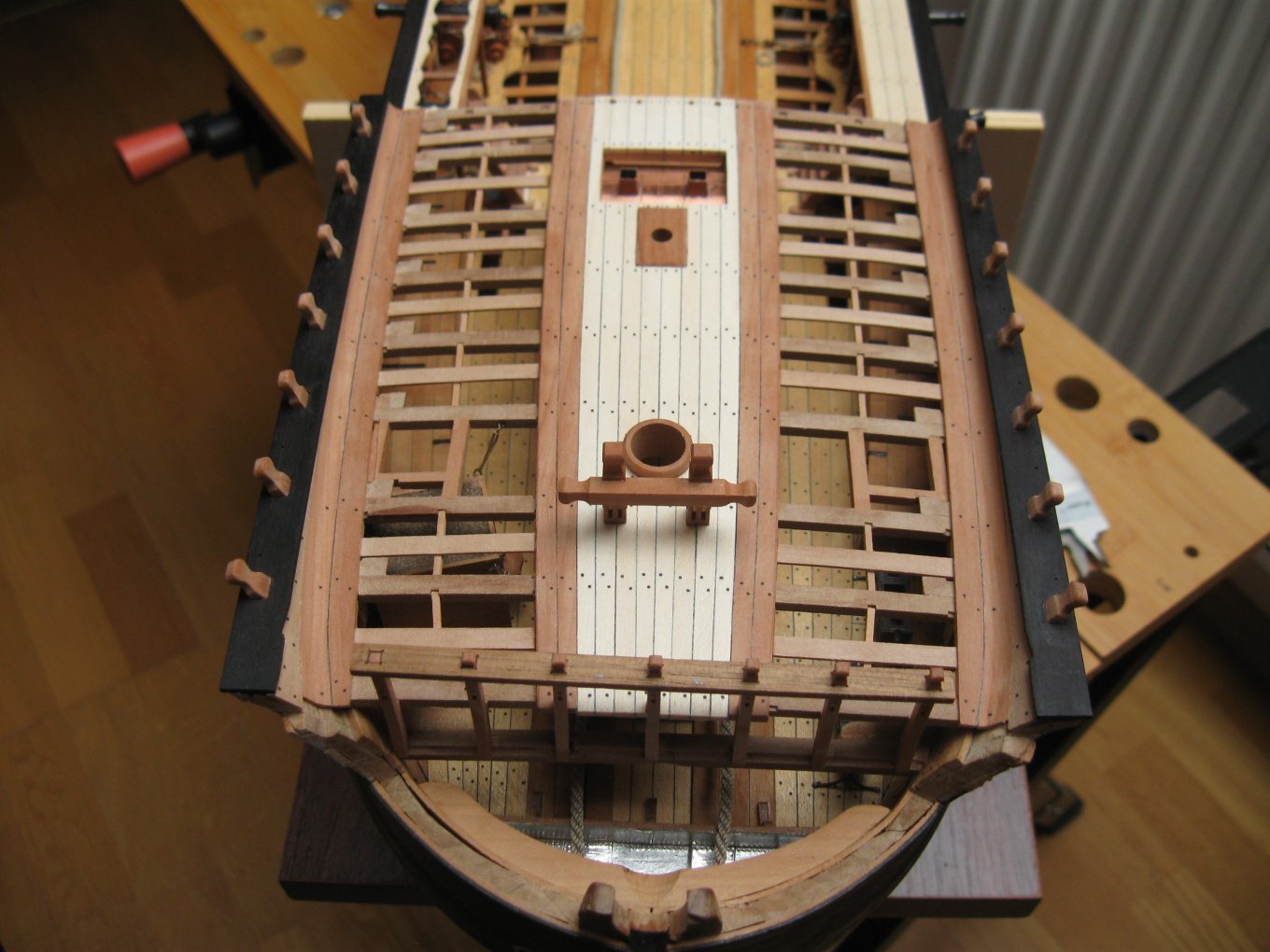

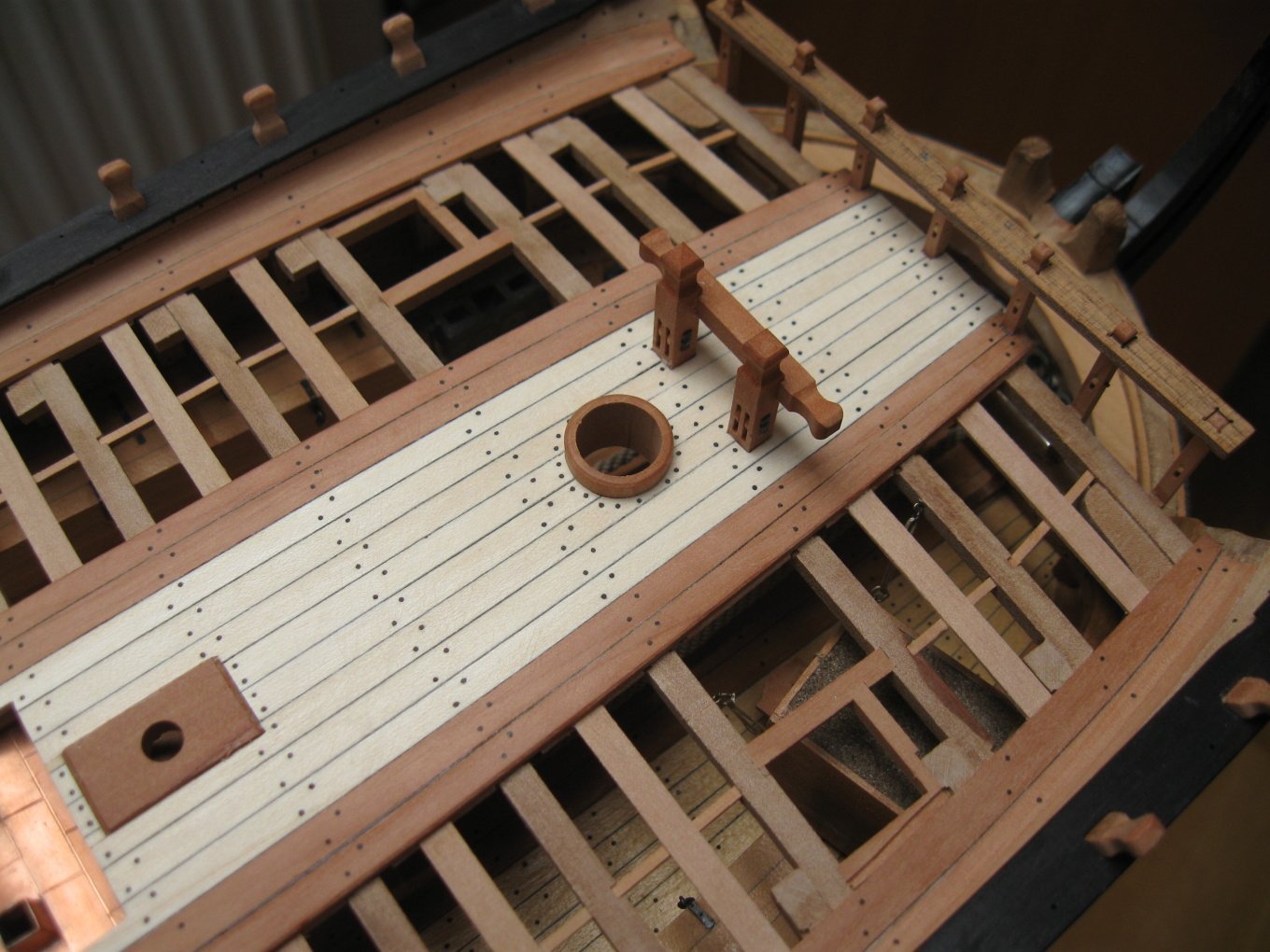

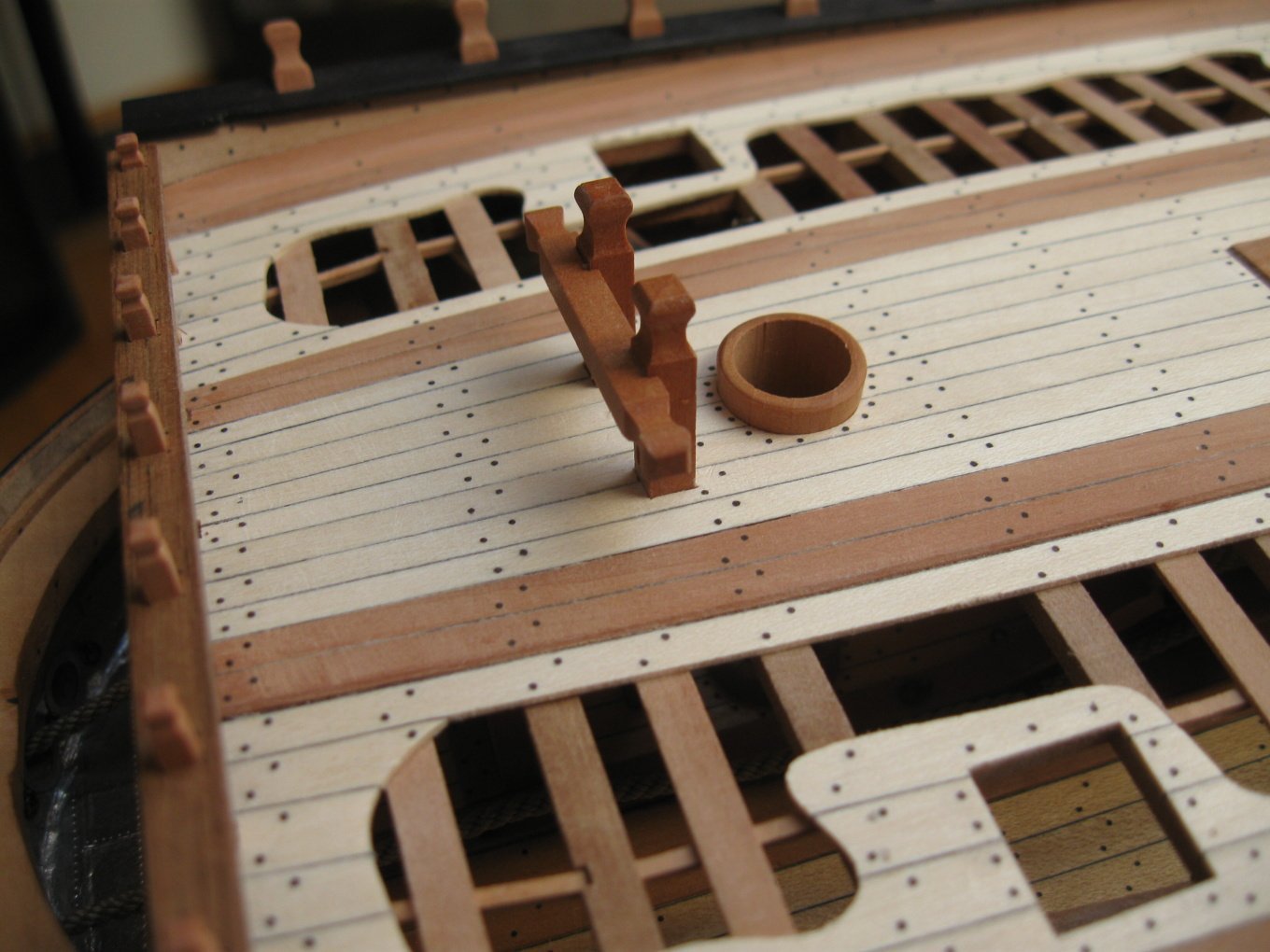

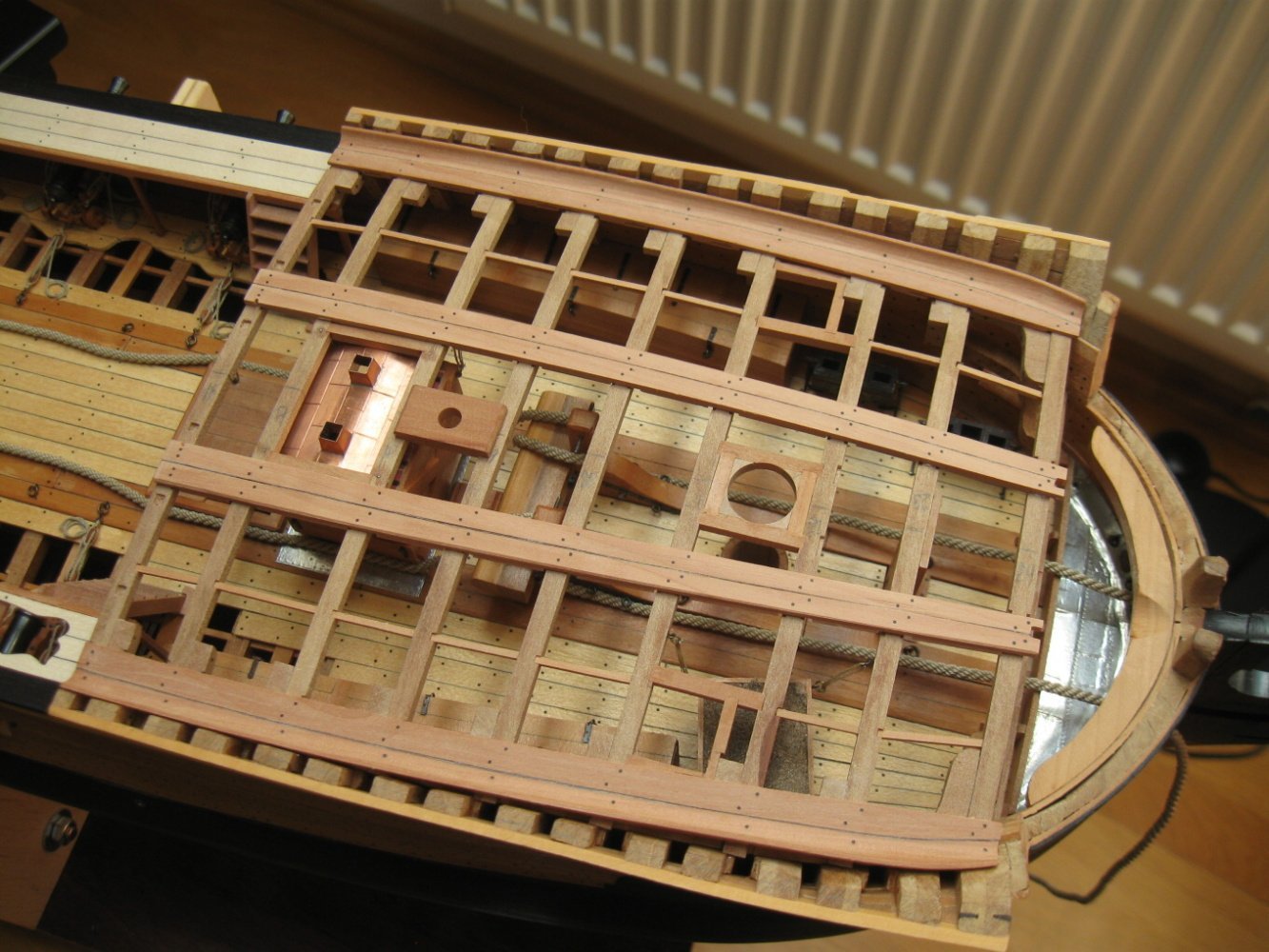

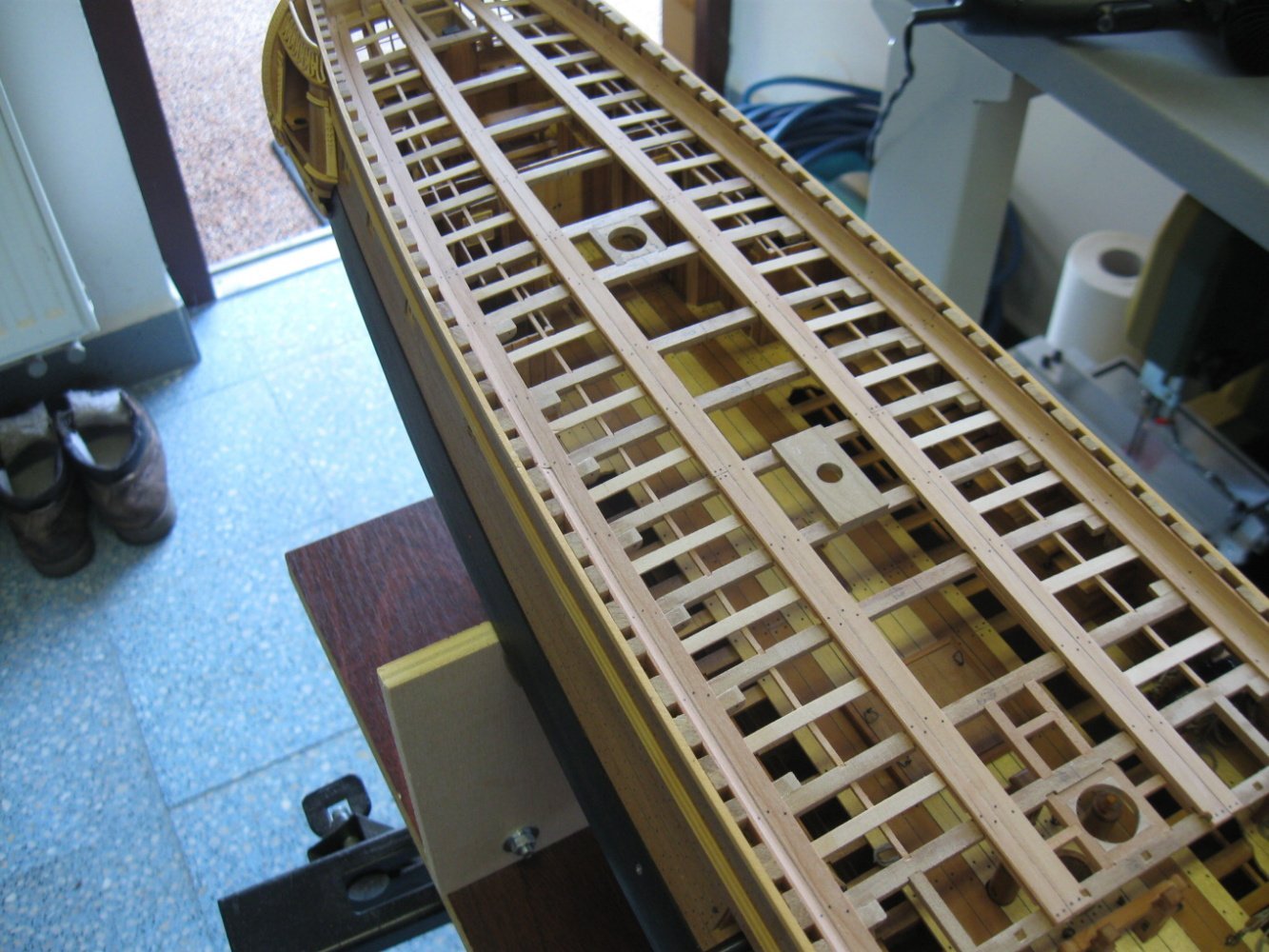

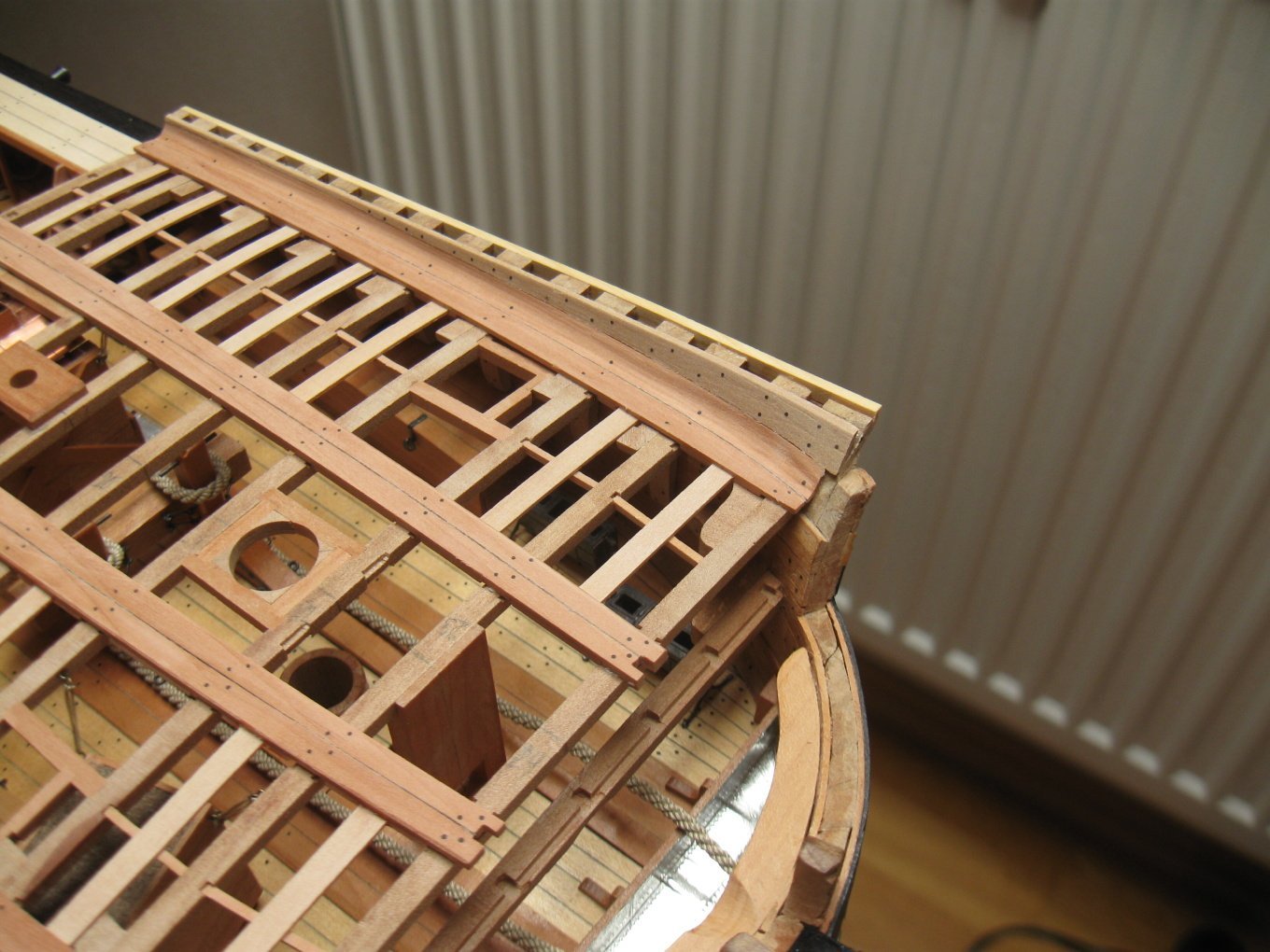

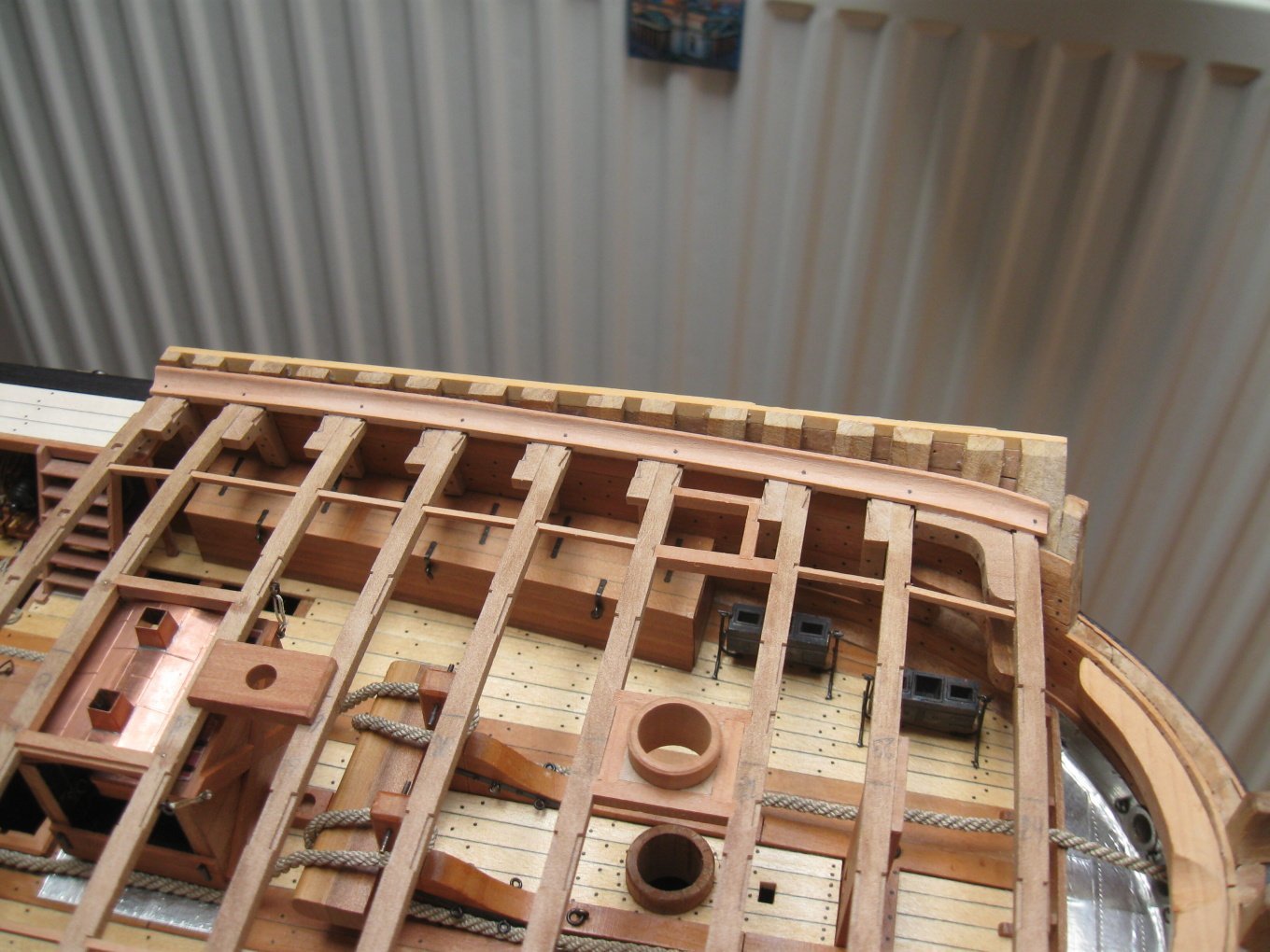

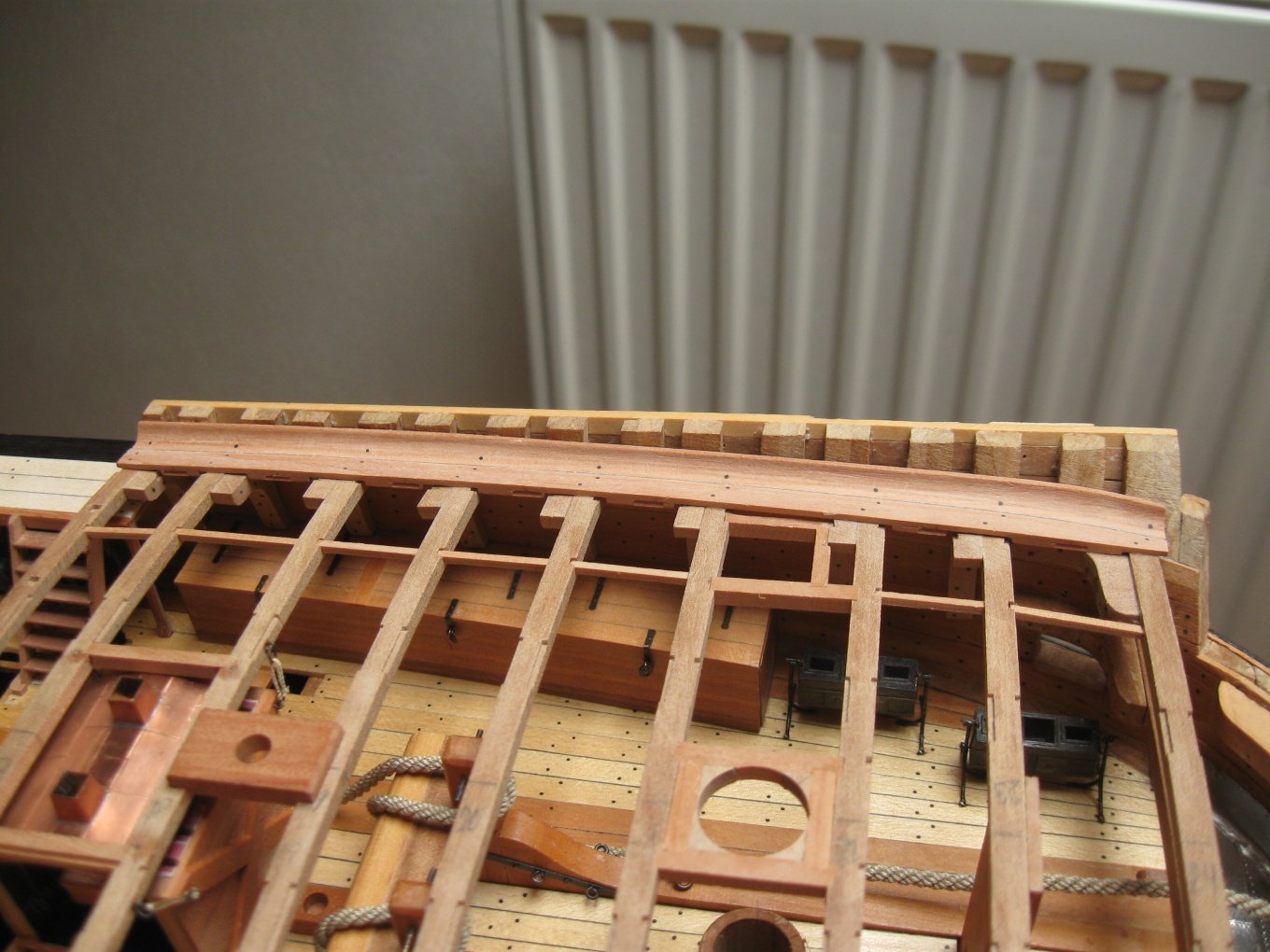

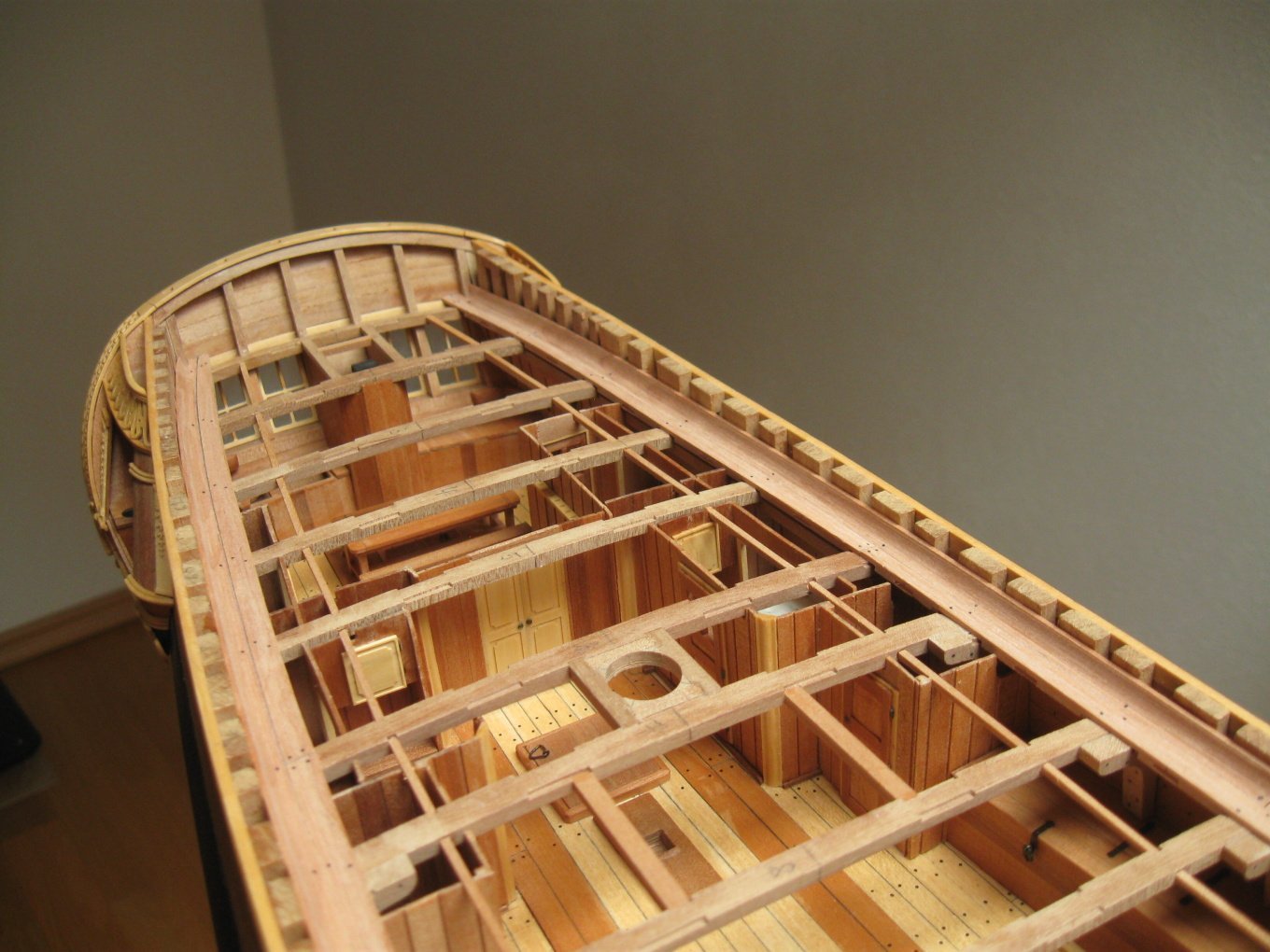

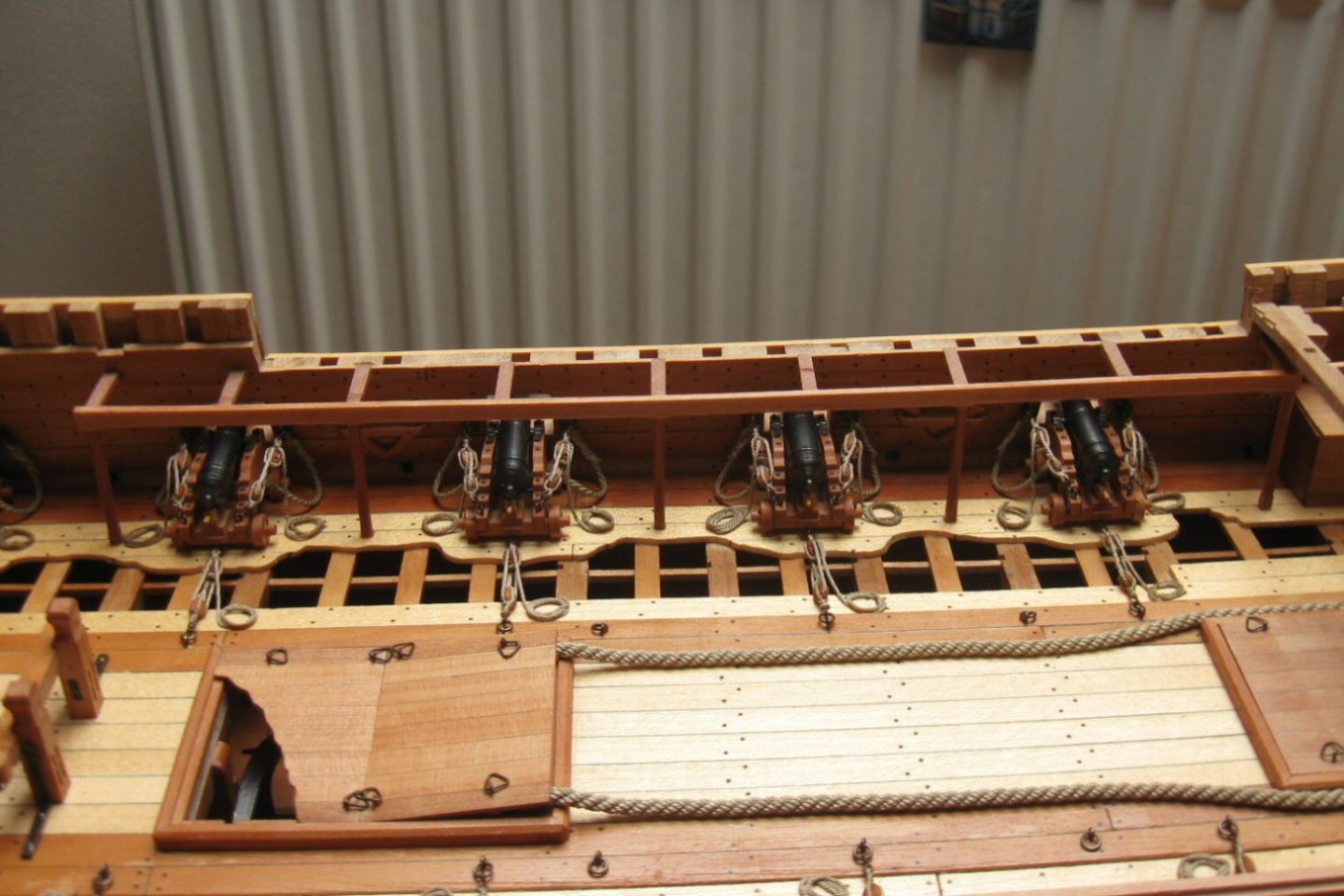

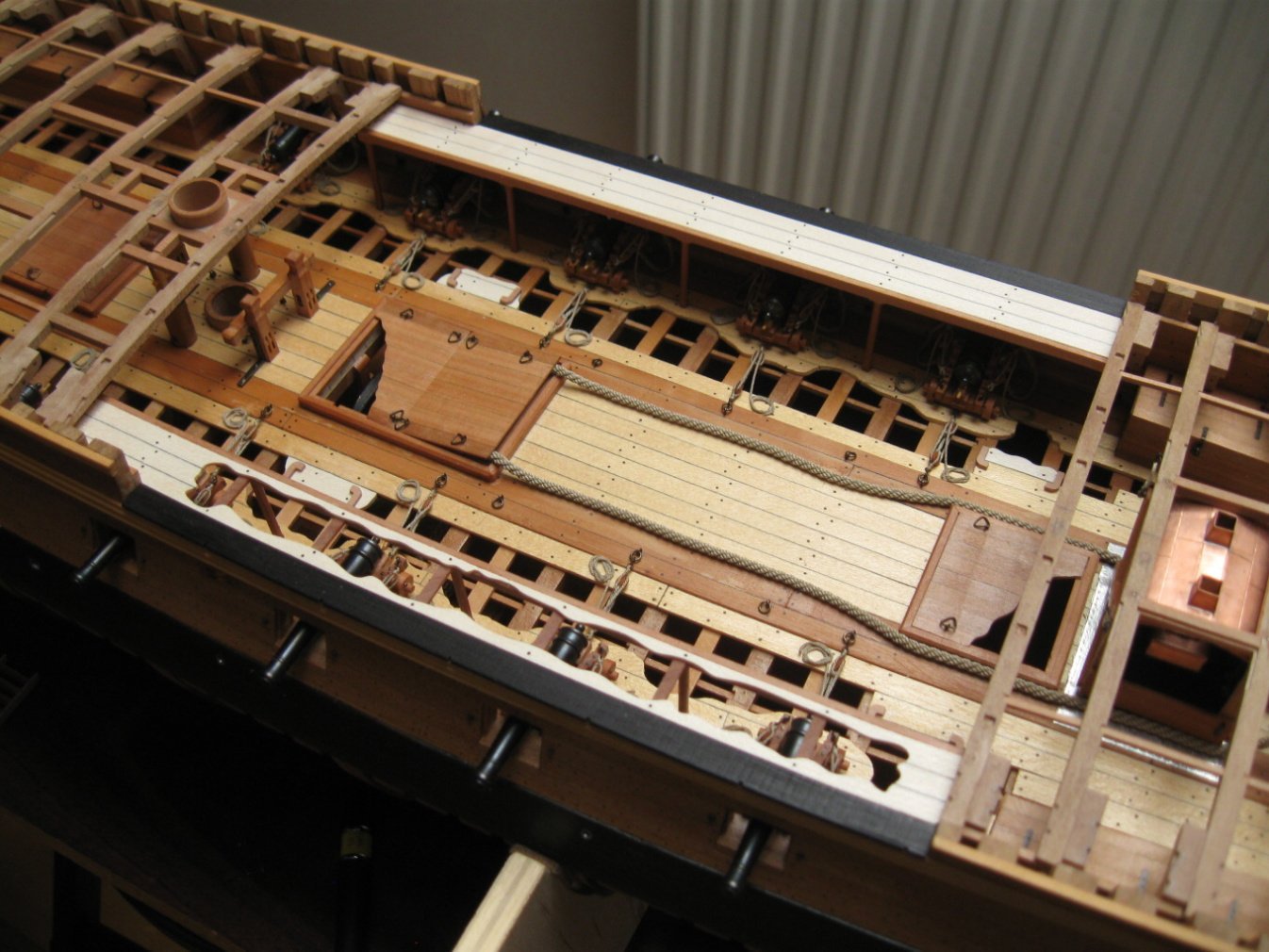

A few components on the quarterdeck have been added.