-

Posts

36 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by bthoe

-

Ok, here we go. In this almost-year away, I've been busy MOSTLY away from the shipyard. However, I did work a little bit and here is what I was working on: I wasn't interested in creating a build log - it was more for a build along-side the full ship. I'm interested in displaying this alongside the full ship to show what things look like below decks. I only plan on finishing the main mast up to the fighting top and leaving the yardarm off. I was also interested in how things were done on the gun deck on this model. Something I got from it was the knees: I traced these and cut them out with a razor saw. Once the basic shape was done, I used a rotary tool with a sander on it to clean them up - here is the results: I used the google maps view of the gun deck to check out the knee placement, and came up with the following table. The bottom and tops are the plank numbers measured from the waterway: Just the other night I drilled the holes around the gun ports, and began manufacturing eyes: That's it for now. I'll be mounting the eyes around the ports next, then putting in the knees.

-

Thanks folks. I can really relate to both of you. Reminds me of back in the 80s when I was finishing my basement, and I'd go down there and just sit and stare at things wondering, "now what the heck am I going to do about that...". It eventually worked itself out, but it really derails you for a time. Anyway, I'm back on track for now, and it feels good to be back.

-

Hi All, Sorry for the REALLY long break, but I needed it. I'm getting back to the shipyard, now that the leaves are beginning to fall (helped by the dry weather conditions here). I've been working on the gun deck knees and will include pics shortly. Welcome Der Alte Rentner! Sorry that you picked a slow time in the shipyard to join in! Hopefully there'll be something for you to see soon. My plans moving forward (at least for now) is to finish up the knees, continue planking the hull, and in between things, I'll begin fabricating the gun deck furnishings, including the ship's stove, capstan, etc.

-

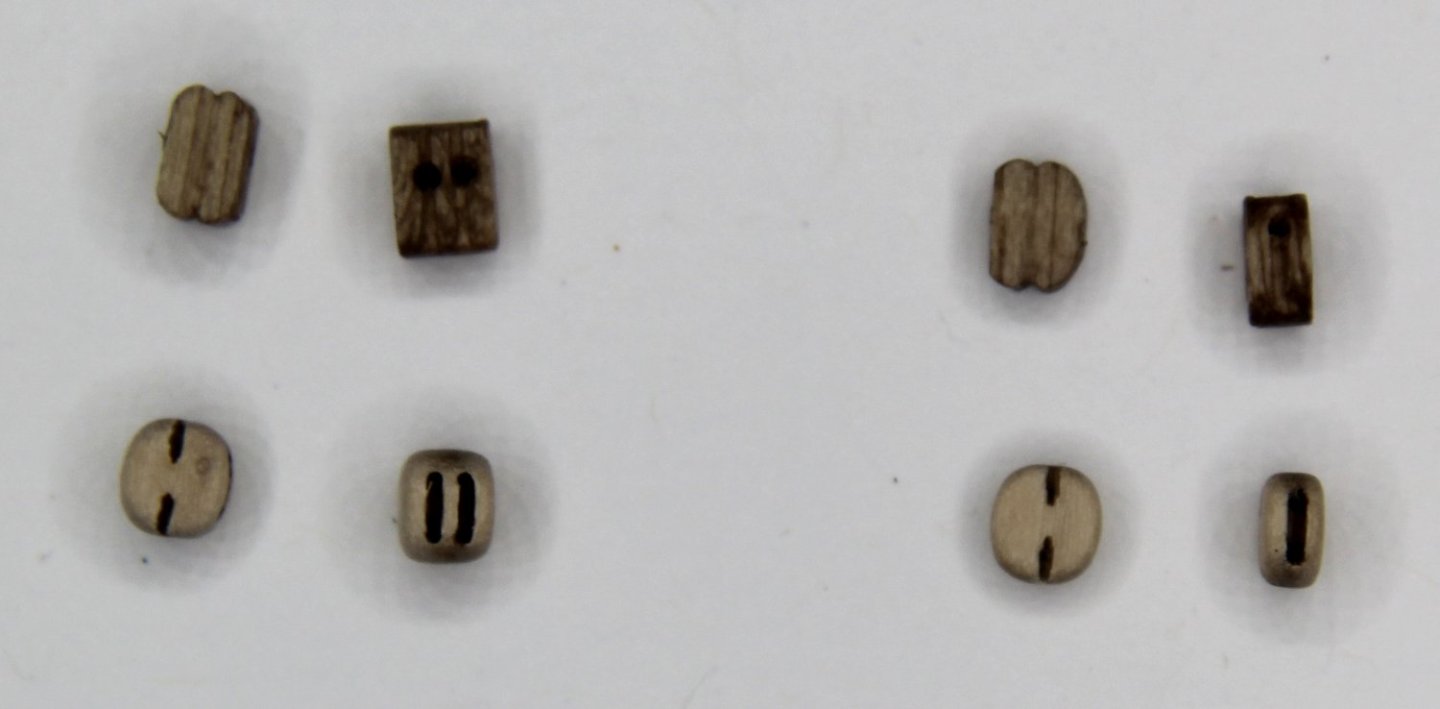

Here's just a quick follow-up from my previous post about blocks. The picture below shows 1/8" single and double blocks that came with the kit, and below them the blocks I purchased from Syren Ship Model Company. The Siren blocks have 2 holes in each of the sheave slots and are over all better in my opinion. (The strange halo effect is because my ring light is only a few inches directly overhead, and I'm shooting thru the magnifier). The coloring is more a medium-brown on the MS blocks, and a yellowish-tan for the Syren blocks.

-

Next up: The Gun Carriages. These took a few weeks prep. I already had added the 1/16” filler to the carriage sides. I needed to make the parts – front axle, rear axle, etc. You can see all of the parts on my Jan 29th post. I made 35 of each, just to make sure of 30 good ones. Once all of the parts were made, I assembled the carriages. Now all I need is to find the right paint color. What colors have you all used for this, or was it a custom mixture? For the gun tackles, I purchased blocks from Chuck P’s Syren Ship Model Company. I just wanted to mention this, because the blocks are spectacular! Makes me want to replace all of the kit’s blocks with Chuck’s, but it’ll cost a lot to do this – they are reasonably priced, but there are so many of them on Constitution. And no, Chuck is NOT paying me for this advertisement! I’m a long way from rigging, so I might start replacing them a little at a time. In the meantime, I’ll be making the gun tackles when I’m closer to installing the guns, probably AFTER the hull is completely planked. I wish you all a wonderful Thanksgiving Holiday. I have many things to be thankful for and will be counting my blessings on Thursday along with many of you. Fair winds, Bob

-

Hi all, thanks for the likes! I really appreciate it, and it encourages me to keep going. With Thanksgiving approaching and family coming over, the Admiral said it was time to shut down the shipyard and make it ship-shape for our guests and safe for the grandkids. Now that I’ve done that, it’s a good time to update the build log. In my last entry, I was going to clean things up on the outer planking and then begin the wales. I DID begin cleaning up the planking, and filling where necessary, but every time I filled and sanded, there were more places I needed to fill and sand. I got frustrated and decided to move to something different for a while. So, on to the bulwarks! I decided to go with the “glue-drop method” of adding the rivets/bolts. I admire the workmanship, and the patience that some of you have gone to in order to make these look more realistic. However, I couldn’t envision spending the next 10 years punching out tiny brass rivet heads (and losing them). Likewise, the thought of drilling tiny holes and going crazy trying to insert tiny plastic rivets was not my cup of tea! So, glue dots it was. First, I made the bulwarks by edge-gluing the planks. For the curved bow section, I soaked the planks, and clamped to the frames to set the curve. I edge glued these as well once they were dry. This didn’t work out as well as I had hoped, because I glued these “on-edge” vs stair-stepped as they probably were when they were wet on the frames. So, I repeated the process, but once dry, I glued the planks to the frames with the intention of adding glue dots to these curved sections on the hull. I did a test application on a mock-up panel. The rivets were difficult to see once dry, but under magnification I noticed that the glue had flattened out too much. Then I did another mock-up panel and applied 3 coats of varnish prior to applying the glue dots. The rivets were much better defined this way. I sanded / varnished all of the panels in a likewise manner. I then sharpened a bunch of toothpicks to apply the glue dots. I applied to one panel and let it dry. I was happy with the results – but then realized that this panel, as well as most of the other panels would have pin rails attached later, and the “rivets” would get in the way. I tried to remove the rivets in the pin rail area and found that they were quite easy – almost too easy – to remove with a simple knife tip scrape. That worried me, that I would knock them off in handling. So as soon as possible, I decided I would paint them. I identified which panels would have pin rails and avoided this area while applying glue dots to all of the remaining panels. I had to keep switching toothpicks as the glue quickly built up on them and had to keep refreshing the glue puddle I was dipping into as it dried/thickened fairly quickly. Under magnification there were some dots that were a bit flat and needed to have extra glue added to define the dots. There were others that needed to be scraped away and redone completely. Once done, I attached the panels to the ship’s frames and added glue dots to the inner planksheer. Then I painted them all. The bulwarks are not as shiny as they look in the photos under bright light. Overall, I am happy with the results. Much better than nothing – it would have looked wrong – and much easier/faster than other techniques.

-

Finally, I decided that I needed to focus on a nice line, and for that, I would use long planks vs short ones. This would minimize all the joints, and the bumpiness I was running into because of them. I also decided that if necessary, I could sand down the planksheer to an even thickness with the rest of the planking, and add a thin planksheer on top of the planking – or not (we’ll see). With those decisions made, I went ahead and began laying planks, and here is where I am at present: Now I need to smooth out the surface, perhaps use some filler where necessary, and clean up gun port and stern window openings. Then I can begin to lay the wales. It's nice to be back in the shipyard, although I think that I'll be making it more of a HOBBY. You're sure welcome to join along - just don't get frustrated with long gaps between posts. I DO want to see this project finished someday, but not at the expense of my sanity . Fair winds to you all! - Bob

-

Thank you all for your likes, and welcome. Sorry for my silence over the last 6 months. I ran into an issue, and rather than ask a community of skilled modelers how to address the problem, I just tried figuring it out myself. I'm sure that you all would have had some great advice on how to proceed. The problem I ran into was the outer planksheer. My first attempt ended up with a wavy line from bow to stern. It ended like below: Then I made a tool to help with consistency - the notch is for the gun port: Unfortunately, while the bottom of the planksheer was a more uniform distance from the gun ports, the result was a planksheer with varying thicknesses, sometimes to so thin as to be almost non-existent: This ended up with a similar pile of sticks as the first.

-

Next came framing the stern windows. Here's the drawing I am basing my stern from: And here is the drawing on how I was framing it: After careful measuring, I noticed that my vertical frames were not exactly where they needed to be, but I could correct by using offset fillers. Here's how it came out. Notice the filler pieces offset on either one side or another from the frames. Also, I put solid fillers below and above the windows to support the planking.

-

Happy with the fit, I went into gun carriage sides manufacturing (I needed another 58 for the gun deck). I sliced them all first using my "carriage slicer" above. Since I was cutting with the grain, pushing down with the razor blade was sufficient to part them. I then inserted a 1/16" piece in between, and once dry, packaged them all up for the time I will be making the carriages.

-

"In our last episode..." I built the test cannon so that when I framed the gun ports, I could verify that the fit was correct. And then no posts for a month. Sorry about that. Here's how I framed the gun ports. All framing pieces are 1/8 x 1/4. First was the lower sill, and per my drawing above, it is 3/32" above the waterway. So, I used a 3/32" spacer to set the lower sill in place as below. Next, I used a 13/32" spacer on top of the lower sill to set the top sill (same idea as above, I don't have a photo of that). Finally, I cut side frames. To do this, I measured each port to determine how far off of vertical it is. That is, at the bottom, how many 32nds off is it. Then I created the below drawing with 2 horizontal lines 13/32" apart, with 1/4" vertical planks at select 1/32" offsets. This drawing helped me to lay out the side frames. I cut all of these together, and then fit them using spacers where necessary. Then I created a gun port sized spacer to install the other side frame. Finally, the moment of truth...how's the fit?

-

JS, The gun carriage thing started because I noticed that the MS carriage side looked different from the U.S. Navy Plan. That's where I have been these last weeks since my last post - measuring, measuring, measuring. And then comparing and scratching my way-too-thin hair with too many "what the heck..."s muttered under my breath. But that is why I haven't committed it for REAL yet. It may end up being that I will still need to modify the height of the carriage to get it right. Mainly, I wanted to make sure that the gun ports would be ok with my heightened gun deck. Ian, Perhaps they painted the waterways "British Racing Green" to needle the British Captains taken aboard - or to help Constitution catch the British ships!

-

Next, time to lay out the rest of the parts. I don't know about the rest of you, but for me, the lack of a plan - or parts layout - for the gun carriages was unsettling. So I did. First, I took the "real" plans, scaled down to 1/76.8, then rounded to measurements of 1/32 - for me, 64ths are just too small, although you might see measurements of 1/2 32nds when it is something worth mentioning - it can be sanded in w/o extreme accuracy. Then I took my CAD program (DeltaCAD - about $35 - deltacad.com, easy to use) and with the new parts "built" the carriage to see how it looks. You can see it all below. We'll see later how it all goes together "for real". Feel free to use this if you find it helpful. And here they are, put together. At least theoretically, as I haven't actually done it yet . Lastly, my measurements of the bulwarks/gun port. Note that my waterway is 3/16" tall, as it was placed directly on top of the bulkhead before the 1/32" plywood was placed on the bulkhead - I needed it to be 1/32" taller than normal. I'm encouraged that after all that work, the center of the gun port shows to be 33/64" above the deck, and the line showing the center of the gun port on the cannon barrel above is also 33/64". That was not planned! -- Note that none of this has been committed to the model as of yet, so if you see any glaring errors, please point them out! Thanks in advance!

-

Next, I was thinking I wanted to get the Gun Deck bulwarks planked. So I took measurements of the Gun Deck bulwarks at each bulkhead - all kinds of measurements - and began figuring out the plank thicknesses to make this happen. Then I realized that I couldn't plank the bulwarks without first framing the gun ports and stern windows. And I couldn't do the gun ports without first making a test cannon for checking measurements, etc. And I knew guns and port alignment were giving people headaches. For everyone's reference, I did NOT cut down the bulkhead Gun Deck, but laid the 1/32" plywood right on top of the cutouts, and then laid the 1/16" planking on top of the plywood. From the plans, my Gun Deck is 3/32" higher than what they indicate. Kick in the nerd in me... I started making measurements of the U.S. Navy gun carriage plans, scaled them down to the model scale, then compared them with the gun carriage laser-cut gun carriage pieces. Here's what I found out. The Model Shipways carriages were 5/64" shorter than scale. The rest looked close enough to not worry about. See below: I'll need to modify the carriage sides to make them scale-like in appearance. I was really bothered about why MS would make this apparent mistake, and then I realized that the carriage is identical to the bowchaser carriage contained in the kit - back to the U.S Navy plans. Yep, the bowchaser was an 18-pounder, and its carriage was 6" shorter height-wise than the 24-pounders on the Gun Deck. 6" at scale is - you guessed it - 5/64"! That established, It was time to modify a set of carriage sides to see how they looked. See below for my methodology in making the new carriage sides. The inserted piece is a 1/16" x 1/16" strip.

-

Hi Folks, time for an update. I sanded down the Gun Deck and prepped for staining. I've been using basswood for everything, and I heard that it's best to use pre-stain on basswood. So, I thought I'd give it a try... Afterwards, I applied Golden Oak stain. A couple of things - first, it took the stain much better than without the pre-stain. Also, it really emphasized the plank ends - for the Spar Deck, I'll really need to get those joints tight.

-

Thanks for the likes folks. And yes, Jon, I agree. At first, I was distressed at the lack of consensus as to how things were "back then". But very slowly, I have come to the same conclusion that you have - that the reason for differences is in the eye of the beholder. Or in the case of now vs then, ladders can't be as narrow and as steep as they probably were if the lawsuit-aware tourists are going to be using them! (I did spend 5 weeks on active duty ) I'll continue on as best I can, continuing to see what others like you are doing, choosing what I like or what makes the most sense, but not sweating it if it's not 100% accurate (hope it doesn't cost me my membership in the NRG...). As Henrik said somewhere above, I only need to make myself happy.

-

Happy New Year everyone! Since my last post, I have been working on Constitution sporadically. Last week I was on vacation, and spent the bulk of the time in the shop – as a result, I’ve finally made some decent progress. - I got the plywood decking done for the Gun Deck. - I decided to make the Fore and Main Hatches open so I could see to the hatches below in the Berth Deck. - I completed the Berth Deck hatches, and a section of decking that will be visible from above. - I built the Gun Deck Hatches - I planked the Gun Deck. All of the above gave me much-needed practice for when I work on the Spar Deck. Next will come sanding / finishing the Gun Deck planking. Full sail ahead! Initial Plans for Spar- and Gun Decks. Later, I changed the Gun Deck Fore Hatch layout (top) to increase size and relocate the ladders down to Berth Deck. I also will replace the anchor chain bitts with cable bitts, and the Main Mast Fife Rail with a curved one like on the Hull Model. Plywood deck support for Gun Deck Carving out space for ladders Painted waterways Patched stairway in Fore Hatch. This would have been much easier had I done the Berth Deck before covering it with the Gun Deck plywood. I made thin planks so I could fit them through the Fore Hatch. Berth Deck Main Hatch (left) and Fore Hatch View through Gun Deck Main / Fore Hatches. Gun Deck Hatches Hatches set in place prior to planking the deck. Beginning planking. I did not taper the planks on the Gun Deck, so when I got to the edges, I needed to create filler pieces. I will be tapering the Spar Deck planks. And here they are installed against the waterway. Finished planking, ready to sand and finish! Hatches set in place to see what it looks like.

-

Well, it's been 2 months since my last confession (or post). Forgive me - I'll try to stay more on top of it. Since September, I have - mounted the filler blocks, - framed in the bow and stern (for 6 windows), - as others have done, I tack-glued battens at the top of the frames to prevent breakage. - added the Spar Deck waterway - cut the tenon on the bowsprit and checked fit over-all - cut 1/32 plywood to size for the Spar Deck, and made a copy of the plan for Spar Deck (mainly for hatch openings) - removed the bulkheads above the Gun Deck - added the Gun Deck waterway - purchased a full set of guns for the Gun Deck from Model Expo. One of the bigger departures was to redo the stern counter and to cut out the R bulkhead to allow gun deck planking all of the way into the captain's/commodore's cabins. I'll be building out the walls in the stern Gun Deck as the build continues. Hopefully this long weekend will allow me to cut a 1/32 plywood deck for the Gun Deck, map out where the Gun Deck hatch openings are, and decide how much detailing to do below down into the berth deck. I'm trying to leave as many options open as I can at this point, as I haven't decided yet how much detailing in the hidden places to do. I welcome comments and questions, along with kindly criticism. Photos below of my progress... Counter - note the surface has been shaved down for deck planking to come Counter and Filler Blocks from below Bow Filler Blocks Bow Framing All of the pieces laid out for building the stern framing. Note that before installing, the entryway to the captain's/commodore's heads in the stern galleries were cut. Also the center frame was tapered so as not to interfere with the rudder head. The short pieces at the top will bridge the gap from the stern frames to bulkhead R (but not until after the deck is planked). And here it is, put together. The paper on top was to help with alignment of the frames. Spar Deck waterway installed at bow. Bowsprit tenon - and no, that's not a stain sample - it's proof positive that I've shed blood, sweat and tears - or at least the blood part over this model! Upper bulkheads removed and Gun Deck waterway installed. Also, mast tenon framing in place. Stern showing both waterways. Note opening for rudder head box. The Gun Deck plywood will end at the Counter Block.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.