-

Posts

28 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Schubbe

-

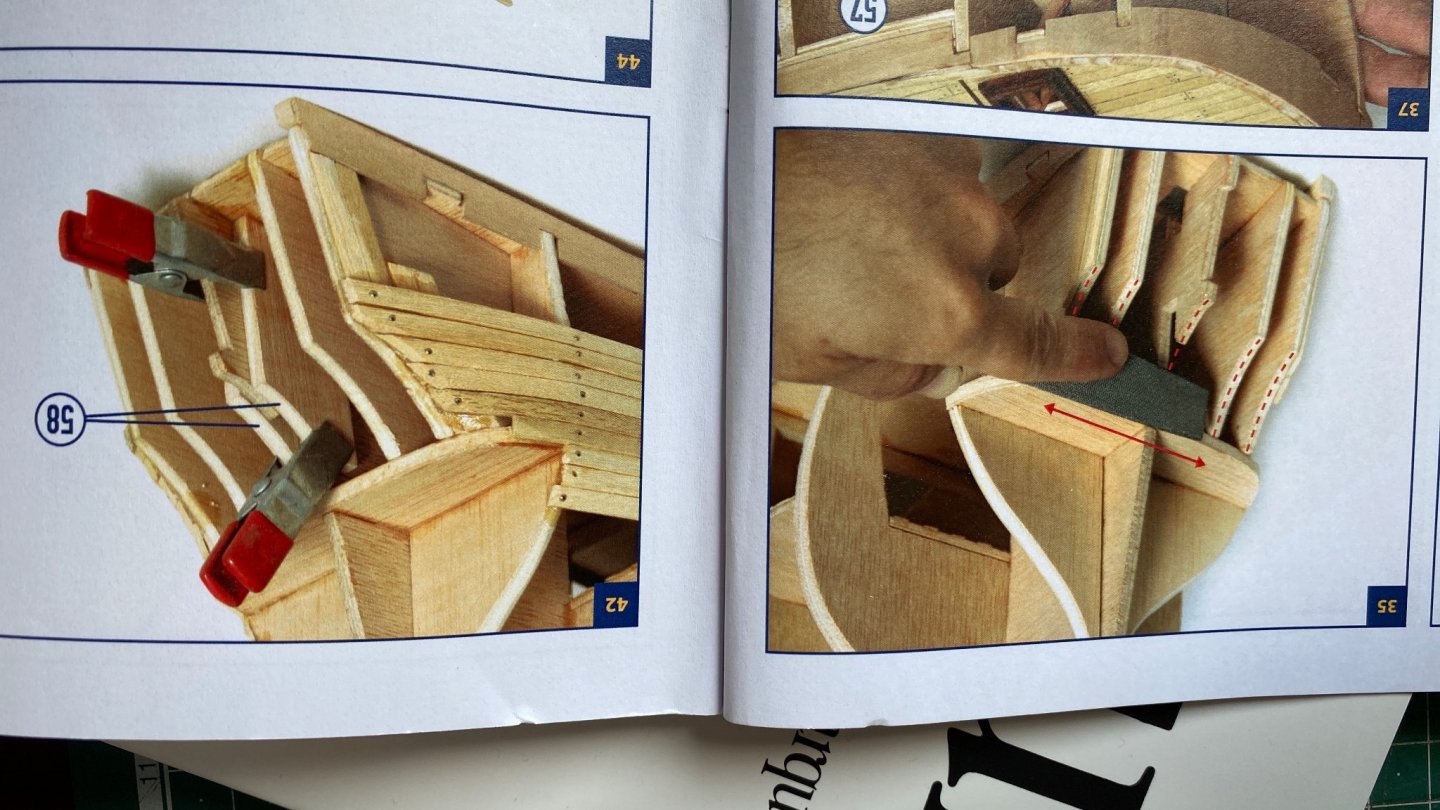

Sooo... I finally began my first attempt at bending and applying the main wales. After two or three ruined woodstrips, I managed to bend this quite complicated form. After that I used rubberbands to let the strips dry in position over night, and then again to hold them in place while the glue dried. This is a milestone for me. After that breakthrough I think things will take up speed again... First step: Bending the broad side in two directions to avoid the wales from coming to far up on the bow. Bending around the slim side to follow the Hull: Holding the plank in place with rubberbands: What do you think. Good approach? Or are there simpler Workflows?

-

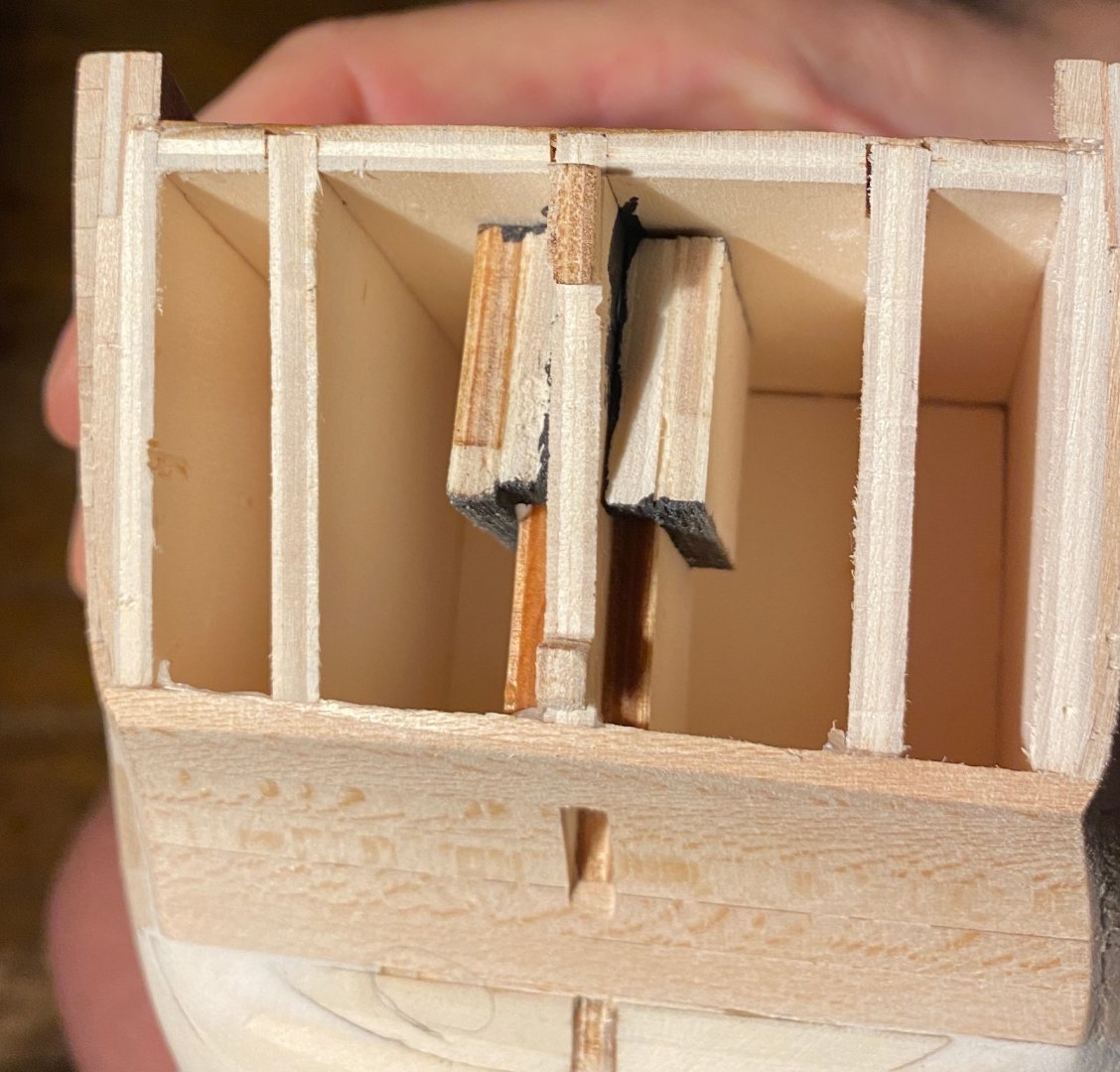

I realized, that to me the ladders or stairs in quite a few models are feeling odd, or out of scale. So I did another test with the ladder going down the main hatch. The attempt was to make the ladder feel more in scale by reducing the width and breadth of the outside boards. To me that is an improvement. What do you think?

-

Hi shipaholic, thank you so much for your effort to upload the fotos. This is what is so absolutely amazing about this forum. Everybody is so helpful and positive. The funny thing is, that I was very focused on how to deal with the lower part of the planking, that I was completely taken by surprise, that you bent the upper planks to match the curvature of the bulwarks. Wich is a great idea of course. So: One more challenge to tackle. Right now I think, I will actually start with the rubbing strakes and after that work my way up and down with the second planking. We'll see... Would you recommend swapping the wood against a thicker material, in order to be able to bend the planks in both directions?

-

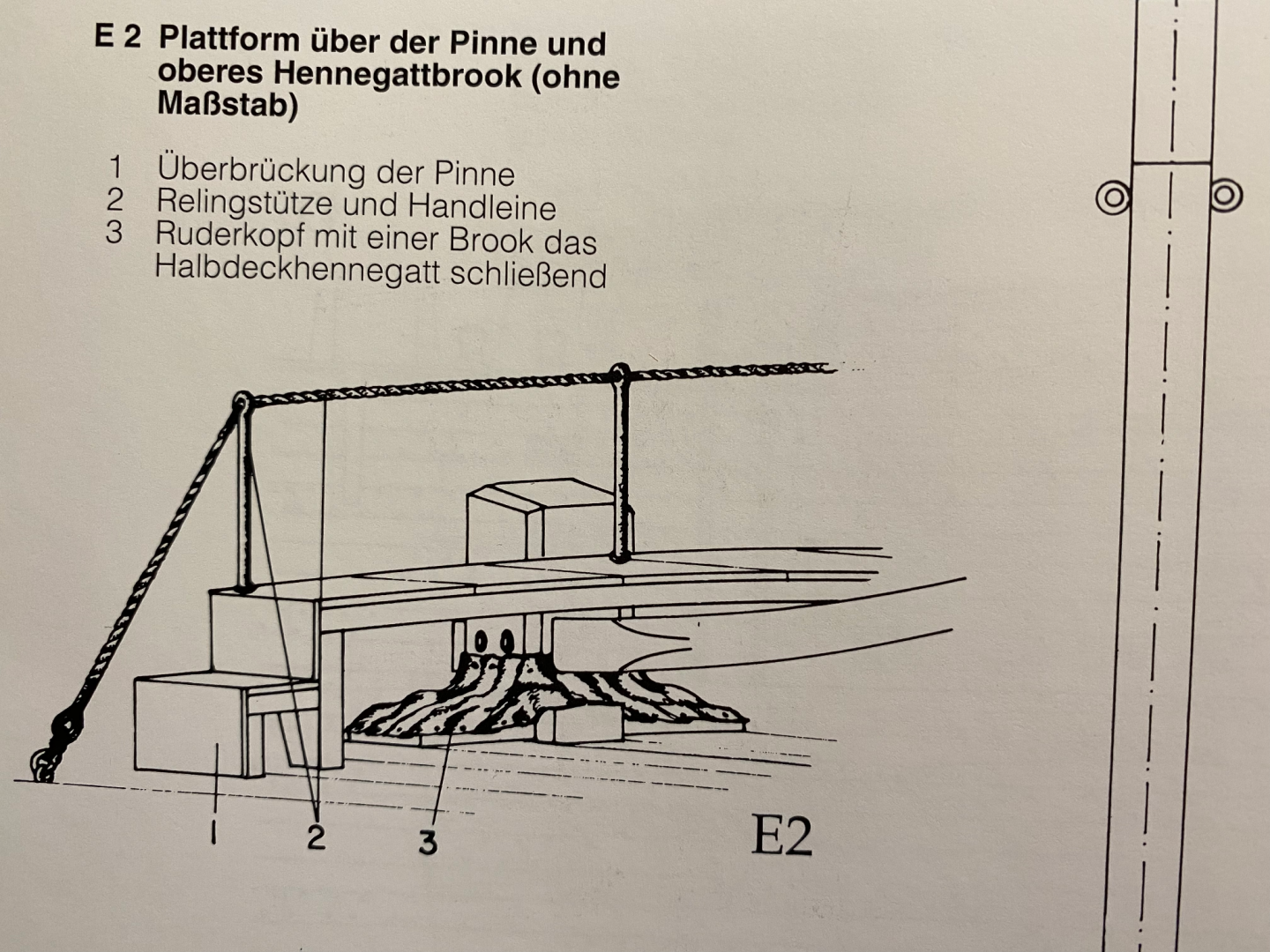

Hi Umber, I had the same issue with the instructions about the rudder, and chose the same solution like you. That leaves two subsequent issues in my mind: 1. The rudder will not be able to be moved, and is fixated in the straight position. Which to me was not a problem but: 2. The opening for the rudder will likely be rectangular and quite tight, so you will SEE that the rudder cannot be moved. Which would be a bummer in my eyes. There's two possible solutions in my head. First you could change the opening to be round. Second you could follow the Marquardt drawings and cover the hole with some piece of cloth or leather. I would really be interested in your thoughts on that matter, as I am not yet decided which way to go...

-

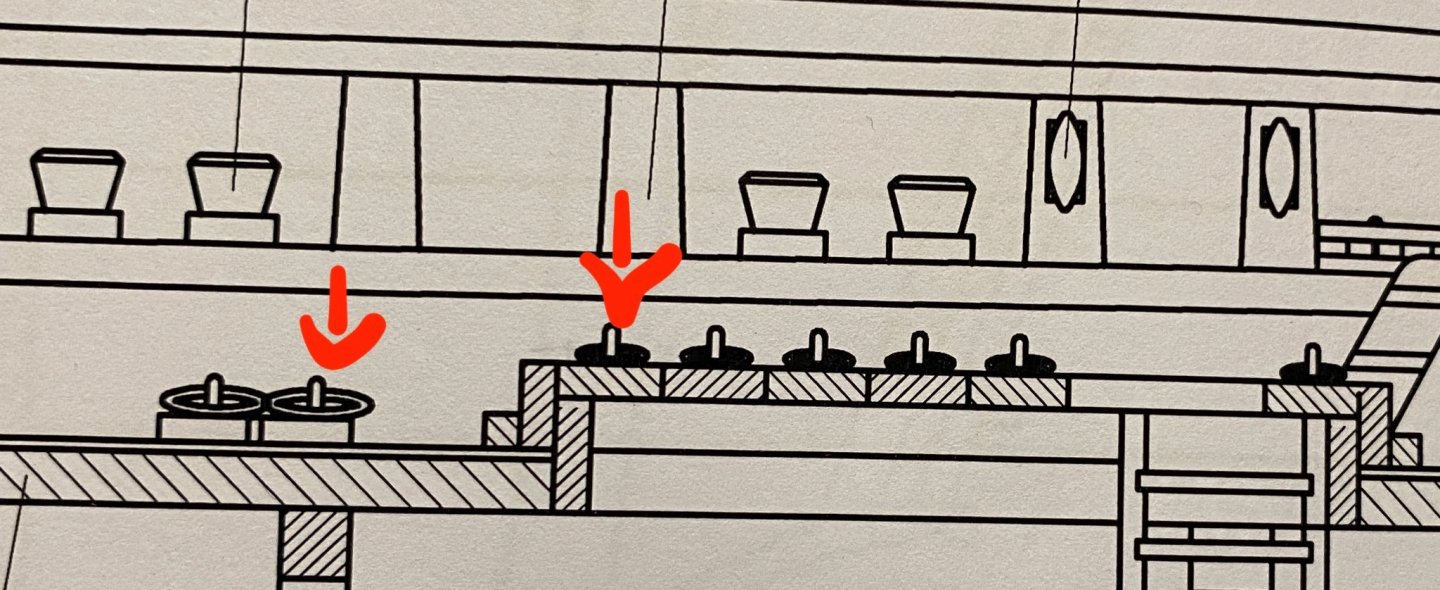

After a long break I am slowly going back to work on the Endeavour. As I had this scale problem with the rings for the boards covering the hatch, I decided to redo them. With that decision came an idea. Before I was trying to sand the boards as smooth as I could get them. Now I did an experiment with wirebrushing the surface to emphasize the grain of the wood. Here is a picture of a test. What do you think, good idea or bad idea?

-

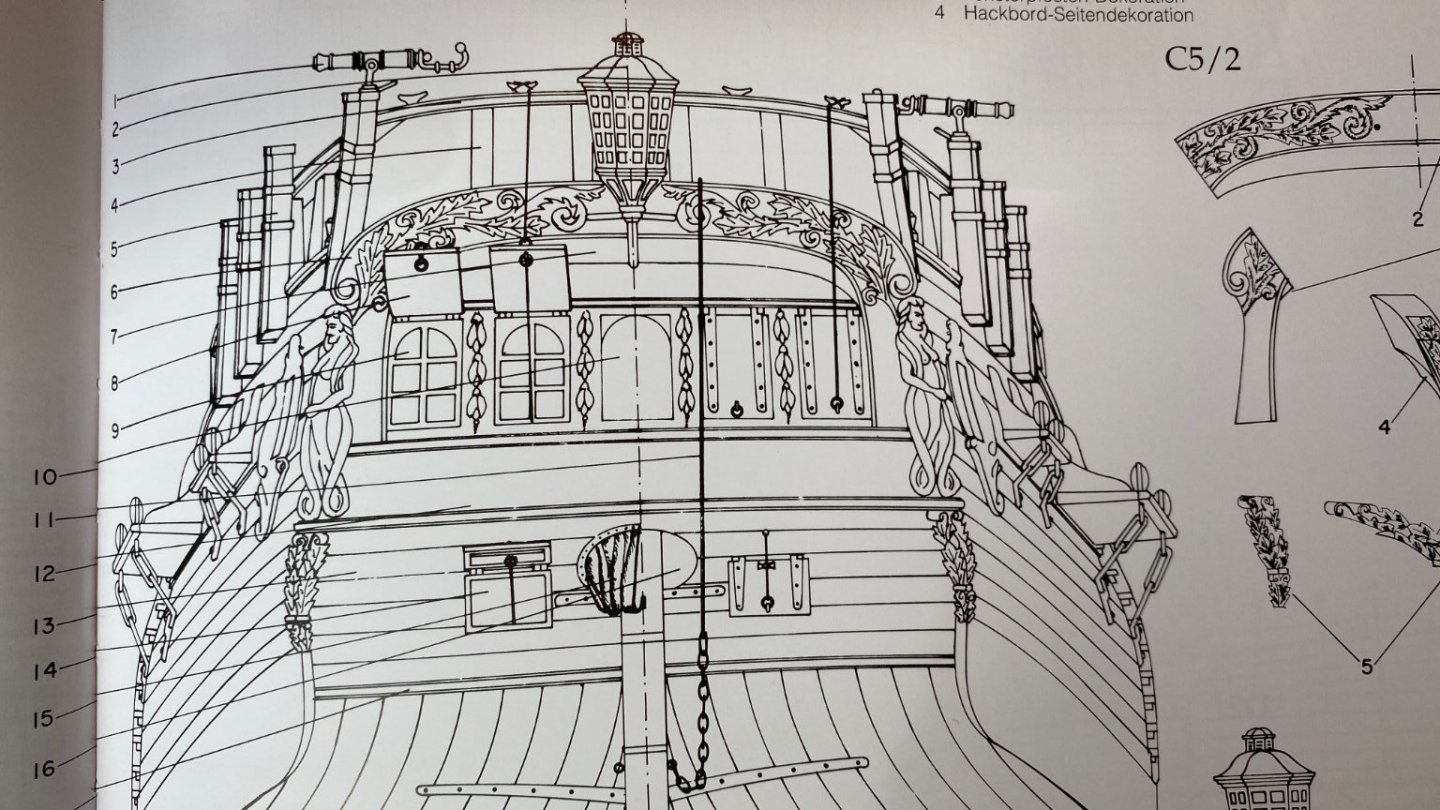

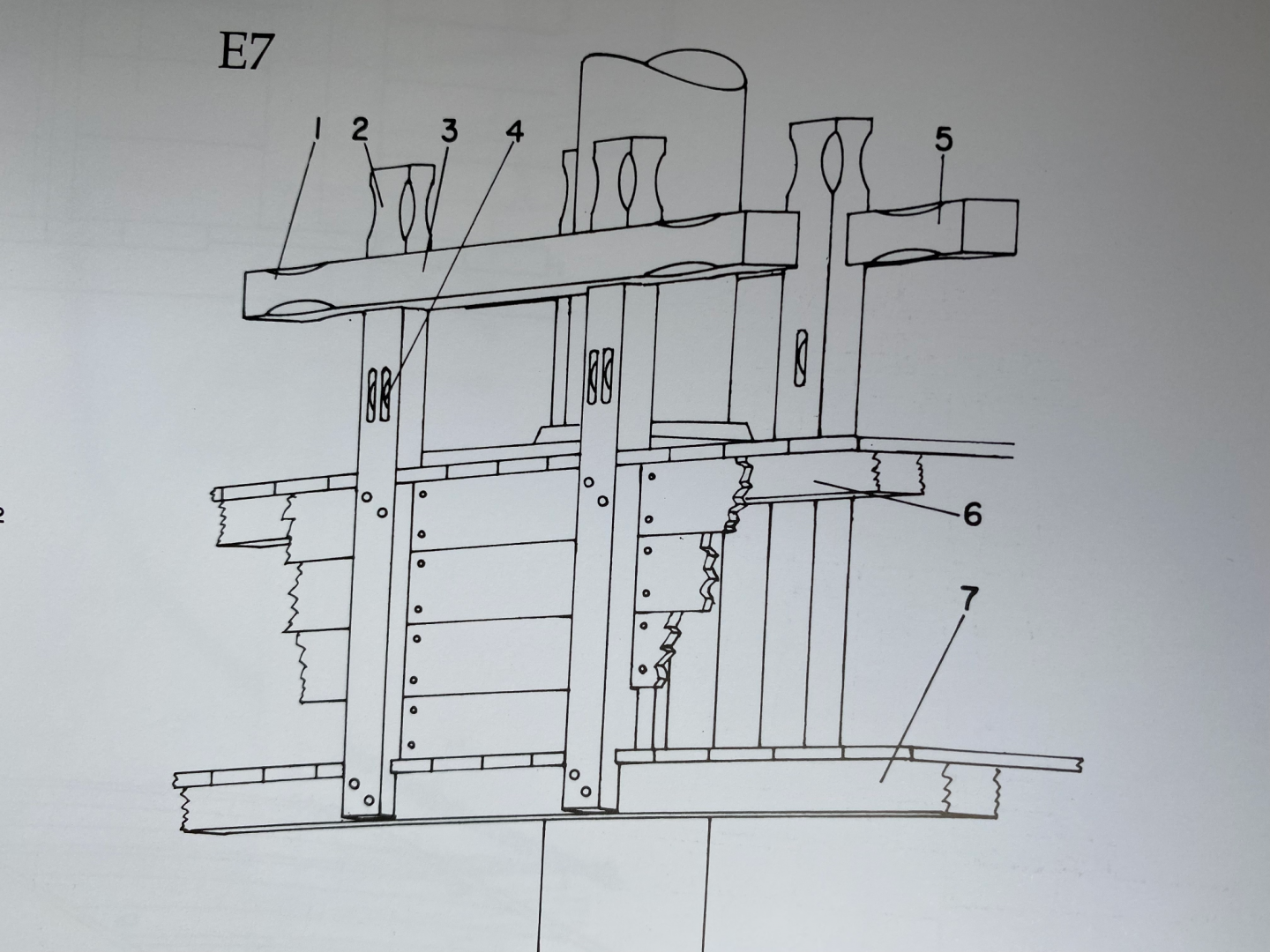

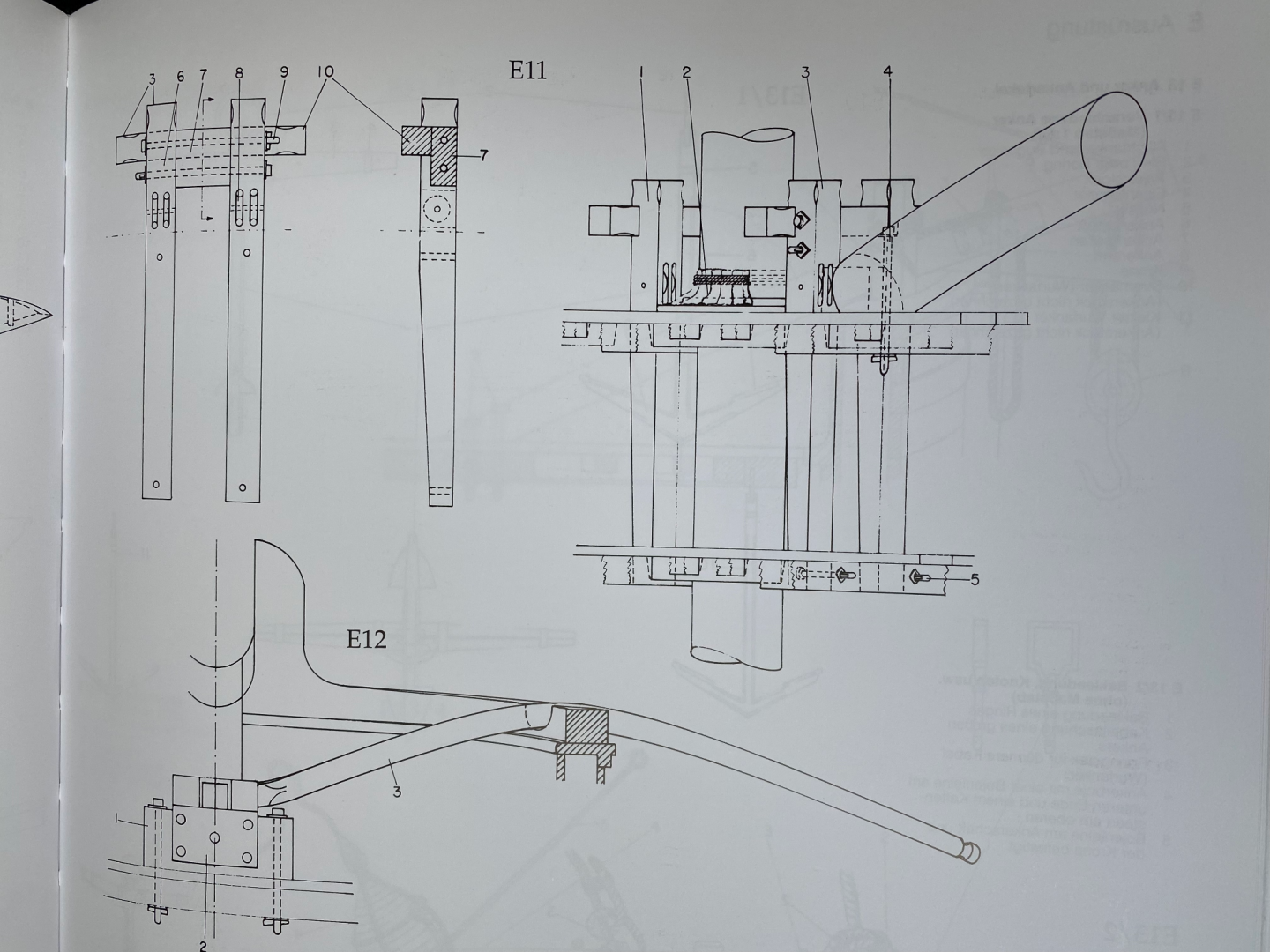

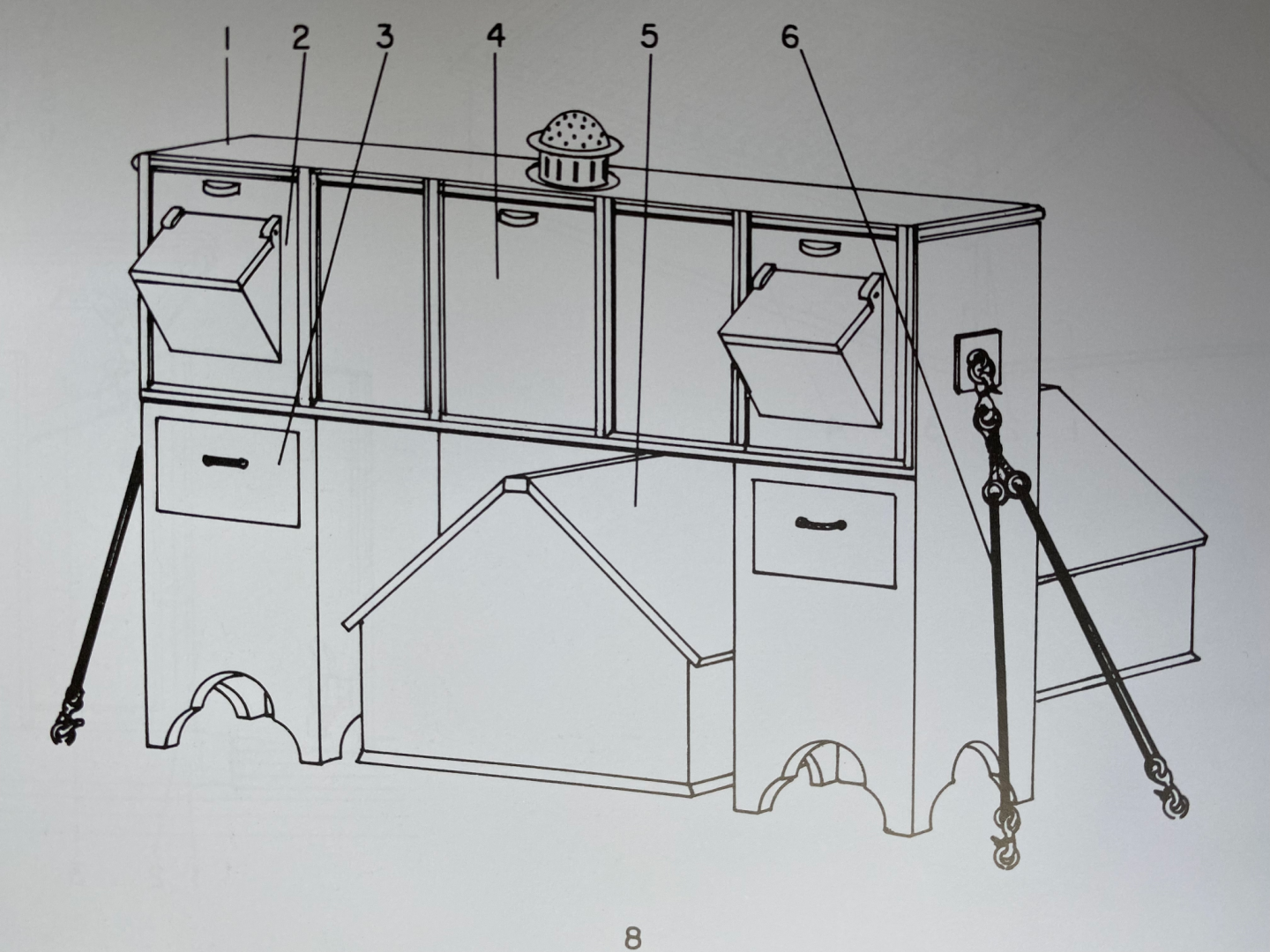

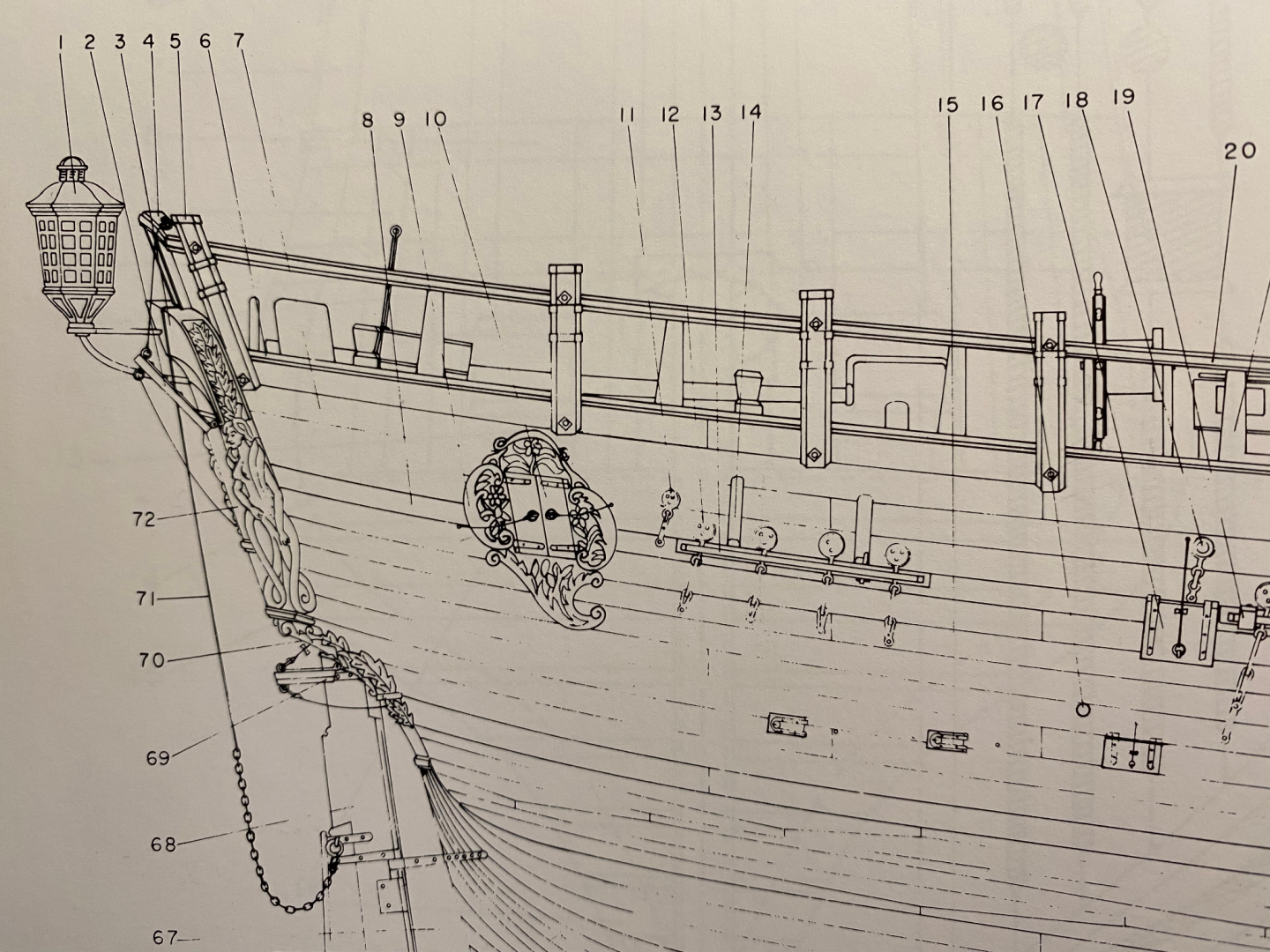

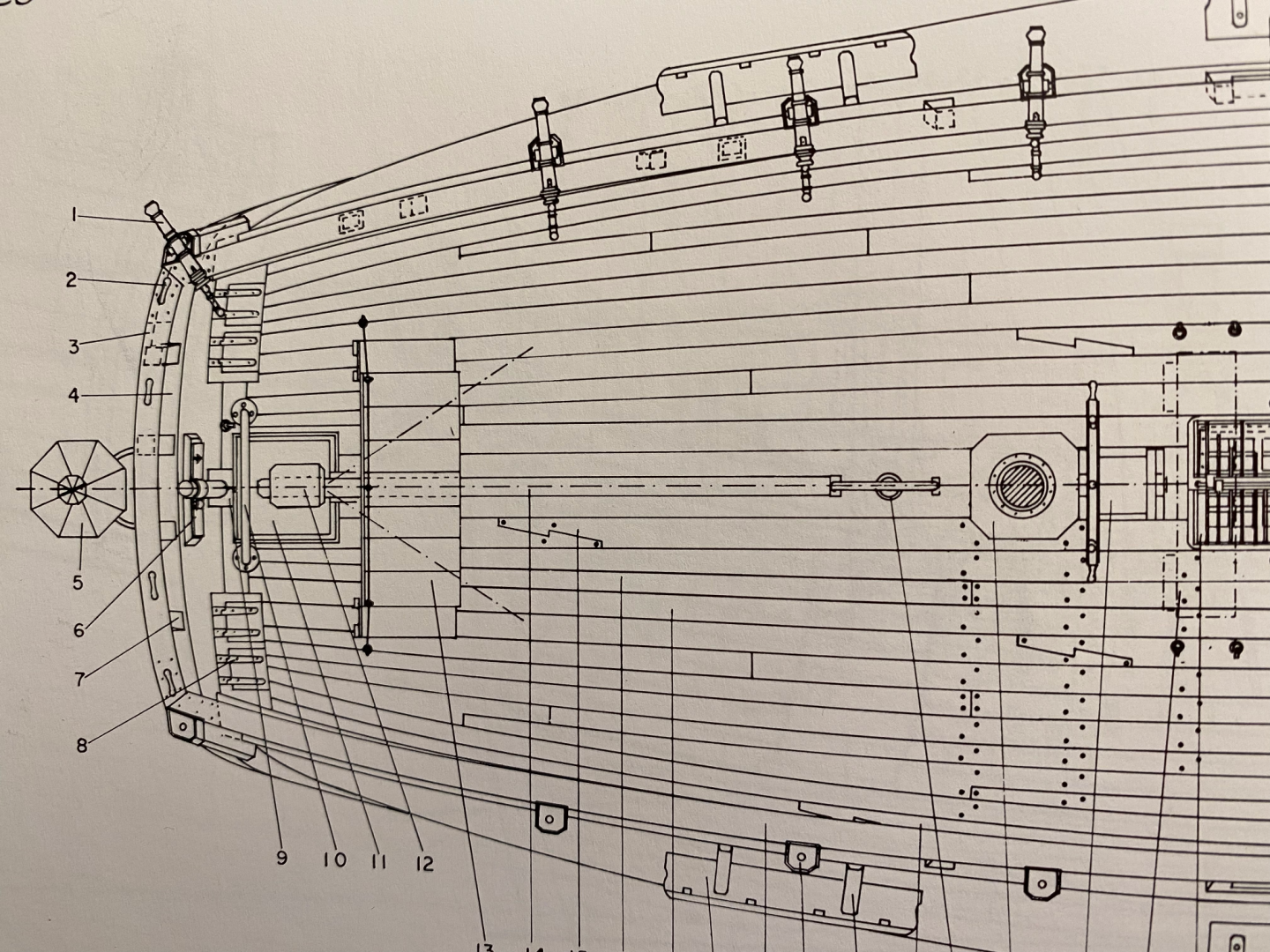

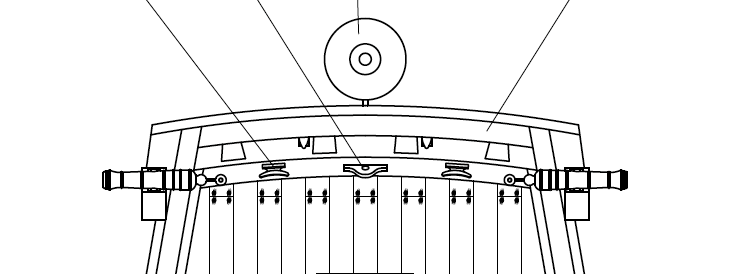

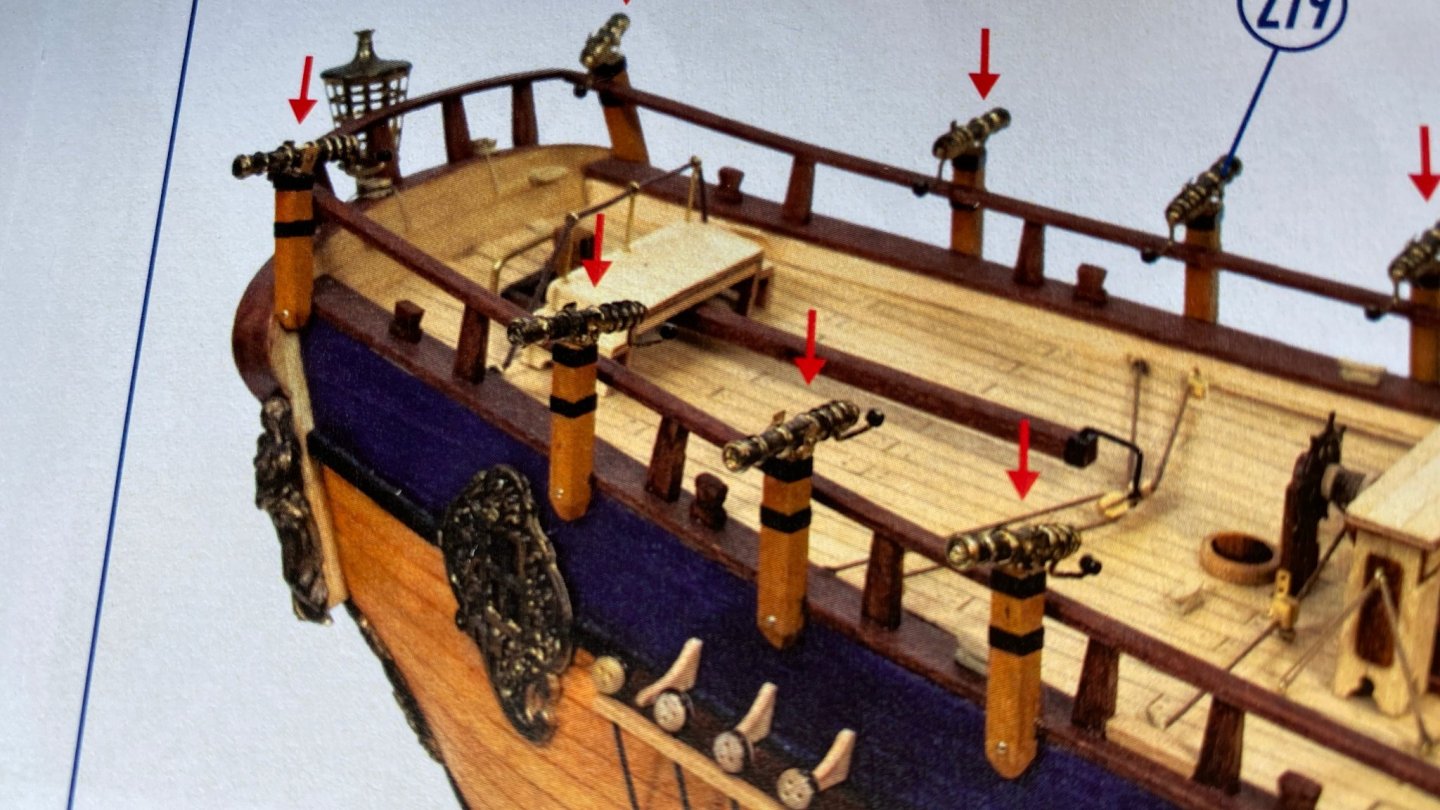

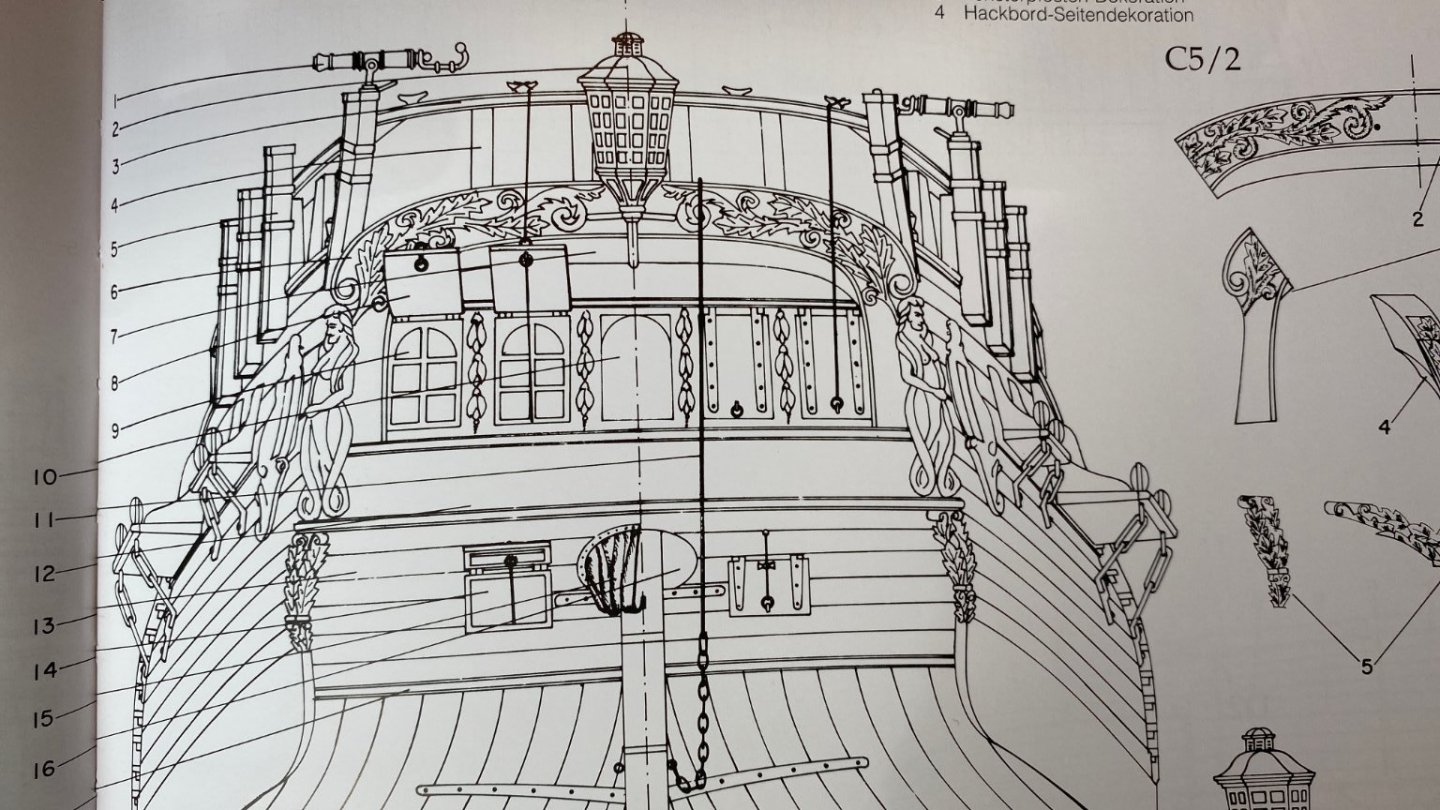

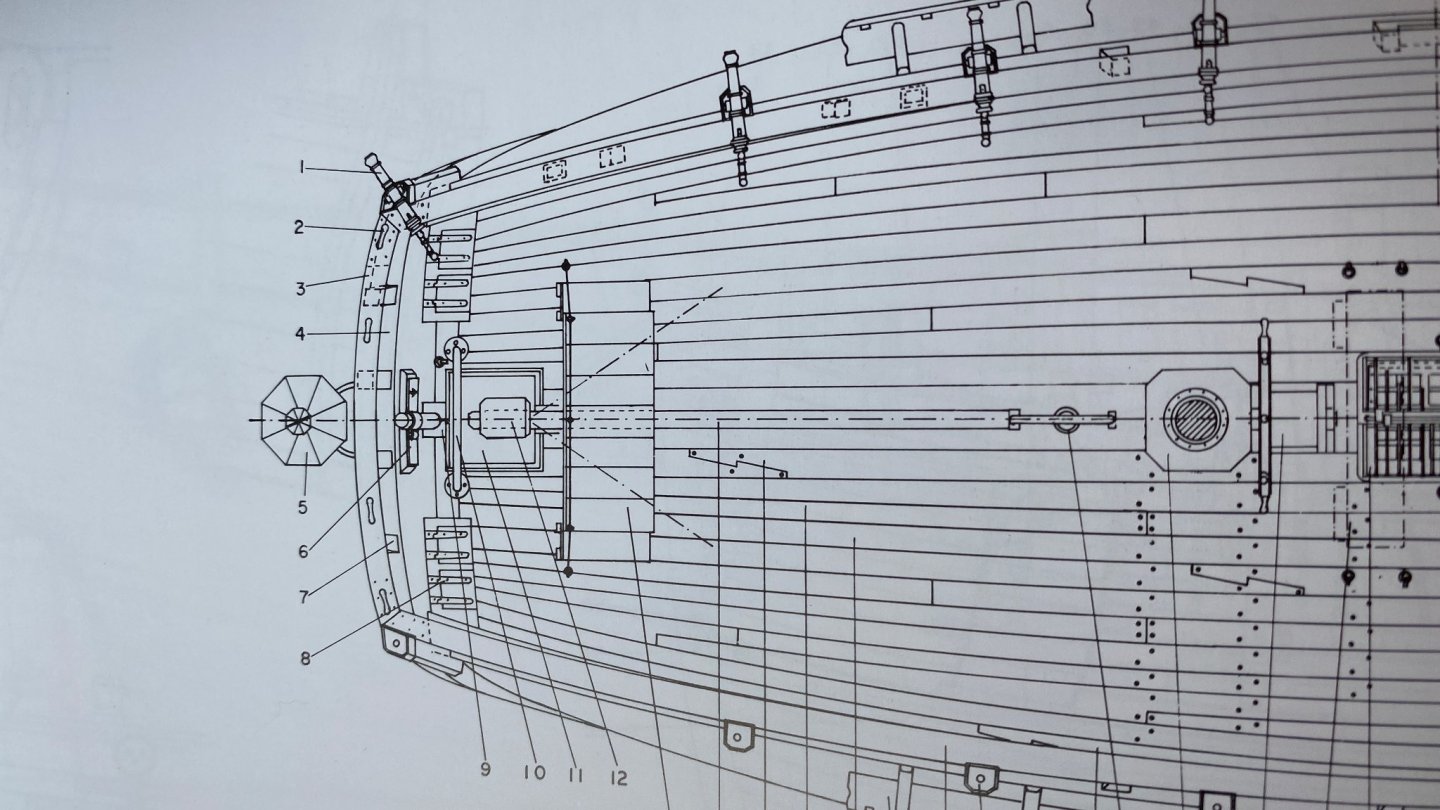

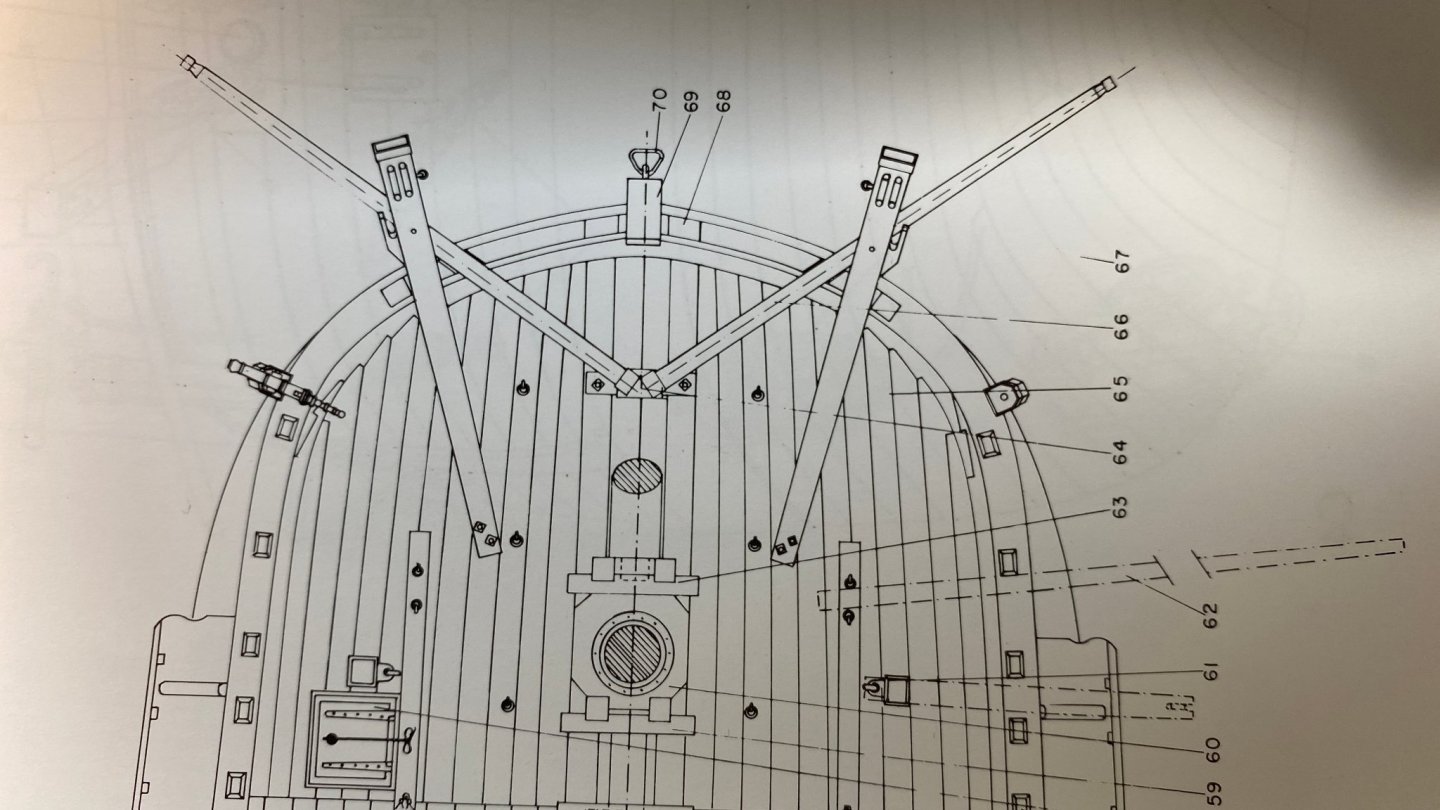

Dear Dave, I had to close down my Workshop over the Summer, because I needed my desk to do home office. Now I come back online and the first thing I see is your amazing progress. I thought we might be working at a similar speed, but now you are way ahead of me. Impressing. I will follow at a slower pace... 😉 As you mentioned the missing AOTS: If you need something, I can send you a picture from my book. Just let me know what you need. The tiller arm is indeed bent to avoid contact with the chimney. These images are what I thought could be useful to you:

-

Oh my. I find myself in some kit bashing situation... Didn't expect that to happen on the first model... But here we are. I am trying to shift the windows of the transon further inward. It seems to be a good decision, because now the windows appear to lead into the ship, not past the outside wall. And now there is enough room to trim the transom to the width of the stern while leaving the top as is, to be able to use the brass decorations of the kit. Well but now I am starting to think about trying to find and buy some pieces of decoration which are a little more "3D". 🙄 "maggsl_01" - whose excellent built I followed - even dared to carve the decorations from scratch. Here is a link to his log: https://modelshipworld.com/profile/7014-maggsl_01/ I am tempted...

-

Thanks for your tip Tim! You are absolutely right with your comment. To be able to decide what exactly is reasonable in my case, I ordered figures in the scale I am working in as a reference. I was surprised by how big they are: So they could have handled the rings I used, but probably they might be a bit too big... 😞 Fun fact: OcCre couldn't decide on the ring size themselves... 🙂

-

Hi Dave, I ordered a 100x1000 sheet of verneer like the one in the photo: But I only needed 100x150 or so. You can even get away with smaller pieces, but I found it convenient to be able to trace the full forecastle deck. In your case, I would probably trace the deck to a sheet of paper. Figure out how to segment the waterway, and then determine the broadest width you need to cut out the parts. I remember it was also important to take into account the grain of the wood in relation to the grain of the deck planking. If that was too cryptic let me know, and try to explain better. 😉

-

Let's see and share what we come up with window-wise... I am looking forward to see your progress on the caldercraft endeavour. The waterway thing is not too much trouble. I am a first time modeller and could pull it off. There is a (german) tutorial on the technique. It's the best I could find: https://www.modellskipper.de/Tipps/Tipps_zu_Decks_und_Beplankung/Einarbeiten_von_Fischungen You might be able to translate it with: https://www.deepl.com/translator I would like to encourage you to give the technique it a try. I happened to find it really rewarding. You'll need an extra (broader) sheet of the same verneer you use for your normal deck planking though.

-

Hi Dave, thanks for your interest and the kind words. What a bugger with your warped parts. I am not shure, if I understand your question about the windows correctly. Do you mean if I plan to somehow give the impression that you could look through the windows? Because that is a good one. I am turning three ideas in my head. One way could be to paint a gradient to give the impression of lantern light. Something like that: Or maybe print some Image of the main cabin and glue it in? But that would probably only work if there was actual depth/room behind the windows. Or just paint it light blue or even black? What are your ideas?

-

I have come to a decision concerning the transom. I was so focused on the AOTS, that I didn't look at the OcCre deckplan. And there was the answer. Duh! So i sanded the Stern section to follow the curve of the deck. Apart from that, I am still thinking about reducing the width of the transom to match the stern of the hull and shift the window positions further in...

-

This is awsome! I played around with the idea of doing that pattern on my endeavour. I already gave that idea up. But now that I saw your post it comes back to live! Can you give any tips? Did you build a jig, or how did you acomplish such a good fit?

- 302 replies

-

- Diana

- Caldercraft

-

(and 1 more)

Tagged with:

-

Right now I am thinking about how to treat the transom. I am not so happy with the OcCre solution. For some reason I do not understand, they have decided to make the transom way too broad as you can see in this picture from the instructions: If you look at the Marquardt drawings you see something completely different: This looks way more elegant, but building it from scratch would mean to completely abandon the decorations. Maybe also the Windows. I am pretty unsure what to do. Beeing a first time modeller, I cannot imagine to carve new decorations from scratch. Or should I file down only the sides of the original transom to match the width of the stern and keep the full round overlap for the decorations? But then I still would have to shift the windows further inward. There is yet another thing bothering me. There is a gap where deck and transom meet. The deck is even rounded. Are you supposed to bend the transom? The instructions don't seem to propose that. On the Marquardt plans it actually seems as if there is a slight bend in the transom. Or should I close the gap using a woodstrip. Hmm. I really would appreciate your opinions on that one... Also: If you are preparing the transom yourself, double check if the holes are centered. I had to shift mine by about a milimetre.

-

Today I want to speak about issues which I encountered during the build so far. As I started the log quite a bit after beginning to build, there wasn't too much process to show. On the way I had some difficulties here and there which might be of interest to all fellow Occre Endeavour builders. The first issue was that I planked the only asymmetrical deck from the wrong side so that the port hatch on the foredeck became the starboard hatch. It wasn't too difficult to repair, but still... So pay double attention to that when you are planking the decks. 😉 The second Problem was that I didn't believe the guys who said the planks might bend when glued with water based PVA glue. Of course it happaned exactly as predicted. Couldn't really get it in the photograph though. It's not a big deal, but I think I will try contact glue next time. Or maybe I might experiment with this other method somebody proposed: He said, he is applying PVA to the deck and the planks. Lets it dry and then glues both parts together using heat from a flat iron. But I do not know if this actually works. The last deck planking issue had to do with not enough forsight again. Idecided to follow Marquardt and build waterways around the decks as can be seen in the pictures below: It worked out quite well for me. Except I didn't expect the inner planking of the bulwark to be so thick. So what happened was that it partially covered the waterways. So if you are planning on doing the same, take those 2mm into account! Then I had a hard time to decide how to deal with the hole for the rudder. As I watched the instructions I saw that the rudderpole has to come through somehow. The text didn't say anything of value on how. I assume they want you to drill the hole after finishing the second planking. I found that rather risky. So I decided to cut the plywood beforehand by applying one reinforcement, then taking out the bridging part and after that glueing in the second reinforcement. You might see what I mean on this photo: So now I have a very nice "channel" through which to put the rudder pole. This way the rudder will be unmovable though, which I don't mind. I will let you know how all that worked out once I get to actually building the rudder. The question remaining is how to prevent the plywood of the reinforcements to be seen from the top. Any Ideas, guys? That's it for now. I hope that was helpful to some of you. If you have comments or even better ideas to deal with these issues, let me know.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.