-

Posts

278 -

Joined

-

Last visited

About Gabek

- Birthday 06/21/1961

Profile Information

-

Gender

Male

-

Location

Winnipeg, Canada

-

Interests

Fishing, painting figurines (Warhammer), wood carving, fly-tying, reading, baking (cheesecakes a specialty), turning pens. Newest hobby: 3D resin printing (I love it!)

Recent Profile Visitors

-

Gabek reacted to a post in a topic:

The Mayflower by Knocklouder - Amati - 1:60

Gabek reacted to a post in a topic:

The Mayflower by Knocklouder - Amati - 1:60

-

Gabek reacted to a post in a topic:

The Mayflower by Knocklouder - Amati - 1:60

Gabek reacted to a post in a topic:

The Mayflower by Knocklouder - Amati - 1:60

-

Gabek reacted to a post in a topic:

The Mayflower by Knocklouder - Amati - 1:60

Gabek reacted to a post in a topic:

The Mayflower by Knocklouder - Amati - 1:60

-

Gabek reacted to a post in a topic:

The Mayflower by Knocklouder - Amati - 1:60

Gabek reacted to a post in a topic:

The Mayflower by Knocklouder - Amati - 1:60

-

Gabek reacted to a post in a topic:

The Mayflower by Knocklouder - Amati - 1:60

Gabek reacted to a post in a topic:

The Mayflower by Knocklouder - Amati - 1:60

-

Gabek reacted to a post in a topic:

The Mayflower by Knocklouder - Amati - 1:60

Gabek reacted to a post in a topic:

The Mayflower by Knocklouder - Amati - 1:60

-

Gabek reacted to a post in a topic:

The Mayflower by Knocklouder - Amati - 1:60

Gabek reacted to a post in a topic:

The Mayflower by Knocklouder - Amati - 1:60

-

Gabek reacted to a post in a topic:

HMS Winchelsea by scrubbyj427 - 1:48

Gabek reacted to a post in a topic:

HMS Winchelsea by scrubbyj427 - 1:48

-

Gabek reacted to a post in a topic:

HMS Agamemnon 1781 by Michael P – scale 1:150 – 64 gun Third Rate Ardent class Man-of-War

Gabek reacted to a post in a topic:

HMS Agamemnon 1781 by Michael P – scale 1:150 – 64 gun Third Rate Ardent class Man-of-War

-

mtaylor reacted to a post in a topic:

The Mayflower by Knocklouder - Amati - 1:60

mtaylor reacted to a post in a topic:

The Mayflower by Knocklouder - Amati - 1:60

-

Knocklouder reacted to a post in a topic:

The Mayflower by Knocklouder - Amati - 1:60

Knocklouder reacted to a post in a topic:

The Mayflower by Knocklouder - Amati - 1:60

-

Keith Black reacted to a post in a topic:

The Mayflower by Knocklouder - Amati - 1:60

Keith Black reacted to a post in a topic:

The Mayflower by Knocklouder - Amati - 1:60

-

Glen McGuire reacted to a post in a topic:

The Mayflower by Knocklouder - Amati - 1:60

Glen McGuire reacted to a post in a topic:

The Mayflower by Knocklouder - Amati - 1:60

-

Gabek reacted to a post in a topic:

The Mayflower by Knocklouder - Amati - 1:60

Gabek reacted to a post in a topic:

The Mayflower by Knocklouder - Amati - 1:60

-

scrubbyj427 reacted to a post in a topic:

6-pounder, Royal Navy cannon barrel - George III era

scrubbyj427 reacted to a post in a topic:

6-pounder, Royal Navy cannon barrel - George III era

-

mtaylor reacted to a post in a topic:

HMS Agamemnon 1781 by Michael P – scale 1:150 – 64 gun Third Rate Ardent class Man-of-War

mtaylor reacted to a post in a topic:

HMS Agamemnon 1781 by Michael P – scale 1:150 – 64 gun Third Rate Ardent class Man-of-War

-

Gabek started following HMS Fly by aliluke - Amati/Victory Models - 1/64

-

Keith Black reacted to a post in a topic:

HMS Pegasus 1776 by Knocklouder - Amati/Victory Models - 1:64

Keith Black reacted to a post in a topic:

HMS Pegasus 1776 by Knocklouder - Amati/Victory Models - 1:64

-

mtaylor reacted to a post in a topic:

HMS Pegasus 1776 by Knocklouder - Amati/Victory Models - 1:64

mtaylor reacted to a post in a topic:

HMS Pegasus 1776 by Knocklouder - Amati/Victory Models - 1:64

-

Hello Alistair, What brought you to our fair (and frigid) province?! And you only got -15C? Come at the end of January/early February and we can give you -35! 🥶 Stay cool, Gabe

- 129 replies

-

- Victory Models

- Pegasus

-

(and 2 more)

Tagged with:

-

You're nailing it, Bro! (Well, actually you're gluing it...but you know what I mean!🤣) - Gabe

- 129 replies

-

- Victory Models

- Pegasus

-

(and 2 more)

Tagged with:

-

Great looking, Bob! This will look spectacular when you're done. Clear skies and sharp tools, Gabe

- 129 replies

-

- Victory Models

- Pegasus

-

(and 2 more)

Tagged with:

-

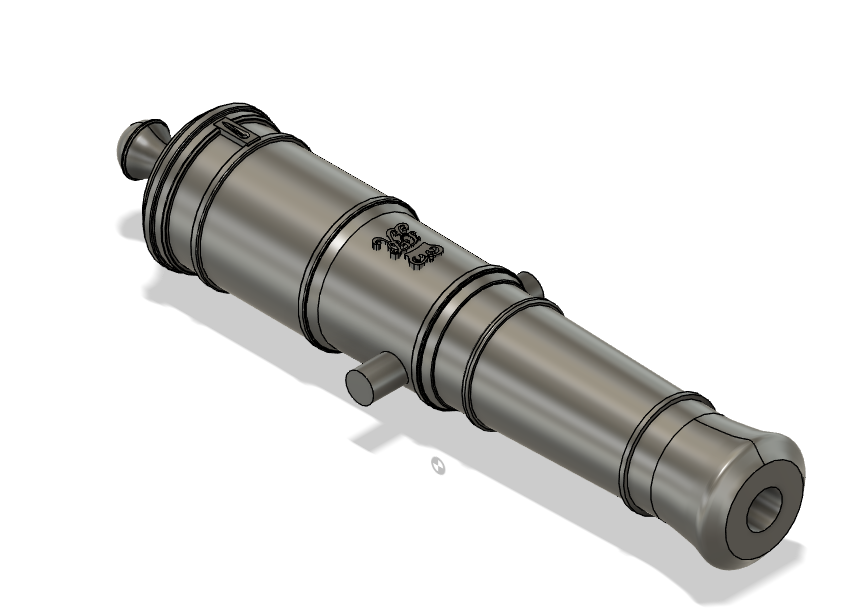

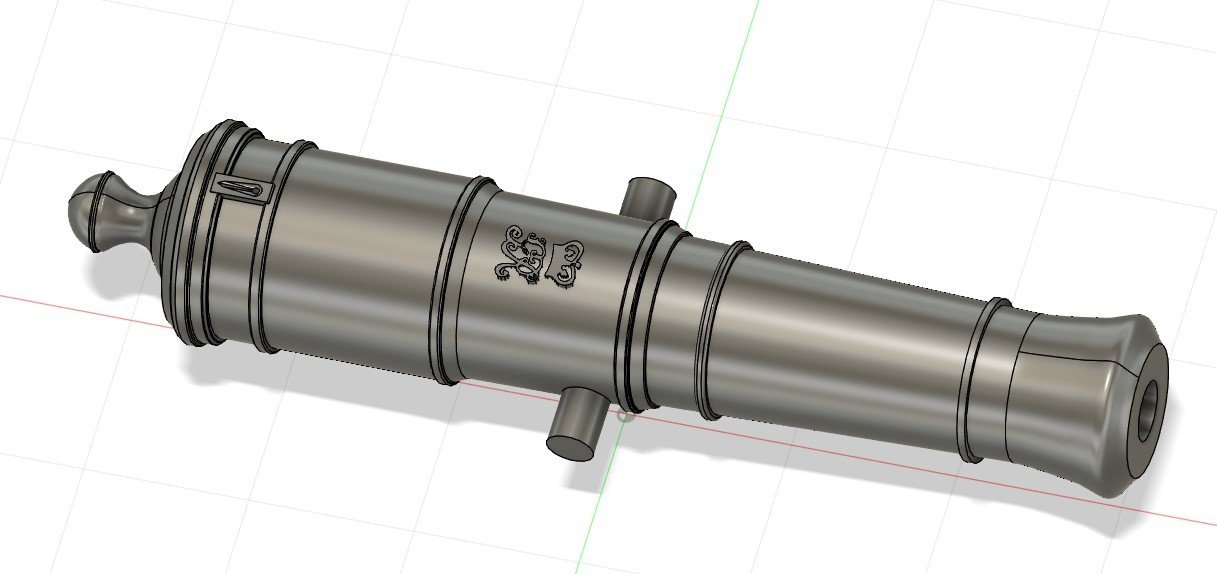

6-pounder, Royal Navy cannon barrel - George III era

Gabek replied to Gabek's topic in 3D-Printing and Laser-Cutting.

Final (?) product. 1:64 6-pounder Royal Navy Cannon - George III era I printed these at 0.03mm resolution in Anycubic ABS+. If anyone wants the .cbddlp file created for these prints (with supports) just send me a message. If anyone chooses to print these out I would appreciate a photo! I hope this helps, Gabe 6-pounder cannon_.stl -

6-pounder, Royal Navy cannon barrel - George III era

Gabek replied to Gabek's topic in 3D-Printing and Laser-Cutting.

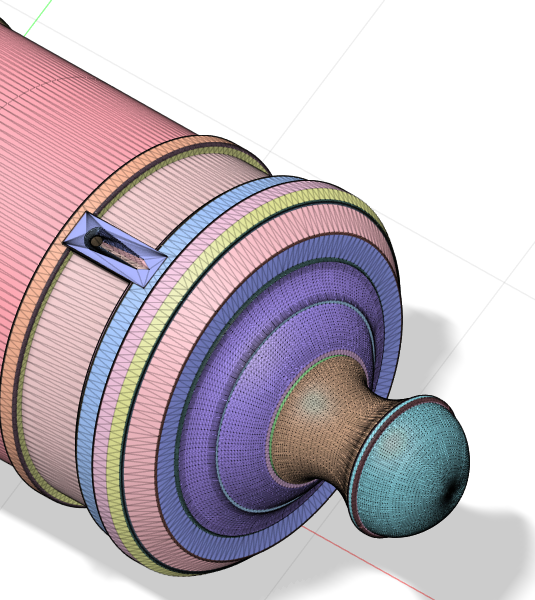

Hello everyone, In response to people who have warned that there might be a split in the .stl where I created the complicated curved bodies I checked the meshes in Fusion 360 and I do believe that they are stitched correctly: Thanks for your input, folks. I will be posting the .stl for this file shortly. Clear skies and sharp tools! - Gabe -

6-pounder, Royal Navy cannon barrel - George III era

Gabek replied to Gabek's topic in 3D-Printing and Laser-Cutting.

Thanks, Phil. I do use Chitubox on occasion so I'll make a point of checking for these errors. Regards, Gabe -

6-pounder, Royal Navy cannon barrel - George III era

Gabek replied to Gabek's topic in 3D-Printing and Laser-Cutting.

Thanks! I had spotted that earlier and they were placed on the end like you recommend on this version. Regards, Gabe -

6-pounder, Royal Navy cannon barrel - George III era

Gabek replied to Gabek's topic in 3D-Printing and Laser-Cutting.

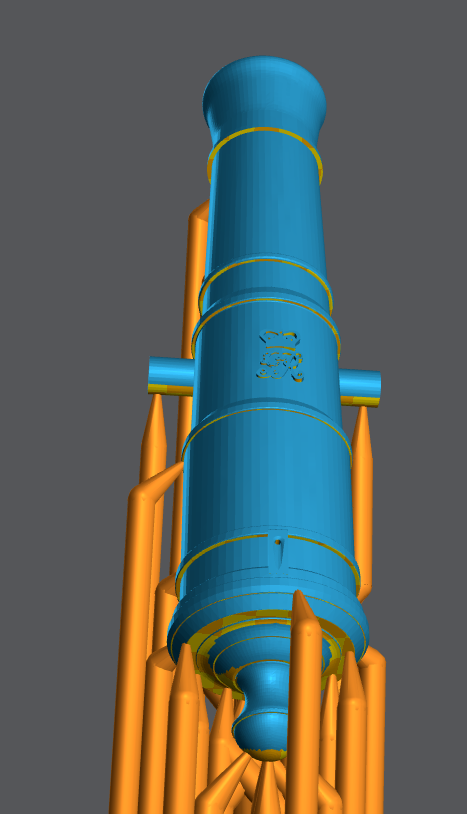

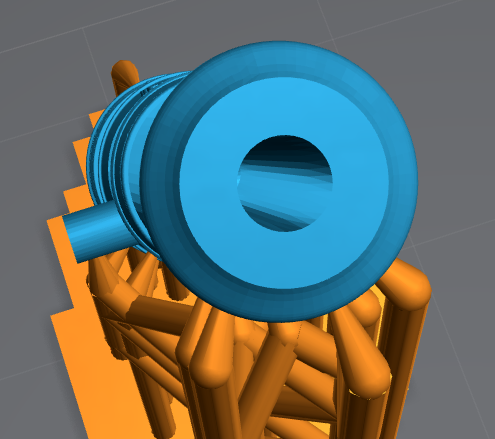

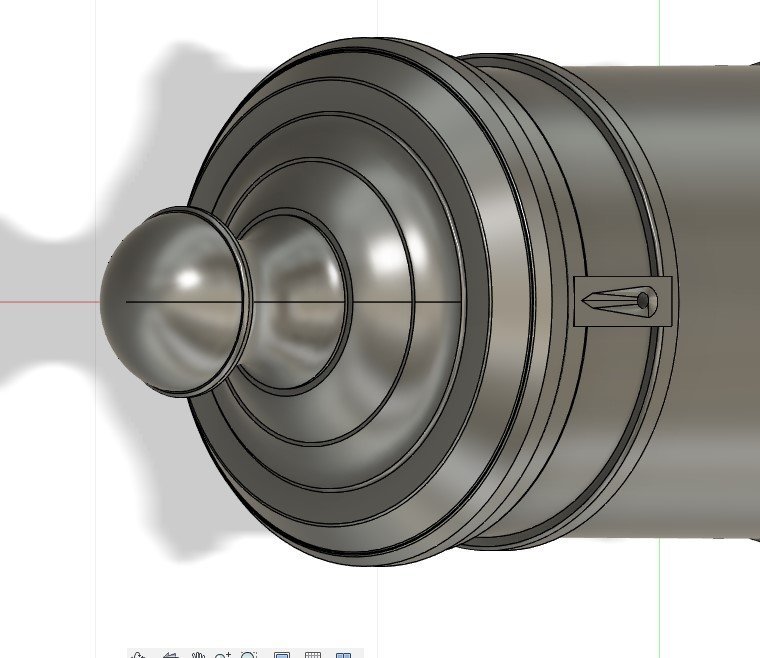

I'm sorry, Lieste - I don't quite follow you. The lines on the cascabel and the muzzle appear to be artefacts of the drawing (Fusion 360), not seams in the model. I'm printing in resin at 0.03mm resolution and have yet to see the line and there isn't any kind of infill. In the slicer (Lychee), here's what the model looks like: -

6-pounder, Royal Navy cannon barrel - George III era

Gabek replied to Gabek's topic in 3D-Printing and Laser-Cutting.

LOL! I'll go 20 cannons for 10lbs, Bob! -

6-pounder, Royal Navy cannon barrel - George III era

Gabek replied to Gabek's topic in 3D-Printing and Laser-Cutting.

Hello folks, Based on suggetions from @thibaultron and @allanyed, I've made some more modifications to the 6-pounder. Namely, I added the trough, reshaped the cascabel, and adjusted the breech rings. Here are a couple of screen shots. Once people are good with these latest changes I'll post the .stl and .cbddlp files for everyone to use. When I feel up to it I'll make a gunlock for this cannon. Regards, Gabe -

6-pounder, Royal Navy cannon barrel - George III era

Gabek replied to Gabek's topic in 3D-Printing and Laser-Cutting.

I actually just guessed at the vent diameter because the drawing I referred to in AotS Diana only showed the barrel with the gunlock. If you have diagram with the trough I can easily add it. To be honest, I knew that this detail would be almost invisible at 1:64 so I didn't fret too much. - Gabe -

6-pounder, Royal Navy cannon barrel - George III era

Gabek replied to Gabek's topic in 3D-Printing and Laser-Cutting.

Thanks for posting this, Ron!

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.