GGibson

NRG Member-

Posts

503 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by GGibson

-

I have no idea what this "sociable" attribute is that you mention, Andre... 🤣 Your shipyard area looks really nice, though! For a long time (for my first three builds), I was in a similar location in our house... tucked away in a corner of our pool table room using a tilting drafting table (but it stayed flat) as my workplace and had all my supplies stacked in a nearby "out-of-sight" storage area. I had windows right there where I could look out to our side yard and occasionally see the neighbor kids out playing, etc., so it was nice. Last summer we did some reorganizing and I move the shipyard to a basement room... which I have pretty much taken over! Purchased a nice-sized L-shaped corner desk that I use for my main building location, the tilting drafting table now holds my plans for easy reference, and I have another rolling table as my soldering station when needed. No windows to look out of and daydream, but definitely quiet... well, unless I get my Pandora music too loud! Excellent work on your Constitution, sir! Following your progress with great interest! 👍🏆

-

USS Constitution by mtbediz - 1:76

GGibson replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

These pumps look great, Mustafa! Excellent detail. -

Oh cool! Mine are "only" 2mm tips! And, according to their website, a local JoAnn's here in KC has 1 of those left in stock of the 1.4mm size. And their website might even be showing a smaller one than that in stock, as well. ROAD TRIP! 👍🤣 And to follow up on Tim's query, I do like your use of the S-shaped hanks on this Bluenose. They do look more "scaley".

-

Thanks for the reminder, Allan, about the internally stropped blocks! I ordered some from Syren a while back... just have to remember where I put them (in a place where I'd remember where they were when I got to this point).... crap... 🤷♀️🤣 The search begins!!! And, yes, I do recall that they were probably going to be a bit challenging to assemble properly. Yes, I have seen Tom Laurie's YouTube video, and I saved it to Favorites so I don't lose it like I've apparently done with some blocks.... and regarding David Antscherl's booklet... ...I purchased it from SeaWatchBooks, and it's in my binder! 👍🏆

-

Interesting question... I guess if you are 'stalking' a particular user, you'll know where to find 'em... <shrug> 🤷♀️🤣

-

It looks like it displays the last topic the user (in this case you, if you are looking at your own status) viewed. Test it by going to another topic, then to your profile. It will show that topic instead of "Status?".

-

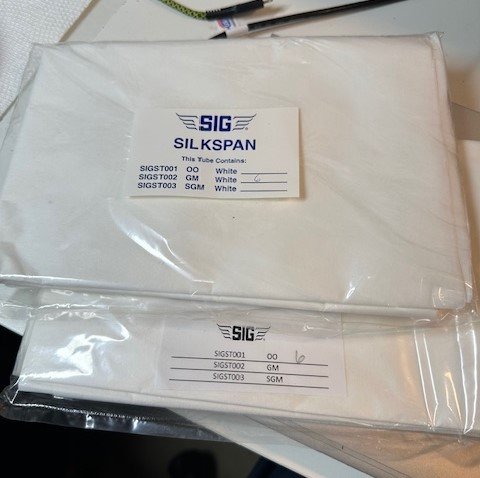

Well, that's pretty much what I've been doing for the past week. Really nothing done on the ship itself, just trying to soak in what many previous Bluenose build log builders have done regarding their rigging, masting and moving forward. Wow! A lot to take in, much more than I remember on my prior builds, but... they have not been as detailed and complicated. Guess that's what we get when we reach for higher ground, right? A few more challenges than before. Ok... While I am researching others and coming up with my own game plan, I thought I would prep all of the blocks that may be needed for the Bluenose and began staining them. Strung them on some thin line and dipped them in stain. First, a bath in some pre-stain, then in some Minwax Golden Oak stain, which is what I also used for the masts. Seemed right. Also, I am replacing as much as I can of the kit-provided blocks with those that I got from Syren Ship Model Company, which I had used in my Ballahoo build and liked their quality. Also, in the "What Did You Receive Today" category, after reading the pros and cons of sail construction, I ordered some Silkspan tissue for this Bluenose. Found what seemed like a reputable vendor in Sig Manufacturing (out of Des Plaines, IL) and ordered two types of silkspan tissue, what they call a LIGHT version and a MEDIUM version, so I can determine which will be best for the sails when I get to them shortly. And kudos to Sig's customer service! I ordered these on Wednesday and received them today. Two thumbs up! I've still been a bit on the fence about whether I was going to do full sails or furled, but think I have convinced myself to do the full sails. Could still convince myself to change, but... <shrug> Either way, these silkspan sheets should look better than the kit-supplied cotton sail cloth... I HOPE!

-

Are you an NRG Member???

GGibson replied to Chuck's topic in How to use the MSW forum - **NO MODELING CONTENT**

I have participated in previous Saturday morning workshops. They are awesome! Definitely interested in the upcoming June 15 workshop on sails! May have to hold off on my Bluenose rigging and sail construction until then!! 🤣🤣 -

USS Constitution by mtbediz - 1:76

GGibson replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

Excellent detail, Mustafa! Are you blackening the brass first before painting? How will you be painting to assure a nice coverage? Especially since it appears to now be all assembled. I am curious, as my brass painting seems to always be spotty, but the blackening technique, along with an acrylic paint on top of it, seems to cover better for me. -

They look similar to these? Solid Brass Miniature Bar Clamps, 3-3/4 Inches Long (Set Of 2), For gluing or fitting, Anti-rust and corrosion resistant, Set of 2 mini solid brass clamps with knurled screws (micromark.com) EDIT: My follow-up question would be - Are these clamps, being made of solid brass and 3 inches long, be sometimes too heavy for some of the clamping we want to do with some of our small parts? I was curious about these, as well, when I saw the picture before I saw Peter's query.

-

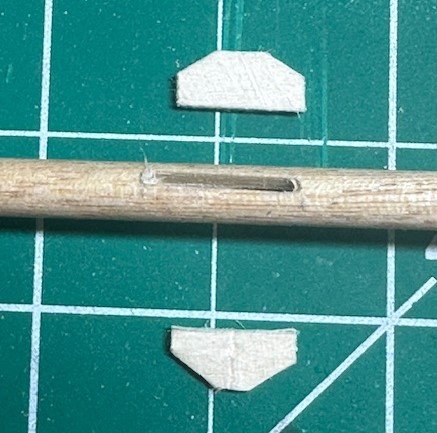

Another update that I'll attempt to do very quickly... (especially since I didn't take many notes during the construction) <shrug> MAIN GAFF - The final spar of the five! This one was actually sorta fun to build for a few reasons. First, it was fairly easy as it repeated several of the build processes that had been used on any of the previous four. Secondly, I was able to utilize some of the special tools to finish it up and make it, in some cases, a better product. First, worked on the gaff jaws and, like I had done on the fore gaff and main boom, used the Proxxon mill to shave down the two sides of the spar to give the jaws a flat surface to adhere to. Drilled the holes for the brass rods, aligned the clapper, and glued everything together. Enjoyed doing this part on all three of the spars. A slightly different configuration on the eyebolt placement on this main gaff, so pay attention to those details. For the stop chocks towards the center of the main gaff, I wanted to give the chocks a bit of an indentation or groove to securely sit in, so started making grooves with the Proxxon mill on the two sides. The stop chocks were measured to be about 10mm long and I had a 1/32" thick piece of scrap wood that I shaped for the stop chocks. After a bit of milling on both sides, I actually found that I had milled all the way through the dowel. But, it worked out well, as I was then able to firmly insert each sides' stop chocks in the main gaff. Secured them with glue and gave them a final sanding to best shape them to form. In the zoomed picture, the two chocks look uneven so may need to work on those a bit to more evenly shape them. Used a #71 drill bit, as I recall, to place a hole for the bridles on both sides. As we moved closer to the other end of the main gaff, five (5) sets of smaller stop chocks were placed on the underside of the main gaff. Those were made from some 1/32" square stock, sanded down a bit and placed with just a toothpick drop of PVA glue. Let those dry overnight before sanding a bit more to give them an angled appearance and then gave them a touch of cherry stain. Drilled a hole using a #65 drill bit through the sides at the indicated location and soldered one more small band at the end using the 1/128" thick brass strip. Again, I found a couple smaller eyelets than what I had previously been using and placed two at the top and bottom sides of the main gaff end. So.... there are the five (5) completed spars. Top to bottom - Main Boom, Main Gaff, Fore Gaff, Fore Boom, Jumbo Jib Boom. All in all, it progressed pretty well. Right at about two weeks' time frame from when I began sanding the five wooden dowels to their needed diameters until now. It was fun and educational, but so glad to move on. So, I guess now it's on to another set of challenges, trials, tribulations and victories. Time to begin rigging, stropping blocks, tying lines, etc. Need to sit down before jumping in head-first and review all of the available build logs before me to assess the challenges and develop a game plan. There are some great rigging examples in that group, I know, so their work is extremely appreciative and inspiring. With that said, I appreciate the likes, comments and criticisms of my work here, hoping that I add at least something to the Bluenose community for future builders. Thanks!

-

Thanks for sharing these pictures from your Constitution visit, sir! They are awesome! And I have always thoroughly enjoyed the pictures that Jon has posted of the Constitution, whether it's on his own build log, or on others' as a means of education/explanation. You guys are great! Will be looking at your build logs constantly whenever I get to my own build! 👍

-

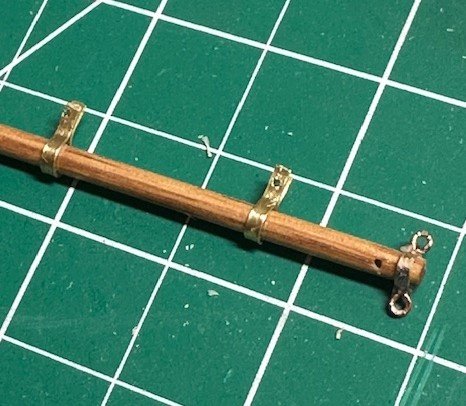

Another update... got another spar completed, so taking a break and getting this down in the build log. FORE GAFF - This one was probably the easiest, or quickest, of the spars I've been working on. As I have done with the others, I first worked on the end closest to the mast, which for this fore gaff meant working on the jaws that will wrap around the fore mast. As I had done on the main boom, I used the Proxxon mill to flatten or shave the gaff on either side of the spar to give the jaws something flat to be secured to. Then, after marking the hole locations for the jaw eyebolts, I used my Proxxon drill press to drill #65 bit holes in the jaw sides for the 0.81mm brass rods. Also drilled the necessary holes for the required eyebolts for the throat halliard linkage on the topside of the fore gaff and for the topsail sheet eyebolts on the underside. Thanks to @John Ruy for his input and clarification on the plans and the needed eyebolts. The first (left) picture is the topside, the second (right) picture is the underside with the additional eyebolt in the spar itself. (There's one eyebolt in that underside picture that looks a bit turned, too. Need to see if I can fix that!) On the other end of the fore gaff, there are a few fittings needed. Two peak halliard bands were shaped and secured in their appropriate locations by using the 1/64" x 1/16" brass strip. Shaped them so they fit snuggly in their locations, removed them to drill the holes for the pins to be placed during rigging, and then glued them in place using CA glue. At the end of the gaff, I shaped a small band using even thinner 1/128" thick brass strip. On the top and bottom of this band, I drilled a small hole to accept eyebolts. I had some smaller 2.07mm wide eyebolts that I used here rather than the thicker 2.78mm ones I have been using elsewhere. Hopefully, these don't look too oversized for the very end of this smaller fore gaff. I also drilled out a 1/32" hole in the side of this fore gaff just behind this band, as shown in the plans. And, here's a picture of the full fore gaff, in all its glory. Going to go back and clean this up a bit, as I am with all these booms and gaffs, once this last one is completed. With that said, I only have one more to work on... the main gaff. See ya later... As always, thanks for the likes, comments and criticisms. All are appreciated.

-

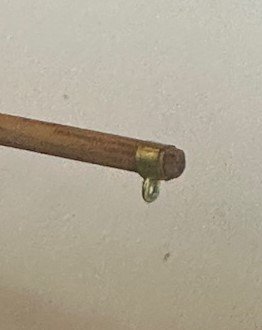

Got a couple more of the booms completed, so a brief update... FORE BOOM: GOOSENECK - Wrapped a 1/64" x 1/16" brass strip (have been using a ton of these!), cut to shape and soldered. Holy moly, the bands on these smaller booms and gaffs are going to be tiny! Bent a small piece of brass strip and glued to the end that attaches to the foremast. Boom Tackle Band - Soldered two strips together on one end, formed around the boom (again, very small!). Drilled holes through the strips on the bottom of the boom to fit a 0.51mm brass rod for the link. The circle link may be too big and I may switch it out before rigging and attaching to the fore mast. Sheet Band - Similar to the Main Sheet Band that was made earlier for the Main Boom, except (yep, saying it again) this one is smaller. Used a 0.51mm brass rod bent around a 1/4" wooden dowel for shape. Clew Band - Did something a bit different for this clew band. I used a 0.2mm brass sheet (half the thickness of the 1/64" strips I had been using) and measured and cut a 1/16" width strip from the sheet. Came out in a nice curl as I cut it with sharp scissors. Similar to what was done on the main boom clew bar, I drilled holes using a #65 micro drill bit for the link bar, but won't put link in until rigging. Glued the clew band in place. Topping Lift Band - Used more of the 1/128" thick brass sheet that I cut to form a band at the very end of this fore boom. After fitting, soldered and secured on the fore boom and added eyebolt. The clew band and topping lift band are not at the very end of the fore boom, as shown in the plans. Noticed this after I was done and looked back at the plans. Hoping this is not critical in the rigging stage. Need to do better on the remaining booms/gaffs. With that said, here's a closeup of the end with the four (4) bands close together, as well as a picture of the entire fore boom completed. JUMBO JIB BOOM: Traveler Band - Used more of the thinner 1/128" brass strip for this band at the fore end of this band. Drilled two small holes in bottom side of band for a staple-type rod insert. Sheet Band - Similar to what I have done on the two previous booms, with the 0.51mm brass rod looped at the bottom. Clew Band & Topping Lift Band - Again, similar to the bands that have been created and fixed to other booms. And a photo of the full Jumbo Jib Boom completed. Pretty straight-forward. Three down, two more to go! Some techniques and operations I know I have improved on, but many, many, many things I need to work better at achieving. Appreciate the likes, comments and criticisms, as always.

-

Thanks, Mustafa! Yes, they are brass strips. And, yes, thought about blackening for a more realistic look, but guess I liked the shininess of the brass, so decided to keep it that way. Easy way out, maybe! I have blackened brass on prior builds but chose this way for the Bluenose. I know I will need to do some blackening, though, on the other ships I will be working on after this one, including the Constitution! Appreciate your input!

-

Love the furled sails! Looking really nice. I'm thinking about doing them on the Bluenose, but not sure I have this skill needed. Your spritsail and foresail look sharp. Kudos!

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.