-

Posts

596 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by ERS Rich

-

Hello from the Scottish North Coast

ERS Rich replied to Scottish Guy's topic in New member Introductions

Fantastic! Sounds like you are ready to go! Same as full size woodworking, just smaller. Cheers -

Hello from the Scottish North Coast

ERS Rich replied to Scottish Guy's topic in New member Introductions

Welcome to Model Ship World. I don’t know about the difference between the 2 Victory kits…. Certainly these kits will help you increase your skill. Consider a plastic kit has all the parts made, each part needs a little work, sanding, filing, to get a good fit. So less time building. Knowing how to apply a finish is crucial. Plastic offers the opportunity to experiment with different paint to find out what works best for you - enamel? Acrylic.? Brush or airbrush? The Hallberg Rassy 57 yacht is certainly a good subject. Recommend that you find a similar wooden Yacht ship kit before trying “scratch building”. Consider jumping from plastic to wood modeling is a big step. Because if it’s new to you, wood working takes some time to learn: understanding tools, sharpening, and wood characteristics. However, you may already understand this! If so you are ahead of the average bear. Another advantage of a kit is the instructions will lead you through the process, and some of the components will be prefabricated, saving time, and there are plenty of parts that require scratch building techniques. Agree that Vanguard is a great way to get started. Good luck with your projects, -Rich -

Hi Kurt, A couple of things if I may. Following up on our conversation about finishing. Understand avoiding oil based products and sticking to acrylics. Shellac is another alternative. It’s alcohol based, so the alcohol evaporates quickly, but there are fumes to manage, though they can dissipate quickly when applied in small amounts with a brush. I use rattle can shellac on hulls, applied outside. Regarding planking. My results improved after understanding the concepts of belts and plank width/tapering. “Planking the Built Up Ship Model” by Jim Roberts is a big help, sold by Model Shipways. And I invested in a pair of proportional dividers - my Constitution Hull build log, link below shows how I used them. And plenty of info about this on MSW. Thanks, have a good day, -Rich

-

Byrnes Table Saw Tips (requested)

ERS Rich replied to Matrim's topic in Modeling tools and Workshop Equipment

Wandered into this discussion…… Circling back to the original post….the questions are relatively basic and reasonable. If you have never owned a table saw, any table saw, respect the machine and the damage it can do to yourself and others. Get basic instruction before using it. Plenty of instruction on Youtube and better yet, look for a local woodworking class. Fundamentally if the blade is stoped midway through a cut, it is a dangerous situation, stop, STEP SIDEWAYS away from the saw and unplug it. Watch out the wood could eject back towards you with enough force to hurt you. Understand that when cutting, one side of the piece, usually the waste, must be free to move away from the blade. That’s why NEVER use the Mitre Gauge and Fence at the same time. A bound piece of wood can easily eject from the machine, back towards you, and hurt you. Lots of great suggestions on this thread. Understand the basics. If you use the saw frequently, stay focused, accidents, and one will most likely happen to you, occur when we let our guard down. Always stand slightly off center, if the machine ejects a piece of wood you will not have time to get out of the way. Again, respect the machine, it doesn’t have a conscious. -

Thanks for mentioning this, given how long it takes to build a ship model, one wonders how much time is taken up with “invisible” things such this, or other trivial details pursued for the sake of “realism”, especially by newcomers. Time which could be spent completing the project and gaining satisfaction from that.

-

A couple of thoughts, Have used AV paint, with a Paasche Talon, for the last few years and happy with the results. Have never tried adding gloss medium to paint, rather I use the Vallejo gloss resin. Have found the gloss finish can be built up with thin coats. Tamiya Flat black may be worth a try. Good luck with it…..

-

Endeavour by Bill97 - OcCre - 1/54

ERS Rich replied to Bill97's topic in - Kit build logs for subjects built from 1751 - 1800

Mucho important. The instructions probably do not emphasize that planks must be tapered. If needed look it up here, along with the concept of planking belts. An understanding of planking is probably the biggest thing one needs to learn when getting started. See my Constitution log, link below for pointers. Have also found if you are on a certain step, it helps to look ahead in the instructions for addition images related to that step. Good luck with your project! -

Hello from Perth, Ontario - On to Victory!

ERS Rich replied to Malcolm Brown's topic in New member Introductions

Welcome to model ship world and good luck with your Victory!- 31 replies

-

- Victory 1:100

- Heller

-

(and 1 more)

Tagged with:

-

Yes Avi, I can’t remember exactly how I prepped the metal before painting. Just tool a look for my painting notebook and can’t find it. My rudder is static. I did paint the hull with Tamiya Dark Copper acrylic, and my build log says the wood was prepped with Varethsne Ipswich pine stain. I like priming with stain, as it seals the wood fibers but doesn’t completely fill the grain. It takes acrylic well and leaves the wood grain, so the surface doesn’t appear plastic. I’m thinking about picking up the Constitution this fall. Working on two other square rig hulls at the moment, the thought is masting and rigging all three simultaneously. I’ve also been experimenting with Mr Metal primer. Brush applied as I don’t want to deal with the spray fumes. It takes acrylic well.

-

My two cents….have found CA on bullkheads does not immediately set, and have to do a second application after the first sort of dries, the first application is probably filling in the end grain. Also, at the bulkhead, CA will easily bond the long grain along the edge of the new plank to the edge of the previous plank. My method is generous Titebond on the plank edge, CA on the bulkheads, install the plank, hold with fingers at the bulkeads, reapply CA if necessary when a plank does not hold at the bulkhead. Then clamp the installed plank along the edge up against the previous plank. Have a rag ready to deal with the squeeze out or scrape after the Titebond sets. The CA provides initial hold, the Titebond provides the ultimate strength. It may be helpful to watch Youtube for cabinetmakers glueing up panels to learn about glue, and dealing with squeeze out. My Constitution build log may be helpful. Good luck.

-

Welcome and greetings from Massachusetts, USA. Good luck with your project. Have fun!

-

Welcome and greetings from USA. Good luck with your work. -Rich

-

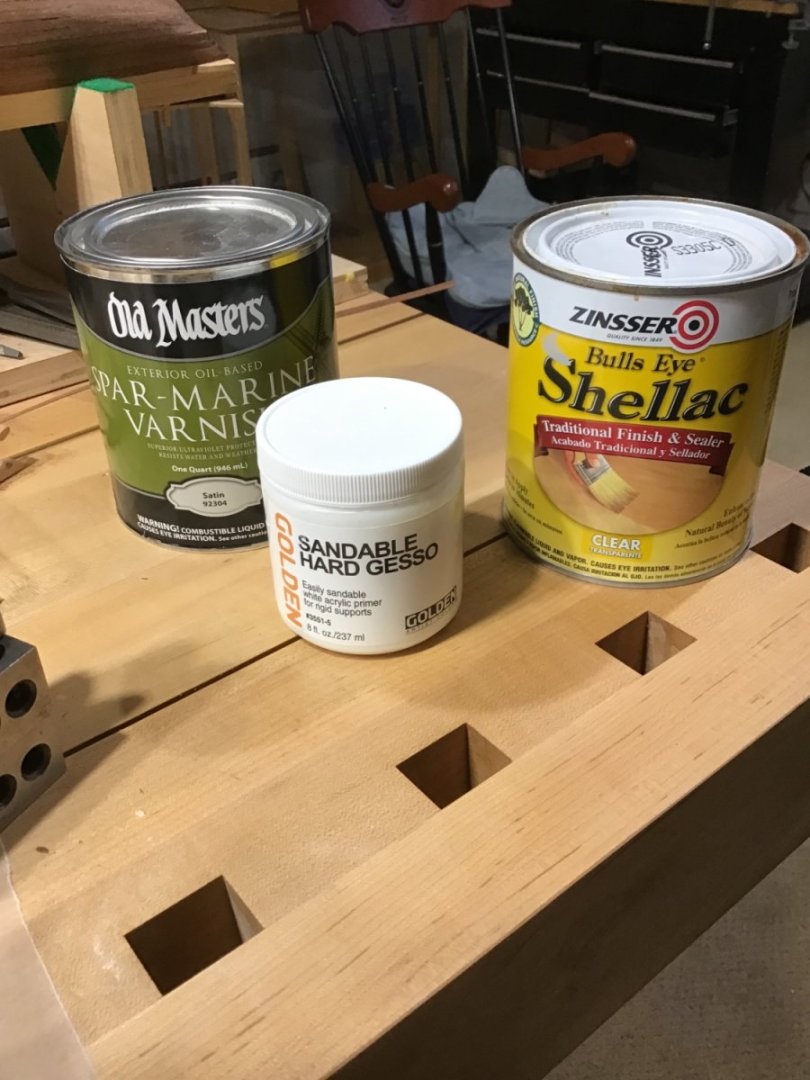

Sort of circling back to the question. I’ll seal with one of these products. Given the coarse grain, leaning towards the Gesso, thinned down and, shot with the Iwata RG-3 mini sprayer. It’s slightly gap filling as well. This Hermione is an old AL kit about 10 or more years old….goal is to practice and improve techniques - get a visually convincing result - a model of the ship, rather than an exact reproduction. Cheers

-

Yes, they are full size files, about 9” long. The hull is the Hermione Lafayette, about 20” long. To clarify stroke the file along the plank at about 45 degrees or so - a shear cut. Light pressure, let the tool do the work - cut the wood, don’t gouge it. With practice you can get control to the point where you can remove small amounts of wood. Control is the difference between a file and sandpaper. The right tool changes this job from a pain to a joy. Practice on poplar or another hardwood. Home improvement stores sell project boards in hardwood. Or go for it on this hull, if it goes wrong strip and redo the planking as others suggest. Good luck

-

Hi, I don’t think all is lost here….. Use toothpicks and fill in the gaps with Titebond. Recommend avoiding covering large areas of the hull with filler, it’s a waste of time removing it, when just the gaps need it. Think of the glue as oakum. It’s good the planks appear to be thick. Sandpaper can be difficult as is it will slowly round over the plank tops - see the bow. I use files, flat and half round to work the hull. Go 90 degrees along the plank to quickly remove wood. Go lightly until you get the hang of. With practice you will get great control, quickly removing wood. Move the file parallel, edge along the planks,for finer control. As Allenyed mentions scrapers work too…. Sandpaper is a drag, and not appropriate, when a lot of wood needs to be removed. It can seem like after a lot of sanding nothing is happening and the planks have humps. Here are a couple of pictures of a hull in progress demonstrating what’s possible. Hang in there and good luck with it! -Rich The lower planks are before working, upper have been worked…. Upper planks mostly done, lower planks need some work…. The files…..

-

Greetings from Massachusetts, USA. Good luck with your woodworking journey! Cheers!

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.